Page 1

OWNEROWNER

OWNER

OWNEROWNER

OPERAOPERA

OPERA

OPERAOPERA

MANUMANU

MANU

MANUMANU

ALAL

AL

ALAL

TT

OR’SOR’S

T

OR’S

TT

OR’SOR’S

5" and 8" Skid5" and 8" Skid

5" and 8" Skid

5" and 8" Skid5" and 8" Skid

Steer ChipperSteer Chipper

Steer Chipper

Steer ChipperSteer Chipper

ModelsModels

Models

ModelsModels

7450074500

74500

7450074500

5" Skid Steer Chipper5" Skid Steer Chipper

5" Skid Steer Chipper

5" Skid Steer Chipper5" Skid Steer Chipper

7480074800

74800

7480074800

8" Skid Steer Chipper8" Skid Steer Chipper

8" Skid Steer Chipper

8" Skid Steer Chipper8" Skid Steer Chipper

(Requires 25 gpm minimum(Requires 25 gpm minimum

(Requires 25 gpm minimum

(Requires 25 gpm minimum(Requires 25 gpm minimum

hydraulic flow)hydraulic flow)

hydraulic flow)

hydraulic flow)hydraulic flow)

Crary Company

A Division of TerraMarc Industries

237 12th St. NW • P.O. Box 849

West Fargo, ND 58078-0849

(701)282-5520 • FAX: (701)282-9522

www.bearcatproducts.com

www.terramarc.com

Manual P/N 13940-00

Rev. 05/02

Companion to 13939-00

Page 2

Before you Begin

DEAR BEAR CAT CUSTOMER,

Thank you for purchasing a Crary Bear Cat Skid Steer Chipper. The Bear Cat Chipper is

designed, tested, and manufactured to give years of dependable performance. To keep your

chipper operating at peak efficiency, it is necessary to adjust it correctly and make regular

inspections. The following pages will assist you in the operation and maintenance of your

machine. Please read and understand this manual before operating the chipper.

If you have any questions or comments about this manual, please call us toll-free at 1-800-247-

7335.

If you have any questions or problems with your chipper, please call or write your local factoryauthorized Bear Cat dealer.

PLEASE SEND US YOUR WARRANTY CARD

A warranty card is included in your owner's kit packaged with your chipper. Please take the

time to fill in the information requested on the card. When you send your completed card to us,

we will register your machine and start your coverage under our limited warranty.

How to Contact

Bear Cat

A

DDRESS

Crary Bear Cat

237 NW 12th Street

PO Box 849

West Fargo, ND 58078

P

HONE

800-247-7335

701-282-5520

Fax: 701-282-

9522

E

MAIL

opesales@crary.com

service@crary.com

H

OURS

M-F, 8 a.m. to 5

p.m. Central Time

Page 3

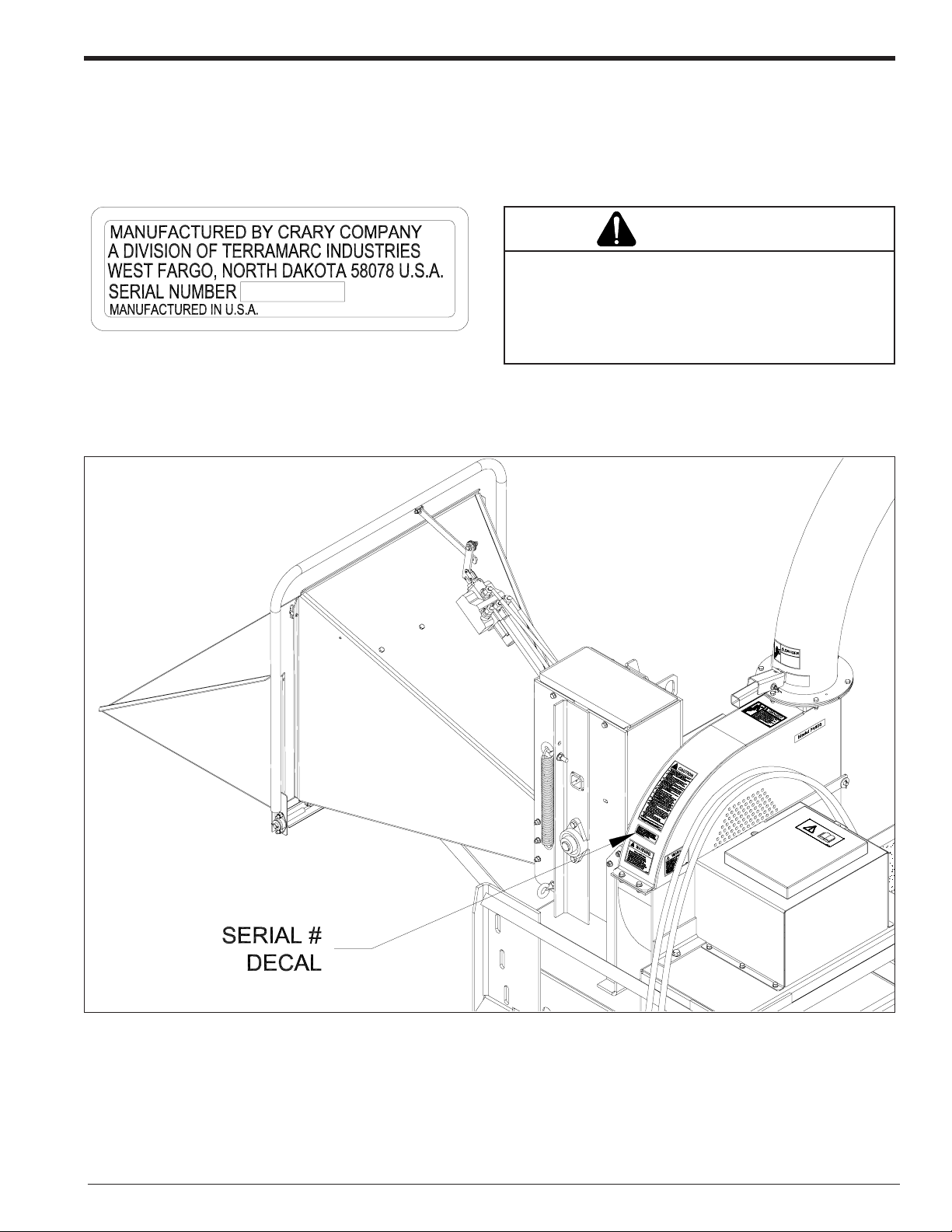

SERIAL NUMBER LOCATION

Always give your authorized Bear Cat dealer the serial number of your Crary Bear Cat Skid Steer Chipper when ordering

parts, requesting service or any other information. The serial number decal for Bear Cat Skid Steer Chipper is on the chipper

housing at the location called out below. Please record the serial number in the space provided below and on the warranty

and registration card.

WARNING

To prevent personal injury or property damage: Shut off

YXXXXX

Fig. # 1 Serial number decal

Serial Number ________________________

skid steer engine, remove ignition key, and make sure

that all moving parts have come to a complete stop,

before obtaining serial number, servicing, adjusting or

repairing.

Fig. # 2, Serial number decal location (Model # 74500 and 74800)

Skid Steer Chipper Operator’s Manual

I

Page 4

Section Description Page

SAFETY .................................................................................................................................... 1

OPERATION SAFETY ................................................................................................................. 2

FEED ROLLER SAFETY ............................................................................................................. 3

MAINTENANCE AND STORAGE SAFETY .................................................................................. 3

SAFETY DECAL LOCATIONS (74500 AND 74800) ...................................................................... 4

ASSEMBLY .................................................................................................................................... 5

MOUNTING THE CHUTE ............................................................................................................. 6

MOUNTING THE 4 POSITION VALVE.......................................................................................... 7

FEATURES AND CONTROLS IDENTIFICATION .......................................................................... 8

DESCRIPTION OF OPERATION .................................................................................................. 8

CHIPPING OPERATION .............................................................................................................. 8

FEATURES & CONTROLS ................................................................................................................................9

FEATURES AND CONTROLS IDENTIFICATION .......................................................................... 9

USE OF CONTROLS ................................................................................................................... 9

OPERATION .................................................................................................................................. 11

MOUNTING THE CHIPPER TO THE SKID STEER .................................................................... 11

INSTALLING THE FLUSH FACE COUPLERS ............................................................................ 12

HYDRAULIC SCHEMATIC ......................................................................................................... 13

OPERATING THE CHIPPER...................................................................................................... 14

CHIPPING GUIDE ...................................................................................................................... 15

FEED ROLLER SECURING INSTRUCTIONS ............................................................................. 16

Contents

SERVICE & MAINTENANCE ............................................................................................................................ 16

MAINTENANCE SCHEDULE ..................................................................................................... 17

SHARPENING CHIPPER BLADES ............................................................................................ 18

CHIPPER BLADE AND ANVIL CLEARANCE ............................................................................ 19

GREASING ............................................................................................................................... 20

CLEANING PLUGGED ROTOR ................................................................................................. 22

TROUBLESHOOTING ................................................................................................................ 23

BOLT TORQUE REQUIREMENTS ............................................................................................. 25

Skid Steer Chipper Operator’s ManualII

Page 5

Chipper Limited Warranty

Crary Bear Cat Chippers are warranted for one year from date of sale for consumers and commercial or

rental operations.

Within the above stated period, Crary Co. will replace any part(s) found to be defective in material and/or

workmanship, after the receipt of the part in our plant. Labor costs to replace these defective parts will be

paid at a Crary established labor rate and time allowed (flat rate) for repair. All transportation charges

incurred in shipping part(s) are the responsibility of the purchaser.

This warranty is void in the case of accidents, failure to perform normal maintenance, or failure to follow

those instructions listed in the service manual. This warranty is also in lieu of all other expressed warranties

and voids any implied warranty as to the merchantability or fitness of the product for a particular purpose

and of any other obligation on the part of Crary Co. Some states do not allow limitations on how long the

implied warranty lasts, so the above limitation may not apply to you.

This warranty applies only to parts or components which are defective, and does not cover necessary

repair due to normal wear, misuse, accidents, or lack of proper maintenance. This includes belts, pulleys,

and chipper blades. Regular routine maintenance of the unit to keep it in proper operating condition is the

responsibility of the owner.

All warranty repair work reimbursable by Crary Co. must be performed by an authorized Bear Cat service

dealer using Bear Cat approved replacement parts. Service dealers must hold onto damaged parts for

inspection at the request of Crary Co. Repair or attempted repair by anyone other than an authorized Bear

Cat service dealer is not reimbursable under the Crary Co. warranty. In addition, these unauthorized repair

attempts may result in additional malfunction, the correction of which is not covered by warranty.

Crary Co. is not liable for indirect, incidental, or consequential damages in connection with the use of this

product including any cost or expense or providing substitute equipment or service during periods of

malfunction or non-use.

Some states do not allow the exclusion of incidental or consequential damages, so the above exclusion

may not apply to you. This warranty gives you specific legal rights. You may also have other rights which

vary from state to state.

Be sure to note the chipper serial number in any correspondence with Crary Co. or any authorized Bear

Cat dealer.

Crary Company

A Division of TerraMarc Industries

237 12th St. NW • P.O. Box 849

West Fargo, ND 58078-0849

(701)282-5520 • FAX: (701)282-9522

www.bearcatproducts.com

www.terramarc.com

Skid Steer Chipper Operator’s Manual

III

Page 6

NOTICE

For testing purposes, fluids may have been added to this machine prior to

shipping. Specifically, this includes hydraulic fluid. Be careful with installing

and handling hydraulic lines, hydraulics may be under pressure. Refer to

page 10 of the owners manual for specific instructions.

Page 7

1

Safety

Section

THE SAFETY ALERT SYMBOL

This is the safety alert symbol. It is used in this Owner / Operator’s Manual and on your machine

to alert you to potential hazards.

Whenever you see this symbol, read and obey the safety message that follows it. Failure to obey

the safety message could result in personal injury, death or property damage

DANGER

WARNING

CAUTION

BEFORE OPERATING

1. Read this Owner / Operator’s

manual carefully before operating

this equipment. Be completely

familiar with the controls and the

proper use of this equipment.

2. To prevent personal injury or death:

Stop chipper and loader engine.

Make sure that all moving parts

have come to a complete stop,

and disconnect quick couplers

from loader before servicing, adjusting or repairing.

Indicates an imminently hazardous situation that, if not avoided, will result in

death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, could result in

death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, may result in

minor or moderate injury.

equipment and on any of it’s attachments or accessories.

5. Do not allow children or any person unfamiliar with the use of the

unit to use this machine.

6. Keep the area of operation clear of

all persons, particularly small children. Keep bystanders at least

50 feet (15 meters) away from the

area of operation.

7. Do not operate this machine if you

are under the influence of alcohol,

medications, or substances that

can affect your vision, balance, and

judgement. Do not operate if tired

or ill. You must be in good health

to operate this machine safely.

8. Use only in daylight or good artificial light.

9. Never use without proper guards

in place.

10. Wear safety glasses at all times

while operating this machine. One

pair of safety glasses is provided.

11. Wear hearing protection at all times

while operating this machine.

3. Keep safety decals clean and legible. Replace missing or illegible

safety decals.

4. Familiarize yourself with all of the

safety and operating decals on this

Page 1Skid Steer Chipper Operator’s Manual

Page 8

Safety

12. Avoid wearing loose fitting clothing. Never operate this machine

wearing clothing with drawstrings

that could wrap around or get

caught in the machine.

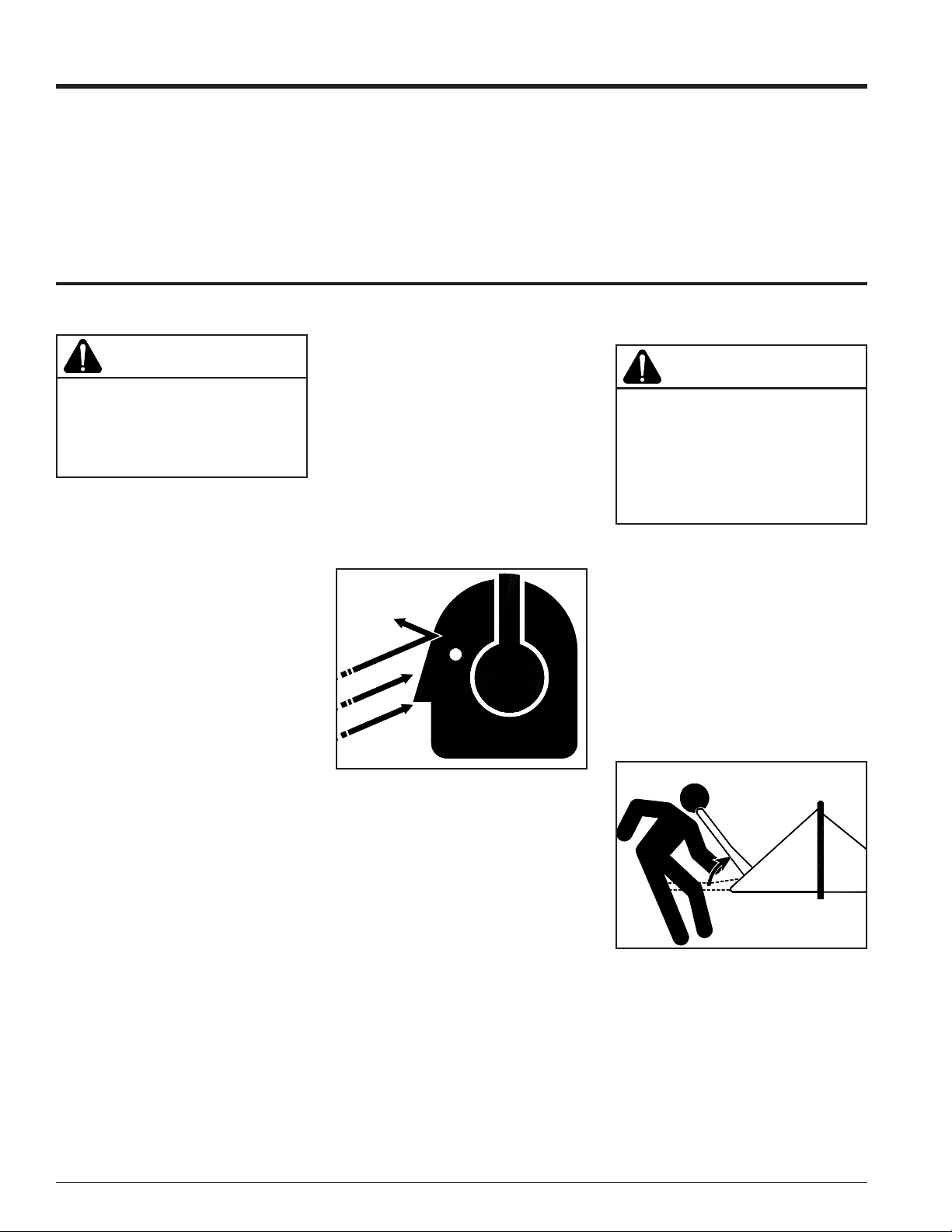

OPERATION SAFETY

DANGER

Keep hands, feet and clothing out of

inlets and discharge openings while

machine is operating to avoid serious personal injury or death.

1. Do not allow hands, or any part of

body or clothing, inside the feeding

chamber, discharge chute, or near

any moving parts.

2. Check the cutting chamber to verify

it is empty before starting the machine.

3. Exclude pieces of metal, rocks,

bottles, cans, and other foreign objects when feeding chipable material into the machine.

13. Check that all screws, nuts, bolts,

and other fasteners are properly secured before starting the machine.

Check all screws, nuts, bolts, and

other fasteners for proper tightness

to ensure everything is in proper

working condition. Check once in

the first two hours and every 10

hours thereafter.

5. Do not allow processed material to

build up in the discharge area; this

may prevent proper discharge and

can result in kickback of material

through the feed opening.

6. Stand clear of the discharge area

when operating this machine.

7. Keep your face and body back from

the feed opening.

14. Keep all guards, deflectors, and

shields in place and in good working condition.

15. Do not transport or move machine

while the machine is running.

WARNING

Material can kickup or shift suddenly

and cause serious injury or death.

• Wear eye, and hearing protection.

• Stand to the side of the feed chute.

• Release material and stand to

side of the feed table and chute.

9. When feeding material into feed

roller:

A. Wear eye, face and hearing

protection.

B. Release material and stand to

side of feed table and chute.

C. Keep metal objects, rocks,

bottles, cans and other foreign

objects out of chipper.

4. Shut off machine immediately if the

cutting mechanism strikes any foreign object or the machine starts

making an unusual noise or vibrating. Allow the machine to stop completely. After machine stops:

A. Shut off skid steer engine.

B. Remove ignition key.

C. Inspect for damage.

D. Replace or repair any

damaged parts.

E. Check for and tighten any

loose parts.

Page 2 Skid Steer Chipper Operator’s Manual

8. Do not climb onto chipper feed

chutes or frame when operating. Do

not overreach. Keep proper balance

and footing at all times.

WRONG

Page 9

Safety

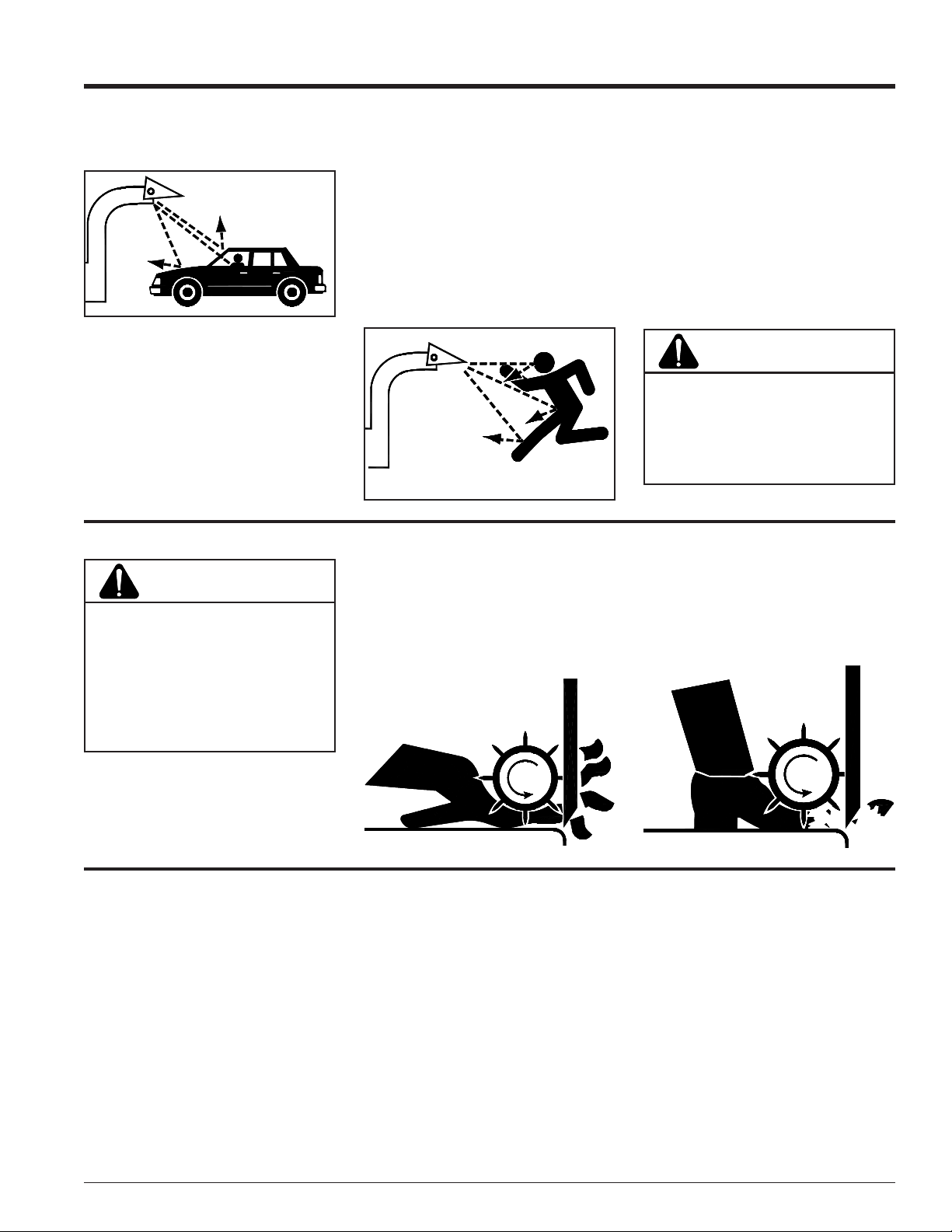

10. Setting up your chipping site so

you are not endangering the

public is critical for safety.

WRONG

11. Check the bolts correct torque

every 10 hours of operation (See

torque chart at back of manual).

12. Rotate the discharge tube to face

the opposite direction of the towing vehicle before towing. This

FEED ROLLER SAFETY

WARNING

prevents the discharge tube from

projecting over the trailer wheels

and striking foreign objects.

13. Flying debris can cause serious

injury or death and property damage.

14. Keep bystanders away from discharge chute.

WRONG

2. Never climb onto chipper feed

chute or table when operating.

15. Position discharge chute away

from bystanders and other property when opening.

16. Keep metal objects, rocks,

bottles, cans, and other foreign

objects out of chipper.

17. Check the bolts torque on the

chipper every 10 hours of operation.

WARNING

Failure to maintain proper fastening torque on chipper blade bolts

may result in severe damage to the

chipper and / or personal injury.

4. No riders allowed, keep off the at-

tachment.

To prevent personal injury or death:

Stop chipper and loader engine.

Make sure that all moving parts

have come to a complete stop, and

disconnect quick couplers from

loader before servicing, adjusting,

or repairing.

1. Feed roller and rotating chipper

can cause serious injury or death.

Keep hands, feet and clothing

away from feed roller chipper

blades.

3. Do not over reach. Keep proper

balance and footing.

WRONG

MAINTENANCE AND STORAGE SAFETY

1. Shut off the skid steer, disconnect

the hydraulics, remove the ignition

key when this equipment is stopped

for service, inspection, storage.

2. Unhook the unit from the machine

and store detached.

3. Do not place the machine in an area

where children can play on or

around.

4. Replace any missing or unreadable

safety decals. Refer to the parts

manual for part numbers when ordering safety decals from an area

Bear Cat dealer.

5. See skid steer owners manual or

contact the manufacturer for safety

instructions and decals.

WRONG

Page 3Skid Steer Chipper Operator’s Manual

Page 10

Safety

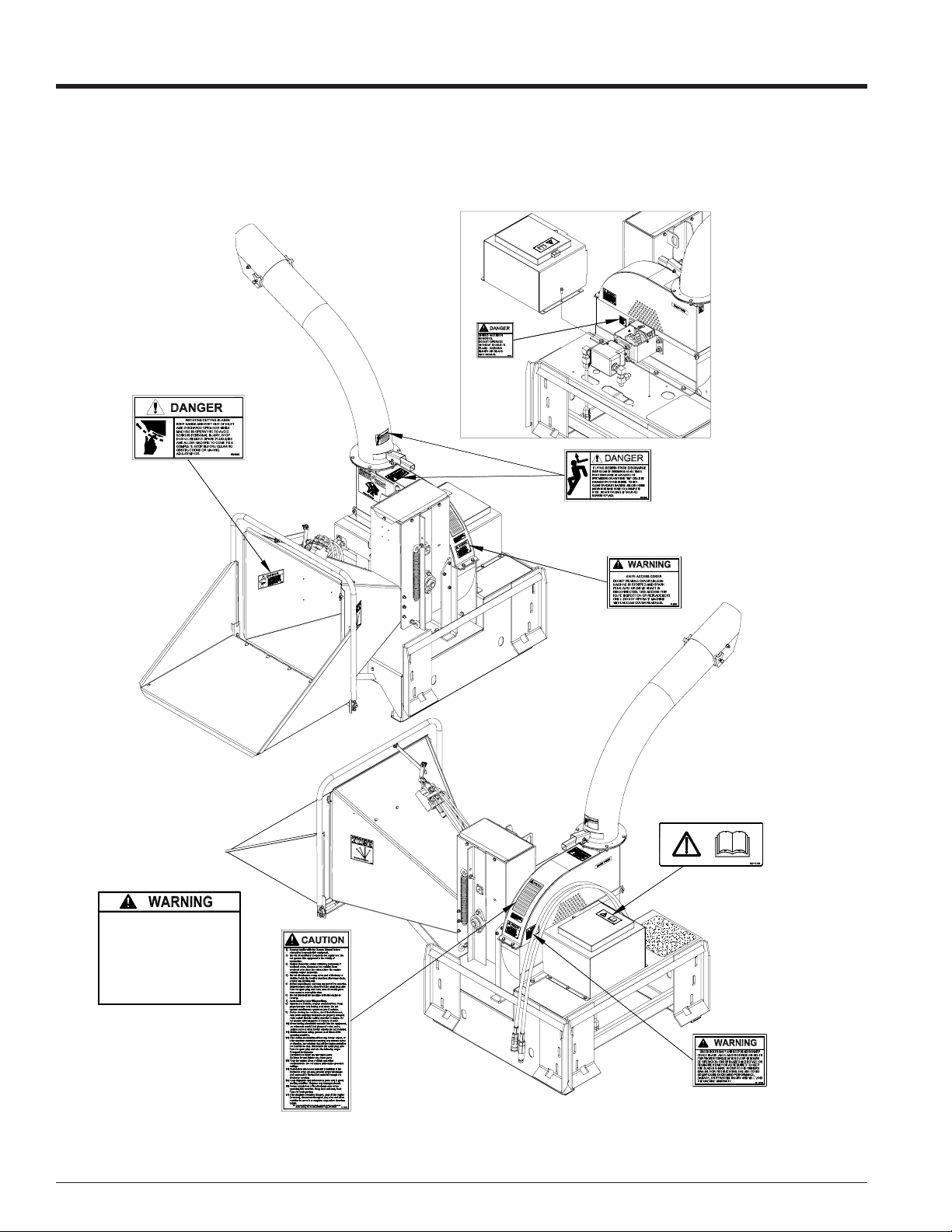

SAFETY DECAL LOCATIONS (74500 AND 74800)

Familiarize yourself with all of the safety and operational decals on the machine and the associated hazards. Make certain

that all safety decals and operational decals on this equipment are kept clean and in good condition. The decals are shown

below at reduced sizes. If you need a replacement decal, please refer to the parts catalog. Decals that need replacement

must be applied to their original locations.

P/N 17423

P/N 17837

P/N 16558

Guards and shields are

removed for illustrative

purposes only; do not

operate without guards

and shields in place and

functioning properly.

P/N 16085

P/N 13711-00

P/N 17846

Fig. #3, 74500 and 74800 decal locations

Page 4 Skid Steer Chipper Operator’s Manual

P/N 12010

Page 11

Assembly

2

Section

Your chipper may arrive totally or partially assembled. If your machine arrives partially assembled, you may need to perform

the steps in this section.

ASSEMBLY INSTRUCTIONS (74500 AND 74800)

Installing the Discharge Tube

WARNING

To prevent personal injury or property damage: Shut off skid steer

engine, disconnect hydraulics, remove ignition key and make sure

that all moving parts have come to

a complete stop, before servicing,

adjusting or repairing.

The Bear Cat Skid Steer Chipper is

shipped an a disassembled state. The

unit will need to be assembled before

use.

1. Remove Bear Cat Skid Steer Chipper from the shipping pallet.

2. Lightly grease the chipper outlet

flange.

3. Position the discharge tube over the

chipper outlet flange and slide on

using the tube latch (See Fig. #4).

4. Install the retaining rings with the

hardware provided in the owners kit.

5. Tighten the bolts so the discharge

tube does not rock on the flange.

Do not over tighten the bolts, as the

flange will distort.

6. Lift the latch on the handle of the

discharge tube and position the tube

in the desired position.

7. Release the latch making sure it

locks in one of the holes on the chipper flange.

8. Add one shot of grease to the greaze

zerk on the discharge flange. Rotate the discharge tube to spread

grease.

SLIDE DISCHARGE

TUBE ONTO CHIPPER

CHIPPER OUTLET

FLANGE

Fig. #4, Attaching discharge tube

CHIPPER

DISCHARGE

SPACER

CHIPPER

DISCHARGE

3/8" NYLOCK

NUT

CLAM

3/8" X 1-1/4"

BOLT

Fig. #5, Securing discharge tube

Page 5Skid Steer Chipper Operator’s Manual

Page 12

Assembly

MOUNTING THE CHUTE

The chipper chute must be mounted to the roller support

weldment. On the 74800 the chute is held in place with 8

bolts, on the 74500the chute is held in place with 6 bolts.

Both models use a chute support.

Fig. #6, Mounting the chute to the roller support. NOTE: The 74800 is

mounted with 8 bolts. The 74500 is mounted with 6.

Mounting the chute to the roller support:

1. Place the chute on the roller support weldment. Have

someone assist if necessary.

2. Align the chute with the mounting holes.

3. Insert all 6 or 8 (depending on model) 3/8” carriage bolts

into the mounting holes. It may be helpful to align the

holes with a punch.

4. Place washers and nuts on the opposite side of the bolts

and tighten to proper torque.

Fig. #7, Mounting the chipper chute support.

Mounting the chute support:

1. Make sure the chute is mounted to the roller support

weldment.

2. Place the chute support underneath the chute.

3. The side of the chute support with the two mounting holes

is orientated towards the chipper base.

4. Attach the chipper chute to the base with the provided 3/

8” bolts, washers and nuts. It may help to slightly lift the

chipper chute.

5. Align the other hole of the chipper chute support with the

hole in the chipper chute.

6. Insert the other 3/8” bolt , washer, and nut. Tighten to

proper torque.

Page 6 Skid Steer Chipper Operator’s Manual

Page 13

MOUNTING THE 4 POSITION VALVE

Assembly

Attaching the 4 position valve:

1. Place the 4 position valve on the chipper chute over the

(3) pre-drilled mounting holes.

2. From the inside of the chipper chute, using the 5/16” x 3/

4” bolts (P/N 15003), and washers (P/N 15250) thread

the bolts into the 4 position valve

3. Tighten 5/16” hardware to proper torque.

4. Attach the valve control lever according to the diagram

below.

5. Tighten the 5/16” bolt to the proper torque.

Fig. #8, Mounting the four position valve.

(as needed)

Fig. #9, Connecting the valve control lever to the 4 position valve.

Page 7Skid Steer Chipper Operator’s Manual

Page 14

COU

3

Features & Controls

Section

FEATURES AND CONTROLS IDENTIFICATION

Learn the location of the features and controls on your machine before operating.

MODEL # 74500 and 74800

CONTROL ARM

CHIPPER CHUTE

EXTENSION

TRAY

DISCHARGE

LOCK

KNIVE ACCESS

COVER BOLT

DISCHARGE

DEFLECTOR

DISCHARGE

TUBE

CHIPPER BLADE

ACCESS COVER

OWNERS MANUAL

COMPARTMENT

UNIVERSAL SKID-STEER

MOUNT

NOTE

All references to left,

right, front and rear of

the machine are determined by the illustrations shown.

UNIVERSAL SKID-STEER

MOUNT

FEMALE HYDRAULIC

COUPLER

MALE HYDRAULIC

PLER

Fig. #10, 74500 and 74800 features and controls

DESCRIPTION OF OPERATION

Understanding how your machine works will help you achieve the best results when using your chipper. The following

description defines the operation of your machine.

CHIPPING OPERATION

The chipping operation takes place at the front side of the machine, where hardened steel chipper blades are mounted on

a rotating rotor assembly. Material fed into the chipper chute is sliced into small chips and propelled out through the

discharge chute. The chips can be diverted into a truck or onto the ground.

Page 8 Skid Steer Chipper Operator’s Manual

Page 15

FEATURES AND CONTROLS IDENTIFICATION

Learn the location of the features and controls on your machine before operating.

MODEL # 74500 and 74800

ROTOR

ASSEMBLY

CHIPPER

BOTTOM

FEED ROLLER

FEED RATE

CONTROL

Features & Controls

FEED ROLLER

HOUSING & FEED

ROLLER

WARNING

To prevent personal injury or property damage: Shut off skid steer

engine, remove ignition key and

make sure that all moving parts have

come to a complete stop, before

servicing, adjusting or repairing.

USE OF CONTROLS

Model # 74500 and 74800.

Control Arm: The control arm has four

postions and is used to engage the feed

roller. The four positions are: reverse,

stop, forward, reverse.

Feed roller rate control: The feed

roller speed is adjustable with a hand

crank located below the chipper feed

table. Use a slower feed roller speed

when feeding large branches into the

chipper. Increase the feed roller speed

when feeding small branches into the

Fig. #11, 74500 and 74800 features and controls

chipper. Turning the crank counterclockwise decreases the feed roller

speed. Turning the crank clockwise increases the feed roller speed.

Discharge deflector: the discharge

deflector can be used to aim the spray

of wood chips from the chipper.

Discharge lock: The discharge lock

serves to lock the rotating discharge

tube. The lock is disengaged by pressing down on the discharge handle. The

discharge tube is then free to pivot. To

engage the lock release the handle and

center the locking pin on a hole in the

chipper outlet flange.

Chipper chute extension tray: The

chipper chute extension tray is lowered

by releasing the chipper chute extension latches.The extension tray then

pivots down.

Page 9Skid Steer Chipper Operator’s Manual

Page 16

4

Operation

Section

WARNING

Before operating your machine, be

sure you read and understand all

safety, controls and operating instructions in this Owner/Operators

manual and on your machine.

Failure to follow these instructions

can result in serious injury or property damage.

As with any other piece of outdoor

power equipment, getting the “feel” for

how your machine operates and getting

to know the best techniques for

particular jobs are important to overall

good performance.

Read this section thoroughly before you

use the machine. The instructions

given here will help you become familiar

with your machine and have you

operating efficiently in a short time.

This Section explains:

• Mounting the Chipper to the Skid Steer

• Installing the Flush Face Couplers

• Operating the chipper

• Chipping Guide

• Feed Roller Securing Instructions

• Loading the Chipper

NOTE

The 74800 requires a minimum hydraulic flow of 25 gallons per minute.

Fig. #12, Connected chipper

Page 10 Skid Steer Chipper Operator’s Manual

Page 17

MOUNTING THE CHIPPER TO THE SKID STEER

The chipper can be mounted to the skid

steer in two locations. The recommended location is with the feed table

sitting at the front of the loader. However, if space is a concern, the unit can

be mounted with the feed table sitting

to the right of the machine.

1. Tilt the universal skid steer mount

forward.

2. Make sure that the wedges are fully

raised.

3. Drive the skid steer forward until the

top edge of the coupler is completely

under the top flange on the chipper.

4. Tilt the unit backward until the chipper is slightly off the ground.

Operation

5. Kill the engine and exit the machine

to push down the wedges using the

universal skid steer mount levers

(See Fig. #10). On automated models stay in the machine and engage

the wedges.

WARNING

The wedges must extend through

the holes in the mounting frame of

the chipper to securely fasten the

chipper to the universal skid steer

mount. Failure to secure wedges

can allow attachment to come off

and cause injury or death.

Fig. #13, Connecting the skid steer

Fig. #14, Securing the wedges

Page 11Skid Steer Chipper Operator’s Manual

Page 18

Operation

INSTALLING THE FLUSH FACE COUPLERS

WARNING

Hydraulic lines may be under pressure due to testing done at the factory.

The Bear Cat Skid Steer Chipper is

equipped to attach to flush face couplers (See Fig. #11). The chipper is

shipped with 12 sized hydraulic couplers fitted on the hoses. A tie wrap is

used to indicate the pressure line. Be

sure to connect the hydraulic hoses

to the proper ports.

If the skid steer is fitted with anything

other than 12 sized flush face couplers,

on the main lines, it will be necessary

to replace the couplers supplied with

the chipper.

The chippers are also equipped with a

case drain hose. The case drain is used

to eliminate pressure on the chipper’s

hydraulic motor. The motor is rated for

250 to 300 psi of back pressure.

Most high flow skid steer loaders are

equipped with case drain line. Standard flow skid steer loaders typically

are not. If the back pressure tandard

flow skid steer is over 300 psi, a

case drain line will have to be

added. Contact your skid steer

dealer for details. Not adding a

case drain line voids chipper warranty.

If the back pressure is below 300 psi

the case drain line can be left idle or

removed.

To connect:

1. Before connecting make sure to relieve the hydraulic pressure in the skid

steer, using the skid steer system to

relieve pressure.

2. Remove dirt and debris from the surface of the couplers.

3. Visually check for the couplers for

damage, replace if damage is found.

4. Install the male coupler into the female coupler. Full connection is made

when the ball release sleeve slides forward on the female coupler.

5. Turn the sleeve so that it is rotated

away from the locking pin to prevent

accidental disconnection.

Fig. #15, Installed couplers

To disconnect:

1. Relieve hydraulic pressure.

2. Rotate ball sleeve so that the grooves

are aligned with the pins in the female

coupler.

3. Retract the sleeve on the female

coupler until the couplers disconnect.

4. Repeat the procedure for all hoses.

6. Repeat procedure for all hoses, including the smaller case drain hose.

Page 12 Skid Steer Chipper Operator’s Manual

Page 19

HYDRAULIC SCHEMATIC

Operation

Fig. #16, Hydraulic Schematic

Page 13Skid Steer Chipper Operator’s Manual

Page 20

Operation

OPERATING THE CHIPPER

WARNING

Do not attempt to bypass the safety systems of the

skid steer loader.

Pre-operation

1. Wear appropriate eye, face, and hearing protection. Wear

gloves that fit tight against the wrist.

2. Remove the rubber latches from both sides of the feed

table.

3. Lower the chipper feed table.

feed roller is in the neutral position) to supply power to

the unit. The chipper will start to spin.

3. Place the feed roller in the opeating position and bring the

unit up to speed.

4. The chipper is ready to chip.

Stopping the chipper

1. One operator should disengage the feed roller after all

material has been cleared from the chipper.

2. The second should then slow down the engine of the skid

steer to idle and after several seconds, disengage the

skid steer hydraulics.

Chipper operation

1. The feed roller control has four positions:

A - Reverse: Reverses the direction of the feed roller. Use

this function to unplug the feed roller.

B - Stop: Stops the feed roller.

C - Forward: Feeds brush into the chipper.

D - Reverse: Reverses the direction of the feed roller.

Fig. #17, Anti-luse coupler

4. Check that the feed roller is clear of material.

5. Place the feed roller control in the “stop” position.

6. Push down the latch and rotate the discharge chute to

the desired position.

7. Release the handle and move the chute until it locks the

chute in position.

Starting the chipper

Running the Bear Cat Skid Steer Chipper is a one or two

man operation. If the system mandates an operator in the

driveseat, two people are needed. The chipper engages with

the hydraulics of the skid steer, as do most skid steer powered attachements.

2. The feed roller speed is adjustable with a hand crank

located below the chipper feed table. Use a slower feed

roller speed when feeding large branches into the chipper. Increase the feed roller speed when feeding large

branches into the chipper. Turning the crank counterclockwise decreases the feed roller speed. Turning the crank

clockwise increases the feed roller speed.

Fig. #18, Feed roller speed adjustment

1. Set parking brake.

2. Engage the hydraulics of the skid steer (providing the

Page 14 Skid Steer Chipper Operator’s Manual

Page 21

CHIPPING GUIDE

Operation

The Bear Cat chipper is designed to chip a variety of materials into a more readily decomposing or handled condition.

The following guidelines can be used to help you get started.

WARNING

Do not leave machine unattended, or attempt any inspection or service unless the skid steer engine is

stopped, the hydraulic system disconnected, and the

key removed from the key switch.

NOTE

Please read and follow all safety instructions in

this manual. Failure to operate the chipper in accordance with the safety instructions MAY RESULT

IN PERSONAL INJURY!

• Run unit at full operating speed before starting to chip

material.

• Feed brush from the side of the chipper chute, rather

than from the front. Then, step aside to avoid being hit by

the brush moving into the chipper.

• Do not lean over the chipper chute to push objects into

the cutting device.

• Never push brush into the chipper chute with your feet.

• Place limb, butt end first, into the chipper chute until it

contacts the feed roller.

• Stop the material feeding and allow the engine to recover

if the engine slows to where it may stall.

• Chipping dead, dry material will create heat and dull the

chipping blades quickly.

• Alternate greener material with dry material to lubricate

the chipping blades for longer life and better performance.

• The chipping blades will become dull and will require periodic sharpening. Refer to Service and Maintenance section.

• The 74500 is most effective when chipping 3” in diameter

material. Five-inch material will fit into the machine, though

it may bog the chipper down. The 74800 is most effective when chipping 5” diameter material. Eight-inch material will fit in the machine, though it may bog the chipper

down.

• As soon as the feed roller has started to pull the brush

into the chipper, let go of the brush and step away from

the feed table.

• Never use shovels or forks to push brush. They can be

chipped, are expensive to replace, and cause extensive

damage. In addition, metal pieces can come back to injure or kill.

IMPORTANT

Exclude pieces of metal, rocks, bottles, cans, and

other foreign objects when feeding chipable material into the machine.

• If brush gets caught in the feed roller, causing a jam,

move the feed roller control to the reverse position. If the

roller is still jammed shut off the skid steer, disconnect

the hydraulic lines, and clean the rotor.

Page 15Skid Steer Chipper Operator’s Manual

Page 22

Operation

FEED ROLLER SECURING INSTRUCTIONS

WARNING

Feed Roller support must be secured in the up position

prior to servicing chipper feed area. Feed Roller can fall

and cause bodily harm.

Before the chipper feed area is serviced, the feed roller support

must be locked in the upright position. To secure the feed

roller support, proceed as follows.

1. Turn the 1/2" wingnut located on the bottom of the bottle

jack to the right, engaging the jack.

2. Using the jack handle, pump the jack to the most upright position. This raises the feed roller support.

3. Place a 1/2” x 1 1/2” bolt, or similar device, through the

hole called out on Fig. #2. This will ensure the feed

roller support cannot fall from the upright position.

4. Service or clear the unit of debris. Do not place hands

underneath the feed roller if possible.

5. To lower the feed roller support, remove the bolt and

then release tension on the jack by turning the 1/2"

wingnut to the left.

6. Before operation turn and tighten the 1/2" wingnut fully

to the right.

Fig. #19, Bolt insertion hole

Page 16 Skid Steer Chipper Operator’s Manual

Page 23

5

Service & Maintenance

Section

WARNING

To prevent personal injury or property damage: Shut

off skid steer engine, disconnect hydraulics, remove

ignition key, and make sure that all moving parts have

come to a complete stop before, servicing, adjusting or

repairing.

SERVICE AND MAINTENANCE SCHEDULE

MAINTENANCE SCHEDULE

The following items listed in the service and maintenance

schedule are to be checked, and if necessary, corrective

action should be taken. The most important maintenance

is to keep the chipper blades sharp. This schedule is designed for units operating under normal conditions. If the

unit is operating in adverse or severe usage conditions it

may be necessary for the items to checked and serviced

more frequently.

FREQUENCY

COMPONENT

NUTS AND BOLTS CHECK

CHIPPER BLADES CHECK, SHARPEN IF NEEDED

ENTIRE MACHINE CLEAN

ENTIRE MACHINE LUBE ALL GREASE POINTS

MAINTENANCE

REQUIRED

BEFORE EACH USE EVERY 50 HOURS

•

•

•

•

Page 17Skid Steer Chipper Operator’s Manual

Page 24

Service & Maintenance

SHARPENING CHIPPER BLADES

The chipper blades will eventually become dull, making chipping difficult and adding extra strain on the machine. It is

recommended that the chipper blades be sharpened

every 5-15 hours of chipper operation. To remove the

chipping blades for sharpening, follow the procedure below

WARNING

To prevent personal injury or property damage: Shut off

skid steer, disconnect hydraulics, remove ignition key,

and make sure that all moving parts have come to a complete stop, before servicing, adjusting or repairing.

The chipping blades are sharp! Use care when working

on machine to avoid injury.

Removing the chipper blades:

1. Disconnect the hydraulic hoses from the skid steer.

2. Position the chipper chute to the side of the chipper.

3. Remove the two bolts on the chipper housing.

4. Tip the chute and housing away from the chipper to ex-

pose the rotor and the blades.

5. Use a pry bar between two of the fan blades to prevent

the chipper from rotating during chipper blade removal

and installation.

6. Remove the blades (Qty. 4) making sure not to slip the

wrench, the chipper blades are sharp.

7. The chipper blades are reversible. If the blades have not

been reversed flip the blades 180 degrees and reinsert.

8. If the chipper blades need to be sharpened refer to the

sharpening blades section of the manual.

9. Inspect all components of the chipper for damage and

replace if necessary.

Sharpening the Blades:

1. When sharpening the blades grind the angled edge of the

chipping blade to 45 degrees. This is best accomplished

on a slow-speed wet grinder. If a bench grinder is used

be careful when grinding so that the blade material does

not get too hot and change color–this will remove the

blade's special heat treated properties.

2. Be sure to use short grinding times and cool with water

between grinding.

3. Try to remove an equal amount off each blade to maintain

balance.

NOTE

Never sharpen or grind on the back side of the chipper

blade. This will cause the edge to roll and the chipping

blade will be damaged, causing poor chipping and feeding of material. Small imperfections, nicks, burrs, etc. on

the flat side of the blade will not affect performance of the

machine.

Installing the blades:

1. Remove any accumulated material in the bottom of the

chipper drum.

2. Reinstall the chipper blades (Qty. 4) and tighten the bolts

to a torque of 20 ft. lbs. (74500) or 75 ft. lbs. (74800).

3. Check anvil clearance and adjust if necessary.

4. Close the chipper housing and reattach with removed

bolts to a torque of 25-28 ft.-lbs.

5. Reconnect machine hydraulics.

IMPORTANT

Do not exceed the recommended torque values of 20

ft. lbs. (74500) or 75 ft. lbs. (74800) when tightening

the bolts for the chipper blades.

MOUNTING

SHARPENED

SURFACE

SURFACE

DO NOT GRIND

45°

MOUNTING

SURFACE

DO NOT GRIND

Fig. #20, Sharpening Chipper Blades

Page 18 Skid Steer Chipper Operator’s Manual

CHIPPER

BLADE

SHARPENED

SURFACE

Tips:

Poor chipping performance is usually a result of dull chipping blades. If your chipper's performance has decreased,

check for the following symptoms. If the machine shows

these symptoms, sharpen the blades.

1. Severe vibration when feeding material into the chipper.

2. Chips discharge unevenly or have stringy tails–especially

when chipping green branches.

Before you sharpen the chipping blades, check for permanent damage. Replace the blade if:

1. The blade is cracked (especially around the bolt holes)

or the edges are too deeply chipped to be ground smooth.

2. The base of the cutting edge is worn or has been resharpened so that it is too close to the rotor chipping

slot.

Page 25

CHIPPER BLADE AND ANVIL CLEARANCE

Setting chipper blade clearance

1. The blade to anvil clearance is 1/16”

to 1/8”. The chipper must be between

these specifications at all times.

2. Adjust the anvil by loosening the two

(74500) or three (74800) anvil bolts.

3. On the 74500 move the anvil assembly in or out by turning the nuts on the

block adjuster weldment.

4. On the 74800, with the three anvil

bolts loosened, adjust the anvil to the

desired position.

4. If the anvil cannot be moved to specifications due to wear, rotate the anvil

or replace the anvil.

Service & Maintenance

5. Secure all hardware and adjust to

torque.

Fig. #21, Anvil and chipper blade clearance

Page 19Skid Steer Chipper Operator’s Manual

Page 26

Service & Maintenance

GREASING

Use an SAE multi-purpose high temperature grease with

extreme pressure (EP) performance meeting or exceeding

the NLGI # 2 rating for all requirements. Also acceptable is

an SAE multi-purpose lithium based grease.

WARNING

To prevent personal injury or property damage: Shut off

skid steer engine, disconnect hydraulics, remove ignition key, and make sure that all moving parts have come

to a complete stop before servicing, adjusting, or repairing.

Care should be taken when re-greasing bearings to not overfill

the bearing. Over greasing can lead to overheating and/or

unsealing the bearing seals.

1. Use a hand-held grease gun for all greasing.

2. Wipe grease fitting with a clean cloth before greasing,

to avoid injecting dirt and grit.

3. Replace and repair broken fittings immediately.

4. If fittings will not take grease, remove and clean thoroughly. Also clean lubricant passageway. Replace fitting if necessary.

5. Grease and oil the unit as illustrated.

Fig. #23, Grease every 50 hours

Fig. #24, Grease every 50 hours

Fig. #22, Oil yearly

Page 20 Skid Steer Chipper Operator’s Manual

Page 27

h50

Service & Maintenance

Fig. #25, Grease every 50 hours

Fig. #27, Grease every 50 hours

Fig. #26, Grease every 50 hours

Fig. #28, Same zerk as Fig. #26, shown with shield removed.

WARNING

The shield was removed for illustrative purposes only; DO

NOT run the machine without guards or shields in place

and functioning.

Page 21Skid Steer Chipper Operator’s Manual

Page 28

Service & Maintenance

CLEANING PLUGGED ROTOR

WARNING

If the machine becomes plugged, shut off the skid steer

engine, disconnect the hydraulics, remove ignition key,

and allow the machine to come to a complete stop before

clearing debris. Do not operate machine without proper

guards and screens in place.

Cleaning the Rotor:

1. Stop skid steer engine, disengage hydraulics, and allow

machine to come to a complete stop.

2. Position the chipper chute to the side of the chipper.

3. Remove the two bolts on the chipper housing.

4. Tip the chute and housing away from the chipper to ex-

pose the rotor and the blades.

5. Clean the debris out of the chipper. Turn the rotor by hand

to be sure it is free to rotate. Check for damage to the

rotor.

Cleaning the Feed Roller:

A bottle jack is mounted on the chipper to raise the feed

roller. This allows plugged debris to be easily removed from

the roller if the reverse function fails to dislodge the debris.

To operate the jack:

1. Turn the 1/2” wingnut located on the bottom of the jack to

the right, engaging the jack.

2. Using the jack handle pump the jack, connected to the

feed roller, to the desired location.

3. Clear the unit of debris. Do not place hands underneath

the feed roller.

4. Once the debris has been cleared release tension on the

jack by turning the 1/2” wingnut to the left and lowering

the feed roller.

5. Before operation turn and tighten the 1/2” wingnut fully to

the right.

6. Close the top housing.

7. Reattach the two bolts securing the chipper housing.

8. The machine is ready for operation.

Page 22 Skid Steer Chipper Operator’s Manual

Page 29

Service & Maintenance

TROUBLESHOOTING

Before performing any of the correction in this troubleshooting chart, refer to the appropriate information contained in this

manual for the correct safety precautions and operating or maintenance procedures. Contact your nearest dealer or the

factory for service problems with the machine.

Problem Possible Cause Correction

Feed roller does not engage.

Chipper is hard to feed.

Chipper vibrates excessively.

Chipper does not turn. No hydraulic flow.

Chipper does not discharge

chips.

Low hydraulic flow due to low engine

RPM.

1 - Plugged discharge chute. 1 - Clear discharge chute.

2 - Dull chipper blades. 2 - Sharpen blades.

3 - Damaged chipper blades. 3 - Replace damaged blades.

4 - Improper blade clearance. 4 - Adjust clearance.

1 - Chipper not correctly attached to

skid steer.

2 - Damaged chipper blades. 2 - Replace damaged blades.

Not enough hydraulic flow.

1 - Wedges are not fully extened. 1 - Retract wedges.

Move loader engine speed to

higher RPM.

1 - Check for correct mounting of

the chipper to the skid steer

Check quick couplers connection.

Check for damaged hose ends

and fittings.

Make sure enough flow is

provided by the skid steer.

Chipper does not seat

properly on the skid steer.

2 - Mud, dirt or stones are lodged

between the chipper and the skid

steer.

2 - Remove debris from between

the chipper and the skid steer.

Page 23Skid Steer Chipper Operator’s Manual

Page 30

Specifications

5” and 8” Skid Steer Chipper (Model 74500 and 74800)

"H"

"I"

"A"

"C"

"G"

"E"

"F"

"B"

"D"

MODEL 74500 & 74800 DIMENSIONAL DATA

MODEL "A" "B" "C" "D" "E" "F" "G" "H" "I"

74500

74800

ROTOR SPEED 1500 RPM 1500 RPM

FRAME MATERIAL 1/4" THICK STEEL CONSTRUCTION 1/4" THICK STEEL CONSTRUCTION

CHUTE SIZE 32" X 36" 32" X 36"

DRIVE SYSTEM HYDRAULICS HYDRAULICS

SKID-STEER HYDRAULICS STANDARD OR HIGH-FLOW HIGH-FLOW

CHIPPER BLADES (QTY. 4) CHIPPER BLADES (TOOL STEEL) (QTY. 4) CHIPPER BLADES (TOOL STEEL)

ROTOR SIZE 20” X 1-1/4", 140 POUNDS 30” X 1-1/4”, 275 POUNDS

WEIGHT 1145 LBS. 1525 LBS.

CHIPPER OPENING SIZE * 5-1/2" X 7" 9" X 9"

CONTINUOUS CHIPPING SIZE * 3” (76.2MM) DIAMETER 5” (127MM) DIAMETER

DISCHARGE TUBE ROTATING ANGLE

RANGE

* Continous Chipping Size rating refers to the suggested feeding size of limbs for normal operat ions. Limbs up to the Chipper O pening Size may be

fed, but decreased per formance will occur.

91.9 102.2 56.4 46.0 48.1 49.2 23.3 29.6 6.0

92.2 103.3 59.6 46.0 45.4 56.5 23.6 37.8 8.0

SPECIFICATIONS

MODEL 74500 74800

360° 360°

Page 24 Skid Steer Chipper Operator’s Manual

Page 31

Specifications

BOLT TORQUE REQUIREMENTS

The tables shown below give correct torque values for various bolts and capscrews. Tighten all bolts to the torques specified

in chart unless otherwise noted. Check tightness of bolts periodically, using this bolt torque chart as a guide. Fasteners

should be replaced with the same grade bolt. Tighten serrated or center-lock nuts to the full torque value.

Do not use these values if a different torque value or tightening procedure is given for a specific application. Torque values

listed are for general use only.

SAE

Grade

and

Head

Markings

SAE - 8SAE - 2ASAE - 5

BOLT DIAMETER

UNIFIED INCH BOLT TORQUE VALUES

(unless otherwise specified in the manual)

Bolt

Diameter

"A"

1/4" 7.5 5.5 12 9 17 12.5

5/16”1511251835 26

3/8” 27 20 44 33 63 46

7/16”44327052100 75

1/2” 67 50 110 80 150 115

9/16” 95 70 155 115 225 160

5/8” 135 100 215 160 300 225

3/4” 240 175 375 280 550 400

7/8” 240 175 625 450 875 650

1” 360 270 925 675 1300 975

1-1/8” 510 375 1150 850 1850 1350

1-1/4” 725 530 1650 1200 2600 1950

1-3/8” 950 700 2150 1550 3400 2550

1-1/2” 1250 930 2850 2100 4550 3350

SAE 2

(N.m) (ft - lb) (N.m) (ft - lb) (N.m) (ft - lb)

Bolt Torque *

SAE 5 SAE 8

Torque figures indicated at left are

valid for non-greased or non-oiled

threads and heads unless otherwise specified. Therefore, do not

grease or oil bolts or capscrews

unless otherwise specified in this

manual. When using locking elements, increase torque values by

5%.

* Torque value for bolts and

capscrews are identified by their

head markings.

SPECIAL TORQUE REQUIREMENTS

LOCATION ON MACHINE HARDWARE DESCRIPTION

74500 CHIPPER BLADE MOUNTING BOLTS 5/16" X 1 1/4" HEX HD. GRADE 8 BOLTS (QTY 8) 20 ft-lbs 27 N.m

74800 CHIPPER BLADE MOUNTING BOLTS 1/2" X 2 1/2" FLAT HYD SKT. (QTY 12) 75 ft-lbs 101 N.m

TORQUE

(UNIFIED INCH))

TORQUE

(METRIC)

Page 25Skid Steer Chipper Operator’s Manual

Page 32

Crary Company

A Division of TerraMarc Industries

237 12th St. NW • P.O. Box 849

West Fargo, ND 58078-0849

(701)282-5520 • FAX: (701)282-9522

www.bearcatproducts.com

www.terramarc.com

Manufactured in the

United States of America

by Crary Company

Loading...

Loading...