Page 1

Instructions

SUBJECT : 12 BLADE CUTTER UPGRADE

KIT # 76906-00

FITS MODELS : STUMP GRINDERS

SERIAL # 100410 - CURRENT

WARNING

Before inspecting or servicing any part of this machine,

shut off power source and make sure all moving parts

have come to a complete stop.

DISASEMBLING THE EXISTING 6 BOLT /12

BLADE CUTING SYSTEM

NOTE

THIS KIT IS DESIGNED TO UPGRADE ANY

EXISTING STUMP GRINDERS OR 12 BLADE

KITS THAT WERE BUILT WITH THE 6 BOLT

COVER PLATE AND SINGLE SPACER PLATE

SYSTEM. IF YOU HAVE A 4 BLADE CUTTING

SYSTEM AND WANT TO UPGRADE, IT WILL BE

NECESSARY TO ORDER KIT, 12 BLADE RETRO

FIT, PN 76903-00..

12 BLADE CUTTER UPGRADE KIT, PN 76906-00

PART # DESCRIPTION QTY

15059 BOLT, 3/8 X 1 3/4" CRG 12

15388 NUT, 3/8 NYLOCK 12

76898-12

76899-12

76900-12

76907-00

PLATE, COVER STUMP GRINDER

HEAD

PLATE, SPACER STUMP GRINDER

HEAD

PLATE, DISK STUMP GRINDER

HEAD

INSTRUCTIONS, SG340 CUTTER

UPGRADE

1

2

1

1

1. Position and secure the machine to best access the

cutter assembly.

2. Loosen and remove the existing 1/2 X 3/4" bolt and

washer from spindle located at the bottom of the cutter

assembly.

3. Remove the plates and blades assembly from the

spindle.

4. Loosen and remove the existing 6 bolts, nuts and

washers in the cutter assembly.

5. Separate the plates, remove the 12 cutting blades and

set blades aside.

6. Discard the three plates

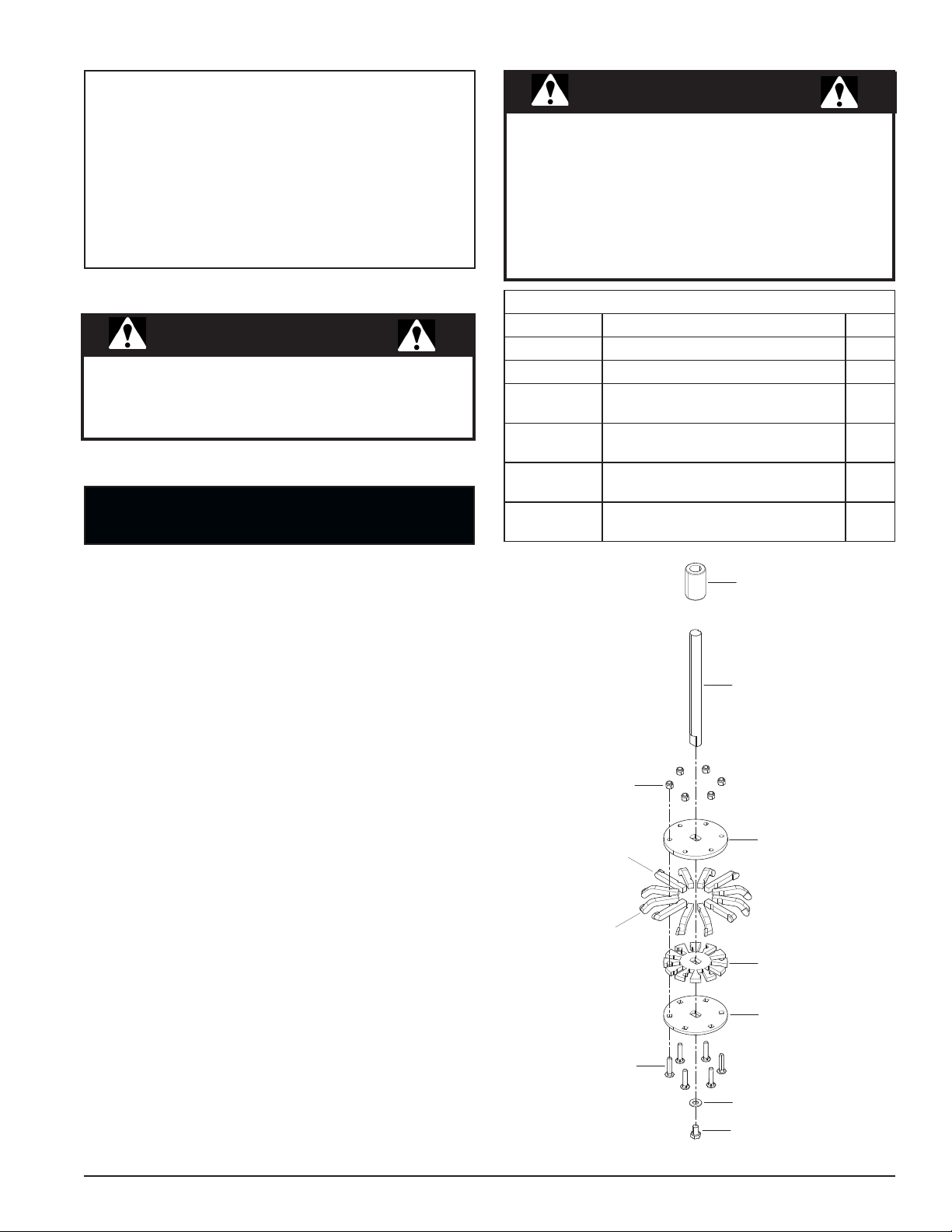

TUBE, SPACER, 1-3/4" X 2.770"

SPINDLE, 12 BLADE RETRO

NUT, 3/8" NYLOCK

PLATE, HEAD DISK

TOOTH, STRAIGHT

TOOTH, CURVED

PLATE, HEAD SPACER

PLATE, HEAD COVER

BOLT, 3/8" X 1-3/4" CRG

INSTRUCTION SHEET

WASHER, 1/2" SAE FLAT

BOLT, 1/2" X 3/4" NF

PN 76907-00

Rev. 092010

Page 2

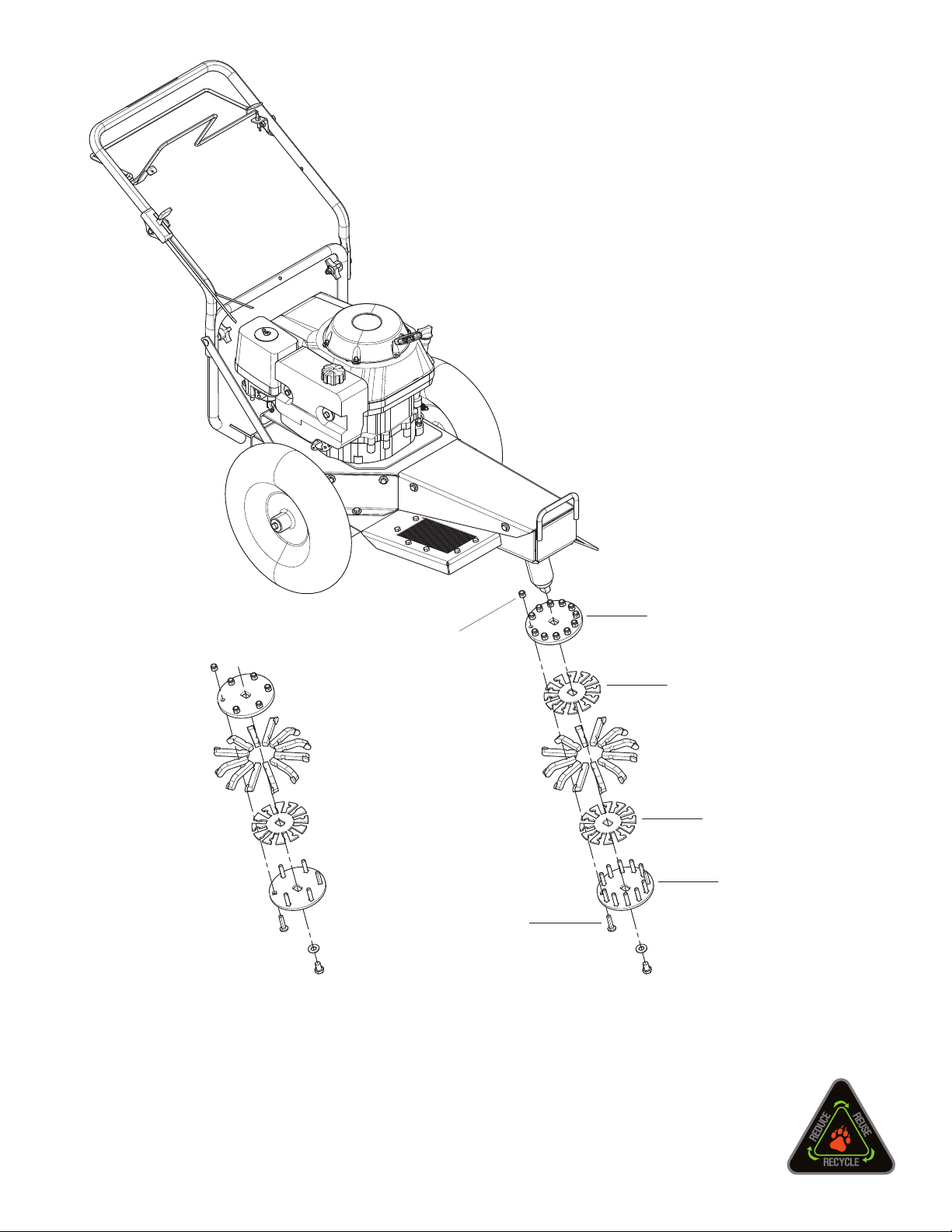

ASSEMBLING THE 12 BOLT/12 BLADE KIT, UPGRADE CUTTING SYSTEM

1. Begin by placing the painted bottom plate (76898-12

(with square holes)) on a flat working area.

2. Place the two spacer plates (76899-12) on the bottom

plate and align center spindle hole and 12 bolt holes

of the spacer plates to the spindle hole and bolt hole

of the bottom plate. (See photos below.)

3. Begin placing the cutting blades (removed in step 5 of

the disassembly) into the blade openings of the aligned

space plates. (Placing two of the new 3/8" X 1 3/4"

carriage bolts (15059), up from the bottom, hrough the

hole locations will help keep the plates aligned during

the following steps.)

Straight Blade Inset

Angled Blade Inset

Spacer plates INCORRECTLY

aligned to bottom plate.

Straight Blade Inset

Angled Blade Inset

Spacer plates CORRECTLY

aligned to bottom plate.

INSTRUCTION SHEET

Page 3

NOTE

IT IS IMPORTANT TO NOTE THE SPECIFIC

SEQUENCE AND ORIENTATION THE BLADES

MUST BE IN FOR SUCCESSFUL ASSEMBLY

AND OPERATION OF THE SUTTER SYSTEM.

6. Put all of the remaining bolts into the holes from the

bottom.

7. Place the painted cover plate (76900-12) over and on

to the 12 bolts of the assembly and secure plate into

place using the twelve 3/8" lock nuts (15388).

Top view of spacer plates with blades in place and properly oriented so

the blade tips point in a clockwise direction.

4. There are four straight cutting blades and eight angled

blades.

5. The angled blades are shorter than the straight blades

and are placed next to each other with a straigh blade

placed next. Continue until all 12 blades are in place.

8. Install the cutter assembly on to the spindle, making

sure the angled blades point down. Also make sure the

end of the spindle is flush with the bottom plate and

secure into place using the 1/2 X 3/4" bolt and washer

removed in step 1 of the disassembly. Torque bolt to

70 ft. lbs.

Bottom view of cutter assembly with the

spindle mounted flush to bottom plate.

INSTRUCTION SHEET

Page 4

NUT, 3/8" NYLOCK

BOLT, 3/8" X

1-3/4" CRG

PLATE, HEAD

DISK

PLATE, HEAD

SPACER

PLATE, HEAD

SPACER

PLATE, HEAD

COVER

ECHO BEAR CAT

www.bearcatproducts.com

237 NW 12th Street, West Fargo, ND 58078-0849

Phone: 701.282.5520 • Toll Free: 800.247.7335 • Fax: 701.282.9522

E-mail: service@bearcatproducts.com • sales@bearcatproducts.com

Loading...

Loading...