Page 1

EZ TrimMower

Owners Manual

Models 73040, 73050, 73450,

74040, 74450, 74455, 74050,

74060, & 74065

Crary Bear Cat

Box 849

West Fargo, ND 58078

800-247-7335

FAX: (701) 282-9522

Manufactured in the

United States of America

by Crary Company

Part No. 12331

Manual No. 598

Page 2

Dear Bear Cat Customer,

Thank you for purchasing a Bear Cat EZ TrimMower. The EZ

TrimMower is designed, tested, and manufactured to give years of

dependable performance. To keep your machine operating at peak

efficiency, it is necessary to correctly adjust it and make regular

inspections. The following pages will assist you in the operation and

maintenance of your machine. Please read and understand this

manual before operating the EZ T rimMower .

If you have any questions or comments about this manual, please

call us at 800-247-7335.

If you have any questions or problems with your machine, please

call or write your local factory-authorized Bear Cat dealer.

How to Contact Bear

A

DDRESS

Crary Bear Cat

237 NW 12th Street

PO Box 849

West Fargo , ND

P

Cat

58078

HONE

Please Send Us Your Warranty Card

A warranty card is included in your owners kit packaged with your

machine. Please take the time to fill in the information requested on the

card. When you send your completed card to us, we will register your

machine and start your coverage under our limited warranty.

Owner's Record

Please take a moment to record the

following information about your new EZ

TrimMower. If you need to call for assistance, please be ready to provide your

model and serial numbers. This inf ormation will allow us (or your dealer) to help

more quickly when you call.

Model Number

Be alert! Your Safety is Involved.

Serial Number

This safety alert symbol identifies important

safety messages in this manual. When you

see this symbol, be alert to the possibility of

personal injury and carefully read the message

that follows.

701-282-5520

F AX (701) 282-9522

E

MAIL

opesales@crary .com

service@crary.com

H

OURS

M-F, 8 a.m. to 5 p.m.

Central Time

Page 3

Table of Contents

Safety Instructions ...................................................................................2

Assembly................................................................................................. 3

Starting ....................................................................................................5

Operation.................................................................................................7

Service and Maintenance ........................................................................ 9

Troubleshooting ..................................................................................... 11

Warranty ................................................................................................ 12

Before You Begin:

When using your new EZ T rimMower please take the time and effort to

do it the safe way. Follow all the safety instructions carefully, and make

sure everyone involved in the assembly does the same.

Do not operate your Machine with any guards or shields

removed!

A Service Tip

Follow the suggestions outlined in this manual. For adjustment, repair, or

service not covered in this manual, contact your nearest authorized Bear

Cat dealer. Your dealer is knowledgeable about your machine and has a

direct line to the factory for assistance.

Torque Chart

Standard minimum

tightening torque for

normal assembly

applications.

Bolts (SAE GR5)

Size Ft. Lbs.

5/16" 20

3/8" 35

1/2" 75

NOTE: All references to left, right, front and

rear of the machine are determined by standing behind the handlebars and facing the

direction the machine is traveling.

Screws

Size Ft. Lbs.

5/16" Set 15

1

Page 4

Safety Instructions

1. Become familiar with the owners manual

and engine manual before attempting to

operate this equipment.

2. Carefully read all safety and operation

decals before operating.

3. Do not allow children or unqualified individuals

to operate this equipment.

4. Do not allo w hands, or any part of body or

clothing, near any moving part.

5. Do not operate this equipment in the vicinity

of bystanders. Keep bystanders and pets at

least 50 feet away from the area of operation.

6. Do not operate barefoot. Wear proper

clothing to protect feet, legs and other

exposed body parts.

7. Wear safety glasses at all times while

operating the machine. One pair of safety

glasses is provided.

8. Do not operate machine while under the

influence of alcohol or medications. Do not

use machine if tired or ill.

4. Always use an approved fuel container. Do

not remove the gas cap or add fuel when

engine is running. Add fuel to a cool engine

only.

5. Do not fill fuel tank indoors. Keep open

flames, sparks, smoking materials, and other

sources of combustion away from fuel.

6. Before inspecting or servicing any part of the

machine, shut off the engine, disconnect the

spark plug, and make sure all moving parts

have come to a complete stop.

7. Inspect area to be trimmed. Remove all

foreign objects (stones, wire, bottles, and

cans) before operating.

Operation

1. Never leave machine unattended when it is

running.

2. Do not tamper with the engine governor

settings on the machine; the governor

controls the maximum safe operating speed

and protects the engine and all moving parts

from damage caused by dangerously high

speeds.

General Operation Safety

1. Wear work gloves, sturdy footwear, and ear

and eye protection when operating this

equipment.

2. Keep all guards and deflectors in place and

in good working condition.

3. Before starting the machine, visually check

that all screws, nuts, bolts, and other fasteners are properly secured. Once every ten

hours of operation, all screws, nuts, bolts

and other fasteners should be checked and

tightened if necessary.

2

3. If the cutting mechanism strikes any foreign

object immediately shut off the engine and

allow the machine to stop before removing

object.

4. If the machine should start vibrating abnormally, stop the engine and correct the problem before restarting.

5. Carbon monoxide can be extremely dangerous in an enclosed area. The exhaust from

the engine contains carbon monoxide, which

is a colorless, odorless, and tasteless gas.

6. Do not transport or move machine when it is

running.

Page 5

Assembly Instructions

Caution: Remove spark plug wire from spark

plug before assembling.

AssembAssemb

Assemb

AssembAssemb

ll

y Requirements:y Requirements:

l

y Requirements:

ll

y Requirements:y Requirements:

• Two (2) 1/2” wrenches

Assembly Steps:

1. Remove units and parts from shipping crate.

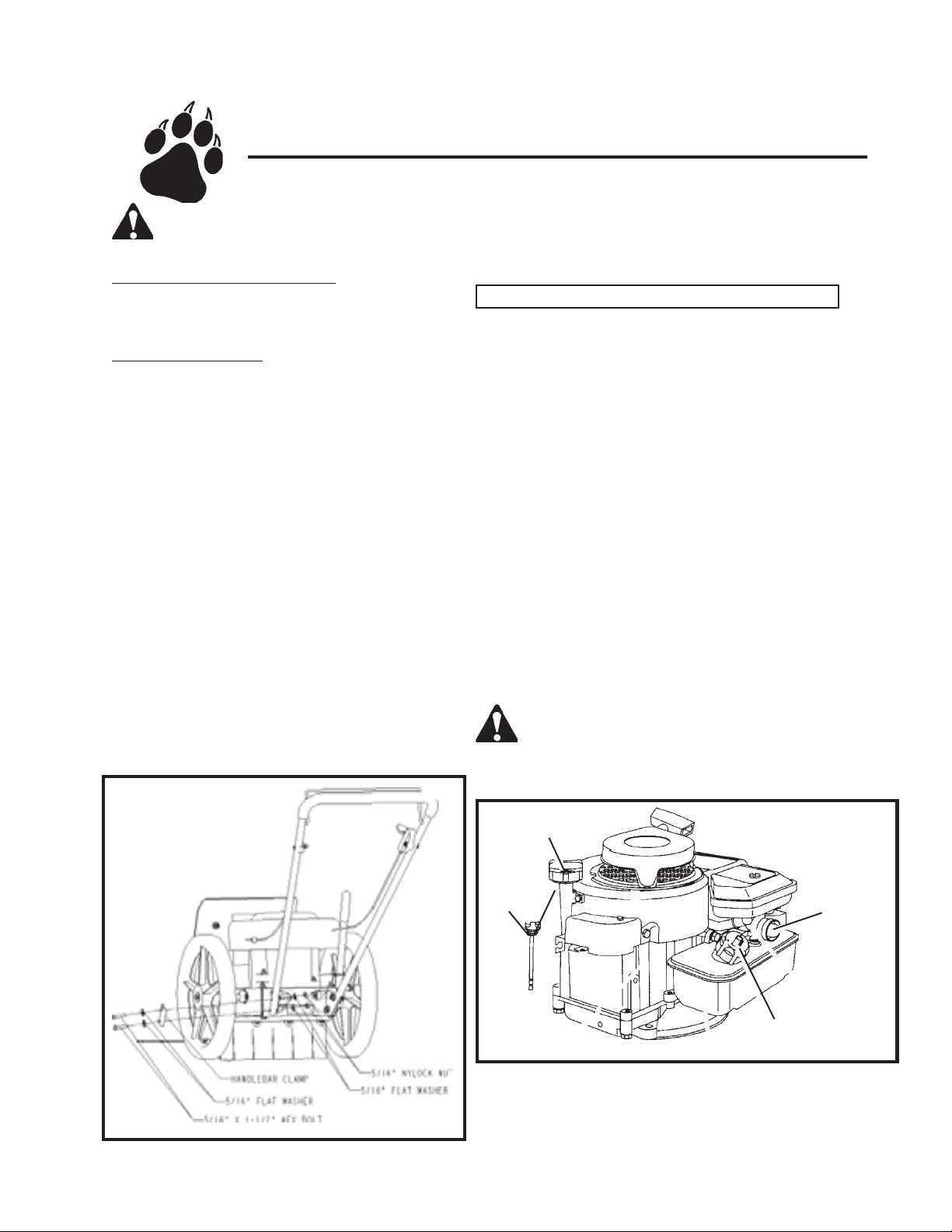

2. Stand handlebar upright. Secured the

bottom of the handlebar by adding the

handlebar clamp and inserting and tightening bolts to the bottom hole on the handle

support channel. Refer to Figure 1.

3. Adjust the handlebar height. The handlebar

height is set by choosing one of the available three holes on the handle support

channel towards the bottom of the

handlebar’s lo wer portion.

4. Align the holes on the bottom portion of the

handlebar with the selected holes on the

handle support channel. Thread bolts

through the holes with the bolt head facing

out.

5. Tighten bolt by turning counterclockwise while

holding the locknut stationary with the other

wrench.

FILL ENGINE WITH OIL BEFORE STARTING

6. Add oil to the engine. Refer to the engine

owners manual for recommended SAE 30 engine

oil types and amounts. No special additives are

used with recommended oil types; do not to mix

with gasoline. Ensure the machine is level when

adding oil. Oil capacity is approximately 20 oz.

7. Check oil level. Remove dipstick and wipe with

clean cloth. Reinsert dipstick and tighten. Remove again to check oil level; oil should be at

the Full mark. See Figure 2 for oil fill location.

8. Fill gas tank with fresh, clean, unleaded gasoline. Do not use fuel that contains Methanol or is

mixed with oil. Ensure the machine is level when

adding fuel. Refer to engine owners’ manual for

additional information.

Warning: Handle fuel with care. Use an

approved container and fill outdoors. Do

not add fuel to a running or hot engine. It

is extremely flammable.

Figure 1

Oil Fill

Dipstick

Primer Bulb

Fuel Fill

Figure 2

4HP Briggs & Stratton

3

Page 6

Assembly Instructions-Cont.

9. Attach the shield. Thread bolts through holes in

shield as shown in Figure 3.

10. Add washers and lockunuts. Tighten bolts by

turning the locknuts counterclockwise.

Figure 3

4

Page 7

Engine Starting Instructions

Models 73040, 73050, 74040, & 74050

Read the safety instructions. Familiarize

yourself with the safety instructions in this

manual and the engine owners manual before

starting the EZ TrimMower.

Fill engine with oil. Do not start before adding

oil to the engine. See engine manual for the

type and amount of oil to use. Machine should

be level when filling.

Caution: Move machine to a clear, level

area outdoors before starting. Do not

operate in the vicinity of bystanders.

1. Check engine oil level and fill if necessary

before each use. See engine manual for filling

and maintenance instructions.

Note: some oil usage is normal. Check level

before each use.

6. If engine does not start after 3 pulls, push

the Primer Bulb 3 times, and repeat step 5.

After first time engine start

3. Move the throttle control to FAST (not

applicable for Models 73040 & 73050).

Refer to Figure 4.

4. Firmly push the Primer Bulb 3 times.

5. Pull trimmer bail back. Grasp the recoil

starter cord handle and slowly pull until

resistance is felt. After resistance is felt, pull

the cord quickly to start the engine and

prevent kickback. Repeat if necessary.

NOTE: When restarting a warm engine after a

short shut down, it may not be necessary to

prime. Refer to the engine owner s manual for

other starting tips.

Warning: Handle fuel (gasoline) with

care. It is highly flammable. Always use

an approved container and fill tank outdoors. Never add fuel to a running or hot

engine.

2. Fill fuel tank with fresh, clean unleaded gasoline. DO NOT MIX OIL WITH GASOLINE.

First time engine start

3. Move the throttle control to FAST (not applicable for Models 73040 & 73050). Refer to

Figure 4.

4. Firmly push the primer bulb 5 times.

5. Pull trimmer bail back. Grasp the recoil

starter cord handle and slowly pull until resistance is felt. After resistance is felt, pull the

cord quickly to start the engine and prevent

kickback. Repeat if necessary.

Throttle Control

Figure 4

Continue to hold the bail after the engine is started.

Releasing will stop the engine.

5

Page 8

Model 73450

Engine Starting Instructions-Cont.

Read the safety instructions. Familiarize

yourself with the safety instructions in this

manual and the engine owners manual before

starting the EZ TrimMower.

Fill engine with oil. Do not start before

adding oil to the engine. See engine manual

for the type and amount of oil to use. Machine

should be level when filling.

Caution: Move machine to a clear,

level area outdoors before starting.

Do not operate in the vicinity of bystanders.

1. Check engine oil level and fill if necessary.

See engine manual for filling and maintenance instructions.

Note: some oil usage is normal. Check level

before each use.

Warning: Handle fuel (gasoline) with

care. It is highly flammable. Always use

an approved container and fill tank outdoors.

Never add fuel to a running or hot engine.

7. Grasp the recoil starter cord handle and slowly

pull until resistance is felt. After resistance is felt,

pull the cord quickly to start the engine and

prevent kickback. Repeat if necessary.

8. Move the throttle from choke to the fast (or high)

position after the engine warms up enough to

operate without the choke.

Throttle Control

Figure 5

2. Fill fuel tank with fresh, clean unleaded

gasoline. DO NOT MIX OIL WITH GASOLINE.

Move engine fuel valve to ON position before starting.

See engine manual complete instructions. See Figure 6.

3. Move the throttle control on the handlebar to

the choke position. Refer to Figure 5.

The choke may not be needed if the air temperature or

engine is warm. If so, move the throttle control slightly

past the idle position Refer to the owners manual for

other starting tips.

6. Pull the trimmer bail back.

Continue to hold the bail after the engine is started.

Releasing will stop the engine.

6

9. Mo ve the throttle level to the desired engine speed

setting for trimming.

Figure 6

Page 9

Operation

Wear safety glasses during operation. Wear

proper clothing to protect feet, legs, and

other exposed body parts.

Do not operate without all guards in place and in the

vicinity of bystanders or personal property.

Warning: Hazardous Operations

within 50 feet of unit

50 ft.

50 ft.

Operating

Area

50 ft.

50 ft.

Model 73040/73050/73450 Trimming

Adjustments

Trimming Adjustments are used to edge

and trim in hard to reach places. To begin

using trimming adjustments:

1. Loosen the right axle nut located directly

behind the trimmer.

2. Lift the right wheel and pull back. The

wheel and axle will rotate backwards due to

a slot cut in the bottom of the trimmer

frame.

3. Tighten the nut loosened in Step 1.

4. Push the trimmer slowly.

5. When finished using the offset feature,

loosen the right axle nut again and lift the

wheel and push forward.

Use caution when operating near loose

gravel or areas where loose debris may be

encountered.

The intended use of the EZ TrimMower is trim-

ming, mowing and edging. It can be used as a

mower or trimmer and edger after mowing with a

lawnmower.

To begin trimming, with the engine running, place

the trimmer head on the ground and begin walking

slowly. The wheels should remain grounded at all

times to prevent undue pressure on the trimmer

head. The cutting radius is dependent on the

amount of cutting string used and type of application. For difficult conditions and edging, using less

than the full cutting radius is recommended.

6. Tighten the right axle bolt and resume

regular trimming/mowing.

Model 74040/74050 Off Center Tilt

Feature (OCT)

The OCT feature is used to edge and trim

in hard to reach places. This features

enables both the trimmer head and body to

tilt for close cutting. The degree of tilt is

dependant on the setting selected on the tilt

control grip located on the right side of the

EZ TrimMower. For maximum tilt, move the

tilt control grip to the setting closest to the

front of the machine. Resume regular

trimming/mowing by placing the tilt control

grip back in the setting near the rear of the

trimmer.

7

Page 10

Operation-Cont.

All Models Cutting Height Adjustment

The EZ TrimMower standard cutting height is 2-3/4 inches. Figure 7 below depicts the trimmer

head assembly when purchased and at the standard cutting height.

Figure 7

The cutting height can be adjust down approximately 3/4 inch by turning the trimmer head disk

over as shown in Figure 8. The timmer head weldment is remove before the disk can be

turned.

8

Figure 8

Page 11

Service & Maintenance

Cutting String Replacement

Warning: Before inspecting or servicing

any part of the machine, disconnect the

spark plug wire from the spark plug and make

sure all moving parts have come to a complete stop.

1. Feed the cutting string through the second

hole on either end of the trimmer head leaving

approximately 8 inches for the cutting surface.

Total recommended string length is 20-1/2

inches.

2. Continue by weaving the cutting string

through the first hole directly beside the

second hole used in Step 1. Pull the cutting

string tight.

3. Loop the cutting string back and feed

through the first hole on the opposite end of

the trimmer head.

4. Feed through the remaining second hole

and pull the cutting string tight. The cutting

strings in the middle two holes should be the

same length. If the length differs, cut to an

even length.

Cutting string is available in two thicknesses,

.130 mil (standard) and .155 mil (heavy duty).

The type of string selected is dependent on the

conditions and material being cut. The cutting

string can also be wrapped in a variety of ways.

Refer to the figures below for two examples.

Figure 10

When completed, the trimmer head should

resemble Figure 9.

Figure 9

Figure 11

The wrapping method and cutting string thickness

chosen is ultimately based on what is determined

the best performers for the operator.

9

Page 12

Service & Maintenance-Cont.

Drive Belt Checking and Replacement

Check the condition of the drive belt annually or

after 30 hours of operation, whichever comes first.

If the belts are cracked, frayed, or worn, replace

them by following the steps below.

Belt Replacement Requirements:Belt Replacement Requirements:

Belt Replacement Requirements:

Belt Replacement Requirements:Belt Replacement Requirements:

• One (1) 1/2” wrench or one (1) 1/2”

socket/ ratchet

Belt Replacement Steps:

1. Shut off the engine. Disconnect the spark

plug wire.

2. Remove the front cover weldment. Requires

loosening and removing three bolts.

3. Loosen the four bolts fastening the spindle

hub to the trimmer bottom frame. This will allow

the spindle hub with the attached trimmer pulley

to move freely.

9. Replace front cover and secure with bolts.

10. Replace the handle support channel (back

cover with handlebar adjustment tabs). The bolts

should be secured with the bolt head beneath and

the nuts and washer above the trimmer body.

Engine Maintenance

Maintenance is essential in preserving engine life.

The engine should be cleaned periodically to

remove grass and build-up. The engine owners

manual addresses cleaning the air filter and

changing the oil. Service engine according to the

maintenance schedule in your engine owners

manual.

4. Remove the handle support channel (back

cover with tabs to adjust the handlebar). Requires loosening and removing four bolts.

5. Loosen the two bolts attaching the flap to the

trimmer bottom frame.

6. Remove worn or broken belt. If the belt is

badly worn and will not be used again, cut for

ease in removal.

7. Install new belt from the front to the back.

Feed belt above the front trimmer pulley and

below the rear pulley.

8. Move the spindle hub by inserting a screwdriver in the slot on the rear side of the spindle

hub and applying pressure forward until belt is

tight. Tighten bolts.

10

Page 13

Troubleshooting

Problem Probable Cause

1. Cutting strings do not

turn.

2. Cutting is slow or rough.

3. Trimmer requires excessive power or stalls.

a)Broken or damaged belts.

b)Broken spindle.

c) Failed bearings.

a)Cutting string too weak.

b)Growth is too thick or

heavy.

a)Cutting string too weak.

b)Drive belts are loose or

worn.

c) Growth is too thick or

heavy.

Suggested Remedies

a)Replace belts.

b)Repair spindle.

c) Repair bearings.

a)Replace with heavier cutting

string (155 mil).

b)Reduce trimming area to 1/2

size or raise the trimmer

head off the ground slightly

to trim top portion of growth.

Follow with trimmer head on

the ground again.

a) Replace with heavier cutting

string (155 mil).

b)Replace drive belts.

c) Reduce size of trimming

area in half. Raise the

trimmer head off the ground

slightly to trim top portion of

growth. Follow with trimmer

head on the ground again.

4. Drive belts squealing or

smoking.

5. Engine won't start or is

hard to start.

a)Drive belts are loose or

worn.

a)Gas tank is empty.

b)Spark plug wire is discon-

nected.

c) Spark plug is defective.

d)Gas line is obstructed.

(bail disconnected)

e)Dirty, stale, water-

contaminated gas.

f) Flooded engine.

g)Dirty or plugged air cleaner

or engine cooling fins.

a)Replace drive belts.

a)Fill gas tank.

b)Connect loose wire to spark

plug.

c) Replace spark plug.

d)Remove gas line at carbure-

tor and check for obstruc-

tion. Drain gas tank and refill

with fresh, clean gasoline.

e)Drain tank and fill with fresh,

clean unleaded gasoline.

f) Put throttle control in run

position and crank engine

several times to clear out

excess gas.

g)Clean air cleaner and re-

place. Clean cooling fins

and shroud area of engine.

11

Page 14

EZ T rimMower Limited Warranty

Crary Bear Cat EZ TrimMower models 73040, 73050, 73450, 74040 and 74050 are warranted for 90

days to rental and commercial users and two years to consumer users from date of sale.

Within the above stated period, Crary Co. will replace any part(s) found to be defective in material

and/or workmanship, after the receipt of the part in our plant. Labor costs to replace these defective

parts will be paid at a Crary established labor rate and time allowed (flat rate) for repair. All transportation charges incurred in shipping part(s) are the responsibility of the purchaser.

This warranty is void in the case of accidents, failure to perfor m normal maintenance, or failure to

follow those instructions listed in the service manual. This warranty is also in lieu of all other expressed warranties and voids any implied warranty as to the merchantability or fitness of the product for a particular purpose and of any other obligation on the part of Crary Co. Some states do not

allow limitations on how long the implied warranty lasts, so the above limitation may not apply to

you.

This warranty applies only to parts or components which are defective, and does not cover necessary repair due to normal wear, misuse, accidents, or lack of proper maintenance. This includes

belts and pulleys. Regular routine maintenance of the unit to keep it in proper operating condition is

the responsibility of the owner.

All warranty repair reimbursable under the Crary Co. warranty must be performed by an authorized

Bear Cat service dealer using Bear Cat approved replacement parts. Repair or attempted repair by

anyone other than an authorized Bear Cat service dealer is not reimbursable under the Crary Co.

warranty. In addition, these unauthorized repair attempts may result in additional malfunction, the

correction of which is not covered by warranty.

Crary Co. is not liable for indirect, incidental, or consequential damages in connection with the use

of this product including any cost or expense or providing substitute equipment or service during

periods of malfunction or nonuse.

Some states do not allow the exclusion of incidental or consequential damages, so the above

exclusion may not apply to you. This warranty gives you specific legal rights. You may also have

other rights which vary from state to state.

Be sure to note the EZ TrimMower serial number in any correspondence with Crary Co. or any

authorized Bear Cat dealer. The serial number is located on the back of the handle support channel.

12

Page 15

HEALTH WARNING

GASOLINE, DIESEL, AND

OTHER PETROLEUM PRODUCTS

Harmful or fatal if swallowed.

Long-term exposure to vapors has caused cancer in

laboratory animals.

• Avoid prolonged breathing of vapors.

• Keep face away from nozzle and gas tank/container

opening.

• Never siphon by mouth.

Failure to use caution ma y cause serious injury or illness.

WARNING

CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS, OR

OTHER REPRODUCTIVE HARM ARE FOUND IN

GASOLINE, DIESEL, CRUDE OIL, AND MANY O THER

PETROLEUM PRODUCTS AND THEIR VAPORS, OR

RESULT FROM THEIR USE.

Box 849

West Fargo, ND 58078

(701) 282-5520

FAX: (701) 282-9522

www.crary.com

READ AND FOLLOW LABEL DIRECTIONS AND USE

CARE WHEN HANDLING OR USING ALL PETROLEUM PRODUCTS.

ENGINE EXHAUST FROM THIS PRODUCT CONT AINS CHEMICALS KNO WN T O THE ST ATE OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS, OR

OTHER REPRODUCTIVE HARM.

Loading...

Loading...