Page 1

9 INCH

MADE WITH PRIDE IN THE...

CHIPPERS

72928 - 28 HP DIESEL HYD

72942 - 42 HP HYD

74950 - 50 HP

OW N E R ' S M A N UAL

PN: 16783 R0900

Companion to 12139

Page 2

Before You Begin

MANUFACTURED BY CRARY INDUSTRIES

MANUFACTURED IN U.S.A.

XXXXXX

WEST FARGO, NORTH DAKOTA 58078 U.S.A.

SERIAL NUMBER

DEAR CRARY BEAR CAT CUSTOMER

Thank you for purchasing a Crary Bear Cat product. The Crary Bear Cat line is designed, tested, and manufactured to give years of

dependable performance. To keep your machine operating at peak efciency, it is necessary to adjust it correctly and make regular

inspections. The following pages will assist you in the operation and maintenance of your machine. Please read and understand this

manual before operating your machine.

If you have any questions or comments about this manual, please call us toll-free at 1-800-247-7335.

If you have any questions or problems with your machine, please call or write your local authorized Crary Bear Cat Dealer.

This document is based on information available at the time of its publication. Crary Bear Cat is continually making improvements

and developing new equipment. In doing so, we reserve the right to make changes or add improvements to our product without

obligation for equipment previously sold.

PLEASE SEND US YOUR WARRANTY CARD

A warranty card is included in your owner's kit packaged with your machine. Please take the time to ll in the information requested

on the card. When you send your completed card to us, we will register your machine and start your coverage under our limited

warranty.

PARTS ORDERING INFORMATION

For service assistance or parts, contact your nearest authorized

Crary Bear Cat dealer or the factory. Your nearest authorized

dealer will need to know the serial number of your machine to

provide the most efcient service. See below for information on

how to identify and record the serial number for your machine.

If you need engine service or parts:

For engine service or parts, contact your nearest authorized

engine dealer. An authorized engine dealer can handle all parts,

repairs, and warranty service concerning the engine.

SERIAL NUMBER LOCATION

Please record the serial number in the space provided and on

the warranty and registration card.

REPLACEMENT PARTS

Only genuine Crary Bear Cat replacement parts should be used

to repair the machine. Replacement parts manufactured by oth-

ers could present safety hazards, even though they may t on

this machine. Replacement parts are available from your Crary

Bear Cat dealer.

Provide the following when ordering parts:

The SERIAL NUMBER of your machine.

The PART NUMBER of the part.

The PART DESCRIPTION.

The QUANTITY needed.

SERIAL NUMBER

HOW TO CO NTA CT CR ARY BE AR CAT

ADDRESS PHONE E-MAIL HOURS

237 NW 12th Street

P.O. Box 849

West Fargo, ND 58078

800-247-7335

701-282-5520

FAX: 701-282-9522

opesales@crary.com

service@crary.com

© 2006, CRARY INDUSTRIES, ALL RIGHTS RESERVED. PRODUCED AND PRINTED IN THE U.S.A.

Monday - Friday,

8 am to 5 pm

Central Time

Page 3

LIMITED WARRANTY

This warranty applies to all AG and Outdoor Power Equipment manufactured by Crary Industries.

Crary Industries warrants to the original owner each new Crary Industries product to be free from defects

in material and workmanship, under normal use and service. The warranty shall extend 1 year from date of

delivery for income producing (commercial) applications and 2 years from date of delivery for non-income

producing (consumer) use of the product. The product is warranted to the original owner as evidenced by a

completed warranty registration on file at Crary Industries. Replacement parts are warranted for (90) days

from date of installation.

ThE WARRANTY REgIsTRATIoN MusT bE coMpLETED AND RETuRNED To cRARY INDusTRIEs

WIThIN 10 DAYs of DELIvERY of ThE pRoDucT To ThE oRIgINAL oWNER oR ThE WARRANTY

WILL bE voID.

In the event of a failure, return the product, at your cost, along with proof of purchase to the selling Crary

Industries dealer. Crary Industries will, at its option, repair or replace any parts found to be defective in material

or workmanship. Warranty on any repairs will not extend beyond the product warranty. Repair or attempted

repair by anyone other than a Crary Industries dealer as well as subsequent failure or damage that may occur

as a result of that work will not be paid under this warranty. Crary Industries does not warrant replacement

components not manufactured or sold by Crary Industries.

This warranty applies only to parts or components that are defective in material or workmanship.

1.

This warranty does not cover normal wear items including but not limited to bearings, belts, pulleys, filters

2.

and chipper knives.

This warranty does not cover normal maintenance, service or adjustments.

3.

This warranty does not cover depreciation or damage due to misuse, negligence, accident or improper

4.

maintenance.

This warranty does not cover damage due to improper setup, installation or adjustment.

5.

This warranty does not cover damage due to unauthorized modifications of the product.

6.

Engines are warranted by the respective engine manufacturer and are not covered by this warranty.

7.

Crary Industries is not liable for any property damage, personal injury or death resulting from the unauthorized

modification or alteration of a Crary product or from the owner’s failure to assemble, install, maintain or operate

the product in accordance with the provisions of the Owner’s manual.

Crary Industries is not liable for indirect, incidental or consequential damages or injuries including but not

limited to loss of crops, loss of profits, rental of substitute equipment or other commercial loss.

This warranty gives you specific legal rights. You may have other rights that may vary from area to area.

Crary Industries makes no warranties, representations or promises, expressed or implied as to the performance

of its products other than those set forth in this warranty. Neither the dealer nor any other person has any

authority to make any representations, warranties or promises on behalf of Crary Industries or to modify the

terms or limitations of this warranty in any way. Crary Industries, at its discretion, may periodically offer limited,

written enhancements to this warranty.

cRARY INDusTRIEs REsERvEs ThE RIghT To chANgE ThE DEsIgN AND/oR spEcIfIcATIoNs

of ITs pRoDucTs AT ANY TIME WIThouT obLIgATIoN To pREvIous puRchAsERs of ITs

pRoDucTs.

Page 4

Contents

Section 1: Safety Instructions .....................................................2

1.2 Safety Decals.................................................................................... 4

Section 2: Assembly, Controls, and Operation..........................5

2.1 Assembly.......................................................................................... 5

2.1.1 Attach the Trailer Wheels............................................................. 5

2.1.2 Attach the Pintle Hitch .................................................................. 5

2.1.3 Attach the Chute Support ............................................................. 6

2.1.4 Attach the Chipper Chute............................................................. 6

2.15 Attach the Chute Extension Tray................................................... 6

2.1.6 Connect the Control Cable .......................................................... 6

2.1.7 Attach the Blower Discharge Tube............................................... 7

2.1.8 Adjusting the Hydrostatic Control Cable ..................................... 7

2.1.9 Before Using................................................................................ 8

2.1.10 Hydraulic Fluids ......................................................................... 8

2.1.11 Prepare Hydraulic System......................................................... 8

2.2 Identification ......................................................................................9

2.3 Operation ........................................................................................ 1 0

2.3.1 Starting: 28 & 50 HP Kubota Model ...........................................10

2.3.3 Starting: 42 HP Ford Model........................................................ 11

2.4 Chipping ..........................................................................................12

2.5 Stopping Instructions....................................................................... 1 2

2.6 Electronic Feed Sensor .............................................................. 13-16

C

ONTENTS

Section 3: Service and Maintenance ........................................17

3.1 Sharpening Chipper Blades ............................................................. 18

3.1.1 Chipping Blade Sharpening Tips .............................................. 18

3.1.2 Setting Chipping Blade Clearance ............................................ 19

3.1.3 Adjusting Drive Belt.................................................................... 19

3.1.4 Replacing Drive Belt .................................................................. 1 9

3.1.5 Clearing Plugged Rotor............................................................. 2 0

3.1.6 Repairing or Replacing Rotor Bearings ................................... 20

3.1.7 Greaseable Bearings ................................................................ 2 0

3.1.8 Trailer Service Tips ....................................................................20

3.2 Hydraulic Feed Maintenance ........................................................... 2 0

3.3 Hydrostatic Pump Troubleshooting .................................................. 20

Troubleshooting..........................................................................21

Specifications ..............................................................................22

Replacement & Maintenance Chart ..........................................

24

Warranty

1

Page 5

S

ECTION

1

Safety Instructions

This chipper is designed and tested to offer

reasonably safe service. However, failure to

operate it in accordance with the following safety

instructions MAY RESULT IN PERSONAL IN-

JURY!

Before Operating

1. Become familiar with the owners manual before

attempting to operate this equipment. See engine

owners manual for additional safety information.

2. Do not allow children to operate this equipment.

3. Do not operate this equipment in the vicinity of

bystanders.

4. Carbon monoxide can be extremely dangerous in

enclosed areas; do not run the machine in an

enclosed area. The exhaust from the engine contains carbon monoxide, which is colorless, odorless,

and tasteless.

5. Do not allow hands, or any part of body or clothing,

inside the feeding chamber, discharge chute, or near

any moving part.

secured. Once every 10 hours of operation, all

screws, nuts, bolts, and other fasteners should be

checked for proper tightness to insure everything is

in proper working condition.

Operation

One of the critical moments in job safety, as well as

chipper safety, is setting up your chipping site so you are

not endangered by traffic and the public is not

endangered by your work. Great care must be taken to

provide adequate warning by way of signage and coning,

if it is necessary to divert vehicle or pedestrian traffic.

A well-prepared traffic plan should include parking off

the highway whenever possible. The work area should

be coned off as soon as the chipper vehicle is stopped.

A void sudden traf fic stoppage or lane diversion. Do not

allow pedestrians to walk through the work area. Make

sure chips or dust do not blow into traffic, parked cars,

or pedestrians.

1. Before starting the machine, make certain that the

cutting chamber is empty.

6. Before inspecting or servicing any part of the

machine, shut off the engine, and make sure all

moving parts have come to a complete stop.

Preparation

1. Obtain and wear safety glasses at all times while

operating the machine. One pair of safety glasses is

provided with each chipper.

2. A void wearing loose-fitting clothing. Never operate

this machine wearing loose clothing particularly if it

has drawstrings which could wrap around or get

caught in the machine.

3. Operate the machine only on a level surface. Do

not operate the machine on a paved, concrete, or

hard gravel surface. Operating on a hard surface

may cause discharged material to rebound and

kickback. It will also cause increased machine

vibration. Increased vibration may cause the machine to move and will promote premature wear of

parts or loosening of fasteners.

4. Before starting the machine, visually check that all

screws, nuts, bolts, and other fasteners are properly

2. When feeding chipable material into the machine, be

extremely careful to exclude pieces of metal, rocks,

bottles, cans, and other foreign objects.

3. If the cutting mechanism strikes any foreign object

or if the machine should start making an unusual

noise or vibration, immediately shut off the engine,

and allow the machine to come to a complete stop.

After machine stops:

a) Inspect for damage.

b) Replace or repair any damaged parts.

c) Check for and tighten any loose parts.

4. Every 10 hours of operation, check the bolts on the

following for correct torque (75 ft. lbs.):

• Hydraulic feed roller bearing

• Hydraulic motor mounting

• Chipper rotor bearing

• Chipper blades

• Rotor paddles

• Chipper anvil

2

Page 6

S

ECTION

1

Failure to maintain proper fastening torque (75 ft.

lbs.) on bolts for the components listed above may

result in severe damage to the chipper and/or

personal injury .

5. Do not allow processed material to build up in the

discharge area; this may prevent proper discharge

and can result in kickback of material through the

feed opening.

6. Do not attempt to operate the chipper with any of

the guards, deflectors, or shrouds removed. Keep

away from moving parts.

7. Keep all guards, deflectors, and shrouds in good

working condition.

8. Always stand clear of the discharge area when

operating this machine.

9. Keep your face and body back from the feed opening.

10. Do not overreach. Keep proper balance and footing

at all times.

1 1. Do not transport or move machine while the ma-

chine is running.

12. If the machine becomes clogged, shut off engine.

Allow machine to come to a complete stop before

clearing debris.

Additional Safety Rules for Towing

1. Before towing, rotate the discharge tube to face in

the opposite direction of the vehicle that is towing it.

This will prevent the discharge tube from projecting

over the trailer wheels and striking foreign objects.

2. Always connect hitch safety chains. Make sure

trailer hitch bolts are tight and secure. Do not

attempt to attach the pintle hitch to a ball type

vehicle hitch.

3. Maximum towing speed should not exceed 55

M.P.H. Inflate tires to manufactures specs. as

stated on the tire sidewall. Check wheel lug bolts

periodically to be sure they are tight and secure.

4. Make sure that the jack stand on trailer is in the UP

position to clear the ground during towing. Place the

jack stand on a level surface and secure it in the

DOWN position before use.

5. Never allow passengers to ride on the infeed chute

while the vehicle is moving, whether the chipper is

running or not.

Maintenance and Storage

1. When this equipment is stopped for servicing,

inspection, storage, or to change an accessory, make

sure that the key is removed from key switch.

Disconnect battery.

2. Store the machine out of the reach of children and

where fuel vapors will not reach an open flame or

spark. For storage periods of three months or more,

drain the fuel and dispose of it in a safe manner.

Always allow the machine to cool before storing.

The Standard muffler installed on the

chipper engine does not include a spark

arrestor. If this machine is to be used in an

area where a spark arrestor is required by

law, one will have to be added before use.

Contact the local authorities to see if these

laws apply to you. See your authorized engine

dealer for spark arrestor options.

3

Page 7

S

ECTION

1

DANGER

1) Become familiar with the Owners Manual before

attempting to operate this equipment.

2) Do not allow children to operate this equipment. Do

not operate this equipment in the vicinity of

bystanders.

3) Carbon Monoxide can be extremely dangerous in

enclosed areas: do not run the machine in an

enclosed area since the exhaust from the engine

contains carbon monoxide.

4) Do not allow hands or any other part of the body or

clothing inside the feeding chamber, discharge chute,

or near any moving part.

5) Before inspecting or servicing any part of the machine,

shut off power source, disconnect the spark plug wire

from the spark plug and make sure all moving parts

have come to a complete stop.

6) Do not transport this machine while the engine is

running.

7) Avoid wearing loose-fitting clothing.

8) Operate the machine only on a level surface. Keep

proper balance and footing at all times. Do not

operate machine on a paved or gravel surface.

9) Before starting the machine, check that all screws,

nuts, bolts and other fasteners are properly secured;

make certain that the cutting chamber is empty. Do

not operate without guards or screens in place.

10) When feeding shreddable material into the equipment,

be extremely careful that pieces of metal, rocks,

bottles, cans or other foreign objects are not included.

11) Obtain and wear safety glasses at all times while

operating machine.

12) If the cutting mechanism strikes any foreign object, or

if the machine should start making any unusual noise

or vibration, immediately shut off the engine and allow

the machine to stop. Disconnect the spark plug wire

from the spark plug and take the following steps:

1) Inspect for damage;

2) Replace or repair any damaged parts;

3) Check for and tighten any loose parts.

13) Keep the engine clean of debris and other

accumulations. Do not tamper with engine governor

settings.

14) Do not allow processed material to build up in the

discharge area; this may prevent proper discharge

and can result in kickback of material through the

discharge opening.

15) Keep all guards and deflectors in place and in good

working condition. Replace any damaged decals.

16) Always stand clear of the discharge area when

operating this machine. Keep face and body back

from the feed opening.

17) If the machine becomes clogged, shut off the engine

(or motor), disconnect the spark plug wire and allow

machine to come to a complete stop before cleaning

debris.

PN 17846

KNIFE ACCESS COVER

DO NOT REMOVE COVER UNLESS

MACHINE IS STOPPED AND SPARK

PLUG WIRE OR DRIVE SHAFT IS

DISCONNECTED. USE ACCESS FOR

KNIFE INSPECTION OR REPLACEMENT

ONLY. DO NOT OPERATE MACHINE

WITH ACCESS COVER REMOVED.

PN 16085

SHIELD HAS BEEN

REMOVED.

DO NOT OPERATE

WITHOUT SHIELD IN

PLACE. SERIOUS

INJURY OR DEATH

MAY OCCUR.

PN 17423

PN 17423

PN 16085

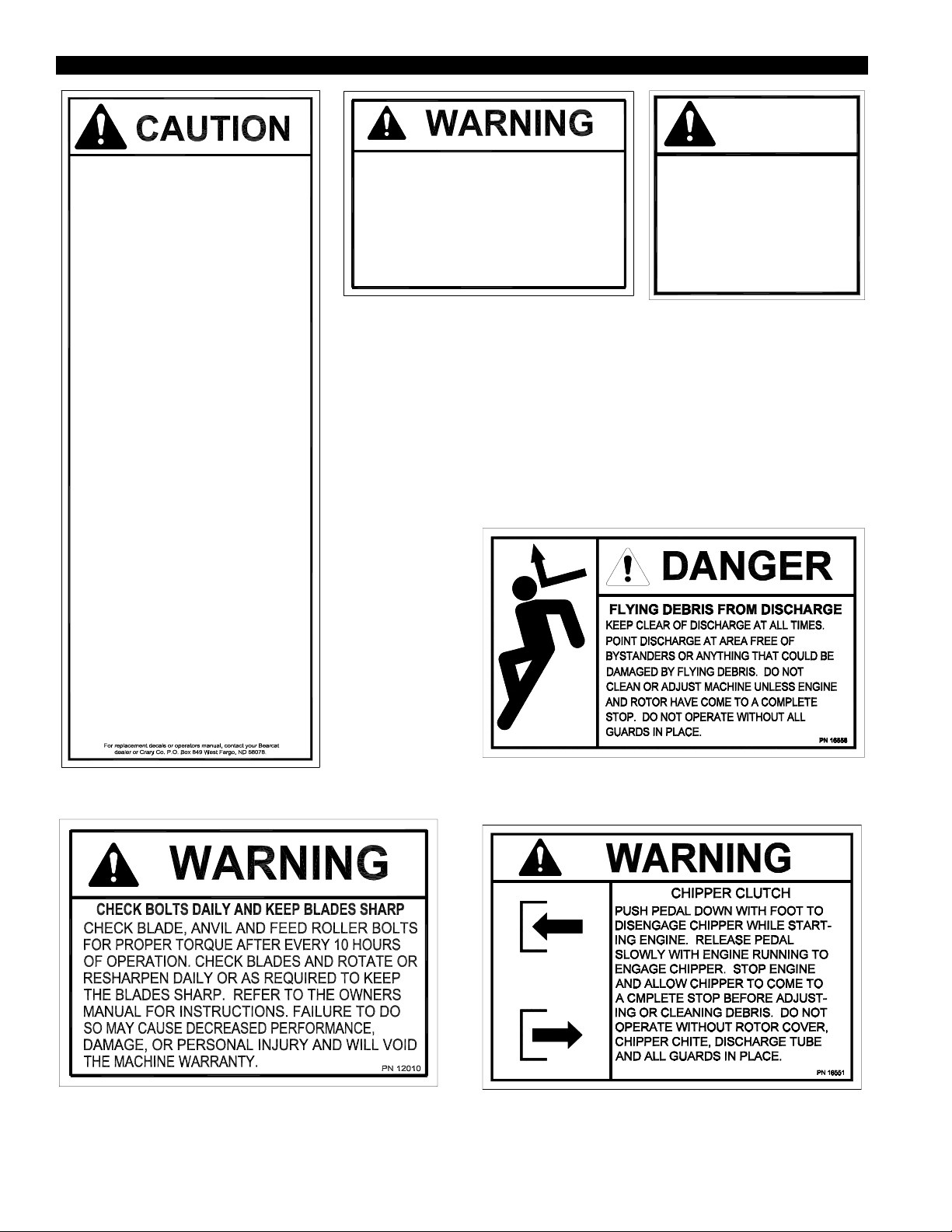

Safety Decals

Safety and instruction decals are located on the chipper frame and engine. Replace any

decal that is damaged or unreadable.

Call dealer for information on decals in Spanish, French, or other languages. For location

of safety decals on the chipper frame, see parts drawings and lists in Parts Manual.

NOTE: For engine safety and instruction decals, see engine owners manual or contact the

engine manufacturer.

PN 17846

PN 16558

PN 12010

PN 16551

4

Page 8

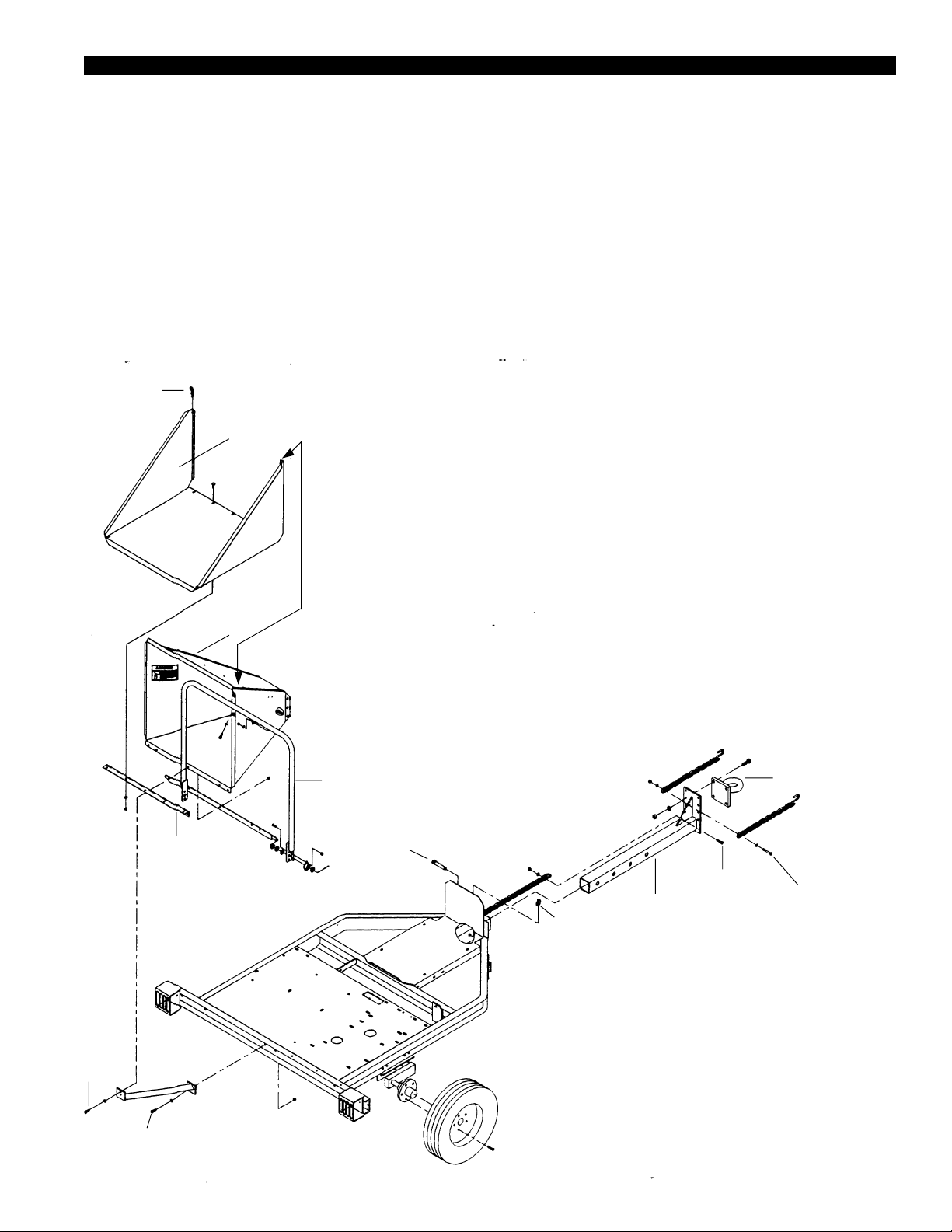

2.1 Assembly

S

ECTION

2

Your chipper may arrive totally or partially assembled. If

your chipper arrives partially assembled, you may need to

perform the steps in this section.

2.1.1 Attach the Trailer Wheels

1. Remove the chipper from its shipping crate. Place the

unit on a level surface before attempting to assemble

it. See the Torque Chart at the bottom of page 8 for

minimum tightening torque of bolts and screws.

Hairpin Clip

Extension

Tray

Chipper

Chute

Position this lip

behind the lip

on the chipper

chute shown

below. Hold the

extension tray

directly above

the chipper

chute and slide

it downward.

2. Raise the trailer several inches from the ground with a

hoist or jack. Support the chipper securely .

3. Lift one wheel to a hub and align the wheel lug holes

with the hub lug holes (see figure 2.1). Thread the lug

bolts into the holes and tighten the lug bolts to 75 ft.

lbs. Follow a star pattern when tightening the lug

bolts. Repeat this step for the remaining wheel.

2.1.2 Attach the Pintle Hitch

1. Insert the adjustable hitch into the hitch opening in the

chipper trailer. Insert a 3/8" x 2" bolt through the bolt

hole in the adjustable hitch as shown in figure 2.1.

Place the end link in the safety chain welded to the

chipper trailer over the 3/8" bolt end. Secure the chain

with a washer and nut.

2. Attach the pintle hitch eye to the adjustable hitch with

3/8" x 2" bolts, washers, and nuts. T orque the bolts to

90 ft. lbs.

3. Connect the safety chains to the adjustable hitch

3/8" x 1"

Bolt

Extension

Hinge

3/8" x 1-1/4"

Bolt

Feed Control

Lever

Top Link Pin

Figure 2.1

Lynch Pin

Adjustable

Hitch

Weldment

3/8" x 2"

Bolt

Pintle Eye

3/8" x 2-1/2"

Bolt

5

Page 9

S

ECTION

2

weldment as shown in figure 2.1. Use a 3/8" x

2-1/2" bolt, washers, and nut to attach the two

safety chains with hooks as shown.

4. Push the top link pin through the holes in the hitch

and trailer. Secure the top link pin with a lynch pin.

Adjust the hitch to make the chipper trailer as level as

possible when connected to the towing vehicle.

2.1.3 Attach the Chute Support

Attach the chute support to the trailer using one 3/8" x

1-1/4" bolt, washer, and locknut. Refer to figure 2.1.

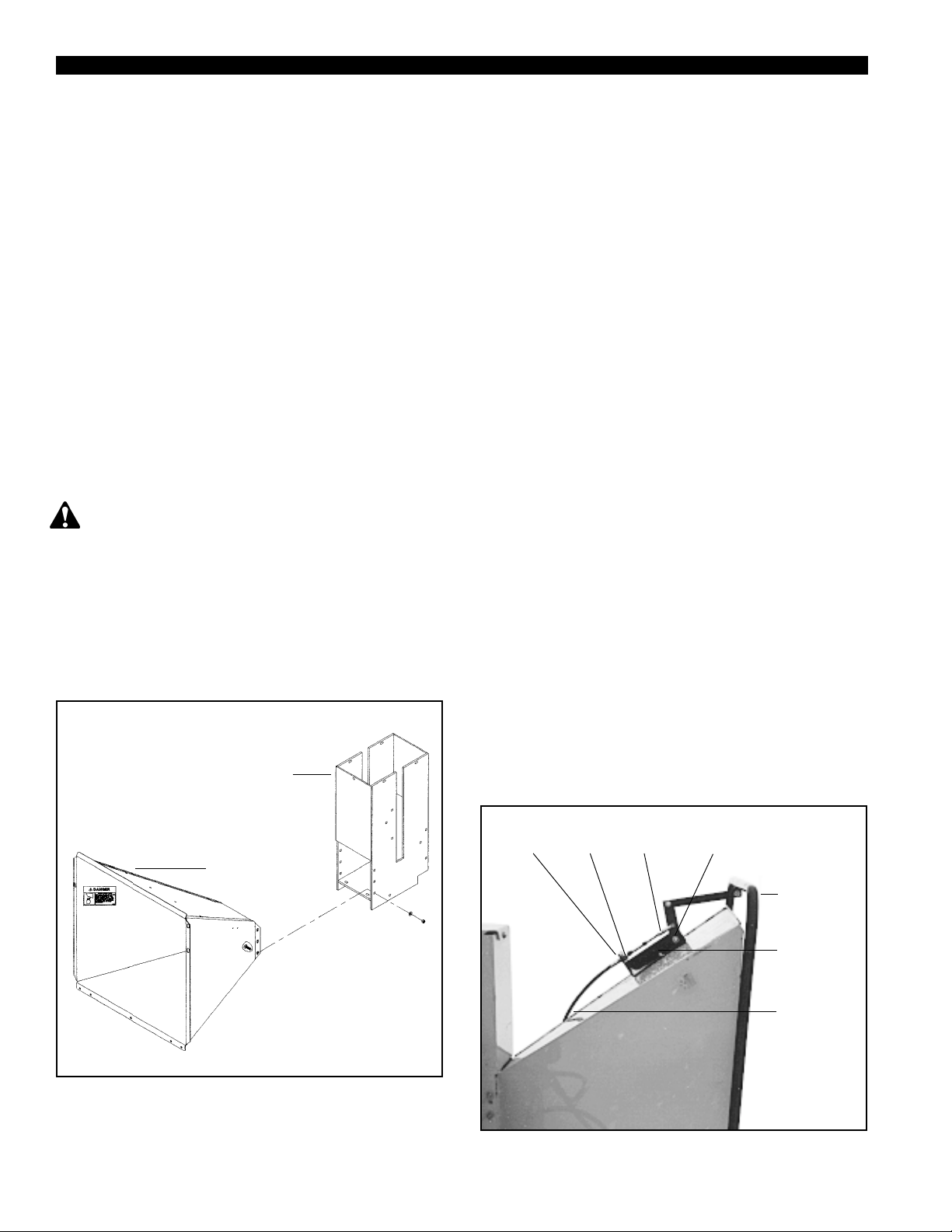

2.1.4 Attach the Chipper Chute

Do not operate this unit without the chipper chute

correctly installed. Rotating cutting blades can cause

serious personal injury .

Mount the chipper chute to the hydraulic feed using

eight 3/8" x 1" bolts and locknuts. T o insert the top

bolts, you may need to temporarily lift the grab roller

with a pry bar. Use three bolts on each side and two on

the bottom (see figure 2.2).

2.1.5 Attach the Chute Extension Tray

1. After mounting the chute to the hydraulic feed, slide

the chute extension tray over the chipper chute as

shown in figure 2.1. Make sure that you posi-

tion the lip on the extension tray behind the

lip on the chipper chute. Align the five bolt holes

in the chute extension tray with the bolt holes in the

extension hinge.

2. Insert a 3/8" x 1" carriage bolt (included in owners

kit packaged with the chipper) through the two

outside holes on the extension tray and the extension hinge. Secure the bolts with washers and

nuts.

3. Insert one 3/8" x 1" carriage bolt through the end of

the chute support and middle holes on the extension hinge and extension tray. Secure the bolts

with washer and nuts. Secure with hairpin clips.

2.1.6 Connect the Control Cable

1. Remove the clevis assembly from the hydrostatic

control cable end (see figure 2.3). Remove one

nut on the cable end. Insert the cable end into the

hole in the cable anchor weldment. Replace the

nut and the clevis assembly .

2. Attach the clevis assembly to the center hole on

the feed control lever.

3. Adjust the cable detent ball to hold the control arm

is in the forward position or neutral position

detents.

2.1.9 Before Using

Hydraulic

Feed

Insert cable

through hole

Chipper

Chute

Clevis

AssemblyNut

Detent

Ball

Feed

Control

Lever

Cable

Anchor

Weldment

Hydrostat

Control

Cable

Figure 2.2

Figure 2.3

6

Page 10

S

ECTION

2

2.1.7 Attach the Blower Discharge Tube

Attach the blower discharge tube to the mounting flange

on the chipper frame (see figure 2.4). Half of the

mounting clamp is already attached to the tube. Slide the

tube into the flange and tighten the bolts to secure it.

Install the second half of the clamp to the tube and

flange. Rotate the tube 360 degrees and lock it in place

with the handle to make sure it is mounted correctly.

Blower Discharge Tube

2.1.8 Adjusting the Hydraulic Feed

Control Cable

Figure 2.5 shows the hydraulic feed control cable

assembly and the detent position slots. The cable is

attached and adjusted from the factory , but it should

be checked and adjusted as needed before use. The

hydraulic feed control lever has three positions:

Forward (lever moved toward the operator)

Neutral (lever in center position)

Reverse (lever moved away from operator; reverse

has no detent position)

When the operator moves the control lever to the

neutral position, the detent ball should be positioned in

the rear detent slot (see figure 2.5). The feed roller

should come to a complete stop when the control

lever is in the neutral position. If it does not stop,

adjust the clevis assembly on the control cable as

follows:

1. If the control lever is in neutral and the roller

creeps forward, the cable is too short; adjust it to

a longer length.

Figure 2.4

Mounting Clamp

Mounting Flange

2. If the roller creeps in a reverse direction, the

cable is too long; adjust it to a shorter length.

3. Adjust the cable as needed to compensate for

cable stretch.

Clevis Assembly

Forward

Detent

Neutral

Detent

Chipper Chute

Adjust cable here as needed.

Figure 2.5

7

Page 11

S

ECTION

2

1. Install battery (not included: use group 22F 300 CCA

min), connect positive and ground battery cables, and

check battery condition. Charge if needed. Note: If

needed, a larger group UB72 battery may be used.

Use caution when connecting battery cables near

fuel. A spark could ignite the fuel and cause a fire.

2. Fill the engine with oil (per instructions in supplied engine manual) and fill the fuel tank with fuel.

Important! See instructions below, for hydrostatic

pump start-up procedure.

2.1.10 Hydraulic Fluids

Handle pressurized hydraulic fluid carefully. Escaping pressurized hydraulic fluid can have sufficient

force to penetrate your skin causing serious injury.

This fluid may also be hot enough to burn. Serious infection or reactions can develop if proper medical treatment

is not administered immediately.

Premium hydraulic fluids containing high quality rust,

oxidation, and foam inhibitors are required. These include

premium turbine oils, API CD engine oils per SAE J183,

M2C33F or G automatic transmission fluids meeting Allison

C-3 or Caterpillar TO-2, and certain specialty agricultural

tractor fluids.

W arning! Do not start engine unless pump is in neutral or detent position on the cable.

4. Start the engine and run at the lowest possible RPM.

5. Loosen the motor fittings until oil bleeds out to

remove air from the system. Retighten fittings.

6. As air is purged from the unit, the oil level in the

reservoir will drop and bubbles may appear in the

fluid. Refill the reservoir as necessary.

7. Run the feed roller in both directions for several

minutes until any remaining air is purged from the

unit. Refill the reservoir as necessary.

8. Shut down the engine, check for and correct any

fluid leaks, and check the reservoir level. Add fluid

if necessary. The hydrostatic pump is now ready for

operation.

Hydrostatic pressure controlled by the crossover relief

valve is factory set at 1750 PSI. A 2000 PSI shim kit is

available for extreme conditions.

2.1.11 Prepare Hydraulic System

Follow this start-up procedure when starting a new

installation or when restarting an installation in which the

hydrostatic pump has been removed from the system.

The flow from the reservoir to the hydrostatic pump and

the flow returning from the hydrostatic pump are always

the same. Hydraulic fluid can flow either direction between

the hydrostatic pump, crossover relief valve, and motor.

1. Before starting the hydrostatic pump, make sure all

system components (reservoir, fittings, etc.) are clean.

2. Fill the reservoir with recommended hydraulic fluid,

which should be filtered before entering the reservoir.

3. The inlet line leading from the reservoir to the charge

pump must be filled before start-up. Loosen the fitting

at the pump on this inlet line until oil bleeds out.

Figure 2.6 Pump-Component Locations

Torque Chart

Standard minimum

tightening torque for normal

assembly applications.

Bolts (SAE GR5)

Size Ft. Lbs.

5/16" 20

3/8" 35

1/2" 75

5/8" 90

Screws

Size Ft. Lbs.

5/16" Set 15

8

Page 12

S

ECTION

2

2.2 Identification

1. Extension Tray: Assists in feeding chipping

material. Folds for towing.

2. Feed Control Lever: Move the arm forward to

increase the feed rate. Push back to reverse the

feed.

3. Chipper Chute: Feeds materials to the chipper

blades for chipping.

4. Discharge Tube: Chipped material exits through

this tube. Tube is adjustable 360 degrees.

5. Drive Belt Shield: Never remove shields when in

use.

6. Control Panel: Contains the key switch, throttle

control, Murphy switch, gauges, and choke control

(gas engine models only).

7. Fuel Tank: Fuel level indicator is located on top.

8. Pintle Hitch: Always use safety chains when

towing chipper.

9. Pivoting Tongue Jack: Always have in UP

position and clear from ground when moving. When

in use, place in DOWN position on a level surface.

Turn handle to raise or lower wheel.

10. Battery: (Not included.) Use group 22F 300 CCA

min.

11. Clutch Foot Pedal: Used to engage rotor assembly

drive belt.

4

NOTE: Your chipper

may be different

3

2

because of design

modifications at the

time of production.

1

5

7

8

11

6

10

9

9

Page 13

S

ECTION

2

2.3 Operation

2.3.1 Starting: 28 & 50 HP Kubota Model

CAUTION: Move machine to a clear, level area

paved, concrete, or gravel surface. Do not operate

in the vicinity of bystanders. Make sure cutting chamber

is empty before starting.

1. Before starting, fill engine with oil to the correct level.

See engine manual for additional starting, operation,

and maintenance instructions.

NOTE: Some oil usage is normal. Check level with each

use.

WARNING: Handle fuel with care. It is highly

flammable. Always use an approved container and

fill tank outdoors.

2. Before starting, fill fuel tank with fresh, clean diesel

fuel. For instructions on bleeding the fuel system on

initial start up or if fuel runs out, see engine manual.

CAUTION: See operation/start-up decal by foot

clutch pedal on machine before starting.

9. Slowly let foot clutch pedal up. This will engage

drive belt and the rotor will turn. If the engine kills

when engaging the drive belt, release foot clutch

pedal more slowly .

10. When clutch is engaged, the foot pedal may vibrate

or shake until the engine and rotor have increased to

full running RPM (3000 RPM).

Do not move chipper during operation.

CAUTION: Obtain and wear safety glasses at all

times when operating the machine. Do not wear

loose fitting clothing. Use common sense and practice

safety to protect yourself from branches, sharp objects

and other harmful objects.

WARNING: Do not leave machine unattended or

attempt any inspection or service unless the engine

is stopped and the key switch is in OFF position.

3. Turn key switch to preheat position. Hold in preheat

position for several seconds until glow plug indicator

light switches off.

4. Push throttle control in until it stops.

5. Depress foot clutch pedal, this will disengage drive belt

and enable engine to start.

6. Push in and hold Murphy switch push-button. Continue to hold Murphy switch in when cranking engine

until engine is running.

7. Activate the starter switch. Release the switch as

soon as the engine starts. Do not crank over for more

than 10 seconds. Release Murphy switch after engine

is running; hold murphy switch in longer if engine

immediately kills after releasing.

Note: The Murphy switch system will shut the engine off

if the oil pressure is too low or if the engine temperature

is too high. If the engine will not run or shuts of for these

reasons, consult your local dealer.

8. Push center throttle control button in. Increase

throttle control to full throttle. Turn throttle control

knob clockwise to achieve maximum RPM.

Throttle

Murphy

Glow Plug

Indicator

No Charge

Indicator

Switch

Hour Meter

(Optional)

Temperature

Gauge

Pressure

Gauge

Key Switch

10

28 & 50 HP Kubota Chipper Control Panel

Page 14

S

ECTION

2

2.3.3 Starting: 42 HP Ford Models

CAUTION: Move machine to a clear, level area out-

doors before starting. Do not operate machine on a

paved, concrete, or gravel surface. Do not operate in the

vicinity of bystanders. Make sure cutting chamber is empty

before starting.

1. Before starting, fill engine with oil to the correct level.

See engine manual for additional starting, operation, and

maintenance instructions.

NOTE: Some oil usage is normal. Check level with each

use.

WARNING: Handle gasoline with care. It is highly

flammable. Always use an approved container and fill

tank outdoors.

2. Before starting, fill fuel tank with fresh, clean unleaded

regular gasoline.

CAUTION: See operation/start-up decal by foot

clutch pedal on machine before starting.

3. Pull choke control out until it stops.

9. Push choke control in after engine is running smoothly .

After a short shutdown, full choke may not be necessary. If engine fails to start, use partial choke.

10. Slowly let foot clutch pedal up. This will engage drive

belt and the rotor will turn. If the engine kills when engaging the drive belt, release foot clutch pedal more

slowly .

1 1. When clutch is engaged, the foot pedal may vibrate or

shake until the engine and rotor have increased to full

running RPM (3000 RPM).

Do not move chipper during operation.

CAUTION: Wear safety glasses at all times when

operating the machine. Do not wear loose fitting clothing. Practice safety to protect yourself from branches, sharp

objects and other harmful objects.

WARNING: Do not leave machine unattended or at-

tempt any inspection or service unless the engine is

stopped and the key switch is in OFF position.

4. Push center throttle control button in. Position the throttle

control 1/3 of the distance between no throttle and full

throttle.

5. Depress foot clutch pedal, this will disengage drive belt

and enable engine to start.

6. Push in and hold Murphy switch push-button. Continue

to hold Murphy switch in when cranking engine until

engine is running.

Note: The Murphy switch system will shut the engine off if

the oil pressure is too low or if the engine temperature is too

high. If the engine will not run or shuts off for these reasons,

consult your local dealer.

7. Activate the starter switch. Release the switch as soon

as the engine starts. Do not operate the starter for periods longer than 10 seconds at a time. If unit does not

stay running, repeat steps 5, 6, and 7 until the engine is

running smoothly. Release the Murphy switch after

engine is running; hold murphy switch in longer if engine immediately kills after releasing.

8. Push center throttle control button in. Increase throttle

control to full throttle. Turn throttle control knob clockwise to achieve maximum operating RPM (3000 RPM).

If needed, the collar on the cable can be rotated to lock

the cable in position.

Choke

Hour Meter

(Optional)

No Charge

Indicator

Temperature

Gauge

Throttle

Murphy

Switch

Pressure

Gauge

Key Switch

Ford Engine Chipper Control Panel

11

Page 15

S

ECTION

2

2.4 Chipping

The Crary Bear Cat chipper is designed to chip a variety

of materials into a more readily decomposing or handled

condition. The following guidelines can be used to help

you get started.

Please read and follow all safety instructions in this

manual. Failure to operate the chipper in accordance with the safety instructions MAY RESULT

IN PERSONAL INJURY!

1. Be sure the unit is at full operating speed before you

start to chip material.

2. Select limbs that are up to 9 inches in diameter. Trim

side branches that cannot be bent enough to feed into

the chipper chute. Small diameter branches can be

held together in a bundle and fed in simultaneously .

3. Feed brush from the side of the infeed chute, rather

than from the front. Then, step aside to avoid being

hit by the brush moving into the chipper.

4. Never lean over the infeed chute to push objects into

the cutting device. Use a push stick or brush paddle.

5. Never use shovels or forks to push brush. They can

go through the chipper, are expensive to replace and

cause major damage. In addition, metal pieces can

come back like shrapnel to injure or kill.

9. If the chipper jams, reverse the feed by moving the

control arm in the reverse direction. Remove the branch

and rotate it before reinserting it into the chute.

Alternately insert and retract the limb or insert

continuously at a rate that will not kill the engine.

Chipping dead, dry material will create heat and dull

the chipping blades quickly. Alternate greener material with dry material to lubricate the chipping blades

for longer life and better performance. When the

chipping blades become dull, they will require periodic

sharpening. Refer to Service and Maintenance,

"Sharpening Chipper Blades."

2.5 Stopping

Instructions

1. Move throttle to slowest position.

2. Depress foot clutch pedal.

3. Turn key switch to off position.

4. Allow machine to come to a complete stop. Release

the foot clutch pedal to help slow the rotor once the

engine has stopped running.

NOTE: The heavy rotor will continue to turn for some

time after the engine. You can tell that the rotor has

stopped when no noise or machine vibration is present.

6. Never push brush into the infeed chute with your

feet.

7. Engage the hydraulic feed by moving the control arm.

Pull the arm toward you to engage the hydraulic feed

(see figure 2.9). In the forward direction, the feed

rate increases as the arm is moved.

8. Place limb, butt end first, into the chipper chute until it

contacts the hydraulic feed roller and is drawn into

the chipper blades. The actual feed rate of the limb

into the chipper will depend on the type of material

fed, and sharpness of the cutting blades.

If the engine slows to where it may stall, push the

control lever inwards to slow or stop the material

feeding and allow the engine to recover. Pull the lever

out to restart feeding when the engine is back to full

speed.

WARNING: Do not leave machine unattended, or

attempt any inspection or service unless the engine is

stopped and the key is removed from key switch.

Reverse

Neutral

Feed Control

Lever

Forward

Figure 2.9

12

Page 16

2.6 Electronic Feed Sensor Installation Insructions

S

ECTION

2

Warning! Shut off the engine and make sure all

moving parts are completely stopped before

inspecting or servicing the machine.

Installation Instructions: All Models

1. Remove drive shaft joint shield ring (PTO only).

2. Remove upper belt guard. * If the serial number is equal

to or greater than X01249, skip to step # 7.

3. Replace sprocket set screw with the 5/16" x 1-1/2" bolt

provided. (See figure 1)

4. Remove the top cover from the Feed Roller Support

unit.

5. Remove the back cover from the LOF A control, center

it 3-1/2" from the top on the front plate of the Feed

Roller Support housing and mark the position of the

holes.

6. Drill four (4) 1/4" holes as marked.

7. Attach the iso-mounts to the controller back plate with

the bolts and nuts provided.

8. Secure the back plate of the controller to the Feed Roller

Support housing with a washer and two (2) M4-0.7 nuts

per bolt.

9. Replace the Feed Roller Support cover.

10. Attach the LOFA control to the back plate.

(See figure 2)

11. Remove outer and inner plugs from the relief valve.

Both plugs are removed using an Allen Wrench. Install

the solenoid cartridge valve and coil. (See figure 3)

12. Secure the sensor bracket with one of the upper bearing bolts and position it so it aligns with the set bolt.

(See figure 4)

13. Position the the proximatey sensor 1/16" - 1/8" from the

head of the bolt.

Figure 1

13

Page 17

S

ECTION

2

14. Replace the belt guard.

Figure 3

14

1/16" - 1/8" GAP

Figure 4

Page 18

Electrical Installation: PTO Models

1. Attach the chipper to the tractor . Connect the Red positive lead to a +12 Volt DC power source on the tractor.

2. Crimp a ring terminal onto the Black, Ground lead.

3. Drill a 3/16" hole in the PTO stand, close to the solenoid

4. Connect the two-pin connector to the top of the valve

coil.

5. Connect the socket connector to the LOFA control.

6. Secure wiring harness with cable ties as appropriate.

valve, and and secure the ground wire with the #10

self-tapping screw provided.

Electrical Installation: Models 620 & 825

1. Crimp a ring terminal onto the Black, Ground lead.

2. Drill a 3/16" hole in the trailer, close to the solenoid

valve, and and secure the ground wire with the #10

self-tapping screw provided.

3. Connect the two-pin connector to the top of the valve

coil.

4. Crimp a spade connector onto the Red wire in the Feed

Sensor harness and connect to the Yellow wire from

the Kohler engine harness .

5. Connect the socket connector to the LOFA control.

6. Secure wiring harness with cable ties as appropriate.

Electrical Installation: Models 928, 942, 950

1. Crimp a ring terminal onto the Black, Ground lead.

2. Drill a 3/16" hole in the trailer, close to the solenoid

valve, and and secure the ground wire with the #10

self-tapping screw provided.

4. Crimp a ring terminal to the Red wire in the Feed Sensor harness and attach to "B" terminal on the back of

the Murphy Switch.

5. Connect the socket connector to the LOFA control.

3. Connect the two-pin connector to the top of the valve

coil.

Electronic Feed Parts List (PN 73244)

PN

12813 Harness, Auto Feed 1

15602 W asher, #6 SAE Flat 4

15640 Nut, M4-0.7 ZP Hex 8

12674 LOFA Hydraulic Control 1

73242-12 Bracket, Proximity Sensor 1

12828 Connector, #10 Insulated Ring 2

12829 Connector, #10 Insulated Fork 3

Description

Qty

.

6. Secure wiring harness with cable ties as appropriate.

PN

12830 Connector, .25 Insulated Male 2

17320 Nyl Cable Tie 4

16967 V alve, Solenoid Cartridge 1

16968 Coil, Solenoid V alve 1

15282 Bolt, 5/16x1-1/2 GR5 Hex 1

15225 Screw, #10x3/4 Hex T ap 1

Description

Qty

.

15

Page 19

Feed Sensor Programming Instructions

Step 1. Initiating Program Mode

1. Hold down the "S" button while turning the engine key to the "on" position until "L" starts to flash on the LCD.

Step 2. Enter Low (L=Low) RPM

The low setting is the RPM speed where the feed roller stops. The "up" arrow increases the RPM setting, while

the "down" arrow decreases the RPM setting. Setting the speed lower causes the engine to lug down more before

the feed roller stops.

1. Hold the appropriate (either up or down) arrow until the desired RPM speed is displayed. (Recommend 1375

rpm.)

2. Push the "S" button once with the desired RPM setting displayed to save.

NOTE: Do not choose a setting equal to or below zero.

Step 3. Enter Normal (N=Normal) RPM

The normal setting is the RPM speed the chipper rotor usually turns.

1. Hold the appropriate (either up or down) arrow until the desired RPM speed is displayed.(Recommend 1500

rpm.)

2. Push the "S" button once with the desired RPM setting displayed to save.

Step 4. Enter High (H=High) RPM

The high setting is not needed with this application.

1. Set to zero to deactivate.

2. Push the "S" button once with zero displayed to save.

Step 5. Enter Return (rEt=Return) RPM

The return setting is the RPM speed where the feed roller restarts. The feed roller should restart before the rotor

reaches "normal" RPM to maximize chipper efficiency. Setting the speed higher allows the engine to recover

more before the feed roller restarts.

1. Hold the appropriate (either up or down) arrow until the desired RPM speed is displayed.(Recommend 1400

rpm.)

2. Push the "S" button once with the desired RPM setting displayed to save.

Step 6. Enter Number of Poles (IPU=Number of Poles)

The number of poles is used to indicate the number of speed pickup devices.

1. Hold the appropriate (either up or down) arrow until one (1) is displayed.

2. Push the "S" button one with one (1) displayed to save.

NOTE: When approaching the end of a log, it might be necessary to manually override the

automatic feed sensor. Be sure to pay attention to the engine speed and feeding of the material.

16

Page 20

3.0 Service and Maintenance

S

ECTION

3

Inspection Items

Check Nuts & Bolts

Engine Oil Level

Change Engine Oil

Replace Oil Filter Cartridge

Check Hydraulic Fluid Level

(3 Gallons)

Replace Air Filter Element

Replace Fuel Filter

Before

Each

Use

Every

10

Hours

Every

25

Hours

Every

50

Hours

Interval

Every

100

Hours

Every

200

Hours

Every

400

Hours

Every

800

Hours

Every

1

years

Check Sharpness of Chipper Blades

Grease Bearings and Pivots

Check Bolts: Chipper Blade, Feed Roller,

Chipper Anvil, Rotor Paddles

Check Drive Belt

Hydraulic Control Cable

(Feed Roller)

Check Water Level

Clean Machine

Indicates first hours of use.

17

Page 21

S

ECTION

3

WARNING: Before inspecting or servicing any part

of the machine, shut off the engine, and make sure

all moving parts have come to a complete stop. The chipping blades are sharp! Use care when working on machine to avoid injury.

WARNING: The rotor assembly has a lock mecha-

nism. When working on the rotor assembly, use the

lock mechanism at all times. Remove the plastic bearing

cover beside the chipper chute. There is a hole in the rotor

shaft and a matching hole in the bracket mounted to the

rotor bearing front side. Install a punch through the rotor

shaft and bracket to lock the rotor in place.

Check the engine oil, and change the oil and filter as recommended in the manual. Service and replace the air

cleaner as recommended.

3.1

Sharpening Chipper Blades

The chipper blades will eventually become dull, making

chipping difficult. The chipper blades are two edged. When

the first edge dulls, flip the blade to use the sharp second

edge. After both edges are dull, sharpen the chipper blades.

It is recommended that the chipper blades are sharpened

every 5-15 hours of chipper operation. To remove the

chipping blades for sharpening:

Use short grinding times and cool with water. T ry to remove

an equal amount off each blade to maintain balance.

Replace the chipping blades and tighten bolts to 75 ft. lbs.

Close cover and replace bolts.

3.1.1 Chipping Blade Sharpening Tips

Poor chipping performance is usually a result of dull chipping

blades. If your chipper's performance has decreased,

check for the following symptoms:

• Severe vibration when feeding material into the chipper.

• Small diameter branches do not self-feed.

• Chips discharge unevenly or have stringy tails–especially when chipping green branches.

Before you sharpen the chipping blades, check for

permanent damage. Replace the blade if:

• The blade is cracked (especially around the bolt holes)

or the edges are too deeply chipped to be ground

smooth.

1. Remove the two 3/8 inch retaining bolts holding access cover to main frame assembly.

2. Tilt access cover over to allow rotor access. Rotate

the rotor so that the bolts holding a chipping blade are

most accessible.

3. Remove the two allen head bolts holding the blade

itself. Repeat for all four blades. The four chipping

blades have two edges per blade and can be reversed

one time each before sharpening. If both sides have

not been used, remove and reverse the chipping blades.

Reinstall chipping blades and proceed with chipping.

T o grind the angled edge of the chipping blade to 45 degrees

(see figure 3.1): Grind the blades on a slow-speed wet

grinder if possible, or have them sharpened by a

professional. If you use a bench grinder, be careful when

grinding so that the blade material does not get too hot and

change color–this will remove the blade's special heat

treated properties.

0.38

Sharpening

Edges

45

Figure 3.1

°°

°

°°

18

Figure 3.2

Page 22

S

ECTION

3

• The base of the cutting edge is worn or has been re-

sharpened so that it is too close to the rotor chipping

slot.

3.1.2 Setting Chipping Blade Clearance

The four chipping blades should clear the chipper anvil

located directly under the chipper chute by 1/16 inch to

1/8 inch. The chipper anvil is adjustable and reversible.

To adjust:

1. Lift rotor access cover and expose rotor (see figure

3.2). Loosen the three 1/2 inch bolts that hold the

chipper anvil to the frame (see figure 3.3).

2. Measure the amount of clearance between chipping

blade and chipper anvil from inside of housing.

3. Adjust inward or outward to desired measurement.

4. Tighten bolts on chipping block to 75 ft. lbs. and

resume operation.

If chipper anvil edge is damaged or worn unevenly,

remove the three bolts holding the anvil and use one of

the other three edges. Adjust for correct measurement.

3.1.3 Adjusting Drive Belt

Check the condition of the drive belt annually or after

every 25 hours of operation, whichever comes first. If

the belt is cracked, frayed, worn, or stretched, replace it.

Only replace belt with original banded type belt, do not use

single type belts. To adjust the belt, proceed as follows:

1. Depress foot clutch pedal. Shut engine off and

disconnect battery cables.

2. Remove large belt guard (three 5/16 inch bolts).

3. Adjust the eyebolt that anchors the idler spring to

adjust the belt tension. Tighten the eyebolt until the

belt deflection at the center of the belt is 7/16" when

a 20 lb. load is placed against the belt (see figure 3.4).

4. Replace belt guard.

5. Start engine and test belt for looseness. Replace the

belt if no adjustment is left.

3.1.4 Replacing Drive Belt

1. Remove large belt guard (three 5/16" bolts).

2. Loosen bolts on hydraulic pump and remove belt.

Chipper Anvil

Rotor Housing

Spacer

3. Lift belt idler pulley off drive belt and remove drive

belt from pulleys.

4. Install new belt on pulleys and lower belt idler.

Check alignment of pulleys and adjust if needed.

5. Check belt tension before start-up. Adjust the

eyebolt that anchors the idler spring to adjust the belt

tension. Tighten the eyebolt until the belt deflection

at the center of the belt is 7/16" when a 20 lb. load is

placed against the belt (see figure 3.4).

7/16" Deflection

(20 lbs.)

Figure 3.3 Figure 3.4

19

Page 23

S

ECTION

3

6. Replace hydraulic pump belt. Readjust hydraulic

pump belt tension by sliding the hydraulic pump in

the mounting slots. Tighten bolts.

7. Replace belt guard.

8. Depress foot clutch pedal, start engine, release foot

clutch pedal to engage belt, and test unit. Readjust

pulleys and belt tension if needed.

3.1.5 Clearing Plugged Rotor

WARNING: If the machine becomes plugged,

depress foot clutch pedal, shut off the engine, and

allow the machine to come to a complete stop before

clearing debris. Do not operate the machine without

proper guards and screens in place.

Feeding too much chipable material at once may plug the

chipper. To clear plugged rotor, proceed as follows:

1. Depress foot clutch pedal and stop engine. Release

foot clutch pedal when engine is stopped.

2. Remove the two 3/8" retaining bolts holding the

access cover to the main frame assembly.

WARNING: The rotor assembly has a lock

mechanism. When working on the rotor assembly ,

use the lock mechanism at all times. Remove plastic

bearing cover under the chipper chute. There is a hole in

the rotor jack shaft and a matching hole in the bracket

mounted to the rotor bearing front side. Install a punch

through the rotor shaft and bracket to lock the rotor in

place.

5. If a rotor bearing needs repair, it is best to remove

the complete rotor assembly from chipper frame.

6. Using an overhead hoist or lifting device, remove the

four 1/2 inch bolts on each rotor bearing and lift the

rotor assembly completely out of the frame. The

complete rotor assembly is 275 lbs.

7. Once the rotor assembly is out of the frame, both

bearings can be removed by a puller and replaced

on the shaft.

8. Use the overhead hoist or lifting device to return the

complete rotor assembly to the chipper frame.

9. Install the four 1/2 inch bolts on each bearing to

secure them to the frame. Tighten bolts to 75 ft. lbs.

3. Lift up rotor access cover.

4. Clean the debris out of the chipper rotor. Turn the

rotor by hand to be sure it is free to rotate.

DANGER: Blades are sharp; avoid contact with

chipper blades.

5. Close rotor access cover and replace bolts.

6. Depress foot clutch pedal, and start engine. Release

foot clutch pedal when engine is running to engage

drive belt. Resume operation.

3.1.6 Repairing or Replacing Rotor

Bearings

1. Remove the two 3/8 inch retaining bolts holding

access cover to main frame assembly. Tilt access

cover over to allow rotor access.

2. Remove large belt guard (three 5/16 inch bolts).

3. Loosen bolts on hydraulic pump and remove hydraulic pump belt. Using the push bolts from the bushing,

remove the bushing and pulley from the rotor shaft.

10. Replace drive belt on pulleys and lower belt idler .

Check alignment of pulleys and adjust engine if

needed.

11. Check belt tension before start-up. Adjust the

eyebolt that anchors the idler spring to adjust the belt

tension. Tighten the eyebolt until the belt deflection

at the center of the belt is 7/16" when a 20 lb. load is

placed against the belt (see figure 3.4, page 15).

12. Close cover and replace bolts.

13. Replace hydraulic pump belt. Readjust hydraulic

pump belt tension by sliding the hydraulic pump in

the mounting slots. Tighten bolts.

14. Replace belt guard and resume operation.

15. Depress foot clutch pedal, start engine, release foot

clutch pedal to engage belt, and test unit. Readjust

pulleys and belt tension if needed.

4. Lift belt idler pulley off drive belt and remove belt

from pulleys. Using the push bolts from the bushing,

remove the bushing and pulley from the rotor shaft.

20

Page 24

S

ECTION

3

3.1.7 Greaseable Bearings and Pivots

The chipper has five greaseable bearings and pivots that

require grease every 50 hours:

• Two bearings on the rotor shaft.

• One greaseable bushing on the foot pedal pivot.

• One grease zerk on idler pivot.

• One grease zerk on discharge chute.

Service engine according to engine manual. Change

engine oil and filter as recommended in manual.

3.1.8 Trailer Service Tips

1. Check wheel bolt torque every 10 hours of towing use.

2. Check air pressure in tires every 10 hours of towing.

3. Check and repack wheel bearings with grease every

12 months.

4. When towing, always connect the safety chains.

Make sure trailer hitch bolts are tight and secure.

5. Check trailer lights.

3.2 Hydraulic Feed Maintenance

NOTE: Check the reservoir daily for proper fluid level,

the presence of water (noted by a cloudy to milky

appearance, or free water in bottom of reservoir), and

rancid fluid odor (excessive heat).

The hydrostatic pump normally does not require regular

fluid changes. The system filter should be changed at

250 hour or annual intervals. The fluid and filter should

be changed and system cleaned if the fluid becomes

contaminated with foreign matter (water, dirt, grease,

etc.) or if the fluid has been subjected to temperature

levels greater than the maximum recommended.

There is a greaseable bearing on each side of the shaft

on the hydraulic feed housing. Grease periodically.

3.3 Hydrostatic Pump Troubleshooting

Symptom

Will not attain normal feed rate.

Will not feed when control arm

is moved.

Feed rate is sluggish under

load.

Hydraulic Feed will not pull in

logs over 4" in diameter, or

continuously stalls or stops.

Probable Cause

Engine not operating at correct speed.

Control linkage damaged or

binding.

Bypass valve stuck partially

open. (Problem in one direction only.)

Control linkage damaged or

not connected.

Drive between engine and

pump damaged.

Pump low on fluid.

Loose drive belt between

engine and pump.

Pump low on fluid.

Large amount of water in hydraulic fluid (evaporates

when hot, resulting in low fluid

level).

Hydraulic system overloading

and causing system to go

over relief.

Suggested Remedy

Repair engine governor.

Repair control linkage.

Repair bypass valve.

Remove foreign material from

valve.

Repair or reconnect control

linkage.

Repair drive (replace broken

belt, repair sheared key, repair splined coupling, etc.).

Refill reservoir. Purge air from

transmission.

Tension drive belt (replace if

necessary).

Refill reservoir. Purge air from

transmission if necessary.

Drain fluid from reservoir and

unit, replace filter element,

and refill with new fluid.

Check relief pressure in system with a pressure gauge

rated to 2500 psi. (System set

by factory at 1750 psi.)

Caution: Hydraulic systems contain

fluid under high pressure. Never check

for leaks with your hands. Relieve

pressure before disconnecting any

hydraulic lines.

Before servicing or

repairing any of the

hydrostatic feed

components (pump,

motor, and/or relief

valve), contact your

dealer or factory

service department.

Warranty on these

items may be void

without prior

authorization.

21

Page 25

T

ROUBLESHOOTING

Troubleshooting

Problem

1. Rotor does not turn

2. Hard to feed chipper

or excessive power

needed to chip

3. Chipper requires

excessive power or

stalls

4. Drive belts squealing

or smoking

5. Vibration while

running

6. Engine dies or runs

poorly

Probable Cause

a) Obstructed

discharge

b) Plugged rotor

a) Obstructed

discharge

b) Dull chipper blades

c) Improper blade

clearance

a) Obstructed

discharge

b) Plugged rotor

c) Green material will

not discharge

a) Plugged rotor

b) Loose or worn belts

a) Drivehead vibration

b) Rotor out of balance

a) Engine problems

Suggested

Remedies

a) Use branch or

similar object to

clear discharge

b) Clear rotor

a) Use branch or

similar object to

clear discharge

b) Sharpen blades

c) Adjust clearance

a) Use branch or

similar object to

clear discharge

b) Clear rotor , feed

material into

shredder more

slowly

c) Alternately feed dry

material, or allow

material to dry

a) Clear rotor

b) Adjust belt tension

or replace belts if

needed

a) Check drive belts

and pulleys for bad

or worn spots.

b) Inspect rotor for

broken or missing

chipper blades and

paddles. Repair if

needed.

c) Check rotor to see if

it wobbles

d) Check to see if rotor

is assembled

correctly

a) Contact local engine

service center

Reference

Service and Maintenance

Service and Maintenance

Service and Maintenance

Service and Maintenance

Service and Maintenance

Engine Manual

22

Page 26

Specifications

S

PECIFICATIONS

Overall Size (LxWxH)

Max. Chipper Cap. (dia.)

Chipper Blade Qty .

Rotor Speed

Rotor Size

Rotor Weight

Rotor Shaft Diameter

Discharge Size

Drive Type

Belt Size

Weight (Lbs.)

Model 72928

119" x 79" x 89"

9"

4 Reversible T ool Steel

1500 RPM

30" Dia. x 1.25"

275 lbs.

1.75"

8"

Belt

3B83

2486

Model 72942

119" x 79" x 89"

9"

4 Reversible T ool Steel

1500 RPM

30" Dia. x 1.25"

275 lbs.

1.75"

8"

Belt

3B85

2540

Model 74950

119" x 79" x 89"

9"

4 Reversible T ool Steel

1500 RPM

30" Dia. x 1.25"

275 lbs.

1.75"

8"

Belt

3B89

2736

Wheel Base

Tire Size

Fuel T ank Cap. (Gal.)

Engine

68"

P215/75R15

18

Kubota 28hp Diesel

68"

P215/75R15

18

Ford 42hp Gasoline

68"

P215/75R15

18

Kubota 50hp Diesel

Specifications are subject to change because of design modifications.

23

Page 27

S

ECTION

3

Replacement & Maintenance Chart

Note: When ordering replacement parts, be sure to identify the

Model and Serial number of the machine.

Replacement Parts Ordered

Date Part Ordered

Date Part Replaced

Replaced By

Checked By

24

Page 28

Declaration of Conformity

The undersigned manufacturer:

Crary Industries, Inc.

237 NW 12

P.O. Box 849

West Fargo, ND 58078-0849

Declares that hereunder specified unit:

CHIPPER

Brand: Crary Bear Cat

Type: Engine driven Chipper

Model Number: 72928S

Complies with the requirements of:

Machinery Directive 2006/42/EC

EN 13525:2005-Forestry Machinery-Wood Chippers -Safety

Emission of Gaseous and Particulate Pollutants Directive 2002/88/EC

EN ISO 12,100, Part 1-Safety of Machinery-Basic Conce pt s, General Principles for Design

EN 982 – Safety of Machinery–Requirements for Fluid Power Systems & their Components-Hydraulics

Noise Emissions Directive 2000/14/EC

-Conformity Assessment Procedure: Annex V

(Use of harmonized standard EN ISO 37 4 4:20 1 0)

Sound Power Level: 95 dB L

Guaranteed Sound Power Level: 112 dB LWA

72928S Serial number Y03136 and up

72928S VIN number 5VJAA00107W000147 and up

West Fargo, ND 58078-0849

June 29, 2011

CRARY INDUSTRIES, INC. The authorized representative in Europe who is authorized to

compile the technical file:

Company: Atlantic Bridge Limited

Address: Atlantic House, PO Box 4800

Earley, Reading RG5 4GB, United Kingdom

______________________________

Arlan Mathias Mr. Phillip Wicks

Senior Project Engineer

PA

th

Street

Data contained in this document pertains only to machines sold in areas that require CE compliance

standards. To identify if your machine is CE compliant, it will have the following CE mark decal:

Page 29

Declaration of Conformity

The undersigned manufacturer:

Crary Industries, Inc.

237 NW 12

P.O. Box 849

West Fargo, ND 58078-0849

Declares that hereunder specified unit:

CHIPPER

Brand: Crary Bear Cat

Type: Engine driven Chipper

Model Number: 74950S

Complies with the requirements of:

Machinery Directive 2006/42/EC

EN 13525:2005-Forestry Machinery-Wood Chippers -Safety

Emission of Gaseous and Particulate Pollutants Directive 2002/88/EC

EN ISO 12,100, Part 1-Safety of Machinery-Basic Conce pt s, General Principles for Design

EN 982 – Safety of Machinery–Requirements for Fluid Power Systems & their Components-Hydraulics

Noise Emissions Directive 2000/14/EC

-Conformity Assessment Procedure: Annex V

(Use of harmonized standard EN ISO 3744:2010)

Sound Power Level: 95 dB L

Guaranteed Sound Power Level: 112 dB LWA

74950S Serial number Y03238 and up

74950S VIN number 5VJAA00157W000136 and up

West Fargo, ND 58078-0849

June 29, 2011

CRARY INDUSTRIES, INC. The authorized representative in Europe who is authorized to

compile the technical file:

Company: Atlantic Bridge Limited

Address: Atlantic House, PO Box 4800

Earley, Reading RG5 4GB, United Kingdom

______________________________

Arlan Mathias Mr. Phillip Wicks

Senior Project Engineer

PA

th

Street

Data contained in this document pertains only to machines sold in areas that require CE compliance

standards. To identify if your machine is CE compliant, it will have the following CE mark decal:

Page 30

Crary Bear Cat

237 NW 12th Street, West Fargo, ND 58078-0849

Phone: 701.282.5520 • Toll Free: 800.247.7335

Fax: 701.282.9522

E-mail: service@crary.com • opesales@crary.com

www.BearCatProducts.com

Loading...

Loading...