Page 1

8" - 9"

MADE WITH PRIDE IN THE...

CHIPPERS

71825S - 25 HP

71854S - 540 PTO

72825S - 25 HP w/HYD

72854S - 540 w/HYD

72928S - 28 HP w/HYD

N - VEILEDNING OG BRUKERHANDBOK

S - BRUKSAVISNING

NL - GEBRUIKS- EN BIZITTERSHANDLEIDING

GB - INSTRUCTION & OWNER'S MANUAL

F - MANUEL D'INSTRUCTIONS ET DU PROPIETAIRE

D - ANLEITUNGS- & BETRIEBSHANDBUCH

PN: 12136 R0498

Companion to 12151

OW N E R ' S M A N UAL

Page 2

Before You Begin

MANUFACTURED BY CRARY INDUSTRIES

MANUFACTURED IN U.S.A.

XXXXXX

WEST FARGO, NORTH DAKOTA 58078 U.S.A.

SERIAL NUMBER

DEAR CRARY BEAR CAT CUSTOMER

Thank you for purchasing a Crary Bear Cat product. The Crary Bear Cat line is designed, tested, and manufactured to give years of

dependable performance. To keep your machine operating at peak efciency, it is necessary to adjust it correctly and make regular

inspections. The following pages will assist you in the operation and maintenance of your machine. Please read and understand this

manual before operating your machine.

If you have any questions or comments about this manual, please call us toll-free at 1-800-247-7335.

If you have any questions or problems with your machine, please call or write your local authorized Crary Bear Cat Dealer.

This document is based on information available at the time of its publication. Crary Bear Cat is continually making improvements

and developing new equipment. In doing so, we reserve the right to make changes or add improvements to our product without

obligation for equipment previously sold.

PLEASE SEND US YOUR WARRANTY CARD

A warranty card is included in your owner's kit packaged with your machine. Please take the time to ll in the information requested

on the card. When you send your completed card to us, we will register your machine and start your coverage under our limited

warranty.

PARTS ORDERING INFORMATION

For service assistance or parts, contact your nearest authorized

Crary Bear Cat dealer or the factory. Your nearest authorized

dealer will need to know the serial number of your machine to

provide the most efcient service. See below for information on

how to identify and record the serial number for your machine.

If you need engine service or parts:

For engine service pr parts, contact your nearest authorized

engine dealer. An authorized engine dealer can handle all parts,

repairs, and warranty service concerning the engine.

SERIAL NUMBER LOCATION

Please record the serial number in the space provided and on

the warranty and registration card.

REPLACEMENT PARTS

Only genuine Crary Bear Cat replacement parts should be used

to repair the machine. Replacement parts manufactured by oth-

ers could present safety hazards, even though they may t on

this machine. Replacement parts are available from your Crary

Bear Cat dealer.

Provide the following when ordering parts:

The SERIAL NUMBER of your machine.

The PART NUMBER of the part.

The PART DESCRIPTION.

The QUANTITY needed.

SERIAL NUMBER

HOW TO CO NTA CT CR ARY BE AR CAT

ADDRESS PHONE E-MAIL HOURS

237 NW 12th Street

P.O. Box 849

West Fargo, ND 58078

800-247-7335

701-282-5520

FAX: 701-282-9522

opesales@crary.com

service@crary.com

© 2006, CRARY INDUSTRIES, ALL RIGHTS RESERVED. PRODUCED AND PRINTED IN THE U.S.A.

Monday - Friday,

8 am to 5 pm

Central Time

Page 3

LIMITED WARRANTY

This warranty applies to Crary Bear Cat, Crary, Load-N-Lift, Lockwood and Weed Roller brand products

manufactured by Crary Industries.

Crary Industries warrants to the original owner each new Crary Industries product to be free from defects

in material and workmanship, under normal use and service. The warranty shall extend 1 year from date of

delivery for income producing (commercial) applications and 2 years from date of delivery for non-income

producing (consumer) use of the product. The product is warranted to the original owner as evidenced by a

completed warranty registration on file at Crary Industries. Replacement parts are warranted for (90) days

from date of installation.

THE WARRANTY REGISTRATION MUST BE COMPLETED AND RETURNED TO CRARY INDUSTRIES

WITHIN 10 DAYS OF DELIVERY OF THE PRODUCT TO THE ORIGINAL OWNER OR THE WARRANTY

WILL BE VOID.

In the event of a failure, return the product, at your cost, along with proof of purchase to the selling Crary

Industries dealer. Crary Industries will, at its option, repair or replace any parts found to be defective in material

or workmanship. Warranty on any repairs will not extend beyond the product warranty. Repair or attempted

repair by anyone other than a Crary Industries dealer as well as subsequent failure or damage that may occur

as a result of that work will not be paid under this warranty. Crary Industries does not warrant replacement

components not manufactured or sold by Crary Industries.

This warranty applies only to parts or components that are defective in material or workmanship.

1.

This warranty does not cover normal wear items including but not limited to bearings, belts, pulleys, filters

2.

and chipper knives.

This warranty does not cover normal maintenance, service or adjustments.

3.

This warranty does not cover depreciation or damage due to misuse, negligence, accident or improper

4.

maintenance.

This warranty does not cover damage due to improper setup, installation or adjustment.

5.

This warranty does not cover damage due to unauthorized modifications of the product.

6.

Engines are warranted by the respective engine manufacturer and are not covered by this warranty.

7.

Crary Industries is not liable for any property damage, personal injury or death resulting from the unauthorized

modification or alteration of a Crary product or from the owner’s failure to assemble, install, maintain or operate

the product in accordance with the provisions of the Owner’s manual.

Crary Industries is not liable for indirect, incidental or consequential damages or injuries including but not

limited to loss of crops, loss of profits, rental of substitute equipment or other commercial loss.

This warranty gives you specific legal rights. You may have other rights that may vary from area to area.

Crary Industries makes no warranties, representations or promises, expressed or implied as to the performance

of its products other than those set forth in this warranty. Neither the dealer nor any other person has any

authority to make any representations, warranties or promises on behalf of Crary Industries or to modify the

terms or limitations of this warranty in any way. Crary Industries, at its discretion, may periodically offer limited,

written enhancements to this warranty.

CRARY INDUSTRIES RESERVES THE RIGHT TO CHANGE THE DESIGN AND/OR SPECIFICATIONS

OF ITS PRODUCTS AT ANY TIME WITHOUT OBLIGATION TO PREVIOUS PURCHASERS OF ITS

PRODUCTS.

Page 4

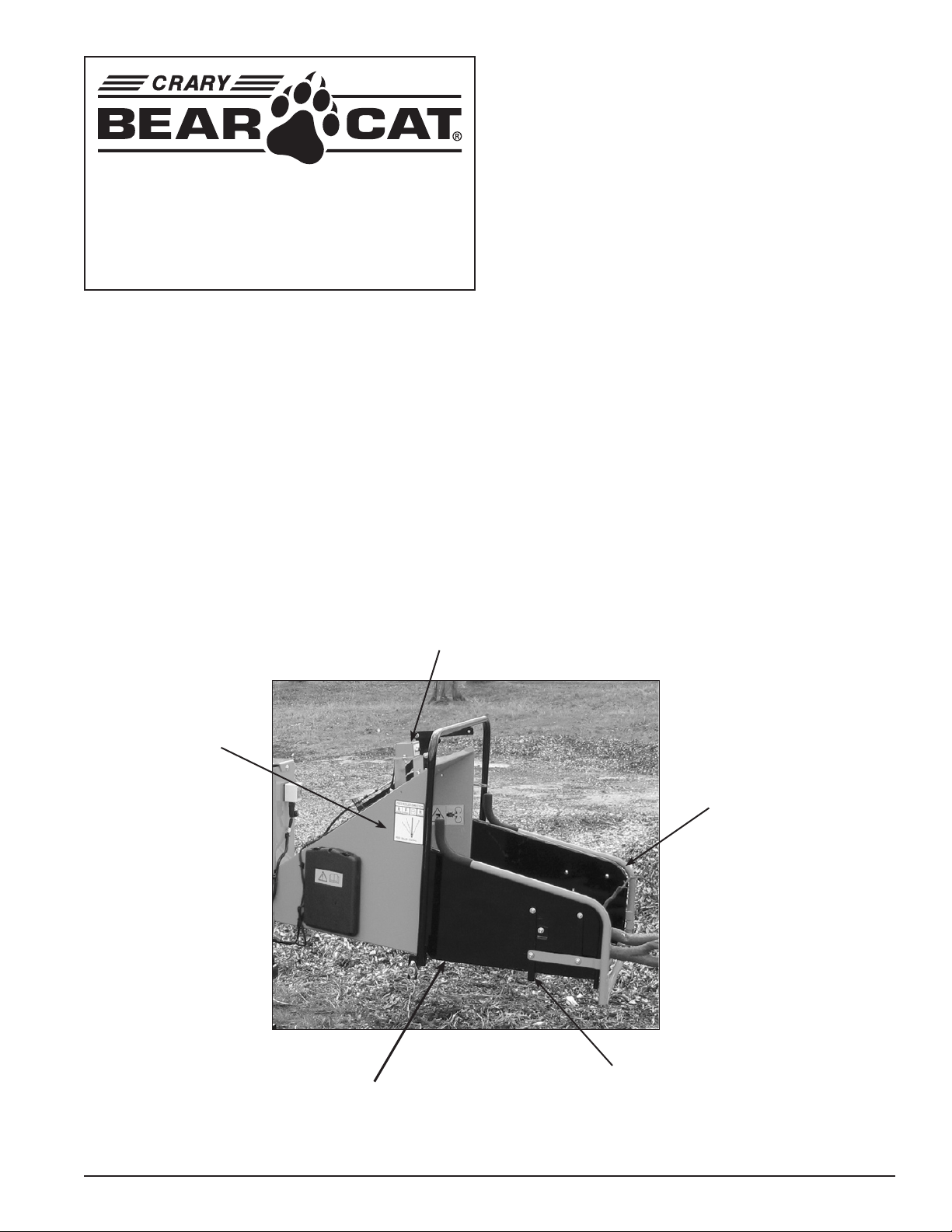

Insert

PRODUCT: BearCat 8" Chippers

SUBJECT: Safety Bar

The feed chute has an extension tray that extends out 29

inches. Around the edge of the tray is an orange comtrol

arm that will contact a safety switch when depressed. The

safety switch will close the solenoid valve, stopping the

hydraulic flow to the feed roller drum. The chipper will not

feed material until the reset button on the top of the feed

chute is pressed.

The switch box has a red light that will indicate the switch

has been triggered and will not go out until the reset button

has been reset. The reset button will release the solenoid

valve allowing the hydrauylic fluid to the feed roller drum.

RESET BUTTON

fEED ChUTE

CONTROL ARM

SAfETY SWITCh

EXTENSION TRAY

Rev 030205

Crary Bear Cat Insert

Page 5

C

ONTENTS

Contents

Section 1: Safety Instructions .........................................................2

1.2 Safety Decals .................................................................................................... 4

Section 2: Assembly ........................................................................6

2.1. 25 HP Models .................................................................................................... 6

2.1.1 Attach the Chipper Chute ...............................................................6

2.1.2 Attach the Chute Extension Tray .................................................... 6

2.1.3 Attach the Blower Discharge Tube................................................ 6

2.1.4 Before Using ...................................................................................6

2.2. 28 HP Models

2.2.1 Attach the Pintle Hitch.....................................................................6

2.2.2 Attach the Chipper Chute ...............................................................7

2.2.3 Attach the Chute Extension Tray .................................................... 7

2.2.4 Attach the Blower Discharge Tube................................................ 7

2.2.5 Before Using ...................................................................................7

2.3 PTO Models ........................................................................................................ 7

2.3.1 Attach the Chipper Chute ...............................................................7

2.3.2 Attach the Chute Extension Tray .................................................... 8

2.3.3 Attach Blower Discharge Tube ...................................................... 8

2.3.4 Connect the PTO Shaft................................................................... 8

2.3.5 Before Using ...................................................................................8

2.4 All Models ...........................................................................................................8

2.4.1 Connect the Hydrostatic Control Cable ........................................ 8

2.4.2 Hydraulic Fluids .............................................................................. 8

2.4.3 Prepare Hydraulic System .............................................................8

Section 3: Controls and Identification ........................................... 10

3.1. 25 HP Model Controls ...................................................................................10

3.2. 25 HP Model Identification ............................................................................ 10

3.3. 28 HP Model Identification ............................................................................ 10

3.4 PTO Model Identification.................................................................................11

Section 4: Operation ..................................................................... 12

4.1 Starting 25 HP Model......................................................................................12

4.2 Starting 28 HP Model......................................................................................12

4.3 Starting PTO Model.........................................................................................13

4.4 Chipping ..........................................................................................................13

4.5 Stopping Instructions......................................................................................14

Section 5: Service and Maintenance .............................................15

5.1 Service and Maintenance: Engine Models...................................................15

5.2 Service and Maintenance: PTO Model ......................................................... 16

5.3 Sharpening Chipper Blades ..........................................................................17

5.4 Chipping Blade Sharpening Tips..................................................................17

5.5 Setting Chipping Blade Clearance................................................................17

5.6 Adjusting Drive Belt.........................................................................................18

5.7 Replacing Drive Belt ....................................................................................... 18

5.8 Clearing Plugged Rotor ................................................................................. 18

5.9 Repairing or Replacing Rotor Bearings ....................................................... 18

5.10 Adjusting the Hydraulic Feed Control Cable ..............................................19

5.11 Greasable Bearings and Pivots ..................................................................19

5.12 Hydraulic Feed Maintenance ....................................................................... 20

5.13 Trailer Service Tips.......................................................................................20

Section 6: Troubleshooting ........................................................... 21

6.1 Troubleshooting..............................................................................................21

6.2 Hydrostatic Pump Troubleshooting ..............................................................22

Section 7: Optional Electronic Feed Sensor .................................23

7.2 Operation of the Electronic Feed Control.......................................................23

Section 8: Specifications ..............................................................24

Section 9: Replacement and Maintenance Chart ..........................25

Section 10: Diagrams and Illustrations ..........................................26

Warranty

1

Page 6

S

ECTION

1

Safety Instructions

This chipper is designed and tested to offer

reasonably safe service. However, failure

to operate it in accordance with the follow-

ing safety instructions MAY RESULT IN PER-

SONAL INJURY!

Before Operating

1. Become familiar with the owner's manual before

attempting to operate this equipment. See engine

owner's manual for additional safety information.

2. Do not allow children to operate this equipment.

3. Do not operate this equipment in the vicinity of

bystanders.

4. Carbon monoxide can be extremely dangerous

in enclosed areas; do not run the machine in an

enclosed area. The exhaust from the engine

contains carbon monoxide, which is colorless,

odorless, and tasteless.

all screws, nuts, bolts, and other fasteners are

properly secured. Once every 10 hours of

operation, all screws, nuts, bolts, and other

fasteners should be checked for proper tightness

to insure everything is in proper working condition.

Operation

One of the critical moments in job safety, as well as

chipper safety, is setting up your chipping site so you

are not endangered by traffic and the public is not

endangered by your work. Great care must be taken to

provide adequate warning. Use signs and/or cones if it

is necessary to divert vehicle or pedestrian traffic.

A well-prepared traffic plan should include parking

off the highway whenever possible. The work area

should be coned off as soon as the chipper vehicle is

stopped. Avoid sudden traffic stops or lane changes.

Do not allow pedestrians to walk through the work

area. Make sure chips or dust do not blow into

traffic, parked cars, or pedestrians.

5. Do not allow hands, or any part of body or

clothing, inside the feeding chamber, discharge

chute, or near any moving part.

6. Before inspecting or servicing any part of the

machine, shut off the engine (disengage PTO),

and make sure all moving parts have come to a

complete stop.

Preparation

1. Obtain and wear safety glasses at all times while

operating the machine. One pair of safety

glasses is provided with each chipper.

2. Avoid wearing loose-fitting clothing. Never

operate this machine wearing loose clothing

particularly if it has drawstrings which could

wrap around or get caught in the machine.

3. Operate the machine only on a level surface. Do

not operate the machine on a paved, concrete, or

hard gravel surface. Operating on a hard surface

may cause discharged material to rebound and

kickback. It will also cause increased machine

vibration. Increased vibration may cause the

machine to move and will promote premature

wear of parts or loosening of fasteners.

4. Before starting the machine, visually check that

1. Before starting the machine, make certain that

the cutting chamber is empty.

2. When feeding chipable material into the machine,

be extremely careful to exclude pieces of metal,

rocks, bottles, cans, and other foreign objects.

3. If the cutting mechanism strikes any foreign

object or if the machine should start making an

unusual noise or vibration, immediately shut off

the engine (or disengage PTO), and allow the

machine to come to a complete stop. After

machine stops:

a) Inspect for damage.

b) Replace or repair any damaged parts.

c) Check for and tighten any loose parts.

4. Every 10 hours of operation, check the bolts on

the following for correct torque (75 ft. lbs.):

• Hydraulic feed roller bearing

• Hydraulic motor mounting

• Chipper rotor bearing

• Chipper blades

• Rotor paddles

• Chipper anvil

2

Page 7

S

ECTION

1

Failure to maintain proper fastening torque (75

ft. lbs.) on bolts for the components listed above

may result in severe damage to the chipper and/

or personal injury!

5. Do not allow processed material to build up in

the discharge area; this may prevent proper

discharge and can result in kickback of material

through the feed opening.

6. Do not attempt to operate the chipper with any of

the guards, deflectors, or shrouds removed. Keep

away from moving parts.

7. Keep all guards, deflectors, and shrouds in good

working condition.

8. Always stand clear of the discharge area when

operating this machine.

9. Keep your face and body away from the feed

opening.

10. Do not overreach. Keep proper balance and

footing at all times.

11. Do not transport or move machine while the

machine is running.

12. If the machine becomes clogged, shut off engine

(or disengage PTO). Allow machine to come to a

complete stop before clearing debris.

Additional Safety Rules for Towing

(Towable Models)

1. Before towing, rotate the discharge tube to face

in the opposite direction of the vehicle that is

towing it. This will prevent the discharge tube

from projecting over the trailer wheels and

striking foreign objects.

2. Always connect hitch safety chains. Make sure

trailer hitch bolts are tight and secure. Do not

attempt to attach the pintle hitch to a ball type

vehicle hitch.

The Standard muffler installed on the

chipper engine does not include a spark

arrestor. If this machine is to be used in an area

where a spark arrestor is required by law, one

will have to be added before use. Contact the

local authorities to see if these laws apply to

you. See your authorized engine dealer for

spark arrestor options.

3. Maximum towing speed should not exceed 55

M.P.H. Inflate tires to manufactures specs. as

stated on the tire sidewall. Check wheel lug bolts

periodically to be sure they are tight and secure.

4. Make sure that the jack stand on trailer is in the

UP position to clear the ground during towing.

Place the jack stand on a level surface and secure

it in the DOWN position before use.

5. Never allow passengers to ride on the infeed

chute while the vehicle is moving (whether the

chipper is running or not).

Additional Safety Rules for PTO Models

Warning: Keep body and clothing away from

PTO shaft when running.

1. Connect 3 pt. hitch pins and snap pins, connect

PTO shaft, and have leg stands solidly on the

ground when in use.

2. Before moving, allow machine to come to a

complete stop. To move unit: shut off PTO, and

lift 3 pt. hitch.

3. Always disengage tractor PTO and shut off

engine before removing guards or shields.

4. Keep hands, feet, and clothing away from all

PTO drive parts. Keep guards and shields in

place at all times while operating.

5. Before starting tractor, always make sure transmission is in neutral or park and PTO is disengaged.

Warning: This chipper is designed to be used

with tractor PTO's rated at 20 to 60 horsepower. Using this chipper with PTO's above 60

horsepower may cause belt and machine damage in

overload conditions.

Maintenance and Storage

1. On engine models, make sure that the key is

removed from key switch. Disconnect battery.

On PTO models, disconnect PTO.

2. Store the machine out of the reach of children

and where fuel vapors will not reach an open

flame or spark. For storage periods of three

months or more, drain the fuel and dispose of it

in a safe manner (engine models). Always allow

the machine to cool before storing.

3

Page 8

S

ECTION

1

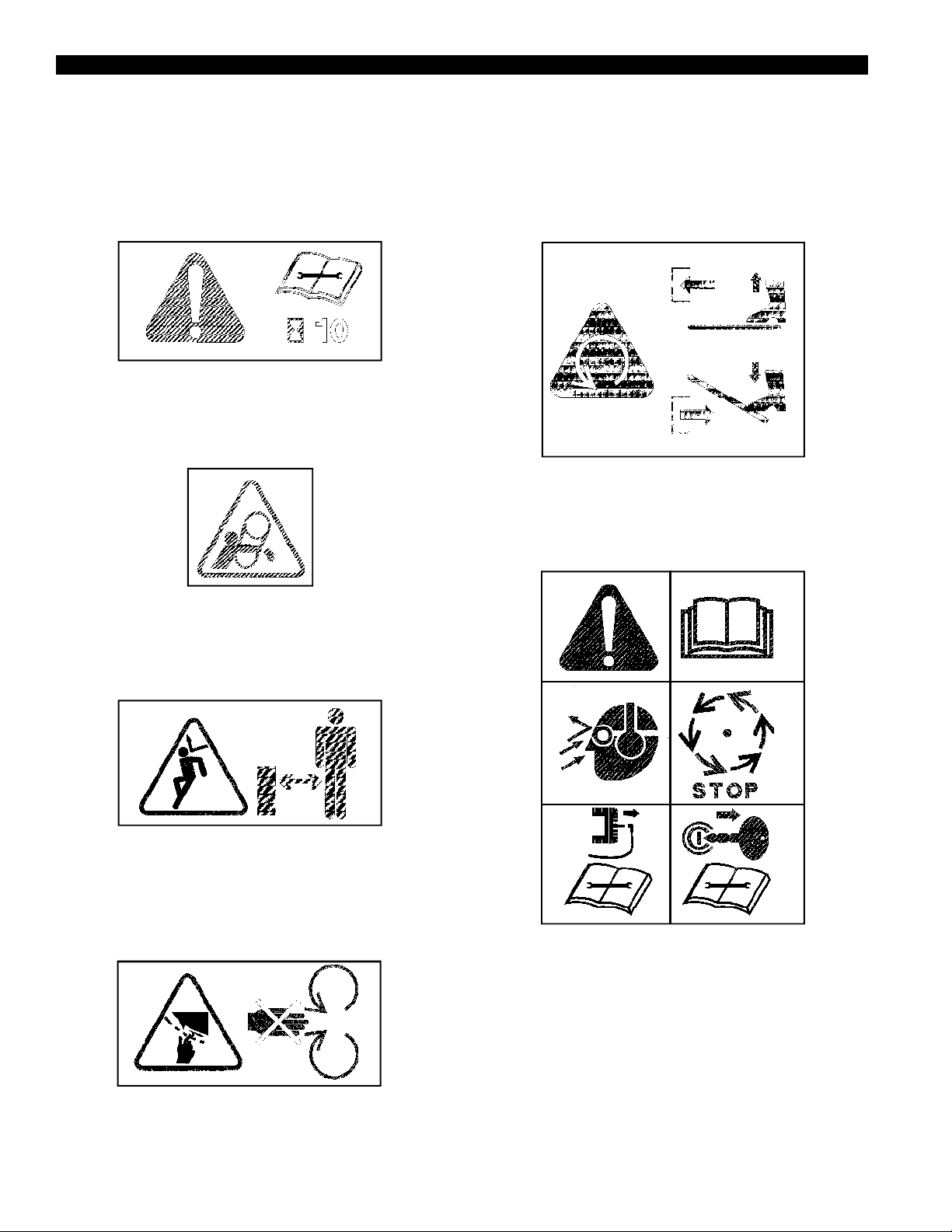

1.2 Safety Decals

Safety and instruction decals are located on the chipper frame and engine. Replace any decal that is damaged or unreadable.

Call dealer for information on decals in Spanish, French, or other languages.

NOTE: For engine safety and instruction decals, see engine owner's manual or contact the engine manufacturer.

12250

Used on All Models: Check chipper blade, anvil and

feed roller bolt for proper torque after every 10 hours of

operation. Refer to Owner's Manual for instructions.

12174

Used on all Models: Keep hands and other body parts

from rotating parts. Replace shields before operating

machine.

12173

12183

Used on 25 and 28 HP Models: Press clutch pedal

down with foot to disengage clutch while starting engine.

Slowly release foot to engage chipper clutch after engine

is running.

12172

1

3 4

2

Used on All Models: Keep away from discharge

opening while machine is operating. Point discharge

away from bystanders or anything that could be damaged

by flying debris.

12175

Used on All Models: Keep hands and feet out of inlet

and discharge openings while machine is operating to

avoid serious injury.

4

5 6

Used on 25 and 28 HP Models:

Panel 1 - Attention

Panel 2 - Read and become familiar with the Owner's

manual before operating this machine.

Panel 3 - Wear proper eye and ear protection while

operating this machine.

Panel 4 -Stop machine and allow all parts to come to a

complete stop before cleaning, making

adjustments or servicing machine.

Panel 5 and 6 - Stop engine and remove spark plug wire

or key before cleaning, making adjustments or

servicing machine.

Page 9

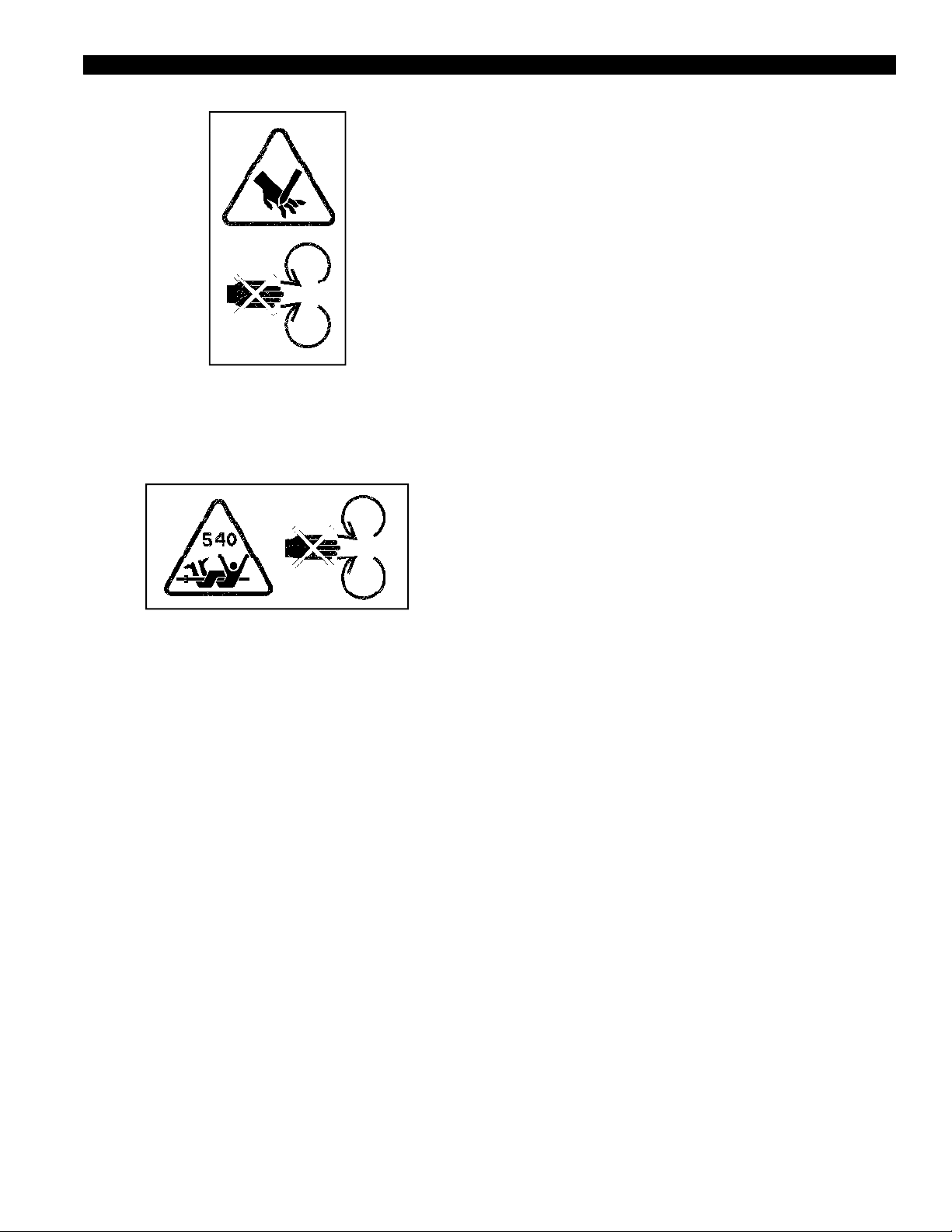

12169

Used on 28 HP and PTO Model: Keep hands and feet

out of inlet and discharge openings while machine is

operating to avoid injury.

12168

S

ECTION

1

Used on PTO Model: Keep hands, feet and body away

from driveshaft while machine is operating to avoid

entanglement. Operate machine at a 540 PRM input

speed.

5

Page 10

S

ECTION

2

Assembly

Your chipper may arrive totally or partially

assembled. If your chipper arrives partially

assembled, you may need to perform the steps in this

section.

2.1. 25 HP Models

1. Remove the chipper from its shipping crate.

Place the unit on a level surface before attempting to assemble it. Support the frame with wood

blocks or other support device before installing

axle. See the Torque Chart, page 7, for minimum

tightening torque of bolts and screws.

2. Your chipper may be shipped without an axle.

You must supply the required axle and install

the axle, wheels, and tires according to the

manufacturer's specifications.

3. Mount the trailer hitch to the frame using three

3/8 X 3-1/2" bolts and locknuts (supplied).

2.1.1 Attach the Chipper Chute

Do not operate this unit without the chipper

chute correctly installed. Rotating cutting

blades can cause serious personal injury.

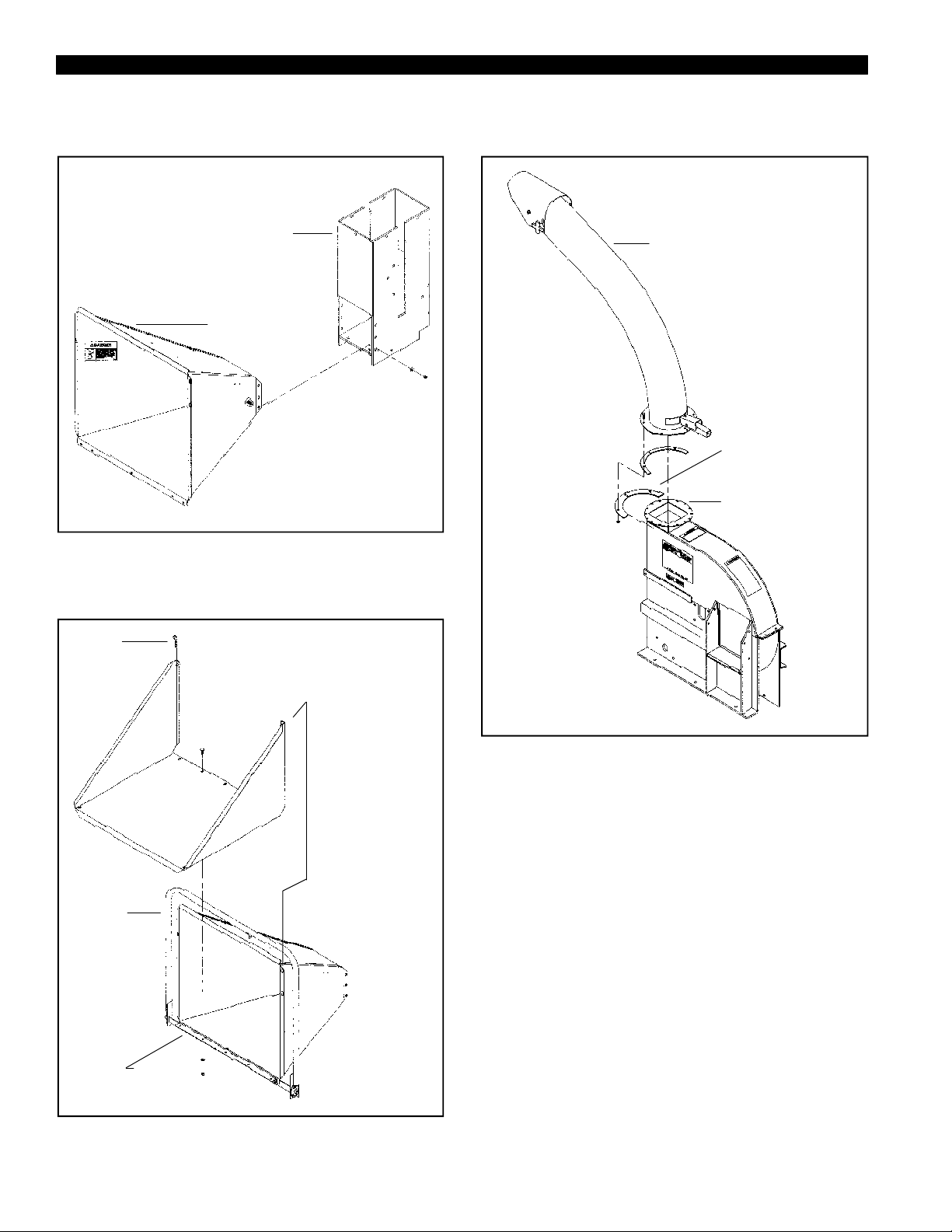

2.1.3 Attach the Blower Discharge

Tube

Attach the blower discharge tube to the mounting

flange on the chipper frame (see figure 10.3). Half of

the mounting clamp is already attached to the tube.

Slide the tube into the flange and tighten the bolts to

secure it. Install the second half of the clamp to the

tube and flange. Rotate the tube 360 degrees and

lock it in place with the handle to make sure it is

mounted correctly.

2.1.4 Before Using

1. Install battery (not included: use group 22F 300

CCA min), connect positive and ground battery

cables, and check battery condition. Charge if

needed. Note: If needed, a larger group UB72

battery may be used.

Use caution when connecting battery cables

near fuel. A spark could ignite the fuel and

cause a fire.

2. Fill the engine with oil (per instructions in

supplied engine manual) and fill the fuel tank

with fuel.

Important! See instructions for hydrostatic pump

start-up procedure, page 8.

Mount the chipper chute to the hydraulic feed using

eight 3/8" x 1" bolts and locknuts. To insert the top

bolts, you may need to temporarily lift the grab roller

with a pry bar. Use three bolts on each side and two

on the bottom (see figure 10.1).

2.1.2 Attach the Chute Extension Tray

1. After mounting the chute to the hydraulic feed,

slide the chute extension tray over the chipper

chute as shown in figure 10.2. Make sure that

you position the lip on the extension tray

behind the lip on the chipper chute. Align the

five bolt holes in the chute extension tray with the

bolt holes in the hinge.

2. Insert five 3/8" x 1" carriage bolts (included in

owner's kit packaged with the chipper) through

the tray and the extension hinge. Secure the bolts

with washers and nuts. Secure with hairpin clips.

2.2. 28 HP Models

1. Remove the chipper from its shipping crate.

Place the unit on a level surface before attempting to assemble it. Support the frame with wood

blocks or other support device before installing

axle. See the Torque Chart, page 7, for minimum

tightening torque of bolts and screws.

2. Your chipper may be shipped without an axle.

You must supply the required axle and install

the axle, wheels, and tires according to the

manufacturer's specifications.

2.2.1. Attach the Pintle Hitch

1. Insert the adjustable hitch into the hitch opening

in the chipper trailer. Insert a 3/8" x 2" bolt

through the bolt hole in the adjustable hitch as

shown in figure 10.4. Place the end link in the

6

Page 11

S

ECTION

2

safety chain welded to the chipper trailer over

the 3/8" bolt end. Secure the chain with a washer

and nut.

2. Attach the pintle hitch eye to the adjustable hitch

with 5/8" x 2" bolts, washers, and nuts. Torque

the bolts to 90 ft. lbs.

3. Connect the safety chains to the adjustable hitch

weldment as shown in figure 10.4. Use a 3/8" x

2-1/2" bolt, washers, and nut to attach the two

safety chains with hooks as shown.

4. Push the top link pin through the holes in the

hitch and trailer. Secure the top link pin with a

lynch pin.

Adjust the hitch to make the chipper trailer as level

as possible when connected to the towing vehicle.

2.2.2 Attach the Chipper Chute

Do not operate this unit without the chipper

chute correctly installed. Rotating cutting

blades can cause serious personal injury.

Slide the tube into the flange and tighten the bolts to

secure it. Install the second half of the clamp to the

tube and flange. Rotate the tube 360 degrees and

lock it in place with the handle to make sure it is

mounted correctly.

2.2.5 Before Using

1. Install battery (not included: use group 22F 300

CCA min), connect positive and ground battery

cables, and check battery condition. Charge if

needed. Note: If needed, a larger group UB72

battery may be used.

Use caution when connecting battery cables near

fuel. A spark could ignite the fuel and cause a fire.

2. Fill the engine with oil (per instructions in

supplied engine manual) and fill the fuel tank

with fuel.

Important! See instructions for hydrostatic pump

start-up procedure, page 8.

Mount the chipper chute to the hydraulic feed using

eight 3/8" x 1" bolts and locknuts. To insert the top

bolts, you may need to temporarily lift the grab roller

with a pry bar. Use three bolts on each side and two

on the bottom (see figure 10.1).

2.2.3 Attach the Chute Extension Tray

1. After mounting the chute to the hydraulic feed,

slide the chute extension tray over the chipper

chute as shown in figure 10.2. Make sure that

you position the lip on the extension tray

behind the lip on the chipper chute. Align the

five bolt holes in the chute extension tray with the

bolt holes in the hinge.

2. Insert five 3/8" x 1" carriage bolts (included in

owner's kit packaged with the chipper) through

the tray and the extension hinge. Secure the bolts

with washers and nuts. Secure with hairpin clips.

2.2.4 Attach the Blower Discharge

Tube

Attach the blower discharge tube to the mounting

flange on the chipper frame (see figure10.3). Half of

the mounting clamp is already attached to the tube.

2.3 PTO Model

2.3.1 Attach the Chipper Chute

Do not operate this unit without the chipper

chute correctly installed. Rotating cutting

blades can cause serious personal injury.

1. Remove chipper from shipping crate. Place unit

on a level surface before attempting to assemble.

See Torque Chart for minimum tightening

torque.

Torque Chart

Standard minimum

tightening torque for normal

assembly applications.

Bolts (SAE GR5)

Size Ft. Lbs.

5/16" 20

3/8" 35

1/2" 75

5/8" 90

Screws

Size Ft. Lbs.

5/16" Set 15

7

Page 12

S

ECTION

2

2. Mount the chipper chute to the hydraulic feed

using eight 3/8" x 1" bolts and locknuts. To

insert the top bolts, you may need to temporarily

lift the grab roller with a pry bar. Use three bolts

on each side and two on the bottom (see figure

10.1).

2.3.2 Attach Chute Extension Tray

1. After mounting the chute to the chipper frame,

slide the chute extension tray over the chipper

chute as shown in figure 10.2. Make sure that

you position the lip on the extension tray

behind the lip on the chipper chute. Align the

five bolt holes in the chute extension tray with the

bolt holes in the hinge.

2. Insert five 3/8" x 1" carriage bolts (included in

owner's kit packaged with the chipper) through

the tray and the extension hinge. Secure the bolts

with washers and nuts. Secure with hairpin clips.

2.3.3 Attach Blower Discharge Tube

1. Attach the blower discharge tube to the mounting flange on the chipper frame (see figure 10.3).

Half of the mounting clamp is already attached

to the tube. Slide the tube into the flange and

tighten the bolts to secure it. Install the second

half of the clamp to the tube and flange. Rotate

the tube 360 degrees and lock it in place with the

handle to make sure it is mounted correctly.

2.3.4 Connect the PTO Shaft

1. Connect the PTO Shaft female end to the rotor

shaft using key stock and two set screws contained in the owner's kit.

2. Connect the opposite end of the PTO shaft to the

tractor.

2.3.5 Before using

Check all screws, bolts and nuts for tightness. See

torque chart on page pg 7 for proper tightening

torque.

Important! See instructions for hydrostatic pump

start-up procedure, at right.

2.4 All Models

2.4.1 Connect the Hydrostatic Control

Cable

1. Remove the clevis assembly from the hydrostatic

control cable end (see figure 10.5). Remove one

nut on the cable end. Insert the cable end into the

hole in the cable anchor weldment. Replace the

nut and the clevis assembly.

2. Attach the clevis assembly to the center hole on

the feed control lever.

3. Adjust the cable detent ball to hold the control

arm is in the forward position or neutral position

detents.

Important! See section below for hydrostatic

pump start-up procedure

2.4.2 Hydraulic Fluids

Handle pressurized hydraulic fluid carefully. Escaping pressurized hydraulic fluid can have sufficient

force to penetrate your skin causing serious injury.

This fluid may also be hot enough to burn. Serious

infection or reactions can develop if proper medical

treatment is not administered immediately.

Premium hydraulic fluids containing high quality

rust, oxidation, and foam inhibitors are required.

These include premium turbine oils, API CD

engine oils per SAE J183, M2C33F or G

automatic transmission fluids meeting Allison C-3

or Caterpillar TO-2, and certain specialty

agricultural tractor fluids.

2.4.3 Prepare Hydraulic System

Follow this start-up procedure when starting a new

installation or when restarting an installation in

which the hydrostatic pump has been removed from

the system.

The flow from the reservoir to the hydrostatic pump

and the flow returning from the hydrostatic pump are

always the same. Hydraulic fluid can flow either

direction between the hydrostatic pump, crossover

relief valve, and motor. Refer to page 10.6 for the

hydraulic Schematic.

8

Page 13

1. Before starting the hydrostatic pump, make sure

all system components (reservoir, fittings, etc.)

are clean.

2. Fill the reservoir with recommended hydraulic

fluid, which should be filtered before entering

the reservoir.

3. The inlet line leading from the reservoir to the

charge pump must be filled before start-up.

Loosen the fitting at the pump on this inlet line

until oil bleeds out.

Warning! Do not start engine unless pump is

in neutral or detent position on the cable.

4. Start the engine and run at the lowest possible

RPM.

5. Loosen the motor fittings until oil bleeds out to

remove air from the system. Retighten fittings.

6. As air is purged from the unit, the oil level in the

reservoir will drop and bubbles may appear in

the fluid. Refill the reservoir as necessary.

S

ECTION

2

7. Run the feed roller in both directions for several

minutes until any remaining air is purged from

the unit. Refill the reservoir as necessary.

8. Shut down the engine, (or disengage PTO) check

for and correct any fluid leaks, and check the

reservoir level. Add fluid if necessary. The

hydrostatic pump is now ready for operation.

Hydrostatic pressure controlled by the crossover

relief valve is factory set at 1750 PSI. A 2000 PSI

shim kit is available for extreme conditions.

9

Page 14

S

ECTION

3

Controls and

Identification

3.1. 25 HP Model Controls

1. Engine Throttle Lever: See figure 10.7.

Changes engine speed. Turn knob clockwise for

full throttle operation. Turn knob counterclockwise for idle on warm up. Turn knob fully

counterclockwise to shut engine off. Refer to

engine manual for further engine operating

instructions.

2. Engine Choke: Use when starting cold engine.

Pull to ON position when starting. Push lever to

OFF position when engine is running. Refer to

engine manual for further engine operating

instructions.

3. Key Switch: (located to the right of the throttle

lever) Turn clockwise to start engine. Release as

soon as engine is running. Do not crank starter

for more than 10 seconds of damage could

result.

4. Other Engine Components: See Figure 10.8.

3.2. 25 HP Model

Identification

1. Engine Fuel Tank: Use unleaded fuel; do not

mix with oil.

2. Trailer Hitch: Always use 2 inch ball and safety

chains.

3. Jack Stand: Always have in UP position and

clear from ground when moving. When in use,

place in DOWN position on a level surface.

4. Engine Drive Belt and Shield: Never remove

shields when in use.

(see figure 10.9)

bearing. Has lock assembly to lock in place

while moving.

10. Clutch Foot Pedal: Used to engage rotor

assembly drive belt.

11. Adjustable Chipping Block

12. Foot Pedal: Used to pivot machine 360 degrees.

3.3. 28 HP Model

Identification

1. Extension Tray: Assists in feeding chipping

material. Folds for towing.

2. Feed Control Lever: Move the arm forward to

increase the feed rate. Push back to reverse the

feed.

3. Chipper Chute: Feeds materials to the chipper

blades for chipping.

4. Discharge Tube: Chipped material exits through

this tube. Tube is adjustable 360 degrees.

5. Drive Belt Shield: Never remove shields when

in use.

6. Control Panel: (figure 10.11) Contains the key

switch, throttle control, gauges, indicator lights,

and Murphy switch.

7. Fuel Tank: Fuel level indicator is located on top.

8. Pintle Hitch: Always use safety chains when

towing chipper.

9. Pivoting Tongue Jack: Always have in UP

position and clear from ground when moving.

When in use, place in DOWN position on a level

surface. Turn handle to raise or lower wheel.

10. Battery: (Not included.) Use group 22F 300

CCA min.

11. Clutch Foot Pedal: Used to engage rotor assembly drive belt.

(see figure 10.10)

5. Chipper Chute: Feed material to be chipped

through the chute.

6. Engine Controls: See figure 10.7.

7. Rotor Access Cover: Open to remove chipper

blades.

8. Engine Battery (not included)

9. Rotor Shaft End Cover: Covers rotor shaft and

10

Page 15

3.4. PTO Model

S

ECTION

3

Identification

(see figure 10.12)

1. Three pt. Hitch Connection: Mounts chipper to

tractor 3 pt. hitch. Connect direct for category 1.

2. PTO Shaft: Connects chipper to tractor PTO

shaft. Avoid driveline angles over 20 degrees on

PTO shaft when unit is in use.

3. Drive Belt Shield: Never remove shield while

machine is running.

4. Chipper Chute: Feeds materials to the chipper

blades for chipping.

5. Leg Stands: Never move machine unless 3

point is lifted and legs clear the ground.

6. Rotor Access Cover: Tilts up to remove chipper

blades and to service rotor assembly.

7. Discharge Tube: Chipped materials will exit

through this tube. Tube is adjustable 360 degrees.

8. Adjustable Chipping Anvil: Adjusts to vary the

size of chips.

9. Rotor Shaft Bearing Cover: Rotor shaft has

lock assembly to lock rotor in place while

servicing.

NOTE: Minimum and maximum telescoping on the

PTO shaft is 20-28 inches. This will leave 4 inches

overlap at maximum telescoping distance (see figure

10.13).

Caution: Wear safety glasses at all times when

operating the machine. Do not wear loose

fitting clothing. The operator should always wear

heavy boots, gloves, pants and shirt. Use common

sense and practice safety to protect yourself from

branches, sharp objects and other harmful objects.

Note: The heavy rotor will continue to turn for some

time after the engine or tractor has been shut off. You

can tell that the rotor has stopped when no noise or

machine vibration is present. Inserting a branch into

the chipper chute to contact the blades will slow the

rotor and shorten stopping time.

11

Page 16

S

ECTION

4

Operation

4.1 Starting 25 HP Model

Caution: Move machine to a clear, level area

outdoors before starting. Do not operate

machine on a paved, concrete, or gravel surface. Do

not operate in the vicinity of bystanders. Make sure

cutting chamber is empty before starting.

1. Before starting, fill engine with oil to the correct

level. See engine manual for engine operation

and maintenance instructions.

Note: Some oil usage is normal. Check level with

each use.

Warning: Handle fuel (gasoline) with care. It

is highly flammable. Always use an approved

container and fill tank outdoors. Never add fuel to a

running or hot engine.

2. Before starting, fill fuel tank with fresh, clean

unleaded regular gasoline. DO NOT MIX OIL

WITH GASOLINE.

3. Place the throttle control midway between slow

and fast positions. Place the choke control to the

ON position.

Caution: See operation/start-up decal by foot

clutch pedal on machine before starting.

4. Depress foot clutch pedal to disengage drive

belts and enable engine to start.

10. The chipper frame assembly can turn 360 degrees clockwise or counterclockwise. Press down

on the foot pedal located underneath the frame

near the tow hitch and the frame will pivot on the

trailer to your desired location. Let up on the foot

pedal and the frame will lock into place for use.

The discharge tube can also turn 360 degrees to

your desired location.

Warning: Return table to towing position and

lock in place before moving machine. Do not

move chipper while machine is operating.

Caution: Wear safety glasses at all times

when operating the machine. Do not wear

loose fitting clothing. Protect yourself from

branches, sharp objects, and other harmful objects

with proper eye protection and clothing.

Warning: Do not leave machine unattended

or attempt any inspection or service unless the

engine is stopped and the spark plug wire is removed from the spark plug.

4.2 Starting 28 HP Model

Caution: Move machine to a clear, level area

outdoors before starting. Do not operate

machine on a paved, concrete, or gravel surface. Do

not operate in the vicinity of bystanders. Make sure

cutting chamber is empty before starting.

1. Before starting, fill engine with oil to the correct

level. See engine manual for additional starting,

operation, and maintenance instructions.

5. Activate the starter switch. Release the switch as

soon as the engine starts. Do not crank engine

for more than 10 seconds.

6. Move choke lever to RUN position. After a short

shut down, full choke may not be necessary. If

engine fails to start, move lever to RUN or partial

choke.

7. Once engine is running and no choke is needed,

slowly let foot clutch pedal up. This will engage

drive belt and the rotor will turn.

8. If engine kills when engaging foot clutch pedal,

either use more choke or increase engine RPM.

9. When clutch is engaged, the foot pedal may

vibrate or shake until the engine and rotor have

increased to full running RPM.

12

NOTE: Some oil usage is normal. Check level with

each use.

Warning: Handle fuel with care. It is highly

flammable. Always use an approved container

and fill tank outdoors.

2. Before starting, fill fuel tank with fresh, clean

diesel fuel. For instructions on bleeding the fuel

system on initial start up or if fuel runs out, see

engine manual.

Caution: See operation/start-up decal by foot

clutch pedal on machine before starting.

3. Turn key switch to preheat position. Hold in

preheat position for several seconds until glow

plug indicator light switches off.

Page 17

S

ECTION

4

4. Push throttle control in until it stops.

5. Depress foot clutch pedal, this will disengage drive

belt and enable engine to start.

6. Push in and hold Murphy switch push-button.

Continue to hold Murphy switch in when cranking engine until engine is running.

7. Activate the starter switch. Release the switch as

soon as the engine starts. Do not crank over for

more than 10 seconds. Release Murphy switch

after engine is running; hold murphy switch in

longer if engine immediately kills after releasing.

Note: The Murphy switch system will shut the

engine off if the oil pressure is too low or if the

engine temperature is too high. If the engine will not

run or shuts of for these reasons, consult your local

dealer.

8. Push center throttle control button in. Increase

throttle control to full throttle. Turn throttle

control knob clockwise to achieve maximum

RPM.

9. Slowly let foot clutch pedal up. This will engage

drive belt and the rotor will turn. If the engine

kills when engaging the drive belt, release foot

clutch pedal more slowly.

10. When clutch is engaged, the foot pedal may

vibrate or shake until the engine and rotor have

increased to full running RPM (3000 RPM).

Caution: Wear safety glasses at all times

when operating the machine. Do not wear

loose fitting clothing. Protect yourself from

branches, sharp objects, and other harmful objects

with proper eye protection and clothing.

Warning: Do not leave machine unattended

or attempt any inspection or service unless the

engine is stopped and the key switch is in OFF

position. Do not move chipper during operation.

the chipper and tractor. Secure connections with

snap pins. Adjust 3 pt. top link so that chipper

sits level.

2. Connect PTO shaft to tractor. Make sure you are

using the correct RPM machine. Do not operate

machine at speeds different than specified on

shield.

3. Never inspect or work on PTO drive area without

first disengaging PTO and shutting off tractor

engine.

4. Start tractor engine and engage PTO drive clutch

(see tractor owner's manual). Increase engine

speed to rated PTO RPM position.

Caution: Wear safety glasses at all times

when operating the machine. Do not wear

loose fitting clothing. Protect yourself from

branches, sharp objects, and other harmful objects

with proper eye protection and clothing.

Warning: Do not leave machine unattended

or attempt any inspection or service unless

PTO is disengaged and the tractor engine is stopped.

Do not move chipper during operation.

4.4 Chipping

Warning: Keep face and body away from the

feed opening. Do not over reach. Keep

proper balance and footing at all times.

The chipper is designed to chip a variety of materials

into a more readily decomposing or handled

condition. The following guidelines can be used to

help you get started. Please read and follow all safety

instructions in this manual. Failure to operate the

chipper in accordance with the safety instructions

MAY RESULT IN PERSONAL INJURY!

1. Be sure the unit is at full operating speed before

you start to chip material.

4.3 Starting PTO Model

Warning: This chipper is designed to be used

with tractor PTO's rated at 20 to 60 horsepower. Using this chipper with PTO's above 60

horsepower may cause belt and machine damage in

overload conditions.

1. Place tractor transmission in park or neutral and

set parking brake. Connect 3 pt. mounts between

2. Select limbs that are up to 8 inches in diameter

for 25 HP model. The 28 HP and PTO models

will chip limbs up to 9 inches in diameter. Trim

side branches that cannot be bent enough to feed

into the chipper chute. Small diameter branches

can be held together in a bundle and fed in

simultaneously.

13

Page 18

S

ECTION

4

3. Feed brush from the side of the infeed chute,

rather than from the front. Then, step aside to

avoid being hit by the brush moving into the

chipper.

4. Never lean over the infeed chute to push objects

into the cutting device. Use a push stick or brush

paddle.

5. Never use shovels or forks to push brush. They

can go through the chipper, are expensive to

replace, and cause major damage. In addition,

metal pieces can come back like shrapnel to

injure or kill.

6. Never push brush into the infeed chute with your

feet.

7. Engage the hydraulic feed by moving the control

arm. Pull the arm toward you to engage the

hydraulic feed (see figure 10.14). In the forward

direction, the feed rate increases as the arm is

moved.

8. Place limb, butt end first, into the chipper chute

until it contacts the hydraulic feed roller and is

drawn into the chipper blades. The actual feed

rate of the limb into the chipper will depend on

the type of material fed, and sharpness of the

cutting blades.

If the engine slows to where it may stall, push

the control lever inwards to slow or stop the

material feeding and allow the engine to recover.

Pull the lever out to restart feeding when the

engine is back to full speed.

Note: The chipping blades will dull with use and will

require periodic sharpening. Refer to page 17,

"Sharpening Chipper Blades" for instructions.

4.5 Stopping Instructions:

Warning: Do not attempt any inspection or

service until machine comes to a complete

stop. To stop machine, proceed as follows:

Engine Models:

1. Move engine throttle to slowest position.

2. Depress foot clutch pedal.

3. Turn key switch to off position.

4. Allow machine to come to a complete stop.

Release the foot clutch pedal to help slow the

rotor once the engine has stopped running.

PTO Models:

1. Move tractor throttle to SLOW position.

2. Disengage PTO lever and shut off tractor engine.

3. Allow machine to come to a complete stop.

Note: The heavy rotor will continue to turn for

some time after the engine. You can tell that the rotor

has stopped when no noise or machine vibration is

present.

9. If the chipper jams, reverse the feed by moving the

control arm in the reverse direction. Remove the

branch and rotate it before reinserting it into the

chute.

Alternately insert and retract the limb or insert

continuously at a rate that will not kill the engine.

Chipping dead, dry material will create heat and

dull the chipping blades quickly. Alternate

greener material with dry material to lubricate the

chipping blades for longer life and better performance. When the chipping blades become dull,

they will require periodic sharpening. Refer to

Service and Maintenance, "Sharpening Chipper

Blades," page 17.

14

Page 19

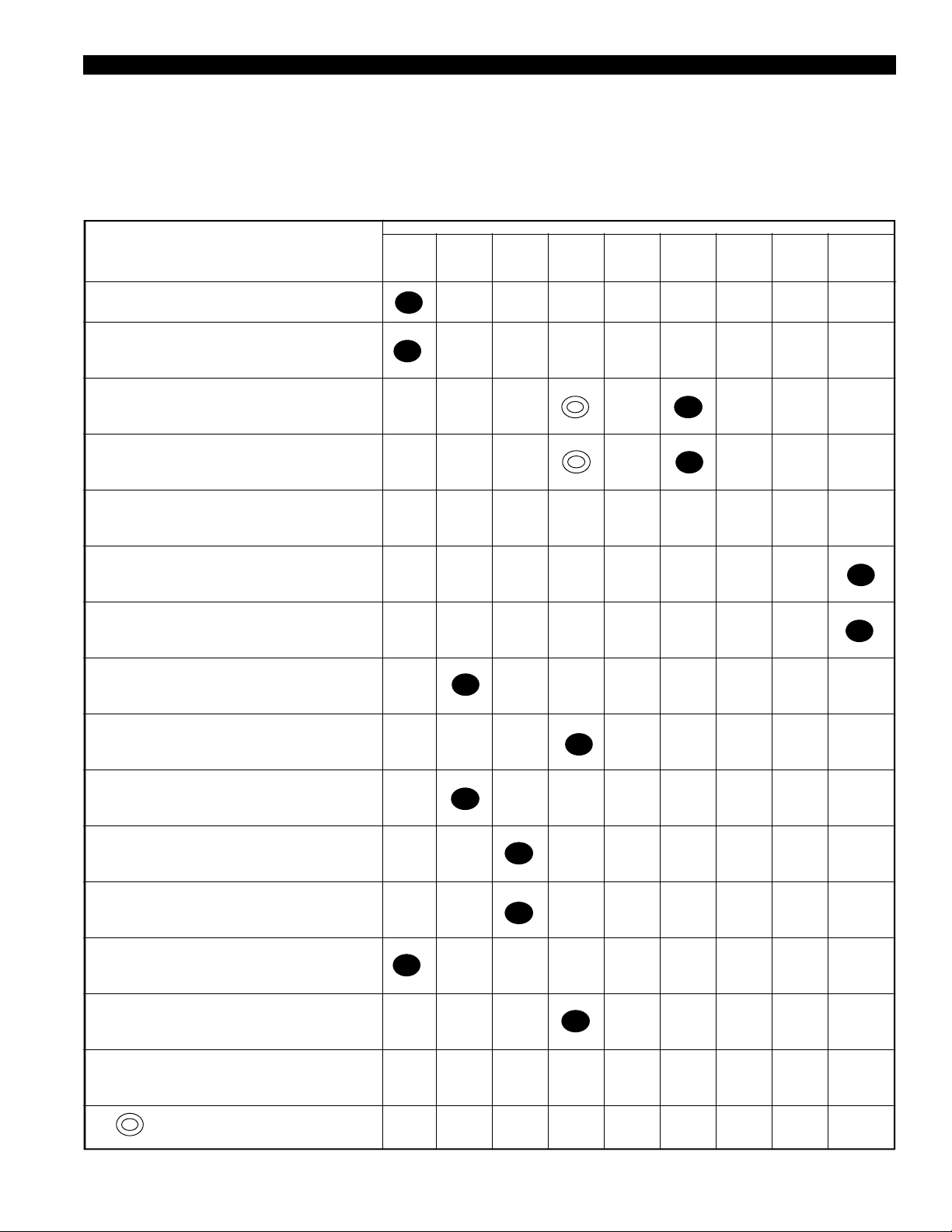

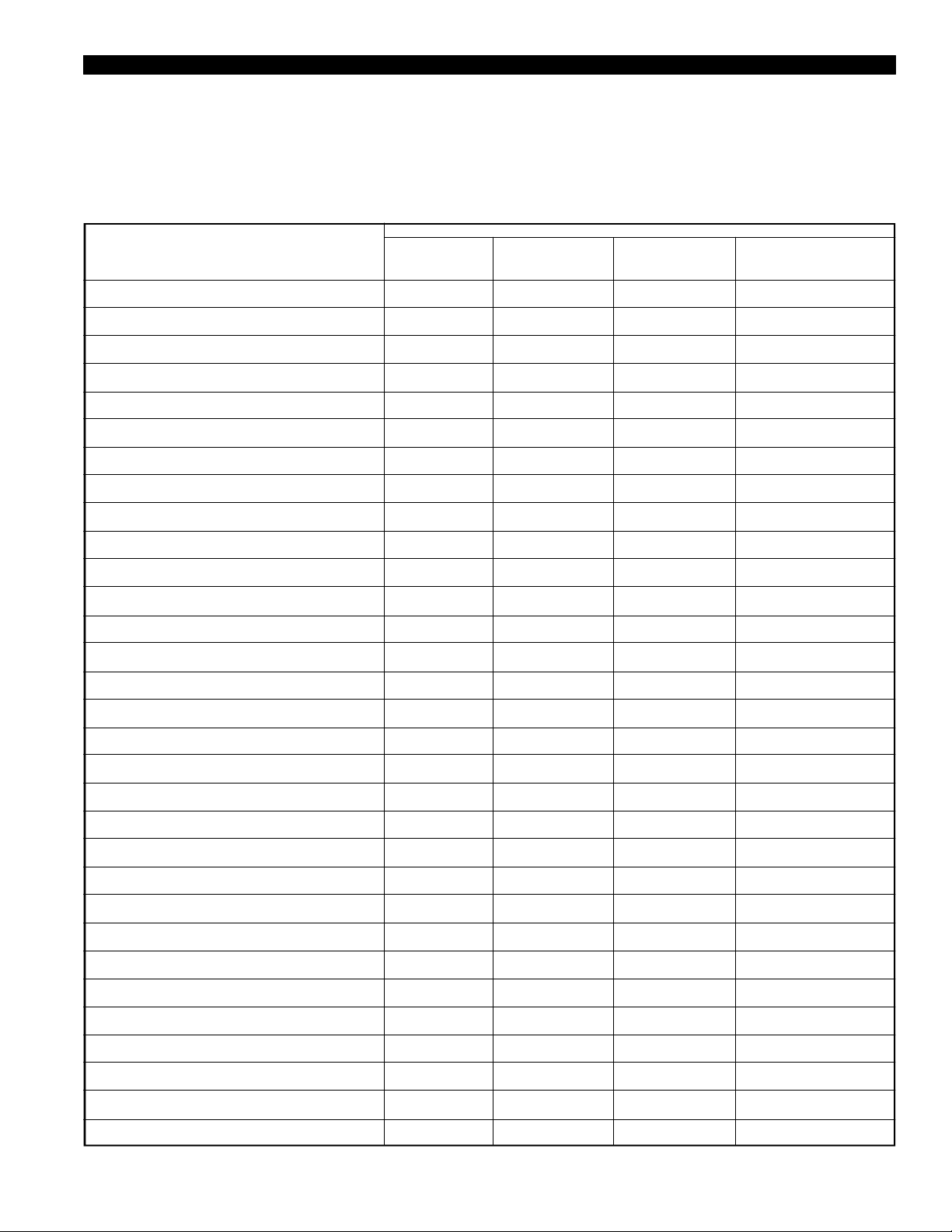

5.1 Service and Maintenance:

Engine Models

S

ECTION

5

Inspection Items

Check Nuts & Bolts

Engine Oil Level

Change Engine Oil

Replace Oil Filter Cartridge

Check Hydraulic Fluid Level

(3 Gallons)

Replace Air Filter Element

Replace Fuel Filter

Before

Each

Use

Every

10

Hours

Every

25

Hours

Every

50

Hours

Interval

Every

100

Hours

Every

200

Hours

Every

400

Hours

Every

800

Hours

Every

1

years

Check Sharpness of Chipper Blades

Grease Bearings and Pivots

Check Bolts: Chipper Blade, Feed

Roller, Chipper Anvil, Rotor Paddles

Check Drive Belt

Hydraulic Control Cable

(Feed Roller)

Check Water Level

Clean Machine

Indicates first hours of use.

15

Page 20

S

ECTION

5

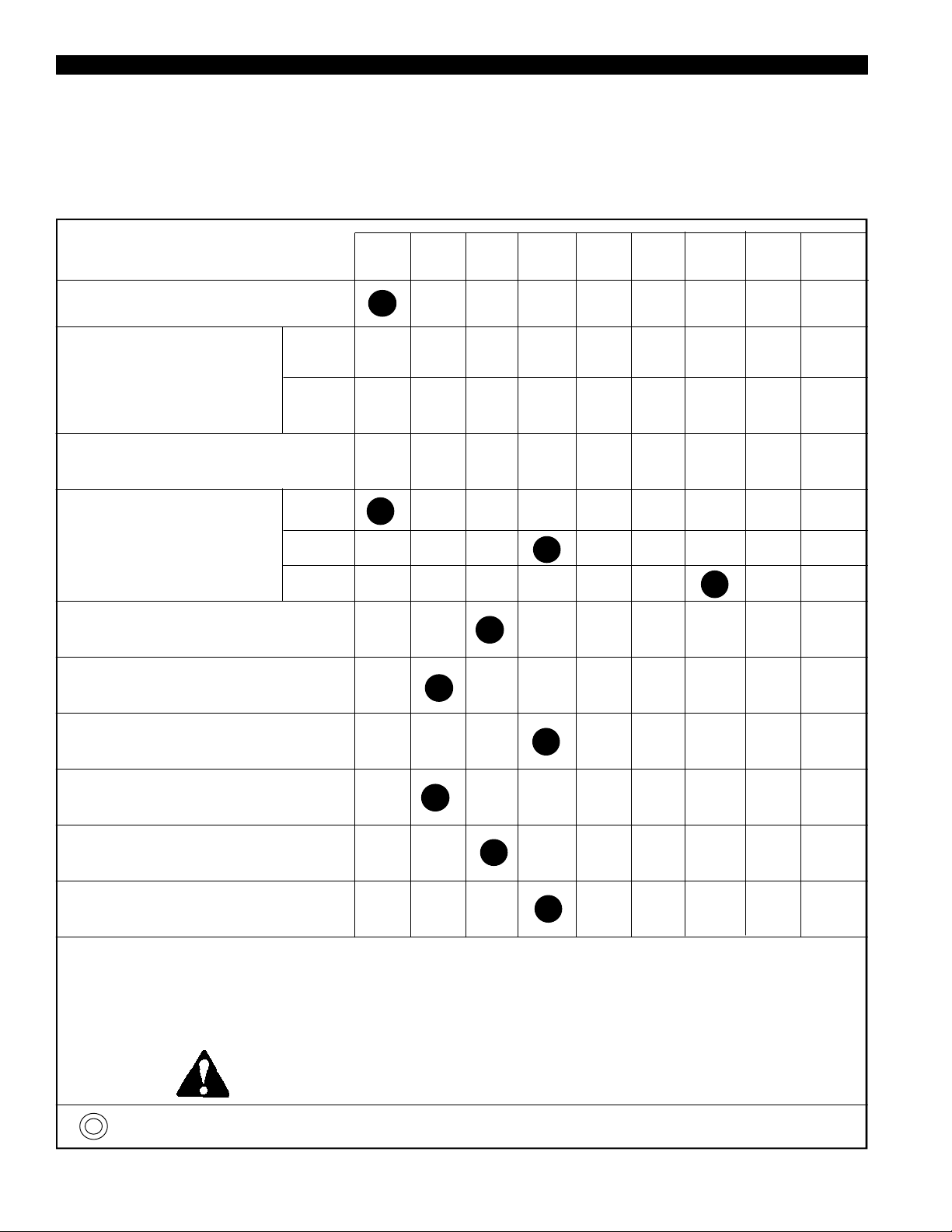

5.2 Service and Maintenance:

PTO Model

Inspection Items

Check Nuts & Bolts (entire machine)

Check

Replace

Before

Each

Use

Every

10

Hours

Every

25

Hours

Every

50

Hours

Interval

Every

100

Hours

Every

200

Hours

Every

300

Hours

Every

800

Hours

Every

1

years

Check

Hydraulic Filter Element

Clean

Replace

Check Hydraulic Control Cable

Check Sharpness of Chipper Blades

Grease Bearings and Pivots

Check Bolts: Chipper Blade, Chipper

Anvil, Rotor Paddles

Check Drive Belt

Clean Machine

Note: (*) Service more frequently when used in dusty conditions

*

16

Before inspecting or repairing any part of the machine, shut off the engine and make sure all

moving parts have come to a complete stop.

Indicates first hours of use.

Page 21

S

ECTION

5

Service and

Maintenance

Warning: Before inspecting or servicing any

part of the machine, shut off the engine, and

make sure all moving parts have come to a complete

stop. The chipping blades are sharp! Use care when

working on machine to avoid injury.

Warning: The rotor assembly has a lock

mechanism. When working on the rotor

assembly, use the lock mechanism at all times.

Remove the plastic bearing cover beside the chipper

chute. There is a hole in the rotor shaft and a matching hole in the bracket mounted to the rotor bearing

front side. Install a punch through the rotor shaft and

bracket to lock the rotor in place.

On engine models, check the engine oil, and change

the oil and filter as recommended in the manual.

Service and replace the air cleaner as recommended.

5.3 Sharpening Chipper Blades

The chipper blades will eventually become dull,

making chipping difficult. It is recommended that

the chipper blades are sharpened every 5-15 hours

of chipper operation. To remove the chipping blades

for sharpening:

1. Remove the two 3/8 inch retaining bolts holding

access cover to main frame assembly.

2. Tilt access cover over to allow rotor access.

Rotate the rotor so that the bolts holding a

chipping blade are most accessible.

3. Remove the two allen head bolts holding the

blade itself. Repeat for all four blades. The four

chipping blades have two edges per blade and

can be reversed one time each before sharpening. If both sides have not been used, remove

and reverse the chipping blades. Reinstall chipping blades and proceed with chipping.

properties. Use short grinding times and cool with

water. Try to remove an equal amount off each blade

to maintain balance. Replace the chipping blades and

tighten bolts to 75 ft. lbs. Close cover and replace bolts.

5.4 Chipping Blade Sharpening Tips

Poor chipping performance is usually a result of dull

chipping blades. If your chipper's performance has

decreased, check for the following symptoms:

• Severe vibration when feeding material into the

chipper.

• Small diameter branches do not self-feed.

• Chips discharge unevenly or have stringy tails–

especially when chipping green branches.

Before you sharpen the chipping blades, check for

permanent damage. Replace the blade if:

• The blade is cracked (especially around the bolt

holes) or the edges are too deeply chipped to be

ground smooth.

• The base of the cutting edge is worn or has been

re-sharpened so that it is too close to the rotor

chipping slot.

5.5 Setting Chipping Blade Clearance

The four chipping blades should clear the chipper

anvil located directly under the chipper chute by

1/16 inch to 1/8 inch. The chipper anvil is adjustable

and reversible.

To adjust:

1. Lift rotor access cover and expose rotor (see

figure 10.16). Loosen the three 1/2 inch bolts

that hold the chipper anvil to the frame (see

figure 10.17).

2. Measure the amount of clearance between

chipping blade and chipper anvil from inside of

housing.

To grind the angled edge of the chipping blade to 45

degrees (see figure 10.15): Grind the blades on a

slow-speed wet grinder if possible, or have them

sharpened by a professional. If you use a bench

grinder, be careful when grinding so that the blade

material does not get too hot and change color–this

will remove the blade's special heat treated

3. Adjust inward or outward to desired measurement.

4. Tighten bolts on chipping block to 75 ft. lbs. and

resume operation.

If chipper anvil edge is damaged or worn unevenly,

remove the three bolts holding the anvil and use one

17

Page 22

S

ECTION

5

of the other three edges. Adjust for correct

measurement.

5.6 Adjusting Drive Belt

Check the condition of the drive belt annually or

after every 25 hours of operation, whichever comes

first. If the belt is cracked, frayed, worn, or stretched,

replace it. Only replace belt with original banded type

belt, do not use single type belts. To adjust the belt,

proceed as follows:

1. Engine Models: Depress foot clutch pedal. Shut

engine off, and disconnect battery cables.

PTO Model: Disengage PTO and shut off tractor

engine. Remove PTO shaft from tractor; disconnect machine from 3 pt. hitch. Remove round

shield connected to belt guard that covers PTO

shaft by removing two 5/16" nuts. Remove PTO

shaft from chipper by removing two set screws

and pulling shaft off.

2. Remove large belt guard (three 5/16 inch bolts).

3. Adjust the eyebolt that anchors the idler spring to

adjust the belt tension. Tighten the eyebolt until

the belt deflection at the center of the belt is

7/16" when a 20 lb. load is placed against the belt

(see figure 10.18).

4. Replace belt guard.

5. Test machine for belt looseness. Replace the belt

if no adjustment is left.

5.7 Replacing Drive Belt

1. Remove large belt guard (three 5/16" bolts).

2. Loosen bolts on hydraulic pump and remove

belt.

3. Lift belt idler pulley off drive belt and remove

drive belt from pulleys.

4. Install new belt on pulleys and lower belt idler.

Check alignment of pulleys and adjust if needed.

5. Check belt tension before start-up. Adjust the

eyebolt that anchors the idler spring to adjust the

belt tension. Tighten the eyebolt until the belt

deflection at the center of the belt is 7/16" when

a 20 lb. load is placed against the belt (see figure

10.18).

6. Replace hydraulic pump belt. Readjust hydraulic

pump belt tension by sliding the hydraulic pump

in the mounting slots. Tighten bolts.

7. Replace belt guard.

8. Test the machine. Readjust pulleys and belt

tension if needed.

5.8 Clearing Plugged Rotor

Warning: If the machine becomes plugged,

depress foot clutch pedal, shut off the engine

(or disengage PTO), and allow the machine to come

to a complete stop before clearing debris. Do not

operate the machine without proper guards and

screens in place.

Feeding too much chipable material at once may

plug the chipper. To clear plugged rotor, proceed as

follows:

1. Engine Models: Depress foot clutch pedal and

stop engine. Release foot clutch pedal when

engine is stopped.

PTO Model: Disengage PTO and shut off tractor

engine.

2. Remove the two 3/8" retaining bolts holding the

access cover to the main frame assembly.

3. Lift up rotor access cover.

4. Clean the debris out of the chipper rotor. Turn

the rotor by hand to be sure it is free to rotate.

Caution: Blades are sharp; avoid contact with

chipper blades.

5. Close rotor access cover and replace bolts.

6. Engine Models: Depress foot clutch pedal, and

start engine. Release foot clutch pedal when

engine is running to engage drive belt. Resume

operation.

PTO Model: Start tractor engine and engage PTO

drive clutch. Increase engine speed to rated PTO

RPM position.

5.9 Repairing or Replacing Rotor

Bearings

1. Remove the two 3/8 inch retaining bolts holding

access cover to main frame assembly. Tilt access

cover over to allow rotor access.

18

Page 23

S

ECTION

5

2. Remove large belt guard (three 5/16 inch bolts).

3. Loosen bolts on hydraulic pump and remove

hydraulic pump belt. Using the push bolts from

the bushing, remove the bushing and pulley

from the rotor shaft.

4. Lift belt idler pulley off drive belt and remove

belt from pulleys. Using the push bolts from the

bushing, remove the bushing and pulley from the

rotor shaft.

Warning: The rotor assembly has a lock

mechanism. When working on the rotor

assembly, use the lock mechanism at all times.

Remove plastic bearing cover under the chipper

chute. There is a hole in the rotor jack shaft and a

matching hole in the bracket mounted to the rotor

bearing front side. Install a punch through the rotor

shaft and bracket to lock the rotor in place.

5. Remove the four 1/2 inch bolts on each rotor

bearing and remove the punch used to lock the

rotor.

6. Using an overhead hoist or lifting device, lift the

rotor assembly completely out of the frame. The

complete rotor assembly is 275 lbs.

7. Once the rotor assembly is out of the frame,

remove 3/8" bolts and collar from front. Remove

both bearings with a puller and place new

bearings on rotor shaft. Replace collar.

8. Use the overhead hoist or lifting device to return

the complete rotor assembly to the chipper

frame.

9. Slide rotor back until front collar is tight against

the front bearing. Lock the front bearing and

install the four 1/2 inch bolts on each bearing to

secure them to the frame. Tighten bolts to 75 ft.

lbs. Check and adjust chipper anvil if needed.

Lock rear bearing.

10. Slide rear collar on shaft against rear bearing.

Slide bushing onto shaft with flange against

collar and lock bushing to shaft. Attach large

pulley to bushing. Replace drive belt on pulleys

and lower belt idler. Check alignment of pulleys

and adjust engine if needed.

11. Check belt tension before start-up. Adjust the

eyebolt that anchors the idler spring to adjust the

belt tension. Tighten the eyebolt until the belt

deflection at the center of the belt is 7/16" when

a 20 lb. load is placed against the belt (see figure

10.18).

12. Close cover and replace bolts.

13. Replace hydraulic pump bushing and pulley.

Replace hydraulic pump belt. Readjust hydraulic

pump belt tension by sliding the hydraulic pump

in the mounting slots. Tighten bolts.

14. Replace belt guard and resume operation. Readjust pulleys and belt tension if needed.

5.10 Adjusting the Hydraulic Feed

Control Cable

Figure 10.19 shows the hydraulic feed control cable

assembly and the detent position slots. The cable is

attached and adjusted from the factory, but it should

be checked and adjusted as needed before use. The

hydraulic feed control lever has three positions:

Forward (lever moved toward the operator)

Neutral (lever in center position)

Reverse (lever moved away from operator; reverse

has no detent position)

When the operator moves the control lever to the

neutral position, the detent ball should be positioned

in the rear detent slot (see figure 10.19). The feed

roller should come to a complete stop when the

control lever is in the neutral position. If it does not

stop, adjust the clevis assembly on the control cable

as follows:

1. If the control lever is in neutral and the roller

creeps forward, the cable is too short; adjust it to

a longer length.

2. If the roller creeps in a reverse direction, the

cable is too long; adjust it to a shorter length.

3. Adjust the cable as needed to compensate for

cable stretch.

5.11 Greaseable Bearings and Pivots

Engine Models: The engine model chippers have

five greaseable bearings and pivots that require

grease every 50 hours:

• Two bearings on the rotor shaft

• One greaseable bushing on the foot pedal pivot

19

Page 24

S

ECTION

5

• One grease zerk on idler pivot.

• One grease zerk on discharge chute.

Service engine according to engine manual.

Change engine oil and filter as recommended in

manual.

PTO Model: The PTO Model has ten greaseable

bearings and pivots that require grease every 50

hours:

• Four grease zerks on the PTO shaft

• Two greaseable bearings on the rotor shaft

• Two greaseable bearings on the bottom jack shaft

• One idler arm pivot

• One on discharge chute

5.12 Hydraulic Feed Maintenance

Note: Check the reservoir daily for proper fluid

level, the presence of water (noted by a cloudy to

milky appearance, or free water in bottom of

reservoir), and rancid fluid odor (excessive heat).

The hydrostatic pump normally does not require

regular fluid changes. The system filter should be

changed at 250 hour or annual intervals. The fluid

and filter should be changed and system cleaned if

the fluid becomes contaminated with foreign matter

(water, dirt, grease, etc.) or if the fluid has been

subjected to temperature levels greater than the

maximum recommended.

There is a greaseable bearing on each side of the

shaft on the hydraulic feed housing. Grease

periodically.

5.13 Trailer Service Tips (Engine

Models Only)

1. Check wheel bolt torque every 10 hours of towing

use.

2. Check air pressure in tires every 10 hours of

towing.

3. Check and repack wheel bearings with grease

every 12 months.

4. When towing, always connect the safety chains.

Make sure trailer hitch bolts are tight and secure.

5. Check trailer lights.

20

Page 25

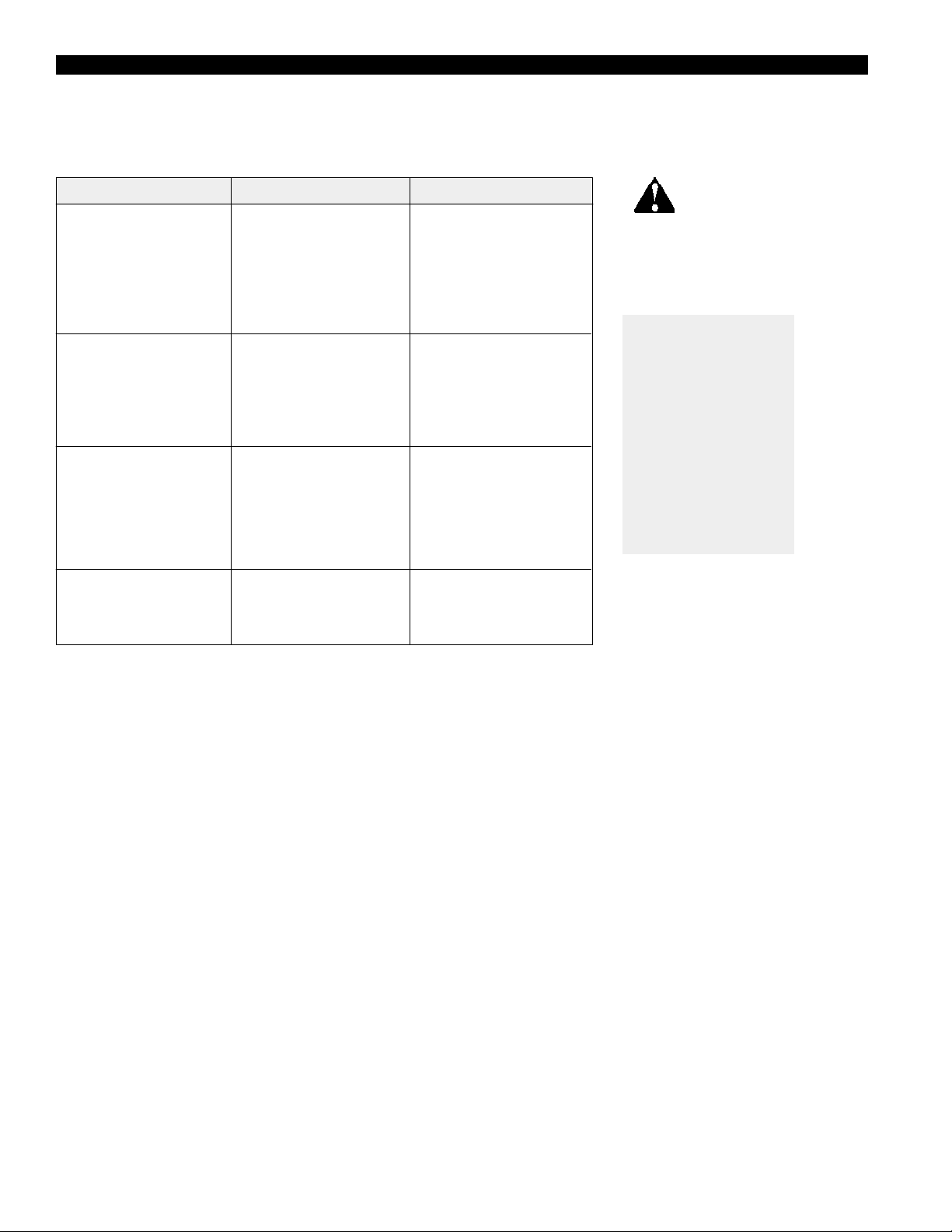

6.1 Troubleshooting

S

ECTION

6

Problem

1. Rotor does not turn

2. Hard to feed chipper

or excessive power

needed to chip

3. Chipper requires

excessive power or

stalls

Probable Cause

a) Obstructed

discharge

b) Plugged rotor

a) Obstructed

discharge

b) Dull chipper blades

c) Improper blade

clearance

a) Obstructed

discharge

b) Plugged rotor

c) Green material will

not discharge

Suggested

Remedies

a) Use branch or

similar object to

clear discharge

b) Clear rotor

a) Use branch or

similar object to

clear discharge

b) Sharpen blades

c) Adjust clearance

a) Use branch or

similar object to

clear discharge

b) Clear rotor, feed

material into

shredder more

slowly

c) Alternately feed dry

material, or allow

material to dry

Reference

Service and Maintenance

Service and Maintenance

Service and Maintenance

4. Drive belts

squealing or

smoking

6. Vibration while

running

7. Engine dies or runs

poorly

8. PTO will not turn or

has slow RPM's

a) Plugged rotor

b) Loose or worn belts

a) Drivehead vibration

b) Rotor out of balance

a) Engine problems

a) PTO shaft not

engaged on tractor

b) PTO shaft loose

a) Clear rotor

b) Adjust belt tension

or replace belts if

needed

a) Check drive belts

and pulleys for bad

or worn spots.

b) Inspect rotor for

broken or missing

chipper blades and

paddles. Repair if

needed.

c) Check rotor to see if

it wobbles

d) Check to see if rotor

is assembled

correctly

a) Contact local engine

service center

a) Engage PTO

b) Check all

connections and

repair if needed.

Service and Maintenance

Service and Maintenance

Service and Maintenance

Engine Manual

Service and Maintenance

21

Page 26

S

ECTION

6

6.2 Hydrostatic Pump Troubleshooting

Symptom

Will not attain normal feed rate.

Will not feed when control arm

is moved.

Feed rate is sluggish under

load.

Hydraulic Feed will not pull in

logs over 4" in diameter, or

continuously stalls or stops.

Probable Cause

Engine not operating at correct speed.

Control linkage damaged or

binding.

Bypass valve stuck partially

open. (Problem in one direction only.)

Control linkage damaged or

not connected.

Drive between engine and

pump damaged.

Pump low on fluid.

Loose drive belt between

engine and pump.

Pump low on fluid.

Large amount of water in hydraulic fluid (evaporates when

hot, resulting in low fluid level).

Hydraulic system overloading

and causing system to go

over relief.

Suggested Remedy

Repair engine governor.

Repair control linkage.

Repair bypass valve.

Remove foreign material from

valve.

Repair or reconnect control

linkage.

Repair drive (replace broken

belt, repair sheared key, repair splined coupling, etc.).

Refill reservoir. Purge air from

transmission.

Tension drive belt (replace if

necessary).

Refill reservoir. Purge air from

transmission if necessary.

Drain fluid from reservoir and

unit, replace filter element,

and refill with new fluid.

Check relief pressure in system with a pressure gauge

rated to 2500 psi (system set

by factory at 1750 psi).

Caution: Hydraulic

systems contain fluid

under high pressure. Never

check for leaks with your

hands. Relieve pressure before

disconnecting any hydraulic

lines.

Before servicing or

repairing any of the

hydrostatic feed

components (pump,

motor, and/or relief

valve), contact your

dealer or factory

service department.

Warranty on these

items may be void

without prior

authorization.

22

Page 27

S

ECTION

7

7. Optional Electronic Feed

Sensor Installation

1. Remove belt guard.

If serial number is equal to or greater than 19317,

skip to step 9.

2. Loosen hydraulic pump mount and remove

pump drive belt.

3. Remove chipper drive belt.

4. Remove the pump and chipper-driven pulley

from the rotor shaft.

5. Replace collar (see figure 10.20) with the

sprocket and collar weldment supplied with the

valve kit.

6. Replace the chipper-driven pulley and pump

pulley.

Note: To maintain the chipper rotor position, push

the chipper pulley bushing tight against the collar

and the collar tight against the rotor bearing before

tightening.

7. Replace the chipper drive belt.

8. Replace the pump drive belt, position the pump

to tension the belt, and tighten the pump mount.

9. Attach the sensor and bracket under one of the

rotor bearing bolts so that it lines up with the

sprocket teeth (pickup should be approximately

.020" from the teeth of the sprocket). See figure

10.21.

10. Mount the speed switch bracket to the center bolt

in the chipper base. (Ref #6)

11. Replace the crossover relief valve with the new

valve suppled with the valve kit (serial number

less than 19317 only). (Ref #3)

12. Remove outer and inner plugs from the relief

valve. Install the solenoid cartridge valve and

coil so that the wires lead down (metal side of

valve coil towards relief valve).

13. Connect the solenoid valve and sensor to the

speed switch and attach the ground wires to the

frame. Route positive to engine (see wiring

diagram). (Ref #4)

14. Mount speed switch and route wires according to

wiring diagram.

15. Attach cover over speed switch with two self

tapping screws.

16. Replace the belt guard.

17. Attach the chipper to the tow vehicle.

18. Operate the chipper per manual instructions.

Note: When approaching the end of a log, it might

be necessary to manually override the automatic

feed sensor. Be sure to pay attention to the engine

speed and feeding of the material.

7.2 Operation of the Electronic Feed

Control

When the speed switch senses that the chipper rotor

has slowed to a certain preset level, the speed switch

will open the crossover valve and allow the oil to

return to the tank.

Operate the chipper as instructed in the chipper

manual. The feed control will start and stop the feed

roller automatically. To maximize performance, there

are two adjustments on the Speed Switch to tailor the

unit to your specific engine and needs.

1. The setpoint screw is used to determine the

engine RPM that the switch opens and halts the

feed.

The setpoint screw is used to adjust the RPM that

the feed roller turns off. Turning the screw

clockwise will increase the speed setting. The

setpoint is a very fine adjustment; it is not recommended to go over 1/2 a turn each adjustment.

It is recommended to have this set so that the roller

shuts off when the engine speed is slightly higher

than the maximum torque speed of the engine.

2. The hysteresis is used to determine the amount

of recovery time the engine is allowed. This is

directly related to the setpoint setting.

Turning the screw clockwise will increase the

speed between when the roller stops and when it

turns on.

It is recommended to have this set at the minimum

by turning the screw counterclockwise

approximately 10 turns. If you don't seem to be

getting any adjustment, you have turned screw to

end of its range.

23

Page 28

S

ECTION

8

8. Specifications

Overall Size (LxWxH)

Max. Chipper Cap. (dia.)

Chipper Blade Qty.

Rotor Speed

Rotor Size

Rotor Weight

Rotor Shaft Diameter

Discharge Size

Drive Type

Belt Size

Weight (Lbs.)

Model 72825

N/A

8"

4 Reversible Tool Steel

1500 RPM

30" Dia. x 1.25"

275 lbs.

1.75"

8"

Belt

N/A

N/A

Model 72928

119" x 79" x 89"

9"

4 Reversible Tool Steel

1500 RPM

30" Dia. x 1.25"

275 lbs.

1.75"

8"

Belt

3B83

2486

Model 72854

45" x 47" x 90"

9"

4 Reversible Tool Steel

1500 RPM

30" Dia. x 1.25"

275 lbs.

1.75"

8"

Belt

BX64 (3)

N/A

Wheel Base

Tire Size

Fuel Tank Cap. (Gal.)

Engine

N/A

N/A

N/A

Kohler 25 HP

N/A

N/A

18

Kubota 28 HP Diesel

N/A

N/A

18

-