Page 1

Instructions

SUBJECT: Electronic Fee d K it

(PN 73244)

FITS MODELS: CH6614H (72620),

74824, 72825, CH911DH (72928),

72942, CH922DH (74950)

WARNING

TOP COVER

FOUR 1/4" HOLES

BEFORE INSPECTING OR SERVICING ANY PART

OF THIS MACHINE, SHUT OFF POWER SOURCE,

DISCONNECT SPARK PLUG WIRE FROM SPARK

PLUG AND MAKE SURE ALL MOVING PARTS HAVE

COME TO A COMPLETE STOP.

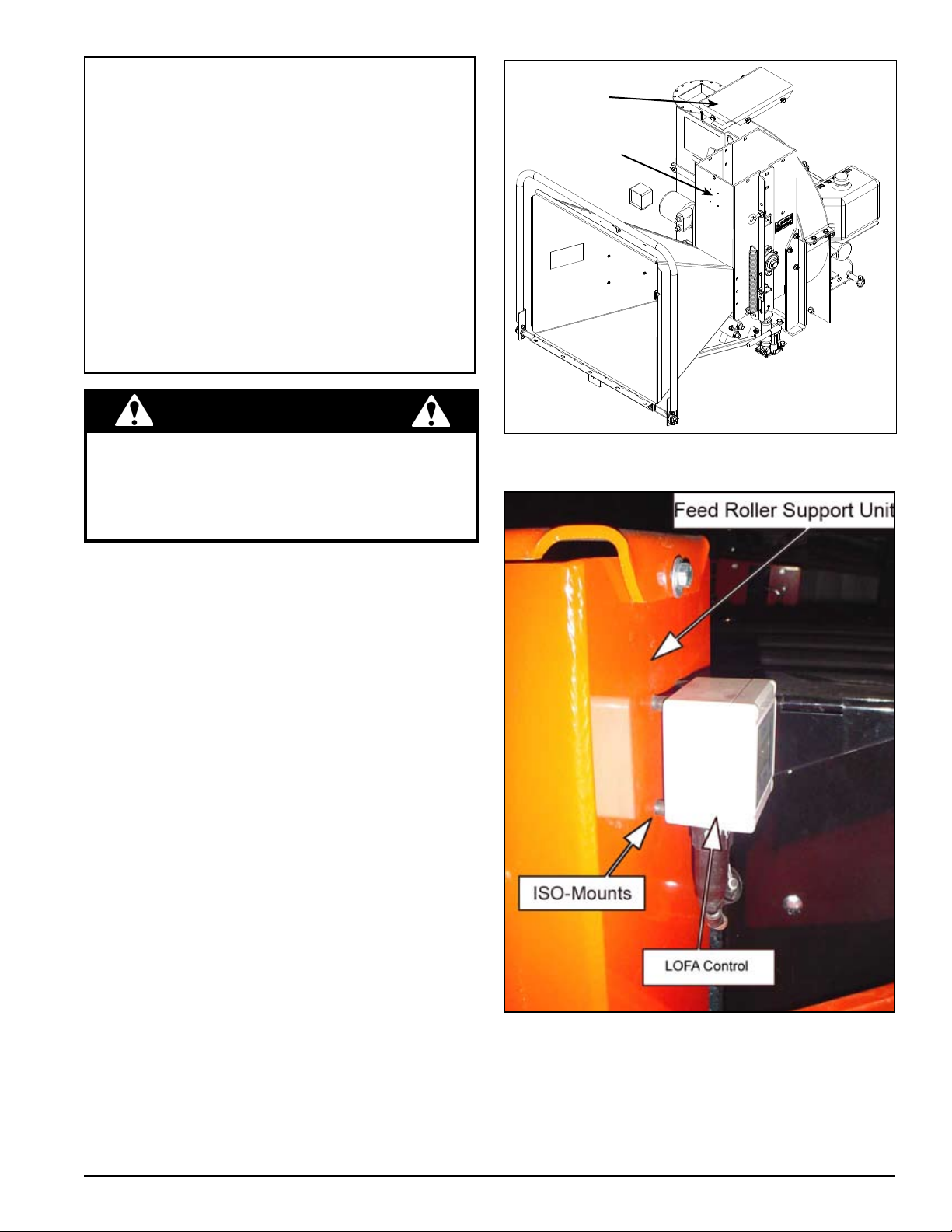

MOUNTING THE LOFA CONTROL

Remove upper belt guard. 1.

Remove the top cover from the Feed Roller Support 2.

unit. If the serial number is equal to or greater than

X01249, skip to STEP 6 (Figure 1).

Remove the back cover from the LOFA control, center it 3.

3-1/2” from the top on the front plate of the Feed Roller

Support housing and mark the position of the holes.

Drill four 1/4” holes (Figure 1).4.

Attach the ISO-Mounts to the controller back plate with 5.

the bolts and nuts provided (Figure 2).

Secure the back plate of the controller to the Feed 6.

Roller Support housing with a washer and one M4-0.7

nuts per bolt, apply locking adhesive and tighten.

Replace the Feed Roller Support cover.7.

Figure 1

Attach the LOFA Control to the back plate (Figure 2)8. .

Instruction Sheet

Figure 2

PN 73243

Rev. 022608

Page 2

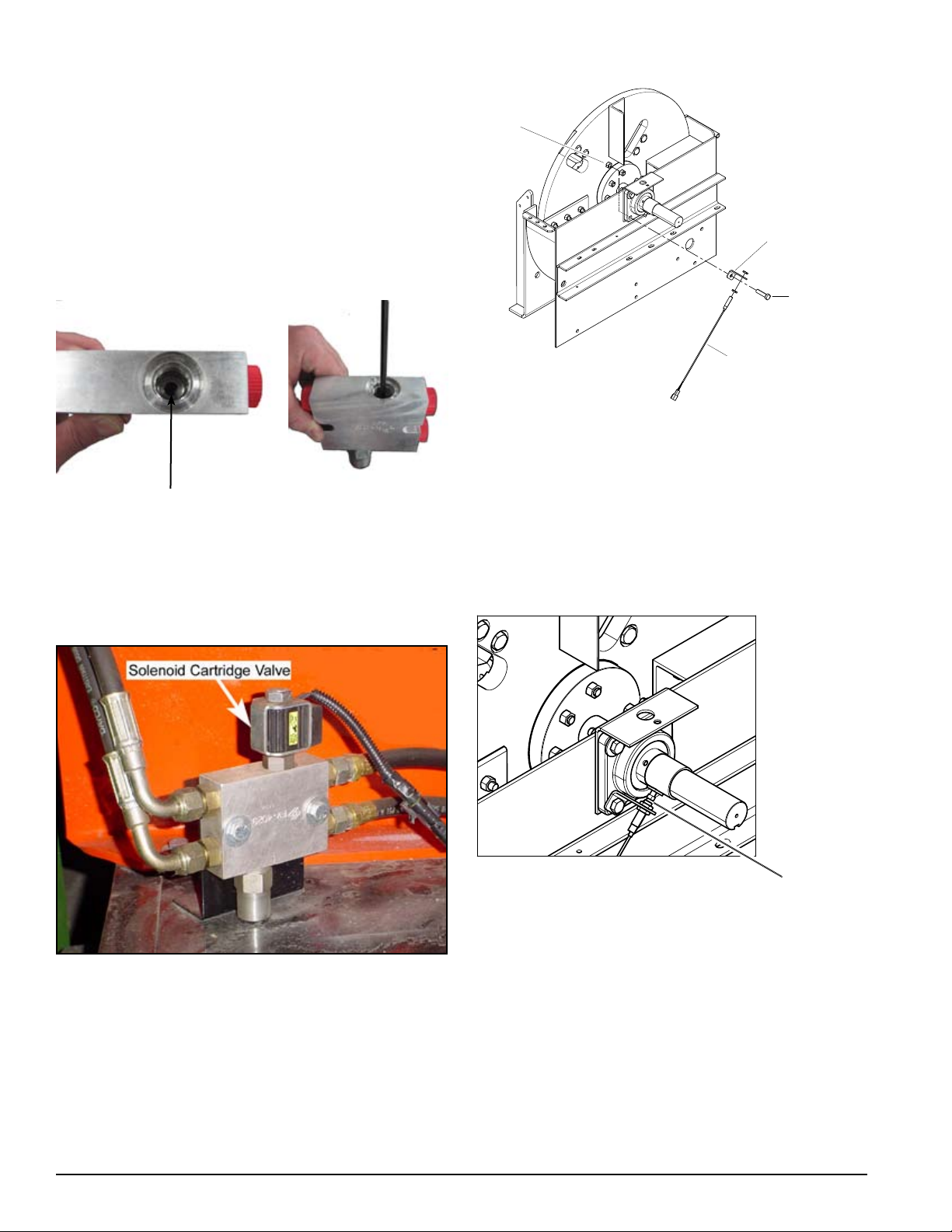

INSTALLING THE SOLENOID

SENSOR

BOLT, 1/2 X 2 HEX

SENSOR BRACKET

NUT, 1/2 CENTERLOCK

1/8" - 1/16"

GAP

CARTRIDGE VALVE

Model 76824 requires the installation of a cross over valve

and hoses. Cross over valve (12820) comes complete with

a solenoid cartridge.

Remove outer plug (using 5/16" allen wrench) from the 1.

top of the valve manifold.

Once the outer plug has been removed, using a 3/16 2.

allen wrench, extract the inner plug located in the relief

valve (Figure 3).

Figure 5

Figure 3, 3/16" inner plug

Replace the removed components with the new sole-3.

noid cartridge valve and coil.

Connect solenoid wiring to LOFA Control wiring har-4.

ness (Figure 4).

POSITIONING THE SENSOR

Position the sensor approximately 1/16” - 1/8” from the 1.

head of the bolt (Figure 6).

Replace the Belt Guard We ldment using 5/16” 2.

hardware.

Figure 6

INSTALLING THE SENSOR

Figure 4

Secure the sensor bracket with the lower left bearing 1.

bolt and position it (the sensor) so it aligns with the set

bolt (Figure 5).

Instruction Sheet

Page 3

ELECTRICAL INSTALLATION

WIRING SCHEMATIC

5

6

4

2

3

1

WIRE COLOR CODE LEGEND

O ORANGE

G GREEN

B BLACK

R RED

BL BLUE

BR BROWN

B

O

G

BR

B

PROXIMITY

SENSOR

B

BL

BR

7

BL

R

FUSE

8 AMP

R

POWER GROUND

B

COIL

CONN

CONN

O G

MODELS: CH6614H (72620), 74824 & 72825

Note: For Models CH6614H (72620) & 74824 (Honda Engines), note STEP 4 and refer to the wiring schematic.

Crimp a ring terminal onto the Black ground lead.1.

Drill a 3/16” hole in the trailer, close to the solenoid 2.

valve, and secure the ground wire with the #10 selftapping screw provided.

Connect the two-pin connector to the top of the valve 3.

coil.

Crimp a spade connector onto the Red wire in the 4.

Feed Sensor harness and connect to the Yellow wire

from the Kohler engine harness. For Honda engines,

the Red wire is attached to the black wire with a yellow

tracer coming from the engine.

Connect the socket connector to the LOFA control.5.

Secure wiring harness with cable ties as appropriate.6.

MOD E LS: CH911DH ( 729 2 8), 7294 2 &

CH922DH (74950)

Crimp a ring terminal onto the Black, Ground lead.1.

Drill a 3/16” hole in the trailer, close to the solenoid 2.

valve, and secure the ground wire with the #10 selftapping screw provided.

Connect the two-pin connector to the top of the valve 3.

coil.

Crimp a ring terminal to the Red wire in the Feed Sen-4.

sor harness and attach to “B” terminal on the back of

the Murphy Switch.

Connect the socket connector to the LOFA control.5.

Secure wiring harness with cable ties as appropriate.6.

Instruction Sheet

Page 4

FE E D S E NS O R P R OGR A MMI N G

INSTRUCTIONS

STEP 1. INITIATING PROGRAM MODE

Hold down the “S” button while turning the engine key to the “on”

position until “L” starts to flash on the LCD.

STEP 2. ENTER LOW (L = LOW) RPM

The low setting is the RPM speed where the feed roller stops.

The “up” arrow increases the RPM setting, while the “down” arrow

decreases the RPM setting. Setting the speed lower causes the

engine to lug down more before the feed roller stops.

Hold the appropriate (either up or down) arrow until the desired 1.

RPM speed is displayed (Recommend 1375 rpm).

Push the “S” button once with the desired RPM setting displayed 2.

to save.

NOTE: Do not choose a setting equal to or below zero.

STEP 3. ENTER NORMAL

(N = NORMAL) RPM

The normal setting is the RPM speed that the chipper rotor

usually rotates

Hold the appropriate (either up or down) arrow until the desired 1.

RPM speed is displayed (Recommend 1500 rpm).

Push the “S” button once with the desired RPM setting 2.

displayed to save.

ELECTRONIC FEED PARTS LIST (PN 73244)

PN DESCRIPTION QTY

12674 CONTROL, LOFA HYDRAULIC 1

12813 HARNESS, AUTO FEED 1

15602 WASHER, #6 SAE FLAT 4

15640 NUT, M4-0.7 ZP HEX 8

73242-12 BRACKET, PROXIMITY SENSOR 1

12828 CONNECTOR, #10 INSULATED RING 2

12829 CONNECTOR, #10 INSULATED FORK 3

12830 CONNECTOR, .25 INSULATED MALE 2

17320 STRAP, NYLON TIE-11” 4

16967 VALVE, SOLENOID CARTRIDGE 1

16968 COIL, SOLENOID VALVE 1

73243 INSTRUCTIONS, AUTO FEED 1

15282 BOLT 5/16*1 1/2 GR5 HEX CPS ZP 1

15225 SCREW, #10 X 3/4 HEX TAP SC 1

STEP 4. ENTER HIGH (H = HIGH) RPM

The high setting is not needed with this application.

Set to zero to deactivate.1.

Push the “S” button once with zero displayed to save.2.

STEP 5. ENTER RETURN

(RET = RETURN) RPM

The return setting is the RPM speed where the feed roller

restarts. The feed roller should restart before the rotor reaches

“normal” RPM to maximize chipper efficiency. Setting the speed

higher allows the engine to recover more before the feed roller

restarts.

Hold the appropriate (either up or down) arrow until the desired 1.

RPM speed is displayed (Recommend 1400 rpm).

WARNING

NOTE: WHEN APPROACHING THE END OF A LOG, IT

MIGHT BE NECESSARY TO MANUALLY OVERRIDE

THE AUTOMATIC FEED SENSOR. BE SURE TO PAY

ATTENTION TO THE ENGINE SPEED AND FEEDING OF

THE MATERIAL.

Instruction Sheet

www.bearcatproducts.com

ECHO BEAR CAT

237 NW 12th Street, West Fargo, ND 58078-0849

Phone: 701.282.5520 • Toll Free: 800.247.7335 • Fax: 701.282.9522

E-mail: service@bearcatproducts.com • sales@bearcatproducts.com

Loading...

Loading...