Page 1

I

nstruction &

Owners Manual

6" & 8"

Chipper

and

Hydraulic

Feed

Models

Crary Company

Box 849

West Fargo, ND 58078

(701) 282-5520 (800) 247-7335

FAX: (701) 282-9522

71620

71825

72620

72825

Cat. No. 16681

Manual No. 1097

Page 2

Dear Bear Cat Customer,

Thank you for purchasing a Crary Bear Cat Chipper. The Bear Cat

Chipper is designed, tested, and manufactured to give years of

dependable performance. To keep your chipper operating at peak

efficiency, it is necessary to adjust it correctly and make regular

inspections. The following pages will assist you in the operation and

maintenance of your machine. Please read and understand this manual

before operating the chipper.

If you have any questions or comments about this manual, please call

us toll-free at 1-800-247-7335.

If you have any questions or problems with your chipper, please call or

write your local factory-authorized Bear Cat dealer.

Please Send Us Your Warranty Card

A warranty card is included in your owner's kit packaged with your

chipper. Please take the time to fill in the information requested on the

card. When you send your completed card to us, we will register your

machine and start your coverage under our limited warranty .

How to Contact

Bear Cat

A

DDRESS

Crary Bear Cat

237 NW 12th Street

PO Box 849

West Fargo, ND 58078

P

HONE

800-247-7335

701-282-5520

Fax: 701-282-9522

H

OURS

M-F , 8 a.m. to 5 p.m.

Central Time

Owner's Record

Please take a moment to record the

following information about your chipper. If

you need to call for assistance, please be

ready to provide your model and serial

numbers. This information will allow us (or

your dealer) to help more quickly when you

call.

Model Number

Serial Number

This safety alert symbol identifies important safety messages in this

manual. When you see this symbol, be alert to the possibility of personal

injury and carefully read the message that follows.

Serial Number Decal Location

Serial Number Decal

Be alert! Your Safety is Involved.

Page 3

Table of Contents

Safety Instructions 2

Assembly 4

Controls 5

Operation 7

Chipping 9

Service and Maintenance 10

Hydraulic Feed Assembly 14

Hydraulic Feed Operation 15

Hydraulic Feed Maintenance 16

Speed Sensor Trouble Shooting Guide 17

Troubleshooting 18

Replacement & Maintenance Chart 19

Specifications 20

Torque Chart

Standard tightening torque

for normal assembly

applications

A Service Tip

Warranty

BOLTS (SAE GR5) SCREWS

MIN. TORQUE MIN. TORQUE

SIZE (FT. LBS.) SIZE (FT. LBS.)

5/16"...................20 5/16" set.......................5

3/8".....................35

1/2".....................75

Follow the suggestions outlined in this manual. For adjustments, repair,

or service not covered in this manual, contact your nearest authorized

BEAR CA T dealer. Y our dealer is knowledgeable about your machine

and has a direct line to the factory for assistance.

1

Page 4

Safety Instructions for Operation

This chipper is designed and tested to offer reasonably safe service.

However, failure to operate it in accordance with the following safety

instructions MAY RESUL T IN PERSONAL INJUR Y!

Before Operating

Preparation

1. Become familiar with the owners manual before attempting to operate this

equipment.

2. Do not allow children to operate this equipment.

3. Do not operate this equipment in the vicinity of bystanders.

4 . Carbon monoxide can be extremely dangerous in enclosed areas; do not run

the machine in an enclosed area. The exhaust from the engine contains carbon

monoxide, which is colorless, odorless, and tasteless.

5. Do not allow hands, or any part of body or clothing inside the feeding chamber,

discharge chute, or near any moving part.

6. Before inspecting or servicing any part of the machine, shut off the power

source, disconnect the spark plug, and make sure all moving parts have come

to a complete stop.

1. Obtain and wear safety glasses at all times while operating the machine. One

pair of safety glasses is provided with each chipper.

2. Avoid wearing loose-fitting clothing.

3. Operate the machine only on a level surface.

4. Do not operate the machine on a paved, concrete, or hard gravel surface.

Operating on a hard surface may cause discharged material to rebound and

kickback. It will also cause increased machine vibration. Increased vibration

may cause the machine to move and will promote premature wear of parts or

loosening of fasteners.

5. Before starting the machine, visually check that all screws, nuts, bolts, and

other fasteners are properly secured. Once every 10 hours of operation, all

screws, nuts, bolts, and other fasteners should be checked with wrenches for

proper tightness to insure everything is in proper working condition.

Operation

2

1. Before starting the machine, make certain the cutting chamber is empty .

2. When feeding chipable material into the machine, be extremely careful to

exclude pieces of metal, rocks, bottles, cans, and other foreign objects.

3. If the cutting mechanism strikes any foreign object or if the machine should

start making an unusual noise or vibration, immediately shut off the engine

and allow the machine to stop.

a) Inspect for damage.

b) Replace or repair damaged parts.

c) Check for and tighten loose parts.

4. Do not allow processed material to build up in the discharge area; this may

prevent proper discharge and can result in kickback of material through the

feed opening.

Page 5

Safety Instructions

Cont.

5. Do not allow hands or other part of the body or clothing inside the feeding

chambers, discharge chute, or near any moving part.

6. Keep all guards and deflectors in place and in good working condition.

7. Always stand clear of the discharge area when operating this machine.

8. Keep your face and body back from the feed opening.

9. Do not over reach. Keep proper balance and footing at all times.

10. Do not transport or move machine while the machine is running.

11. If the machine becomes clogged, shut off engine. Allow machine to come to a

complete stop before clearing debris.

Additional Safety

Rules for Towable

Models

Maintenance and

Storage for Towable

Models

1. Before towing, rotate the chipper chute opening to face in the opposite

direction of the vehicle that is towing it. This will prevent the chipper chute

from projecting over the trailer wheels and striking foreign objects.

2. Lock the rotor by inserting a bolt or punch through the locking holes on the side

of the rotor housing.

3. Use a 2 inch trailer ball, and always connect safety chains. Make sure trailer

hitch bolts are tight and secure.

4. Maximum towing speed should not exceed 55 MPH. Tire pressure should be 60

psi; check wheel lug bolts periodically to be sure they are tight and secure.

5. Make sure that the jack stand on trailer is in the UP position to clear the

ground during towing. Place the jack stand on a level surface and secure it in

the DOWN position before use.

6. Shut off fuel supply to engine when towing.

1. When this equipment is stopped for servicing, inspection, storage, or to change

an accessory , disconnect the spark plug wire from the spark plug. Disconnect

battery.

2. Store the machine out of the reach of children and where gasoline vapors will

not reach an open flame or spark. For storage periods of three months or more,

drain the gasoline and dispose of it in a safe manner. Always allow the machine

to cool before storing.

3

Page 6

Assembly, Controls, and Engine Operation

Assembly

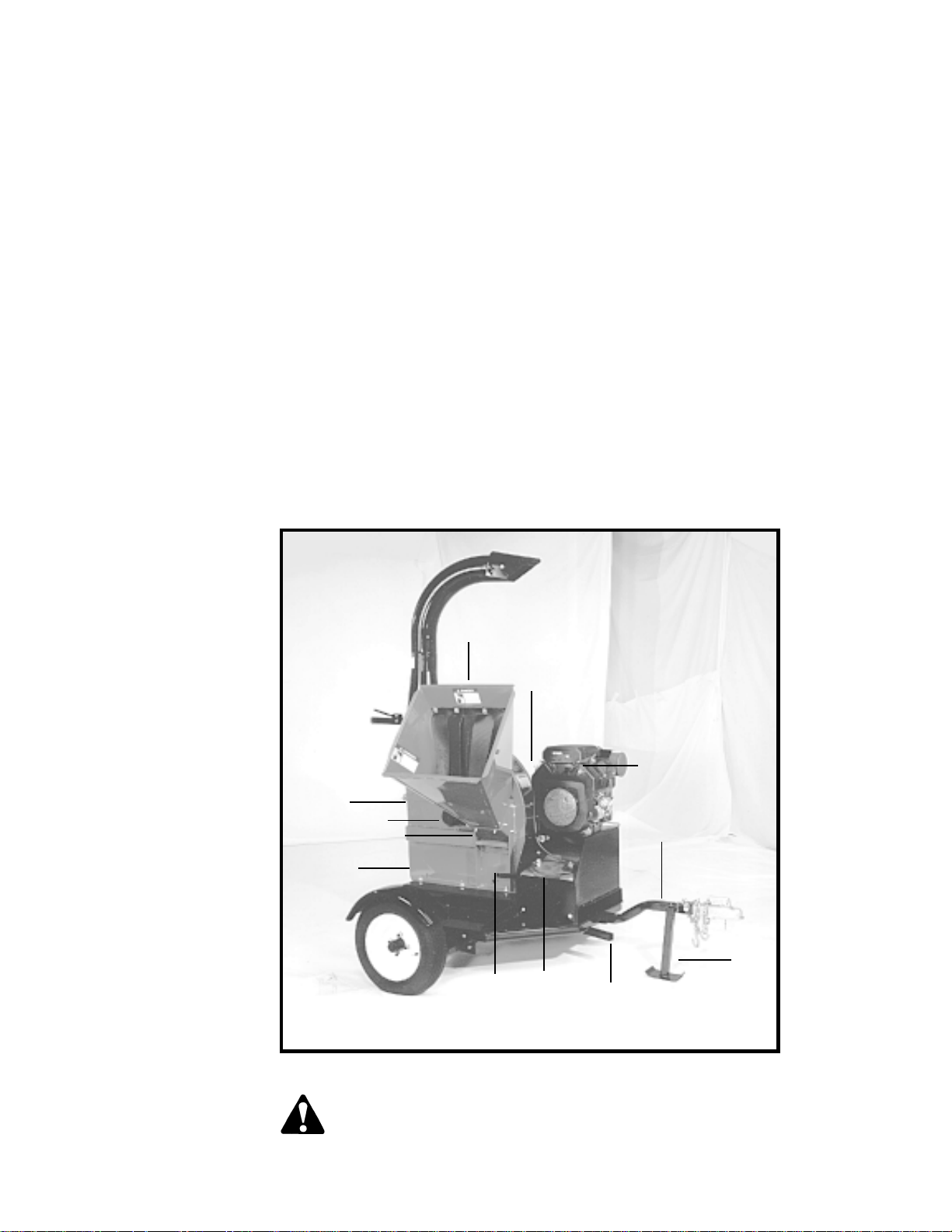

See Figure 1

1. Remove from shipping crate.

2. Support the frame on wood blocks or other support device.

3. Mount the two tires and rims to the axle assembly with the lug nuts (supplied).

4. Mount the trailer hitch assembly to the frame using three 3/8 X 3-1/2 inch bolts

and locknuts (supplied).

5. Fasten the chipper chute to the main frame mounting bracket using eight 3/8 X

1 inch bolts and locknuts. Use three bolts on each side and two on the bottom.

6. Attach the blower discharge tube to the mounting flange on the chipper frame.

Half of the mounting clamp is already attached to the tube. Slide the tube into

the flange and tighten the bolts to secure it. Install the second half of the

clamp to the tube and flange. Rotate the tube 360 degrees and lock it in place

with the handle to make sure it is mounted correctly .

7. Install battery , connect positive and ground battery cables, and check battery

condition. Charge if needed.

Use caution when connecting battery cables near fuel. A spark could ignite

the fuel and cause a fire.

8. Fill the engine with oil (per instructions in supplied engine manual) and fill the

gas tank with gasoline.

9. Y our chipper should be ready to use.

Figure 1

4

Page 7

Controls: Engine

Dipstick

1. Engine Throttle: (Gasoline models only) changes engine speed. Turn knob

clockwise for full throttle operation. Turn knob counterclockwise for idle on

warm up. Turn knob fully counterclockwise to shut engine off. Refer to engine

manual for further engine operating instructions.

2. Engine Choke: (Gasoline models only) use when starting cold engine. Pull to

ON position when starting. Push lever to OFF position when engine is running.

Refer to engine manual for further engine operating instruction.

3. Key Switch: Located on engine case. Release switch as soon as engine is

running. Do not crank starter for more than ten seconds or damage could

result.

4. Other Engine Components: See Figures 2 and 3.

Air Cleaner

Oil Fill

Electric

Starter

Side Oil Drain Plugs

Figure 2

Fuel

Pump

Oil

Filter

Oil Cooler

Figure 3

5

Page 8

Controls Cont.

See Figure 4

5. Engine Fuel Tank: Use unleaded fuel—do not mix with oil.

6. Trailer Hitch: Always use 2 inch ball and safety chains.

7. Jack Stand: Always have in UP position and clear from ground when

moving. When is use, place in DOWN position on a level surface.

8. Engine Drive Belts and Shield: Never remove shields when in use.

9. Chipper Chute: Feed materials to be chipped through the chute.

10. Engine Controls

11. Rotor Access Cover: Used to remove chipper blades.

12. Engine Battery (not included)

13. Rotor Shaft End Cover: Covers rotor shaft and bearing. Has lock

assembly to lock in place while moving.

14. Clutch Foot Pedal: Used to engage rotor assembly drive belt.

15. Adjustable Chipping Anvil

16. Foot Pedal: Used to pivot machine 360 degrees.

11

12

13

15

9

14 5

Figure 4

8

10

6

7

16

CAUTION: The chipper rotor may continue to rotate even with the engine

stopped. Do not attempt any repair or adjustments until the entire

machine has come to a complete stop and spark plug wire is removed.

Never operate this machine without all safety shields in place.

6

Page 9

Engine Operation:

Starting

CAUTION: Move machine to a clear, level area outdoors before starting.

Do not operate machine on a paved, concrete, or gravel surface. Do not

operate in the vicinity of bystanders. Make sure cutting chamber is empty

before starting.

1. Before starting, fill engine with oil to the correct level. See engine manual

for operation and maintenance instructions.

Note: Some oil usage is normal. Check level with each use.

WARNING: Handle fuel (gasoline) with care. It is highly flammable. Always

use an approved container and fill tank outdoors. Never add fuel to a

running or hot engine.

2. Before starting, fill fuel tank with fresh, clean unleaded regular gasoline.

DO NOT MIX OIL WITH GASOLINE.

3. Place the throttle control midway between slow and fast positions. Place

the choke control to the ON position.

CAUTION: See operation/start-up decal by foot clutch pedal on machine

before starting.

4. Depress foot clutch pedal down, this will disengage drive belts and enable

engine to start.

5. Activate the starter switch. Release the switch as soon as the engine

starts. Do not crank over for more than 10 seconds.

6. Move choke lever to RUN position. After a short shut down, full choke

may not be necessary . If engine fails to start, move lever to RUN or partial

choke.

7. Once engine is running and no choke is needed, slowly let foot clutch

pedal up. This will engage drive belt and the rotor will turn.

8. If engine kills when engaging foot clutch pedal, either use more choke or

increase engine RPM.

9. When clutch is engaged, the foot pedal may vibrate or shake until the

engine and rotor have increased to full running RPM.

10. The chipper frame assembly can turn 360 degrees clockwise or

counterclockwise. Press down on the foot pedal located underneath the

frame near the tow hitch and the frame will pivot on the trailer to your

desired location. Let up on the foot pedal and the frame will lock into

place for use. The discharge tube can also turn 360 degrees to your

desired location.

WARNING: Return table to towing position and lock in place before moving

machine. Do not move chipper while machine is running.

Note: When restarting a warm engine after a short shut down, it may not be

necessary to use full choke. If the engine fails to start, move lever to run or

partial choke.

CAUTION: Obtain and wear safety glasses at all times when operating the

machine. Do not wear loose fitting clothing. The operator should always

wear heavy boots, gloves, pants, and shirt. Use common sense and

practice safety to protect yourself from branches, sharp objects, and other

harmful objects.

WARNING: Do not leave machine unattended or inspect or service unless

the engine is stopped and the spark plug wire is removed from the spark

plug.

7

Page 10

Engine Operation:

Stopping

1. Move throttle to SLOW position.

2. Depress foot clutch pedal.

3. Move throttle to STOP position (or shut off key switch) and remove spark

plug wire from spark plug.

4. Allow machine to come to a complete stop. Y ou may release the foot

clutch pedal to help slow the rotor once the engine has stopped running.

Note: The heavy rotor will continue to turn for some time after the engine has

been shut off. Y ou can tell that the rotor has stopped when no noise or

machine vibration is present. Inserting a branch into the chipper chute to

contact the blades will slow the rotor and shorten stopping time.

CAUTION: Obtain and wear safety glasses at all times when operating

the machine. Avoid wearing loose fitting clothing. Always wear heavy

boots, gloves, pants, and shirt. Use common sense and practice

safety to protect yourself from branches, sharp objects, and other

harmful objects.

CAUTION: Move machine to a clear, level area outdoors before

starting. Do not operate machine on a paved, concrete, or gravel

surface. Do not operate in the vicinity of bystanders. Make sure cutting

chamber is empty .

8

Page 11

Chipping

WARNING: Keep face and body away from the feed opening. Do not

overreach. Keep proper balance and footing at all times.

The Bear Cat chipper is designed to chip a variety of materials into a more

readily decomposing or handled condition. The following guidelines can be

used to help you get started.

1. Select limbs that are up to 8 inches in diameter. T rim side branches that

cannot be bent enough to feed into the chipper chute. Hold small diameter

branches together in a bundle and fed in simultaneously .

2. Place limb, butt end first, into the chipper chute until it contacts the

chipper blades. The actual feed rate of the limb into the chipper depends

on the type of material fed and sharpness of the cutting blades.

Alternately insert and retract the limb or insert continuously at a rate that

will not kill the engine or stall the tractor.

• Rotating the branch to improve cutting action.

The chipping blades dull with use and require periodic sharpening. Refer to

Service and Maintenance, "Sharpening Chipper Blades" for instructions.

Figure 5

9

Page 12

Service and Maintenance

WARNING: Before inspecting or servicing any part of the machine, shut off

the power source, disconnect the spark plug wire from the spark plug, and

make sure all moving parts have come to a complete stop. The chipping

blades are sharp! Use care when working on machine to avoid injury .

WARNING: The rotor assembly has a lock mechanism. When working on

the rotor assembly , use the lock mechanism at all times. Remove plastic

bearing cover under chipper chute. There is a hole in the rotor jack shaft

and a matching hole in the bracket mounted to the rotor bearing front side.

Install a punch through the rotor shaft and bracket to lock the rotor in

place.

Check the engine oil, and change the oil and filter as recommended in the

manual. Service and replace the air cleaner as recommended.

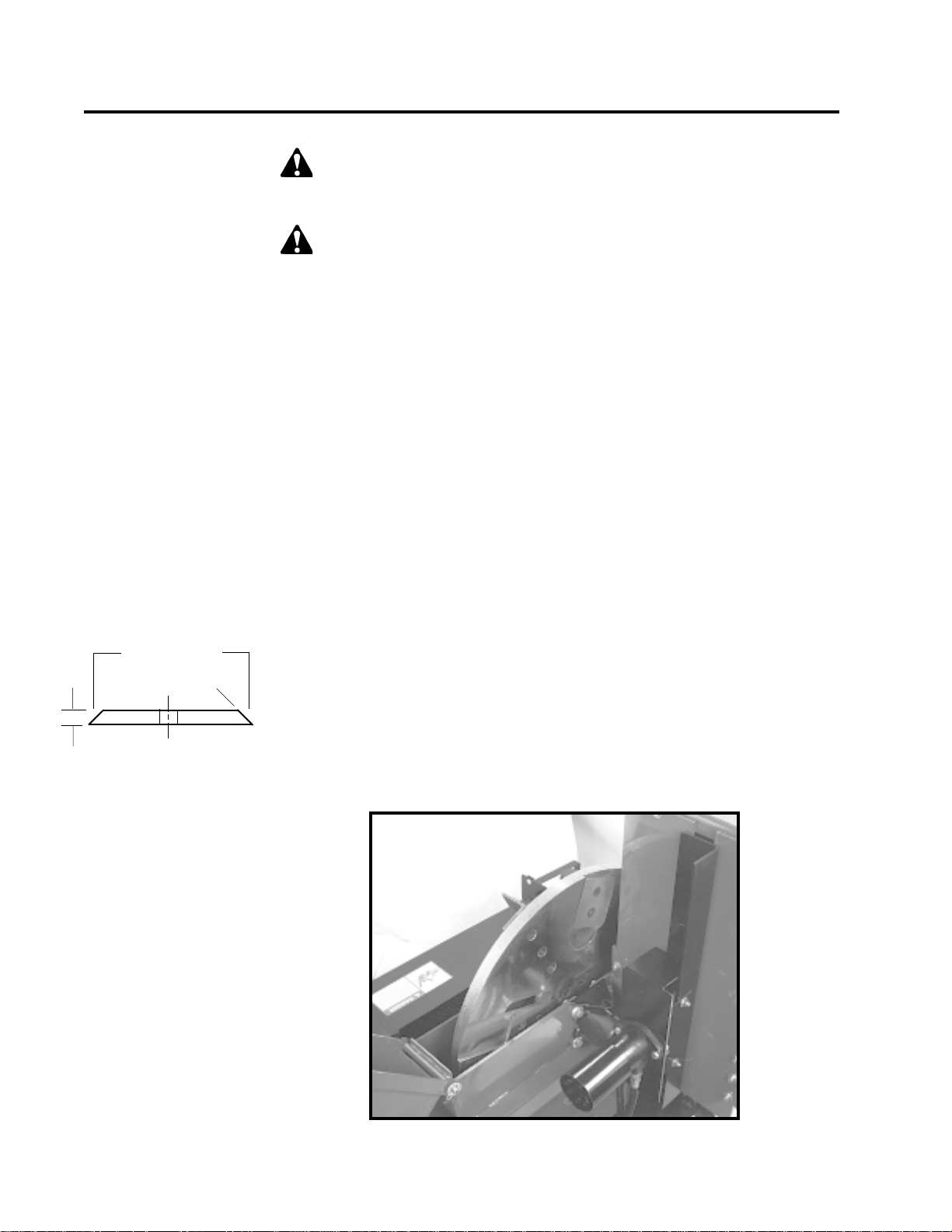

Sharpening Chipper

Blades

See Figure 7

Sharpening

Edges

⋅⋅

45

⋅

t

0.38

s

t

⋅⋅

Figure 6

The chipper blades dull, making chipping difficult. The chipper blades are two

edged. When the first edge dulls, flip the blade to use the sharp second edge.

After both edges are dull, sharpen the chipper blades. It is recommended that

the chipper blades are sharpened every 5-15 hours of chipper operation. T o

remove the chipping blades for sharpening:

1. Remove the two 3/8 inch retaining bolts holding the access cover to main

frame assembly .

2. Tilt access cover over to allow rotor access. Rotate the rotor so that the

bolts holding a chipping blade are most accessible.

3. Remove the two hex head bolts holding the blade itself. Repeat for all four

blades. The four chipping blades have two edges per blade and can be

reversed one time each before sharpening. Reinstall chipping blades and

proceed with chipping.

T o grind the angled edge of the chipping blade to 45 degrees (see figure 6):

t

Grind the blades on a bench grinder or have them sharpened by a professional.

Be careful when grinding so that the blade material does not get too hot and

change color–this will remove the blade's special heat treated properties. Use

short grinding times and cool with water. T ry to remove an equal amount off

each blade to maintain balance. Replace the chipping blades and tighten bolts

to 75 ft. lbs.

10

Figure 7

Page 13

Setting Chipping

Blade Clearance

The four edged chipping blades should clear the chipping anvil located directly

under the chipper chute by 1/16 inch to 1/8 inch. The chipping anvil is

adjustable and reversible.

To Adjust:

Adjusting Drive

Belts

1. Lift rotor access cover and expose rotor (see figure 7). Loosen the three

1/2 inch bolts that hold the chipper anvil to the frame.

2. Measure the amount of clearance between chipping blade and chipping

anvil from inside of housing.

3. Adjust inward or outward to desired measurement.

4. Tighten bolts on chipping anvil to 75 ft. lbs. and resume operation.

If chipping anvil edge is damaged or worn unevenly , remove the three bolts

holding the anvil and use one of the other three edges. Adjust for correct

measurement.

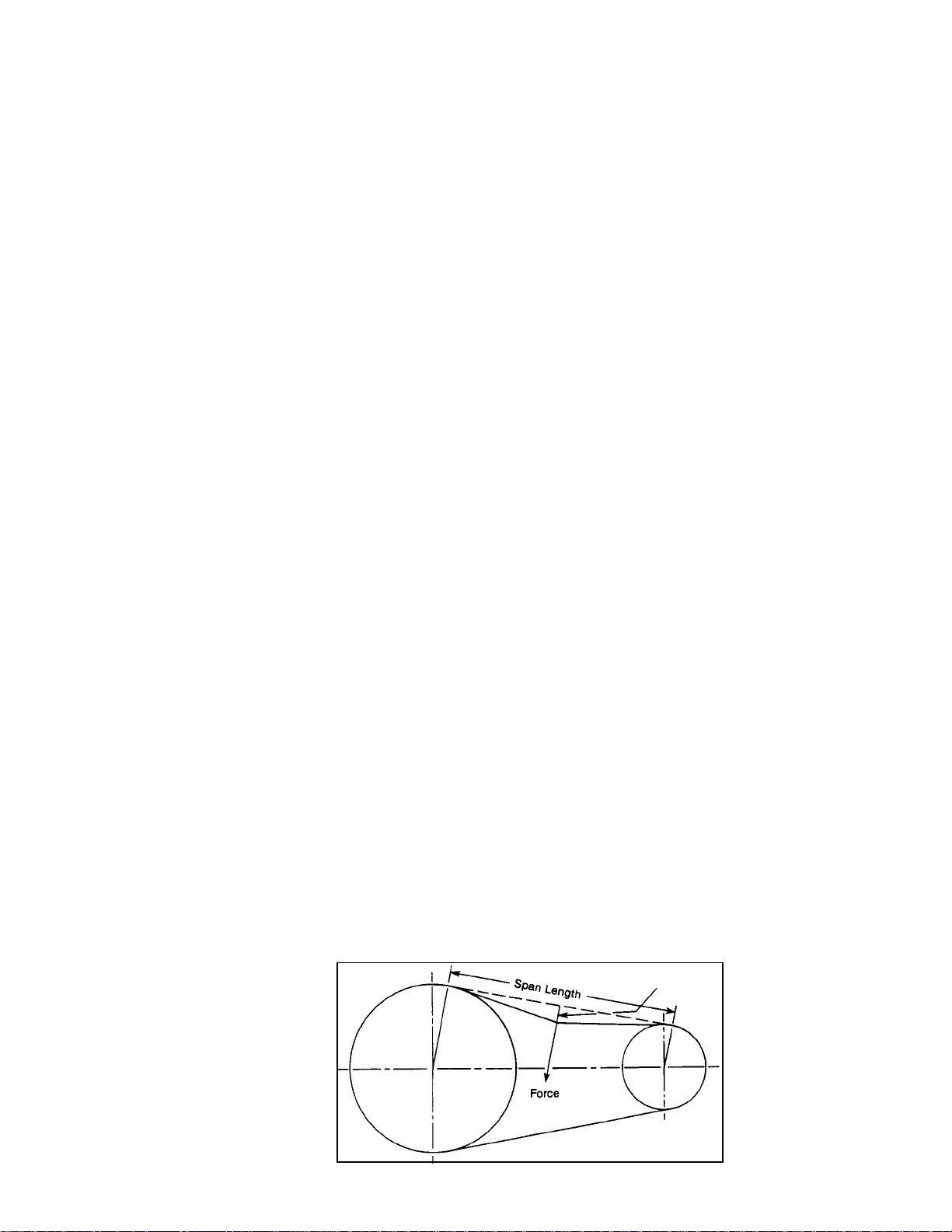

Check the condition of the drive belt annually or after every 30 hours of

operation, whichever comes first. If the belt is cracked, frayed, worn, or

stretched, replace it. Only replace belt with original banded type belt, do not

use single type belts. T o adjust the belt, proceed as follows:

1. Depress foot clutch pedal. Shut engine off and disconnect battery cables.

2. Remove large belt guard (three 5/16 inch bolts).

3. Adjust the eyebolt that anchors the idler spring to adjust belt tension.

Tighten the eyebolt until the belt deflection at the center of the belt is

7/16" when a 20 lb. load is place against the belt (see figure 8).

Replacing Drive

Belt

Figure 8

4. Replace belt guard.

5. Start engine and test belt for looseness. Replace the belt if no adjustment

is left.

1. Remove large belt guard (three 5/16" bolts).

2. Lift belt idler pulley off drive belt and remove drive belt from pulleys.

3 . Install new belt on pulleys and lower belt idler. Check alignment of pulleys

and adjust if needed.

4. Adjust the eyebolt that anchors the idler spring to adjust belt tension.

Tighten the eyebolt until the belt deflection at the center of the belt is

7/16" when a 20 lb load is place against the belt (see figure 8).

5. Replace belt guard.

6. Depress foot clutch pedal, start engine, release foot clutch pedal to

engage belt, and test unit. Readjust pulleys and belt tension if needed.

7/16" Deflection

11

Page 14

Replacing Drive

Belt-Hydraulic

Models

1. Remove large belt guard (three 5/16" bolts).

2. Loosen bolts on hydraulic pump and remove belt.

3. Lift belt idler pulley off drive belt and remove drive belt from pulleys.

4 . Install new belt on pulleys and lower belt idler. Check alignment of pulleys

and adjust if needed.

5. Adjust the eyebolt that anchors the idler spring to adjust belt tension.

Tighten the eyebolt until the belt deflection at the center of the belt is

7/16" when a 20 lb load is place against the belt (see figure 8).

6. Replace hydraulic pump belt. Readjust hydraulic pump belt tension by

sliding the hydraulic pump in the mounting slots. Tighten bolts.

7. Replace belt guard.

8. Depress foot clutch pedal, start engine, release foot clutch pedal to

engage belt, and test unit. Readjust pulleys and belt tension if needed.

WARNING: If the machine becomes plugged, depress foot clutch

pedal, shut off the engine, disconnect the spark plug wire, and allow

the machine to come to a complete stop before clearing debris. Do not

operate the machine without proper guards and screens in place.

Feeding too large or too much chipable material at once may plug the chipper.

T o clear plugged rotor , proceed as follows:

Clearing Plugged

Rotor

Repairing or

Replacing Rotor

Bearings

1 . Depress foot clutch pedal and stop engine. Release foot clutch pedal when

engine is stopped.

2. Remove the two 3/8" retaining bolts holding the access cover to the main

frame assembly .

3. Lift up rotor access cover.

4. Clean the debris out the chipper rotor. T urn the rotor by hand to be sure it is

free to rotate.

5. Close rotor access cover and replace bolts.

6. Depress foot clutch pedal, and start engine. Release foot clutch pedal

when engine is running to engage drive belt. Resume operation.

CAUTION: Remember to use rotor shaft lock when working on rotor.

1. Remove the two 3/8 inch retaining bolts holding access cover to main

frame assembly . T ilt access cover over to allow rotor access.

2. Remove large belt guard (three 5/16 inch bolts).

3. Lift belt idler pulley off drive belt and remove belt from pulleys. Using the

push bolts from the bushing, remove the bushing and pulley from the rotor

shaft.

12

WARNING: The rotor assembly has a lock mechanism. When working

on the rotor assembly , use the lock mechanism at all times. Remove

plastic bearing cover under the chipper chute. There is a hole in the

rotor jack shaft and a matching hole in the bracket mounted to the

rotor bearing front side. Install a punch through the rotor shaft and bracket to

lock the rotor in place.

Page 15

4. If a rotor bearing needs repair, it is best to remove the complete rotor assembly from chipper frame.

5. Using an overhead hoist or lifting device, remove the four 1/2 inch bolts on

each rotor bearing and lift the rotor assembly completely out of the frame. The

complete rotor assembly is 275 lbs.

6. Once the rotor assembly is out of the frame, both bearings can be removed by

a puller and replaced on the shaft.

7. Use the overhead hoist or lifting device to return the complete rotor assembly

to the chipper frame.

8. Install the four 1/2 inch bolts on each bearing to secure them to the frame.

Tighten bolts to 75 ft. lbs.

9. Replace drive belt on pulleys and lower belt idler. Check alignment of pulleys

and adjust engine if needed.

10. Check belt tension before start-up. Adjust the eyebolt that anchors the idler

spring to adjust the belt tension. Tighten the eyebolt until the belt deflection at

the center of the belt is 7/16" when a 20 lb. load is placed against the belt (see

figure 8, page 11 ).

11. Close cover and replace bolts.

12. Replace belt guard and resume operation.

13. Depress foot clutch pedal, start engine, release foot clutch pedal to engage

belt, and test unit. Readjust pulleys and belt tension if needed.

Greaseable

Bearings and Pivots

Other Service Tips

Trailer Service T ips

• Hydraulic units remove hydraulic pump and belts prior to step 3 and replace

prior to step 12.

The models have five greaseable bearings and pivots that require grease every 50

hours:

• Two bearings on the rotor shaft.

• One greaseable bushing on the foot clutch pedal pivot.

• One grease zerk on idler pivot.

• One grease zerk on discharge chute.

1. Service engine according to engine manual. Change engine oil and filter as

recommended in manual.

2. Every 10 hours of operation, all bolts and other fasteners should be checked

for correct torque.

1. Check wheel bolt torque every 10 hours of towing use.

2. Check air pressure in tires every 10 hours of towing. Maximum 60 psi.

3. Check and repack wheel bearings with grease every 12 months.

4. When towing, use a 2 inch trailer ball, and always connect the safety chains.

Make sure trailer hitch bolts are tight and secure.

13

Page 16

Hydraulic Feed Assembly (For Units With Optional Hydraulic Feed)

Fluids

Pump Component

Locations

Hydrostatic Pump

Start Up Procedure

Handle pressurized hydraulic fluid carefully . Escaping pressurized

hydraulic fluid can have sufficient force to penetrate your skin causing

serious injury . This fluid may also be hot enough to burn. Serious

infection or reactions can develop if proper medical treatment is not

administered immediately .

Premium hydraulic fluids containing high quality rust, oxidation, and foam

inhibitors are required. These include premium turbine oils, API CD engine oils

per SAE J183, M2C33F or G automatic transmission fluids meeting Allison C3 or Caterpillar TO-2, and certain specialty agricultural tractor fluids.

Follow this start-up procedure when starting a new installation or when restarting an installation in which the hydrostatic pump has been removed from the

system.

1. Before starting the hydrostatic pump, make sure all system components

(reservoir, fittings, etc.) are clean.

Hydrostatic pressure

controlled by the

crossover relief valve is

factory set at 1500 PSI.

A 2000 PSI shim kit is

available for extreme

conditions.

2. Fill the reservoir with recommended hydraulic fluid, which should be

filtered before entering the reservoir.

3. The inlet line leading from the reservoir to the charge pump must be filled

before start-up. Loosen the fitting on this inlet line until oil bleeds out.

Warning! Do not start engine unless pump is in neutral or detent

position on the cable.

4. Start the engine and run at the lowest possible RPM.

5. As air is purged from the unit, the oil level in the reservoir will drop and

bubbles may appear in the fluid. Refill the reservoir as necessary .

6. Run the unit and move the control arm in both directions for several

minutes until any remaining air is purged from the unit. Refill the reservoir

as necessary .

Note: A motor fitting may have to be loosened and oil-bled to remove air

from the system (use same procedures as steps 3-5).

7. Check to ensure feed roller stops when control arm is in the neutral

position. Adjust the cable clevis or anchor if the feed roller doesn't stop.

8. Shut down the engine, check for and correct any fluid leaks, and check

the reservoir level. Add fluid if necessary . The hydrostatic pump is now

ready for operation.

14

Page 17

Hydraulic Feed Operation

Please read and

follow all safety

instructions in this

manual. Failure to

operate the chipper in

accordance with the

safety instructions MAY

RESUL T IN PERSONAL

INJURY!

Control Arm

Operation

1. Start the chipper engine. Bring the chipper up to operating speed. See

"Controls and Operation" section for starting, operation, and stopping

instructions.

2. Engage the hydraulic feed by moving the control arm as shown below. In

the forward direction, the feed rate increases as the arm is moved.

3. Feed the branch (up to 8 inches in diameter).

4. If the chipper jams, reverse the feed by moving the control arm in the

reverse direction. Remove the branch and rotate it before reinserting it into

the chute again.

Reverse

s

Neutral

s

Forward

Control

Arm

Hydraulic Feed

Component

Locations

Reservoir

Hydrostatic

Pump

Roller Assembly

Hydraulic

Motor

Chipper

Chute

Crossover

Relief

Valve

15

Page 18

Hydraulic Feed Maintenance

Maintenance

Hydrostatic Pump

Troubleshooting

Before servicing or

repairing any of the

hydrostatic feed

components (pump,

motor, and/or relief valve),

contact your dealer or

factory service

department. Warranty on

these items may be void

without prior authorization.

Note: Check the reservoir daily for proper fluid level, the presence of water

(noted by a cloudy to milky appearance, or free water in bottom of reservoir),

and rancid fluid odor (excessive heat).

The hydrostatic pump normally does not require regular fluid changes. The

system filter should be changed at 250 hour or annual intervals. The fluid and

filter should be changed and system cleaned if the fluid becomes contaminated with foreign matter (water, dirt, grease, etc.) or if the fluid has been

subjected to temperature levels greater than the maximum recommended.

There is a greaseable bearing on each side of the main jack shaft on the main

hydraulic feed housing. Grease periodically .

Symptom

Will not attain normal feed rate.

Will not feed when control arm

is moved.

Feed rate is sluggish under

load.

Probable Cause

Engine not operating at correct speed.

Control linkage damaged or

binding.

Bypass valve stuck partially

open. (Problem in one direction only.)

Control linkage damaged or

not connected.

Drive between engine and

pump damaged.

Pump low on fluid.

Loose drive belt between

engine and pump.

Pump low on fluid.

Large amount of water in hydraulic fluid (evaporates when

hot, resulting in low fluid level).

Suggested Remedy

Repair engine governor.

Repair control linkage.

Repair bypass valve.

Remove foreign material from

valve.

Repair or reconnect control

linkage.

Repair drive (replace broken

belt, repair sheared key, repair splined coupling, etc.).

Refill reservoir. Purge air from

transmission.

Tension drive belt (replace if

necessary).

Refill reservoir. Purge air from

transmission if necessary.

Drain fluid from reservoir and

unit, replace filter element,

and refill with new fluid.

16

Hydraulic Feed will not pull in

logs over 4" in diameter, or

continuously stalls or stops.

Hydraulic system overloading

and causing system to go

over relief.

Caution: Hydraulic systems contain

fluid under high pressure. Never check

for leaks with your hands. Relieve

pressure before disconnecting any

hydraulic lines.

Check relief pressure in system with a pressure gauge

rated to 2500 psi. (system set

by factory at 1750 psi.)

Page 19

17

Page 20

Troubleshooting

Problem

1. Rotor does not turn

2. Hard to feed chipper

or excessive power

needed to chip

3. Chipper requires

excessive power or

stalls

Probable Cause

a) Obstructed

discharge

b) Plugged rotor

a) Obstructed

discharge

b) Dull chipper blades

c) Improper blade

clearance

a) Obstructed

discharge

b) Plugged rotor

c) Green material will

not discharge

Suggested

Remedies

a) Use branch or

similar object to

clear discharge

b) Clear rotor

a) Use branch or

similar object to

clear discharge

b) Sharpen blades

c) Adjust clearance

a) Use branch or

similar object to

clear discharge

b) Clear rotor , feed

material into

shredder more

slowly

c) Alternately feed dry

material, or allow

material to dry

Reference

Service and Maintenance

Service and Maintenance

Service and Maintenance

4. Drive belts

squealing or

smoking

5. Vibration while

running

6. Engine dies or runs

poorly

a) Plugged rotor

b) Loose or worn belts

a) Drivehead vibration

b) Rotor out of balance

a) Engine problems

a) Clear rotor

b) Adjust belt tension

or replace belts if

needed

a) Check drive belts

and pulleys for bad

or worn spots.

b) Inspect rotor for

broken or missing

chipper blades and

paddles. Repair if

needed.

Check rotor to see if

it wobbles

Check to see if rotor

is assembled

correctly

a) Contact local engine

service center

Service and Maintenance

Service and Maintenance

18

Page 21

Replacement & Maintenance Chart

Note: When ordering replacement parts, be sure to identify the

Model and Serial number of the machine.

Replacement Parts Ordered

Date Part Ordered

Date Part Replaced

Replaced By

Checked By

19

Page 22

Specifications

Overall Size (LxWxH)

Max. Chipper Cap. (dia.)

Chipper Blade Qty .

Rotor Speed

Rotor Size

Rotor Weight

Rotor Shaft Diameter

Discharge Size

Drive Type

Belt Size

Weight (Lbs.)

Wheel Base

Tire Size

Fuel T ank Cap. (Gal.)

Model 71620

76 x 80 x 90"

6"

4 Reversible T ool Steel

1500 RPM

30" Dia. x 1.25"

275 lbs.

1.75"

8"

Belt

3B83

1445

66"

5.31-12

6

Model 72620

93 x 80 x 90"

6"

4 Reversible T ool Steel

1500 RPM

30" Dia. x 1.25"

275 lbs.

1.75"

8"

Belt

3B83

1865

66"

5.31-12

6

Model 71825

76 x 80 x 90"

8"

4 Reversible T ool Steel

1500 RPM

30" Dia. x 1.25"

275 lbs.

1.75"

8"

Belt

3B83

1450

66"

5.31-12

6

Model 72825

93 x 80 x 90"

8"

4 Reversible T ool Steel

1500 RPM

30" Dia. x 1.25"

275 lbs.

1.75"

8"

Belt

3B83

1870

66"

5.31-12

6

Engine

Specifications are subject to change because of design modifications.

Kohler 20 HP

Kohler 20 HP

Kohler 25 HP

Kohler 25 HP

20

Page 23

Chipper and Hydraulic Feed Limited Warranty

Crary Bear Cat Chipper models 71620, 71825, 72620, and 72825 are warranted for one year from

date of sale.

Within the above stated period, Crary Co. will replace any part(s) found to be defective in material

and/or workmanship, after the receipt of the part in our plant. Labor costs to replace these defective

parts will be paid at a Crary established labor rate and time allowed (flat rate) for repair. All

transportation charges incurred in shipping part(s) are the responsibility of the purchaser.

This warranty is void in the case of accidents, failure to perform normal maintenance, or failure to

follow those instructions listed in the service manual. This warranty is also in lieu of all other

expressed warranties and voids any implied warranty as to the merchantability or fitness of the

product for a particular purpose and of any other obligation on the part of Crary Co. Some states do

not allow limitations on how long the implied warranty lasts, so the above limitation may not apply to

you.

This warranty applies only to parts or components which are defective, and does not cover

necessary repair due to normal wear, misuse, accidents, or lack of proper maintenance. This

includes belts, pulleys, and chipper blades. Regular routine maintenance of the unit to keep it in

proper operating condition is the responsibility of the owner.

All warranty repair reimbursable under the Crary Co. warranty must be performed by an authorized

Bear Cat service dealer using Bear Cat approved replacement parts. Repair or attempted repair by

anyone other than an authorized Bear Cat service dealer is not reimbursable under the Crary Co.

warranty . In addition, these unauthorized repair attempts may result in additional malfunction, the

correction of which is not covered by warranty.

Crary Co. is not liable for indirect, incidental, or consequential damages in connection with the use of

this product including any cost or expense or providing substitute equipment or service during

periods of malfunction or non-use.

Some states do not allow the exclusion of incidental or consequential damages, so the above

exclusion may not apply to you. This warranty gives you specific legal rights. You may also have

other rights which vary from state to state.

Be sure to note the Chipper serial number in any correspondence with Crary Co. or any authorized

Bear Cat dealer. The serial number is located on the rotor assembly cover.

Page 24

HEAL TH WARNING

GASOLINE, DIESEL, AND

OTHER PETROLEUM PRODUCTS

Harmful or fatal if swallowed.

Long-term exposure to vapors has caused cancer in

laboratory animals.

• Avoid prolonged breathing of vapors.

• Keep face away from nozzle and gas tank/container

opening.

• Never siphon by mouth.

Failure to use caution may cause serious injury or illness.

W ARNING

CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS, OR

OTHER REPRODUCTIVE HARM ARE FOUND IN

GASOLINE, DIESEL, CRUDE OIL, AND MANY OTHER

PETROLEUM PRODUCTS AND THEIR V APORS, OR

RESULT FROM THEIR USE.

READ AND FOLLOW LABEL DIRECTIONS AND USE

CARE WHEN HANDLING OR USING ALL PETROLEUM PRODUCTS.

ENGINE EXHAUST FROM THIS PRODUCT CONT AINS CHEMICALS KNOWN TO THE ST A TE OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS, OR

OTHER REPRODUCTIVE HARM.

Box 849

West Fargo, ND 58078

(701) 282-5520 (800) 247-7335

FAX: (701) 282-9522

http://www.crary.com

Loading...

Loading...