Earthway C25HDS User Manual

C25 SerieS profeSSionAl tow

EV-N-SPRED

EV-N-SPRED

EarthWay

EarthWay

OVER

3 MPH

Do not tow

faster than

3 MPH

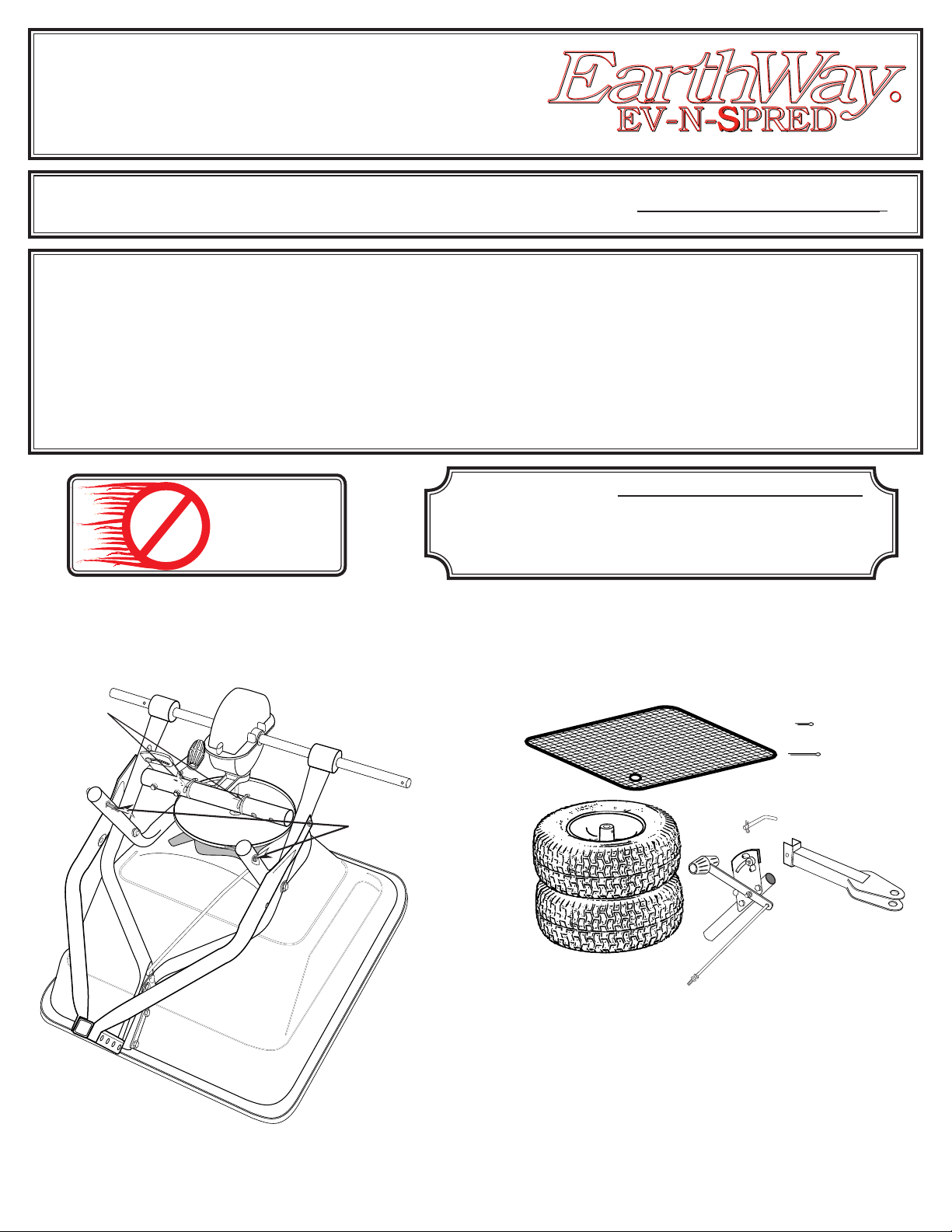

#40003

Screen

#19117 Wheels

#36103

1” Cotter Pin

#36104

2” Cotter Pin

Hitch

Assembly

#42251 Clevis Pin

#36108 Hair Pin Clip

Control Support

Assembly

R

broAdCASt SpreAder

ASSEMBLY and OPERATING INSTRUCTIONS

PLEASE CALL IF YOU ARE MISSING ANY PARTS, HAVE ANY DIFFICULTY IN ASSEMBLY, OR HAVE ANY QUESTIONS

REGARDING THE SAFE OPERATION OF THIS SPREADER. THIS MODEL INCLUDES LIFETIME TECHNICAL SUPPORT

SUPPORT HOT LINE: 574-848-7491 or 800-294-0671, emAil: teChSupport@eArthwAy.Com

HELPFUL HINTS: READ THE DIRECTIONS BEFORE ASSEMBLY

; If your spreader does not spread evenly, be sure the FRONT on the gear box points away from the tow bar of the spreader.

The impeller must turn clockwise. Reversing the gearbox will cause the impeller to turn counter clockwise. Clean the

impeller plate after each use. Fertilizer stuck on the impeller blades will cause uneven spreading.

; Your spreader is designed to be pulled at three miles per hour, which is a brisk walking speed. Slower or faster speeds will

change the spread patterns. Wet fertilizer will also change the spread pattern and ow rate. Clean and dry your spreader

thoroughly after each use. A coating of light spray oil on all metal parts, (including the inside of the frame tubing) will help

prevent corrosion. Wash between the shut off plate and bottom of the hopper.

; Gears are permanently lubricated at the factory. Do not open the gearbox or dirt may enter.

ROCK SALT and POWDERED MATERIALS

should not be used in this spreader as it will

damage gearbox and can void warranty.

Use only granular materials.

R

Your spreader is shipped semi assembled, you will need (2) 7/16” wrenches, a cutting tool to cut through the plastic zip-ties,

and a pair of pliers to bend the cotter pins that hold the wheels to the axle.

1. Remove the spreader and identify all loose parts from carton.

Remove

Zip-ties

Remove

¼-20 x 2¼” Bolts

washers & lock nuts

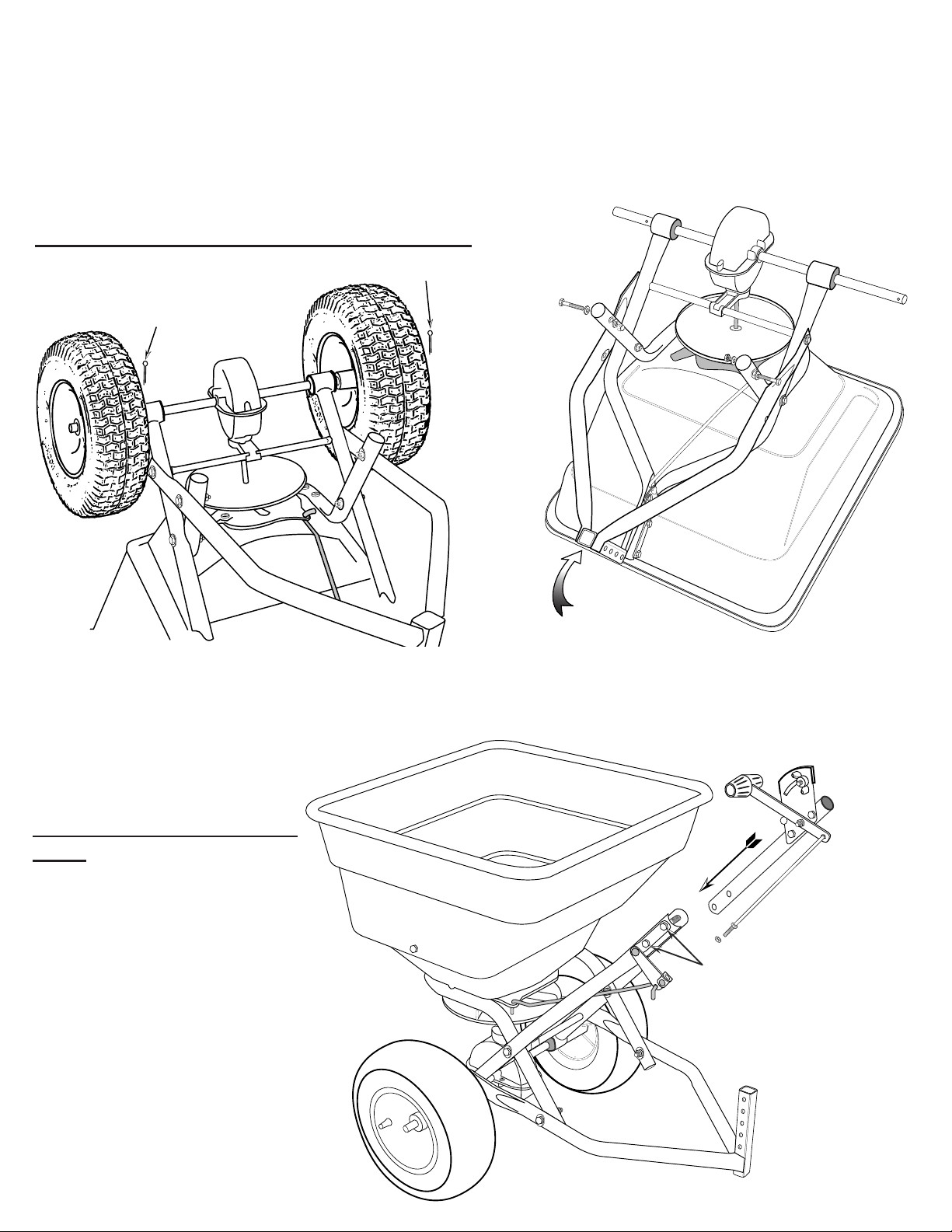

2. Remove the Zip-ties holding the Control Support ASSembly to the CroSS brACe and the 2 bolts that are in the frame

12-2011 Pt# 52155 PAGE 1

3. Lift the drAw bAr into position and replace the ¼-20 x 2 ¼” bolts washer and nut as shown below. Now tighten those bolts

and ¼-20 x 1¾" Bolts, cupped

and the other frame bolts.

4. Install drive wheel to the Axle using pin hole nearest to lower handles as shown. Insert 2” cotter pin through wheel and

through Axle. Bend with pliers to prevent pin from falling out.

5. Install CoASt wheel to Axle, using outside pin hole, insert the 1” cotter pin through Axle (not thru the wheel). Bend with

pliers to prevent pin from falling out.

TURN SPREADER UPRIGHT ON TO WHEELS.

1” Cotter Pin

2” Cotter Pin

Remove

bolts

Rotate Draw

Bar up

6. Remove the (2) ¼-20 x 1¾” bolts, washers, nuts, and pivot And brACket from the lower hAndleS as shown below.

7. Install Control Support ASSembly by sliding between lower hAndleS and inserting (2) 1¾” bolts thru the pivot brACket

and the lower hAndleS and secure

with (2) lock nuts and cupped washers

as shown below.

TIGHTEN ALL FASTENERS

NOW.

Remove Pivot Bracket

and ¼-20 x 1¾" Bolts,

cupped washers & lock nuts.

Slide the Control Assembly

into Lower Handles.

Next Replace Pivot Bracket

washers & lock nuts.

PAGE 2

Loading...

Loading...