Earthway 2150SU User Manual

ASSEMBLY and OPERATING INSTRUCTIONS

for

EarthWay

EV-N-SPRED

®

PLEASE CALL IF YOU ARE MISSING ANY PARTS, HAVE ANY DIFFICULTY IN

ASSEMBLY, OR HAVE ANY QUESTIONS REGARDING THE SAFE OPERATION OF

THIS SPREADER. THIS MODEL INCLUDES LIFETIME TECHNICAL SUPPORT

S

UPPORT HOT LINE: 574-848-7491 or 800-294-0671

E

MAIL: support@earthway.com

Broadcast Spreader rev 10-06

MODEL 2150

HELPFUL HINTS:

If your spreader does not spread evenly, be sure the FRONT on the gear box points to the front of the spreader. The impeller must turn

clockwise. Reversing the gearbox will cause the impeller to turn counter clockwise. Clean the impeller after each use as some fertilizer

may become stuck on the impeller blades and will cause uneven spreading.

Your spreader is designed to be pushed at three miles per hour, which is a brisk walking speed. Slower or faster speeds will change the

spread patterns. Wet fertilizer will also change the spread pattern and flow rate. Clean and dry your spreader thoroughly after each use.

Wash between the shut off plate and bottom of the hopper.

Gears are permanently lubricated at the factory. Do not open the gearbox or dirt may enter.

When using Rock Salt remove the agitator to prevent damage to the gearbox and remove salt from the hopper daily. Rock Salt will re-

constitute back into a solid block over night with humidity and will damage your spreader.

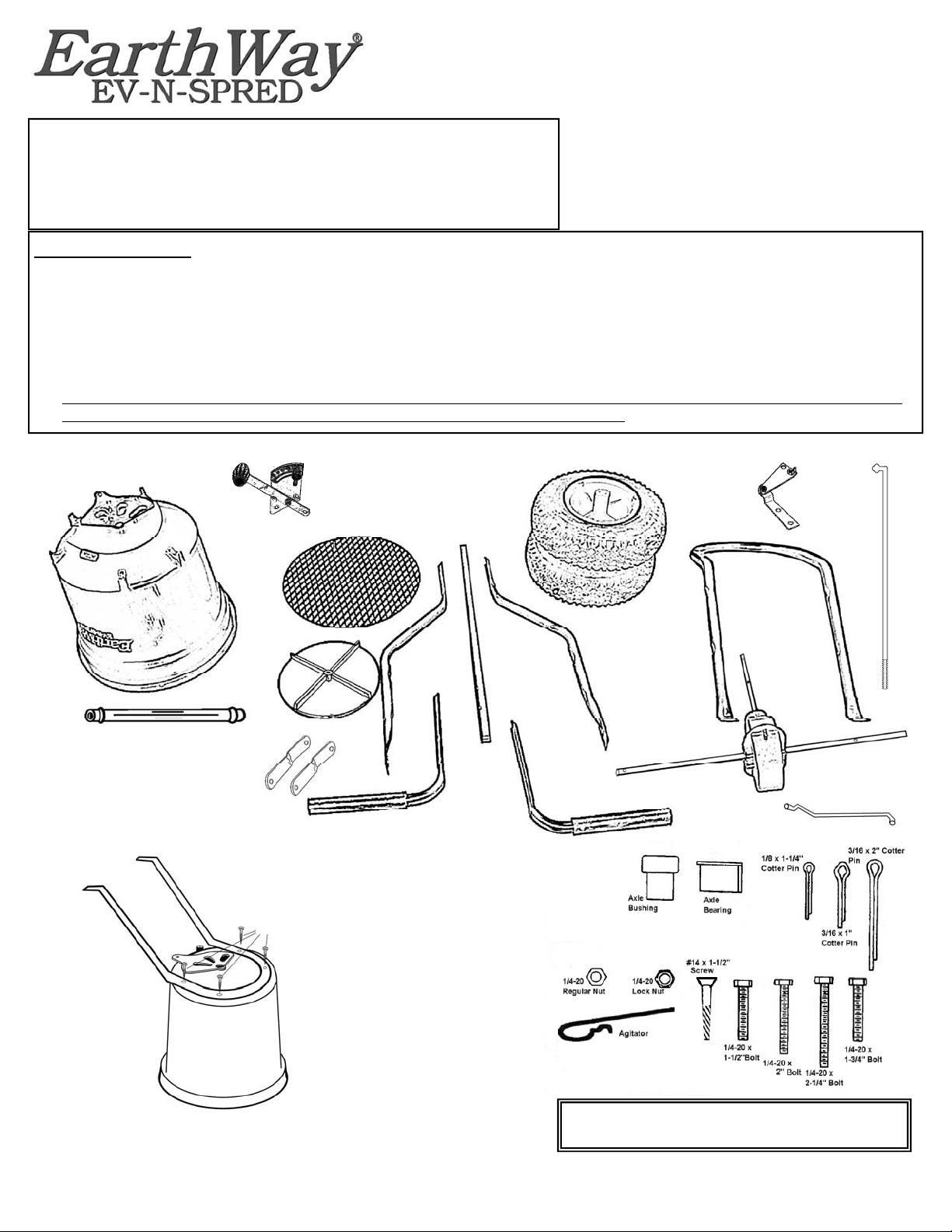

1. Remove and identify loose

parts from carton.

#14 X 1-1/2”

2. Position hopper upside down and install frame using

(4) #14 x 1-1/2” flat head Phillips screws.

ROCK SALT IS NOT RECOMMENDED FOR USE IN THIS

SPREADER. REMOVE AGITATOR WHEN USING ICE MELT.

PAGE 1

Pt. #52157

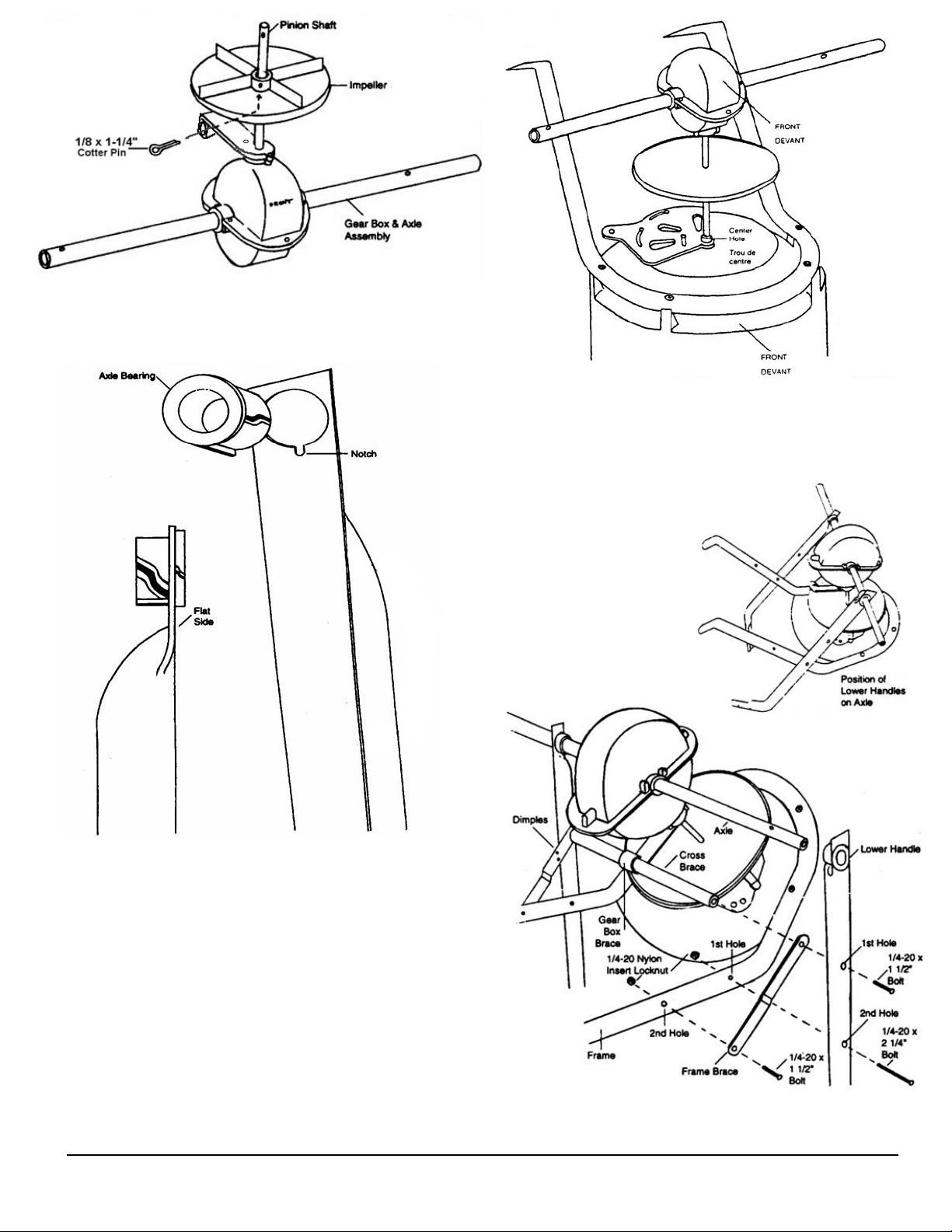

3. Install impeller onto pinion shaft. Insert ⅛”x 1-1/4” cotter pin

through impeller then through pinion shaft. Use hole closest to the

gear box. Spread cotter pin to prevent from falling out.

4. Install gear box by inserting the pinion shaft into hole in

center of hoppers bottom.

must point to Front of the hopper. Follow label instructions on

hopper.

The word “FRONT” on the gearbox

5. Install axle bearings to both lower handles. NOTE: Notch on bearings

and lower handles. Bearings must go thr ough flat side of lower handle.

6. A - Install lower handles onto axle to both sides as shown. Insert 2 ¼”

bolt through second hole in lower handle and through first hole in frame

install locknut. DO NOT TIGHTEN.

B - Now insert 1

frame brace. NOTE: Dimples on frame brace must be facing toward gear

box as shown. Next into threaded connector in cross brace. DO NOT

TIGHTEN.

C - Next insert 1

second hole in frame install locknut.

NOW GO BACK AND TIGHTEN ALL NUTS AND BO LTS STARTING WITH FIRST STEP. DO NOT OVER TIGHTEN.

PAGE 2

½” bolt through first hole in lower handle. Then through

½” bolt through other end of frame brace and through

Loading...

Loading...