EarthQuake 600050B User Manual [en, es, fr]

Operator's Manual

Original Operating Instructions

Trimmer

Mower

600050 Series

INCLUDES MODELS: |

English:.................... |

Pages 1-28 |

600050V |

Español:............. |

Páginas 29-56 |

Français: .............. |

Pages 57-84 |

|

600050B |

|

|

600050BCE |

|

|

(Illustrations may not match product) |

|

|

|

|

P/N: 14505 |

|

|

ECN: 10252 |

|

|

REV3: 11/26/13 |

Get parts online at |

|

© 2014 Ardisam, Inc. |

www.GetEarthquake.com |

|

All Rights Reserved |

Operator's Manual

Trimmer Mower 600050 Series

INTRODUCTION

Congratulations on your investment in quality. Thank you for purchasing an Earthquake™ String Trimmer. We have worked to ensure that the string trimmer meets the highest standards for usability and durability. With proper care, your string trimmer will provide many years of service.

Please read this entire manual before installation and use. Earthquake reserves the right to change, alter or improve the product and this document at any time without prior notice.

CONTENTS |

|

|

Registration......................................................................................................................................................................................................................................... |

2 |

|

Warnings and Safety Precautions........................................................................................................................................................................................... |

3-6 |

|

Features................................................................................................................................................................................................................................................ |

7 |

|

Assembly.......................................................................................................................................................................................................................................... |

8-9 |

|

Operation.................................................................................................................................................................................................................................... |

10-11 |

|

Maintenance, Service and Storage.................................................................................................................................................................................... |

12-17 |

|

|

Maintenance................................................................................................................................................................................................................................. |

12 |

|

Servicing and Adjustment.................................................................................................................................................................................................. |

13-16 |

|

Storage........................................................................................................................................................................................................................................... |

17 |

Troubleshooting....................................................................................................................................................................................................................... |

17-18 |

|

Slope Guide....................................................................................................................................................................................................................................... |

19 |

|

Parts Breakdown...................................................................................................................................................................................................................... |

20-23 |

|

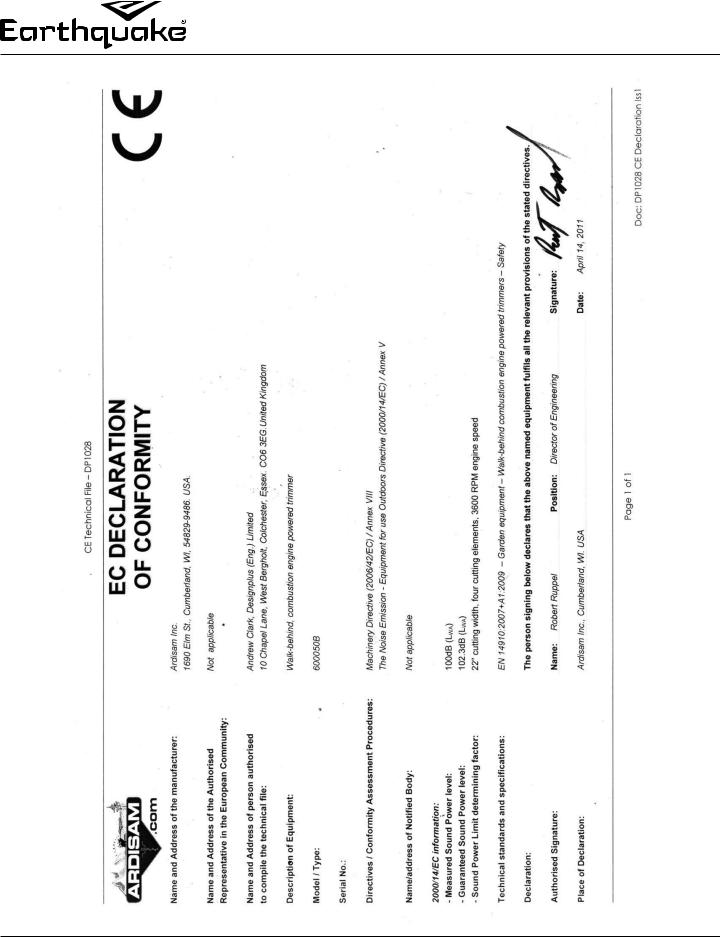

CE Declaration of Conformity..................................................................................................................................................................................................... |

24 |

|

Warranty............................................................................................................................................................................................................................................. |

25 |

|

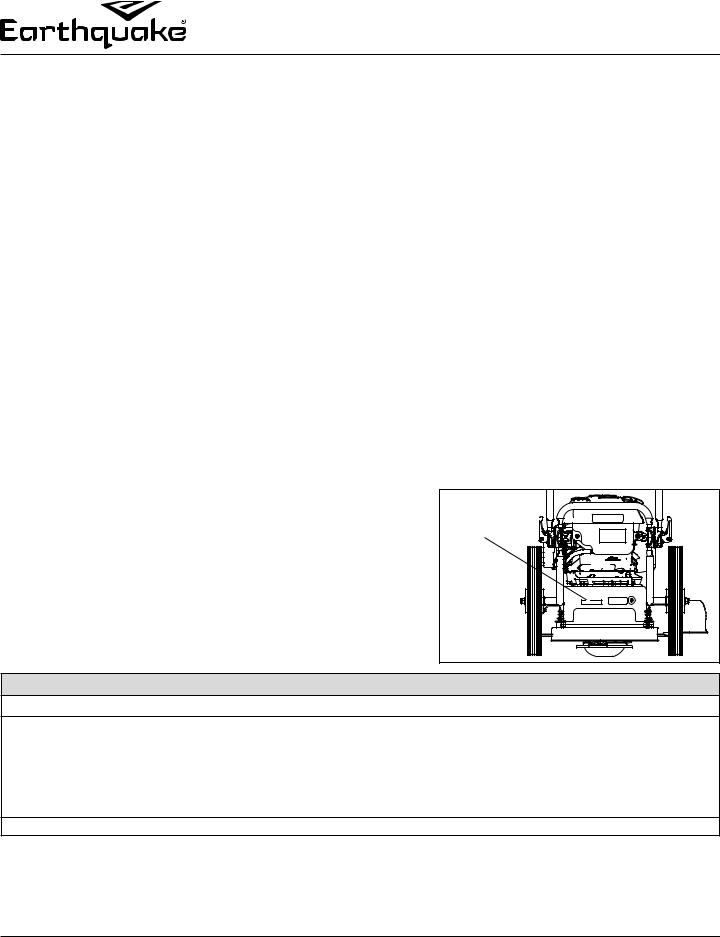

REGISTRATION, SERVICE AND MAINTENANCE LOG

Record the model number and serial number in the space provided for easy reference. Warranty is valid only if the completed registration is received by Earthquake within 30 days of purchase. You can register your warranty online by visiting www.getearthquake.com. If you do not have a computer, call our customer service department at (800) 345-6007 Mondays through Fridays from 8 a.m. to 5 p.m. CST.

model and serial |

number location |

OWNERSHIP RECORDS

Owner’s Name:

Owner’s Address:

City: |

State/Province: |

Zip Code/Postal Code: |

Model Number: |

Serial Number: |

|

Date of Purchase: |

|

|

Notes: |

|

|

This manual may contain information for several models. Read and keep this manual for future reference. This manual contains important information on SAFETY, ASSEMBLY, OPERATION, AND MAINTENANCE. The owner must be certain that all the product information is included with the unit. This information includes the MANUAL, the REPLACEMENT PARTS and the WARRANTIES. This information must be included to make sure state laws and other laws are followed. All persons to whom rent/loan this unit must have access to and understand this information. This manual should remain with the product even if it is resold.

2 |

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

Operator's Manual

Trimmer Mower 600050 Series

WARNINGS AND SAFETY PRECAUTIONS

OWNER’S RESPONSIBILITY

Accurate assembly and safe and effective use of the string trimmer is the owner’s responsibility.

•Read and follow all safety instructions.

•Carefully follow all assembly instructions.

•Maintain the string trimmer according to directions and schedule included in this Earthquake operator’s manual.

•Ensure that anyone who uses the string trimmer is familiar with all controls and safety precautions.

NOTE: All images shown in this manual of your rolling string trimmer are of 600050V. The 600050B/600050BCE models have slight variations.

SPECIAL MESSAGES

Your manual contains special messages to bring attention to potential safety concerns, machine damage as well as helpful operating and servicing information. Please read all the information carefully to avoid injury and machine damage.

NOTE:Generalinformationisgiventhroughoutthemanual that may help the operator in the operation or service of the machine.

This symbol points out important safety instructions which if not followed could endanger your personal safety. Read and follow all instructions in this manual before attempting to operate this equipment.

BEFORE OPERATING ENGINE:

Please read this section carefully. Read entire operating and maintenance instructions AND the entire engine manual which accompanies this product. Failure to follow instructions could result in serious injury or death. Operate the string trimmer according to the safety instructions outlined here and inserted throughout the text. Anyone who uses this string trimmer must read the instructions and be familiar with the controls.

INTENDED USE / FORESEEABLE MISUSE

INTENDED USE / FORESEEABLE MISUSE

This is a motorized string trimmer that cuts long grasses and weeds. It is pedestrian-controlled, but not self-propelled. It has a petrol-fuelled internal combustion engine that powers the cutting head. It shall not be used for any other purpose.

WARNING

WARNING

WARNING INDICATES A HAZARD WHICH, IF NOT AVOIDED, COULD RESULT IN DEATH OR SERIOUS INJURY AND/OR PROPERTY DAMAGE.

CAUTION

CAUTION

CAUTION INDICATES YOU CAN BE HURT OR YOUR EQUIPMENT DAMAGED IF THE SAFETY INSTRUCTIONS THAT FOLLOW THIS SIGNAL WORD ARE NOT OBEYED.

IMPORTANT

IMPORTANT

INDICATES HELPFUL INFORMATION FOR PROPER ASSEMBLY, OPERATION, OR MAINTENANCE OF YOUR EQUIPMENT.

WARNING

WARNING

CALIFORNIA PROPOSITION 65 WARNING

ENGINE EXHAUST FROM THIS PRODUCT CONTAINS CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS, OR OTHER REPRODUCTIVE HARM.

WARNING

WARNING

THIS CUTTING MACHINE IS CAPABLE OF THROWING OBJECTS.

WARNING

WARNING

DEBRIS THROWN FROM THE TRIMMER CAN RESULT IN FOREIGN OBJECTS BEING THROWN INTO THE EYES, WHICH CAN CAUSE SEVERE EYE DAMAGE AND INJURY. ALWAYS WEAR SAFETY GLASSES OR EYE SHIELDS WHEN OPERATING THE TRIMMER.

IF YOU WEAR EYE GLASSES, PUT A WIDE VISION SAFETY MASK OVER THEM.

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

3 |

Operator's Manual

Trimmer Mower 600050 Series

GENERAL SAFETY RULES

•Read,understand,andfollowallinstructionsonthemachine and in the manual(s). Be thoroughly familiar with the controls and the proper use of the trimmer before starting.

•Familiarize yourself with all of the safety and operating decals on this equipment and on any of its attachments or accessories.

•Do not put hands or feet near or under rotating parts.

•Onlyallowresponsibleindividuals,whoarefamiliarwiththe instructions, to operate the trimmer.

•Thoroughly inspect the area where the machine is to be used and remove all foreign objects. Your equipment can propel small objects at high speed causing personal injury or property damage. Stay away from breakable objects, such as house windows, automobile, greenhouses, etc.

•Keep the area of operation clear of all persons, particularly small children, and pets.

•Wear appropriate clothing such as a long-sleeved shirt or jacket. Also wear long trousers or slacks. Do not wear shorts.

•Donotwearlooseclothingorjewelry.Theycangetcaught in moving parts.

•Alwayswearsafetygogglesorsafetyglasseswithsideshields when operating trimmer to protect your eyes from foreign objects which can be thrown from the unit.

•Alwayswearworkglovesandsturdyfootwear.Wearfootwear that will improve footing on slippery surfaces. Leather work shoes or short boots work well for most people. These will protect the operator’s ankles and shins from small sticks, splinters, and other debris.

•It is advisable to wear protective headgear to prevent the possibility of being struck by small flying particles, or being struck by low hanging branches, twigs, or other objects which may be unnoticed by the operator.

•Donotoperatethetrimmerwithoutproperguardsorother safety protective devices in place.

•Use this equipment for its intended purpose only.

•See manufacturer’s instructions for proper operation and installation of accessories. Only use accessories approved by the manufacturer.

•Operate only in daylight or good artificial light.

•Do not operate product when fatigued or under the influence of alcohol, drugs or other medication which can cause drowsiness or affect your ability to operate this machine safely.

•Before each use, inspect the throttle control lever and cable. Make sure that the cable is free and that the lever is not damaged. Also check the cable linkage running to the carburetor for kinks, loose fittings, and obstructions. Verify that the control bail is working properly.

•Stoptherotatingtrimmerheadwhencrossinggraveldrives, walks, or roads. Wait for the cutting lines to stop rotating.

•Watch for traffic when operating near, or when crossing roads.

•Stoptheengine(motor)wheneveryouleavetheequipment, before cleaning, repairing or inspecting the unit, be sure the trimmer head and all moving parts have stopped. Let the engine cool, disconnect the spark plug wire and move it away from the spark plug.

•Iftheequipmentshouldstarttovibrateabnormally,stopthe engine (motor), disconnect the spark plug wire and prevent it from touching the spark plug. Check immediately for cause. Vibration is generally a warning of trouble.

•After striking a foreign object, stop the engine (motor).

Remove the wire from the spark plug. Inspect the trimmer for damage. If damaged, repair before starting and operating the trimmer.

•Never leave the trimmer unattended when the engine is running. Remove the wire from the spark plug.

•Regularlyinspectthetrimmer.Makesurepartsarenotbent, damaged or loose.

•Allow muffler and engine areas to cool before touching.

Never pick up or carry the trimmer while the engine is running.

•Prolonged exposure to noise and vibration from gasoline engine powered equipment should be avoided. Take intermittent breaks and/or wear ear protection from engine noise as well as heavy work gloves to reduce vibration in the hands.

•Check local regulations for age restrictions on use of this machine.

•If the noise or vibrations of the machine increase, stop immediately and perform an inspection.

•The fuel used in this machine is considered extremely flammable and should be handled with care. When storing extra fuel be sure that it is in an appropriate container and away from any fire hazards.

•Neveroperatetrimmerinwetgrass.Alwaysbesureofyour footing; keep a firm hold on the handle and walk; never run.

4 |

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

Operator's Manual

Trimmer Mower 600050 Series

SLOPE OPERATION

Slopes are a major factor related to slip and fall accidents which can result in severe injury. All slopes require extra caution. If you feel uneasy on a slope, do not trim it. Do trim across the face of slopes; never up and down. Do not trim excessively steep slopes (maximum 15 degrees) or areas where the ground is very rough. See the “Slope Guide” in the back of this manual to check a slope. Exercise extreme caution when changing direction on slopes.

•Remove objects such as rocks, tree limbs, etc.

•Watch for holes, ruts, or bumps. Tall grass can hide obstacles.

•Do not trim near drop-offs, ditches, or embankments. The operator could lose footing or balance.

•Do not trim excessively steep slopes.

•Do not trim on wet grass. Reduced footing could cause slipping.

CHILDREN

Tragic accidents can occur if the operator is not alert to the presence of children. Children are often attracted to the trimmer and the trimming activity. Never assume that children will remain where you last saw them.

•Keepchildrenoutofthetrimmingareaandunderthewatchful care of a responsible adult.

•Be alert and turn trimmer off if children enter the area.

•Before and while moving backwards, look behind and down for small children.

•Engines give off carbon monoxide, an odorless, colorless, poison gas. Breathing carbon monoxide can cause nausea, fainting or death. Always start and run engine outdoors. Do not start or run engine in an enclosed area, even if doors or windows are open.

•Never make adjustments or repairs with the engine (motor) running. Disconnect the spark plug wire, and keep the wire away from the plug to prevent accidental starting (remove the ignition key if equipped with an electric start). Always wear eye protection when you make adjustments or repairs.

•Check the trimmer head and engine mounting bolts at frequent intervals for proper tightness.

•Keep all nuts and bolts tight and keep equipment in good condition. Check mounting hardware on trimmer head every time you change trimmer line and prior to each use.

•Never tamper with safety devices. Check their proper operation regularly.

•When servicing or repairing the trimmer, do not tip the machine over or up unless specifically instructed to do so in this manual. Service and repair procedures can be done with the trimmer in an upright position. Some procedures will be easier if the machine is lifted on a raised platform or working surface.

•To reduce fire hazard, keep trimmer free of grass, leaves, or other debris build-up. Clean up oil or fuel spillage. Allow trimmer to cool before storing.

•Never allow children to operate the trimmer.

•Useextracarewhenapproachingblindcorners,shrubs,trees, or other objects that may obscure vision.

SERVICE

•Useextracareinhandlinggasolineandotherfuels.Theyare flammable and vapors are explosive.

•Useonlyanapprovedcontainer.

•Never remove gas cap or add fuel with the engine running. Allow engine to cool before refueling. Do not smoke while refueling.

•Fill fuel tank outdoors with extreme care. Never fill fuel tank indoors or near appliances with pilot lights, heaters, or other ignition sources. Replace fuel cap securely. If fuel is spilled, do not start the engine but move product and fuel container from area. Clean up spilled fuel and allow to evaporate.

•Never store the machine or fuel container inside where there is an open flame (such as a water heater), or other ignition source.

•If the fuel has to be drained, this should be done outdoors. The drained fuel should be stored in a container specifically designed for fuel storage or it should be disposed of carefully.

•Stop and inspect the equipment if you strike an object. Repair, if necessary, before restarting.

•Always disconnect spark plug wire before cleaning, repairing, or adjusting.

•Do not change the engine governor setting or over-speed the engine.

•Clean and replace safety and instruction decals as necessary.

•To guard against engine over-heating, always have engine debris filter mounted and clean.

•Inspect trimmer before storage. When not in use, disconnect spark plug lead and store indoors in a dry place locked or otherwise inaccessible to children.

•Use only original equipment or authorized replacement parts.

•Never replace the cutting lines with metal parts.

•When storing gasoline or equipment with fuel in the tank, store away from furnaces, stoves, water heaters or other appliances that have a pilot light or other ignition source because they can ignite gasoline vapors.

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

5 |

Operator's Manual

Trimmer Mower 600050 Series

SAFETY DECALS AND WARNINGS

Pictured below are safety and hazard symbols on the unit or in this manual. Before you operate your unit, learn and understand the purpose for each symbol.

CONTROL AND OPERATING SYMBOLS

Pictured below are control and operating symbols on the unit or in this manual. Before you operate your unit, learn and understand the purpose for each symbol.

|

|

|

|

Slow |

Fast |

Fuel |

Oil |

|

|

|

|

A B C D E F

G H I J K L

M N O P

A:Warning!

B:Read Owner's Manual Before Operating Machine.

C:Do Not Operate While Others Are Around.

D:Remove Objects that Could Be Thrown By This Machine.

E:Never Operate Machine Up and Down Slopes, ALWAYS

Operate Trimmer Across Slopes.

F:Be Aware of Moving and Rotating Parts.

G:Wear Ear and Eye Protection At All Times.

H:Do Not Service or Adjust Moving Parts Unless Engine is

Stopped and Spark Plug Wire is Disconnected.

I:Direction of Rotating Trimmer Lines.

J:Toxic Fumes—Do Not Operate in Unventilated Areas.

K:Hot Surfaces.

L:Fire Hazards.

M.Do Not Use In Thunderstorms--For severe weather, stop operation of this machine and seek shelter.

N.Team Lift--For your safety, always have at least two people when lifting this machine.

O.Never Fit Metal Cutting Parts--Do not attach any metal parts to the cutting head of this machine.

P.Do Not Operate When Children Or Others Are Around.

NAMEPLATE DETAILS

NAMEPLATE DETAILS

ARDISAM, INC.

1160 8th Avenue | Cumberland, WI 54829 | USA

Serial No.

LBLINFO600050BCE

Model: 600050BCE Type: Trimmer

Year: 2011 Mass: 30.3 kg

Max. Operating Speed: 3600 rpm

SOUND AND VIBRATION LEVELS

SOUND AND VIBRATION LEVELS

Model |

600050BCE |

|

|

|

|

2006/42/EC Operator Ear LPA (dBA) |

84 |

|

2006/42/EC Sound Power Level |

102.3 |

|

LWA (dBA) |

||

|

||

2006/42/EC Hand/Arm Vibration |

5.4 |

|

Max m/s2 |

||

|

||

2006/42/EC Vibration Time Limit |

EAV= 1h 43mins. |

|

ELV= 6h 52mins. |

||

|

||

|

|

Sound levels tested in accordance with ISO 3744 & ISO 11094Grade 2 (Engineering) Method. Readings taken with engine at full throttle. EAV= Exposure Action Value, ELV= Exposure Limit

Value

102.3

LBLNOISE102

SPARE PARTS

Only use approved Earthquake spares.

6 |

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

Operator's Manual

Trimmer Mower 600050 Series

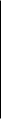

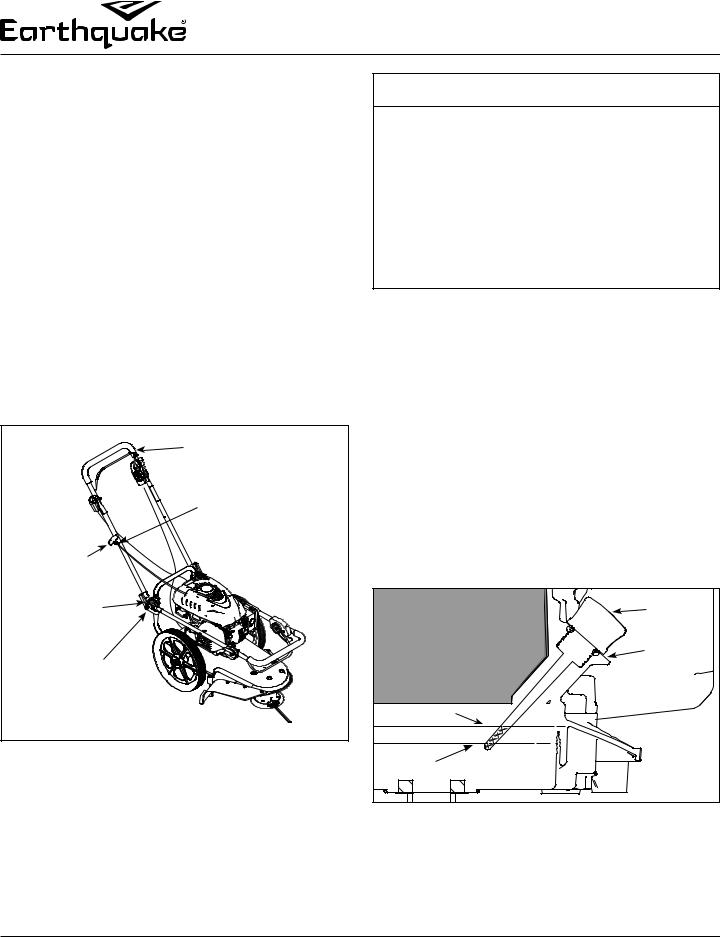

FEATURES

Read this owner’s manual and safety rules before operating your trimmer. Take time to compare the following illustration with the trimmer to familiarize yourself with the product and its controls.

control bail

trimmer head drive lever (not all models)

upper handle

throttle control lever (some models utilize ON/OFF switch)

fuel cap

recoil starter handle

debris screen

handle adjustment cam lever

primer bulb

dipstick

trimmer head  (generic representation)

(generic representation)

rubber extension may not |

trimmer line |

|

appear on all models |

||

(generic representation) |

||

|

FIGURE 1: Your new string trimmer

Trimmer Head Drive Lever - Engages the rotation of the trimmer head.

Control Bail - Release to stop the rotation of the trimmer head. Throttle Control Lever - Controls the speed or stops the engine.

Primer Bulb - Injects fuel directly into the carburetor manifold for faster starts

Recoil Starter Handle - The engine is equipped with an easy pull recoil starter.

Shield Edge Guard - Protects the shield by automatically cutting the line to the correct length.

SPECIFICATIONS

Trimmer Line Diameter: 0.155 inches Trimmer Line Length: 21.5 inches Wheel Diameter: 14"

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

7 |

Operator's Manual

Trimmer Mower 600050 Series

ASSEMBLY

Contents of Part Bag

Owner’s manual

Engine manual

Warranty card

Replacement trimmer line

L-handle allen wrench

Spark plug wrench (600050V only)

Safety goggles

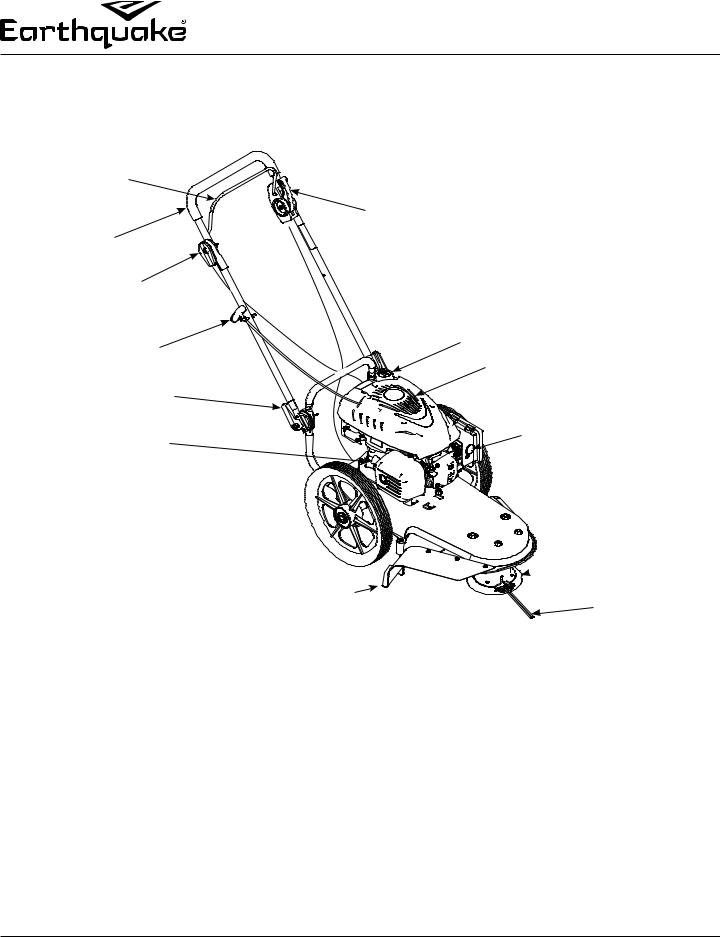

To Remove the Trimmer from the Carton

1.Remove any of the loose parts in packaging, including the parts bags, from the carton.

2.Remove the packing material positioned around the unit.

3Cut down all four corners of the carton and lay the side panels flat.

4.Pull the trimmer out of the carton. SEE FIGURE 2

WARNING

WARNING

ALWAYS WEAR SAFETY GLASSES OR EYE SHIELDS WHILE ASSEMBLING THE TRIMMER.

WARNING

WARNING

BEFORE DOING ANY ASSEMBLY OR MAINTENANCE TO THE TRIMMER, REMOVE THE WIRE FROM THE SPARK PLUG.

FIGURE 2: Your new trimmer as it is shipped to you.

Illustration is for reference only.

8 |

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

Operator's Manual

Trimmer Mower 600050 Series

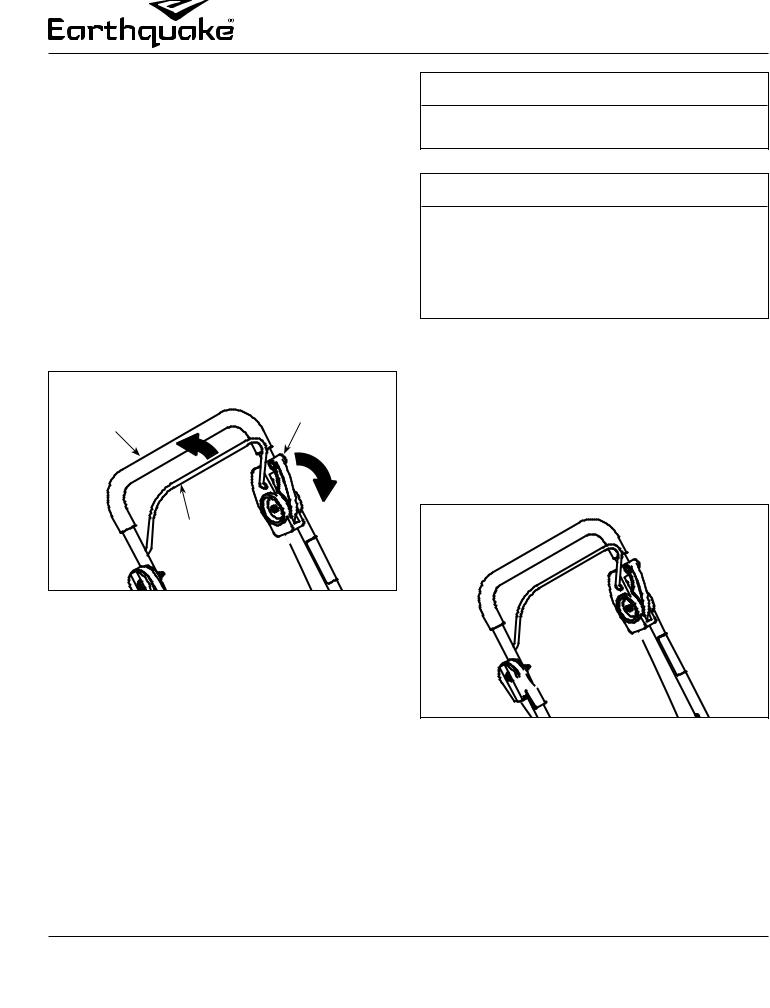

How to Raise the Handle

1.Hold the handle with one hand and loosen both handle adjustment cams until the ratchet teeth are disengaged. Do not remove the handle adjustment levers.

2.Raise the handle to the operating position.

3.Stand in the operator’s position behind the trimmer. Put the handle in a comfortable position. Make sure both sides of the handle are level.

NOTE: Make sure the cables are not caught between the upper and lower handle.

4.Tighten the handle adjustment levers. Make sure the handle pivots are locked in place.

WARNING

WARNING

FOLLOW THE ENGINE MANUFACTURER’S INSTRUCTIONS FOR THE TYPE OF GASOLINE AND OIL TO USE.

ALWAYS USE A SAFETY GASOLINE CONTAINER. DO NOT SMOKE WHEN ADDING GASOLINE TO THE ENGINE.

WHEN INSIDE AN ENCLOSURE, DO NOT FILL WITH GASOLINE. BEFORE YOU ADD GASOLINE, STOP THE ENGINE. LET THE ENGINE COOL FOR SEVERAL MINUTES.

NOTE: The handle height is adjustable. See “How To Adjust The Height Of The Handle” in the Service and Adjustment section.

5.To attach the recoil start handle to the rope guide, twist the rope through the rope guide mounted on the right side of the handle. SEE FIGURE 3

ENGINE PREPARATION

See the engine manufacturer’s instructions for the type of gasoline and oil to use. Before you use the unit, read the information on safety, operation, maintenance, and storage.

NOTE: Engine does not contain OIL or GASOLINE.

handle |

rope guide |

recoil start |

handle |

handle pivot |

handle adjustment |

cam lever |

FIGURE 3: Adjusting the handle bars.

Illustration is for reference only.

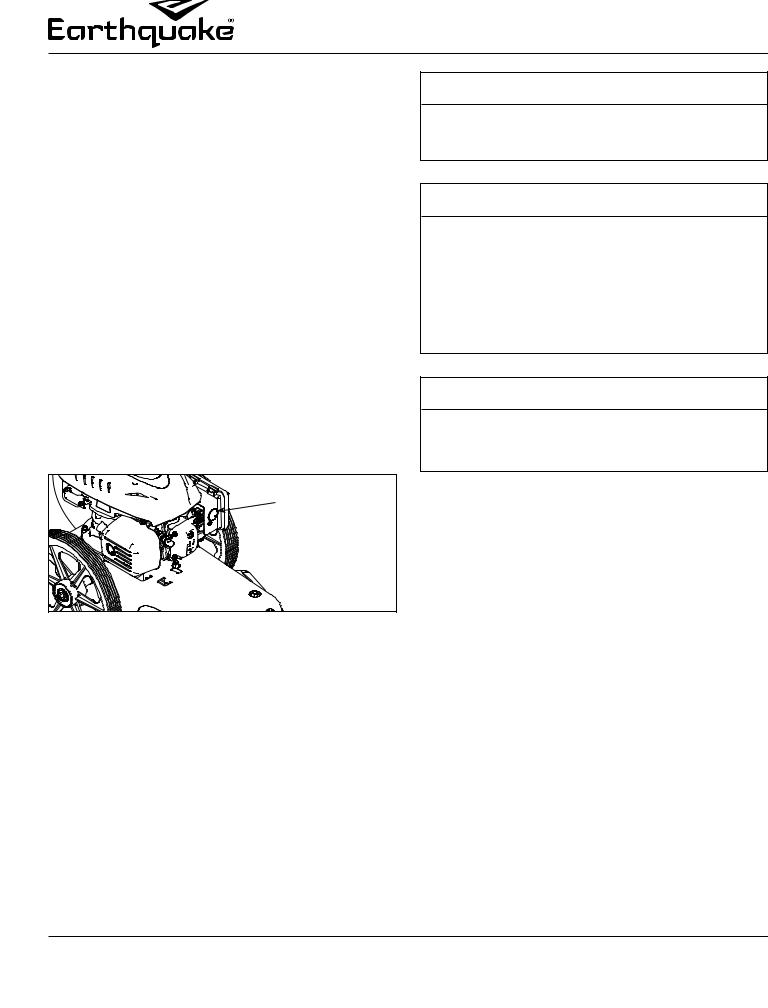

Fill Crankcase With Oil

1.Remove the oil dipstick. Fill the crankcase to the FULL line on dipstick. DO NOT OVERFILL. SEE FIGURE 4

2.Install the oil dipstick and tighten securely.

Fill Fuel Tank With Gasoline

See the engine manufacturer’s instructions for the type of gasoline to use.

oil dipstick |

oil fill area |

upper level |

lower level |

FIGURE 4: Filling the engine with fuel and oil.

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

9 |

Operator's Manual

Trimmer Mower 600050 Series

OPERATION

How to Stop the Trimmer Head

Release the control bail. It will return to its open position and disengage the trimmer head.

How to Stop the Engine

Move the throttle control lever completely back to the STOP position or turn ON/OFF switch to OFF position.

How to Use the Trimmer Head Drive Lever (not all models)

1.To engage the trimmer head, hold the control bail against the handle. Move the trimmer head drive lever forward to engage the trimmer head. The faster the engine runs, the faster the trimmer head will rotate. SEE FIGURE 5

2.Once the trimmer head is rotating, push the trimmer forward to trim.

trimmer head drive lever

handle

control bail

FIGURE 5: Using the trimmer head drive lever

WARNING

WARNING

THE TRIMMER HEAD WILL CONTINUE TO ROTATE FOR SEVERAL SECONDS AFTER THE ENGINE HAS STOPPED.

CAUTION

CAUTION

IMPROPER TREATMENT OF THE STRING TRIMMER CAN DAMAGE IT AND SHORTEN ITS LIFE.

•DO NOT ATTEMPTTO CRANK OR STARTTHE ENGINE

BEFORE IT HAS BEEN PROPERLY SERVICED WITH THE RECOMMENDED OIL. THIS MAY RESULT IN AN ENGINE FAILURE.

How to Use the Throttle Control (not all models)

1.During normal use, set the throttle control lever in the FAST position to run the engine at full speed. SEE FIGURE 6

2.Pull the throttle control lever back to decrease engine speed. Push the throttle control lever forward to increase engine speed.

3.To stop the engine, pull the throttle control lever completely back to the stop position.

throttle control

throttle control

lever

lever

FIGURE 6: Using the throttle control

How to Use the Primer Bulb

1.Push the primer bulb five times. Wait approximately two seconds between each push. SEE FIGURE 7

NOTE: Do not use the primer bulb to restart a warm engine after a short shutdown.

10 |

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

Operator's Manual

Trimmer Mower 600050 Series

How to Start the Engine

NOTE: DO NOT BE ALARMED, your engine will smoke the first time it is started. It is burning off the protective coating that is on the internal engine parts.

1.Before each use, remove debris from the debris screen. SEE FIGURE 1 IN "FEATURES" SECTION. Debris can cause the engine to overheat. Wipe the debris screen with a cloth or paper towel.

2.Move the throttle control lever forward to the FAST position or place ON/OFF switch to ON.

3.To start a cold engine, push the primer bulb five times. Wait two seconds between each push of the primer bulb.

SEE FIGURE 7

NOTE: Do not use the primer to start a warm engine.

4.Firmly hold the recoil starter handle with your right hand.

5.Pull back sharply on the recoil starter handle. DO NOT allow the starter rope to snap back. Let the starter rope slowly rewind as you hold the recoil starter handle.

TIP: If the engine fails to start after three pulls, push the primer bulb two times and pull the recoil starter handle again.

primer bulb

WARNING

WARNING

NEVER LEAVE THE TRIMMER UNATTENDED WHILE THE ENGINE IS RUNNING. WAIT FOR THE TRIMMER LINES TO STOP ROTATING.

WARNING

WARNING

NEVER RUN THE ENGINE INDOORS OR IN A POORLY VENTILATED AREA. ENGINE EXHAUST CONTAINS CARBON MONOXIDE, AN ODORLESS AND DEADLY GAS. KEEP HANDS, FEET, HAIR AND LOOSE CLOTHING AWAY FROM THE TRIMMER AND ANY MOVING PARTS ON THE ENGINE. AVOID TOUCHING THE MUFFLER AND SURROUNDING AREAS. TEMPERATURES MAY EXCEED 150 DEGREES FAHRENHEIT.

WARNING

WARNING

DEBRIS SUCH AS STICKS, GRAVEL OR ROCKS CAN BE THROWN WITH SUFFICIENT FORCE TO CAUSE PERSONAL INJURY OR PROPERTY DAMAGE.

Trimmer Tips

•Set the throttle control in the FAST position. If the weeds or grass are tall and thick, operate the trimmer at a slower walking speed.

•Frequently clean the underside of the trimmer to remove any grass build up. See the “Maintenance, Service and Storage”section for details.

FIGURE 7: Primer Bulb |

• For best results and longer lasting line, use the ends of the |

|

line to do the cutting. This is easily done by moving slowly |

|

through very thick or heavy weeds. |

• If the trimmer lines become too short, it will take longer to complete the job. If the trimmer lines are worn to less than half their original length, change to a new trimmer line. See more on how to replace the trimmer line in the "Maintenance, Service and Storage" section.

• Donottrimonexcessivelysteepslopes.Ifaslopeisdifficult to stand on, do not trim. Do not trim on slopes when the ground is slippery or wet. Trim across the face of a slope, not up and down.

• Trimmer head contact to concrete, asphalt and harder surfaces may create premature wear to the height guide.

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

11 |

Operator's Manual

Trimmer Mower 600050 Series

MAINTENANCE, SERVICE, AND STORAGE

Maintenance, replacement or repair of the emissions control devices and systems may be performed by any non-road engine repair establishment or individuals. However, items must be serviced by an authorized dealer to obtain “no charge” emissions control service.

Good maintenance is essential for safe, economical and trouble-free operation. It will also help reduce air pollution.

Maintenance Schedule

Service Records |

Before Each Use |

Every 25 Hours |

As Noted |

Service Date |

|

|

|

|

|

Check engine oil level |

X |

|

|

|

|

|

|

|

|

Check trimmer lines |

X |

|

1 |

|

|

|

|

|

|

Check trimmer head engagement |

X |

|

|

|

|

|

|

|

|

Engine/machine cleaning |

X |

|

2 |

|

|

|

|

|

|

Check nuts and bolts |

X |

|

|

|

|

|

|

|

|

Check spark plug |

|

X |

|

|

|

|

|

|

|

Change engine oil* |

|

X |

|

|

|

|

|

|

|

Service air filter* |

|

X |

3 |

|

|

|

|

|

|

Lubricate jackshaft assembly |

|

X |

|

|

|

|

|

|

|

Lubricate wheel bearings |

|

X |

|

|

|

|

|

|

|

Note 1 - When old line is half the original length, replace with new line. Note 2 - Clean daily if used in extremely dusty or dirty conditions.

Note 3 - Change more often if used in extremely dusty or dirty conditions.

* To service the air filter and change the oil in the 600050V model, you must remove the wheels on the string trimmer.

General Recommendations

The warranty on this trimmer does not cover items that have been subjected to operator abuse or negligence. To receive full value from the warranty, the operator must maintain the trimmer as instructed in this manual.

Some adjustments must be made periodically to properly maintain your trimmer. All adjustments in the “Service and Adjustments” section of this manual must be checked at least once each season.

12 |

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

Operator's Manual

Trimmer Mower 600050 Series

SERVICE AND ADJUSTMENT

How to Change Engine Oil

Be sure the engine is not operating and is located on a level surface before checking or refilling oil. Engine should be warm for easy removal of oil.

1.Detach spark plug wire and move away from spark plug. If the engine uses a battery, disconnect at negative terminal.

WARNING

WARNING

BEFORE YOU INSPECT, CLEAN OR SERVICE THE TRIMMER, STOP THE ENGINE. MAKE SURE THAT ALL MOVING PARTS HAVE STOPPED. DISCONNECT THE WIRE FROM THE SPARK PLUG.

2.Remove dipstick and carefully tip the engine toward the dipstick side to empty oil from oil fill area. Empty oil into a suitable oil container and dispose of oil properly. SEE FIGURE

8

3.Tip engine back onto a level surface and fill with appropriate oil to the top of the marking on the dipstick (SEE FIGURE 9). DO NOT OVERFILL. For proper oil capacity, see the engine manufacturer's instructions.

4.Reinsert dipstick and tighten. SEE FIGURE 9

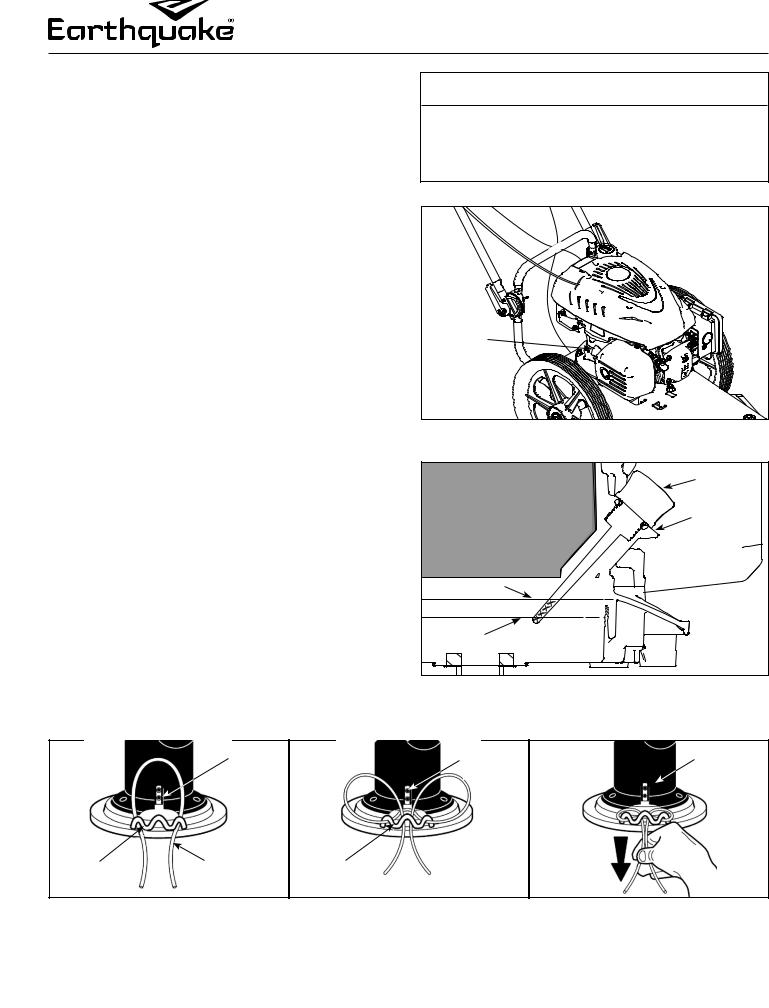

How to Replace the Trimmer Line on Standard Head

For the best performance, use a heavy gauge (0.155" diameter) trimmerline.Cutthelengthofthetrimmerlineto21.5".Usethe length guide, located on the shield, to make sure the trimmer line is the correct length.

oil dipstick |

FIGURE 8: Oil dipstick location

Do not allow the length of the lines to vary more than one inch. This is important to make sure the trimmer head is balanced and does not vibrate.

NOTE: To extend the life of the trimmer line, keep the trimmer line moist. If not kept moist, the nylon trimmer line will become dry and brittle. Keep extra trimmer line in a can of water. The line will then stay flexible and easy to change. A flexible line will also last much longer.

1.Stop the engine. Wait for all moving parts to stop.

2.Remove the worn trimmer line from the line retainer.

3.First, thread the ends of the new trimmer line through the outside loops. SEE FIGURE 10

4.Next, take the ends of the line, cross over the line retainer, and thread the ends through the center hold. SEE FIGURE

11

5.Then, check to make sure that the ends of the line are even.

SEE FIGURE 12

dipstick |

oil fill area |

upper level |

lower level |

FIGURE 9: Dipstick and oil levels

|

cap screws |

cap screws |

cap screws |

||

|

|

|

|

|

|

|

|

|

line |

|

|

|

|

|

|

|

|

line |

||

|

retainer |

|

trimmer |

|

|

|

|

|

retainer |

||

|

|

|

line |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

FIGURE 10: Threading the new trimmer line. |

FIGURE 11: Threading trimmer line through center |

FIGURE 12: Check ends of line. |

|

hold. |

|

|

|

|

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

13 |

|

Operator's Manual

Trimmer Mower 600050 Series

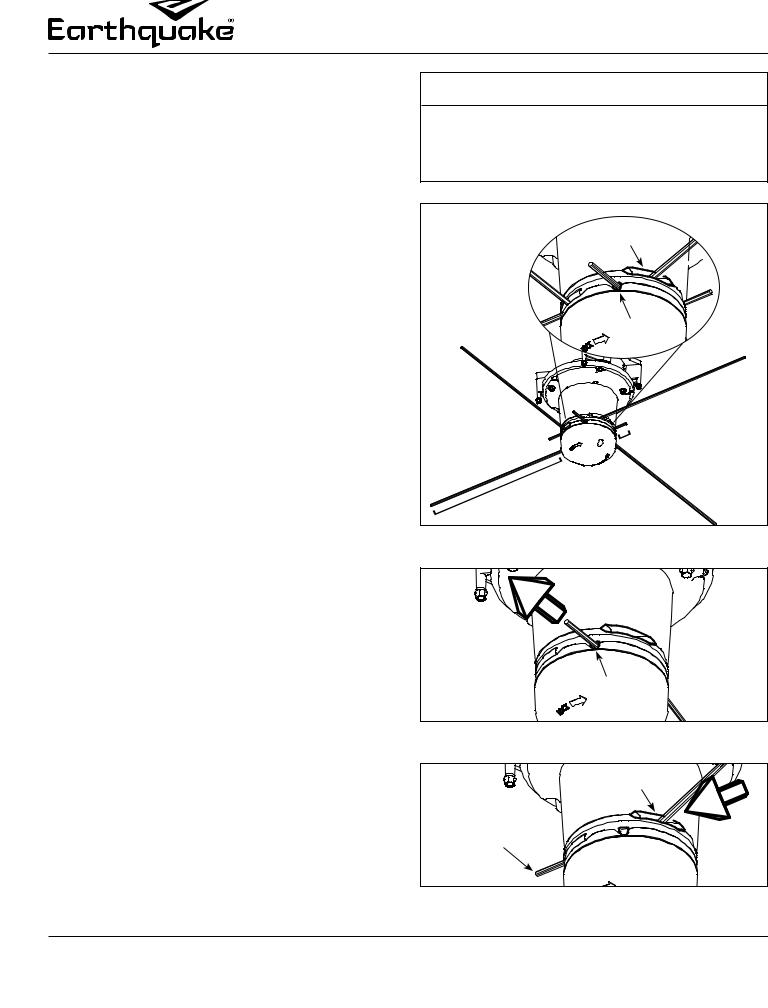

TRIMMER HEAD SERVICE AND ADJUSTMENT, SLIDE-THROUGH VERSION

Trimmer Line on Slide-Through Version

For the best performance, use a heavy gauge (0.155" diameter) trimmer line. Recommended line cut to proper length can be obtained through your dealer. If necessary cut the length of the trimmer line to 15".

Do not allow the length of the lines to vary more than one inch. This is important to make sure the trimmer head is balanced and does not vibrate.

NOTE: To extend the life of the trimmer line, keep the trimmer line moist. If not kept moist, the nylon trimmer line will become dry and brittle. Keep extra trimmer line in a can of water. The line will then stay flexible and easy to change. A flexible line will also last much longer.

How to Replace the Trimmer Line on Slide-Through Version

Familiarize yourself with the trimmer head. (SEE FIGURE 6) Trimmer head has four small exit holes and four large entrance holes. Properly loaded trimmer line will have one inch exposed out the small exit hole and the remaining portion of the line sticking out of the large entrance hole.

1.Before replacing the trimmer line make sure the engine is stopped and wait for all moving parts to come to a stop.

2.Remove old line pieces from trimmer head.

NOTE: One inch of trimmer line should be exposed from the small exit hole. Grab onto this exposed line a pull old line out of trimmer head through the exit hole. SEE FIGURE 7

3.Install the new trimmer line into the large entrance hole, making sure to only expose one inch of line out of the exit hole. SEE FIGURE 8

NOTE: Too little of line exposed on the exit side can make it difficult to remove old line. Too much line exposed can cause the line to pull out of the trimmer head.

4.Pull with force on the entrance hole side of the line to ensure that the line is securely seated in the trimmer head.

NOTE: Trimmer line should only be able to feed in one direction through the trimmer head. Use of recommended line is important for proper function.

5.Repeat steps 1-4 for each piece of replacement trimmer line.

WARNING

WARNING

BEFORE YOU INSPECT, CLEAN OR SERVICE THE TRIMMER, STOP THE ENGINE. MAKE SURE THAT ALL MOVING PARTS HAVE STOPPED. DISCONNECT THE WIRE FROM THE SPARK PLUG.

entrance hole |

exit hole |

1" of exposed trimmer |

line on exit hole side |

remaining trimmer line |

on entrance hole side |

FIGURE 6: Trimmer head and trimmer line

exit hole

FIGURE 7: Pull old trimmer line out through exit hole

entrance hole

stop with 1" exposed out exit hole

FIGURE 8: Insert new trimmer line into entrance hole

14 |

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

Operator's Manual

Trimmer Mower 600050 Series

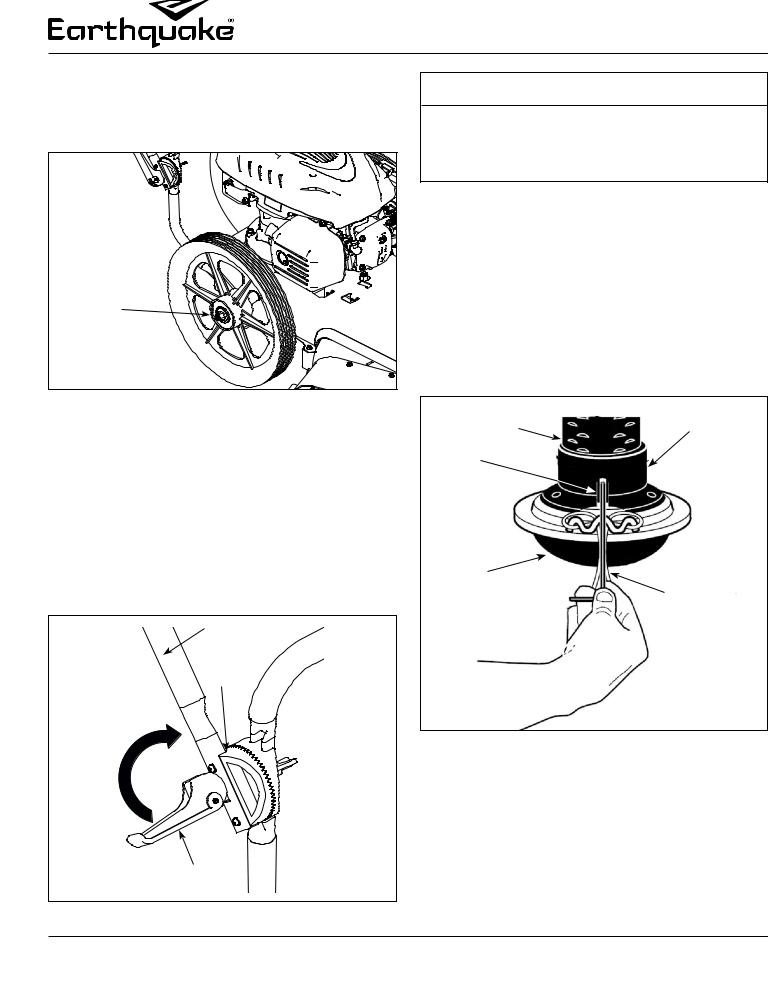

To Detach the Tires

To detach the tires, loosen the axle nuts and remove the wheel, spacer and washer. Reverse instructions to reattach tire. SEE

FIGURE 13

axle nut |

WARNING

WARNING

BEFORE YOU SET THE HEIGHT OF THE CUT, STOP THE ENGINE. WAIT FOR ALL MOVING PARTS TO STOP. ALLOW THE ENGINE TO COOL AND DISCONNECT THE SPARK PLUG WIRE.

How to Set the Height of the Cut (not all models)

The height of the cut can be set from 1-1/2 inches to three (3) inches. The recommended cutting height for the average yard is two (2) inches. SEE FIGURE 15

1.Use the L-handle wrench found in the parts bag to loosen the socket head cap screws shown in the figure below.

NOTE: There are two socket head cap screws.

2.Set the trimmer head at the desired height.

3.Tighten the socket head cap screws.

FIGURE 13: Detaching tires. Illustration is for reference only.

How to Adjust the Height/Angle of the Handle

Use the cam levers on each side of the handle to adjust the height of the handle. SEE FIGURE 14

1.Hold the handle with one hand and open both cam levers until the ratchet teeth are disengaged. Do not remove the nuts.

2.Move the handle up or down to the desired position, then align the ratchet teeth. Make sure both sides of the handle are level.

3.Tighten (lock) the lever.

handle

ratchet teeth

locked

open

cam lever

height of cut

positions |

trimmer head |

|

|

socket head |

|

cap screws |

|

height guide |

L-handle |

|

wrench |

FIGURE 15: Setting the height of your cut.

FIGURE 14: Adjusting the height of the handle. (Lever shown in OPEN position)

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

15 |

Operator's Manual

Trimmer Mower 600050 Series

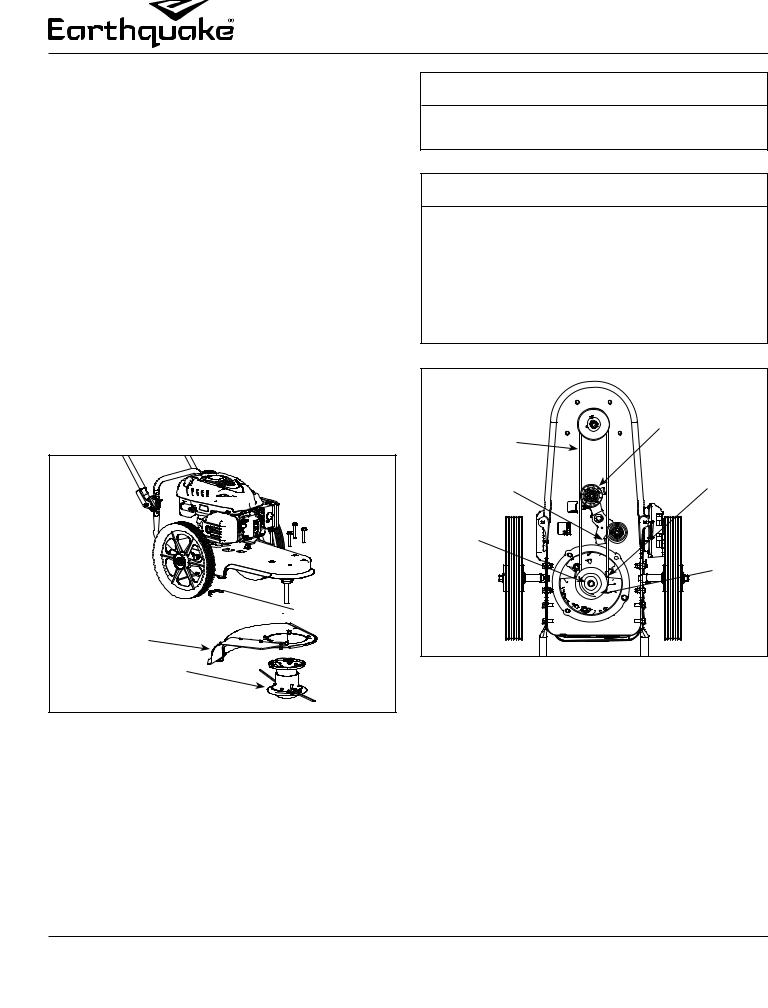

How to Replace the Drive Belt

To replace the drive belt, the trimmer head and shield must be removed as explained below. SEE FIGURES 16 AND 17

1.Remove the two fasteners that hold the rear of the shield to the trimmer housing.

2.Remove the four fasteners that hold the front of the shield and trimmer head to the trimmer housing.

3.Remove the “V” pulley from the idler bracket.

4.Raise the front of the trimmer housing and remove the drive belt.

*On some models, it is necessary to loosen the mounting bolt for the drive pulley to remove the drive belt . Do not bend the belt guides.

NOTE: Use only OEM replacement belts.

5.To assemble the drive belt, reverse the above steps. Make sure all fasteners are tight. Make sure the mounting bolt for the drive pulley is tight.

6.Check the routing of the drive belt. Make sure the drive belt is inside of all belt guides as shown.

drive belt

shield

trimmer head

WARNING

WARNING

BEFORE YOU REMOVE THE DRIVE BELT, DISCONNECT THE WIRE FROM THE SPARK PLUG.

IMPORTANT

IMPORTANT

TEST THE DRIVE SYSTEM. START THE ENGINE AND MOVE THE THROTTLE CONTROL TO THE FAST POSITION. ENGAGE AND DISENGAGE THE TRIMMER HEAD SEVERAL TIMES. WHEN DISENGAGED, MAKE SURE THE TRIMMER HEAD COMPLETELY STOPS WHEN RESTING ON THE GROUND. IF THE TRIMMER HEAD CONTINUES TO ROTATE, TAKE THE TRIMMER TO AN AUTHORIZED SERVICE CENTER.

"V" pulley

drive belt

belt guide |

belt guide |

mounting bolt

drive pulley

FIGURE 17: Routing the drive belt

FIGURE 16: Trimmer housing

16 |

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

Operator's Manual

Trimmer Mower 600050 Series

STORAGE

When the trimmer is put in storage for thirty days or more, follow the steps below to make sure the trimmer is in good condition the following season.

Trimmer:

Completely clean the trimmer

Put the trimmer in a building that has good ventilation.

NOTE: A yearly check-up or tune-up at an authorized service dealer will ensure that the trimmer will provide maximum performance for the next season.

Engine:

IMPORTANT NOTE: It is important to prevent gum deposits from forming in fuel system parts such as the carburetor, fuel filter, fuel hose, and tank during storage. Also, using alcohol blended fuels (called gasohol, ethanol or methanol) can attract moisture which leads to separation and formation of acids during storage. Acidic gas can damage the fuel system of an engine while in storage.

1.Drain all gasoline from the fuel tank. Let the engine run until it is out of gasoline. If you do not want to remove gasoline, add a fuel stabilizer to any gasoline left in the tank. A fuel stabilizer will minimize the formation of gum deposits and acids. If the tank is almost empty, mix the fuel stabilizer with fresh gasoline in a separate container and add the mixture to the tank. Always follow the instructions on the stabilizer container. Run the engine at least ten minutes after stabilizer is added to allow the mixture to reach the carburetor.

2.Drain the oil from a warm engine. Fill the engine crankcase with new oil.

3.Remove the spark plug from the cylinder. Pour one ounce of oil into the cylinder. Slowly pull the recoil starter handle so that the oil will protect the cylinder. Install a new spark plug in the cylinder.

4.Completely clean the trimmer, including dirt and debris from the cylinder cooling fins and the engine housing.

5.When not in use, disconnect spark plug lead and store in a well-ventilated area inaccessible to children.

WARNING

WARNING

DO NOT REMOVE GASOLINE WHILE INSIDE A BUILDING, NEAR A FIRE, OR WHILE YOU SMOKE. GASOLINE FUMES CAN CAUSE AN EXPLOSION OR A FIRE.

TROUBLESHOOTING & REPAIR

At Earthquake, we build quality and durability into the design of our products; but no amount of careful design by us, and careful maintenance by you, can guarantee a repair-free life for your Earthquake String Trimmer. Most repairs will be minor, and easily fixed by following the suggestions in the troubleshooting guide in this section.

The guide will help you pinpoint the causes of common problems and identify remedies.

For more complicated repairs, you may want to rely on an authorized service center in the US or your dealer in Europe. A parts breakdown is located toward the end of this manual.

We will always be glad to answer any questions you have, or help you find suitable assistance. To order parts or inquire about warranty, call or email us using the contact information found below.

ORDERING REPLACEMENT PARTS

Parts can be obtained from the store where the string trimmer was purchased or direct from the factory. To order parts visit www.getearthquake.com or call 1-800-345-6007.

For other general questions, you can e-mail us at info@ getearthquake.com.

Please include the following information with your order:

1)Part numbers

2)Part description

3)Quantity

4)Model number and serial number

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

17 |

|

|

Operator's Manual |

|

|

Trimmer Mower 600050 Series |

|

|

|

TROUBLESHOOTING GUIDE |

|

|

|

|

|

Trouble |

Cause |

Correction |

|

|

|

Engine does not start |

Spark plug wire disconnected |

Connect spark plug wire |

|

|

|

|

Engine not primed |

Prime engine |

|

Defective or incorrectly gapped spark plug |

Inspect or replace spark plug |

|

|

|

|

Fuel tank empty |

Add fuel |

|

|

|

|

Dirty carburetor or fuel line |

Clean carburetor or fuel line |

|

Dirty air filter |

Replace air filter |

|

|

|

|

Carburetor out of adjustment |

For carburetor adjustment, take the unit to an |

|

|

authorized service center |

|

|

|

|

Engine flooded |

Wait several minutes before starting |

|

Throttle control lever in incorrect position |

Move throttle lever to FAST or START position |

|

|

|

|

Stale gasoline |

Drain old gasoline and add fresh gas |

|

|

|

|

Defective throttle control lever or wire |

Inspect lever and wire. Replace if damaged or defective. |

Engine runs poorly |

Bad spark plug |

Replace spark plug |

|

|

|

|

Dirty air filter |

Replace air filter |

|

|

|

|

Carburetor out of adjustment |

For carburetor adjustment, take the unit to an |

|

|

authorized service center |

|

Stale gasoline |

Drain old gasoline and add fresh gas |

|

|

|

|

Engine cooling system clogged |

Clean debris screen and engine cooling fins |

|

|

|

Engine overheats |

Engine cooling system clogged |

Clean debris screen and engine cooling fins |

|

Carburetor out of adjustment |

For carburetor adjustment, take the unit to an |

|

|

authorized service center |

|

|

|

|

Oil level is low |

Add oil |

|

|

|

Engine will not stop |

Defective throttle control lever or wire |

Inspect and replace damaged parts |

running |

Throttle not adjusted properly |

Move throttle to the full OFF position |

|

||

|

|

|

Poor trimming |

Trimmer line length is too short |

Correct line length is 21.5 inches. When the line is less |

performance |

|

than 1/2 of this length, replace the line. |

|

|

|

|

Engine not set at FAST speed |

Move engine throttle lever to FAST position |

Trimmer vibrates |

Socket head cap screws for the trimmer |

Tighten socket head cap screws with L-handle wrench |

|

head are loose |

|

|

|

|

|

Trimmer line lengths are substantially |

Adjust trimmer line to approximately equal lengths |

|

different |

|

|

|

|

|

Loose nuts or bolts |

Check all bolts and nuts, including engine bolts |

|

Broken trimmer head |

Replace broken part |

|

|

|

Trimmer head does not |

Trimmer line not properly attached |

Follow instructions on decal or in the "Maintenance, |

retain line |

|

Service and Storage" section of the owner's manual |

|

|

|

|

Broken line retainer |

Replace trimmer head assembly |

|

Trimmer line not correct size |

Use a 0.155" diameter trimmer line |

|

|

|

NOTE: Please see the engine manual for a full troubleshooting guide for any engine issues.

18 |

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

Operator's Manual

Trimmer Mower 600050 Series

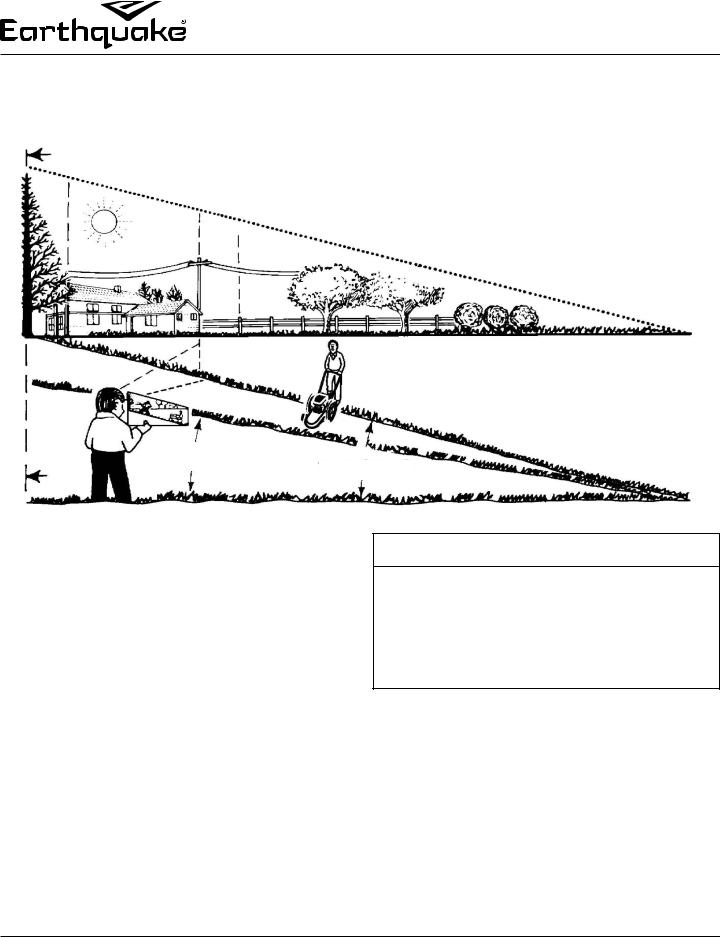

SLOPE GUIDE

15 |

DEGREES |

|

SIGHT AND HOLD THIS GUIDE LEVEL WITH A VERTICAL TREE, A CORNER OF A STRCUTURE, A POWER LINE POLE, OR A FENCE.

FOLD ALONG DOTTED LINE

Operate a trimmer across the face of slopes, never up or down slopes

10 DEGREES

15 DEGREES

Use this guide and do not trim on a slope greater than 15 degrees.

A 10 degree slope is a hill that increases in height at approximately 1.76 feet in 10 feet.

A 15 degree slope is a hill that increases in height at approximately 2.68 feet in 10 feet.

WARNING

WARNING

USE EXTREME CARE AT ALL TIMES AND AVOID SUDDEN TURNS OR MANEUVERS. FOLLOW OTHER INSTRUCTIONS IN THIS MANUAL FOR SAFETY IN TRIMMING ON SLOPES. OPERATE A TRIMMER ACROSS THE FACE OF SLOPES, NEVER UP OR DOWN SLOPES. USE EXTRA CARE WHEN OPERATING ON OR NEAR SLOPES AND OBSTRUCTIONS.

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

19 |

Operator's Manual

Trimmer Mower 600050 Series

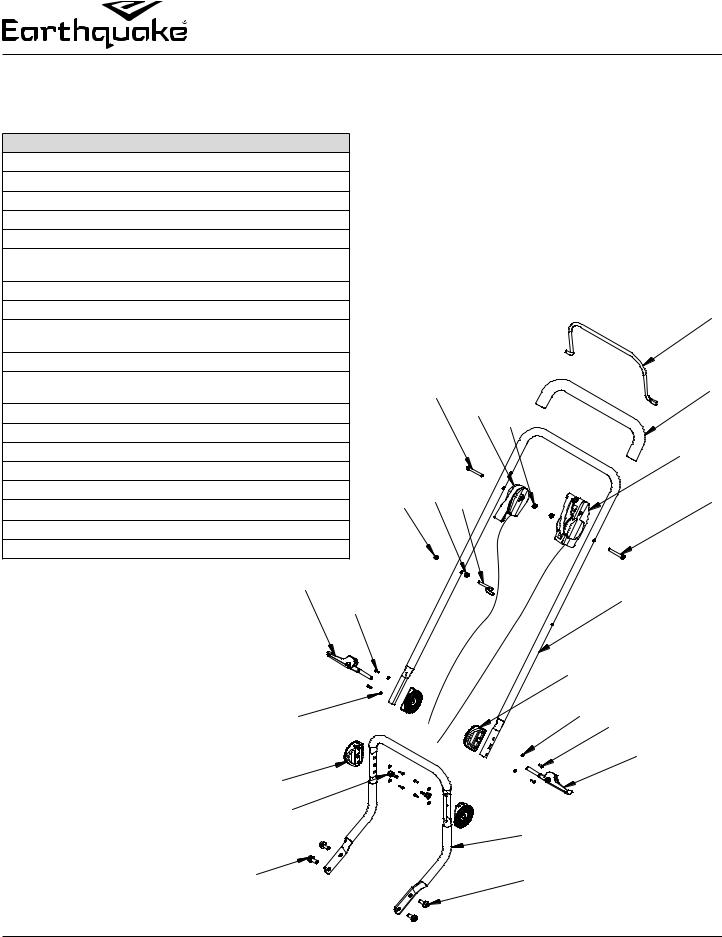

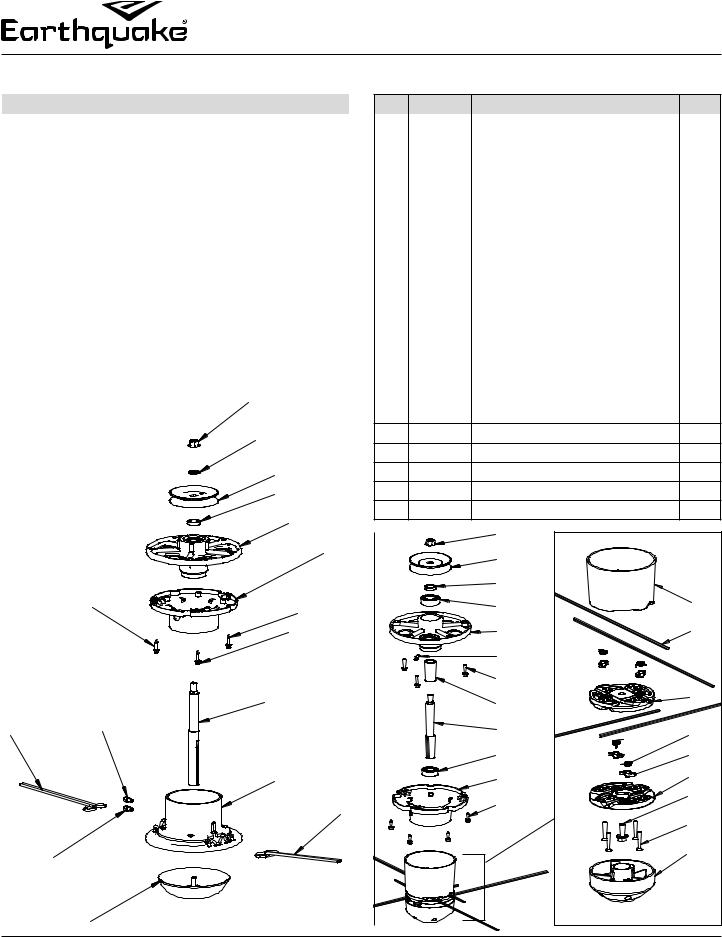

PARTS BREAKDOWN

Handlebars

KEY |

PART # |

DESCRIPTION |

QTY. |

1 |

19942 |

HANDLEBAR UPPER CAM ADJUST |

1 |

2 |

19901 |

GRIP HANDLEBAR FOAM |

1 |

3 |

19941 |

HANDLEBAR LOWER CAM ADJUST |

1 |

4 |

19912 |

HANDLE PIVOT PLASTIC MOLDING |

4 |

5 |

19913 |

CAM LEVER BOLT ASSEMBLY |

2 |

6 |

19914 |

THROTTLE CONTROL CABLE 21 MM |

1 |

|

|

TRAVEL |

|

6* |

17471 |

ASSY SWITCH ON/OFF |

1* |

7 |

60005019 |

CABLE & LEVER CONTROL LATCHING |

1 |

7* |

17527 |

CABLE CLUTCHWITH OUT |

1* |

|

|

SECONDARY ENGAGE |

|

8 |

19943 |

CONTROL BAIL |

1 |

8* |

17528 |

ACONTROL DIAL WITH CABLE |

1* |

|

|

ATTACHED |

|

9 |

19911 |

SCREW M2.9 X 13 PPHAB |

8 |

10 |

19975 |

WASHER M3 X 7 X .5 FLAT |

8 |

11 |

19908 |

BOLT M6 X 1.0 X 50 PPHMS |

2 |

12 |

19902 |

ROPE GUIDE M6 X 1.0 OPEN EYE |

1 |

13 |

19939 |

NUT M6 X 1.0 HBW |

1 |

14 |

W1265V0913 |

NUT M6 X 1.0 HNYLK GR8.8 ZN |

3 |

15 |

19910 |

NUT M8 X 1.25WBW |

2 |

16 |

19945 |

BOLT M8 X 1.25 X 20 HHFCS GR8.8 ZN |

4 |

|

|

|

|

* Not shown in image. |

5 |

|

8

11 |

|

2 |

|

|

|

|

6 |

14 |

|

|

|

|

|

7 |

14 |

13 |

12 |

11 |

|

|

1

9

4

10 |

10 |

|

9 |

||

|

5

4

15

3

16 |

16 |

20 |

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

Operator's Manual

Trimmer Mower 600050 Series

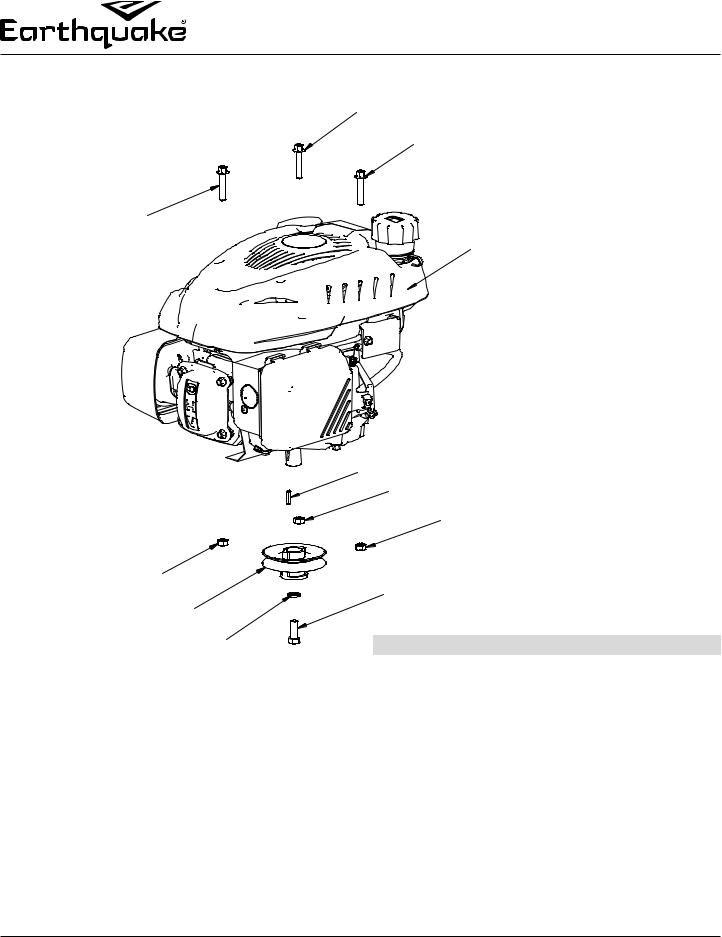

Engine and Pulley Attachment

6

7

3

4

6

6

1

2

7

7

5

KEY |

PART # |

DESCRIPTION |

QTY. |

|

|

|

|

|

186000 |

ENGINE 173CC VIPER VERT (SHOWN, |

1 |

|

|

FOR 600050V ONLY) |

|

|

|

|

|

1 |

60005070 |

ENGINE VERT BRIGGS 675 ST |

1 |

|

(NOT SHOWN, FOR 600050B ONLY) |

|

|

|

|

|

|

|

|

|

|

|

60005071 |

ENGINE VERT BRIGGS 675 CE ST |

1 |

|

|

(NOT SHOWN, FOR 600050BCE ONLY) |

|

|

|

|

|

2 |

19971 |

KEY 4MM X 4MM X 20MM |

1 |

|

|

|

|

3 |

19970 |

PULLEY AND BUSHINGWELDMENT |

1 |

|

|

(FOR 6000050V ONLY) |

|

|

|

|

|

|

60005013 |

PULLEY AND BUSHINGWELDMENT |

1 |

|

|

(FOR 6000050B/600050BCE) |

|

|

|

|

|

4 |

1916965 |

WASHER LOCK SPRING . 375 |

1 |

|

|

|

|

5 |

53194 |

BOLT 3/8-24 X 1 HH GR5 ZN F-T |

1 |

|

|

|

|

6 |

19922 |

BOLT M8 X 1.25 X 40 HHFCS GR8.8 ZN |

3 |

|

|

|

|

7 |

W1265V0900 |

NUT M8 X 1.25 H NYLK GR8.8 ZN |

3 |

|

|

|

|

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

21 |

Operator's Manual

Trimmer Mower 600050 Series

Trimmer Head - Standard Version |

Trimmer Head - Slide-Through Version |

KEY |

PART # |

DESCRIPTION |

QTY. |

|

|

|

|

1 |

19928 |

CUTTING HEAD SHAFT M10 X 1.5TOP |

1 |

|

|

THREAD |

|

|

|

|

|

2 |

19924 |

ASSEMBLY CUTTER HEAD ANDWRAP |

1 |

|

|

METRIC |

|

|

|

|

|

3 |

19923 |

HEIGHT GUIDE ASSEMBLY METRIC |

1 |

|

|

|

|

4 |

19958 |

ASSEMBLY JACKSHAFT HOUSING AND |

1 |

|

|

BEARINGS |

|

|

|

|

|

5 |

60005054 |

WRAP WEED |

1 |

|

|

|

|

6 |

19925 |

SPACER M17.5 X 23.5 X 6 |

1 |

|

|

|

|

7 |

19929 |

PULLEY CUTTING HEAD METRIC |

1 |

|

|

|

|

8 |

19920 |

SCREW M5 X 3 X 20 HWHA YLZN |

3 |

|

|

|

|

9 |

19919 |

BOLT M6 X 1.0 X 10 SRHCS |

2 |

|

|

|

|

10 |

19926 |

WASHER M10 X 21 X 1.1 FLAT |

1 |

|

|

|

|

11 |

64491 |

NUT FLANGE M10 |

1 |

|

|

|

|

12 |

60005009 |

LINE TRIM .125 X 21.25 RED |

2 |

|

|

|

|

|

|

11 |

|

|

10 |

|

7 |

|

6 |

|

4 |

|

5 |

8 |

8 |

|

|

|

8 |

1

12 |

9 |

|

2

12

9

3

KEY |

PART # |

DESCRIPTION |

QTY. |

|

|

|

|

1 |

16317 |

HOUSING JACKSHAFT STRINGTRIMMER |

1 |

|

|

|

|

3 |

16321 |

JACKSHAFT STRINGTRIMMER |

1 |

|

|

|

|

4 |

16337 |

WEED WRAP STRING TRIMMER |

1 |

|

|

|

|

5 |

16595 |

PULLY ASSEMBLY STRINGTRIMMER |

1 |

|

|

|

|

6 |

16598 |

FITTING GREASE STRAIGHT M6-1 |

1 |

|

|

|

|

7 |

16662 |

WEED HEAD TOP STRING TRIMMER |

1 |

|

|

|

|

8 |

16663 |

WEED HEAD MIDLEVEL STRING TRIMMER |

1 |

|

|

|

|

9 |

16664 |

WEED HEAD BOTTOM STRING TRIMMER |

3 |

|

|

|

|

10 |

16666 |

BUMP HEAD 2 STRINGTRIMMER |

2 |

|

|

|

|

11 |

16669 |

CAM WEED HEAD STRING TRIMMER |

4 |

|

|

|

|

12 |

16670 |

SPRING WEED HEAD STRING TRIMMER |

4 |

|

|

|

|

13 |

16779 |

BOLT M5-.8X20 SFH GR8.8 ZN |

3 |

|

|

|

|

14 |

16817 |

BOLT M5-.8X30 P FHMS GR8.8 ZN P-T |

4 |

|

|

|

|

15 |

17897 |

LINE 4M STRING TRIMMER |

PACK |

|

|

|

|

16 |

16903 |

NUT M10-1.5X13 HF NYLK GR8.8 ZN |

1 |

|

|

|

|

17 |

19925 |

SPACER M17.5 X 23.5 X 6 |

1 |

19 |

19931 |

SCREW M5 X 3 X 15 PHWH AB |

4 |

20 |

19945 |

BOLT M8 X 1.25 X 20 HHFCS GR8.8 ZN |

1 |

21 |

19959 |

BEARING ID 17 OD35 W10 |

1 |

22 |

19960 |

SPACER JACKSHAFT |

1 |

23 |

19966 |

BEARING ID17 OD40 W12 |

1 |

|

|

16 |

|

|

|

5 |

|

|

|

17 |

|

|

|

23 |

7 |

|

|

1 |

15 |

|

|

6 |

|

|

|

13 |

|

|

|

22 |

8 |

|

|

|

|

|

|

3 |

12 |

|

|

|

|

|

|

21 |

11 |

|

|

4 |

9 |

|

|

19 |

20 |

|

|

|

|

|

|

|

14 |

|

|

|

10 |

22 |

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

Operator's Manual

Trimmer Mower 600050 Series

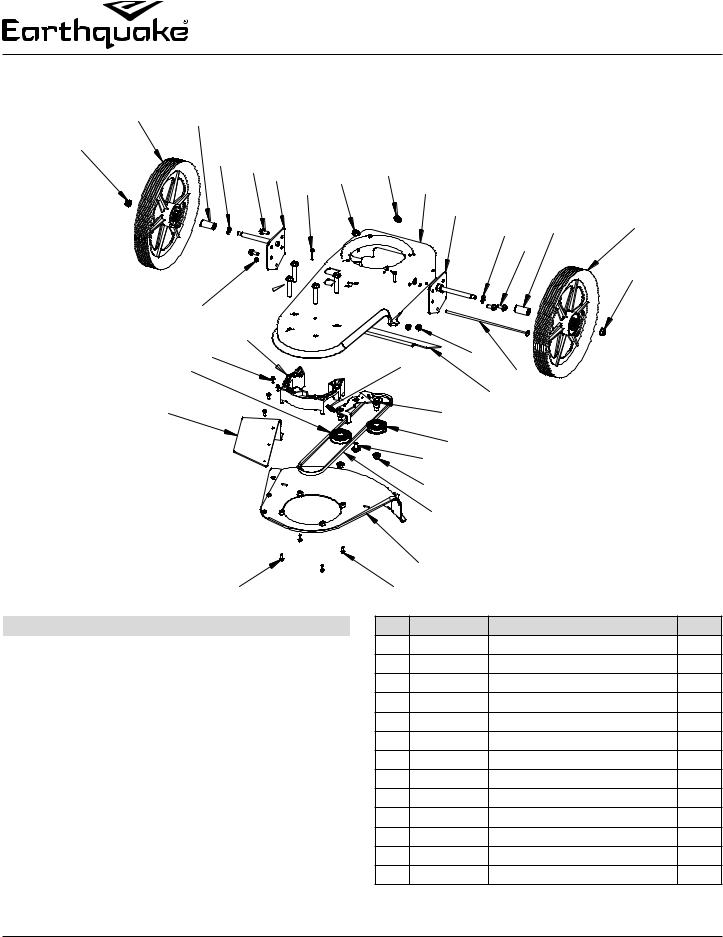

Base Unit

25 23

18

24 |

20 |

|

|

|

9 |

18 |

|

|

|

||

|

|

|

8 |

225

2

21

12

4

|

|

6 |

|

|

|

|

|

KEY |

PART # |

DESCRIPTION |

QTY. |

|

|

|

|

1 |

19961 |

DECK FRAME METRIC |

1 |

|

|

|

|

2 |

60005024 |

JACKSHAFT ASSEMBLY SPACER |

1 |

|

|

|

|

3 |

60005021 |

SHIELDTRIMMER BLK |

1 |

|

|

|

|

4 |

60005010 |

ASSEMBLY GUARD |

1 |

|

|

|

|

5 |

19927 |

BOLT M10 X 1.5 X 60 HHFCS |

4 |

|

|

|

|

6 |

19920 |

SCREW M5 X 3 X 20 HWHA YLZN |

4 |

|

|

|

|

7 |

19944 |

BUSHING M12 X 23 RUBBER |

1 |

|

|

|

|

8 |

19940 |

SCREW M5 X 3 X 30 |

2 |

|

|

|

|

9 |

19938 |

AXLE AND BRACKET ASSEMBLY METRIC |

2 |

|

|

|

|

10 |

19932 |

IDLER ASSEMBLY DBL/ZINC METRIC |

1 |

|

|

|

|

11 |

60005008 |

SPRING EXTENSION 1.5LG |

1 |

|

|

|

|

12 |

19968 |

ASSEMBLYV PULLEY AND BEARING |

1 |

|

|

|

|

7

1

9

24 23 25

20

18

19

11 |

|

16 |

|

|

|

|

|

|

|

17 |

|

|

10 |

|

|

|

13 |

|

|

|

15 |

|

|

|

18 |

|

|

|

14 |

|

|

|

3 |

|

|

6 |

|

|

|

KEY |

PART # |

DESCRIPTION |

QTY. |

13 |

19934 |

ASSEMBLY 3L PULLEY AND BEARING |

1 |

14 |

60005003 |

BELT |

1 |

15 |

19936 |

BOLT M10 X 1.5 X 20 HHF SHLDR 1 |

1 |

16 |

19937 |

BOLT M6 X 1.0 X 285 CRG P-T |

1 |

17 |

60005018 |

TRAILING SHIELD 13.28 V |

1 |

18 |

64491 |

NUT FLANGE M10 |

5 |

19 |

64132 |

NUT M8 X 1.25 HSF |

4 |

20 |

19945 |

BOLT M8 X 1.25 X 20 HHFCS GR8.8 ZN |

4 |

21 |

19931 |

SCREW M5 X 3 X 15 PHWH AB |

4 |

22 |

W1265V0913 |

NUT M6 X 1.0 HNYLK GR8.8 ZN |

1 |

23 |

19904 |

SPACER WHEEL 14 X 22 X 43 |

2 |

24 |

60005029 |

WASHER SPRING 1/2 X 1 X .021 |

2 |

25 |

19983 |

ASSEMBLY TIRE RIM AND BEARINGS |

2 |

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

23 |

Operator's Manual

Trimmer Mower 600050 Series

24 |

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

Operator's Manual

Trimmer Mower 600050 Series

WARRANTY TERMS AND CONDITIONS

PRODUCT WARRANTY: 1-YEAR LIMITED WARRANTY

Ardisam, Inc. (Ardisam) warrants the product(s) under a one-year limited warranty to be free from defects in the material or workmanship or both for a period not exceeding twelve consecutive months from the date of original purchase by the first retail consumer or first commercial end user.“Consumer use“ means personal recreational use by a retail consumer.“Commercial use“ or “commercial application“ means all other uses, including use for commercial, income producing or rental purposes. Once a product has experienced commercial use, it shall thereafter be considered as a commercial use product for the purpose of this warranty. This warranty applies to the original owner that provides a proof of purchase. The warranty is not transferable. The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues for the twelve month consecutive period thereafter. Any unit used in a commercial application is covered for a period of 90 days after purchase by the first commercial end user. For the warranty to be valid, the product must be registered online, or the warranty card must be filled out and received by Ardisam, within 30 days of purchase. Ardisam shall not be obligated to ship any repair or replacement product to any location outside of the United States of America or Canada.*

For replacement parts, phone 800-345-6007.

*This warranty policy applies only to products which have not been subjected to negligent use, misuse, uses other than those indicated in the product’s operator’s manual, alteration, accident, use of unauthorized parts, failure to perform periodic maintenance as specified in product’s operator’s manual, normal wear and tear, use of unauthorized parts or repairs performed at unauthorized service centers. There is no other expressed warranty. Implied warranties, including those of merchantability and fitness for a particular purpose, are limited to one year from purchase, or to the extent permitted by law. All other implied warranties are excluded. Liability for incidental or consequential damages are excluded to the extent exclusion is permitted by law. Ardisam does not assume, and does not authorize any other person to assume for Ardisam, any liability in connection with the sale of Ardisam products. To be at“No Charge,”warranty work must be sent directly to and performed by Ardisam or an Ardisam Authorized Warranty Service Facility. To obtain warranty service and/or replacement instructions, contact the Ardisam Customer Service Department at 800-345-6007. If you choose to ship your product to Ardisam for warranty repair, you must first have prior approval from Ardisam by calling the Ardisam Customer Service Department for a return material authorization number (RMA#). Under these circumstances, all items must be shipped prepaid. Ardisam will at no charge, repair or replace, at the discretion of Ardisam, any defective part which satisfies all conditions stated above. Ardisam retains the right to change models, specifications and price without notice. Ardisam shall not be obligated to ship any repair or replacement product to any location outside of the United States of America or Canada.

NOTE: For detailed information on this product’s Engine Warranty, refer to the warranty section in the Engine Manual that accompanies this Operator’s Manual.

17649-REV1

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

25 |

Operator's Manual

Trimmer Mower 600050 Series

NOTES

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

_______________________________________________________________________________________________________

26 |

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5 |

Loading...

Loading...