EarthQuake 1692327, 9010140, 9070300, 9010400, 9050300 User Manual

...

Operator's Manual

Original Operating Instructions

Chipper/

Shredders

|

|

|

|

Includes: |

|

|

|

Model No. |

Description |

||

9050300 |

196cc Viper Earthquake Chipper / Shredder |

||

9050140 |

196cc Viper Earthquake Chipper / Shredder (CE) |

||

9060300 |

8.50 Torque Rated Briggs Earthquake Chipper / Shredder |

||

9060140 |

8.25 Torque Rated Briggs Earthquake Chipper / Shredder (CE) |

||

9070300 |

11.50 Torque Rated Briggs Earthquake Chipper / Shredder |

||

9010400 |

14.50 Torque Rated Briggs Earthquake Chipper / Shredder |

||

9010140 |

14.50 Torque Rated Briggs Earthquake Chipper / Shredder (CE) |

||

1692327 |

Tow Bar Kit |

||

1692210 |

Vacuum Kit |

||

Get parts online at www.getearthquake.com

1713250 Rev. 04/19/12

|

Table of Contents |

Safety Rules & Information...................................................................................................................................... |

3 |

Safety Decals............................................................................................................................................................................................................................. |

7 |

Safety Icons...................................................................................................................................................................................................................... |

8 |

Identification Numbers................................................................................................................................................................................................ |

9 |

Initial Assembly..................................................................................................................................................... |

10 |

Features & Controls............................................................................................................................................... |

14 |

Operation............................................................................................................................................................... |

15 |

General Operating Safety.......................................................................................................................................................................................... |

15 |

Adding Fuel.................................................................................................................................................................................................................... |

15 |

Starting the Engine...................................................................................................................................................................................................... |

15 |

Stopping the Engine................................................................................................................................................................................................... |

16 |

Processing Materials.................................................................................................................................................................................................... |

16 |

Chipping / Shredding Recommendations.......................................................................................................................................................... |

17 |

Storage............................................................................................................................................................................................................................. |

17 |

Regular Maintenance............................................................................................................................................ |

18 |

Maintenance Schedule & Procedures................................................................................................................................................................... |

18 |

Check for Loose Hardware........................................................................................................................................................................................ |

18 |

Check Safety Labels..................................................................................................................................................................................................... |

18 |

Inspect Cone, Hopper, & Guards............................................................................................................................................................................. |

18 |

Clean Debris from Engine & Chipper.................................................................................................................................................................... |

19 |

Inspect / Rotate Shredding Hammers.................................................................................................................................................................. |

19 |

Inspect Chipping Knives............................................................................................................................................................................................ |

20 |

Check / Change Engine Air Cleaner....................................................................................................................................................................... |

20 |

Replace Spark Plug...................................................................................................................................................................................................... |

20 |

Engine Oil Type and Capacity.................................................................................................................................................................................. |

21 |

Check Engine Oil Level............................................................................................................................................................................................... |

21 |

Change Engine Oil....................................................................................................................................................................................................... |

21 |

Troubleshooting & Repair.................................................................................................................................... |

22 |

Troubleshooting Chart............................................................................................................................................................................................... |

22 |

Repair................................................................................................................................................................................................................................ |

23 |

Specifications........................................................................................................................................................ |

25 |

Parts & Accessories................................................................................................................................................ |

25 |

Parts Explosions & Listings......................................................................................................................................................................................... |

26-32 |

Certificates of Conformity........................................................................................................................................................................................... |

33-39 |

Warranty................................................................................................................................................................................................................................... |

40 |

NOTE: In this manual, “left” and “right” are referred to as seen from the operating position.

Page 2 |

1-800-345-6007 |

GetEarthquake.com

Safety Rules & Information

Operating Safety

Congratulations on purchasing a superior-quality piece of lawn and garden equipment. Our products are designed and manufactured to meet or exceed all industry standards for safety.

Power equipment is only as safe as the operator. If it is misused, or not properly maintained, it can be dangerous! Remember, you are responsible for your safety and that of those around you.

Use common sense, and think through what you are doing. If you are not sure that the task you are about to perform can be safely done with the equipment you have chosen, ask a professional: contact your local authorized dealer.

Read the Manual

The operator’s manual contains important safety information you need to be aware

of BEFORE you operate your unit as well as DURING operation.

Safe operating techniques, an explanation of the product’s features and controls, and maintenance information is included to help you get the most out of your equipment investment.

Be sure to completely read the Safety Rules and Information found on the following pages. Also completely read the Operation section.

Children

Tragic accidents can occur with children. Do not allow them anywhere near the area of operation. Children are often attracted to the unit and usage activity. Never assume

that children will remain where you last saw them. If there is a risk that children may enter the area where you are operating, have another responsible adult watch them.

1-800-345-6007 |

Page 3 |

GetEarthquake.com

Safety Rules and Information

Moving Parts

This equipment has many moving parts that can injure you or someone else. However, if you follow all the rules in this book, the unit is safe to operate.

The chipper/shredder has spinning blades that can amputate hands and feet. Do not allow anyone near the equipment while it is running! Do not place hands or feet in the hopper or chipper cone, or discharge chute.

Thrown Objects

This unit discharges debris at high speeds. Always wear protective goggles and do not operate without the debris bag in place. Also, do not allow anyone in the area while the unit is running! If someone does enter the area, shut the unit off immediately until they leave. Organize the work area prior to starting work.

Fuel and Maintenance

Gasoline is extremely flammable. Its vapors are also extremely flammable and can travel to distant ignition sources. Gasoline must only be used as a fuel, not as a solvent or cleaner. It should never be stored any place where its vapors can build up or travel to an ignition source like a pilot light. Fuel belongs in an

approved, plastic, sealed gas can, or in the fuel tank with the cap securely closed. Spilled fuel needs to be cleaned up immediately.

Proper maintenance is critical to the safety and performance of your unit. Be sure to perform the maintenance procedures listed in this manual, especially periodically testing the safety system.

Page 4 |

1-800-345-6007 |

GetEarthquake.com

Safety Rules & Information

Read these safety rules and follow them closely. Failure to obey these rules could result in loss of control of unit, severe personal injury or death to you, or bystanders, or damage to property or equipment.

This unit is capable of amputating hands and feet and throwing objects. The triangle in text signifies important cautions or warnings which must be followed.

in text signifies important cautions or warnings which must be followed.

Preparation

1.Do not operate the equipment without wearing adequate outer garments and safety goggles. Avoid loose-fitting clothes and use protective footwear that will improve footing on slippery surfaces.

Training

1.Read the operating and service instructions carefully. Be thoroughly familiar with the controls and the proper use of the equipment. Know how to stop the unit and disengage the control quickly.

2.Keep the area of operation clear of all persons, particularly small children, and pets.

General operation

1.Read, understand, and follow all instructions in the manual and on the unit before starting.

2.Do not put hands or feet near rotating parts or under the machine. Keep clear of the discharge opening at all times.

3.Only allow responsible adults, who are familiar with the instructions, to operate the unit (local regulations can restrict operator age).

4.Be sure the area is clear of other people before operating. Stop the unit if anyone enters the area.

5.Never direct discharge material toward anyone. Avoid discharging material against a wall or obstruction. Material may ricochet back toward the operator.

6.Operate the machine only in daylight or good artificial light.

7.Do not operate the unit while under the influence of alcohol or drugs.

8.Always wear eye and hearing protection when operating this unit.

9.Keep in mind the operator is responsible for accidents occurring to other people or property.

10. It is a violation of California Public Resource Code Section 4442 to use or operate the engine on or near any forestcovered, brush-covered, or grass-covered land unless the exhaust system is equipped with a spark arrester meeting any applicable local or state laws. Other states or federal areas may have similar laws.

11. Always operate the chipper/shredder outdoors, on a firm, level, earthen or grassy surface where the unit will be stable and stay in position. Never attempt to operate the unit on a slope, or on a wet or slippery surface where you could slip and fall toward the chipper cone or hopper openings.

12. Never operate the chipper/shredder on asphalt, concrete, or other hard surfaces as material being ejected out of the discharge chute could ricochet, causing injury to you or bystanders.

13. Always obey the size limitations for tree limbs and branches stated in the Waste Materials Guide portion of this manual.

14. Never leave the machine running unattended. Always

turn off the engine, wait for the rotor to come to a complete stop, and disconnect the spark plug before leaving the area. Always move the unit to a safe storage area when not in use.

15. Always maintain secure footing and solid balance while starting or operating the chipper/shredder. Never lean directly over the machine.

16. Always stand to the side of the chipper cone when feeding tree limbs and branches into the unit, as tree limbs, branches, and harder woods may kick back while being chipped.

17. Always keep hands out of the chipper cone and shredder hopper when feeding materials. Never wrap fingers tightly around branches as you are feeding them into the unit, as a sudden inward surge could pull your hands and arms into the unit.

18. Never allow material to build up in the discharge area or shredding chamber, as this may cause new material being fed into the machine to kickback with sufficient force to injure you or other bystanders.

19. Never allow material to build up around the engine during chipper/shredder operation. This could result in a fire, or overheating of the engine.

20. Never attempt to reposition or move the chipper/ shredder unit while it is running. Doing so could cause the machine to tip over, and reaching to steady the unit could result in accidental insertion of your hands into the chipper cone or shredder hopper areas.

21. Never continue to operate the machine if it starts making unusual noise or vibration. Shut the engine off immediately, allow the rotor to stop, disconnect the spark plug wire and secure the wire away from the spark plug. Inspect the unit for any signs of damage or foreign material in the chipping or shredding areas. Remove any solid material that may be preventing the unit from operating properly.

22. Never attempt to clear clogs from the chipper cone, shredder hopper or discharge chute while the unit is running. Always shut the engine off, allow the rotor to come to a complete stop, and remove the spark plug wire from the spark plug before removing excess materials.

23. Never attempt to perform any maintenance, repairs, or attachment of accessories while the unit is running. Always shut the unit off, allow the rotor to come to a

complete stop, and remove the spark plug wire from the spark plug before beginning these activities.

24. Always make sure that the shredding chamber, shredder hopper, and chipper cone are empty before starting the unit after it has been idle. Attempting to start the unit with material in these areas could cause the engine starting cord to stop suddenly, injuring your hand and fingers, or toppling the unit over. Vibration is generally a warning sign of trouble.

25. Before cleaning, repairing, or inspecting, shut off the engine and make certain that all moving parts have

1-800-345-6007 |

Page 5 |

GetEarthquake.com

come to a complete stop. Disconnect the spark plug wire and secure the wire away from the spark plug to prevent accidental starting.

26. Do not operate the engine in a confined space where dangerous carbon monoxide fumes can collect.

27. Never operate the machine without proper guards, plates, or other safety protective devices in place.

28.Use only attachments and accessories approved of by the manufacturer of the machine.

transporting and storage

1.Always observe safe refueling and fuel handling practices when refueling the unit after transportation or storage.

2.Never store the unit (with fuel) in an enclosed poorly ventilated structure. Fuel vapors can travel to an ignition source (such as a furnace, water heater, etc.) and cause an explosion. Fuel vapor is also toxic to humans and animals.

3.Always use the hopper handle and built-in wheels to move the chipper/shredder. Never lift the unit using the fuel tank for support. If the unit must be lifted , always use at least two people, and always grip the unit securely using the front leg and hopper handle.

4.Always follow the engine manual instructions for storage preparations before storing the unit for both short and long term periods.

5.Always follow the engine manual instructions for proper start-up procedures when returning the unit to service.

6.Never store the unit or fuel container inside where there is an open flame or pilot light, such as in a water heater. Allow unit to cool before storing.

Children

Tragic accidents can occur if the operator is not alert to the presence of children. Children are often attracted to the unit and the operating activity. Never assume that children will remain where you last saw them.

1.Keep children out of the work area and under the watchful care of another responsible adult.

2.Be alert and turn unit off if children enter the area.

3.Never allow children to operate the unit.

Emissions

1.Engine exhaust from this product contains chemicals known, in certain quantities, to cause cancer, birth defects, or other reproductive harm.

2.Look for the relevant Emissions Durability Period and Air Index information on the engine emissions label.

Ignition System

1.This spark ignition system complies with Canadian ICES002.

Safety Rules and Information

Service and Maintenance

Safe Handling of Gasoline

1.Extinguish all cigarettes, cigars, pipes, and other sources of ignition.

2.Use only approved gasoline containers.

3.Never remove the gas cap or add fuel with the engine running. Allow the engine to cool before refueling.

4.Never fuel the machine indoors.

5.Never store the machine or fuel container where there is an open flame, spark, or pilot light such as near a water heater or other appliance.

6.Never fill containers inside a vehicle or on a truck bed with a plastic bed liner. Always place containers on the ground away from your vehicle before filling.

7.Remove gas-powered equipment from the truck or trailer and refuel it on the ground. If this is not possible, then refuel such equipment on a trailer with a portable container, rather than from a gasoline dispenser nozzle.

Page 6 |

1-800-345-6007 |

GetEarthquake.com

Safety Rules and Information

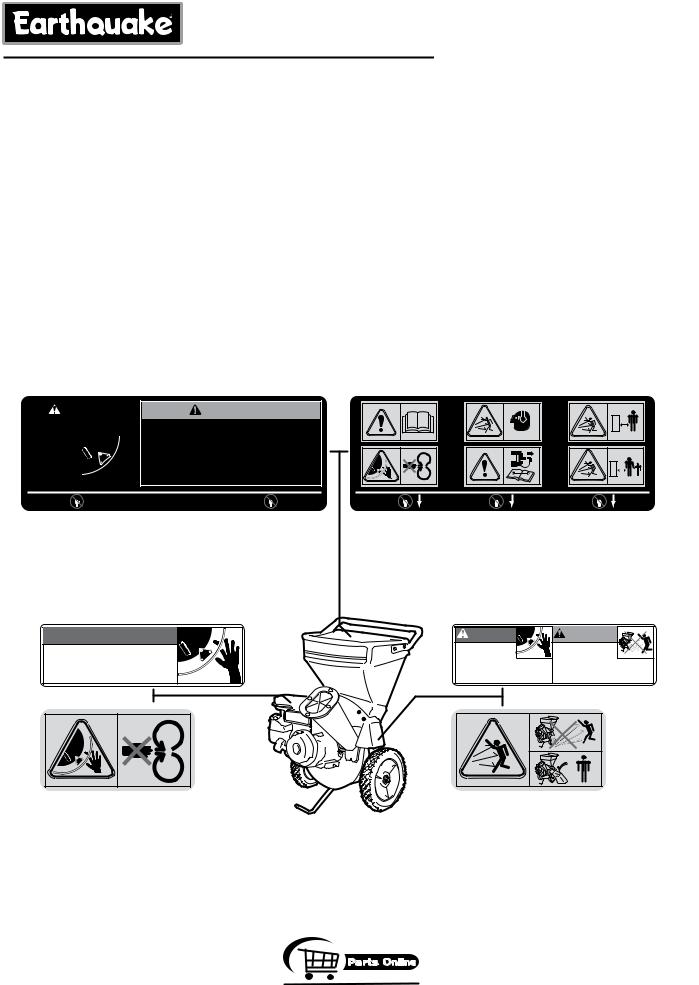

Safety Decals

This unit has been designed and manufactured to provide you with the safety and reliability you would expect from an industry leader in outdoor power equipment manufacturing.

Although reading this manual and the safety instructions it contains will provide you with the necessary basic knowledge to operate this equipment safely and effectively, we have placed several safety labels on the unit to remind you of this important information while you are operating your unit.

All DANGER, WARNING, CAUTION and instructional messages on your unit should be carefully read and obeyed. Personal bodily injury can result when these instructions are not followed. The information is for your safety and it is important! The safety decals below are on your unit.

If any of these decals are lost or damaged, replace them at once. See your local dealer for replacements.

These labels are easily applied and will act as a constant visual reminder to you, and others who may use the equipment, to follow the safety instructions necessary for safe, effective operation.

Decal - Operating Instructions,

North American Models

DANGER |

WARNING |

|

||

Amputation Hazard |

Avoid Serious Injury or Death |

|

||

To avoid serious |

|

•Read and follow the operating instructions. |

•Keep safety devices (guards & shields) |

|

|

•Know the location and function of all controls. |

in place and working. |

|

|

personal injury from |

|

•Wear proper safety goggles and hearing |

•Do not operate when children or others |

|

rotating cutting |

|

protection. |

are present. |

|

blades, keep hands |

|

•Never wear loose clothing. |

•Be sure all moving parts have stopped |

|

out of inlet while |

|

•Keep hands and clothing clear of material |

before placing hands near the cutting |

|

|

being pulled into the unit. |

blades. |

|

|

machine is running. |

|

|

||

|

•Keep hands and feet away from the discharge |

•When leaving the machine, shut off the |

||

|

|

chute area. |

engine. |

|

|

NO HANDS BELOW THIS LINE |

1731918 |

||

Decal - Danger,

Rotating Cutting Blades,

North American Models

DANGER

DANGER

Amputation Hazard

To avoid serious personal injury from rotating cutting blades, keep hands out of inlet while

machine is running. |

1732039 |

1731920

Decal - Danger,

Rotating Cutting Blades,

CE Models

Decal - Operating Instructions, CE

Models

1731919

Decal - Danger,

Rotating Cutting Blades, Warning, Debris,

North American Models

DANGER |

WARNING |

Amputation |

Thrown Objects |

Hazard |

Hazard |

To avoid serious personal injury from |

To avoid serious personal injury from |

1732181 |

rotating cutting blades, keep hands out |

discharged debris, never operate |

|

of discharge while machine is running. |

without the discharge bag installed. |

1731921 |

Decal - Danger,

Thrown Objects, Do Not Operate

Without Collection Bag,

CE Models

1-800-345-6007 |

Page 7 |

GetEarthquake.com

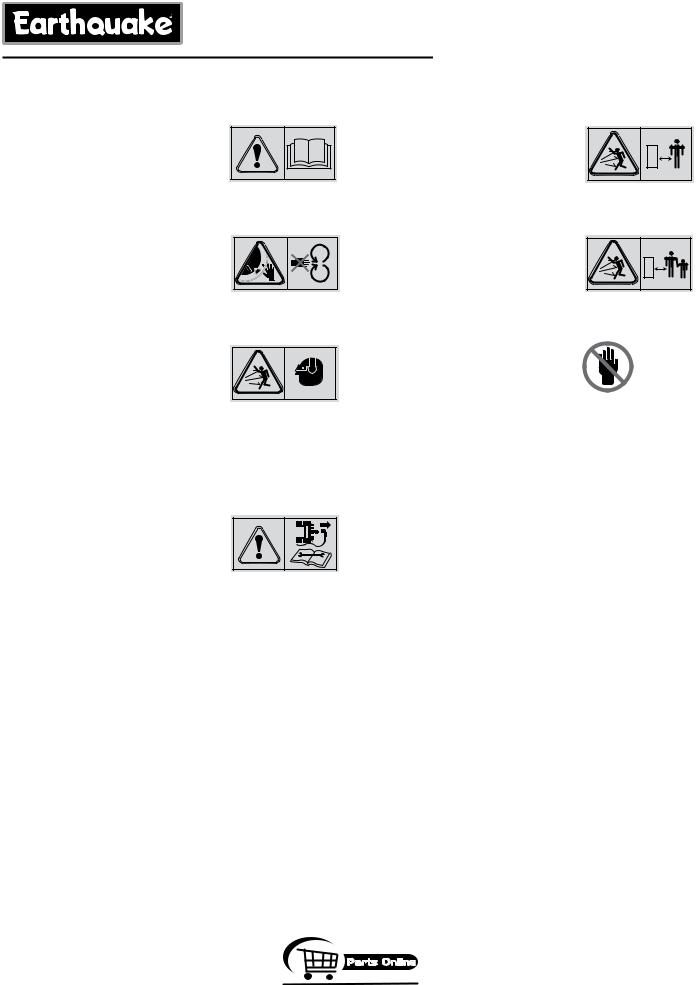

Safety Icons (European Models)

Warning: Read Operator’s Manual.

Read and understand the Operator’s

Manual before using this machine.

Danger: Amputation Hazard.

To avoid serious personal injury from rotating cutting blades, keep hands out of inlet while machine is running.

Danger: Wear Appropriate Safety Equipment.

This machine is capable of throwing objects and debris. Always wear safety goggles while operating.

This machine’s operating sound power level is 109 dB(A) or more. Wear hearing protection while operating.

Warning: Disconnect the Spark Plug Wire Before Servicing.

Disconnect the spark plug wire, and secure it away from the spark plug before servicing the unit.

Safety Rules and Information

Danger: Thrown Objects.

This machine is capable of throwing objects and debris. Keep bystanders away.

Danger: Thrown Objects.

This machine is capable of throwing objects and debris. Keep bystanders and children away when engine is running.

Danger: Do Not Place Hands in the Machine.

To avoid serious personal injury from rotating cutting blades, keep hands out of inlet while machine is running. Do not place hands in areas where this symbol is present.

Page 8 |

1-800-345-6007 |

GetEarthquake.com

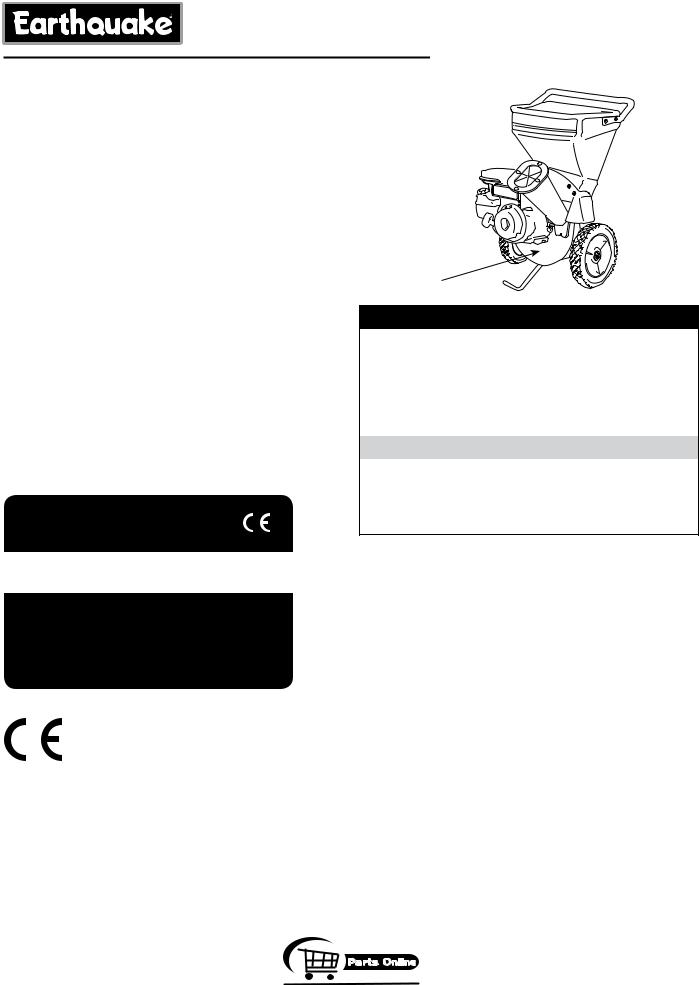

Identification Numbers

When contacting your authorized dealer for replacement parts, service, or information you MUST have these numbers.

Record your model name/number, manufacturer’s identification numbers, and engine serial numbers in the space provided for easy access. These numbers can be found in the locations shown.

NOTE: For location of engine identification numbers, refer to the engine owner’s manual.

CE Models: Place the extra copy of the identification tag in the manual.

CE Identification Tag Markings

This unit complies with European Harmonized Lawn Mower Standard EN 836, European Machinery Directive 98/37/EC, and European EMC Directive 89/336/EC

*Tested according to EN836:1997/A2:2001

**Tested according to 2000/14/EC

ARDISAM, INC.

1160 8th Avenue | Cumberland, WI 54829 | USA

Serial No.

LBLINFOXXXXXX

Model: XXXXXXX Year: XXXX

Type: Chipper Shredder Mass: XX kg

Max. Operating Speed: XXXX rpm

LPA (dBA): XXX LWA (dBA): XXX

Intended Use / Foreseeable Misuse

This is a petrol engine-powered chipper/shredder that breaks up leaves and wooded pieces such as tree branches, brush and limbs into smaller volume via a high-speed rotor containing chipping blades and shredding hammers. It shall not be used for any other purpose.

Safety Rules and Information

ID Tag

PRODUCT Reference Data

Model Description Name/Number

Unit PART Number |

Unit SERIAL Number |

|

|

Dealer Name |

Date Purchased |

|

|

|

ENGINE Reference Data |

|

|

|

|

Engine Make |

|

Engine Model |

|

|

|

Engine Type/Spec |

|

Engine Code/Serial Number |

|

|

|

CE Specifications

Model Number: 9060140 / 9010140

Engine Maximum RPMs: 3700

Power Rating: 4 kW

Mass: 52kg

Noise Guaranteed Sound Power (LwA): 109 dB(A)

Noise Sound Pressure Level (LpA): 96 dB(A)

1-800-345-6007 |

Page 9 |

GetEarthquake.com

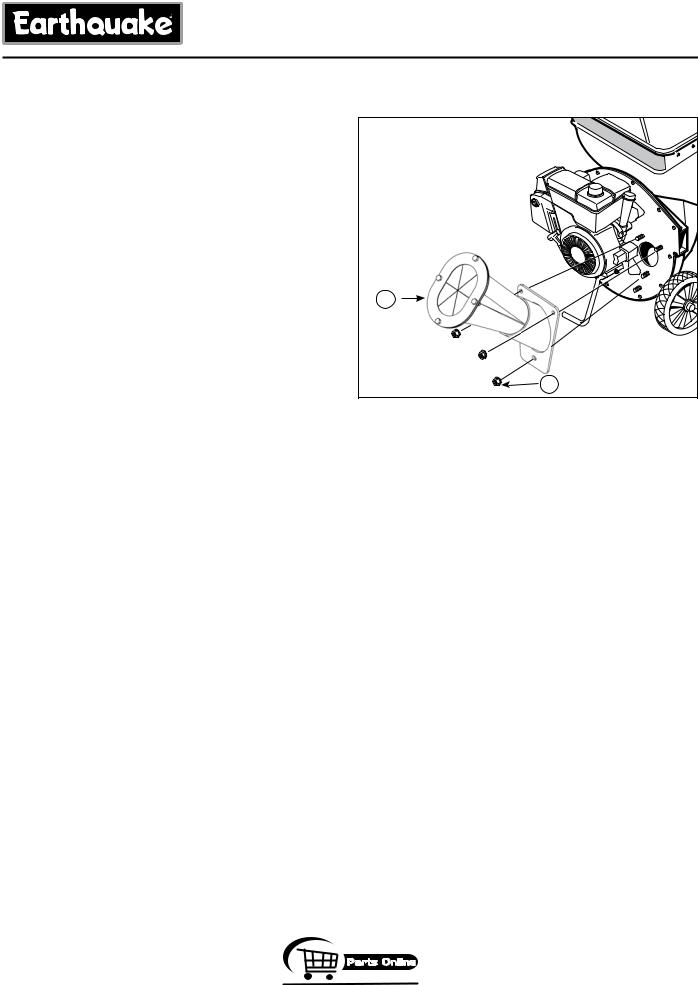

Initial Assembly

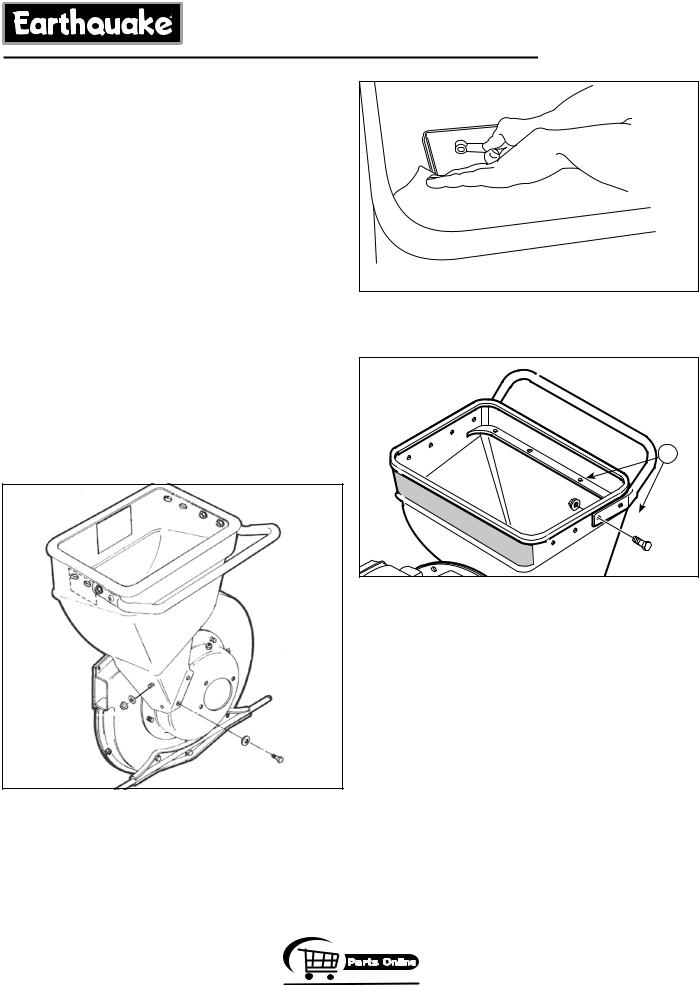

Install Chipper Cone - All Models

1 . Position the chipper cone (A) over the three 5/16-18 threaded studs protruding from the engine plate, and attach using three 5/16-18 flange nuts (B).

2.Rotate cone and cone base away from engine so cone does not contact engine.

3.Tighten the flange nuts securely.

Initial Assembly

A |

B |

Figure 18. Installing the Chipper Cone

A.Metal Cone Assembly

B.5/18-18 Flange Nut

Page 10 |

1-800-345-6007 |

GetEarthquake.com

Install the Hopper - All Models

1.Attach the hopper to the rotor housing. Make sure to engage the metal lip of the hopper liner inside the housing.

2.Secure the hopper to the rotor housing using two 5/16 x 1/2 hex head bolts, two 5/16 flat washers (Figure 19). Do not tighten hardware at this time.

3.See Figure 20. From the inside of the hopper install one 5/16-18 flange nut on each 5/16 weld stud. Finger tighten only at this time.

4.Check that the hopper is seated correctly and tighten all hardware.

Install the Handle - All Models

1.Lift the hopper handle up until the outer holes in the handle align with the holes in the shredder hopper and secure with 1/4-20 x 3/4 screws, washers, and nuts (A, Figure 21). Insert the screws from the outside of the shredder hopper.

Initial Assembly

Figure 20. Installing Hardware Inside the Hopper

A |

Figure 21. Installing the Hopper Handle

A. 1/4-20 x 3/4 Screw & Nut

Figure 19. Attaching the Hopper

1-800-345-6007 |

Page 11 |

GetEarthquake.com

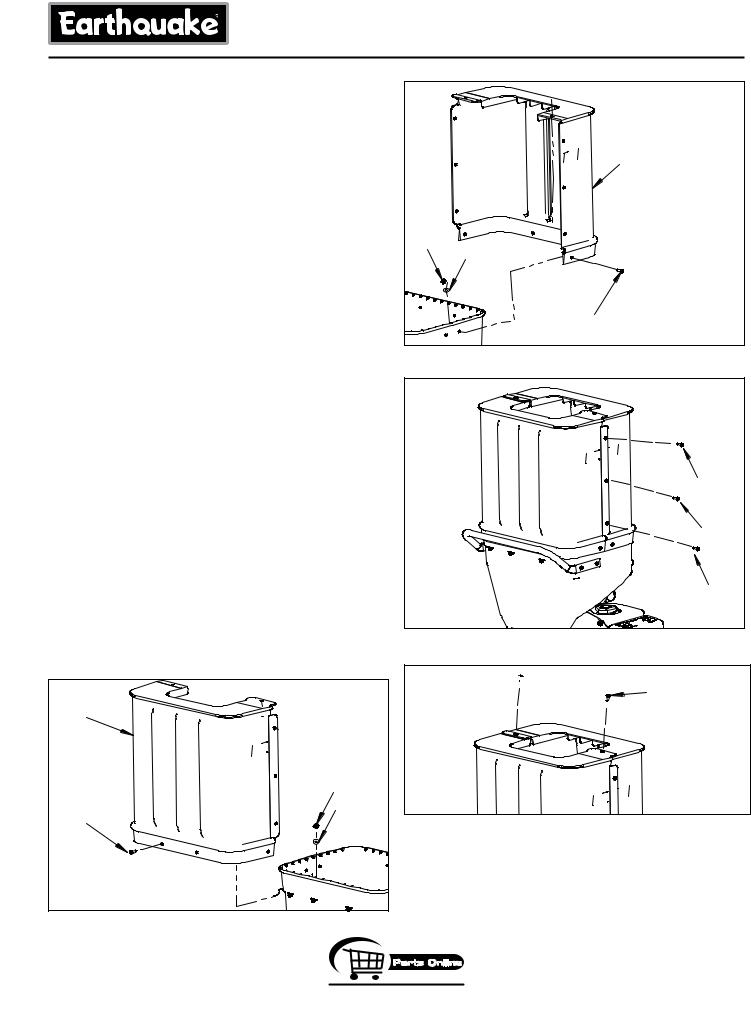

Attaching hopper extension to hopper

For European models only (9050140, 9060140, and 9010140)

Tools Required:

5/32” Hex drive wrench (i.e: allen wrench) 7/16”Wrench for 1/4-20 flange nut

NOTE: Assemble extension before adding fuel or engine oil.

To attach the hopper extension:

1)Before bolting the handle into position, slide one hopper extension half (1709470) over the rim of the hopper. The groove

around the inside bottom of the hopper extension should fit over the rim around the top of the hopper. SEE FIGURE 22.

2)Ensuring the hopper and hopper extension holes are now aligned along the top rim of the hopper, place a 1/4-20 x 3/4 bolts (1960507) through each of the four holes in the extension

and hopper. Secure bolts in place with the included 17/64 x 5/8 flat washers (1921319) and 1/4-20 flange nuts (1930642). DO

NOT fully tighten hardware at this point. SEE FIGURE 22.

3)Bolt handle into position using appropriate hardware. Lay the unit down, resting the handle on a piece of cardboard to prevent scratching.

4)Follow Step 1 to install the second extension half to the opposite side of the hopper. Again, the bottom groove of the hopper extension should fit over the rim at the top of the hopper. Align

the bolt holes between the top of the hopper and bottom of the hopper extension and insert hardware. SEE FIGURE 23.

5)Place a 1/4-20 x 3/4 bolt (1960507) in each of the three holes

along the two seams of the joined hopper extension halves. Secure each bolt with a flat washer and flange nut. DO NOT fully tighten. SEE FIGURE 24.

6)Place bolt through each of the two holes on top of the joined hopper extension. Secure with flat washer and flange nut. SEE FIGURE 25.

7)Once all hardware has been inserted, use 5/32” allen wrench and 7/16” wrench to fully tighten all hardware, including those around hopper rim and along the hopper extension seams.

hopper extension |

ange nut |

at washer |

1/4-20 bolt |

Figure 22

hopper extension

ange nut

at washer

1/4-20 bolt

Figure 23

1/4-20 bolt

1/4-20 bolt

1/4-20 bolt

Figure 24

1/4-20 bolt

1/4-20 bolt

1/4-20 bolt

Figure 25

Page 12 |

1-800-345-6007 |

GetEarthquake.com

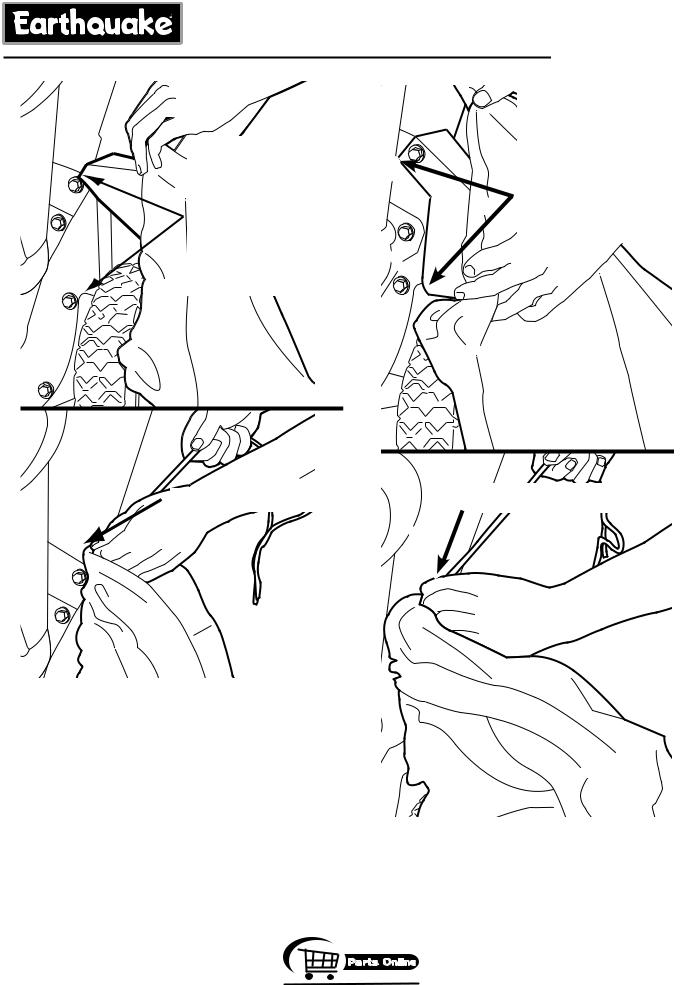

Lift discharge |

chute and slide |

bag over chute. |

Make sure bag |

noose fits over |

top of discharge |

chute and notch |

in chute bottom. |

Pull drawstring tight. |

Figure 26. Discharge Bag - North American Models

Install Discharge Bag

This product comes with a discharge bag for collection of debris as it exits the discharge chute. Install the bag as shown in Figure 26 or 27.

Add Engine Oil

Refer to “Engine Oil Type and Capacity” in the Regular Maintenance section for oil type and fill procedures.

Initial Assembly

Slide bag over discharge chute. Make sure bag noose fits over top of discharge chute and notch in chute bottom.

Pull drawstring tight.

Figure 27. Discharge Bag - CE Models

Add Fuel

Refer to “Adding Fuel” in the Operation section for fuel specifications and filling procedures.

1-800-345-6007 |

Page 13 |

GetEarthquake.com

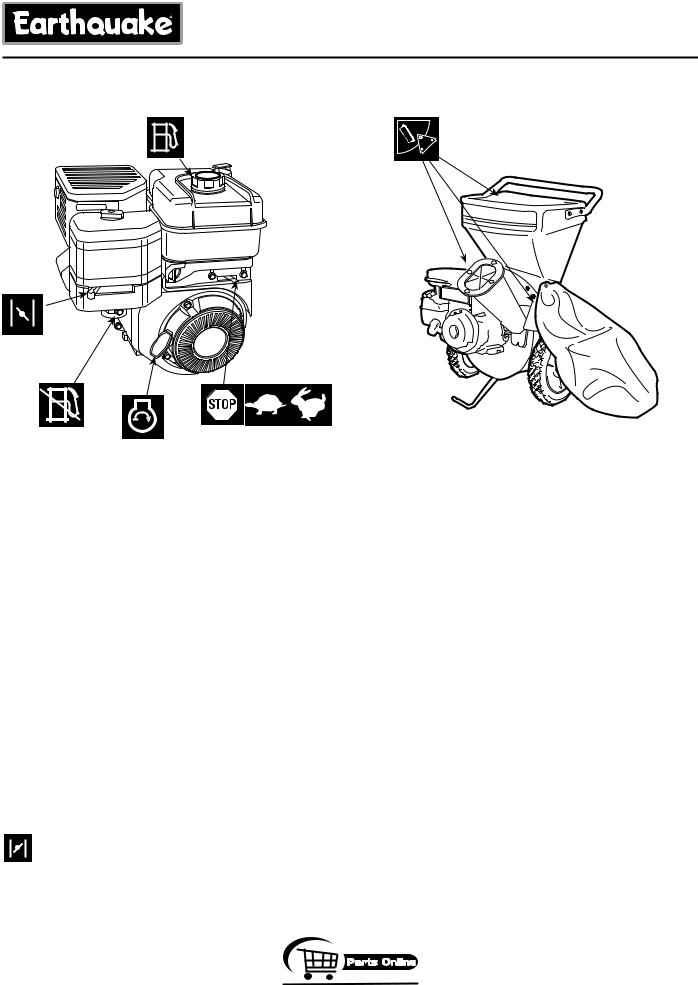

Features and Controls

Figure 1. Controls

Control Functions

The information below briefly describes the function of individual controls. Operating requires the combined use of several controls applied in specific sequences. To learn what combination and sequence of controls to use for various tasks see the OPERATION section.

Engine Stop / Throttle Control

Engine Stop / Throttle Control

The engine stop / throttle control lever controls turn the engine off and controls the engine speed. Move the throttle right to increase engine speed and left to decrease engine speed. Moving the lever all the way to the left stops the engine. Always operate at FULL throttle (lever fully right).

Recoil Starter

Recoil Starter

The recoil starter is used to turn the engine over for starting.

Fuel Shut-Off Valve

Fuel Shut-Off Valve

The fuel shut-off valve is located below the air cleaner housing. Always close the valve when the unit is not in use.

Fuel Tank

Fuel Tank

To remove the cap, turn counterclockwise.

Chipper Cone / Shredder Hopper

Chipper Cone / Shredder Hopper

Chipper Cone: The chipper cone is located on the front of the unit next to the engine. Insert branches and tree limbs up to approximately 3” (7.6 cm) in diameter into the chipper cone. NEVER insert hands past the mouth of the cone.

Shredder Hopper: The shredder hopper is on top of the unit. Leaves and other light waste can be loaded into the shredder hopper. NEVER insert hands into the hopper .

Debris Bag: Use the debris bag to collect the material discharged from the unit. Do not operate the unit without the debris bag in place.

Choke

Close the choke for cold starting. Open the choke once the engine starts. A warm engine may not require choking. Move the lever right to close the choke.

Page 14 |

1-800-345-6007 |

14

GetEarthquake.com

Loading...

Loading...