Page 1

Owner’s Manual

GAS/OIL

RATIO

50:1

CHIPPER SHREDDER

Model #’s: 18493 / 22752 /

22754 / 30520 / 32013

ENGLISH

SERIAL NO.

DATE OF PURCHASE:

THIS INSTRUCTION BOOKLET CONTAINS IMPORTANT SAFETY INFORMATION. PLEASE READ AND KEEP FOR FUTURE REFERENCE.

Get parts or technical assistance online at

www.GetEarthquake.com or call (800) 345-6007

© 2018 Ardisam

All Rights Reserved

P/N: 32409

REV 1: 08/29/2018

Page 2

Owner’s Manual

CHIPPER SHREDDER

STOP! ACTIVATE YOUR WARRANTY BEFORE USE

All products must be registered within 30 days from the date of purchase in order to be covered under

warranty. For more information regarding Warranty and Registration please review the Warranty and Registration terms and conditions expressed in the warranty insert.

INTRODUCTION

Thank you for purchasing your product from Earthquake®. We have worked to ensure that this product meets the highest standards for usability and durability. With proper care, your purchase will provide many years of service.

Please read this entire manual before installation and use. Earthquake® reserves the right to change, alter or improve the product

and this document at any time without prior notice. Due to continuous product improvements, product images may not be exact.

Some assembly may be required.

Read and keep this manual for future reference. This manual contains important information regarding safety, assembly, operation

and maintenance. The owner must be certain that all the product information is included with the unit. This information includes

the manual, the replacement parts and the warranties. This information must be included to make sure state laws and other laws

are followed. All persons to whom rent/loan this unit must have access to and understand this information. This manual should

remain with the product even if it is resold.

CONTENTS

Introduction/Contents ..................................................................................................................................................................................................................2

Bolt Identication Chart ................................................................................................................................................................................................................3

Warnings and Safety Precautions ..........................................................................................................................................................................................4-9

Features ............................................................................................................................................................................................................................................10

Specications ..................................................................................................................................................................................................................................11

Unpacking and Assembly ................................................................................................................................................................................................... 12-14

Operation .................................................................................................................................................................................................................................. 15-16

Maintenance and Storage ................................................................................................................................................................................................... 17-19

Troubleshooting and Repair ...............................................................................................................................................................................................20-22

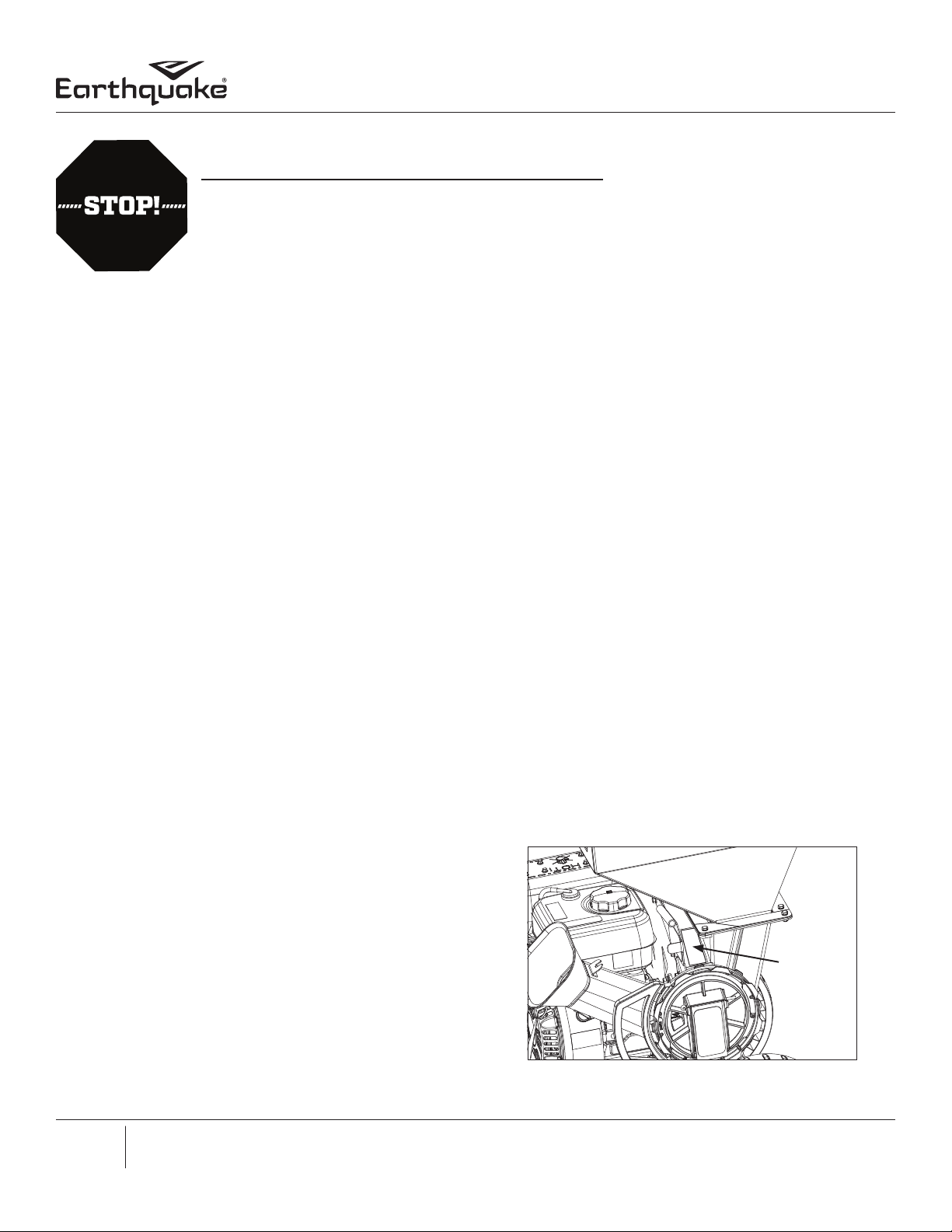

REGISTRATION AND SERVICE

Record the product model number and serial number in the

space provided for easy reference when ordering parts or

requesting technical support. Excluding emissions-related

warranty items, the warranty is valid only if the completed

registration is received by Ardisam within 30 days of purchase. You can register your warranty online by visiting www.

GetEarthquake.com, or by mailing it to: Ardisam, 1160 8th

Avenue, Cumberland, WI 54829. You may also call our Customer Service department at (800) 345-6007 Mondays through

Fridays from 8 a.m. to 5 p.m. CST.

Serial

Number

Decal

2

Get parts online at www.GetEarthquake.com or Call 800-345-6007 M-F 8-5 CST

Page 3

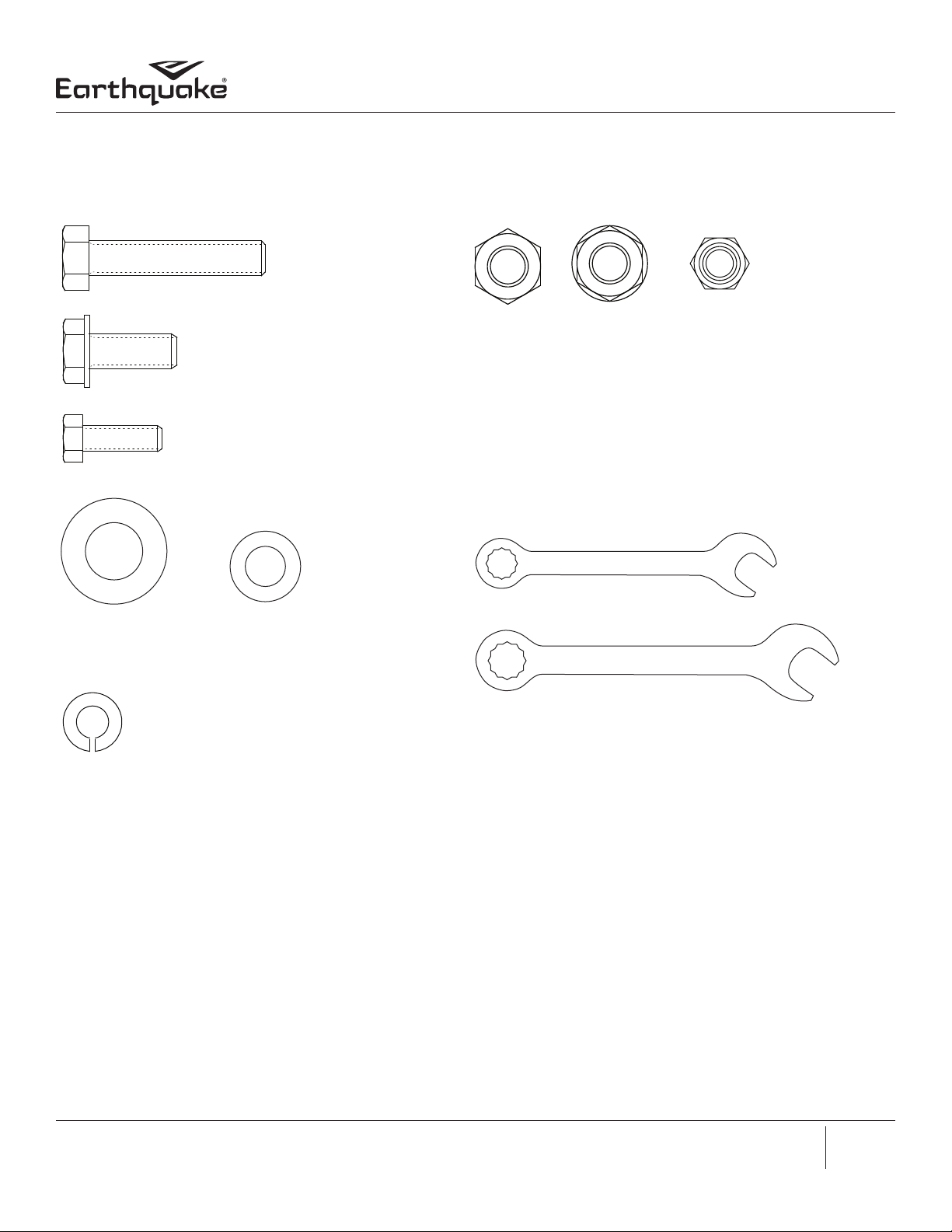

BOLT IDENTIFICATION CHART

Bolts shown are for size reference only. Extra hardware may be

included in the parts bag.

(A)

M8 x 40 MM Bolt

Qty 4

Owner’s Manual

CHIPPER SHREDDER

(B)

M8 x 20 MM Flange Bolt

Qty 4

(C)

M6 x 16 MM Bolt

Qty 3

(D)

12 X 24 MM Washer

Qty 2

(F)

M6 Spring Lock Washer

Qty 3

(E)

M8 Washer

Qty 12

(G)

M8 Nut

Qty 8

(H)

M8 Nyloc Nut

Qty 3

(I)

M6 Nut

Qty 3

TOOLS NEEDED - NOT INCLUDED

8 MM Wrench - Qty 1

10 MM Wrench - Qty 1

Get parts online at www.GetEarthquake.com or Call 800-345-6007 M-F 8-5 CST

3

Page 4

Owner’s Manual

CHIPPER SHREDDER

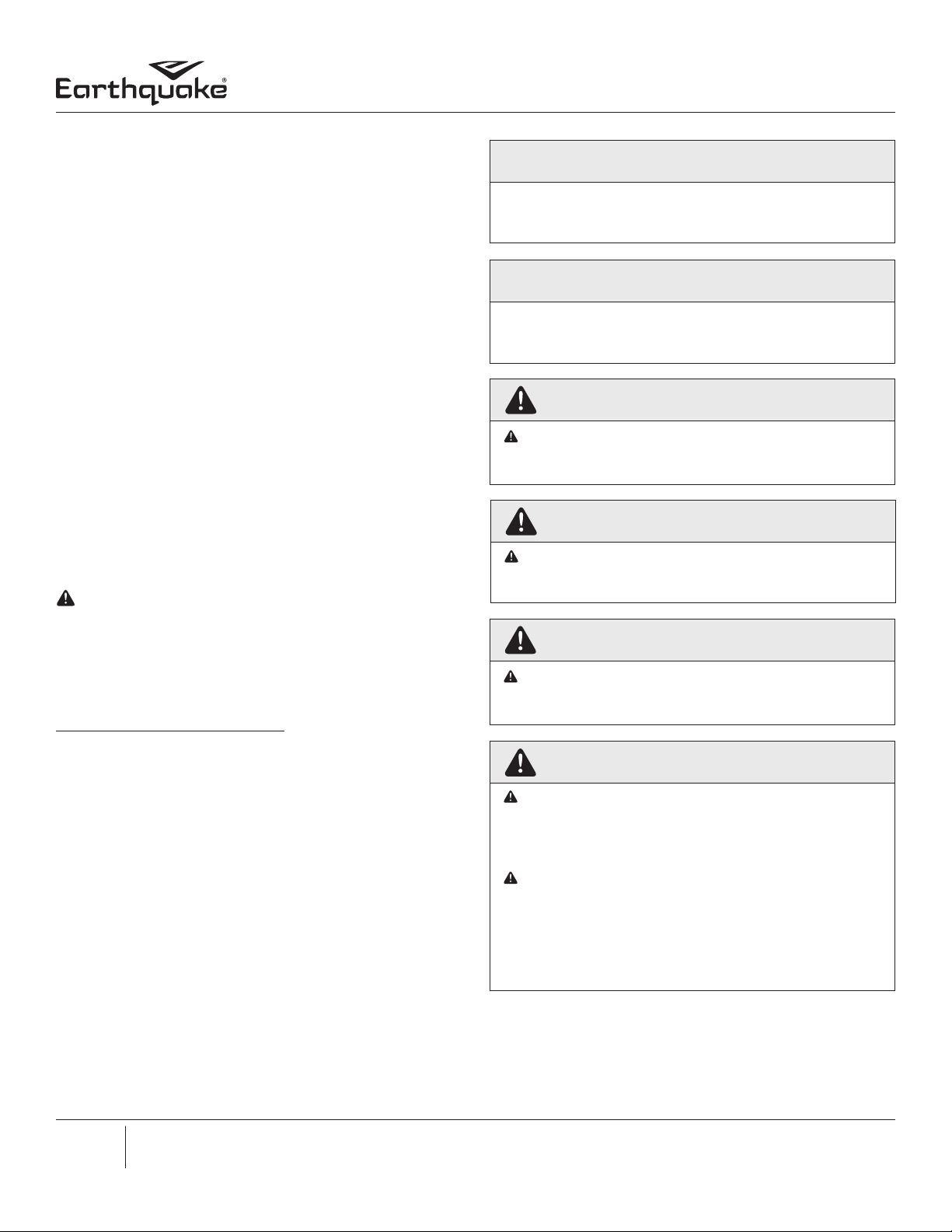

WARNINGS AND SAFETY PRECAUTIONS

OWNER’S RESPONSIBILITY

Accurate assembly and safe and eective use of the machine is

the owner’s responsibility.

• Read and follow all safety instructions.

• Carefully follow all assembly instructions.

• Maintain the machine according to directions and

schedule included in this Earthquake® operator’s manual.

• Ensure that anyone who uses the machine is familiar with

all controls and safety precautions.

SPECIAL MESSAGES

Your manual contains special messages to bring attention to

potential safety concerns, machine damage as well as helpful

operating and servicing information. Please read all the information carefully to avoid injury and machine damage.

NOTE: General information is given throughout the manual

that may help the operator in the operation or service of the

machine.

This symbol points out important safety instructions

which if not followed could endanger your personal

safety. Read and follow all instructions in this manual

before attempting to operate this equipment.

BEFORE OPERATING EQUIPMENT:

Please read this section carefully. Read entire operating and

maintenance instructions for this product. Failure to follow instructions could result in serious injury or death. Operate the

machine according to the safety instructions outlined here and

inserted throughout the text. Anyone who uses this machine

must read the instructions and be familiar with the controls.

NOTICE

NOTICE INDICATES YOUR EQUIPMENT CAN BE DAMAGED

IF THE SAFETY INSTRUCTIONS THAT FOLLOW THIS SIGNAL

WORD ARE NOT OBEYED.

IMPORTANT

IMPORTANT INDICATES HELPFUL INFORMATION FOR

PROPER ASSEMBLY, OPERATION OR MAINTENANCE OF

YOUR EQUIPMENT.

CAUTION

CAUTION INDICATES A HAZARD WHICH, IF NOT AVOIDED,

COULD RESULT IN PERSONAL INJURY AND/OR PROPERTY

DAMAGE.

WARNING

WARNING INDICATES A HAZARD WHICH, IF NOT AVOIDED,

COULD RESULT IN DEATH OR SERIOUS INJURY AND/OR

PROPERTY DAMAGE.

DANGER

DANGER INDICATES A HAZARD WHICH, IF NOT AVOIDED,

CERTAINLY WILL RESULT IN DEATH OR SERIOUS INJURY

AND/OR PROPERTY DAMAGE.

WARNING

YOU MUST READ, UNDERSTAND AND COMPLY WITH ALL

SAFETY AND OPERATING INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO SETUP AND OPERATE YOUR

MACHINE.

FAILURE TO COMPLY WITH ALL SAFETY AND OPERATING

INSTRUCTIONS CAN RESULT IN LOSS OF MACHINE

CONTROL, SERIOUS PERSONAL INJURY TO YOU AND/OR

BYSTANDERS, AND RISK OF EQUIPMENT AND PROPERTY

DAMAGE. THE TRIANGLE IN THE TEXT SIGNIFIES

IMPORTANT CAUTIONS OR WARNINGS WHICH MUST BE

FOLLOWED.

4

Get parts online at www.GetEarthquake.com or Call 800-345-6007 M-F 8-5 CST

Page 5

GENERAL OPERATING SAFETY

• Read the operating and service instruction manual

carefully. Be throughly familiar with the controls and the

proper use of the equipment. Know how to stop the unit

and disengage the controls quickly.

• Do not operate the equipment without wearing adequate

outer garments and safety goggles. Avoid loose-tting

clothes and use protective footwear that will improve

footing on slippery surfaces.

• Dress appropriately when operating the chipper shredder.

Always wear sturdy footwear and safety goggles. Never

wear sandals, sneakers or open shoes, and never operate

the chipper shredder with bare feet. Do not wear loose

clothing that might get caught in moving parts.

• Never allow children to operate the equipment. Never

allow adults to operate the equipment without proper

instruction.

• Only allow responsible adults, who are familiar with the

instructions, to operate the unit (local regulations can

restrict operator age).

• Keep the area of operation clear of all persons, particularly

small children and pets.

• Always maintain secure footing and solid balance while

starting or operating the chipper shredder. Never lean

directly over the machine.

• Never operate the machine at high transport speeds on

hard or slippery surfaces.

• Operate the machine only in daylight or good articial

light.

• Do not operate the unit while under the inuence of alcohol or drugs.

• Exercise caution to avoid slipping or falling.

• Always wear eye and hearing protection when operating

this unit.

• Keep in mind the operator is responsible for accidents

occurring to other people or property.

• Never operate the machine without proper guards, plates,

or other safety protective devices in place.

• Do not put hands or feet near or under rotating parts or at

inlet or discharge openings.

• Thoroughly inspect where equipment is to be used and

remove all foreign objects.

Owner’s Manual

CHIPPER SHREDDER

DANGER

THE CHIPPER SHREDDER HAS SPINNING BLADES THAT

CAN AMPUTATE HANDS AND FEET. DO NOT PLACE HANDS

OR FEET IN THE HOPPER OR CHIPPER CONE, OR DISCHARGE

CHUTE.

WARNING

COMBUSTIBLE DEBRIS CAN CATCH FIRE. IT IS A VIOLATION

OF CALIFORNIA PUBLIC RESOURCE CODE, SECTION 4442,

TO USE OR OPERATE ENGINE-POWERED PRODUCTS

ON ANY FOREST-COVERED, BRUSH-COVERED, OR GRASS COVERED LAND UNLESS THE EXHAUST SYSTEM IS

EQUIPPED WITH A SPARK ARRESTER, AS DEFINED IN

SECTION 4442, MAINTAINED IN EFFECTIVE WORKING

ORDER. OTHER STATES OR FEDERAL JURISDICTIONS MAY

HAVE SIMILAR LAWS. CONTACT THE ORIGINAL EQUIPMENT

MANUFACTURER, RETAILER, OR DEALER TO OBTAIN A

SPARK ARRESTER DESIGNED FOR USE WITH THIS PRODUCT.

WARNING

THIS UNIT DISCHARGES DEBRIS AT HIGH SPEEDS. ALWAYS

WEAR PROTECTIVE GOGGLES AND DO NOT OPERATE

WITHOUT THE DEBRIS BAG IN PLACE.

DO NOT ALLOW ANYONE IN THE AREA WHILE THE UNIT IS

RUNNING. IF SOMEONE DOES ENTER THE AREA, SHUT THE

UNIT OFF IMMEDIATELY UNTIL THEY LEAVE. ORGANIZE

THE WORK AREA PRIOR TO STARTING WORK.

• Exercise extreme caution when operating on or crossing

gravel drives, walks or roads. Stay alert for hidden hazards

or trac.

• Never allow bystanders near the unit while running.

• Do not put hands or feet near rotating parts or under the

machine. Keep clear of the discharge opening at all times.

• Always operate the chipper shredder outdoors, on a rm,

level, earthen or grassy surface where the unit will be

stable and stay in position. Never attempt to operate the

unit on a slope, or on a wet or slippery surface where you

could slip and fall toward the chipper cone or hopper

openings.

• If the machine should start to vibrate abnormally, stop

the engine (motor) and check immediately for the cause.

Vibration is generally a warning sign of trouble.

Get parts online at www.GetEarthquake.com or Call 800-345-6007 M-F 8-5 CST

5

Page 6

Owner’s Manual

CHIPPER SHREDDER

• Do not operate without the debris bag in place because

this unit discharges debris at high speeds. If the unit is

operated on hard ground, asphalt, concrete, or other hard

surfaces without the collection bag in place. Material can

ricochet o of the hard surface and cause an unsafe condition for users and bystanders.

• Always obey the size limitations for tree limbs and branches stated in the Waste Materials Guide portion of this

manual.

• Never leave the machine running unattended. Always turn

o the engine, wait for the rotor to come to a complete

stop, and disconnect the spark plug before leaving the

area. Always move the unit to a safe storage area when

not in use.

• Never direct discharge material toward anyone. Avoid discharging material against a wall or obstruction. Material

may ricochet back toward the operator.

• Always stand to the side of the chipper cone when feeding tree limbs and branches into the unit, as tree limbs,

branches, and harder woods may kick back while being

chipped.

• Always keep hands out of the chipper cone and shredder

hopper when feeding materials. Never wrap ngers tightly

around branches as you are feeding them into the unit,

as a sudden inward surge could pull your hands and arms

into the unit.

• Never allow material to build up in the discharge area or

shredding chamber, as this may cause new material being

fed into the machine to kickback with sucient force to

injure you or other bystanders.

• Never allow material to build up around the engine during

chipper shredder operation. This could result in a re, or

overheating of the engine.

to tip over, and reaching to steady the unit could result in

accidental insertion of your hands into the chipper cone

or shredder hopper areas.

• Never continue to operate the machine if it starts making

unusual noise or vibration. Shut the engine o immediately, allow the rotor to stop, disconnect the spark plug wire

and secure the wire away from the spark plug. Inspect

the unit for any signs of damage or foreign material in the

chipping or shredding areas. Remove any solid material

that may be preventing the unit from operating properly.

• Never attempt to clear clogs from the chipper cone, shredder hopper or discharge chute while the unit is running.

Always shut the engine o, allow the rotor to come to a

complete stop, and remove the spark plug wire from the

spark plug before removing excess materials.

• Never attempt to perform any maintenance, repairs, or attachment of accessories while the unit is running. Always

shut the unit o, allow the rotor to come to a complete

stop, and remove the spark plug wire from the spark plug

before beginning these activities.

• Always make sure that the shredding chamber, shredder

hopper, and chipper cone are empty before starting the

unit after it has been idle. Attempting to start the unit with

material in these areas could cause the engine starting

cord to stop suddenly, injuring your hand and ngers, or

toppling the unit over. Vibration is generally a warning

sign of trouble.

• Use only attachments and accessories approved of by the

manufacturer of the machine.

• Make sure chipper shredder is free of debris before starting the engine.

• Never attempt to make any adjustments while the engine

is running.

• Take all possible precautions as recommended by the

manufacturer when leaving the machine unattended.

• Do not overload the machine by attempting to chip or

shred any material beyond manufacturers recommendations.

• Use extreme caution when reversing or pulling the machine towards you.

• Do not change the engine governor settings or overspeed

the engine.

• Never attempt to reposition or move the chipper shredder

unit while it is running. Doing so could cause the machine

6

Get parts online at www.GetEarthquake.com or Call 800-345-6007 M-F 8-5 CST

• After striking a foreign object, stop the engine (motor),

remove spark plug wire, and wait for all moving parts to

come to a complete stop. Thoroughly inspect the machine

for any damage, repair the damage before restarting and

operating the machine.

• Start the engine or switch on the motor carefully according to the manufacturers instructions. Keep hands and

feet away from inlet and discharge areas.

• Never pick up or carry the machine while the engine is

running.

Page 7

ENGINE SPECIFIC SAFETY

• Before cleaning, repairing, or inspecting, shut o the

engine and make certain that all moving parts have come

to a complete stop. Disconnect the spark plug wire and

secure the wire away from the spark plug to prevent accidental starting.

• Stop the engine (motor) when leaving the operating

position and when making any repairs, adjustments and

inspections.

MAINTENANCE AND STORAGE

• Keep machine, attachments, and accessories in safe working condition.

• Check engine mounting bolts and other hardware at frequent intervals for proper tightness to be sure the equipment is in safe working condition.

• Never store machine with fuel in the fuel tank inside a

building where ignition sources are present, such as hot

water and space heaters, clothes dryers and the like. Allow

the engine to cool before storing in any enclosure.

• Always refer to the operator’s manual for important details

if the machine is to be stored for an extended period.

• If the fuel tank has to be drained, do this outdoors.

• Follow the manufacturer’s recommendations for safe loading, unloading and storage of machine.

PREVENTING CARBON MONOXIDE POISONING

• Always start and run engine outdoors. Do not start or run

engine in an enclosed area, even if doors or windows are

open.

• Never try to ventilate engine exhaust indoors. Carbon

monoxide can reach dangerous levels very quickly.

• Never run engine outdoors where exhaust fumes may be

pulled into a building.

• Never run engine outdoors in a poorly ventilated area

where the exhaust fumes may be trapped and not easily

taken away. (Examples include: in a large hole or areas

where hills surround your working area.)

• Never run engine in an enclosed or partially enclosed area.

(Examples include: buildings that are enclosed on one or

more sides, under tents, car ports or basements.)

• Always run the engine with the exhaust and muer pointed in the direction away from the operator.

Owner’s Manual

CHIPPER SHREDDER

WARNING

ENGINE GIVES OFF CARBON MONOXIDE, AN ODORLESS,

COLORLESS, POISON GAS. CARBON MONOXIDE MAY BE

PRESENT EVEN IF YOU DO NOT SMELL OR SEE ANY ENGINE

EXHAUST. BREATHING CARBON MONOXIDE CAN CAUSE

NAUSEA, FAINTING OR DEATH, IN ADDITION TO

DROWSINESS, DIZZINESS AND CONFUSION. IF YOU

EXPERIENCE ANY OF THESE SYMPTOMS, SEEK FRESH AIR

AND MEDICAL ATTENTION IMMEDIATELY.

IF YOUR MACHINE COMES WITH A SEPARATE ENGINE

MANUAL, BE SURE TO READ AND FOLLOW ALL SAFETY AND

WARNING PRECAUTIONS OUTLINED THERE, IN ADDITION

TO ANY IN THIS MANUAL.

WARNING

FUEL IS HIGHLY FLAMMABLE. TAKE THE FOLLOWING

PRECAUTIONS:

• STORE FUEL IN CONTAINERS SPECIFICALLY DESIGNED FOR

THIS PURPOSE.

• REFUEL OUTDOORS ONLY AND DO NOT SMOKE WHILE

REFUELING.

• ADD FUEL BEFORE STARTING THE ENGINE. NEVER REMOVE

THE CAP ON THE FUEL TANK OR ADD FUEL WHILE THE

ENGINE IS RUNNING OR WHEN THE ENGINE IS HOT.

• IF FUEL IS SPILLED, DO NOT ATTEMPT TO START THE

ENGINE BUT MOVE THE MACHINE AWAY FROM THE AREA

OF SPILLAGE AND AVOID CREATING ANY SOURCE OF

IGNITION UNTIL FUEL VAPORS HAVE DISAPPEARED.

• REPLACE ALL FUEL TANK AND CONTAINER CAPS SECURELY.

• Never point the exhaust muer towards anyone. People

should always be many feet away from the operation of

the engine and its attachments.

• Do not change the engine governor settings or overspeed the engine.

• Do not operate the engine in a conned space where

dangerous carbon monoxide fumes can collect.

GASOLINE FIRES AND HANDLING FUEL SAFELY

• Use extra care in handling gasoline and other fuels. They

are ammable and vapors are explosive.

• When storing extra fuel be sure that it is in an appropriate

container and away from any re hazards.

Get parts online at www.GetEarthquake.com or Call 800-345-6007 M-F 8-5 CST

7

Page 8

Owner’s Manual

CHIPPER SHREDDER

• Prevent re and explosion caused by static electric

discharge. Use only nonmetal, portable fuel containers

approved by the Underwriter’s Laboratory (U.L.) or the

American Society for Testing & Materials.

• Always ll fuel tank outside in a well ventilated area. Never

ll your fuel tank with fuel indoors. (Examples include:

basement, garage, barn, shed, house, porch, etc.) Never

ll tank near appliances with pilot lights, heaters, or other

ignition sources. If the fuel has to be drained, this should

be done outdoors. The drained fuel should be stored in a

container specically designed for fuel storage or it should

be disposed of carefully.

• Never remove the fuel cap or add fuel with the engine

running. Stop engine and allow to cool before lling.

• Do not smoke while refueling or operating engine.

• Never drain fuel from the engine in an enclosed area.

• Always wipe up excess (spilled) fuel from engine before

starting. Clean up spilled fuel immediately. If fuel is spilled,

do not start the engine but move machine and fuel container from area. Clean up spilled fuel and allow to evaporate

and dry after wiping and before starting.

• Allow fuel fumes/vapors to escape from the area before

starting engine.

• Test the fuel cap for proper installation before starting and

using engine.

• Always run the engine with fuel cap properly installed on

the engine.

• During storage, keep machine so gas cap is up.

• Never siphon fuel by mouth to drain fuel tank.

fuel such equipment on a trailer with a portable container,

rather than from a gasoline dispenser nozzle.

BURNS AND FIRES

• The muer, muer guard and other parts of the engine

become extremely hot during the operation of the engine.

These parts remain extremely hot after the engine has

stopped.

PREVENTION OF BURNS AND FIRES

• Never remove the muer guard from the engine.

• Never touch the muer guard because it is extremely hot

and will cause severe burns.

• Never touch parts of the engine that become hot after

operation.

• Always keep materials and debris away from muer guard

and other hot parts of the engine to avoid res.

CHILDREN AND BYSTANDERS

• Tragic accidents can occur if the operator is not alert to

the presence of children and/or bystanders. Never assume

that others will remain where you last saw them.

• Keep the area of operation clear of all persons, especially

small children and pets. Keep children under the watchful

care of a responsible adult.

• Be alert and turn the machine o if children enter the area.

• Before and while moving backwards, look behind and

down for small children.

• Never allow children to operate the machine

• Always have an adult ll the fuel tank and never allow

children to ll the engine.

• Never allow an adult or anyone under the inuence of

drugs or alcohol to ll engine.

• When storing gasoline or equipment with fuel in the tank,

store away from furnaces, stoves, water heaters or other

appliances that have a pilot light or other ignition source

because they can ignite gasoline vapors.

• Never ll containers inside a vehicle or on a truck bed with

a plastic bed liner. Always place containers on the ground

away from your vehicle before lling.

• Remove gas-powered equipment from the truck or trailer

and refuel it on the ground. If this is not possible, then re-

8

Get parts online at www.GetEarthquake.com or Call 800-345-6007 M-F 8-5 CST

Page 9

A

G

A: Warning!

B: Read Owner's Manual Before Operating Machine.

C: Do Not Operate While Others Are Around.

D: Remove Objects that Could Be Thrown By This Machine.

E: Never Operate Machine Up and Down Slopes, ALWAYS

Operate Mower Across Slopes.

F: Beware of Moving and Rotating Parts.

G: Wear Ear and Eye Protection At All Times.

H: Do Not Service or Adjust Moving Parts Unless Engine is

Stopped and Spark Plug Wire is Disconnected.

I: Direction of Rotating Mower Lines.

J: Toxic Fumes —Do Not Operate in Unventilated Areas.

K: Hot Surfaces.

L: Fire Hazards.

M. Do Not Use In Thunderstorms--For severe weather, stop

operation of this machine and seek shelter.

N. Team Lift--For your safety, always have at least two people

when lifting this machine.

O. Never Fit Metal Cutting Parts--Do not attach any metal parts

to the cutting head of this machine.

P. Do Not Operate When Children Or Others Are Around.

B

H

M N

DC

I

O

E

KJ

P

F

L

Owner’s Manual

CHIPPER SHREDDER

SAFETY DECALS

This unit has been designed and manufactured to provide you

with the safety and reliability you would expect from an industry leader in outdoor power equipment manufacturing.

Although reading this manual and the safety instructions it

contains will provide you with the necessary basic knowledge

to operate this equipment safely and eectively, we have

placed several safety labels on the unit to remind you of this

important information while you are operating your unit.

All DANGER, WARNING, CAUTION and instructional messages on your unit should be carefully read and obeyed. Personal bodily injury can result when these instructions are not

followed. The information is for your safety and it is important!

The safety decals below are on your unit.

If any of these decals are lost or damaged, replace them at

once. See your local dealer or contact Earthquake directly for

replacements.

These labels are easily applied and will act as a constant visual

reminder to you, and others who may use the equipment,

to follow the safety instructions necessary for safe, eective

operation.

Get parts online at www.GetEarthquake.com or Call 800-345-6007 M-F 8-5 CST

9

Page 10

Owner’s Manual

CHIPPER SHREDDER

FEATURES AND CONTROLS

CONTROL FUNCTIONS

The information below briey describes the function of individual controls. Operating requires the combined use of several

controls applied in specic sequences. To learn what combination and sequence of controls to use for various tasks see the

OPERATION section.

*For engine features and controls see engine manual.

SHREDDER HOPPER

CHIPPER CONE

FUEL CAP

DEBRIS BAG CONNECTOR

KICKSTAND

CHIPPER CONE/SHREDDER HOPPER

Chipper Cone: The chipper cone is located on the front of the unit next to the engine. Insert branches and tree limbs up to

approximately 3” (7.6 cm) in diameter into the chipper cone. NEVER insert hands past the mouth of the cone.

Shredder Hopper: The shredder hopper is on top of the unit. Leaves and other light waste can be loaded into the shredder hopper.

Nothing over 1/2 inch in diameter should go into shredder. NEVER insert hands into the hopper .

Debris Bag: Use the debris bag to collect the material discharged from the unit. Do not operate the unit without the debris bag

in place.

10

Get parts online at www.GetEarthquake.com or Call 800-345-6007 M-F 8-5 CST

Page 11

Owner’s Manual

CHIPPER SHREDDER

SPECIFICATIONS

Model # 18493 / 30520 22752 32013 22754

Chipping Capacity Approx. 3” Approx. 3” Approx. 3” Approx. 3”

Shredding Capacity 1/2” x 18” long 1/2” x 18” long 1/2” x 18” long 1/2” x 18” long

Chipping Knives 2 2 2 2

Shredding

Hammers

Waste Reduction

Ratio

Start Type Recoil Recoil Recoil Recoil

Rotor Material Steel Steel Steel Steel

Hopper Dimensions 16.75” x 13.25” 16.75” x 13.25” 16.75” x 13.25” 16.75” x 13.25”

Bag Dimensions 24” x 36” 24”x 36” 24” x 36” 24” x 36”

Limb Chute Ye s Yes Yes Yes

Tire Diameter 11” 11” 11” 11”

Tire Width 2” 2” 2” 2”

Tire Material Rubber Rubber Rubber Rubber

Wheel Type Non-pneumatic Non-pneumatic Non-pneumatic Non-pneumatic

Net Weight 121 lb 118 lb 126 lb 119 lb

2 J-Hammers,

2 Triangle-

Hammers

20:1 20:1 20:1 20:1

2 J-Hammers,

2 Triangle-

Hammers

2 J-Hammers,

2 Triangle-

Hammers

2 J-Hammers,

2 Triangle-

Hammers

Gross Weight 131 lb 131 lb 139 lb 129 lb

Assembled

Dimensions

Boxed Dimensions 32.2” x 23.9” x 23.1” 32.2” x 24.6” x 24.6” 32.2” x 23.9” x 23.1” 32.2” x 23.9” x 23.1”

Vacuum Kit Yes Yes Ye s Ye s

Vacuum

Measurement

Vacuum Air Gate Yes Ye s Yes Yes

Rotor Diameter 14” 14” 14” 14”

Quick Attach

Bag System

ANSI Yes Ye s Yes Yes

25.4” x 29.9” x 51.9” 25.4” x 29.9” x 51.9” 25.4” x 29.9” x 51.9” 25.4” x 29.9” x 51.9”

20” of Water 20” of Water 20” of Water 20” of Water

Yes Ye s Yes Yes

Get parts online at www.GetEarthquake.com or Call 800-345-6007 M-F 8-5 CST

11

Page 12

UNPACKING AND ASSEMBLY

CARTON CONTENTS

TILLER ASSEMBLY

• Manual Parts Bag:

• Hardware Parts Bag:

• A - (4) M8 x 40 MM Bolts

• B - (4) M8 x 20 MM Bolts

• C - (3) M6 x 16 MM Bolts

• D - (2) 12 x 24 MM Washers

• E - (12) M8 Washers

• F - (3) M6 Spring Lock Washers

• G - (8) M8 Nuts

• H - (3) M8 Nyloc Nuts

• I - (3) M6 Nuts

• Cone Cover

• Debris Bag

• Safety Goggles

• (2) Wheels

• Hopper

• Bag Connector

• Bottle of 4-cycle Engine Oil

• Cone

• Chipper Assembly

• Handlebar

• Kickstand

• Hopper Guard

• Bag Support Rod

Owner’s Manual

CHIPPER SHREDDER

G

WHEEL AXLE

E

KICKSTAND

Position the kickstand underneath the engine with the

loop of the kickstand pointing away from the wheel axle.

Using the four M8 x 40 MM bolts (A), eight M8 washers

(E) and four M8 nuts (G), secure the kickstand to the base

plate of the engine.

FIGURE 1

WHEEL AXLE

A

12

COTTER PIN

D

Slide the wheel so that the ange on the tire points out-

ward away from the unit, onto the axle and slide a 12 MM

washer (D) onto the axle against it. Insert the a cotter pin

into the hole in the end of the axle. Bend the cotter pin

over to secure the wheel to the axle. Repeat for opposite

side.

FIGURE 2

Get parts online at www.GetEarthquake.com or Call 800-345-6007 M-F 8-5 CST

Page 13

CHIPPER CONE

H

Position the chipper cone over the three M8 x1.25 threaded

studs protruding from the engine plate, and attach using

three M8 nyloc nuts (H). Rotate cone and cone base away

from engine so cone does not contact engine. Tighten the

three M8 nyloc nuts (H) securely.

Owner’s Manual

CHIPPER SHREDDER

DAMPER

STUD PLATE

I

Remove back four M6 nuts (I) and set nuts and rear stud

plate aside. Loosen front four M6 nuts (I). Note: These will

not need to removed. Install the damper between the stud

plates as shown.

FIGURE 3

HOPPER

STUD PLATES

I

SLOTTED HOLES

Install hopper by sliding slotted holes on the front side of

hopper onto the four studs on the front stud plate with

the previously loosened four M6 nuts (I). Reinstall rear

stud plate and back four M6 nuts (I) that were previously

removed in Figure 4. Tighten all eight M6 nuts (I).

I

FIGURE 4

I

HOPPER GUARD

HOPPER

F

C

Hold the hopper guard so that the rubber guard is directed

down towards the bottom of the hopper. Align the assembly holes with the holes in the hopper. Using the three M6

x 16 MM bolts (C), three M6 spring lock washers (F) and

three M6 nuts (I), secure the hopper guard to the hopper.

Insert the bolts with washers from the outside of the

hopper.

FIGURE 5

FIGURE 6

Get parts online at www.GetEarthquake.com or Call 800-345-6007 M-F 8-5 CST

13

Page 14

HOPPER HANDLE

G

E

Owner’s Manual

CHIPPER SHREDDER

BRACKET

Hold the hopper handle up so that the outer holes in the

handle align with the holes in the hopper and secure with

four M8 x 20 MM bolts (B), four M8 washers (E) and four M8

nuts (G). Insert the screws from the outside of the hopper.

FIGURE 7

TABS

B

TAB

Slide the support rod into the bracket. Rotate the rod so

that it sits below the front tab of the bracket.

FIGURE 8

SUPPORT ROD

Slide the tabs on the debris bag onto the support rod.

Secure the bag connector onto the chipper by rotating

the connector until locked in.

FIGURE 9

14

Get parts online at www.GetEarthquake.com or Call 800-345-6007 M-F 8-5 CST

Page 15

OPERATION

Be sure to read all information in the Safety and Operation

section before attempting to operate this unit. Become familiar

with all of the controls and how to stop the unit.

Check all hardware (bolts, screws, etc) before every use for tightness to be sure machine is in safe working condition.

Upon start-up and shut-down, you may hear the metal-tometal sound of the triangular hammers and J-hammers

positioning themselves on the rotor. This is normal. If this

sound continues after the machine has reached full speed,

contact your dealer or Earthquake for an inspection of the unit.

Overloading the equipment will shorten its life, and can cause

mechanical failures.

CHIPPER OPERATION

The chipper is designed to handle tree limbs and branches up

to approximately 3” (7,6 cm) in diameter. The chipping knives

also permit the processing of course organic matter like corn

stalks. Tree branches must be inserted large-end rst into the

chipper cone. Since occasional kick-backs may occur, always

stand o to the side of the unit. Allow the self-feeding action

of the unit to draw the sticks in.

SHREDDER OPERATION

The shredder is designed to shred light brush, leaves, and

other soft but bulky organic waste. As material (no larger than

1/2 inch in diameter) is loaded into the shredder hopper it is

pulled into the path of the triangular and J-hammers by air

ow.

VACUUM ATTACHMENT (OPTIONAL)

Owner’s Manual

CHIPPER SHREDDER

DANGER

THE EXHAUST FROM THIS PRODUCT CONTAINS CARBON

MONOXIDE GAS. CARBON MONOXIDE IS A COLORLESS,

ORDERLESS AND TASTELESS GAS THAT CAN CAUSE

DIZZINESS, NAUSEA, UNCONSCIOUSNESS OR EVEN BRAIN

DAMAGE AND DEATH IF INHALED FOR PROLONGED

PERIODS.

OPERATE THE UNIT OUTDOORS IN A WELL VENTILATED

LOCATION ONLY. KEEP CHILDREN, PETS AND BYSTANDERS

AW AY.

WARNING

TO AVOID SERIOUS PERSONAL INJURY FROM ROTATING

CUTTING BLADES, KEEP HANDS OUT OF INLET WHILE

MACHINE IS RUNNING.

GASOLINE IS HIGHLY FLAMMABLE AND MUST BE HANDLED

WITH CARE. NEVER FILL THE TANK WHEN THE ENGINE IS

STILL HOT FROM RECENT OPERATION. DO NOT ALLOW

OPEN FLAME, SMOKING OR MATCHES IN THE AREA. AVOID

OVER-FILLING AND WIPE UP ANY SPILLS.

DO NOT USE GASOLINE CONTAINING METHANOL,

GASOHOL CONTAINING MORE THAN 10% ETHANOL,

GASOLINE ADDITIVES OR WHITE GAS BECAUSE ENGINE/

FUEL SYSTEM DAMAGE COULD RESULT.

IMPORTANT

ENGINE IS SHIPPED FROM FACTORY WITHOUT OIL. YOU

MUST ADD ENGINE OIL BEFORE STARTING ENGINE.

In addition to the chipper cone and hopper, loose debris may

be processed by the Vacuum hose adapter kit. Leaves may be

raked directly into the leaf tray where vacuum action will draw

them into the shredder. For hard-to-reach areas, the nozzle

and hose assembly may be used. The strength of the Vacuum

may be changed using the rotating sleeve on the nozzle.

The optional Tazz vacuum kit and can be ordered by

contacting Earthquake customer service or ordering online at

getearthquake.com as listed below.

OPERATING LOCATION

Select an area with rm, level ground, covered by dirt or grass.

Do not operate on wet or slick surfaces, or near bystanders.

Locate and organize the materials to be processed so that you

don’t have to walk in front of the inlet or discharge openings,

and so you have adequate room to work safely.

Get parts online at www.GetEarthquake.com or Call 800-345-6007 M-F 8-5 CST

ADDING OIL

Refer to engine manual for information on adding oil.

ADDING FUEL

1. Remove the fuel cap. (See Features and Controls)

2. Fill the tank. Do not overll. Leave room in the tank for fuel

expansion. Refer to your engine manual for specic fuel

recommendations.

3. Install and hand tighten the fuel cap.

STARTING THE ENGINE

1. See engine manual for start up instructions.

2. Ensure engine is running full throttle before beginning

15

Page 16

Owner’s Manual

CHIPPER SHREDDER

chipping operation. On some engines, the throttle may

not be adjustable.

STOPPING THE ENGINE

See engine manual for shut down procedure.

PROCESSING MATERIALS

Most materials to be processed can be handled more eciently by following these tips.

CHIPPING TIPS:

• Prune branches down close to the main branch to make

feeding them into the chipper cone easier.

• Large, hard, dried tree branches that resist chipping can

be processed by rotating them as you alternately insert

and retract them.

• If the material to be chipped is extremely hard, kicks back

forcefully when being fed into the chipper cone, or cannot

be easily controlled, remove the material immediately and

set it aside.

• If additional force is required to insert materials into the

chipper, the blades probably need to be sharpened.

Consult the Troubleshooting and Repair section of this

manual, or see your authorized dealer.

• Maintain control of the materials you are feeding to prevent them from whipping around.

• Do not insert short pieces of material into the chipper

cone by hand. Use a larger piece of material to feed them

into the chipper cone.

SHREDDING TIPS:

• Don’t overload the shredder by dumping large volumes of

material into the hopper opening.

• Alternate loads of wet and dry material to prevent the

discharge from becoming plugged.

• Never use any object to force material into the shredding

chamber. It could get caught in the shredding hammers

and damage the unit.

OPERATION TYPE OF WASTE PERMITTED SIZE LIMITATIONS NOTES

Shredding Dry or moist organic material

including leaves, plants, owers, fruits, or vegetables.

Chipping Long, thicker tree limbs or

small bunches of smaller

sticks grouped together for

ease of handling.

Vacuum Attachment

(Optional Accessory)

Light, loose, dry waste such

as leaves, grass clippings, or

sawdust.

Branches and twigs up to 1/2”

diameter and 18” long.

Tree limbs and branches,

or bundles of small sticks

grouped for easier handling.

Maximum diameter of approximately 3” (7,6 cm).

Small materials that will not

obstruct the vacuum hose.

Alternately chip or shred moist green

waste with dry waste to avoid plugging of the discharge chute.

Process at a feeding rate that allows

the rotor to keep up and maintain a

high rate of speed.

Bulky tree limbs should be pruned

close to the main stem. Always use

a shorter piece of wood to push end

pieces into the chipper cone. Never

place hands in the chipper cone.

Never chip very hard or dry materials

such as kiln dried dimensional lumber

(2x4’s etc.) or other building materials.

Never use the chipper to process pressure-treated wood products.

The vacuum is engineered for small,

loose waste and for cleaning around

decorative landscaping and ower

beds. Twigs, wet leaves, and other

bulky materials will clog the hose or

obstruct the shredding chamber.

16

Get parts online at www.GetEarthquake.com or Call 800-345-6007 M-F 8-5 CST

Page 17

Owner’s Manual

CHIPPER SHREDDER

TRANSPORTING AND STORAGE

• Always observe safe refueling and fuel handling practices

when refueling the unit after transportation or storage.

• Never store the unit (with fuel) in an enclosed poorly

ventilated structure. Fuel vapors can travel to an ignition

source (such as a furnace, water heater, etc.) and cause an

explosion. Fuel vapor is also toxic to humans and animals.

• Always use the hopper handle and built-in wheels to

move the chipper shredder. Never lift the unit using the

fuel tank for support. If the unit must be lifted , always

use at least two people, and always grip the unit securely

using the front leg and hopper handle.

• Always follow the engine manual instructions for storage

preparations before storing the unit for both short and

long term periods.

• Always follow the engine manual instructions for proper

start-up procedures when returning the unit to service.

• Never store the unit or fuel container inside where there

is an open ame or pilot light, such as in a water heater.

Allow unit to cool before storing.

STORAGE

Perform engine maintenance and storage measures listed in

the engine owner’s manual. This includes draining the fuel

system, or adding stabilizer to the fuel.

MAINTENANCE

SCHEDULE AND PROCEDURES

The following schedule should be followed for normal care of

your unit.

BEFORE

SAFETY ITEMS

Check for loose

hardware

Check all safety

labels

CHIPPER

MAINTENANCE

ITEMS

Clean debris from

engine and

chipper. **

Inspect/Rotate

Shredding

Hammers

Inspect/Rotate

Chipping Knives

** More often in hot (over 85° F: 30° C) weather or dusty

operating conditions.

EACH

USE

BEFORE

EACH

USE

x

EVERY

5

HOURS

x x

EVERY

5

HOURS

EVERY

25

HOUR

EVERY

25

HOURS

x

x

SPRING

& FALL

x

SPRING

& FALL

NOTE: Do not store a fueled unit in an enclosed structure. (See

Gasoline Fires and Handling Fuel Safety

BEFORE STARTING THE UNIT AFTER IT HAS BEEN STORED:

1. Check all uid levels. Check all maintenance items.

2. Perform all recommended checks and procedures found

in the engine owner’s manual.

3. Allow the engine to warm up for several minutes before

use.

WARNING

AMPUTATION HAZARD. TO AVOID SERIOUS INJURY FROM

ACCIDENTAL STARTING, ALWAYS DISCONNECT THE SPARK

PLUG WIRE AND SECURE IT AWAY FROM THE SPARK PLUG

WHEN SERVICING THE UNIT.

Get parts online at www.GetEarthquake.com or Call 800-345-6007 M-F 8-5 CST

ENGINE MAINTENANCE

Refer to the engine manual included in your parts packet for

information on engine maintenance. Your engine manual provides information and a maintenance schedule for performing

the following tasks:

1. Check oil level before each use or after every 8 hours of

operation.

2. Change oil after rst 5-8 hours of operation. Change oil

while engine is warm. Rell with new oil of recommended

grade.

4. Check spark plug seasonally or every 100 hours of operation.

5. Service air cleaner.

6. Keep engine and parts clean.

7. Check engine and equipment often for loose nuts and

bolts, keep these items tightened.

17

Page 18

Owner’s Manual

CHIPPER SHREDDER

CHECK FOR LOOSE HARDWARE

Service Interval: Every 5 hours; every spring and fall.

Inspect the unit, checking for loose hardware or components.

Pay special attention to the hardware attaching the chipper

cone, hopper, axle, and front leg.

CHECK SAFETY LABELS

Service Interval: Every spring and fall.

Check that the safety labels are in place and undamaged.

Replace any damaged or missing decals.

INSPECT CONE, HOPPER AND GUARDS

Service Interval: Every spring and fall.

Check that the chipper cone, shredder hopper, and discharge

guards are in place, undamaged, and secure. Replace any

damaged or missing parts.

CLEAN DEBRIS FROM ENGINE AND CHIPPER

Service Interval: Before each use and every 100 hours.

The engine requires air ow to cool itself and for combustion.

Before each use, clean any debris from the unit especially from

around the air shroud intake, air lter, and muer. Every 100

hours, remove the engine air shroud and clean out any debris

from the engine cooling ns SEE FIGURE 10. We recommend

having this service performed by an authorized repair center.

AIR

SHROUD

INTAKE/

AIR FILTER

COOLING FINS

MUFFLER

DEBRIS OFTEN GATHERS IN

THIS AREA

FIGURE 10

INSPECT / ROTATE SHREDDING HAMMERS

Service Interval: Every 25 Hours, or As Necessary

The shredding hammers of this unit can be rotated to provide

a new cutting surface as required. The triangular hammers

can be rotated twice, then ipped over for a total of 6 sharp

cutting surfaces. The J-hammers can be ipped over once. To

inspect the shredding hammers:

1. Disconnect the spark plug wire and secure it away from

the spark plug. SEE FIGURE 14 (on page 19).

2. Remove the small circular access panel (B) from the back

of the shredder housing. SEE FIGURE 11.

3. Inspect the cutting edges of the triangular hammers (A)

and J-hammers (A). SEE FIGURES 11 AND 12.

To rotate or replace the shredding hammers, see the Troubleshooting and Repair section.

ACCESS PANEL

J-HAMMER

WEAR AREA

FIGURE 11

TRIANGULAR-HAMMER

WEAR AREA

FIGURE 12

18

Get parts online at www.GetEarthquake.com or Call 800-345-6007 M-F 8-5 CST

Page 19

INSPECT CHIPPING KNIVES

Service Interval: Every 25 hours, or as necessary

CAUTION

Owner’s Manual

CHIPPER SHREDDER

The chipping knives of this unit can be rotated or sharpened

to provide a new cutting surface as required. When inspecting the knives be careful to avoid touching the sharpened

edges. To inspect the chipping knives:

1. Disconnect the spark plug wire and secure it away from

the spark plug. SEE FIGURE 14.

2. Remove the nuts securing the chipper cone to the front

of the chipper. Remove the chipper cone (A) to access the

knives. SEE FIGURE 13.

3. Using the recoil starter, slowly pull the starter rope to

rotate the rotor into position so the blades can be seen.

To sharpen or replace the chipper knives, see the Troubleshooting and Repair section.

CHECK / CHANGE ENGINE AIR CLEANER

Service Interval: Every 25 hours

The engine air cleaner assembly should be opened, inspected,

and the lter element replaced every 25 hours, or as required if

debris has built up in the assembly.

To replace the air lter, see engine manual.

FOR THE SAFETY OF THE USER, AND TO MAXIMIZE THE

LIFE OF THE ENGINE, IT IS CRUCIAL TO TAKE TIME TO

CHECK THE CONDITION OF THE ENGINE. PROBLEMS MUST

BE CORRECTED BEFORE OPERATING.

AVOID INJURY! ENGINE OIL IS HAZARDOUS TO YOUR

HEALTH. DISPOSE OF OIL APPROPRIATELY. USE A SAFE

DISPOSAL/RECYCLING CENTER.

CHIPPER CONE

FIGURE 13

REPLACE SPARK PLUG

Please contact your authorized repair center to perform

this service.

OIL MAINTENANCE

Refer to engine manual for oil maintenance.

SPARK PLUG

FIGURE 14

Get parts online at www.GetEarthquake.com or Call 800-345-6007 M-F 8-5 CST

19

Page 20

Owner’s Manual

CHIPPER SHREDDER

TROUBLESHOOTING

While normal care and regular maintenance will extend the life of your equipment, prolonged or constant use may eventually

require that service be performed to allow it to continue operating properly.

The troubleshooting guide below lists the most common problems, their causes, and remedies.

See the information on the following pages for instructions on how to perform most of these minor adjustments and service

repairs yourself or by your local authorized repair center.

PROBLEM CAUSE REMEDY

Engine will not start. 1. Out of fuel.

2. Spark plug wire disconnected.

3. Engine controls not set correctly.

4. Spark plug fouled.

5. No compression. Recoil starter pulls

with no resistance.

6. No spark. Ignition problems.

7. Old or stale fuel.

Engine exhaust is black. 1. Dirty air lter

2. Choke closed.

Engine runs but no material is

discharged.

Excessive branch vibration

when chipping materials.

Unusual noise or vibration

when chipping materials.

Vacuum not working. 1. Hopper gate not closed.

1. Discharge chute clogged.

2. Engine not running at full speed.

1. Chipper knives dull.

2. Tree limbs are extremely hard or dried

out.

1. Rotor overloaded with material.

2. Hammers are broken, bent, or loose.

3. Hammers frozen in place.

2. Cone cover not installed.

3. Hose not attached properly.

4. Hose obstructed or damaged.

5. Engine not running at full RPM.

1. Add Fuel.

2. Reconnect spark plug wire as recommended in engine manual.

3. Refer to STARTING in the engine manual.

4. Remove spark plug. Clean/replace as

recommended in engine manual.

5. See your authorized service center.

6. See your authorized service center.

7. See your authorized service center.

1. Replace air lter. See engine manual.

2. Open choke.

1. Clean out debris.

2. Set throttle control to FAST if equipped.

For xed throttle engines see your

authorized service center.

1. Sharpen/Replace chipper knives.

2. Material is not suitable for chipping.

1. Allow unit to clear itself before adding

more material to the hopper.

2. Check assembly. Tighten or replace as

necessary.

3. Check for obstructions and debris. Repair

or replace as necessary.

1. Slide gate to closed position.

2. Allow material to dry.

3. Attach hose per instructions (See Hose

Kit).

4. Clear blockage or replace.

5. Set throttle control to FAST if equipped.

For xed throttle engines see your

authorized service center.

20

Get parts online at www.GetEarthquake.com or Call 800-345-6007 M-F 8-5 CST

Page 21

REPAIR

ROTOR REMOVAL

NOTE: The rotor does not need to be removed to change the

hammers and knives. However, the removal and installation of the knives will be easier with the rotor removed.

NOTE: If using a unit that has socket head bolts with no locking plates on them, the hardware will need to be upgraded to

new hardware kit.

Owner’s Manual

CHIPPER SHREDDER

WARNING

CUTTING HAZARD. TO AVOID SERIOUS INJURY, AVOID

CONTACTING THE SHARP CUTTING EDGES OF THE

CHIPPING KNIVES.

To remove the rotor from the drive shaft:

1. Turn the engine o and wait for all moving parts to stop.

2. Disconnect the spark plug wire and secure it away from

the spark plug. SEE FIGURE 15.

3. Detach the rotor housing and hopper from the rotor

plate. SEE FIGURE 16.

4. Bend the side tabs away from the center mounting bolt

and remove the bolt (8).

5. Carefully remove the rotor plate, spacer, and key (10) from

the crankshaft. SEE FIGURE 17.

HAMMER REMOVAL AND INSTALLATION

NOTE: The cutting edges of the shredding hammers may

eventually wear out requiring rotation of the hammer or

replacement if all cutting edges have been dulled.

NOTE: Triangular hammers can be rotated twice after the

rst edge dulls, then ipped over once and rotated again

for a total of six edges. J-hammers can be ipped over

once for a total of two cutting edges.

1. Remove the hammers by rst bending the lock plate

tabs down away from the hex head bolt securing the

hammers. Remove the bolt. SEE FIGURES 18 AND 19

(next page).

NOTE: the assembly sequence of the hardware used to

secure the hammers.

SPARK

PLUG

WIRE

FIGURE 15

ROTOR PLATE

ROTOR HOUSING

FIGURE 16

3/8 X 2” BOLT

KEY

SPACER

2. Inspect the hammers, spacers, and hardware. If the spacer

tube shows signs of wear, replace it. Inspect and ip, or

replace the hammers. The lock plate should always be

replaced when replacing or rotating hammers.

3. Inspect the hammers, spacers, lock plate and bolts. Torque

the bolt to 30-35 ft -lb (41-47 N.m.). The J-hammer on the

Get parts online at www.GetEarthquake.com or Call 800-345-6007 M-F 8-5 CST

ROTOR PLATE

FIGURE 17

21

Page 22

opposite side of the rotor faces outward for balanced rotation. Two faces of the bolt should align in parallel with the

lock plate tabs.

NOTE: We recommend the use of high-strength thread

locker on mounting bolts.

4. Bend the lock plate tabs up to secure the bolt and preventing rotation. The tabs should sit at on a face of the

bolt. SEE FIGURE 18.

5. Repeat for all hammers.

CHIPPING KNIFE REMOVAL AND INSTALLATION

To inspect or replace the chipping knives:

1. Bend the lock plate tabs away from the bolts securing the

chipping knives.

2. Remove the two bolts and the chipping knife. SEE

FIGURE 20.

Owner’s Manual

CHIPPER SHREDDER

LOCK PLATE

TABS

FIGURE 18

ROTOR PLATE

TRIANGULAR-HAMMER

3. Inspect or replace the chipper knife.

4. Reinstall the chipper knife and tighten the bolts to 18-20

ft-lb (24-27 N.m.). Ensure that the knife is sitting squarely

against the stop that has been formed into the rotor. If it is

not sitting square, the knives will perform as if they are extremely dully. Always use a new lock plate when installing

knives. Two of the bolt faces should align in parallel with

the lock plate tabs.

Note: We recommend the use of high-strength thread locker

on mounting bolts.

5. Bend the lock plate tabs up to prevent bolt rotation. The

tabs should sit at on a face of the bolt. SEE FIGURE 18.

INSTALL THE ROTOR ON THE CRANKSHAFT

To install the rotor on the crankshaft:

1. Replace the rotor onto the crankshaft, careful to replace

the spacer and key. SEE FIGURE 17.

2. Torque the mounting bolt to 30-35 ft-lb (41-47 N.m.).

3. Bend the lock plate tabs up to secure the mount bolt and

prevent rotation. The tabs should sit at on the face of the

bolt.

M10 X 50 MM

BOLT

LOCK

PLATE

M8 X 16 MM

BOLT

LOCK

PLATE

SPACERS

J-HAMMER

FIGURE19

KNIFE

ROTOR PLATE

FIGURE 20

4. Reinstall rotor housing and hopper. SEE FIGURE 16.

22

Get parts online at www.GetEarthquake.com or Call 800-345-6007 M-F 8-5 CST

Page 23

NOTES:

Owner’s Manual

CHIPPER SHREDDER

Get parts online at www.GetEarthquake.com or Call 800-345-6007 M-F 8-5 CST

23

Page 24

ARDISAM, INC.

1160 Eighth Avenue

PO Box 755

Cumberland, WI 54829

Phone: (800) 345-6007

Fax: (715) 822-2124

www.GetEarthquake.com

Loading...

Loading...