HVLP SSppray Guun

( High Volume Low Pressure)

OPERATING INSTRUCTIONS

Thank you for purchasing the Earlex HVLP Spray Gun. This can only

be used with an Earlex Combivac or Combi Power Vac so if you don’t

have one of these please do not proceed with using the gun. This is a

highly versatile spray gun and can be used on a variety of

applications.

BEFORE USE - PLEASE READ THE SAFETY &

OPERATING INSTRUCTIONS.

Please retain for future reference

final.qxd 22/02/00 11:05 Page 1

SAFETY OPERATING INSTRUCTIONS

2

PLEASE READ BEFORE USE

NEVER under any

circumstances aim the nozzle

at another person or animal. In the

event of injury occuring seek expert

medical advice immediately.

The spray gun must only be used

with paints and solvents that have a

suitable flash point for spraying. If in

doubt consult paint or solvent manufacturer’s data.

Always ensure there is adequate

ventilation when spraying.

NEVER spray near a naked flame,

including appliance pilot flame.

NEVER smoke whilst spraying.

NEVER allow children to operate or

play with the spray gun.

Always read the paint manufacturers

thinning instructions before using.

Always disconnect Combivac from

mains supply when refilling the paint

container.

Before cleaning, always disconnect

Combivac from the mains supply.

Always wear the correct protective

mask mask when spraying. We would

also recommend the use of gloves

and goggles.

After every use ensure that you clean

your spray gun thoroughly and

grease the packing piece.

WARNING: The substances used with

this spray gun (paint, thinner etc)

may contain hazardous, harmful,

explosive or corrosive materials.

ALWAYS COMPLY WITH THE SAFETY

INSTRUCTIONS ISSUED WITH THIS

PRODUCT AND THE MATERIAL

!

INTRODUCTION

HVLP stands for High Volume, Low Pressure. This is a type of spraying that

allows you to spray extremely accurately but without all the overspray that occurs

with the high pressure tank type equipment. In fact, in some parts of the world

the high pressure systems are banned by law on environmental grounds and

HVLP type systems are the only alternative for professional type spraying. This

gun is extremely easy to use, very safe and reduces the amount of paint used .

PLEASE NOTE

We have done all we can to ensure that used correctly and according to these

instructions, this spray gun will give long and trouble free life. We accept no

responsibility for damage caused by the use of incorrect or unsuitable

substances, paints or fluids which have not been thinned correctly or are

unsuitable for the surfaces to which they are applied, health hazards arising from

lack of ventilation when working in confined spaces or failure of the equipment

due to inadequate cleaning of the components after use.

If in doubt, always test a small inconspicuous area first. Always read the paint

manufacturer’s instructions first.

Neither our guarantee nor the above statement affects your statutory rights.

final.qxd 22/02/00 11:05 Page 2

3

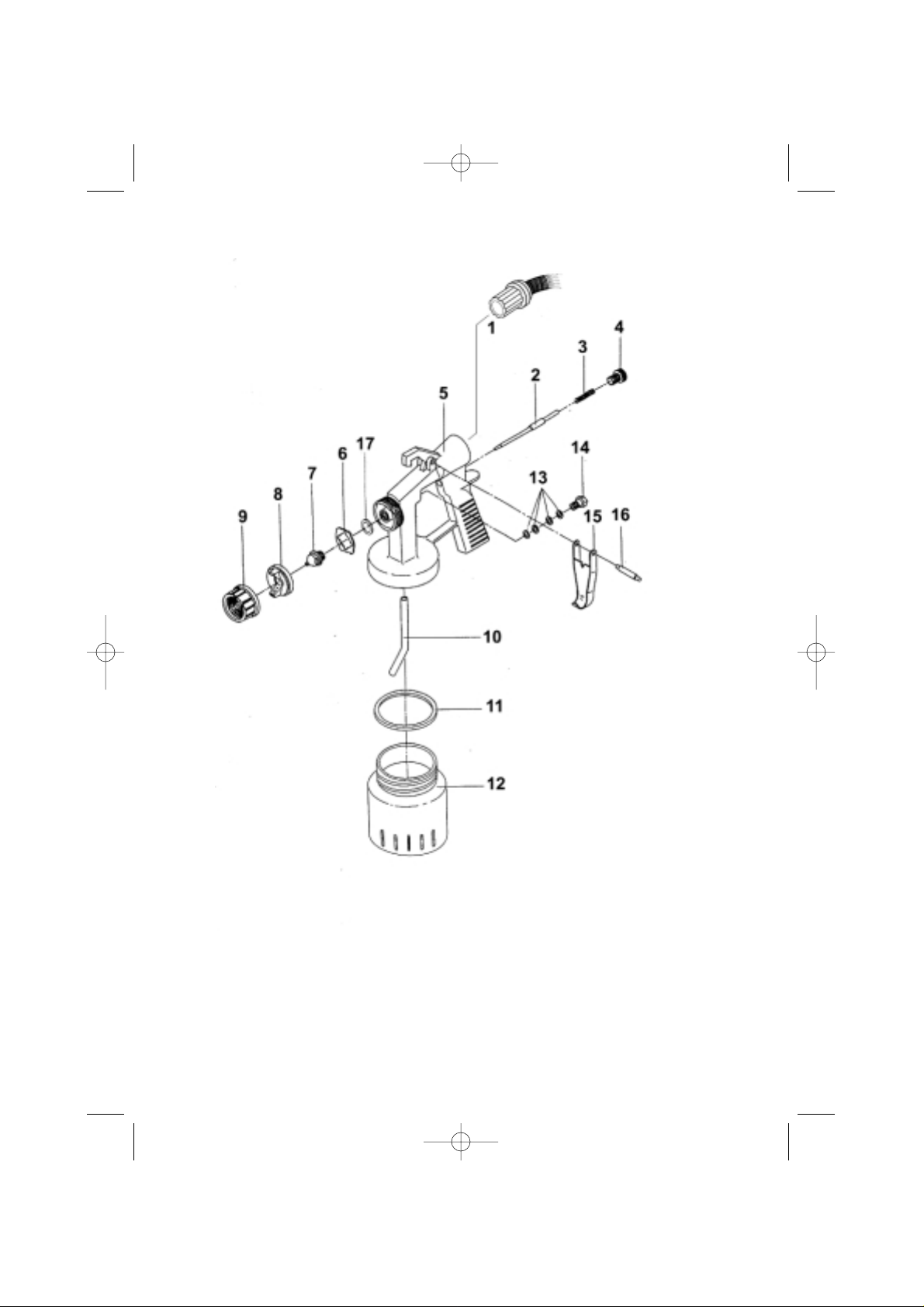

PARTS LIST

Key Discription Part No.

No.

01. Hose Connector WD0194

02. Fluid Needle Assembly WD0198

03. Spring WD0199

04. Fluid Adjusting Screw WD0200

05. Gun Body WD0201

06. Air Flow Plate WD0202

07. Fluid Tip WD0203

08. Nozzle WD0204

09. Adjustment Ring WD0205

10. Fluid Tube WD0206

11. Container Gasket WD0207

12. Container WD0208

13. Fluid Needle Packing WD0209

14. Needle Packing Screw WD0210

15. Trigger WD0211

16. Trigger Pin WD0212

17. Nozzle Washer WD0213

final.qxd 22/02/00 11:05 Page 3

IMPORTANT – SELECTING PAINT

This is a highly versatile spray gun that

can be used with several different spray

mediums including varnishes, wood

preservatives, enamels, oil and water

based paints and cellulose. However

some materials cannot be sprayed so

please check the manufacturer’s recommendation before buying the paint. If a

material refers to brush application only

then it cannot be sprayed.

THIS CANNOT BE USED FOR TEXTURED EXTERIOR WALLPAINTS OR

INTERIOR COATINGS. USE OF

THESE MATERIALS WILL CAUSE

PREMATURE WEAR, WHICH WILL

VOID THE GUARANTEE.

TO OBTAIN THE BEST RESULTS

FROM YOUR SPRAY GUN PLEASE

READ THE INSTRUCTIONS CAREFULLY BEFORE

USE.

PREPARATION

Preparation of the surface and thinning

of the paint are the two most important

areas to be concerned with to obtain

the best results from your spray gun.

Ensure all surfaces are free from dust,

dirt, rust and grease. If necessary rub

down with sandpaper, or similar.

Masking of areas is important to ensure

you do not spray those areas you wish

to remain untouched.

THINNING

Your spray gun is supplied with a viscosity cup. Viscosity is a technical term

used to indicate if a product is very liquid or very thick. If liquid, the viscosity

is said to be low, while if very thick the

viscosity is said to be high.

Viscosity is measured in seconds. In

order to spray some materials they

need to be “thinned”.

Thinning is very important when spraying. Most paints etc are supplied ready

for brush application and may need to be

thinned (diluted) for spraying purposes.

Follow the manufacturer’s guide for thinning in conjunction with a spray gun. If in

doubt please contact the manufacturer’s

of the paint. The viscosity cup supplied

will help you determine the correct thickness of the paint. Paint is “thinned” by

adding the substance which the paint is

based upon. If a water based paint then

water is added, if oil based then white

spirit, if cellulose then a cellulose thinner

is added.

As some paints, wood preservatives

and other sprayable materials contain

particles that have differing qualities,

please ensure that when filling the paint

container of the spray gun, that the

paint is filtered through either a funnel

with a filter on it or through nylon tights

or stockings. This will ensure that no

large particles enter the paint container,

so preventing blockages and provide

you with trouble free spraying. Ensure

that a face mask, gloves and goggles

are worn at all times when spraying.

IDEAL VISCOCITY

Water based paints 45 - 60 seconds

Oil based paints 45 - 50 seconds

Wood preservatives No dilution

Primers 45 - 50 seconds

Varnishes No dilution

Aluminium paints No dilution

Wood stains No dilution

Cellulose Manufacturers ratio

This gun can be used having products

with a viscosity ranging from 10 to a

maximum of 60 seconds.

4

final.qxd 22/02/00 11:05 Page 4

Dip the viscosity cup into the material

and fill up. Time how long it takes for

the viscosity cup to empty (Fig 1).

Using the above chart (or manufacturer’s instructions) as a guide determine

if the material requires further thinning,

if so then thin accordingly.

OPERATION

Fill the paint container with the material

to be sprayed. DO NOT OVERFILL.

Screw the container onto the body tightly.

The spray gun is supplied with a hose.

This is designed to fit into the hose

supplied with the Combivac to give you

sufficient length of hose to be able to

spray most objects without limiting the

spraying action.

The Combivac hose needs to be fitted

to the “Blower” outlet (Fig.2) – this is

the outlet at the top of the machine.

Connect the additional hose, supplied

with the Spray Gun into the end of the

Combivac hose and the other end into

the back of the Spray Gun.

ALWAYS KEEP THE COMBIVAC UNIT

AS FAR AWAY FROM THE SPRAYING

AREA AS POSSIBLE TO PREVENT

PAINT CONTAMINATING THE

MOTOR.

MASK ANY AREA YOU DO NOT WISH

TO BE SPRAYED

Once you have set up ready to spray,

switch on the Combivac. No paint will

be sprayed from the gun until the trigger on the Spray Gun is pulled. Before

starting any work on spraying actual

objects we suggest you spend a small

amount of time practicing on cardboard

or newspaper until you have got used

to how the gun works.

Position the fluid tube in the paint container to provide the best angle to pick

up all the paint in the container

SPRAY PATTERNS

The gun has both adjustable volume

control and 3 different spray patterns –

Horizontal, Vertical and Round (Fig.3)

The horizontal and vertical are recommended for large surfaces. The round

spray is used for small objects or for

areas - such as corners – that are difficult to reach.

To adjust the spray pattern, loosen the

adjustment ring (9), adjust the position

of the nozzle (8) to obtain either a vertical, horizontal or round pattern then retighten the adjustment ring.

5

Fig.1

Fig.2

Fig.3

Vertical Jet

Round JetHorizontal Jet

final.qxd 22/02/00 11:05 Page 5

6

PAINT VOLUME

The volume of paint sprayed is easily

adjustable.(Fig.4)

Completely close adjustment screw (4)

by turning this clockwise as far as it will

go. Whilst pulling the trigger, begin turning the adjustment screw anti-clockwise

until the volume of paint you require is

obtained.

If the paint spray is too wide or contains

too much paint turn the adjustment

screw clockwise again. Once the correct spray pattern is obtained you are

able to commence spraying.

SPRAYING TECHNIQUE

1.To obtain the best results always keep

your spray gun level and spray equally from

side to side or up or down 25-30cm (10”-12”)

from the surface. Avoid spraying at an angle

as this will lead to runs on the surface (fig.5).

2. Let your arm control the left to right

movement rather than your wrist as this will

aid even paint distribution over the whole

area (fig.5).

3. Do not tip the sprayer to more than 45

o

angle.

HELPFUL HINTS

1. Evenly control the speed of movement of

the spray gun. A fast speed will give a thin

coat and a slow speed will give a heavy

coat.

2. Only apply one coat at a time. If a further

coat is required follow the paint

manufacturer’s instructions for drying times.

3. If spraying small areas or objects keep the

output setting low as this will avoid

excessive use of paints and will minimise

overspray.

Fig.5

Fig.4

Fig.6

final.qxd 22/02/00 11:05 Page 6

4. When spraying large areas or objects, it is

best to use a criss-cross pattern, either from

left to right then up or down or vice-versa.

This will ensure maximum coverage (Fig. 6).

5. Avoid stopping and starting when spraying

as this can lead to too much or not enough

material on a surface.

6. To ensure edges are covered, commence

spraying just to the side of area being

sprayed

7. CLEAN SPRAYER AFTER EVERY USE

(SEE CLEANING INSTRUCTIONS)

CLEANING INSTRUCTIONS

THE SPRAY GUN MUST BE

THOROUGHLY CLEANED

IMMEDIATELY AFTER USE.

IF THE PAINT DRIES INSIDE THE

GUN, CLEANING WILL BECOME

MUCH MORE DIFFICULT AND

MAY RENDER THE GUN INOPERABLE. THIS IS NOT COVERED BY

GUARANTEE.

The spray gun is the same as a paintbrush, if it is not cleaned it will go hard

and can become useless. You must

therefore clean this out after use.

GUN

! Disassemble the gun container

! Pour any residual material into its con-

+tainer so that it can be used for the

future.

! Pour a quantity of the respective thin

ner into container, shake the gun

lightly , reassemble the gun, then spray

this liquid through the gun. Repeat this

until the thinner being sprayed is com

ing through with no traces of paint.

! Clean any traces of paint off the out

side of the gun

! Clean the gasket (11) inside the gun

body

NOZZLE AND NEEDLE

! Unscrew Adjustment Ring (9)

! Remove the Nozzle (8)

! Completely remove Adjustment

Screw (4)

! Remove the Spring (3)

! Push out the Needle (2) – do not use

tools for this

! Remove the Fluid Tip (7)

! Remove Air Flow Plate (6)

! Remove Nozzle Washer (17)

! Place all of these items into a

container and clean them using a

brush and clean thinners

! Clean the inside of the gun

!Thoroughly dry these parts before

reassembling

! Grease the Fluid Needle Packing (13)

! Reassemble parts in reverse order. It

is recommended fitting the fluid tip (7)

prior to the needle

NEVER DISPOSE OF PAINTS OR

SOLVENTS INTO DRAINS.

CONTACT YOUR LOCAL COUNCIL TO ARRANGE COLLECTION

OR FOR DETAILS OF NEAREST

REGISTERED DISPOSAL SITE.

7

final.qxd 22/02/00 11:05 Page 7

8

TROUBLE SHOOTING

PROBLEM CAUSE ACTION REQUIRED

The paint drips onto item Paint too diluted Add undiluted material

being painted Fluid adjustment screw Reduce the paint flow by

adjusting screw (4)

Moving too slowly Increase speed of application

Gun trigger being held Release trigger earlier

for too long

Gun too close Increase the distance

between the gun and work

piece

Paint is thin or irregular Paint too diluted Add thinner

Fluid adjustment screw Increase the paint flow by

adjusting screw (4)

Moving too fast Reduce speed of application

Gun clogged Clean the gun

Gun too far away Reduce the distance

between gun and work

No paint being produced Paint too thick Add thinner

Gun clogged Clean the gun

Pick up pipe clogged Clean pick up pipe

Air hose split Replace air hose

Grainy paint Filter the paint

Container almost empty Refill container

Gun at an Angle Ensure Fluid Tube (10) is

angled towards paint

GUARANTEE

This product is guaranteed for a period of 12 months against faulty manufacture

and materials. It is not guaranteed for industrial or hire purposes. The guarantee

does not affect your statutory rights. In the event of any problem occurring please

contact us on our Helpline No during the hours of 8.30 a.m. and 5 p.m. Monday

to Thursday and 8.30 am - 4.30pm Friday or visit our Website on www.earlex.co.uk

final.qxd 22/02/00 11:05 Page 8

9

OTHER PRODUCTS FROM EARLEX

COMBIVAC ACCESSORIES

WDACC2 - Deluxe Floor Head with hard floor, brush and squeegee attachments. Wider head for

greater coverage, suitable for carpets and faster pickup of debris and spills.

WDACC10 - Pack of three spare foam filters.

WDACC11 - Pack of three spare paper filters.

WDACC12 - Power Tool Adapter.

WDACC13 - Combined Wet & Dry Filter no need for foam filter or paper filter and no need to

changebetween filters for dry or wet pickup.

WDACC14 - Wide Bore Tool Kit for larger debris such as rubble and leaves.

WDACC15 - Mini Cleaning Set - ideal for cleaning/blowing computers, video recorders, air vents in

cars.

WDACC16 - Sink Deblocker - clears blockages from sinks, baths and showers.

Earlex also manufacture a wide range of steam wallpaper strippers and other decorative power

tools to help in your DIY efforts.

STEAM WALLPAPER STRIPPERS

Designed to remove all types of wallpaper, multi-layered painted papers and Artex.

SS100 Super Steamer - 2300W 4.5 ltr steam wallpaper stripper.

SS50 Warrior - 2000W 4.5 ltr steam wallpaper stripper.

A range of steam cleaning accessories is also available to be used in conjunction with the steam

wallpaper strippers. The accessories can be used to clean and rejuvenate carpets, floor tiles,

unblock sinks or waste outlets, clean work surfaces, defrost fridges and freezers, clean windows

and tiles, remove soiling from upholstery and curtains.

Alternatively the Combi-Steam combines the versatility of the steam wallpaper stripper with a

selected range of accessories providing you with a complete steam cleaning kit and wallpaper

stripper. SC165 - 1500W 4.5 ltr steam cleaning kit, including carpet cleaner, window/tile cleaner, jet

nozzle cleaner, upholstery cleaner/small steam plate, large wallpaper stripping plate.

PR9 Autofeed Cordless Painting System - Portable battery operated paint rolling system. It has

a 3 litre paint reservoir and 23cm (9”) roller and automatically feeds paint to the roller head.

Easy to use the PR9 provides enough capacity to apply one coat to a 3.6m x 2.7m (12’ x 9’) room

without having to refill.

PRA1 1.4m Extension Pole - Used in conjunction with the PR9 the PRA1 allows you to paint ceilings and high areas without the use of step ladders or having to move furniture.

HG1600K - Heat Gun Kit. The Earlex Heat Gun Kit offers a 1600 Watt heat gun in a strong carry

case and includes a range of useful accessories. With two heat settings the heat gun can be set at

4000C or 5900C. It is provided with a selection of four nozzles, three shavehooks and a scraper to

suit different tasks and it all stores away conveniently in the carry case.

final.qxd 22/02/00 11:05 Page 9

10

WD0215 02/00

Earlex Ltd., Earlex House,

Moorfield Road, Slyfield Industrial Estate,

Guildford, Surrey, GU1 1RU.

Tel: 01483 - 454666.

Fax: 01483 - 454548

E.mail: enquires@earlex.co.uk

Website: www.earlex.co.uk

final.qxd 22/02/00 11:05 Page 10

Loading...

Loading...