Page 1

EAGLE

Installation, Operation and

Maintenance Instructions

Lubrication information is

in Section III-A, Item 1b.

and Section IV-A.

EAGLE MODEL A100

ANSI PUMPS

Page 2

TABLE OF CONTENTS

SECTION I—GENERAL

Introduction .................................................................................................................................................................3

I-A Importance of Instructions ........................................................................................................................... 3

I-B Special Warnings .......................................................................................................................................... 3

I-C Receiving Inspection—Shortages................................................................................................................. 3

I-D Preservation and Storage.............................................................................................................................. 3

I-E Handling Techniques.................................................................................................................................... 3

SECTION II—INSTALLATION

II-A Location........................................................................................................................................................ 3

II-B Foundations .................................................................................................................................................. 3

II-C Leveling and Grouting of Baseplate ............................................................................................................. 4

II-D Piping Practices ............................................................................................................................................ 4

II-E Alignment—Preliminary .............................................................................................................................. 4

II-F Stuffing Box .................................................................................................................................................. 5

SECTION III—OPERATION

III-A Startup .......................................................................................................................................................... 5

III-B Operation Checks......................................................................................................................................... 6

III-C Shutdown Procedure .................................................................................................................................... 6

SECTION IV—PREVENTIVE AND CORRECTIVE MAINTENANCE

IV-A Lubrication ................................................................................................................................................... 6

IV-B Stuffing Box.................................................................................................................................................. 6

IV-C Vibration....................................................................................................................................................... 6

IV-D Alignment—Final......................................................................................................................................... 6

IV-E Performance.................................................................................................................................................. 6

SECTION V—DISASSEMBLY AND REASSEMBLY

V-A Disassembly................................................................................................................................................... 7

V-B Inspection and Parts Replacement Guidelines............................................................................................. 7

V-C Reassembly Procedures................................................................................................................................. 7

V-D Additional Details ........................................................................................................................................ 9

SECTION VI—PRODUCT DESCRIPTION

Product Description............................................................................................................. 9,10,11,12,13,14

SECTION VII—TROUBLE SHOOTING

Troubleshooting.......................................................................................................................................... 15

SECTION VIII—ORDERING SPARE PARTS

VIII-A Spare Parts.................................................................................................................................................. 15

VIII-B Instructions for Ordering Spare Parts......................................................................................................... 15

2

Page 3

SECTION I—GENER AL

LEAVE 3/4" TO11/2" UNDER

BEDPLATE FOR GROUT

WEDGES

DAM

WASTE

BEDPLATE

GROUT

LEAVE TOP OF

FOUNDATION ROUGH,

AND WET BEFORE

GROUTING.

CONCRETE

FOUNDATION

Introduction

This instruction manual is intended to assist those involved

with the installation, operation and maintenance of Eagle

Model A100 pumps. It is recommended that this manual be

thoroughly reviewed prior to installing or performing any work

on the pump or motor.

I-A. Importance of Instructions

The design, material and workmanship incorporated in the

construction of Eagle pumps make them capable of giving

long, trouble–free service. The life and satisfactory service of

any mechanical unit, however, is enhanced and extended by

periodic inspection and careful maintenance. This instruction

manual was prepared to assist operators in understanding the

construction and correct methods of installing, operating, and

maintaining these pumps.

Study thoroughly Sections I, II, III, and carefully follow the

instructions for installation and operation. Sections IV, V, VI,

VII, and VIII are answers to trouble and maintenance questions.

Keep this instruction manual handy for reference.

I-B. Special Warnings

Eagle Pump and Compressor will not be liable for any damages

or delay caused by failure to comply with the provisions of this

instruction manual. This pump is not to be operated at speeds,

working pressures, discharge pressures, or temperatures higher

than nor used with liquids other than originally intended for,

without written permission of Eagle Pump.

Instruction sheets on various components as well as the

Instruction Book for the pump are included in the shipment.

DO NOT DISCARD!

I-D. Preservation and Storage

Eagle’s normal domestic shipping and storage preparation is

suitable for protecting the pump during shipment in covered

trucks. It also provides protection during covered storage at the

jobsite, and for a short period between installation and start-up.

If the pump is to be idle and exposed to the elements for

an extended period, either before or after installation, special

precautions are required. One approach is to provide special

preservatives and wrapping before shipment. However, after

installation the protective wrappings will have been removed.

Therefore, application of preservatives after installation is

considered a good practice.

The driver, coupling, and mechanical seal manufacturers should

be contacted for their recommendations on preservation and

protection procedures.

I-E. Handling Techniques

Care should be used in moving pumps. Pumps should not be

hoisted by eyebolts. These eyebolts are intended for removing

the back pull–out assembly for maintenance and inspection. An

assembled pump should be hoisted using a sling under suction

flange and under rear of bearing frame. Bedplate mounted units

should be hoisted using slings under bedplate below both pump

and driver.

I-C. Receiving Inspection—Shortages

Care should be taken when unloading pumps. If shipment is

not delivered in good order and in accordance with the Bill–of–

Lading, note the damage or shortage on both receipt and freight

bill. MAKE ANY CLAIMS TO THE TRANSPORTATION

COMPANY PROMPTLY.

SECTION II—INSTALLATION

II-A. Location

Pumping unit should be placed as close as practical to the

source of supply. Floor space and headroom allotted to the unit

must be sufficient for inspection and maintenance. Be sure to

allow for crane or hoist service.

II-B. Foundations

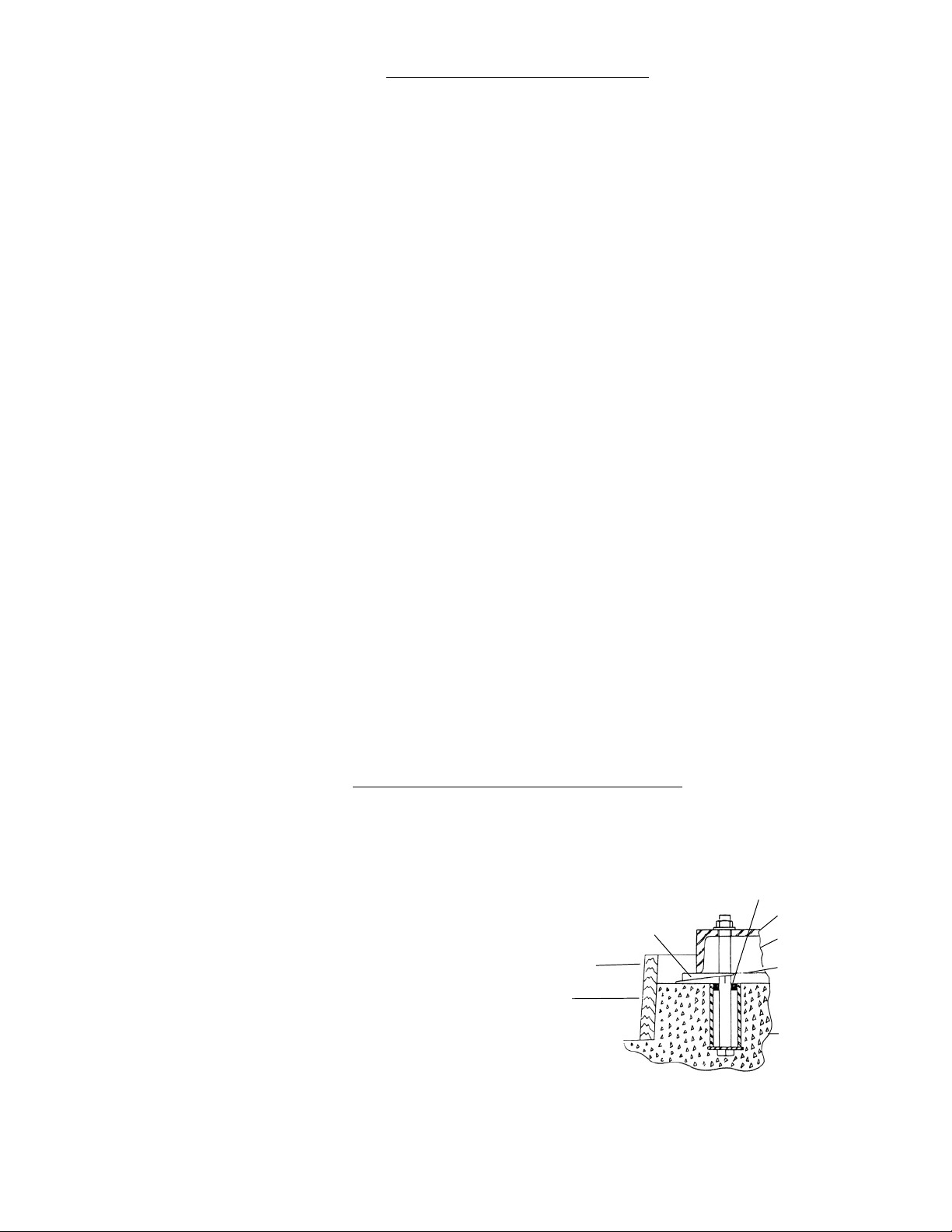

1. Grouted—Bedplate mounted units are normally grouted–in

on a concrete foundation, which has been poured on a solid

footing. This allows a permanent, vibration–absorbing base for

the unit. The location and size of foundation bolts are shown

on the outline assembly drawings supplied for the unit. Fig. 1

illustrates a typical foundation bolt installation.

2. Flexibly Mounted—Installation and leveling of the optional

flexibly mounted bedplate should be carried out in accordance

with assembly drawings supplied in the data package for the

unit.

Figure 1

3

Page 4

II-C. Leveling and Grouting of

Baseplate Initial Alignment Check

1. Put the unit in place on wedges located at four points as

shown in Fig. 2. Some long installations may require additional

wedges near center of bedplate.

WEDGES

Figure 2

2. Adjust wedges to level unit (approximately), placing unit

between ” and 1” above foundation. Level or plumb suction

and discharge flanges. Then, bring the coupling halves into

reasonable alignment by adjusting the wedges as needed.

3. Make sure that the baseplate is not distorted and that final

accurate coupling alignment can be established within the limits

of movement of motor and by shimming motor if necessary.

II-E. Alignment—Preliminary

Alignment of the pump and driver is of extreme importance

for trouble–free mechanical operation. Alignment should be

obtained by adding or removing shims from under the motor

feet. The pump bearing frame foot should never be adjusted

to obtain alignment. The proper shimming is installed under

the bearing frame foot at the factory on units shipped with

bedplates. Changing the pump casing or bearing frame in the

field will require a reshimming of the frame foot. The proper

number of shims is installed when the pump shaft is level and

parallel to the bedplate surface. Proper shimming is achieved

by loosening frame foot and tightening casing foot. This should

create a gap between the frame foot and bedplate between 0

and .040 inches (1mm). This must be filled with shims and

the frame foot retightened. If this procedure is not followed,

mechanical problems can result. The final alignment is done

after the unit has been run under actual operating conditions.

The following are suggested steps for aligning the unit, prior to

initial startup.

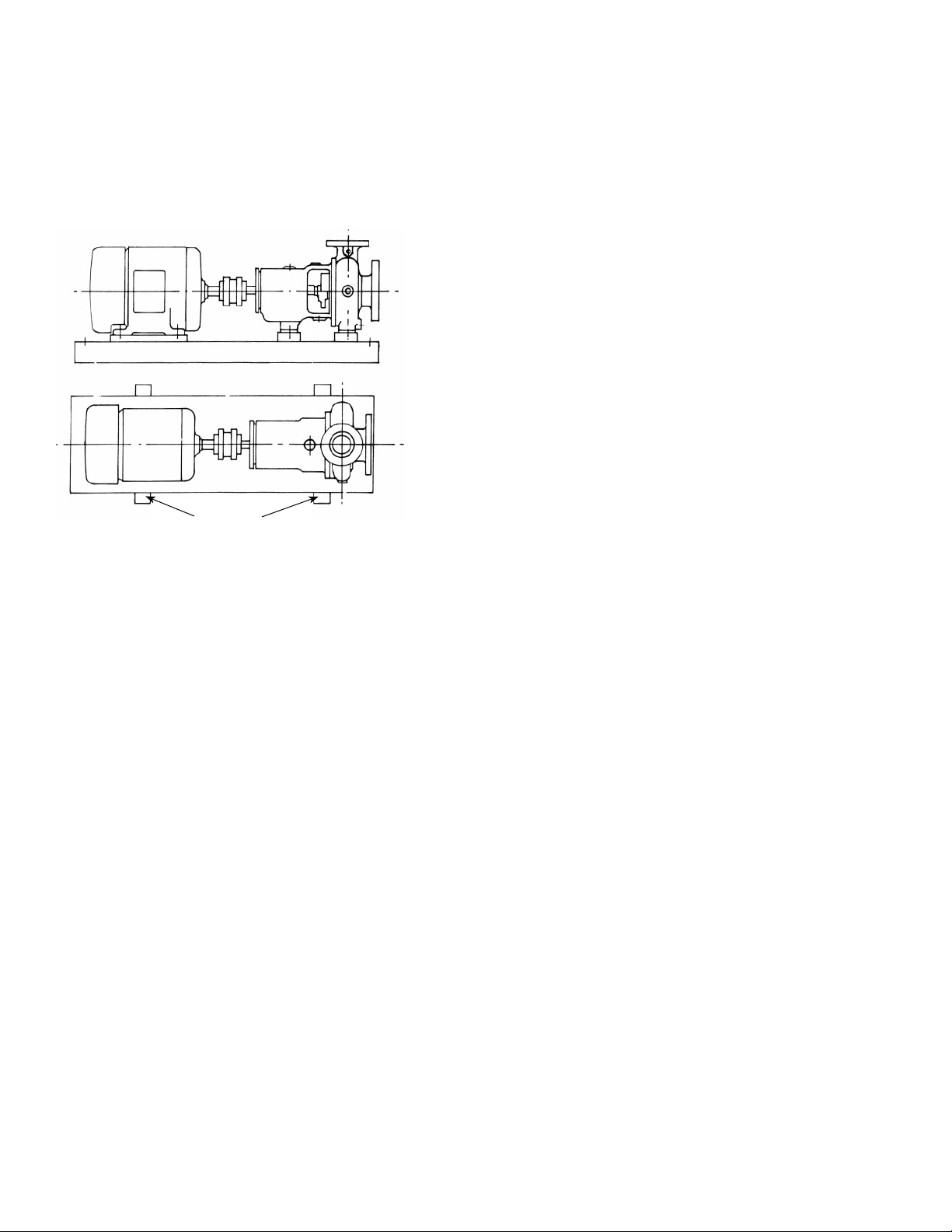

1. Parallel Alignment: The unit is in parallel misalignment

when the shaft axes are parallel, but not concentric. During

initial alignment, vertical parallel alignment may be different,

due to thermal expansion of the unit at actual operating

conditions. The following is a suggested cold setting for motor

driven units:

Pumpage

Temperature

Above Ambient Set Motor Shaft

Ambient .002–.004” low (.05–.10 mm)

100° F. .000–.002” high (.00–.05 mm)

200° F. .004–.006” high (.10–.15 mm)

300° F. .008–.010” high (.20–.25 mm)

400° F. .012–.014” high (.30–.35 mm)

500° F. .016–.018” high (.40–.45 mm)

4. Tighten foundation bolts finger tight. Build dam around

foundation and pour grout. Fill to level of grout hole making

sure that the areas under the pump and motor feet are filled

solid. Allow grout to harden at least 48 hours before further

tightening foundation bolts. Tighten pump hold down bolts.

II-D. Piping Practices

Guidelines for piping are given in the “Hydraulic Institute

Standards” and should be reviewed prior to pump installation.

All piping should be supported independently of, and line up

naturally with, the pump flanges. NEVER DRAW PIPING

INTO PLACE BY USE OF FORCE AT THE FLANGED

CONNECTIONS OF THE PUMP.

Both suction and discharge piping should be as short and direct

as possible to minimize friction losses. Foundation, pump and

driver hold–down bolts should be tightened prior to connecting

suction or discharge piping to the pump.

On units handling corrosives, the piping can be arranged to

allow flushing of the pump prior to opening of the unit for

servicing. After connecting suction and discharge piping to the

pump, rotate pump by hand to be sure that there is no binding.

2. To check the parallel alignment of “spider–insert” couplings,

place a straight edge across both hubs at four points, 90° apart

(see Fig. 3). To check the parallel alignment of flexible spacer

couplings, place a dial indicator on one hub and rotate that

hub 360° while taking readings on the outside diameter of the

other hub. Alignment occurs when indicator deflection does

not exceed .002” T.l.R. (see Fig. 4) of the recommended cold

setting in elevation and not more than .002” T.l.R. side to side.

To check angular alignment of a “spider–insert” coupling, use

calipers at 90° intervals on the circumference on the outer end

of hubs. When caliper measurements are identical, the unit is

in angular alignment. The correct gap between the hub and

insert will be given in the coupling manufacturer’s instructions

supplied for the pump.

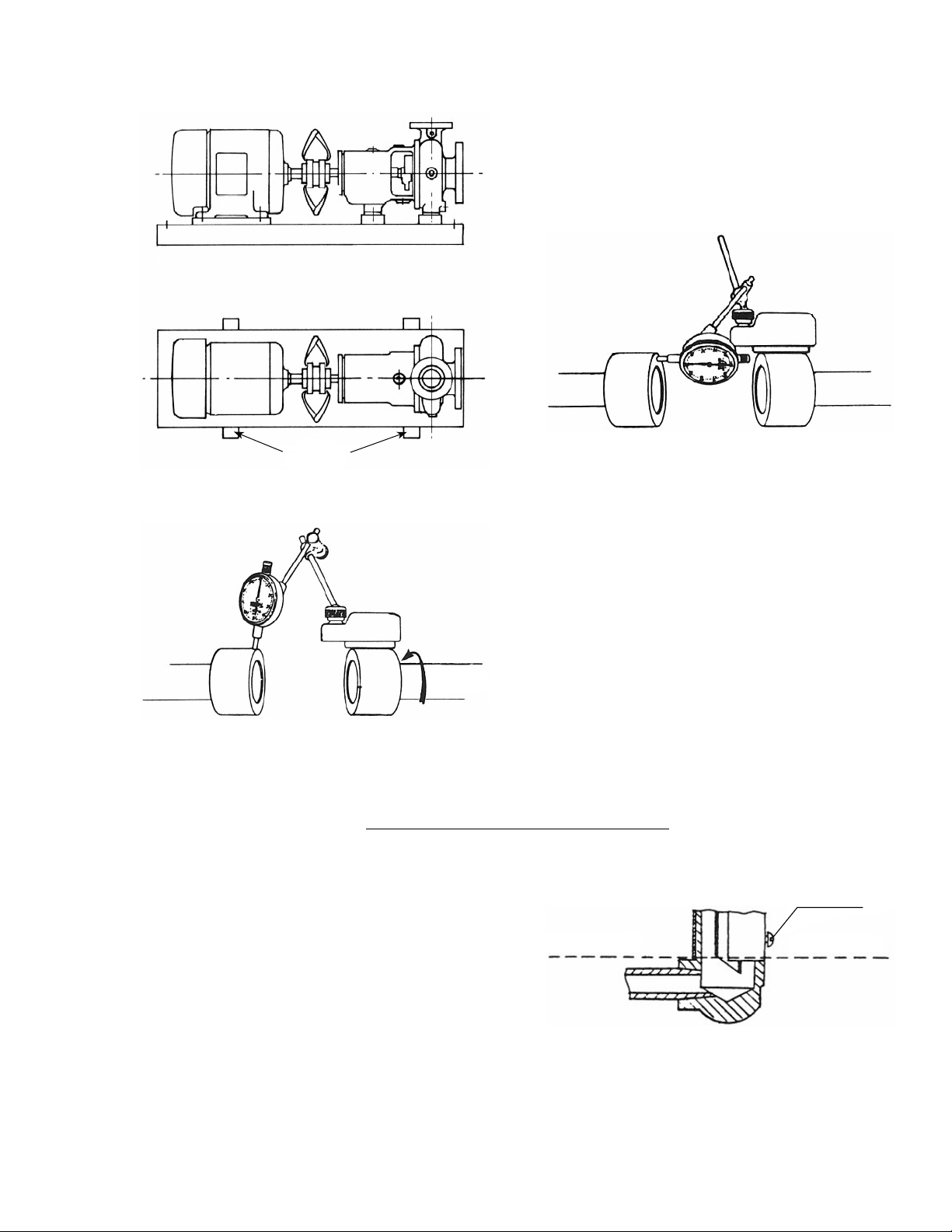

To check angular alignment of flexible spacer couplings, place

a dial indicator on one shaft hub and rotate the hub 360°. Take

readings from the face of the other hub. Alignment is achieved

when deflection does not exceed .002” (see Fig. 5).

4

Page 5

PRIOR TO COUPLING DRIVER TO PUMP, ROTATION OF

OIL LEVEL

OIL LEVEL

SET SCREW

DRIVER SHOULD BE CHECKED! Serious damage can result

if pump is rotated in wrong direction. Once motor rotation

is checked, connect coupling, following the manufacturer’s

instructions. If a coupling guard is furnished with the unit,

ensure that it is securely fastened in place.

WEDGES

Figure 3

Figure 4

R O T A T E

THIS HUB

Figure 4

SECTION III—OPERATION

III-A. Startup

1. Check List

a. Lubrication—Pump bearings are normally oil lubricated.

(THE BEARINGS ARE NOT LUBRICATED AT THE

FACTORY.) These pumps are supplied with an oiler which

maintains a constant oil level in the bearing frame. Locate

oiler as shown on the outline drawings supplied for the

unit. See Fig. 6 for correct adjustment of oiler.

Figure 5

II-F. Stufng Box

1. Packing:

If the pumpage is dirty or hot, it is not suitable to lubricate the

packing. An external source must be utilized, unless the bypass

is equipped with proper separator, filter, and/or cooling system.

This must be piped into the lantern ring connection, also (refer

to packing recommendations).

2. Mechanical Seals:

When mechanical seals are supplied, they are installed and

adjusted at the factory. They must not run dry or in abrasives.

Connect recirculation, flush and/or cooling lines as required,

following instructions on the seal print supplied for the unit.

Figure 6

5

Page 6

b. A high quality turbine type oil with rust and oxidation

inhibitors should be used. Under normal operating

conditions, an oil of 300 SSU viscosity at 100° F.

(approximately SAE 20) should be used. Fill oiler bottle

and replace in oiler housing. Repeat until oil remains

visible in bottle. Do not add oil through the vent or

breather. Optional grease lubricated bearings are lubricated

at the factory and need lubrication only after 2,000

hours of operation, or every 3 months, which ever occurs

first. On pumps supplied with greased–for–life bearings,

no additional lubrication is required for the life of the

bearing.

Oil Mist lubrication of bearings is available on A100–X

frames. This can be supplied at time of order, or field

conversion can be done. Refer to the instructions of the

manufacturer of the Oil Mist System.

c. Priming—Pump and suction piping must be full of liquid

before pump is started. Usually suction supply will be

primed when shutoff valves are opened, if pump is below

suction supply. If suction supply is below pump, priming

by other means, such as a foot valve or ejector, will be

required.

d. Free Rotation—Rotate shaft by hand to make sure it is

free. Drag from packing or seal is normal but, if pump

cannot be rotated by hand or binding or rubbing is noticed,

correct before starting pump.

2. Startup

a. Valves—Be sure suction valve is fully open. Normally,

discharge valve should be at least partially closed for flow

control.

b. Rotation Check—if not already done, uncouple the unit

and jog the motor to check for proper rotation (refer to

Section II–E–2, page 5).

III-B. Operation Checks

Inspect pump carefully and frequently during the first few hours

of operation. If packing runs hot, shut pump down, allow box

to cool, loosen gland if necessary. (Do not loosen gland until

packing has cooled.) Mechanical seal may weep slightly, but

should “run–in” in a few hours. Be sure all auxiliary lines

(cooling, flushing, sealing, etc.) are functioning properly. Check

pump bearings for excessive heating. Bearing housing operating

temperatures vary depending on a wide variety of conditions.

However, normal temperatures should be 120° to 180° F. (49° to

82° C). A change of temperature can indicate a problem, and

operating temperatures outside of the normal range should be

addressed with manufacturer. Check complete unit for excessive

vibration and unusual noises. Do not run pump at greatly

reduced flow because damage can result.

III-C. Shutdown Procedure

Back flow through pump will cause reverse rotation. If backflow

is excessive, and there is a possibility of the pump being turned

on during this period of reverse rotation, then precautions

should be taken to prevent the backflow. This can be done

by installing a check valve in the discharge line, or by closing

a discharge valve immediately prior to shutting down the

pump. NOTE: IT IS NOT RECOMMENDED THAT THE

PUMP RUN LONGER THAN ABSOLUTELY NECESSARY

AGAINST A CLOSED DISCHARGE VALVE.

SECTION IV—PREVENTIVE AND CORRECTIVE MAINTENANCE

IV-A. Lubrication

Oil lubricated units require that oil be visible in the reservoir at

all times. Oil should be changed every 4000 hours of operation.

Grease lubricated units should be regressed every 2000 hours

or 3 month intervals, whichever occurs first. Use a sodium

or lithium grease and fill until grease comes out grease relief

fittings. Follow motor and coupling manufacturers’ lubrication

instructions.

IV-B. Stufng Box

1. Packing Stuffing Box:

Periodically inspect stuffing box to see that there is sufficient

leakage to lubricate the packing and maintain a cool box. Never

restrict the leakage from the packing as this will cause damage

to both packing and shaft sleeve. Draw up gland nuts slowly

and evenly and only while pump is running.

After pump has been in operation for some time and the packing

has been completely “run–in”, a leakage of 40 to 60 drops per

minute of the liquid should be allowed to flow from the stuffing

box at all times for cooling and lubricating the packing and

shaft sleeve.

2. Stuffing Boxes with Mechanical Seal:

Although this type of box requires no attention, a periodic

inspection of the circulating lines will ensure that they do not

become clogged.

IV-C. Vibration

It is good practice to periodically monitor vibration of the

pump. Normally, the vibration level will be well within accepted

standards. Of equal importance is that the vibration level not

increase. If a problem with vibration is encountered, refer to

Trouble Shooting, Section VII.

IV-D. Alignment—Final

Alignment should be checked after unit has reached operating

temperature, following startup. Repeat alignment procedures

outlined in Section II–E. Check alignment again after one week

of operation.

IV-E. Performance

If performance deteriorates, refer to Trouble Shooting, Section

VII.

6

Page 7

SECTION V—DISASSEMBLY AND REASSEMBLY

V-A. Disassembly

(refer to Sectional Views in Part VI)

1. Prepare pump for disassembly as follows:

a. Lock out power supply to motor.

b. Shut off valves controlling flow to and from pump.

c. Flush pump of all corrosive or toxic liquid, if required.

d. Remove all auxiliary tubing and piping.

e. Disconnect coupling and remove coupling spacer.

f. Drain oil.

g. On units with packed stuffing box, unbolt packing gland

(107).

2. Disassemble pump as follows:

a. Place sling from hoist through eyebolt (132). On S units,

place sling through frame (228A) above shaft (122).

b. Remove frame foot hold down bolts.

c. Remove bolts (370) holding frame (228A) or frame adapter

(108) to casing (100).

d. Slide back pull–out assembly from casing, using jacking

bolts (418) provided.

e. Remove casing gasket (351).

f. Unscrew impeller (101) from shaft (122). The threads are

right hand. Remove O–ring (412A) which seals between

the impeller and shaft or sleeve.

g. (1) On units with inside mechanical seal, remove gland

stud nuts (355) and carefully slide gland toward bearing

frame (228A).

(2) On units with outside mechanical seal, loosen set

screws holding rotary portion of seal to shaft and slide

seal toward bearing frame. Remove gland stud nuts and

carefully slide gland off studs.

h. Remove stud nuts (370H) which hold stuffing box cover

(184) to frame adapter. Pull stuffing box cover from frame

or adapter. Slide sleeve (if any) off shaft.

i. On units with mechanical seal, loosen set screws holding

rotary portion of seal to shaft, and carefully slide seal and

gland assembly off shaft. On units having a shaft sleeve,

it is not necessary to remove rotary portion of seal from

sleeve unless replacement of seal is required.

j. Slide deflector (123) off shaft.

k. Scribe shaft at coupling hub for proper positioning of hub

during reassembly and remove hub.

l. Remove bearing housing bolts (370C). Using impeller

adjustment bolts (370D) for jacking, remove shaft and

bearing assembly from frame. This will include the shaft,

both bearings (112A) and (168A), and bearing housing

(134A). Do not lose or damage O–ring (496).

m. Remove inboard bearing (168A) using a bearing puller.

Never use a hammer to drive shaft through bearing!

Protect bearing from contamination.

n. Scribe bearing housing for proper positioning prior to

disassembly on S, M and L models, remove bearing housing

retaining ring (361A) and slide bearing housing off ball

bearing. Do not damage oil seal (332A). On X units,

remove bearing end cover bolts (109A) and slide cover

off shaft. Do not damage oil seal (332A). Slide bearing

housing off shaft.

o. Straighten tang in lock washer and remove bearing

locknut (136) and lock washer (382). Remove ball bearing

(112A) using a bearing puller. Protect bearing from

contamination.

p. On units with stuffing boxes, remove lantern ring (105)

and packing rings (106) from stuffing box cover (184).

V-B. Inspection and Parts

Replacement Guidelines

1. Impeller—Replace if impeller shows excessive erosion,

corrosion, extreme wear, or vane breakage. O–ring groove and

impeller hub must be in good condition. Check impeller balance

if possible. Reduction in hydraulic performance and reduced

mechanical seal, packing or thrust bearing life may be caused

by excessive impeller wear.

2. Shaft—Check for runout (.005” max) to see that shaft has

not been bent. On pumps without shaft sleeves, shaft surface in

stuffing box area must be smooth and free of grooves. Bearing

seats and oil seal area must be smooth and free of scratches or

grooves. Shaft threads must be in good condition. Metalize or

replace shaft if necessary.

3. Shaft Sleeve—Sleeve surface in stuffing box must be smooth.

If grooved, replace or metalize.

4. Mechanical Seal—Seal faces, gaskets, and shaft sealing

members must be in perfect condition or leakage may result.

Replace worn or damaged parts.

5. Ball Bearings—Replace if worn, loose or rough and noisy

when rotated.

6. Oil Seals—Replace if worn or otherwise damaged.

7. General—All parts should be clean before assembly. All burrs

should be removed.

V-C. Reassembly Procedures

This procedure covers reassembly of pump after complete

disassembly. Make sure all directions outlined in Section V–B

have been followed.

1. Oil shaft at thrust bearing fit on coupling end of shaft

(122A). Slide thrust (coupling end) bearing (112A) on shaft as

far as possible by hand. Place pipe or driving sleeve over shaft,

making sure it rests against inner face only. Make sure bearing

is “square” on shaft. Tap or press evenly until bearing is seated

firmly against shaft shoulder. Do not mar the shaft.

2. Place lockwasher and bearing locknut (136) on shaft and

tighten firmly. Bend “tang” of lockwasher into slot in locknut.

3a. On S, M and L models. Take care not to damage oil seal

(332A), slide the bearing housing (134A) with O–ring

(496) in place over drive end of the shaft, and in place

over the bearing.

b. On X models. Slide bearing housing (134A) with O–ring

over impeller end of the shaft, and in place ove the bearing.

Install O–ring (496A) on bearing end cover (109A) and

slide into bearing housing (134A) and tighten into place

with fasteners and ensure that there is no remaining

end float in bearing outer race and that bearing operates

smoothly.

7

Page 8

4. On S, M and L models, insert retaining ring (361A) into

groove in bearing housing (134A). Flat side of retaining ring

must be against bearing (112A). On X units, slide bearing end

cover (109A) and gasket (360C) on shaft. Ensure the “top” of

end cover (109A) lines up with the “top” of bearing housing

(134A), check scribe marks. If the bearing housing (134A) is

not installed properly (oil drain groove in bottom), oil will not

be able to drain from bearing causing it to overheat and fail

prematurely.

5. Oil inboard bearing seat on shaft. Slide inboard ball bearing

(168A) on shaft (122) as far as possible by hand. Continue as

in Step 1 above.

6. Place a small amount of O–ring lubricant on inside of

bearing frame (228A) at bearing housing (134A), at inboard

bearing seats (168A), on O-ring (496), and on inboard oil seal

(333A). Carefully slide shaft assembly into bearing frame. Do

not damage inboard oil seal (333A). Screw bearing housing

bolts (370C) about ” into bearing frame (228A) .

7. Slide deflector (123) on shaft (122).

8. If unit has packed stuffing box, place stuffing box cover (184)

against adapter (108), making sure that studs (370H) align with

proper holes in adapter. Replace nuts and firmly tighten. Slide

sleeve (if any) on shaft. Make sure grooves in end of sleeve

engage drive pin on shaft. Continue assembly at Step 10.

9. If unit has mechanical seal:

The following instructions refer to pumps equipped with

mechanical seals, either with or without sleeves.

(4) Slide the rotary portion of the seal on the shaft (122)

(or shaft sleeve) (126) establishing its location from

the scribe line to the dimension as shown on the seal

manufacturer’s drawing. Tighten set screws.

(5) Reinstall the stuffing box cover and tighten. Do not

damage the seal parts.

(6) Reinstall the impeller with O-ring.

(7) Slide the gland assembly against the stuffing box and

tighten the nuts evenly. Do not damage the seal

parts.

(8) Refer to Step 12 for further assembly details.

b. Double Seals

(1) Scribe the shaft (122) or shaft sleeve (126) lightly at

the face of the stuffing box.

(2) Remove the impeller and stuffing box.

(3) Assemble the gland (250) with gaskets and stationary

seat and slide the assembly over the shaft (122) or

shaft sleeve (126).

(4) Slide the rotary portion of the seal on the shaft (122)

or shaft sleeve (126) establishing its location from

the scribe line to the dimension as shown on the seal

manufacturer’s drawings. Tighten set screws.

(5) Place inboard stationary seat and gaskets into bottom

of stuffing box.

(6) Reinstall the stuffing box cover and tighten. Do not

damage seal parts.

(7) Reinstall the impeller with O–ring.

(8) Slide the gland assembly against the stuffing box and

tighten the nuts evenly. Do not damage seal parts.

(9) Refer to Step 12 for further assembly details.

If the unit has a single inside or double seal, a preliminary impeller

adjustment must be performed to assure proper positioning of

mechanical seal.

(1) Position sleeve (126), if any, on shaft (122) and engage

groove in sleeve with drive pin (469) on shaft. Place

stuffing box cover (184) against frame (228). Make sure

studs (370H) align with proper holes in frame. Firmly

tighten nuts or bolts.

(2) Screw impeller (101) with O-ring (412A) in place on shaft.

Make sure that shaft assembly extends through stuffing

box cover (184) so that the impeller will NOT contact

face of stuffing box cover.

(3) Using impeller adjusting bolts (370C and 370D), adjust

the impeller end clearance 0.015 with volute in place.

Mark shaft sleeve.

The following instructions are for three basic seal types:

Single Inside, Single Outside, and Double Seals. Refer to seal

manufacturer’s drawing seal type and positioning dimension.

Follow pertinent procedures.

a. Single Inside Seal

(1) Scribe the shaft (122) or shaft sleeve (126) lightly at

the face of the stuffing box.

(2) Remove the impeller and stuffing box.

(3) Assemble the gland (250) with gaskets and stationary

seat and slide the assembly over the shaft (122) or

shaft sleeve (126).

c. Single Outside Seal

Preliminary impeller adjustment is not necessary with this

type of mechanical seal.

(1) If unit has shaft sleeve (126), slide on shaft (122)

and engage groove in sleeve with drive pin (469) on

shaft.

(2) Lubricate rotary portion of seal and slide on shaft

sleeve. Do not tighten set screws.

(3) Assemble gland (250), gaskets, and stationary seat

and slide assembly on shaft or sleeve.

(4) Place stuffing box cover (184) against frame making

sure that the studs (370H) align with the proper holes

in frame. Firmly tighten nuts.

(5) Screw impeller with O–ring on shaft making sure

impeller does not make contact with stuffing box

cover. If the impeller does hit, use impeller adjusting

cap screws to correct.

(6) Place gland assembly against face of stuffing box and

firmly tighten stud nuts.

(7) Slide rotary portion toward gland until it contacts

stationary seat. Compress the rotary. Tighten screws.

10. Screw impeller (101) with O–ring (412A) in place, on the

shaft (122).

11. On units with stuffing box packing (106), repack stuffing

box as outlined in Section II–F. Assemble gland stud nuts finger

tight.

12. Install and position coupling hub at scribe mark on shaft.

8

Page 9

13. Place casing gasket (351) against shoulder in casing.

14. Slide the pullout assembly into the casing (100). Drain slot

in stuffing box cover (184) should line up with drain connection

in casing. Install frame–to–casing bolts (370) and tighten evenly

while rotating shaft (122) by hand. If impeller ceases to turn

freely, stop tightening operation and adjust the impeller setting

with the adjusting bolts (370C and 370D) before resuming

tightening of frame-to-casing bolts (370).

15. Impeller Clearance

The impeller clearance is an important factor in maintaining

optimum pump performance. The nominal clearance is .015”

with the recommended minimum being .008”. The actual

clearance setting is dependent on the specific operating

conditions, taking into account temperature, solids, etc. For

maximum service flexibility pumps are shipped from the factory

with the clearance set at .015”. The desired clearance is

obtained in the following manner:

a. Loosen bolts (370C and 370D).

b. Tighten bolts (370C) with turning shaft clockwise until

impeller starts to rub against casing.

c. Loosen bolts (370C) until a feeler gauge, corresponding

to the desired clearance, can be placed between the bolt

head and bearing housing.

d. Tighten bolts (370D) evenly. Bearing housing shaft and

impeller will be jacked to proper clearance from casing.

Tighten bolts (370C) and jam nuts on bolts (370D).

e. If desired, a dial indicator can be used instead of a feeler

gauge to check that the bearing housing has been moved

the correct distance.

V-D. Additional Details

An alternate method for setting inside mechanical seals is the

“Modified Visegrip Method”.

1. Follow assembly up to Step 7.

2. Assemble the gland with stationary seat and gaskets.

3. Install the shaft sleeve, if used on the shaft, and engage

groove in sleeve with drive pin (469) on shaft.

4. Slide gland assembly over the shaft or shaft sleeve.

5. Install the stuffing box cover and impeller. Establish a

preliminary rotor adjustment (refer to Section V–C–9).

6. Slide gland assembly against stuffing box. Do not bolt the

gland to the stuffing box.

7. Clamp the modified visegrip on the shaft or sleeve directly

behind and against the gland.

8. Leave the visegrip in place and remove the impeller and

stuffing box cover.

9. Lubricate the rotary portion of seal and slide it on the shaft

until it comes in contact with the stationary seat in the gland.

10. Compress rotary portion of seal to correct dimension as

shown on seal manufacturer’s drawing. Tighten set screws.

11. Remove visegrip and reinstall stuffing box cover and

tighten.

12. Reinstall impeller with O–ring.

13. Slide the gland assembly against the stuffing box and tighten

nuts evenly.

14. Refer to Step 12, etc.

SECTION VI—PRODUCT DESCRIPTION

See pages 10, 11,12, 13 and 14 for Sectional

Views, Parts List and Materials of Construction.

9

Page 10

101

106

112A

126

168A

261

332A

333A

351

360C

360D

412A

469D

496

1

1 set

1

1

1

1

1

1

1

1

1

1

1

1

Impeller

Stuffing Box Packing (2)

Ball Bearing-Outboard.

Shaft Sleeve

Ball Bearing-Inboard

Mechanical Seal Gland Gasket (3)

Oil Seal-Outboard

Oil Seal-Inboard

Gasket-Casing

Gasket-Bearing End Cover-Bearing Housing

Gasket-Bearing Frame-Adaptor (not shown) (4)

“O” Ring-Impeller

Drive Pin-Shaft Sleeve

“O” Ring Bearing Housing

Mechanical Seal (3)

Recommended Spare Parts

NOTES: (2) - Required on packed pumps only.

(3) - Required on pumps equipped with mechanical seal only.

(4) - For M & L pumps only.

Item No.

100

304

304

Steel

C S

C S

C S

C S

4340

4340

Stainless Steel

Stainless Steel

Stainless Steel

316

316

316

316

316

316

316

CD4M

CD4M

CD4M

CD4M

CD4M

C-20

C-20

C-20

C-20

C-20

C-20

Monel

Monel

Monel

Monel

Monel

Monel

Nickel

Nickel

Nickel

Nickel

Nickel

Nickel

Hast.

Hast.

Hast.

Hast.

Hast.

Hast.

C S 316 CD4M C-20 Monel Nickel Hast. Titanium

Monel

Monel

304

Titanium

Titanium

Titanium

Titanium

C S

316 CD4M C-20 Monel Nickel Hast. Titanium

Titanium

Titanium

101

105

106

107

108

109A

112A

113A

122*

122A

123

126

131

132

134A

136

168A

184

184A

210

228A

239

241

251

261

332A

333A

351

353

355

360D

361A

370

370C

370D

370E

370F

370H

371C

382

412A

418

469B

469D

496

496A

503

All

Carbon

Steel

All

316SS

All

CD4MCu

All

C-20

All

Monel

All

Nickel

*All

Hast.

All

1

Titanium

MATERIAL

Part Name

No. Reqd.

Per Pump

Parts List and Materials of Construction

1

1

1

1 Set

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

4

1

1

4-24

3-4

3-4

2

1-2

2

6

1

1

2-3

2

1

1

1

1

Casing

Impeller

Lantern Ring

Gland (Packed Box)

Stuffing Box Packing

Frame Adaptor

Bearing End Cover

Ball Bearing-Outboard

Bearing Frame Breather

Pump Shaft (Less Sleeve)

Pump Shaft (With Sleeve)

Deflector

Shaft Sleeve

Casing Foot

Eye Bolt

Bearing Housing

Bearing Locknut

Ball Bearing-Inboard

Stuffing Box Cover-Standard

Stuffing Box Cover-Jacketed

Mechanical Seal Guard

Bearing Frame

Drain Plug

Bearing Frame Foot

Constant Level Oiler (Not Illustrated)

Mechanical Seal Gland Gasket

Oil Seal-Outboard

Oil Seal-Inboard

Gasket-Casing

Gland Stud

Gland Stud Nut

Gasket-Brg Frame-Adaptor

Retaining Ring-Bearing Housing

Cap Screw-Frame Adapt. to Casing

Cap Screw-Bearing Housing

Cap Screw-w/Jam Nut-Impeller Adjust.

Cap Screw-Casing Foot

Cap Screw-Frame Foot

Stud & Nut-Cover to Adaptor

Cap Screw-End Cover to Brg. Housing

Bearing Lockwasher

“O” Ring-Impeller

Cap Screw-Jacking (not shown)

Dowel Pin-Frame to Adaptor

Drive Pin-Shaft Sleeve

“O” Ring-Bearing Housing

“O” Ring-Bearing End Cover

Adaptor Ring

Teflon

Cast Iron

Cast Iron

Cast Iron

Cast Iron

Aluminum Alloy/Plastic

Manila Paper

Vellumoid

Steel

Steel

Steel

Steel

Steel

Steel

Steel

Teflon

304

Steel

420

Buna Rubber

Buna Rubber

Cast Iron

304

Buna Rubber

Buna Rubber

Non-Asbestos (C4400)

316

Cast Iron

Cast Iron

Steel

Steel

Steel

Steel

*Available in Hast-B or Hast-C Material. NOTES: Not available on all sizes.

1

10

Page 11

Model A100 S, M, L

100

239105

106

412A

469D

101

351 122A355353107 333A

370D

113A

496361A

168A

123210261126370H184370

228A

112A

134A

332A

136 & 382

370C

370

503

Assembly View of 8” Pumps Only

11

Page 12

132370 184 168A360D 496108 107 355 353 123 113A

228A

370C

134A

136 & 382

332A

112A

370D

361A

370E 370H 126 122A 210 333A 106 370F

131

239

105

469D

412A

106

101

351

100

Model A100 M, L

12

Page 13

101

412A

469D

106

105

184

351

100

370H

239

355107370370E131 228A370F106333A469B353

113A168A123261126108 210132 122A360D

370D

371C

109A

332A

136 & 382

496A

134A

112A

496

Model A100 X

13

Page 14

SECTION VII—TROUBLE SHOOTING

Problem

A. No liquid delivered,

not enough liquid

delivered, or not

enough pressure

1, 2, 3 ,4, 5, 6, 7, 8, 9,

10 11, 12, 13, 14, 18,

19, 20.

4, 5, 7, 8, 9, 11, 12, 20.

6, 13, 14, 15, 16, 21,

22, 23, 24, 31.

15, 16, 17, 28, 31.

8, 24, 25, 26, 27.

8, 24, 25, 26, 27.

15, 16, 17, 29, 30, 31.

B. Pump works a while

and then quits

C. Pump takes too much

power

D. Pump is noisy or

vibrates

E. Pump leaks

excessively at stuffing

box

F. High bearing

temperature

G. Stuffing box

overheating

Possible Causes

& Corrections

10. Foot valve too small—install correct size foot valve.

11. Foot valve or suction pipe not immersed deep enough—

consult factory for proper depth. Use baffle to eliminate

vortices.

12. Entrained air or gases in liquid—consult factory.

13. Impeller clearance too great—check for proper clearance.

14. Impeller damaged—inspect and replace as required.

15. Rotating parts bind—check internal wearing parts for proper

clearances.

16. Shaft bent—straighten or replace as required.

17. Coupling or pump and driver misaligned—check alignment

and realign if required.

18. Impeller diameter too small—consult factory for proper

impeller diameter.

19. Improper pressure gauge location—check correct position

and discharge nozzle or pipe.

Causes & Corrective Measures

1. Pump not primed or properly vented—check that casing and

suction pipe are completely filled with liquid.

2. Speed too low—check whether motor wiring is correct and

receives full voltage or turbine receives full steam pressure.

3. System discharge head too high—check system head

(particularly friction losses).

4. Suction lift too high—check NPSH available (suction piping

too small or long may cause excessive friction losses). Check

with vacuum or compound gauge.

5. Impeller or piping obstructed—check for obstructions.

6. Wrong direction of rotation—check rotation.

7. Air pocket or leak in suction line—check suction piping for

air pockets and/or air leaks.

8. Stuffing box packing or seal worn allowing leakage of air into

pump casing—check packing or seal and replace as required.

Check for proper lubrication.

9. Not enough suction head for hot or volatile liquids—increase

suction head, consult factory.

20. Casing gasket damaged—check gaskets and replace as

required.

21. Speed too high—check motor winding voltage or steam

pressure received by turbine.

22. Head lower than rating; pumps too much liquid—consult

factory. Install throttle valve, cut impeller.

23. Liquid heavier than anticipated—check specific gravity and

viscosity.

24. Stuffing box not properly packed (insufficient packing, not

properly inserted or run in, packing too tight)—check packing

and repack stuffing box.

25. Incorrect packing or mechanical seal—consult factory.

26. Damaged mechanical seal—inspect and replace as required.

Consult factory.

27. Shaft sleeve scored—remachine or replace as required.

28. Cavitation—increase NPSH available. Consult factory.

29. Pump capacity too low—consult factory for minimum

continuous flow.

30. Excessive vibration—See Section D.

31. Improper bearing lubrication or bearings worn out—inspect

and replace as required.

14

Page 15

SECTION VIII—ORDERING SPARE PARTS

VIII-A. Spare Parts

To insure against possible long and costly downtime periods,

especially on critical services, it is advisable to have spare parts

on hand.

1. For critical services: It is recommended that a “back pull–out

assembly” be kept on hand. This is a group of assembled parts

which includes all parts except the casing and the coupling.

If this unit is equipped with stuffing box packing, one set of

stuffing box packing (item 106) should be on hand.

2. An alternative, though not as desirable as that stated above,

can be used on non–critical services. This involves having on

hand parts that are most likely to wear and can be used as

needed. See Section VI, Parts List, for these recommended

spares.

VIII-B. Instructions for Ordering Spare

Parts

Repair orders will be handled with the minimum of delay if the

following directions are followed:

1. Give model number, size of pump, and serial number. These

can be obtained from the nameplate on the pump.

2. Write plainly the name, part number, and material of each

part required. These names and numbers should agree with

those on the sectional drawing in Section VI.

3. Give the number (quantity) of parts required.

4. Give complete shipping instructions.

15

Page 16

EAGLE

EAGLE

PUMP & COMPRESSOR LTD.

7025 - 5 Street S.E., Calgary, AB T2H 2G2 Canada

ANSI Centrifugal Pumps

Multistage Horizontal Pumps

Vertical Sump Pumps

Rotary Screw Compressor

Air/Gas Dryers

www.eagle-pc.com

Printed in Canada01/2000

Loading...

Loading...