Page 1

LP4310 FLOOR SCALE

OPERATION INSTALLATION AND SERVICE MANUAL

366 CIRCLE OF PROGRESS POTTSTOWN, PA 19464

(610)323-2250 FAX: (610)323-0114

LP4310 IB.DOC

9/16/04

Page 2

TABLE OF CONTENTS

CONTENTS

SECTION 1.0 DESCRIPTION.

SECTION 2.0 PREPARATION FOR USE

SECTION 2.1 RECEIVING INSPECTION

SECTION 2.2 SHIPMENT

SECTION 2.3 SITE SELECTION

SECTION 2.4 INSTALLING

SECTION 2.5 LEVELING

SECTION 2.6 HOOK-UP CABLE

SECTION 3.0 TROUBLE SHOOTING

SECTION 4.0 SERVICING

SECTION 4.1 CHECKING THE LOAD CELL

SECTION 4.2 REPLACING THE LOAD CELL

SECTION 5.0 SPECIFICATIONS

SECTION 6.0 SPARE PARTS LIST

LIST OF ILLUSTRATIONS

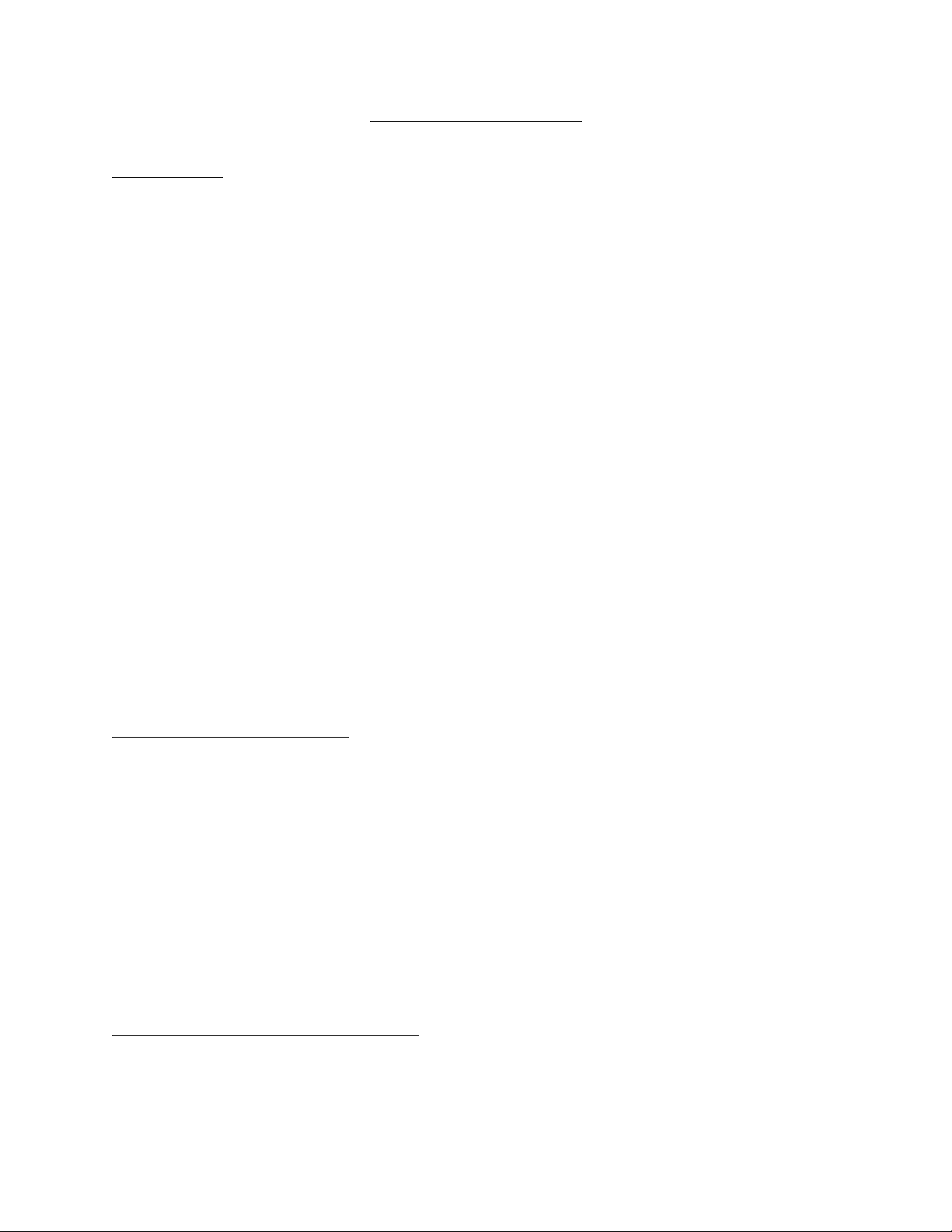

FIGURE 1 LP4310

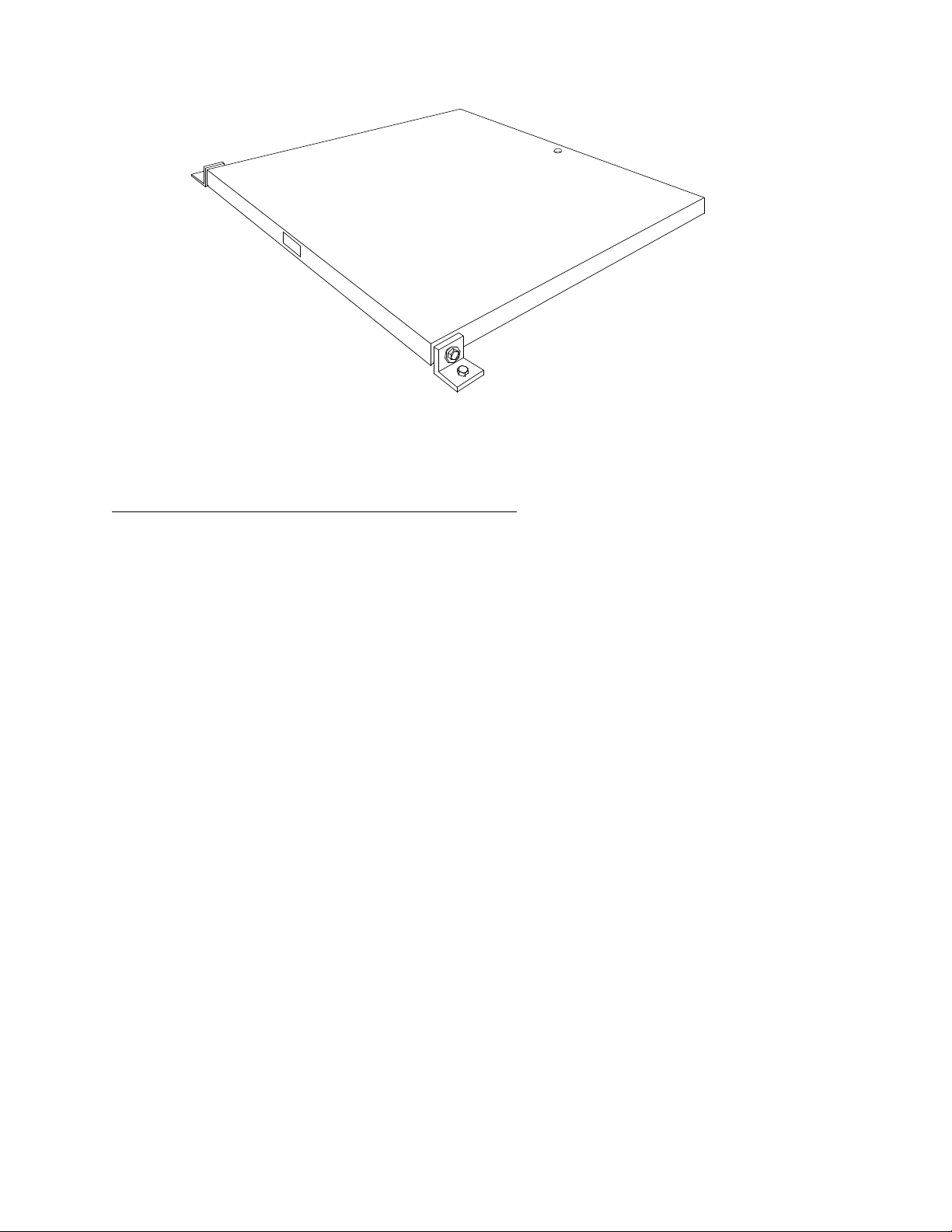

FIGURE 2 LEVELING OPERATION

FIGURE 3 RESISTANCE TABLES

FIGURE 4 OUTPUT TABLES

FIGURE 5 LP4310 OUTLINE and INTERCONNECT

TABLE 1 CONNECTION COLOR CODE

SECTION 1.0 DESCRIPTION

The Eagle Microsystems Model LP4310 is a low profile industrial floor scale available in four sizes; 30" x

30", 36" x 36", 42" x 42" and 48" x 48".

LP4310 IB.DOC

9/16/04

Page 3

Fig. 1: LP4310

The LP4310 was designed for easy installation and maintenance. All maintenance and calibration work is

performed from the top surface and does not require the removal of any decking or lifting the scale to

adjust the leveling

SECTION 2.0 PREPARAT ION FOR USE

2.1 RECEIVING INSPECTION

1. Upon receiving the scale, carefully inspect the condition of the crate including the banding

and any protective covering used for shipping. Report any damage to the shipper and to

Eagle Microsystems.

2. Remove the scale from crating and inspect for damage. Report any damage to the shipper

and to Eagle Microsystems.

3. The scale is shipped with one (1) leveling feet removed. The leveling foot is packaged and

Strapped to the cable. Keep this with the scale untill instllation time.

2.2 SHIPMENT

Should re-shipment of your scale become necessary.

1. Use a strong, well built crate. The crate must be larger than the outer dimensions of the

scale to protect it in shipping.

2. Make sure the hook-up cable is protected and secured in crate.

4. Use strong banding to secure scale in shipment.

2.3 SITE SELECTION

1. Line power devices causing large inductive currents should not run off the same circuit as

the scale. Fluctuations in line voltage caused by such devices may result in display instability.

LP4310 IB.DOC

9/16/04

Page 4

2. The hook-up cable to the read-out should not run close to other unshielded cables. Display

instability may result.

3. For best accuracy, a flat, level, and rigid surface is recommended to support the scale.

5. The area should be accessible for periodic cleaning.

2.4 INSTALLING ( refer to LP4310 Outline & Interconnect Dwg. at the end of this manual)

1. Clean the site area of dirt and debris.

2. The scale should be oriented so that loading will be from the hinge side of the scale. Secure the 2

“hinge brackets” to the floor with four (4) appropriately selected 3/8” diameter anchor bolts.

3. With the bottom of the scale exposed, install the leveling foot in the load cell. Screw the foot all

the way untill it bottoms out on the load cell.

2.5 LEVELING

SLOT TYPE

SCREW DRIVER

ADJUSTMENT

ACCESS HOLE

FOOT

Fig. 2: Detail showing easy leveling adjustments

with scale in place. A screw driver is the only tool needed.

1. For best scale performance scale should be level within 1/2 degree.

.

2.6 HOOK-UP CABLE

Table 1 shows the wiring connections necessary to attach the platform to the read-out instrument. The

color code and function are as noted.

COLOR FUNCTION

BLACK – EXCITATION

WHITE – SIGNAL

GREEN + SIGNAL

RED + EXCITATION

Table 1

SECTION 3.0 TROUBLE SHOOTING

The following is a list of potential problems and likely cures.

LP4310 IB.DOC

9/16/04

Page 5

1. Inaccurate but repeatable weight readings:

a. Adjust span on read-out (see instrument manual)

2. Blank or drifting display:

a. Consult the instrument manual.

b. Look for loose connection in hook-up cable at the instrument.

c. Test for bad load cell (Section 4.1).

SECTION 4.0 SERVICING

4.1 Checking the load cell.

1. Load Cell resistance test:

a. Disconnect the load cells from the instrument and measure the resistance as shown in

Figure 3.

b. Any electrical leakage between the leads and the load cell case is usually caused by moisture

leakage into the load cell or by moisture in a damaged load cell cable.

c. If a load cell does not pass the above resistance tests, replace it with a known good one.

LOAD CELL WIRING

LOAD

CELL

LOAD CELL RESISTANCE CHECK

RED TO BLACK 360

GREEN TO WHITE 350 +/- 5

RED, BLACK, GREEN,

WHITE, OR YELLOW

TO CASE

* Using a portable Ohm meter on highest range you should read infinity

2. Load Cell zero shift test:

a. Remove all the weight from the load cell and measure the output as shown in

Figure 4.

b. Connect a DC power supply of 10 or 15 volts to the Red (+) and Black (-) excitation load cell

leads.

RED +EXT

BLK -EXT

GRN +SIG

WHT -SIG

YEL SHLD

Ω

Ω

GREATER THAN 200

MEGOHMS *

FIGURE 3

c. The measured output between the Green (+) and White (-) signal leads should be less

than 5 millivolts.

LP4310 IB.DOC

9/16/04

Page 6

d. An output signal greater than 5 millivolts indicates a zero shift caused by mechanical

overload.

e. If the output signal is between 5 and 15 millivolts, the load cells zero has shifted but will

probably still continue to work.

f. If the output signal is greater than 15 millivolts, the load cell should be replaced with a

known good one.

LOAD CELL WIRING

RED +EXT

LOAD

CELL

LOAD CELL VOLTAGE CHECK (WITH 15V EXCITATION)

BLACK TO WHITE: +7.5V (EXCITATION / 2)

BLACK TO GREEN: +7.5V (EXCITATION / 2)

BLACK TO RED: +15V

LOAD CELL OUTPUT

GREEN TO WHITE: LESS THEN +/- 5 MILLIVOLTS (NO DEAD LOAD)

LESS THEN 25 MILLIVOLTS (EXACT OUTPUT

VOLTAGE DEPENDS ON DEAD LOAD WEIGHT)

NOTE: If the load cell's zero has shifted due to a mechanical overload, the reason for the

overload should be determined before a new load cell is installed.

4.2 REPLACING THE LOAD CELL

BLK -EXT

GRN +SIG

WHT -SIG

YEL SHLD

FIGURE 4

Call the factory to advise that the load cell is defective. Report model and serial numbers for both load cell

and scale.

1. Remove all weight from scale.

2. Stand the scale on its side. Use caution; make sure that the hook-up cable is not being damaged.

3. Disconnect the wires of defective load cell being replaced. Gently pull cable out of the frame.

4. Use 3/4 wrench to remove 2 hext head cap screws which secure load cell to frame.

5. Install new load cell using 35 ft. lbs. torque to screws.

6. Insert leads into terminal as before and tighten.

7. With a screw driver, adjust the leveling foot until scale is level.

SECTION 5.0 SPECIFICATIONS

PHYSICAL SIZE: Model LP4310

LP4310 IB.DOC

9/16/04

Page 7

30" x 30", 36" x 36", 42" x 42", and 48" x 48".

WEIGHT: 33" x30" = 96 lbs, 36" x 36" = 115 lbs

42" x 42" = 135 lbs, 48" x 48" = 162 lbs

CONSTRUCTION: Welded steel and formed plate.

FINISH: Primer and Poline paint

CAPACITY: 1000, 2000 and 4000 LB cap.

SAFE OVERLOAD: 200% of Rated Capacity.

ULTIMATE OVERLOAD: 400% of Rated Capacity.

NOMINAL OUTPUT: 1.0 mV/V at full scale

OPERATING ACCURACY: 0.5% of Capacity with repeatable load placement.

REPEATABILITY: 0.2 % of Capacity with repeatable load placement.

LOAD CELL: 1 stainless steel strain gage beam, 350 Ω.

HOOK-UP CABLE: 15' of 4 conductor color coded shielded cable.

SECTION 6.0 SPARE PARTS LIST

PART DESCRIPTION MODEL/CAPACITY

S.S. Load Cell 1,000 lbs F.S.

S.S. Load Cell 3,000 lbs F.S.

S.S. Load Cell 4,000 lbs F.S.

S.S. 1/2-20 live foot All sizes and capacities

LP4310 IB.DOC

9/16/04

Loading...

Loading...