Page 1

E15 SPRAYER Operators Manual

KEE E15 Horticultural Sprayer Console

W117 V1.0

Page 2

V 3.0 100903

Major Topic Heading

How to use this operator’s manual

As with any computer operated equipment, software and/or hardware is in many cases changed

and upgraded over the life of the equipment.

KEE Technologies software engineers are constantly working on software enhancements which

will provide you with many additional benefits and features in the future.

The EAGLE System will keep on evolving! ...to ultimately improve your ‘bottom line”!

KEE Technologies personnel have records of all changes implemented to your system with the

subsequent serial number.

When talking to KEE Technologies Support staff, always have this manual with you, as we may

ask you what version manual you are currently looking at to ensure we all talk the same

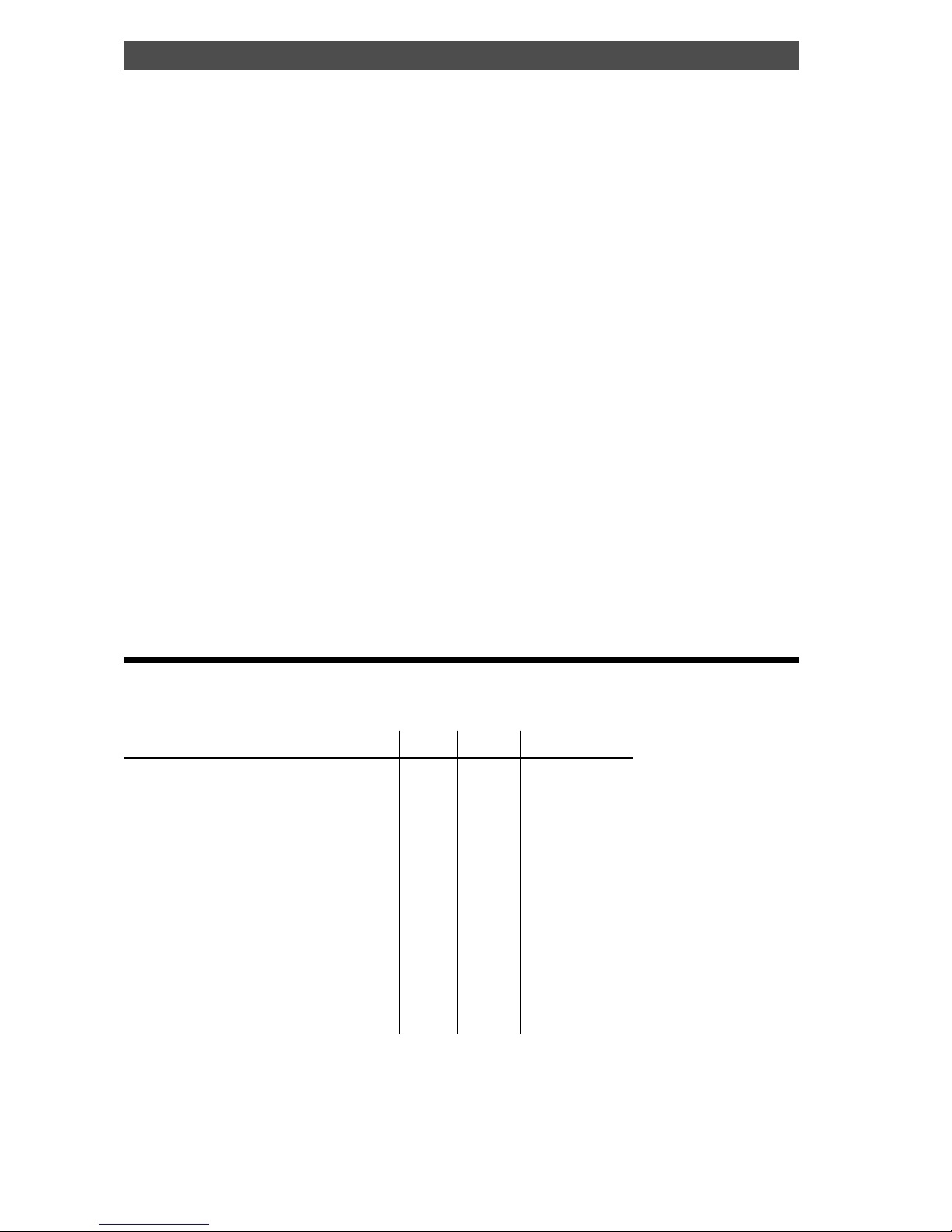

language. For this purpose all pages are coded as follows.

Page number Date when written Software version

Below is space provided to keep records of any software and hardware upgrades you may have

received.

The Software Version Number of the Eagle Console can be located when the console first powers

up. The File name which contains the Software version number will be displayed for about 2-3

seconds.

The name of the file will be on the last line, it will look like this.

KEE_HSC_1_0_13.HEX

Where: KEE_HSC_ -shows the type of software, is a KEE Horticultural Sprayer Complete.

1_0_13 - The software version number

HEX - Type of file.

Type of upgrade (software or hardware) Version Date Manual upgraded

KEE Eagle E15 Horticultural Sprayer

1.0.13 11/05

11/05

Page 3

V1.86

V 1.86

3.0 SPRAYER SETUP MENU

19

3.1 SET THE PRESET RATE 1 20

3.2 SET THE PRESET RATE 2 20

3.3 MINIMUM FLOW HOLD 20

3.4 SET THE PRESET ROW WIDTH AND SECTIONS WIDTHS 21

3.5 SET THE LOW SPEED SHUT OFF 23

3.6 SET THE TANK VOLUME 23

3.7 APPLICATION MODE 23

3.8 SET THE WHEEL CALIBRATION FACTOR 24

3.8.1 SELECT SPEED SOURCE 25

3.8.2 AUTOMATIC WHEEL CALIBRATION 25

3.8.3 MANUAL ENTRY OF WHEEL FACTOR 25

3.9 SET THE FLOW CALIBRATION FACTOR 26

3.9.1 AUTOMATIC FLOW CALIBRATION 27

3.9.2 MANUAL FLOW CALIBRATION 27

3.10 SPRAYER SETUP 2 MENU 28

3.11 SET A MANUAL SPEED 29

3.12 SET RATE INCREMENT 29

3.13 SET NUMBER OF BOOM SECTIONS 29

3.14 ENABLE DATA LOGGER 30

3.15 ENABLE FLUSH OUTPUT 30

3.16 SET FLUSH TIME 30

3.17 ENABLE FULL ROW PER SECTION 31

3.18 ENABLE AUXILIARY FUNCTION 31

3.19 SPRAYER SETUP 3 MENU 32

3.20 ENABLE PUMP SPEED SENSOR 33

3.21 ENABLE AUXILIARY SHAFT SENSOR 33

3.22 ENABLE DUMP OVERRIDE 33

3.23 SELECT DUMP MODE 34

3.24 SET THE VALVE TYPE 34

3.25 SET THE CONSOLE UNITS 34

3.26 ENABLE FAN MONITORING 35

3.27 SET NUMBER OF FANS 35

3.28 SPRAYER SETUP 4 MENU 36

3.29 ENABLE PRESSURE1 SENSOR 37

3.30 SETTING THE PRESSURE GAIN 37

3.31 SETTING THE TYPE OF PRESSURE SENSOR 37

3.32 PRESSURE SENSOR 1 CALIBRATION 38

Content Page No.

Table of Contents

1.0 MENU OVERVIEW 11

2.0 CONSOLE OVERVIEW 12

2.1 WORKING SCREEN DISPLAY 12

2.2 WORKING SCREEN BUTTON FUNCTIONS 14

2.3 MAIN MENU 17

2.4 SETUP MENU 18

3

V 1.0 11/05

Page 4

4. ALARMS SETUP MENU 40

4.1 RATE ALARMS 41

4.1.1 ENABLE THE MINIMUM FLOW ALARM 42

4.1.2 ENABLE THE APPLICATION RATE LOW ALARM 42

4.1.3 SET THE APPLICATION RATE LOW POINT 42

4.1.4 ENABLE THE APPLICATION RATE HIGH ALARM 43

4.1.5 SET THE APPLICATION RATE HIGH POINT 43

4.2 SHAFT ALARMS 44

4.2.1 ENABLE THE PUMP SPEED LOW ALARM 45

4.2.2 SET THE PUMP SPEED LOW ALARM POINT 45

4.2.3 ENABLE THE PUMP SPEED HIGH ALARM 45

4.2.4 SET THE PUMP SPEED HIGH POINT 46

4.2.5 ENABLE THE AUXILIARY SHAFT LOW ALARM 46

4.2.6 SET THE AUXILIARY SHAFT LOW ALARM POINT 46

4.2.7 ENABLE THE AUXILIARY SHAFT HIGH ALARM 47

4.2.8 SET THE AUXILIARY SHAFT ALARM HIGH POINT 47

4.3 SPEED ALARMS 48

4.3.1 ENABLE THE SPEED LOW ALARM 49

4.3.2 SET THE SPEED LOW ALARM POINT 49

4.3.3 ENABLE THE SPEED HIGH ALARM 49

4.3.4 SET THE SPEED HIGH ALARM POINT 50

4.4 TANK ALARMS 51

4.4.1 ENABLE THE VOLUME LOW ALARM 52

4.4.2 SET THE VOLUME LOW POINT 52

4.5 PRESSURE ALARMS 53

4.5.1 ENABLE THE PRESSURE 1 LOW ALARM 54

4.5.2 SET THE PRESSURE 1 LOW ALARM POINT 54

4.5.3 ENABLE THE PRESSURE 1 HIGH ALARM 54

4.5.4 SET THE PRESSURE 1 HIGH ALARM POINT 55

Table of Contents

Content Page No.

6. OPERATING HISTORY 60

6.1 TOTALS HISTORY 61

6.1.1 RESET THE TOTAL VOLUME 62

6.1.2 RESET THE SUB VOLUME 62

6.1.3 RESET THE TOTAL AREA 62

6.1.4 RESET THE SUB AREA 62

6.1.5 RESET THE TOTAL DISTANCE 63

6.1.6 RESET THE SUB DISTANCE 63

6.1.7 RESET THE TOTAL TIME 63

6.1.8 CHANGE TO A DIFFERENT SUB AREA 63

6.2 SHAFT SPEED HISTORY 64

6.3 MACHINE HISTORY 65

4

5. CONTROLLER SETUP MENU 56

5.1 SET CONTROL MODE 57

5.2 SET THE MAX ON TIME 57

5.3 SET THE MIN ON TIME 57

5.4 SET THE GAIN SETTING 58

5.5 SET THE PWM SETTING 58

5.6 SET THE FLOW METER SENSITIVITY 58

5.7 SELECT CLOSE VALVE WHEN OFF 59

5.8 TOGGLE THE VALVE REVERSE 59

V 1.0 11/05

Page 5

7. OPERATIONS: SPRAYER 66

7.1 OPERATION OF THE SPRAYER 67

7.1.1 DISPLAY THE VOLUME REMAINING IN THE TANK 67

7.1.2 DISPLAY THE VOLUME USED 67

7.1.3 FILL THE TANK 67

7.1.4 FILL THE TANK TO A SET VOLUME 67

7.1.5 TO DISPLAY SUB AREA, TOTAL AREA AND SUB AREA NUMBER 67

7.1.6 TURN A SECTION ON 67

7.1.7 TO CLEAR A SUB AREA 68

7.1.8 TO CHANGE THE SUB AREA NUMBER 68

7.1.9 RESET TOTAL AREA 68

7.1.10 SELECT BETWEEN MANUAL AND AUTO SPRAYING 68

7.1.11 SELECT BETWEEN COVERAGE RATE, ROW WIDTH, PRESSURE1,

& FAN SPEED1 69

7.1.12 SELECT BETWEEN FLOW RATE,PUMP SPEED,AUX SHAFT SPEED

& FAN SPEED 69

7.1.13 SELECT BETWEEN VOLUME LEFT AND FLUSH FUNCTION 70

7.1.14 SELECT BETWEEN VOLUME USED, AUX FUNCTION, DUMP OVERRIDE

& DATA 70

7.1.15 SELECT ROW WIDTH 70

7.1.16 ACTIVATE FLUSH FUNCTION 71

7.1.17 ACTIVATE DUMP OVERRIDE FUNCTION 71

7.1.18 ACTIVATE AUXILIARY FUNCTION 72

7.1.19 DISPLAY FAN SPEED MONITORING SCREEN 72

7.2 TO BEGIN SPRAYING 73

7.2.1 TO BEGIN SPRAYING (MANUAL MODE) 73

7.2.2 INCREASE OR DECREASE the APPLICATION RATE (MANUAL MODE) 73

7.2.3 BEGIN SPRAYING (AUTO MODE) 73

7.2.4 CHOOSE A PRESET APPLICATION RATE (AUTO MODE) 73

7.2.5 INCREASE OR DECREASE the APPLICATION RATE (AUTO MODE) 73

7.3 OPERATIONS: DATA LOGGER 74

7.3.1 CONNECT THE DATA LOGGER INTERFACE TO THE EAGLE E15H 75

7.3.2 CONNECT A MODULE TO THE DATA LOGGER INTERFACE 75

7.3.3 REMOVE A MODULE FROM THE DATA LOGGER INTERFACE 75

7.3.4 SPRAY TO A PROGRAMMED RATE 75

7.3.5 CHANGE THE JOB NUMBER 76

7.3.6 SPRAY WITHOUT USING PROGRAMMED RATE 76

Table of Contents

Content Page No.

5

V 1.0 11/05

Page 6

8.0. CONFIGURATION OPTIONS 77

8.1 KEY CONFIGURATION 78

8.1.1 ENABLE THE KEY BEEPER ON OR OFF 79

8.1.2 SET THE KEY BEEPER TIME 79

8.1.3 ENABLE THE KEY REPEAT 79

8.1.4 SET THE KEY REPEAT DURATION 79

8.2 ALARM CONFIGURATION 80

8.2.1 ALARM BEEPER OVERVIEW 81

8.2.2 SET THE ALARM CYCLE TIME 82

8.2.3 SET THE ALARM DUTY CYCLE 82

8.2.4 SET THE NUMBER OF ALARM CYCLES 82

8.2.5 ENABLE THE ALARM BEEPER ON/OFF 82

8.3 GENERAL CONFIGURATION 83

8.3.1 COLD RESET 83

8.3.2 FACTORY RESET 83

8.4 SWITCH CONFIGURATION 84

Table of Contents

Content Page No.

9.0. DIAGNOSTICS MODE 85

9.1 LED TEST 86

9.2 SWITCH TEST 87

9.3 KEYS TEST 88

9.4 SENSORS TEST 89

9.4.1 CHECKING LOOM VOLTAGES, FOR 3 PIN SENSORS 90

9.5 RELAYS TEST 91

9.6 REGULATOR VALVE TEST 92

9.7 EEPROM TEST 93

9.8 DISPLAY TEST 93

10. ALARM MESSAGES 94

10.1 ALARM MESSAGES OVERVIEW 94

10.2 ALARM MESSAGES 95

11. SPECIFICATIONS 98

12. WIRING DIAGRAMS

12.1 ECONOMY LOOMS 100

EAGLE CONSOLE PIN OUTS 100

TRACTOR LOOM 101

TRACTOR LOOM 102

SPRAYER LOOM 103

MK5 TO E15h ADAPTOR LOOM 104

6

V 1.0 11/05

Page 7

E15h SPRAYER

Features of the E15h EAGLE HORTICULTURAL SPRAYER CONSOLE:

• 4 Preset Widths can be entered.

• 4 Row Section switches can control (solenoid, 2 or 3 wire Valves)

• Sprayer can be setup as a:

2 section sprayer

3 section sprayer (2 left and 1 right)

3 section sprayer (2 right and 1 left)

OR 4 section sprayer

• The Sprayer can be setup to switch

1/2 a row per section switch

OR switch a Full row per section switch.

• Auxiliary Function to operate ‘Work Lights’ or ‘Foam Marker’

• Displays PTO SHAFT in rpm, with alarms points. Also display readouts and alarms

which are settable for an Auxiliary Shaft sensor.

• Displays and Monitors up to 12 Fans.

• The KEE Data Logger can be connected to the E15h console to create and

recored all spray jobs.

• Automatic Dump and Flush Functions

• Master ON/OFF switch

• 2 Dedicated Rate buttons (RATE 1/ RATE 2) ; gives the operator finger-tip control

• Rate can be displayed in volume/area (eg. L/Ha) OR volume/distance (eg. L/100m)

• Can control different types of Flow Control (Servo) Valves

• Audio and Visual alarms; low and high alarm points settable for each alarm

• Large Full Visual display

• Displays 8 functions at once; Ground Speed, Rate, Sub-Area, Coverage Rate,

Volume Left, Volume Used, Flow Rate and current alarms ALL on the one screen

• Selectable units (Gallons/Acre, Litres/Hectare etc)

• Machine history data

• Self diagnosis tests

• Back lit keys, with separate contrast knob for full screen control

• 10 Sub Areas keeps records on Hectares sprayed and Volume Used

• Easily Setup and Simple to use

7

V 1.0 11/05

Page 8

E15h SPRAYER

The EAGLE E15 Sprayer Console replaces the KEE Technologies Mk3 and Mk5 Spray

Controllers, which have been in the market for the past 25 years. The EAGLE is a

breakthrough replacement for the Mk5, with many more features at no extra cost. It

takes into account the current Mk5 operators, and the transition from the Mk5 to the

EAGLE is minimal, to the point where it is fully compatible with all Mk5 hardware. It is as

simple as swapping the consoles!

The development of the EAGLE has been totally driven by input and suggestions from

farmers and contractors from around the world, making the EAGLE the most advanced

Spray Rate Controller in the world.

The KEE Eagle Horticultural console is a dedicated horticultural sprayer console

developed specifically for the horticultural market.

The Eagle has many new features and easy operation, that has leap-frogged the current

competition which is a considerable bonus to the end user. Including all the features of

its predecessor, the MK5, the EAGLE has four sections, separately indicated section

switches, can display in volume/area or volume/distance, can connect to 2 section, 3

section (3L or 3R) and 4 section sprayers.

The E15h console can monitor 1 to 2 fans. If the optional FAN MONITOR ECU is used

then up to 12 Fans can be monitored and each Fans RPM can be displayed.

The Data Logger (optional) can be connected to the E15h console to set the application

rate for up to 9 jobs and create job sheets for each job; then the Data Logger will record

application rate, which sections where switched ON/OFF, pressure, speed etc to a

Module. The Module can be taken back to the office and create records of jobs done;

graphs can then be created using the Data Logger software.

New features include the all screen display that allows viewing of all the sprayer

functions at a glance, backlight control keys and positive sectional switches.

8

V 1.0 11/05

Page 9

Major Topic Heading

V 1.2

Personal Notes

9

Page 10

Major Topic Heading

V 1.2

Major Topic Heading

V 1.2

Personal Notes

10

Page 11

E15h SPRAYER- Console Overview

1.0 MENU OVERVIEW

1.1 TO MOVE THE FOCUS AROUND THE SCREEN

• The buttons along the left hand side (LINE 1, LINE 2, LINE 3 AND LINE 4) of the

screen are aligned with a row on the screen.

• Pressing a left hand button will hightlight the first focus square on that row

• If there is no text on a row, you will not be able to set the focus to that row

• If a value is uneditable (ie a title or display value) you may not be able to set the

focus to that state.

• To move between windows on a single row, press the corresponding (LINE 1,

LINE 2,LINE 3 or LINE 4) button repeatedly. The focus will switch between available

fields on the row.

1.2 TO ENTER THE MENU FROM THE WORKING SCREEN

• Ensure the Master Switch is in the OFF (hold) position

• Press the MENU button

• You will be taken to the MAIN MENU screen

1.3 TO RETURN TO THE WORKING SCREEN

• Ensure that you are not editing a value (if you are editing a value an asterisk (*)

will be shown in the box the focus is set to)

• Press the MENU key

• You will be returned to the previous menu screen

1.4 TO ENTER A MENU SCREEN

• Highlight the field displaying the menu you wish to enter

• Press the ENTER key

• You will be taken to the corresponding menu

1.5 TO EDIT A VALUE

• Highlight the field displaying the value you wish to edit

• Press the ENTER button. An asterisk (*) will appear in the field you are editing

• Use the INC/DEC buttons to adjust the value

• Press the ENTER button to accept the changed value. The asterisk (*) will

disappear.

11

V 1.0 11/05

Page 12

E15h SPRAYER- Console Overview

2.0 CONSOLE OVERVIEW

2.1 WORKING SCREEN DISPLAY

Volume

(Flow Rate)

Coverage

Rate

Application Rate

Ground Speed

Volume Left

Alarm Window

Volume Used

Working Screen

12

The above “Working Screen” is what is displayed when the console is first switched ON.

The “Working Screen” is the screen displayed when spraying.

Below is a brief description of what is displayed in each window. The functions listed below

are the default settings, for each window.

Some windows can display more than one function, these are explained on the next page.

Ground Speed- Displays the ‘live’ ground speed from the wheel sensor on the sprayer.

Rate- Displays the ‘live‘ spray rate.

Sub Area- Displays area covered for the active sub area.

The Sub Area window can be selected to display the “Sub Area Number”

and “Total Area”.

Coverage Rate- Displays the working rate of the sprayer in units/hr.

Volume Left-Displays the volume left in the spray tank.

Flow rate-Displays the ‘live’ flow rate in units/minute

Volume Used-Displays the volume used.

Alarm Window-Displays all alarms, actions or warnings in this window.

Sub Area

or Sub Area Number

or Total Area

V 1.0 11/05

Page 13

E15h SPRAYER- Console Overview

Below will show all the functions that can be displayed in each window. Most of the

functions will have to be enabled in the “Sprayer Setup” before the functions can

be displayed in the windows. The first function listed is the default function

displayed on the screen. See Operation of Sprayer (Section 7.0) on how to access

these functions.

Sub Area Window-

1. Sub Area

- Displays area covered for the active sub area.

2. Sub Area Number-

Displays the active Sub Area number.

3. Total Area-

Displays the total area accumulated by the sprayer since the last reset.

Coverage Rate-

1. Coverage Rate-

Displays the working rate of the sprayer in units/ha.

2. Row Width-

Displays the current preset ‘Row Width’ of the sprayer. 4 preset Row

Widths can be set. The current ‘Row Width’ displayed is indicated by the number

(1,2,3 or 4) in the bracket.

3. Pressure1-

Displays the ‘live’ pressure reading from the electronic pressure sensor.

4. Fan 1 Speed-

Displays the actual fan speed (in RPM) of the shaft speed the sensor

is fitted to, marked ‘Fan 1 Speed’ on the loom. Is only displayed when 1 or 2 Fan

Monitors are selected in Section .

Volume Left Window-

1. Volume Left-

Displays the amount of product left in the tank.

2. Flush-

Displays the status of the Flush function whether OFF or ON; if ON

displays the countdown in seconds of the time left for the flush function to finish

flushing out the boomspray. See Section 3.12.2 to enable Flush function if fitted.

Flow Rate Window-

1. Flow Rate-

Displays the ‘live’ Flow rate in volume/minute.

2. Pump Speed-

Displays the actual speed (in RPM) of any shaft the sensor is fitted

to. Example would be a PTO input shaft. See Section 3.20 to enable, if fitted.

3. Aux Shaft Speed-

Displays the actual speed (in RPM) of any shaft the sensor is

fitted to. See Section 5.11 to enable, if fitted.

4. Fan 2 Speed-

Displays the actual fan speed (in RPM) of the shaft speed the sensor

is fitted to, marked ‘Fan 1 Speed’ on the loom. Is only displayed when 2 Fan

Monitors are selected in Section .

Volume Used Window-

1. Volume Used-

Displays the amount of product applied, since the last reset.

2. Auxiliary-

Displays the status of the Auxiliary switch, whether OFF or ON. Enable

this function for example, if Working Lights are fitted to the sprayer loom. See

Section 3.12.2 to enable, if fitted.

3. Dump Override-

Displays the status of the Dump Override, whether ON or OFF.

The Dump Override allows a ‘Chemical Induction’ pump to be fitted to the sprayer.

All Section and Master switches have to be switched OFF to enable ,Dump Override’.

See Section 3.22 to enable.

4. Data Logger Status-

Displays the current ‘JOB NUM:’ (Job Number) and ‘SET

RATE:’ if the ‘Data Logger’ is ENABLED. See Section 3.14 to enable, if fitted.

13

V 1.0 11/05

Page 14

Major Topic Heading

V 1.2

E15h SPRAYER-Console Overview

Line 1 Button

Line 3 Button

Line 2 Button

Power Switch

Auxiliary

Rate 2

Rate 1

Line 4 Button

Auto/Manual

Master Switch

Menu Button:

Gateway to set up

Section Switches

2.2 WORKING SCREEN BUTTON FUNCTIONS

INC Button (Up Arrow)

DEC Button (Down Arrow)

Enter

Power Switch

The Eagle console is switched ON and OFF by this switch on the front panel. By

default down is ON.

Master Switch

The MASTER switch turns all sections selected for operation, ON or OFF. By default

down is ON

LED

Light Emitting Diode (LED). The LED’s aligned above (front boom) the section

switches and below (back boom) the section switches indicate the status of the

sections.

The LED’s for the MASTER switch indicates the status of the switch ON or OFF.

The LED’s near the RATE 1 and RATE 2 button indicate which preset spraying RATE

has been selected.

The LED’s near the AUTO/MANUAL button indicates the status whether in AUTO

(LED light is ON) or MANUAL (LED light is OFF).

14

V 1.0 11/05

Page 15

E15h SPRAYER- Console Overview

SECTION SWITCHES

1. These switches turn individual Sections ON or OFF. By default down is ON

2. The red LED’s aligned above and below each section switch, indicates the status of

each Section

When the LED light is:

• OFF- The Section switch for that section is switched OFF, temporarily

• Flashing- The Section switch is switched ON but not spraying. Master is OFF

or ground speed is below the LOW SPEED CUT-OFF value.

• On- The Section switch is switched ON, MASTER is ON and nozzles are

spraying at the calibrated spraying rate which is displayed ‘live’ in the

‘Application Rate’ window.

Note: The section LED’s will only turn on for the number of sections set in the

Sprayer Setup Menu. If the sprayer has been setup as a 2 section sprayer, then only

sections LED’s ‘Left Inner’ and Right Inner’ will turn on, when the sections are

switched ON. The led's for sections ‘Left Outer’ and ‘Right Outer’ will not come on,

even if the actual switches are switched ON or OFF.

RATE 1 BUTTON

Sets the application rate to the normal programmed rate when in AUTO.

When LED near RATE 1 button is:

1. Flashing-

RATE 1 is selected but MASTER switched OFF or spraying in MANUAL.

2. ON-

RATE 1 is selected and spraying to the set rate in AUTOMATIC.

RATE 2 BUTTON

Sets the application rate to a second alternative rate, selectable any time in AUTO.

When LED near RATE 2 button is:

1. Flashing-

RATE 2 is selected but MASTER switched OFF or spraying in MANUAL.

2. ON-

RATE 2 is selected and spraying to the set rate in AUTOMATIC.

AUTO/MANUAL BUTTON

1. Press AUTO/MANUAL button to select between AUTO or MANUAL.

2. When the sprayer is operating in MANUAL the LED near the button will be OFF.

3. When the sprayer is operating in AUTO the LED near the button will be ON.

AUX. BUTTON

The Auxiliary Button is used in conjunction with the Navigation Buttons (LINE 2,

LINE 3 and LINE 4) when on the ‘Working Screen’. The operator uses the LINE 2,3 or

4 buttons to select and highlight a window, the window will stay highlighted for 5

seconds, while the window is highlighted and the AUX. button is pressed then

various functions will be displayed in each window. Each time the AUX. button is

pressed the next function is displayed.

What is displayed in each window will depend what functions have been enabled in

the Sprayer Setup Menu. See ‘Working Screen Display’ to view what functions are

displayed in each window.

The AUX. button will only scroll through the various functions while the window is

highlighted. The LINE 2,3 or 4 buttons may have to pressed again to re- highlight

the window.

The last option displayed in the window will stay until changed or the E15h console

is switched OFF, then the windows will display the default options.

15

V 1.0 11/05

Page 16

E15h SPRAYER- Console Overview

NAVIGATION BUTTONS

1) MAIN MENU-

The Navigation Buttons(LINE 1, LINE 2, LINE 3 AND LINE 4) allow

the operator to navigate in the MAIN MENU.

LINE 1 selects line 1 of the display; LINE 2 selects line 2 of the display and so on

for LINE 3 and LINE 4. If the operator selects LINE 3 then the window on LINE 3

will be highlighted. If the operator presses LINE 3 again then the column 2 will

be highlighted; if permitted. When LINE 3 is pressed again, column 3 will be

highlighted. If LINE 3 is pressed a third time, the first column will be highlighted

again.

2) ‘Working Screen’-

When on the Working screen the Navigation Buttons (LINE

2, LINE 3 and LINE 4) can be used in conjuction with AUX. button to scroll

through the various options within each window so the ‘Working Screen’ can be

tailored made to suit different operators needs. See AUX. button on previous

page.

INC/DEC Buttons-

The Increase and Decrease(INC/DEC) buttons when on the

‘Working Screen’ allow the operator to increase or decrease the spraying rate,

while spraying in Manual or Auto.

The INC/DEC buttons when in the MAIN MENU allow the operator to increase

and decrease factors (when a asterisk (*) appears next to the value), in the MAIN

MENU. When using the INC/DEC buttons to change a value, the operator may

press the INC/DEC button repeatedly to change the value OR the operator may

press and hold the INC or DEC button and the value will change while the button

is depressed; the longer the button is depressed the faster the values will change.

ENTER-

When the ENTER button is pressed, the value within the highlighted

window, has an asterisk (*) appear next to the value. The value can be increased

or decreased using the INC/DEC buttons. Press the ENTER button again to lock-in

and save the value.

MENU-

When the MASTER switch is in the OFF position, the MENU button,

when pressed, is the gateway into the MAIN MENU’s for the Console.

MENU also returns to the Working Screen from any menu, (the button may have

to be pressed several times to return to the WORKING SCREEN).

Press MENU once to return to the previous menu.

When the MASTER switch is ON and the MENU button is pressed, the Fan Speed

Monitoring screen is displayed when a FAN MONITOR ECU is connected to the

E15h console.

V 1.0 11/05

16

Page 17

E15h SPRAYER- Console Overview

• Press MENU. To enter the MAIN MENU screen

To enter the MENU screens ensure the MASTER switch is in the OFF position.

Note: All procedures assume the operator is starting from the “Working Screen”.

• To advance to the SETUP MENU see Section 2.5

• To advance to the OPERATING HISTORY see Section 6.0

2.3 MAIN MENU

Operations Menu Screen

17

V 1.0 11/05

Page 18

E15h SPRAYER- Console Overview

• Press MENU.

To enter OPERATIONS MENU screen

• Press ENTER.

To enter SETUP MENU screen

• To advance to the SPRAYER SETUP MENU see Section 3.0

• To advance to the ALARMS SETUP MENU see Section 4.0

• To advance to the CONTROLLER SETUP MENU see Section 5.0

2.4 SETUP MENU

Setup Menu Screen

V 1.0 11/05

18

Page 19

E15h SPRAYER- Sprayer Setup Operation

3.0 SPRAYER SETUP MENU

Sprayer Setup Screen

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

19

V 1.0 11/05

Page 20

E15h SPRAYER- Sprayer Setup Operation

3.1 SET THE PRESET RATE 1

Note: This sets the “Main Target” Rate for the sprayer, and activated by the

RATE 1 button on the console.

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP.

The focus window will be on

TARGET RATE

• Press ‘RATE 1’ button.

The LED next to the ‘RATE 1’ button will light up.

The current TARGET RATE will be displayed in the window.

• Press ENTER to edit TARGET RATE.

An asterisk (*) should appear after

“TARGET RATE”

• Use Inc/Dec (Up and down arrows) to set the TARGET RATE 1

• Press ENTER to accept the changes

3.2

SET THE PRESET RATE 2

Note: This sets the “2nd Target” Rate for the sprayer, and is activated by the

RATE 2 button on the console.

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP.

The focus window will be on

TARGET RATE

• Press RATE 2 button.

The LED next to the RATE 2 button will light up.

The current TARGET RATE will de displayed in the window.

• Press ENTER to edit TARGET RATE.

An asterisk( *) should appear after

“TARGET RATE”

• Use INC/DEC buttons to set the TARGET RATE

• Press ENTER to accept the changes

3.3.

MINIMUM FLOW HOLD VALUE

NOTE: This feature alarms the operator when the flow of liquid going through

the flowmeter drops below the value set in the MINIMUM FLOW VALUE.To

switch the MINIMUM FLOW HOLD alarm ON or OFF, go to Section 4.1.1

If this feature is not required, then set the MINIMUM FLOW to ‘0’

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press LINE 1 button to move the focus to MINIMUM FLOW (1)

The current value

is displayed in the window.

• Press ENTER.

An asterisk (*) will be displayed after MINIMUM

• Press INC/DEC buttons, to set the MINIMUM FLOW value.

20

V 1.0 11/05

Page 21

E15h SPRAYER- Sprayer Setup Operation

3.4 SET THE PRESET ROW WIDTH and SECTION WIDTHS

Note: This sets the Section widths of each row. 4 Preset Widths can be set.

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press LINE 2 when the focus is on PRESET WIDTH.

This window shows

the current width of the sprayer. The number in the bracket displays which

Preset Width (1,2,3 or 4) the Total Width is representing.

• Press ENTER to advance to the next screen (Section Widths Setup), as

shown below.

TOTAL WIDTH

- window displays the current Preset Width selected, the

number in the bracket indicates which Preset Width is displayed.

4 Preset Widths can be stored,(1,2,3 or 4). The TOTAL WIDTH window

selects which Preset Width is to be edited.

ROW WIDTH-

Displays the current Row Width.

SECTIONS-

Displays the number of sections and section configurations,

these are set in Section 3.13. The section widths for each section are

displayed under each section. The Sections widths can be edited, as the

Sections are edited the TOTAL WIDTH and ROW WIDTHS will reflect the

changes made.

LEFT 2 represents LEFT OUTER on the console section switch.

LEFT 1 represents LEFT INNER on the console section switch.

RIGHT 1 represents RIGHT INNER on the console section switch.

RIGHT 2 represents RIGHT OUTER on the console section switch.

Section Widths Setup Screen

21

V 1.0 11/05

Page 22

E15h SPRAYER- Sprayer Setup Operation

• With the focus on TOTAL WIDTH. Press the INC or DEC buttons, to select the

Preset Width to change, (1,2,3 or 4). The current TOTAL WIDTH and ROW

WIDTH will be displayed for that number.

• Press the LINE 3 button, the focus will be on the first Section to be set.

• Press ENTER to edit the section width.

An asterisk (*) will appear.

• Use the INC/DEC buttons to change the section width.

As the section is changed

the TOTAL WIDTH and ROW WIDTH values will automatically change.

• Press ENTER to accept the changes

• Press the LINE 3 button to move the focus window to the next section that

requires setting.

• Use the INC/DEC buttons to change the section width.

As the section is changed

the TOTAL WIDTH and ROW WIDTH values will change accordingly

•

Repeat the process for as many section widths that need changing.

• Once all section widths have been entered for that Preset With, then select

another Preset Width Number.

• Press MENU to go back to the previous Spray Setup Screen.

V 1.0 11/05

22

Page 23

E15h SPRAYER- Sprayer Setup Operation

3.5 SET THE LOW SPEED SHUTOFF

Note: This sets the LOW SPEED SHUTOFF value, so when the boomspray slows

down below this value , the boom spray will turn all sections OFF, and the

sections will stay on HOLD, the regulator valve will hold the same position when

the ‘Low Speed Shutoff’ came into affect; till the boomspray increases speed

above the LOW SPEED SHUTOFF value.

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press LINE 2 button until the focus is on LOW SPEED SHUTOFF

• Press ENTER.

An asterisk (*) will appear after SPEED

• Use the INC/DEC buttons to change the LOW SPEED SHUTOFF value

• Press ENTER to accept the changes

3.6

SET THE TANK VOLUME

Note: This sets the size of the boomspray tank.

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press LINE 3 so the focus is on TANK VOLUME (1)

• Press ENTER.

An asterisk (*) will appear after

TANK

• Use the INC/DEC buttons to change the tank volume.

Volume

changes in 50 litres increments.

• Press ENTER to accept the changes

3.7

APPL’N MODE (Application Mode)

Note: This sets the way application rate is displayed on the ‘Working Screen, the

Rate can be displayed as volume/area OR volume/distance; eg.‘L/Ha’ or ‘L/100m.

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press LINE 3 until the focus is on APPL’N MODE

• Press ENTER.

An asterisk (*) will appear after

APPL’N.

• Use the INC/DEC buttons to select either ‘L/Ha’ or ‘L/100m’

• Press ENTER

to accept the changes.

23

V 1.0 11/05

Page 24

E15h SPRAYER- Sprayer Setup Operation

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press LINE 4 until the focus window is on SPEED CAL.

The focus window

displays the current SPEED CAL factor

• Press ENTER.

Screen will change to SPEED CAL SETUP screen. Go to Section 3.8.2

for Automatic Speed Calibration; or Section 3.8.3 for Manual Speed Calibration

Entry

When the STANDARD is selected for the SPEED SOURCE:

STANDARD is the default, which means the speed source is taken from the wheel

sensor on the Sprayer Loom.

This wheel factor value is the distance travelled by the sprayer, per pulse from

the wheel (speed)sensor. The value will vary considerably between different

sprayers, with typical values between .25 and 1 meter per pulse. Values more

than 5.0 meters will not give good spray rate control and must be avoided.

When the RADAR is selected for the SPEED SOURCE:

If the RADAR is selected, then the speed source is taken from the 3 pin weather

pak connector on the loom going into the back of the E15 console;

The RADAR SOURCE is used if the operator wants to use the tractor radar.

The wheel factor value will vary between different tractor radar models, a typical

value will be between 0.1 and 0.0005.

Speed Cal Screen

3.8 SET THE WHEEL CALIBRATION FACTOR

24

V 1.0 11/05

Page 25

E15h SPRAYER- Sprayer Setup Operation

3.8.1 SELECT SPEED SOURCE

• Press Line 4 to highlight SPEED SOURCE

• Press ENTER.

An asterisk (*) will appear.

• Use INC/DEC buttons to select STANDARD or RADAR.

• Press ENTER to accept changes.

3.8.2

AUTOMATIC WHEEL CALIBRATION

• Select Line 1 to highlight PULSES.

• Press ENTER to begin wheel factor calibration

• Drive forward a measured distance, say 100m.

The PULSES count will

accumulate as you travel forwards. The DISTANCE value and ESTIMATED value

will accumulate in metres as you travel forwards. These values will accumulate

reflecting the current WHEEL FACTOR value; if the value is close then then the

ESTIMATED and DISTANCE value will also be close to the actual distance

travelled.

The DISTANCE value is the value to be edited and the ESTIMATED value is

a display value only.

• Once the known distance is reached, press ENTER.

Focus will

automatically jump to

DISTANCE

line of the screen

• Use Inc/Dec buttons to change the DISTANCE value to reflect the actual

distance travelled

• Press ENTER to accept the value. The

Wheel factor will be automatically

calculated and displayed, on the SPEED CAL line.

3.8.3 MANUAL ENTRY OFF WHEEL FACTOR

• Press LINE 3 until the focus is on SPEED CAL

• Press ENTER to edit the value. An asterisk (*) will appear next to SPEED.

• Use INC/DEC buttons to change the wheel factor.

Wheel factor

changes in 1cm increments, when STANDARD is selected. The Increment

changes are a lot smaller when RADAR is selected.

• Press ENTER to accept the value

• Press MENU to go back to previous Sprayer Setup Screen

25

V 1.0 11/05

Page 26

3.9 SET THE FLOW CALIBRATION FACTOR

E15h SPRAYER- Sprayer Setup Operation

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press LINE 4 twice until the focus is on FLOW CAL.

The focus window will

display the current FLOW CAL factor in pulses/volume

• Press ENTER.

Screen will advance to FLOW CAL SETUP screen. Go to Section

3.9.1 to continue setup using Automatic Flow Calibration method

or

go to

Section 3.9.2 to manually enter the Flow Calibration which is located on the

Flow Meter body, on the sprayer. The number located on the Flow Meter must

be in “pulses per volume” for the number to be entered in manually. The

number used must reflect the units selected in the console. For example if the

number is in ‘pulses per litre’ then ‘Metric’ must be selected in console units.

See Section 3.25 to select ‘Console Units’.

Flow Cal Screen

26

V 1.0 11/05

Page 27

E15h SPRAYER- Sprayer Setup Operation

3.9.1 AUTOMATIC FLOW CALIBRATION

• Fully prime the flow sensor and hose

• Disconnect one of the section lines from the spray manifold

• Place a bucket under the output of the section valve

• Ensure the relevant boom section switch is switched ON, on the console.

• Press ENTER to begin flow factor calculation

• The valve will open and fluid will begin to pump through the manifold.

The

pulse count will begin accumulating as you meter out liquid

• Once a sufficient volume has accumulated( 20 litres is a good amount), press

ENTER, this will automatically turn OFF the section valve. The

Focus will

automatically jump to ACTUAL FLOW line of the screen

• Use INC/DEC buttons to change the volume, to reflect the actual

volume collected in the bucket

• Press ENTER to accept the value.

Flow cal factor will be automatically

calculated and displayed.

3.9.2 MANUAL FLOW CALIBRATION

Note: If the Flow Meter has a ‘Flow Cal’ value stamped on the flow meter then

that value can be entered in here. The value must be in “pulses per volume”. The

units that are stamped on the‘Flow Cal’, must be the same units, the E15 console

is using; otherwise a conversion will have to be performed.

• Press LINE 3 until the focus is on FLOW CAL

• Press ENTER to edit the value

• Press INC/DEC buttons to change the FLOW CAL factor

• Press ENTER to accept the value

Note: Press MENU to get back to the previous Sprayer Setup Screen once the

calibration is finished.

27

V 1.0 11/05

Page 28

E15h SPRAYER- Sprayer Setup Operation

3.10 SPRAYER SETUP 2 MENU

Sprayer Setup 2 Screen

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press the DEC button to advance to the SPRAYER SETUP 2 screen

28

V 1.0 11/05

Page 29

E15h SPRAYER- Sprayer Setup Operation

3.11 SET A MANUAL SPEED

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press Dec (down arrow), the screen advances to SPRAYER SETUP 2

• Press LINE 1 until focus is on MANUAL SPEED

• Press ENTER,

An asterisk (*) will appear after MANUAL

• Press INC/DEC buttons to set the manual speed.

A value of OFF and

number between 1 kph and 40kph can be set.

• Press ENTER, to accept changes

Note: The manual speed will not be able to be set if there is a valid speed

source present, this can only be done whilst the vehicle is stationary. As soon as

a valid speed is present this will override the manual speed. This value is not

saved in memory, if the console is turned OFF the ‘Manual Speed’ value will

need to be re-entered

3.12 SET RATE INCREMENT

Note: The units displayed will be (L/Ha or L/100m), for the rate increment, this

will depend on whether ‘L/Ha’ or ‘L/100m’ was selected for the APPL’N MODE.

See Section 3.7.

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press Dec (down arrow), the screen advances to SPRAYER SETUP 2

• Press LINE 1 until the focus is on RATE INCREMENT

• Press ENTER.

An asterisk (*) will appear after RATE

• Press INC/DEC buttons, to set RATE INCREMENT value.

Rate increment values changes in 1 (L/ha or L/100m) increments.

• Press ENTER to accept the changes

3.13

SET THE NUMBER OF BOOM SECTIONS

Note: This sets the number boom sections and the configuration of boom

sections to suit the sprayer configuration being used.

When 2 sections are selected then ‘Left Inner’ and ‘Right Inner’ section switches

are enabled.

When ‘3L’ sections are selected then ‘Left Outer’, ‘Left Inner’ and ‘Right Inner’

section switches are enabled.

When ‘3R’ sections are selected then ‘Left Inner’, Right Inner’ and ‘Right Outer’

section switches are enabled.

When ‘4’ is selected then the ‘Left Outer’, ‘Left Inner’, ‘Right Inner’ and ‘Right

Outer’ section switches are selected

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press Dec (down arrow), the screen advances to SPRAYER SETUP 2

• Press LINE 2, until the focus is on BOOM SECTIONS.

The focus window displays

the number of sections and sprayer configuration currently selected.

• Press ENTER to set the number and configuration of BOOM SECTIONS.

An asterisk (*) will appear.

• Press INC/DEC buttons, to select between ‘2’, ‘3L’, ‘3R’ and 4 SECTIONS

• Press ENTER to accept the changes

29

V 1.0 11/05

Page 30

E15h SPRAYER- Sprayer Setup Operation

3.14 ENABLE DATA LOGGER

Note: Only enable the ‘Data Logger’ if an optional A1920 Data Logger kit is

connected to the CON 3 plug at the back of the E15h console.

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press Dec (down arrow), the screen advances to SPRAYER SETUP 2

• Press LINE 2 until focus is on DATA LOGGER

• Press ENTER.

An asterisk (*) will appear.

• Press INC/DEC buttons, to select ON or OFF.

• Press ENTER to accept changes.

3.15

ENABLE FLUSH OUTPUT

Note: This feature can only be enabled when the ‘Fully Featured Horticultural

Loom’ is fitted to the sprayer.

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press Dec (down arrow), the screen changes to SPRAYER SETUP 2

• Press LINE 3. The focus will be on FLUSH ENABLED

• Press ENTER.

An asterisk (*) will appear.

• Press INC/DEC buttons, to select both FLUSH ON or OFF

OUTPUTS, ON or OFF.

When the FLUSH AND AUXILIARY OUTPUTS are switched

ON, this enables two relays within the console. The FLUSH function enables the

operator to flush the spray boom out with clean water. Connect the solenoid on

the Flush Line to the plug marked “Flush” on the F/F “Horticultural Sprayer

Loom”.When the FLUSH function is enabled ON, then a FLUSH TIME is enabled,

on LINE 4 in the right column and a FLUSH TIME value is able to be entered.

• Press ENTER to accept changes

3.16 SET FLUSH TIME

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press Dec (down arrow), the screen advances to the SPRAYER SETUP 2 screen

• Press LINE 4. The focus will be on FLUSH AND AUXILIARY

• Press ENTER.

An asterisk (*) will appear.

• Press INC/DEC buttons, enable FLUSH ENABLED, ON.

It must be switched ON to

allow a FLUSH TIME value to be entered

• Press LINE 4, to highlight FLUSH TIME

• Press ENTER to edit the value.

An asterisk (*) will appear.

• Press INC/DEC buttons, to set the FLUSH TIME, values can be set

between 10 and 60 seconds, increments are in 5 second steps.

• Press ENTER to accept changes

30

V 1.0 11/05

Page 31

E15h SPRAYER- Sprayer Setup Operation

3.17 ENABLE FULL ROW PER SECTION

Note: By default this function is selected OFF; therefore each section switch,

switches half a row ON and OFF.

When FULL ROW PER SECTION is enabled ON, then each section switch, switches

1 row ON and OFF. For example a 2 row sprayer which has only 1 solenoid

controlling each row, then ‘2’ sections would be selected in BOOM SECTIONS,

(see Section 3.13) and FULL ROW PER SECTION enabled ON.

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press DEC (down arrow) button, the screen advances to SPRAYER SETUP 2

• Press LINE 4 until focus is on FULL ROW PER SECTION

• Press ENTER.

An asterisk (*) will appear.

• Press INC/DEC buttons, to select ON or OFF.

• Press ENTER to accept changes.

3.18

ENABLE AUXILIARY FUNCTION

Note: The AUXILIARY function enables the operator to connect a set of lights OR

foam marker to the AUXILIARY plug on the sprayer wiring loom and switch the

lights OR foam marker ON or OFF from the console.

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press DEC (down arrow) button, the screen advances to SPRAYER SETUP 2

• Press LINE 4 until focus is on FULL ROW PER SECTION

• Press ENTER.

An asterisk (*) will appear.

• Press INC/DEC buttons, to select ON or OFF.

• Press ENTER to accept changes.

31

V 1.0 11/05

Page 32

E15h SPRAYER- Sprayer Setup Operation

3.19 SPRAYER SETUP 3 MENU

Sprayer Setup 3 Screen

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press the DEC button to advance to the SPRAYER SETUP 2 screen

• Press the DEC button to advance to the SPRAYER SETUP 3 screen

V 1.0 11/05

32

Page 33

E15h SPRAYER- Sprayer Setup Operation

3.20 ENABLE PUMP SPEED SENSOR

Note: Select ON if a PUMP SPEED SENSOR is fitted to the sprayer loom, to the

plug marked PUMP SPEED. The PUMP SPEED plug is only available on the ‘FULLY

FEATURED HORTICULTURAL LOOM’.

When enabled ON , the PUMP SPEED RPM can be displayed in the FLOW RATE

window.

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press the DEC button to advance to the SPRAYER SETUP 2 screen

• Press the DEC button to advance to the SPRAYER SETUP 3 screen

• Press LINE 1, to highlight PUMP SPEED SENSOR

• Press ENTER to edit the PUMP SPEED SENSOR.

• Press INC/DEC buttons, to enable the PUMP SPEED SENSOR ON or OFF

• Press ENTER to accept changes

3.21

ENABLE AUXILIARY SHAFT SENSOR

Note: Select ON if a AUXILIARY SHAFT SENSOR is fitted to the sprayer loom, to

the plug marked AUXILIARY SHAFT The AUXILIARY SHAFT plug is only available

on the ‘FULLY FEATURED HORTICULTURAL LOOM’.

When enabled ON , the AUXILIARY SHAFT RPM can be displayed in the FLOW

RATE window.

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press the DEC button to advance to the SPRAYER SETUP 2 screen

• Press the DEC button to advance to the SPRAYER SETUP 3 screen

• Press LINE 1, to highlight AUX. SHAFT SENSOR

• Press ENTER to edit the AUX.SHAFT SENSOR.

• Press INC/DEC buttons, to enable the AUX. SHAFT SENSOR ON or OFF

• Press ENTER to accept changes

3.22

ENABLE DUMP OVERRIDE

Note: Select ON to enable the DUMP OVERRIDE feature. This allows a Chemical

Induction Pump to suck premix chemical into the main tank. Don’t enable this

function unless your sprayer has been plumbed up correctly. When enabled ON ,

the DUMP OVERRIDE can be displayed in the VOLUME USED window.

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press the DEC button to advance to the SPRAYER SETUP 2 screen

• Press the DEC button to advance to the SPRAYER SETUP 3 screen

• Press LINE 2, to highlight DUMP OV’RIDE ENABLED

• Press ENTER to edit the DUMP OV’RIDE ENABLED.

• Press INC/DEC buttons, to enable the DUMP OV’RIDE ENABLED ON or OFF

• Press ENTER to accept changes

33

V 1.0 11/05

Page 34

E15h SPRAYER- Sprayer Setup Operation

3.23 SELECT DUMP MODE

Note: If connecting a DUMP VALVE to the ‘37 Pin’ plug marked DUMP on the

sprayer loom, then select STANDARD. STANDARD is the default. Normally

STANDARD is selected when using a ‘Fully Featured Horticultural Loom’.

If connecting the DUMP valve to the ‘24 Pin’ plug marked ‘SECT. 6’ on the

‘Economy Sprayer’ or using the ‘Horticultural Adaptor’ loom, then select ‘SECT 6’.

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press the DEC button to advance to the SPRAYER SETUP 2 screen

• Press the DEC button to advance to the SPRAYER SETUP 3 screen

• Press LINE 1, to highlight DUMP MODE

• Press ENTER to edit the DUMP MODE.

• Press INC/DEC buttons, to select the DUMP MODE as STANDARD OR SECT. 6.

• Press ENTER to accept changes

3.24

SET THE VALVE TYPE

*Note: If connecting the sprayer loom to ‘2 Wire Valves’ via an ARAG interface

then select SOLENOID as the VALVE TYPE.

Only select ‘2 Wire Valves’ as the VALVE TYPE when the sprayer loom connects

directly to the ‘2 Wire Valves’.

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press the DEC button to advance to the SPRAYER SETUP 2 screen

• Press the DEC button to advance to the SPRAYER SETUP 3 screen

• Press LINE 3, to highlight VALVE TYPE

• Press ENTER to edit VALVE TYPE.

An asterisk (*) will appear.

• Press INC/DEC buttons, to select between SOLENOID, 2-WIRE*

or 3-WIRE.

• Press ENTER to accept the changes

3.25

SET THE CONSOLE UNITS

Note: Default is METRIC.

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press the DEC button to advance to the SPRAYER SETUP 2 screen

• Press the DEC button to advance to the SPRAYER SETUP 3 screen

• Press LINE 3, to highlight CONSOLE UNITS

• Press ENTER to edit CONSOLE UNITS.

An asterisk (*) will appear.

• Press INC/DEC buttons, to select between: METRIC, IMP’L(IMPERIAL),

U.S.(U.S. IMPERIAL), CAN. IMP(CANADIAN IMPERIAL),

or CAN.MET(CANADIAN METRIC)

• Press ENTER to accept the changes

V 1.0 11/05

34

Page 35

E15h SPRAYER- Sprayer Setup Operation

Note: If no fans are to be monitored then set FAN MONITOR to OFF and set

FANS ENABLED to ‘0’

When FAN MONITOR is selected to OFF, then there is noFAN MONITOR ECU

fitted to the E15 h console. When FAN MONITOR is selected to ON, then there is

a FAN MONITOR ECU connected to the E15h console

If a ‘Fully Featured Horticultural Loom’ is fitted to the sprayer then up to 2 fan

imputs can be monitored, without the need to install a FAN MONITOR ECU. In

this case select FAN MONITOR to OFF and select either 1 or 2 from FANS

ENABLED.

If the Economy Horticultural Loom is fitted OR more than 2 fans need to be

monitored then a Fan Monitor ECU needs to be installed. In this case select FAN

MONITOR to ON and then select the number of fans to be monitored from FANS

ENABLED.

The Fan Monitor ECU can monitor up to 12 fans.

3.26 ENABLE FAN MONITORING

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press the DEC button to advance to the SPRAYER SETUP 2 screen

• Press the DEC button to advance to the SPRAYER SETUP 3 screen

• Press LINE 4, to highlight FAN MONITOR

• Press ENTER to edit the FAN MONITOR.

• Press INC/DEC buttons, to select either ON (if a FAN MONITOR ECU is

connected) OR OFF ( if noFAN MONITOR ECU is connected).

• Press ENTER to accept changes.

3.27

SET NUMBER OF FANS

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press the DEC button to advance to the SPRAYER SETUP 2 screen

• Press the DEC button to advance to the SPRAYER SETUP 3 screen

• Press LINE 4, to highlight FANS ENABLED

• Press ENTER to edit the FANS ENABLED.

• Press INC/DEC buttons, to set the number of fans to be monitored.

Note: If FAN MONITOR was selected to OFF, then only ‘0’ (monitoring no fans),

‘1’ (monitoring 1 fan) OR ‘2’ (monitoring 2 fans) can be selected.

If FAN MONITOR was selected to ON, then select between ‘2’, ‘4’, ‘6’, ‘8’, ‘10’, or

‘12’ fans to monitor.

• Press ENTER to accept changes.

V 1.0 11/05

35

Page 36

3.28 SPRAYER SETUP 4 MENU

Sprayer Setup 4 Screen

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press the DEC button to advance to the SPRAYER SETUP 2 screen

• Press the DEC button to advance to the SPRAYER SETUP 3 screen

• Press the DEC button to advance to the SPRAYER SETUP 4 screen

E15h SPRAYER- Sprayer Setup Operation

V 1.0 11/05

36

Page 37

E15h SPRAYER- Sprayer Setup Operation

3.29 ENABLE PRESSURE1 SENSOR

Note: Select ON if a pressure transducer is fitted to the plug marked “PRESSURE

SENSOR” on the Sprayer Loom.

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press the DEC button to advance to the SPRAYER SETUP 2 screen

• Press the DEC button to advance to the SPRAYER SETUP 3 screen

• Press the DEC button to advance to the SPRAYER SETUP 4 screen

• Press LINE 1, to highlight PRESSURE1 SENSOR

• Press ENTER to edit the PRESSURE1 SENSOR.

• Press INC/DEC buttons, to enable the PRESSURE1 SENSOR ON or OFF

• Press ENTER to accept changes

3.30

SETTING THE PRESSURE GAIN

Note: PRESSURE GAIN is setting the gain for the pressure sensor connected to the

plug marked “PRESSURE SENSOR” on the “Sprayer Loom”. The default is “x2”

Only use “x1” if the Eagle E15h console was purchased before June 2005.

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press the DEC button to advance to the SPRAYER SETUP 2 screen

• Press the DEC button to advance to the SPRAYER SETUP 3 screen

• Press the DEC button to advance to the SPRAYER SETUP 4 screen

• Press LINE 3, to highlight PRESSURE GAIN (1)

• Press ENTER to edit the PRESSURE GAIN (1)

• Press INC/DEC buttons, select between 1x or 2x

• Press ENTER to accept changes

3.31

SETTING THE TYPE OF PRESSURE SENSOR

Note: PRESSURE SENSOR is sets the type of pressure sensor connected to the plug

marked “PRESSURE SENSOR” on the “Sprayer Loom”

The default is 5 BAR. Most sprayers will use this setting.

10 BAR Pressure Sensors is only used for special purposes like “Air Blast” sprayers

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press the DEC button to advance to the SPRAYER SETUP 2 screen

• Press the DEC button to advance to the SPRAYER SETUP 3 screen

• Press the DEC button to advance to the SPRAYER SETUP 4 screen

• Press LINE 4, to highlight PRESSURE SENSOR

• Press ENTER to edit the PRESSURE SENSOR

• Press INC/DEC buttons, select between 5BAR or 10BAR

• Press ENTER to accept changes

V 1.0 11/05

37

Page 38

E15h SPRAYER- Sprayer Setup Operation

3.32 PRESSURE SENSOR 1 CALIBRATION

Pressure Cal Screen

38

V 1.0 11/05

Page 39

E15h SPRAYER- Sprayer Setup Operation

3.32 PRESSURE SENSOR 1 CALIBRATION

Note: A “Glass Pressure Gauge” should be connected as close to the electronic

pressure sensor as possible. The “Glass Gauge” will give the actual pressure, so

the electronic pressure transducer can be calibrated.

• Press MENU

• Press ENTER to select SETUP

• Press ENTER to select SPRAYER SETUP

• Press the DEC button to advance to the SPRAYER SETUP 2 screen

• Press the DEC button to advance to the SPRAYER SETUP 3 screen

• Press the DEC button to advance to the SPRAYER SETUP 4 screen

• Press LINE 2 to highlight PRESSURE CAL

• Press ENTER,

screen will change to Pressure Calibration Screen. ‘TURN PUMP

OFF’. is highlighted

• Turn pump OFF

. Make sure the spray pump is turned OFF

• Press ENTER.

The focus window will move to the next window ‘IS PUMP OFF?’

then Press ENTER. at this point the Eagle console is taking a zero point for the

electronic pressure sensor while the spray pump is switched OFF.

• Switch the pump ON; switch the sections ON; switch the MASTER ON; and take

the pump up to ‘operating pressure’; once at operating pressure.

• Press ENTER the focus window will move to ‘IS PUMP AT OPERATING

PRESSURE’, reminding the operator to have the spray pump at operating

pressure.

• Press ENTER again to move the focus window to ACTUAL PRESSURE.

• Press ENTER to edit the ACTUAL PRESSURE.

An asterisk (*) will appear.

• Press the INC/DEC buttons, till the actual pressure as displayed by the

“Glass Pressure Gauge” is reflected in ACTUAL PRESSURE” window.

• Press ENTER to accept changes

V 1.0 11/05

39

Page 40

4.0 ALARMS SETUP MENU

Alarms Menu Setup

40

E15h SPRAYER- Alarm Setup

V 1.0 11/05

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2, the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

Page 41

E15h SPRAYER- Alarm Setup

4.1 RATE ALARMS

Rate Alarms Screen

V 1.0 11/05

41

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2, the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press ENTER to select RATE ALARMS

Page 42

E15h SPRAYER- Alarm Setup

4.1 RATE ALARMS

4.1.1 ENABLE THE MINIMUM FLOW ALARM

NOTE: To set the MINIMUM FLOW value, see Section 3.3.

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2, the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press ENTER to select RATE ALARMS

• Press ENTER to select MIN FLOW ALARM.

An asterisk (*) will be displayed

• Press INC/DEC buttons, to set the alarm ON or OFF

• Press ENTER to accept the changes

4.1.2

ENABLE THE APPLICATION RATE LOW ALARM

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2, the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press ENTER to select RATE ALARMS

• Press LINE 2, the focus is on RATE LOW ALARM

• Press ENTER to select RATE LOW ALARM.

An asterisk( *) will be displayed

• Press INC/DEC buttons, to set the alarm ON or OFF

• Press ENTER to accept the changes

4.1.3 SET THE APPLICATION RATE LOW ALARM POINT

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2, the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press ENTER to select RATE ALARMS

If alarm is OFF, switch the alarm ON as previously explained in Section 4.1.2

• Press LINE 2 twice to move the focus to ALARM POINT

• Press ENTER to edit the value.

An asterisk(*) will be displayed

• Press INC/DEC buttons, to set the ALARM POINT as a percentage (%).

• Press ENTER to accept the changes.

42

V 1.0 11/05

Page 43

E15h SPRAYER- Alarm Setup

4.1.4

ENABLE THE APPLICATION RATE HIGH ALARM

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2, the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press ENTER to select RATE ALARMS

• Press LINE 3, the focus is on RATE LOW ALARM

• Press ENTER to select RATE HIGH.

An asterisk (*) will be displayed

• Press INC/DEC buttons, to set the alarm ON or OFF

• Press ENTER to accept the changes

4.1.5

SET THE APPLICATION RATE HIGH ALARM POINT

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2, the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press ENTER to select RATE ALARMS

Note:If alarm is OFF, switch the alarm ON as previously explained in Section 4.1.4

• Press LINE 3 twice to move the focus to ALARM POINT

• Press ENTER to edit the value.

An asterisk (*) will be displayed

• Press INC/DEC buttons to set the ALARM POINT as a percentage (%).

• Press ENTER to accept the changes

43

V 1.0 11/05

Page 44

E15h SPRAYER- Alarm Setup

4.2 SHAFT ALARMS

Shaft Alarms Screen

44

V 1.0 11/05

Page 45

E15h SPRAYER- Alarm Setup

NOTE: For the PUMP LOW SPEED and PUMP HIGH SPEED ALARMS to be enabled

on the SHAFT ALARMS screen, the PUMP SPEED SENSOR has to be set to ON.

See Section 3.22 to enable the PUMP SPEED SENSOR ON or OFF

4.2.1 ENABLE THE PUMP SPEED LOW ALARM

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2 the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press LINE 2, the focus is on SHAFT ALARMS

• Press ENTER to select SHAFT ALARMS

• Press ENTER to edit PUMP SPEED LOW.

An asterisk(*) will be displayed

• Press INC/DEC buttons, to set the alarm ON or OFF

• Press ENTER to accept the changes

4.2.2

SET THE PUMP SPEED LOW ALARM POINT

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2 the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press LINE 2, the focus is on SHAFT ALARMS

• Press ENTER to select SHAFT ALARMS

Note:

If alarm is OFF, to switch the alarm ON, see Section 4.2.1

•Press LINE 1 until the focus is on the ALARM POINT

• Press ENTER to edit the value.

An asterisk(*) will be displayed

• Use INC/DEC buttons, to set the alarm point in 50 rpm increments

• Press ENTER to accept the changes

4.2.3

ENABLE THE PUMP SPEED HIGH ALARM

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2 the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press LINE 2, the focus is on SHAFT ALARMS

• Press ENTER to select SHAFT ALARMS

• Press LINE 2, the focus is on PUMP SPEED HIGH

• Press ENTER to edit PUMP SPEED HIGH.

An asterisk (*) will be displayed

• Press INC/DEC buttons, to switch the alarm ON or OFF

• Press ENTER to accept the changes

45

V 1.0 11/05

Page 46

E15h SPRAYER- Alarm Setup

4.2.4 SET THE PUMP SPEED HIGH ALARM POINT

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2 the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press LINE 2, the focus is on SHAFT ALARMS

• Press ENTER to select SHAFT ALARMS

• If alarm is off, turn the alarm ON, see Section 4.2.3

• Press LINE 2 until the focus is on the ALARM POINT

• Press ENTER to edit the value.

An asterisk (*) will be displayed

• Press INC/DEC buttons, to set the alarm point in 50rpm increments

• Press ENTER to accept the changes

4.2.5

ENABLE THE AUX SHAFT LOW ALARM

NOTE: For the AUX SHAFT LOW and AUX SHAFT HIGH ALARMS to be enabled on

the SHAFT ALARMS screen, the AUX SHAFT SENSOR has to be toggled ON.

See Section 3.22 to switch the AUX SHAFT SENSOR ON or OFF

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2 the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press LINE 2, the focus is on SHAFT ALARMS

• Press ENTER to select SHAFT ALARMS

• Press LINE 3, the focus is on AUX SHAFT LOW

• Press ENTER to edit AUX SHAFT LOW.

An asterisk (*) will be displayed

• Press INC/DEC buttons to switch the alarm ON or OFF

• Press ENTER to accept the changes

4.2.6

SET THE AUX SHAFT LOW ALARM POINT

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2 the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press LINE 2, the focus is on SHAFT ALARMS

• Press ENTER to select SHAFT ALARMS

Note: If alarm is OFF, switch the alarm ON, see Section 4.2.5

• Press LINE 3 until the focus is on the ALARM POINT

• Press ENTER to edit the value.

An asterisk (*) will be displayed

• Press INC/DEC buttons, to set the alarm point in 50rpm increments

• Press ENTER to accept the changes

46

V 1.0 11/05

Page 47

E15h SPRAYER- Alarm Setup

4.2.7 ENABLE THE AUX SHAFT HIGH ALARM

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2 the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press LINE 2, the focus is on SHAFT ALARMS

• Press ENTER to select SHAFT ALARMS

• Press LINE 4, the focus is on AUX SHAFT HIGH

• Press ENTER to edit AUX SHAFT HIGH.

An asterisk (*) will be displayed

• Press INC/DEC buttons, to enable the alarm ON or OFF

• Press ENTER to accept the changes

4.2.8

SET THE AUX SHAFT HIGH ALARM POINT

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2 the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press LINE 2, the focus is on SHAFT ALARMS

• Press ENTER to select SHAFT ALARMS

Note: If alarm is OFF, to switch the alarm ON, see Section 4.2.7

• Press LINE 4 until the focus is on the ALARM POINT

• Press ENTER to edit the value.

An asterisk (*) will be displayed

• Press INC/DEC buttons, to set the alarm point in 50rpm increments

• Press ENTER to accept the changes

47

V 1.0 11/05

Page 48

E15h SPRAYER- Alarm Setup

4.3 SPEED ALARMS

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2 the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press LINE 3, the focus is on SPEED ALARMS

• Press ENTER to select SPEED ALARMS

Speed Alarms Screen

48

V 1.0 11/05

Page 49

E15h SPRAYER- Alarm Setup

4.3.1 ENABLE THE SPEED LOW ALARM

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2 the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press LINE 3, the focus is on SPEED ALARMS

• Press ENTER to select SPEED ALARMS

• Press ENTER to edit SPEED LOW.

An asterisk (*) will be displayed

• Press INC/DEC buttons, to set the alarm ON or OFF

• Press ENTER to accept the changes

4.3.2

SET THE SPEED LOW ALARM POINT

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2, the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press LINE 3 the focus is on SPEED ALARMS

• Press ENTER to select SPEED ALARMS

• Press LINE 1, until focus is on ALARM POINT

Note: If alarm is OFF, switch the alarm ON. See Section 4.3.1

• Press ENTER to edit the value.

An asterisk (*) will be displayed

• Press INC/DEC buttons, to set the alarm point

• Press ENTER to accept the changes

4.3.3

ENABLE THE SPEED HIGH ALARM

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2 the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press LINE 3, the focus is on SPEED ALARMS

• Press ENTER to select SPEED ALARMS

• Press LINE 2, the focus is on SPEED HIGH

• Press ENTER to edit SPEED HIGH.

An asterisk (*) will be displayed

• Press INC/DEC buttons, to set the alarm ON or OFF

• Press ENTER to accept the changes

49

V 1.0 11/05

Page 50

E15h SPRAYER- Alarm Setup

4.3.4

SET THE SPEED HIGH POINT

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2, the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press LINE 3, the focus is on SPEED ALARMS

• Press ENTER to select SPEED ALARMS

Note: If alarm is off, turn the alarm on. See Section 4.3.3

• Press LINE 2, until focus is on ALARM POINT

• Press ENTER to edit the value.

An asterisk (*) will be displayed

• Press INC/DEC buttons, to set the alarm point

• Press ENTER to accept the changes

50

V 1.0 11/05

Page 51

E15h SPRAYER- Tank Alarm

4.4 TANK ALARMS

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2, the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press LINE 4, the focus is on TANK ALARMS

• Press ENTER to select TANK ALARMS

Tank Alarms Screen

51

V 1.0 11/05

Page 52

4.4.1

ENABLE THE VOLUME LOW ALARM

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2, the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press LINE 4, the focus is on TANK ALARMS

• Press ENTER to select TANK ALARMS

• Press ENTER to edit VOLUME LOW (1).

An asterisk (*) will be displayed

• Press INC/DEC buttons to set the alarm ON or OFF

• Press ENTER to accept the changes

4.4.2

SET THE VOLUME LOW POINT

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2 the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press LINE 4, the focus is on TANK ALARMS

• Press ENTER to select TANK ALARMS

Note: If alarm is OFF, switch the alarm ON. See Section 4.4.1

• Press LINE 1, to move to the ALARM POINT

• Press ENTER to edit the value.

An asterisk (*) will be displayed

• Press INC/DEC buttons, to set the alarm point, in 10L increments.

• Press ENTER to accept the changes

E15h SPRAYER - Tank Alarms

52

V 1.0 11/05

Page 53

E15h SPRAYER- Pressure Alarm

4.5 PRESSURE ALARMS

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2 the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press LINE 1,until the focus is on PRESSURE ALARMS

• Press ENTER to select PRESSURE ALARMS

Pressure Alarms Screen

53

V 1.0 11/05

Page 54

E15h SPRAYER- Pressure Alarm

4.5.1 ENABLE THE PRESSURE 1 LOW ALARM

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2 the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press LINE 1,until the focus is on PRESSURE ALARMS

• Press ENTER to select PRESSURE ALARMS

• Press ENTER to edit PRESSURE 1 LOW.

An asterisk (*) will be displayed

• Press INC/DEC buttons to switch the alarm ON or OFF

• Press ENTER to accept the changes

4.5.2 SET THE PRESSURE 1 LOW ALARM POINT

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2, the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press LINE 1, until the focus is on PRESSURE ALARMS

• Press ENTER to select PRESSURE ALARMS

• Press LINE 1, until focus is on ALARM POINT

Note:

If alarm is OFF, to switch the alarm ON. See Section 4.5.1

• Press ENTER to edit the value.

An asterisk (*) will be displayed

• Press INC/DEC buttons to set the alarm point in 10kPa increments

• Press ENTER to accept the changes

4.5.3

ENABLE THE PRESSURE 1 HIGH ALARM

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2 the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press LINE 1,until the focus is on PRESSURE ALARMS

• Press ENTER to select PRESSURE ALARMS

• Press LINE 2, the focus is on PRESSURE 1 HIGH

• Press ENTER to edit PRESSURE 1 HIGH.

An asterisk (*) will be displayed

• Press INC/DEC buttons, to switch the alarm ON or OFF

• Press ENTER to accept the changes

54

V 1.0 11/05

Page 55

E15h SPRAYER- Pressure Alarm

4.5.4 SET THE PRESSURE 1 HIGH ALARM POINT

• Press MENU

• Press ENTER to select SETUP

• Press LINE 2, the focus is on ALARM SETUP

• Press ENTER to select ALARM SETUP

• Press LINE 1, until the focus is on PRESSURE ALARMS

• Press ENTER to select PRESSURE ALARMS

Note:

If alarm is OFF, to switch the alarm ON. See Section 4.5.3

• Press LINE 2, until focus is on ALARM POINT

• Press ENTER to edit the value.

An asterisk (*) will be displayed

• Press INC/DEC buttons, to set the alarm point in 10kPa increments

• Press ENTER to accept the changes

55

V 1.0 11/05

Page 56

E15h SPRAYER- Controller Setup

5. CONTROLLER SETUP MENU

• Press MENU

• Press ENTER to select SETUP

• Press LINE 3, the focus is on CONTROLLER SETUP

• Press ENTER to CONTROLLER SETUP

Controller Setup Screen

56

V 1.0 11/05

Page 57

E15h SPRAYER- Controller Setup

5.1 SET CONTROL MODE

Note: This setting is selecting the type of regulator valve connected to the plug

marked ‘REG VALVE 1” on the “Sprayer Loom”. When the type of regulator valve

is selected, the defaults are automatically set for: “MAX ON TIME”, “MIN ON

TIME”, “GAIN SETTING” and “PWM SETTING”. There should be no need to alter

these defaults settings unless instructed by a KEE Service Person. If the regulator

valve being used is not listed then select “STANDARD”.

Standard Types: Arag Type, KEE Type, Hardi type Regulator Valves

Raven: Raven Fast Regulator Valves

Micro-Track: Micro-Track Regulator Valves

Dickey-John: Dickey John Regulator Valves

• Press MENU

• Press ENTER to select SETUP

• Press LINE 3, the focus is on CONTROLLER SETUP

• Press ENTER to CONTROLLER SETUP

• Press ENTER to edit CONTROL MODE. An asterisk (*) will appear.

• Press INC/DEC buttons to select between: STANDARD, RAVEN, DICKEY-J

(Dickey-John) and M-TRACK (Mirco-Track)

• Press ENTER to accept the changes

5.2

SET THE MAX ON TIME

• Press MENU

• Press ENTER to select SETUP

• Press LINE 3, the focus is on CONTROLLER SETUP

• Press ENTER to CONTROLLER SETUP

• Press LINE 2, the focus is on MAX ON TIME

• Press ENTER to edit MAX ON TIME

An asterisk (*) will appear.

• Press INC/DEC buttons to set the value.

Depending on the type of regulator

valve selected in Section 5.1, will determine what range of values (mS) are

available, there are four values to select from.

• Press ENTER to accept the changes

5.3

SET THE MIN ON TIME

• Press MENU

• Press ENTER to select SETUP

• Press LINE 3, the focus is on CONTROLLER SETUP

• Press ENTER to CONTROLLER SETUP

• Press LINE 2, till the focus is on MIN ON TIME)

• Press ENTER to edit MIN ON TIME.

An asterisk (*) will appear.

• Press INC/DEC buttons to set the value.

Depending on the type of regulator

valve selected in Section 5.1, will determine what range of values (mS) are

available, there are four values to select from.

• Press ENTER to accept the changes

57

V 1.0 11/05

Page 58

E15h SPRAYER- Controller Setup

5.4 SET THE GAIN SETTING

• Press MENU

• Press ENTER to select SETUP

• Press LINE 3, the focus is on CONTROLLER SETUP

• Press ENTER to CONTROLLER SETUP

• Press LINE 3, the focus is on GAIN SETTING

• Press ENTER to edit GAIN SETTING.

An asterisk (*) will appear.

• Press INC/DEC buttons to set the value.

Depending on the type of regulator

valve selected in Section 5.1, will determine what range of values (mS/%) are

available, there are four values to select from.

• Press ENTER to accept the changes

5.5

SET THE PWM SETTING

• Press MENU

• Press ENTER to select SETUP

• Press LINE 3, the focus is on CONTROLLER SETUP

• Press ENTER to CONTROLLER SETUP

• Press LINE 3, the focus is on PWM SETTING

• Press ENTER to edit PWM SETTING.

An asterisk (*) will appear.

• Press INC/DEC buttons to set the value.

Depending on the type of regulator

valve selected in Section 5.1, will determine what range of values (%) are

available, there are four values to select from.

• Press ENTER to accept the changes

5.6

SET THE FLOWMETER SENSITIVITY

Note: DeFault is STANDARD

• Press MENU

• Press ENTER to select SETUP

• Press LINE 3, the focus is on CONTROLLER SETUP