Opsys MW

Please read carefully before using the Opsys MW

™

Microplate Washer

User’s Guide

IMPORTANT

Part No. 91000051, Revision B

This manual is published by DYNEX Technologies, Inc.

Questions or comments regarding the content of this manual can be

directed to the address below or to your DYNEX Technologies

representative.

DYNEX Technologies

14340 Sullyfield Circle

Chantilly, VA 20151-1683 USA

Tel. (703) 631-7800

(800) 288-2354

Fax. (703) 803-1441

TM

OPSYS MW

© 2006 This document is the copyright of DYNEX Technologies and must

not be copied or reproduced in any form without prior consent.

is a trademark of DYNEX Technologies, Inc.

DYNEX Technologies reserves the right to make technical improvements to

this equipment and documentation without prior notice as part of a

continuous program of product development. This manual supersedes all

previous editions.

Warranty and Special Provisions Limited Warranty

DYNEX Technologies products are fully guaranteed for one year against defects in

parts, materials, and workmanship. Defective parts and materials will be replaced

or, at the discretion of DYNEX Technologies, repaired at no charge for a period of

one year and labor required for such replacement or repair will be provided at no

charge for a period of one year, provided that the products are utilized and

maintained in accordance with the instructions in the applicable operating and

servicing manual, and provided further that the products have not, as determined

solely by DYNEX Technologies, been subject to misuse or abuse by the Customer

or other parties unrelated to DYNEX Technologies. DYNEX Technologies makes

no warranty, expressed or implied, as to the fitness of any product for any particular

purposes other than those purposes described in the applicable operating and

servicing manual, nor does DYNEX Technologies make any other warranty,

whether expressed or implied, including merchantability, other than those appearing

on the face hereof. Where DYNEX Technologies guarantees any product, whether

under this Warranty or as a matter of law, and there is a breach of such guarantee,

the Customer’s only and exclusive remedy shall be the replacement or repair of

defective parts and materials, as described above. This shall be the limit of DYNEX

Technologies’ liability. Furthermore, DYNEX Technologies shall not be liable for

incidental or consequential damages. Failure of the Customer to notify DYNEX

Technologies of a claimed defect by registered mail within thirty days of the

discovery thereof shall constitute a waiver of any claim for breach of warranty.

When a product is required by DYNEX Technologies to be installed by a DYNEX

Technologies engineer or technician, the period of this Warranty shall begin on the

date of such installation, provided however, that any use of the product prior to such

installation shall, at sole election of DYNEX Technologies, void this Warranty.

When installation by DYNEX Technologies personnel is not required, the period of

this Warranty shall begin on the date of shipment from DYNEX Technologies. The

period of this Warranty shall begin as described above whether or not the product

has been installed pursuant to a purchase order, and any trial period shall be

deducted from the Warranty period that would otherwise apply under a subsequent

placed purchase order for that product.

Limitation of Liability. Notwithstanding anything to the contrary contained herein,

the liability of Seller (whether by reason of breach of warranty, breach of contract,

tort, or otherwise), including without limitation under any indemnification provision

contained herein, shall be limited to replacement of goods returned to DYNEX

Technologies which are shown to DYNEX Technologies’ reasonable satisfaction to

have been nonconforming or to refund the purchase price, or, if not paid, to a credit

amount of the purchase price therefore.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND ARE GIVEN AND

ACCEPTED IN LIEU OF ANY AND ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING WITHOUT LIMITATION, THE IMPLIED WARRANTY OF

MECHANTABILITY AND THE IMPLIED WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE. NEITHER PARTY SHALL BE LIABLE TO THE OTHER

FOR ANY INCIDENTAL, INDIRECT, SPECIAL, OR CONSEQUENTIAL

DAMAGES.

Table of Contents

Table of Contents

About this Manual iii

Chapter 1 Introduction 1

Description 1

Programming 2

Wash Head 3

Wash Head Positions 4

Wash Fluid 5

Waste 5

Features 7

Specifications 9

Warning Labels 11

Chapter 2 Installation 13

Unpacking 13

Materials Provided 13

Hardware Components 15

Positioning the Instrument 18

Installing the Wash Head 19

Installing the Wash Container 20

Installing the Waste Container 21

Turning on the System 22

Chapter 3 Configuration 23

The Keypad 23

Menus 26

The SETUP Menu 27

The PROGRAM Menu 27

Configuring the System 28

Specifying the Wash Head 29

Specifying Plate Parameters 30

Displaying the Software Version 35

Specifying the Pump Parameters 36

Selecting Clean 37

Chapter 4 Wash Protocols 39

Wash Protocol Operations 39

Creating a New Wash Protocol 41

Specifying the Header 41

Specifying Wash Cycle Operations 45

Ending a MOVE Cycle 53

Modifying a Wash Protocol 56

Copying a Wash Protocol 61

Chapter 5 Washing a Plate 63

Preparation 63

Washing a Plate 65

Chapter 6 Routine Maintenance 67

Routine Maintenance Procedures 67

Opsys MW™ User’s Guide i

Table of Contents

Cleaning and Decontamination 69

Cleaning the Containers 70

Replacing the Tubing 71

Pump Calibration 74

Chapter 7 Troubleshooting 77

Operational Problems 77

Chapter 8 Service 81

Service Procedures 81

Spare Parts 82

Returning a Washer for Service 83

Contact DYNEX Technologies 85

Index 86

ii Opsys MW™ User’s Guide

About this Manual

About this Manual

This manual has been written for laboratory technicians and provides

detailed instructions for using the Opsys MW™ system.

This manual gives you the information needed to:

• Review safety precautions.

• Install the Opsys MW™ system.

• Understand the Opsys MW™ menus.

• Set the Opsys MW™ system up to suit your exact needs.

• Create or modify wash protocols.

• Run wash protocols using the Opsys MW™ system.

• Perform required preventive maintenance.

• Troubleshoot the system.

Opsys MW™ User’s Guide iii

About this Manual

This page is intentionally left blank

iv Opsys MW™ User’s Guide

Description

Chapter 1 Introduction

The Opsys MW™ is a microprocessor-controlled microplate washing system

that performs wash protocols that are defined by the user. It is designed to

wash all of the wells in one column or one row of a 96-well plate at once.

The washing protocol can be programmed so that all of the columns (or

rows) are washed in the same manner, or different wash cycles can be

applied to specified columns (or rows) on the plate.

Description

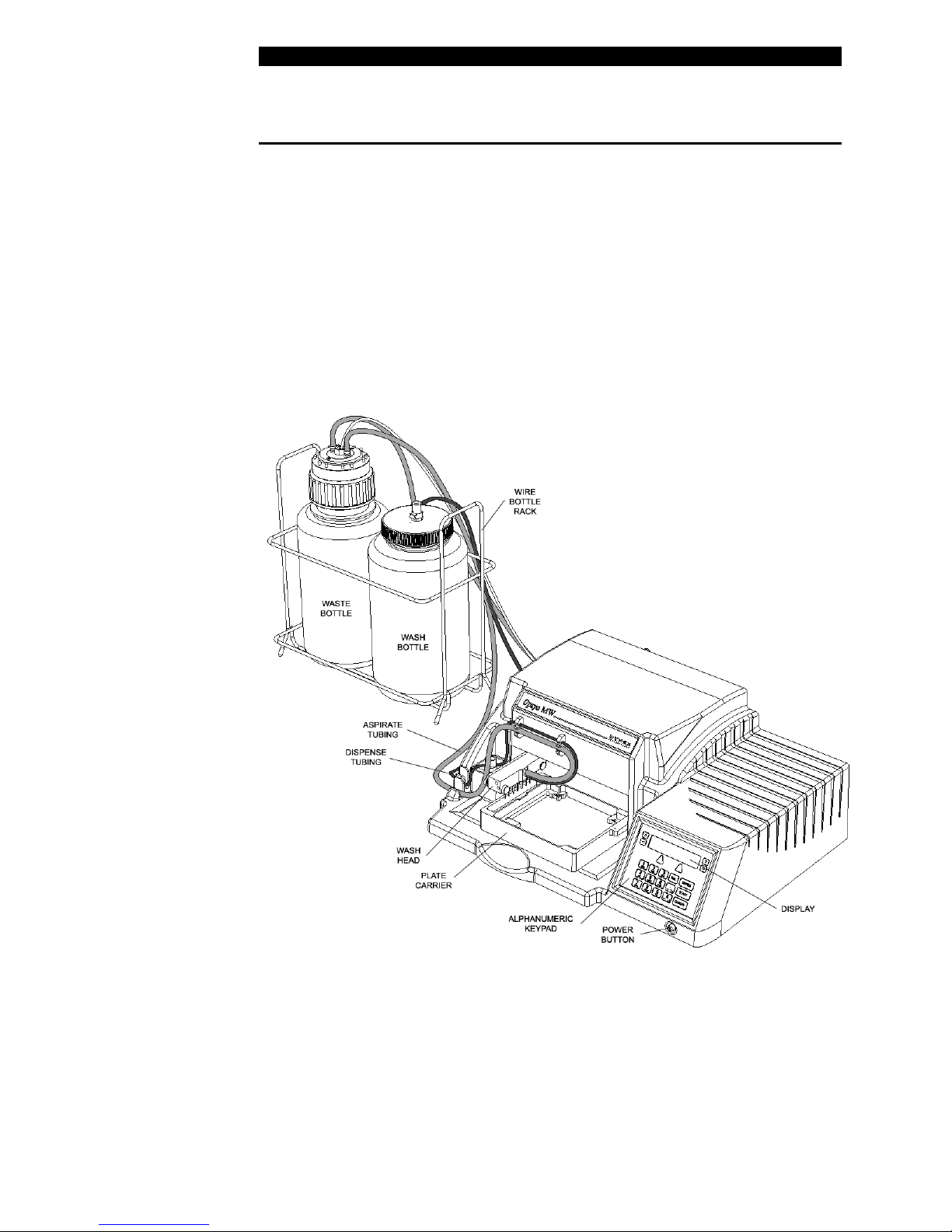

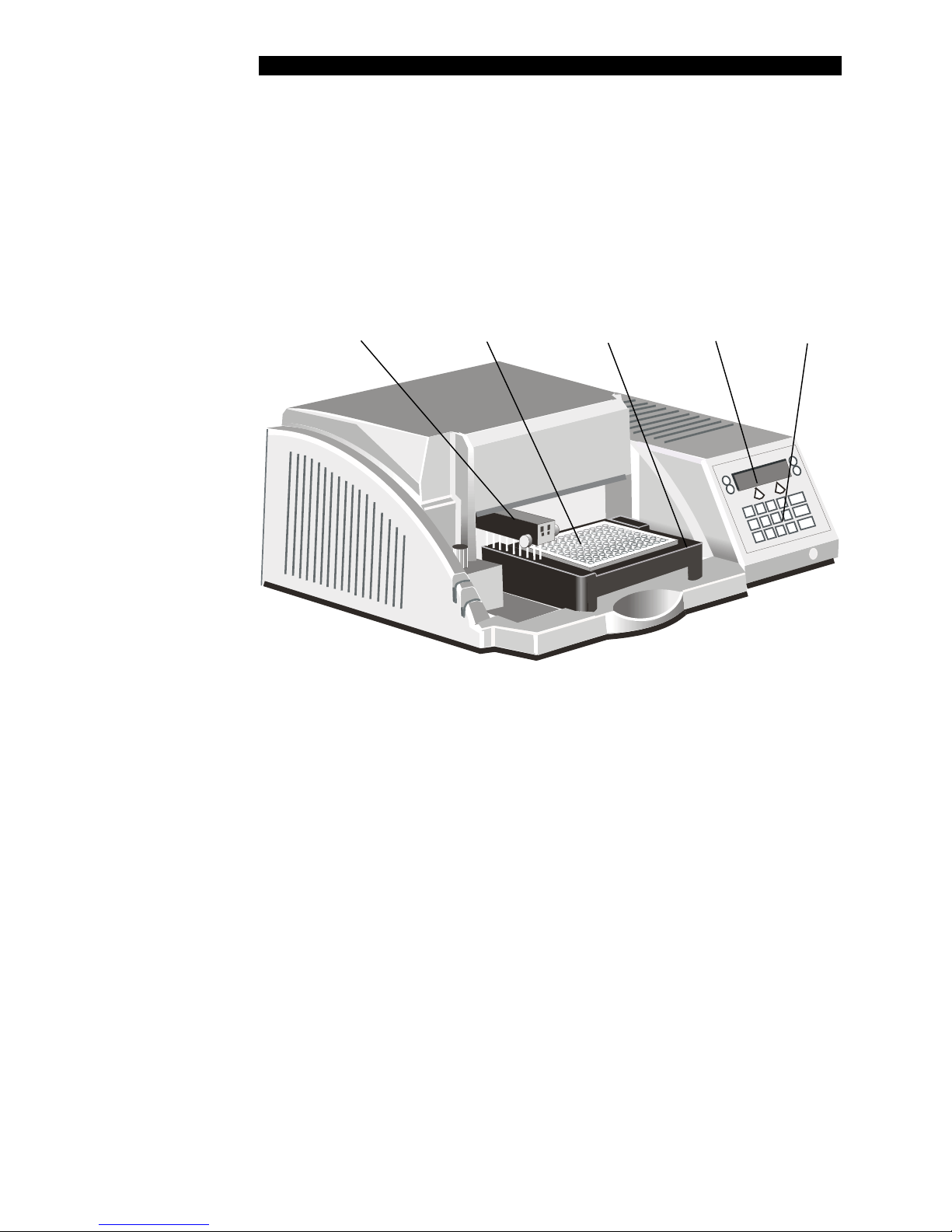

The Opsys MW Microplate Washer is shown in Figure 1.

Figure 1. The Opsys MW™ Microplate Washing System

Opsys MW™ User’s Guide 1

Description

Programming

All wash protocols on the Opsys MW™ Microplate Washer are user-defined.

Up to 40 wash protocols can be contained on the system.

In addition, the system can be configured with up to ten different plate types

so that the wash head positions for each plate type can be specified.

Programming of a new wash protocol (or modifying an existing one) and

configuration of the system are carried out using the keypad and display.

Note: Memory limitations may restrict the size

and complexity of an individual wash protocol.

2 Opsys MW™ User’s Guide

Description

Wash Head

The wash head on the Opsys MW™ Microplate Washer contains multiple

sets of dual wash pins. Each set of dual wash pins consists of a

dispense pin and an aspirate pin that are closely spaced so that fluid can

be aspirated from and dispensed into a well simultaneously.

The following wash heads can be fitted on the Opsys MW™:

Wash Head Description

1 x 8

Eight sets of dual wash pins for washing a 96-well

microplate one column (8 wells) at a time.

1 x 12

If a wash head is installed to wash plates by columns, the plates are placed

on the instrument so that the columns of the plate are aligned with the wash

head. If a wash head is installed to wash plates by row, the plate is rotated

90 degrees and placed on the instrument so that the rows of the plate are

aligned with the wash head.

The wash pins are fixed to the wash head. During operation, the wash head

assembly is lowered to insert the wash pins into the wells or raised to

remove the wash pins from the wells. Lowering the wash head assembly

allows the well contents to be aspirated or a bottom wash to be performed.

Raising the wash head assembly allows the plate to be moved so another

column (or row) can be washed or so the wells can be filled.

Twelve sets of dual wash pins for washing a

96-well microplate one row (12 wells) at a time.

Opsys MW™ User’s Guide 3

Description

Wash Head Positions

The vertical positions that the wash head can assume are described below.

Each wash head position can be specified by the user to within 0.1 mm.

Wash Head Position Description

Dispense Height

Well Top

Aspiration Height

Sweep Height

Note: Procedures for specifying wash head

positions for various plate types are described

on page 30.

Positions the aspiration pins slightly

below the top of the well so that fluid can

be dispensed into the well up to a certain

level before it is aspirated.

Positions the aspiration pins so they are

aligned with the top of the well.

Positions the aspiration pins at the bottom

of the well so that the contents of the well

can be completely aspirated.

Raises the aspiration pins slightly above

the Aspiration Height (see above) so that

the aspiration pins can be moved back

and forth in the well while the fluid is

being aspirated.

Bottom Wash Height

In protocols with a bottom wash, lowers

the wash head during dispense so that

the force of the dispensed fluid can wash

the bottom of the wells.

4 Opsys MW™ User’s Guide

Description

Wash Fluid

A single wash fluid is used on the Opsys MW™ Microplate Washer. The

wash fluid is contained in the Wash Container and is dispensed into the

wells whenever a Dispense or Fill operation is specified in the wash

protocol. In addition, wash fluid is dispensed into the purge tray during a

Purge operation.

Dispensing of the fluid from the Wash Container is controlled by a pump

attached to the back of the Opsys MW™ Microplate Washer and a dispense

valve located near the wash head (Figure 1).

Waste

Fluid is removed from the wells during an Aspirate or Dispense operation

and collected in the Waste Container. The Waste Container contains a level

sensor to alert the operator when the container is full.

Removal of the fluid from wells is controlled by lowering the wash head so

that the aspiration pins are immersed into the well fluid (the aspiration

height). A vacuum is applied to the aspiration pins at all times during

operation so that the contents of a well are aspirated whenever the wash

head is lowered to the aspiration height.

Opsys MW™ User’s Guide 5

Description

This page is intentionally left blank

6 Opsys MW™ User’s Guide

Features

Features

The Opsys MW™ system has a number of performance and convenience

features. These are summarised below:

• Small footprint

• Up to 40 wash protocols can be programmed

• Up to ten plate types can be programmed

• Two wash head configurations (1 x 8 and 1 x 12)

• On-board self diagnostics

• SHOW function allows visual verification of wash head height

settings

• High-level alarm on Waste Container

Opsys MW™ User’s Guide 7

Features

This page is intentionally left blank

8 Opsys MW™ User’s Guide

Specifications

Specifications

Dimensions and Weight

Length 49 cm (19.3 in)

Width 38 cm (15.0 in)

Height 19 cm (7.5 in)

Weight 9.1 kg (20 lbs)

Operation

Dispense Range

Dispense Precision

Residual Aspirate Volumes

Washing Time Typical 5 cycle wash: 5 min 30 sec

Power < 100 W

Display 2 by 20 character back lit LCD

Keypad 21 key tactile membrane

Output Display, Printer, RS232

50 – 999 µL

5% CV (with 300 µL distilled water)

< 1 µL for U and V bottom plates

< 5 µL for flat bottom plates

Environmental

Operating Range 15° C to 30° C

15% to 85% relative humidity (non-condensing)

2000m altitude

Computer Interface

Port Serial RS-232 port (Service Access)

Baud Rate 19200. Character format

Character Format 7 data bits, 1 stop bit, no parity

Power Requirements

Voltage Power Frequency

Main Unit 100 - 240 V 200 VA 50/60 Hz

Line Voltage Variation

Line Frequency Variation

Opsys MW™ User’s Guide 9

±

10%

±

3 Hz

Specifications

Input Ranges

Assay Programming

Assay Name Up to 10 characters

Password Up to 8 characters

Move: Start Strip 1 - 8 for 1 x 8 heads and 1 - 12 for 1 x 12 heads (Increment: 1)

Move: End Strip 1 - 8 for 1 x 8 heads and 1 - 12 for 1 x 12 heads (Increment: 1)

Move: #Cycles 1 - 9 (Increment: 1)

Aspirate: Cycles 1 - 9 (Increment: 1)

Dispense

Purge

Fill

Soak 1 - 999 (Increment: 1 second)

50 - 999 (Increment: 1 µL)

50 - 9999 (Increment: 1 µL)

50 - 300 (Increment: 1 µL)

Plate Setup

Plate Name Up to 10 characters

Dispense Height 001 - 999 (Increment: 1)

Top of Well Height 001 - 999 (Increment: 1)

Aspirate Height 001 - 999 (Increment: 1)

Sweep Height 001 - 999 (Increment: 1)

Sweep Stroke 001 - 999 (Increment: 1)

Bottom Wash: Dispense

Height

001 - 999 (Increment: 1)

Standards

The instrument is designed in accordance with CSA 1010.1-92, UL 3101-1, EN61010-1

and EN61326.

10 Opsys MW™ User’s Guide

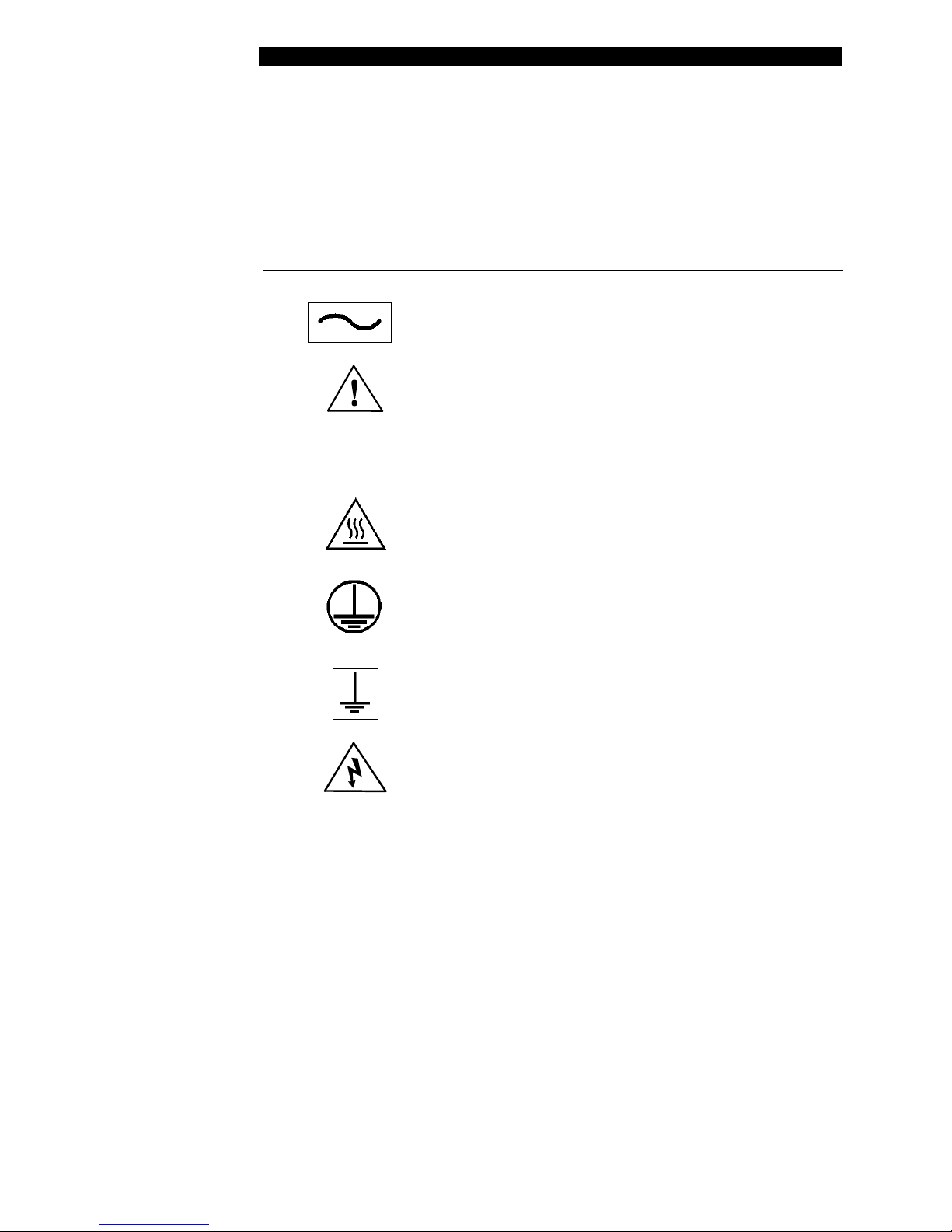

Warning Labels

Warning Labels

The Opsys MW™ or its components may contain certain labels that that

either warn the user of a hazard or note an electrical connection. The labels

that may be used on the Opsys MW™ system are described below.

Label Description

Alternating current is present.

(English) Caution symbol. Refer to the

Routine Maintenance chapter.

(French) Attention (voir documents

d’accompagnement).

(English) Caution, hot surface.

(French) Attention, surface chaude.

Protective conductor terminal.

Earth (ground) terminal.

(English) Caution, risk of electric shock.

(French) Attention, risque de choc électrique.

Opsys MW™ User’s Guide 11

Warning Labels

This page is intentionally left blank

12 Opsys MW™ User’s Guide

Unpacking

Chapter 2 Installation

Unpacking

Materials Provided

The main carton contains the instrument. The contents of this carton are

listed below:

Article Quantity

Opsys MW™ System 1

Instrument Power Cable 1

Cleaning Wire, Aspirate 1

Cleaning Wire, Dispense 1

Instrument Configuration Report 1

User’s Guide 1

Declaration of Conformity 1

Wash Head, 1 x 8 or 1 x12 1

Plate Holder 1

A sub-carton contains the wash container and waste container assemblies.

The contents of this carton are listed below:

Article Quantity

Wash Container Assembly 1

Waste Container Assembly 1

Opsys MW™ User’s Guide 13

Unpacking

To unpack the components:

1. Place the Opsys MW™ instrument in the position where it will be

located for use.

2. Place the Wash Container, Waste Container and Foam/Aerosol

Trap at the rear of the instrument.

3. Examine the packaging to be sure that the power cord and other

materials have been removed. Please save packaging material

for future use.

4. Verify that all of the materials listed above have been unpacked.

5. Inspect the components for damage. If damage is observed,

contact your shipper or service representative immediately.

14 Opsys MW™ User’s Guide

Hardware Components

Hardware Components

Hardware components of the Opsys MW™ instrument are shown in

Figure 2 and described below.

Wash Head Microtiter® Plate Plate Carrier Display Panel Keypad

Note: The Wash Container, Waste Container

and Foam/Aerosol Trap are external to the

instrument and are not shown in Figure 2.

Figure 2. The Opsys MW™ System

• Wash Head. The wash head contains sets (1 x 8 or 1 x 12) of dual

wash pins. Each set of wash pins consists of a dispense pin and

an aspirate pin, closely spaced so that fluid can be aspirated from a

well while fluid is being dispensed into the same well. The wash

head moves back and forth to wash each row (or column, depending

on the wash head that is used) of the plate by lowering the wash

pins into the corresponding wells.

• Plate Carrier. The plate carrier holds the plate in a fixed position so

that the wash pins can be precisely lowered to the correct height and

position in the wells during the washing procedure.

• Display Panel. The display panel is the means by which the system

communicates to the user. All messages, commands, and wash

parameters entered by the user are displayed.

Opsys MW™ User’s Guide 15

Hardware Components

• Keypad. The keypad is used by the operator to select commands

and enter wash parameters.

• RS232 Interface. The system includes an RS232 interface so that

an external computer can be connected for technical service

purposes.

• Wash Container. (Shown in Figure 1). The wash container contains

the wash fluid that is used for Dispense, Fill and Purge operations.

• Waste Container. (Shown in Figure 1). The waste container

contains the fluid that is aspirated from the wells. A level sensor is

contained inside of the waste container.

16 Opsys MW™ User’s Guide

Hardware Components

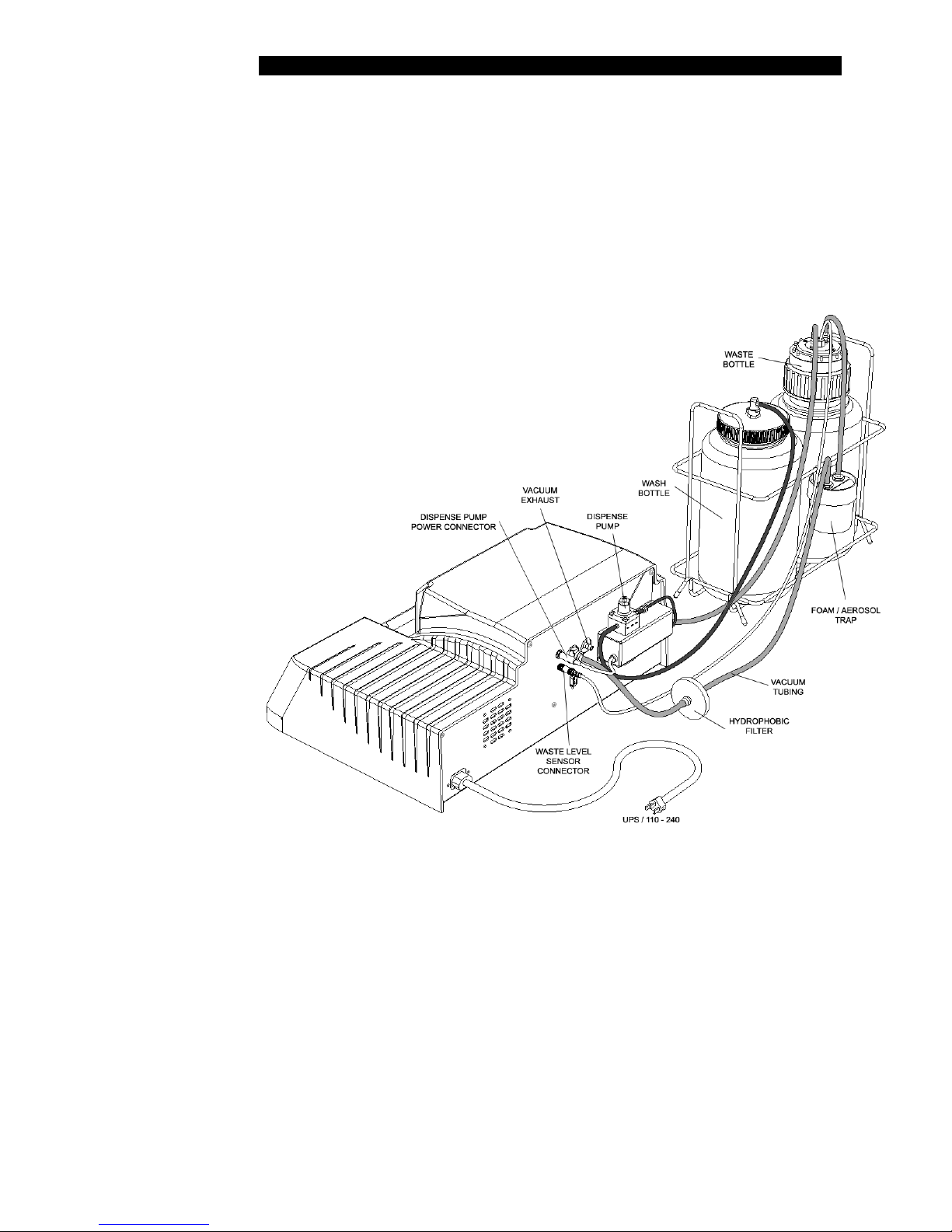

Connectors at the rear of the Opsys MW™ system are shown in Figure 3.

Connections for the power cord, dispense pump power, waste bottle level

sensor, waste bottle vacuum line and an external computer are made at the

rear of the system.

Important: Be sure that the vacuum exhaust

is not obstructed.

Figure 3. Rear View of the Opsys MW™ System

Opsys MW™ User’s Guide 17

Positioning the Instrument

Positioning the Instrument

Determine the area where the system will be located. You will need a firm

and level area that is approximately 51 cm (20 inches) wide, 62 cm (24

inches) deep, and 40 cm (16 inches) high for the Opsys MW™.

18 Opsys MW™ User’s Guide

Installing the Wash Head

Installing the Wash Head

The Wash Head must be located on the Wash Head Arm.

To install the Wash Head:

1. Position the Arm over the Purge Reservoir portion of the Plate

Holder.

2. Place the Wash Head on the two Arm Pins, being careful to

properly seat the Wash Head on the support pins.

3. Level the Wash Head in relation to the Plate Holder and tighten

the two thumbscrews at the front of the Wash Head / Arm

Assembly.

Opsys MW™ User’s Guide 19

Installing the Wash Container

Installing the Wash Container

The dispense tubing and dispense pump power cable must be connected.

To install the Wash Container:

1. Fill the Wash Container with the wash solution that is to be used.

2. Insert the Pick-Up Filter into the Wash Container and secure the

cap. Attach the Quick-Connector at the end of the pump tubing,

to the mating connector in the cap.

3. Route the dispense tubing through the upper slot at the front

corner of the instrument and through the routing clips at the front

of the instrument.

4. Connect the end of the dispense tubing to the wash tubing

connector on the wash head.

5. Thread the dispense tubing through the dispense valve.

(Figure 1).

6. Connect the dispense pump power cable to the dispense pump

power connector at the rear of the instrument (Figure 3).

Note: The Wash Container contains up to

4 liters.

Note: The tubing must be inserted fully into

the dispense valve opening to ensure proper

operation.

20 Opsys MW™ User’s Guide

Installing the Waste Container

Installing the Waste Container

To install the Waste Container and Foam/Aerosol Trap:

1. Insert the Quick-Connect end of the vacuum tubing on the

Foam/Aerosol Trap to the Quick-Connect vacuum connector at

the rear of the instrument Figure 3).

2. Screw on the Waste Container cap.

3. Route the waste tubing through the lower slot at the front corner

of the instrument and through the routing clips at the front of the

instrument.

4. Connect the end of the waste tubing to the waste tubing

connector on the wash head.

5. Connect the waste level sensor cable to the waste level sensor

connector at the rear of the instrument (Figure 3).

Opsys MW™ User’s Guide 21

Turning on the System

Turning on the System

1. Connect the Opsys MW™ to the laboratory electrical supply

outlet.

2. Push the instrument power switch once. After a series of selftests, the software version is displayed momentarily

before the main menu is displayed:

Note: Depending upon local electrical codes,

an uninterruptible power system (UPS) may be

required in your laboratory. A UPS is not

provided with the Opsys MW™ system.

CAUTION: The Opsys MW™ instrument must

be connected to properly grounded electrical

outlets. Obtain assistance from a qualified

electrician to verify that your electrical outlets

are properly grounded.

Before connecting the power cable, be sure

that the components have been connected to

each other as outlined in the previous section.

Opsys MW. v1.0

1: - - - - - - - -

SETUP PROGRAM

Note: The self-test results indicate whether

the system is operating properly. If a self-test

failure is reported, it is recommended that you

call Technical Service.

Dashes are initially displayed after the wash

protocol number (i.e., 1: - - - - - - - - in the

above example) if a wash protocol has not yet

been named.

22 Opsys MW™ User’s Guide

The Keypad

Chapter 3 Configuration

The Keypad

The keypad is used to access the menus and commands for setting up the

Opsys MW™ entering new wash protocols and running the wash protocols.

The keypad contains scroll keys, function keys, and alphanumeric keys.

The keys on the keypad are shown in Figure 4.

Scroll Keys Display Panel Function Keys Scroll Keys

Alphanumeric

Keys

1

ABC

2

DEF

3

GHI

DEL

ENTER

4

JKL

MNO

89

7

STU VWX

PQR

YZ

+-*/=

0

<>_()

6

5

Figure 4. Keys on the Keypad

START

CANCEL

Opsys MW™ User’s Guide 23

The Keypad

The use of each of the keys is summarized below:

Key Purpose

Scroll keys

Function keys

The functionality of the scroll keys depends upon

what is being displayed.

During display of the main menu (page 26),

pressing the up or down scroll keys will display

successive wash protocol numbers and names (or

dashes, if a protocol is not yet named).

Horizontal scrolls will scroll through selections for

the selected menu. Repeatedly pressing the

horizontal scroll button will show the next two

items in a list. A list with one item will have a

blank entry.

If you are entering or editing information, a

scroll will move the cursor through edit fields.

When editing an existing plate or protocol name,

you may either type over the existing name, or

press the DEL key to delete the characters from

the existing name. (NOTE:To delete the entire

name, either type over it or press the right arrow

key and DEL to delete all characters to the right of

the cursor. The first character of an existing name

cannot be deleted, but it can be overwritten.)

Two function keys select the item or execute the

command shown directly above each key on the

second line of the display.

“Del” key

“Enter” key

“Start” key

“Cancel” key

When a modifiable entry is displayed, selecting

Delete will allow the entry to be modified. While

editing a field, selecting Delete removes the

character at the cursor location and all characters

to the right of the cursor.

Completes an entry of characters, accepts default

prompt data, and displays the next prompt in a

series of commands

Starts a wash protocol. This can only be done

while the main menu is being displayed.

Returns to the previous menu within the function

24 Opsys MW™ User’s Guide

The Keypad

Key Purpose

Alphanumeric

Keys

The numeral shown on the key is displayed by

pressing the key once. If the key is pressed two to

seven times rapidly, one of the letters on the key

will be displayed. The letter that is displayed

depends upon the number of times the key is

pressed.

Opsys MW™ User’s Guide 25

Menus

Menus

The Opsys MW™ menus are hierarchical and are organised by function.

There are two main menus: Setup and Program.

Menu Purpose

SETUP

PROGRAM

* A protocol includes general information (e.g. the type of microplate to be

washed) as well as a listing of the various steps to be used in the washing

process.

Once the instrument is switched on and the self-test is successfully

completed, the main menu is displayed. It contains SETUP and PROGRAM

menu headers:

Configure the Instrument

Create or edit plate washing protocols *

1: -------SETUP PROGRAM

Display a different wash protocol number and name (there can be up to 40)

by pressing the up or down scroll keys or by entering the protocol number

using the keypad.

Access a menu by pressing the function key beneath the menu header.

Cancel a menu selection and display the previous (higher level) menu by

pressing the CANCEL key.

Note: Dashes are initially displayed after the

wash protocol number (i.e., 1: - - - - - - - - in

the above example) if a wash protocol has not

yet been named. Once a wash protocol is

named, the name is displayed after the

protocol number. Refer to page 41 for the

procedure to create and name a wash

protocol.

26 Opsys MW™ User’s Guide

Menus

The SETUP Menu

Press the function key under SETUP to display the SETUP menu

(Figure 5). The SETUP menu contains commands to configure the

instrument.

1: TESTNAME

SETUP PROGRAM

Select Option

HEAD PLATE

Select Option

VERSION CAL.

Figure 5. SETUP Menu

The PROGRAM Menu

Press the function key under PROGRAM to display the PROGRAM menu

(Figure 6). The PROGRAM menu contains commands to name and create a

new wash protocol or to edit an existing wash protocol.

1:TESTNAME

SETUP PROGRAM

Enter name

– – – – – – – – –

or:

Edit name

4: WASHNAME

or:

Enter password

Figure 6. PROGRAM Menu

(If selected protocol has

not been named)

(If selected protocol has

been named and has no

password)

(If selected protocol has

been named and has a

password)

Opsys MW™ User’s Guide 27

Configuring the System

Configuring the System

The Opsys MW™ must be configured before it is operated for the first time.

The commands for doing this are contained in the SETUP menu (Figure 7).

Use ARROW keys to scroll through the menus.

1: TESTNAME

SETUP PROGRAM

Select Option

HEAD PLATE

Select Option

VERSION CAL.

Figure 7. SETUP Menu

The purpose of each command on the SETUP menu is summarised below:

Command Purpose

HEAD

PLATE

VERSION

CAL.

CLEAN

Specify the type of head that is fitted

Displays the PLATE menu. The commands on this

menu allow parameters (such as well top height,

dispense height and wash height) for various plate

types to be specified.

Displays the version number of the software

Displays the CAL. menu. The commands on this

menu allow the pump parameters to be specified.

The CLEAN command enables the washer to be

cleaned automatically at a specified interval. This

feature assists in assuring that tubing and dispense

pins are free from potential salt build up.

28 Opsys MW™ User’s Guide

Configuring the System

Specifying the Wash Head

The HEAD command allows the installed wash head to be specified:

1. Select SETUP. The display will read:

Select option

HEAD PLATE

2. Select HEAD. The current wash head selection is displayed in

the upper line:

Wash head? 8

8

If needed, scroll right to view the remaining selection:

Wash head? 8

12

3. Select the desired option using the function key. After the

selection is made, the display will again read:

Select option

HEAD PLATE

Opsys MW™ User’s Guide 29

Configuring the System

Specifying Plate Parameters

The PLATE command allows plate parameters to be specified for up to 10

plate types.

When setting plate parameters, a default value is displayed for each of the

wash head positions. The default values are factory-set and represent

approximate starting values for each wash head position.

Increasing the value of a wash head position by one unit lowers the head

0.1 mm and decreasing the numerical value of a wash head position by one

unit raises the head 0.1 mm. (e.g. an increment of 20 steps equals one

millimeter of vertical pin travel (+20 = 1mm up, -20 = 1mm down)).

The SHOW command is available when setting each wash head position.

Select SHOW to move the wash head to the indicated position so that the

height can be observed.

For example, when setting dispense height, the default value is 180:

If, after selecting SHOW, the dispense pins are found to be too low by

approximately 1.0 mm, the dispense height position can be raised by 1.0

mm by entering 170 for the dispense height.

When using the SHOW function when defining the aspirate height, if the

aspirate pins touch the well bottom, increase the aspirate height. If you

cannot move the plate slightly side-to-side and up-down without immediate

interference from the aspirate pins, increase the aspirate height.

Note: The wash head positions are described

on page 4.

DISP. HEIGHT? 180

SHOW

30 Opsys MW™ User’s Guide

Configuring the System

To specify parameters for a plate type:

1. Obtain an empty plate of the plate type being specified and place

it in the plate holder.

2. Select SETUP (if needed). The display will read:

Select option

HEAD PLATE

3. Select PLATE. The name of the first plate is displayed in the

lower line:

Select plate

1: - - - - - - - - - -

4. If needed, display a different plate number using the up or down

scroll keys (or use the keypad to enter the desired plate number).

When the desired plate number is displayed, press ENTER. The

display will read:

5. Use the keypad to enter the plate name (up to

10 characters).

6. Press ENTER. The display will read:

Note: Dashes will be displayed if the plate has

not yet been named.

Enter name

- - - - - - - - - -

Note: Refer to page 23 for instructions on

entering alphabetic characters.

DISP. HEIGHT? 180

SHOW

Note: The default value is displayed. Select

SHOW to move the wash head to the default

dispense position so that the height can be

checked. Then, determine the correct value as

outlined on page 30. Repeat the procedure as

needed.

Opsys MW™ User’s Guide 31

Configuring the System

7. Enter the dispense height using the keypad and press ENTER.

The display will read:

Well top? 160

SHOW

8. Enter the desired value using the keypad and press ENTER. The

display will read:

9. Enter the desired value using the keypad and press ENTER. The

display will read:

Note: The default value is displayed. Select

SHOW to move the wash head to the default

well top position so that the height can be

checked. Then, determine the correct value as

outlined on page 30. Repeat the procedure as

needed.

ASP. HEIGHT? 380

SHOW

Note: The default value is displayed. Select

SHOW to move the wash head to the default

aspiration position so that the height can be

checked. Then, determine the correct value as

outlined on page 30. Repeat the procedure as

needed.

Sweep? NO

YES NO

10. Select YES to specify a sweep. The display will read:

All cycles? NO

YES NO

32 Opsys MW™ User’s Guide

Note: If a sweep is specified, the wash pins

are moved up and down and across the

bottom of the well during aspiration to better

remove all droplets of liquid. If NO is selected,

the Wash height? prompt (Step 14) will be

displayed.

Note: Use the sweep function with Flat or “C”

bottom plates only. Sweeping aspirates fluid

more completely from the wells than a regular

aspiration. Sweep all cycles to get the most

thorough well aspiration when using multiple

aspiration cycles, but remember that each

sweep adds seconds to the protocol.

Configuring the System

Remember if your protocol requires sweeping,

that must first be specified in the plate

definition used in the protocol.

11. Select YES to specify a sweep on all aspiration cycles. The

display will read:

Sweep height? 370

SHOW

12. Enter the desired value using the keypad and press ENTER. The

display will read:

13. Enter the desired value using the keypad and press ENTER. The

display will read:

Note: The default value is displayed. Select

SHOW to move the wash head to the default

sweep position so that the height can be

checked. Then, determine the correct value as

outlined on page 30. Repeat the procedure as

needed.

Sweep stroke? 100

Note: There isn’t a SHOW function for the

sweep stroke. Determine optimum sweep

stroke setting by starting with a small number

and increase it if the residual aspirate volume

is not acceptable. If you run a protocol and

the wash pins strike the sides or bottom of the

well, reduce the sweep stroke and review your

plate setup parameters.

14. Select YES if a bottom wash is to be included. The display will

Opsys MW™ User’s Guide 33

read:

Bottom wash? NO

YES NO

Wash height? 368

SHOW

Note: The default value for bottom wash

height is displayed. Select SHOW to move the

wash head to the default bottom wash position

so that the height can be checked. Then,

determine the correct value as outlined on

page 30. Repeat the procedure as needed.

Configuring the System

15. Enter the desired value using the keypad and press ENTER. The

display will read:

Select option

HEAD PLATE

Note: If NO is selected for Bottom wash?

(Step 13), the display will read as shown

above.

34 Opsys MW™ User’s Guide

Configuring the System

Displaying the Software Version

The VERSION command displays the software version that is currently

installed on the Opsys MW™ instrument:

1. Select SETUP (if needed). The display will read:

Select option

HEAD PLATE

2. Scroll right to display the next selection:

Select option

VERSION CAL.

3. Select VERSION. The display will momentarily read:

Opsys MW. v1.0

Note: The software version that is displayed

will depend on the version installed in the

instrument.

Opsys MW™ User’s Guide 35

Configuring the System

Specifying the Pump Parameters

The CAL. command allows the calibration values for each pump to be

specified:

1. Select SETUP (if needed). The display will read:

Select option

HEAD PLATE

2. Scroll right to display the next selection:

Select option

VERSION CAL.

3. Select the pump pressure (high or low). The display will read:

Pump speed? 190

4. Enter the desired value using the keypad and press ENTER. The

display will read:

Slope? 2.1

5. Press ENTER to keep the existing value. The display will read:

6. Press ENTER to keep the existing value. The display will again

read:

Note: The Slope and Intercept values should

only be changed by

Service Personnel.

Intercept? 24

Select option

VERSION CAL.

Note: Refer to page 74 for additional pump

calibration instructions.

DYNEX Technologies

36 Opsys MW™ User’s Guide

Configuring the System

Selecting Clean

The CLEAN command enables the washer to be cleaned automatically at a

specified interval.

1. Scroll right to display the next section:

Select option

CLEAN

2. Select CLEAN. The display will read:

Auto Clean?

YES NO

3. Select YES if you want periodic automatic cleaning. The display will

read:

Interval (Hrs) 1

4. Enter the desired interval using the up/down scroll keys and press

ENTER.

The display will read:

5. Enter the desired volume of fluid to be dispensed.

6. Press ENTER. The display will read:

Note: The minimum interval is 1 hour, and the

maximum interval is 9 hours.

Fluid Volume? 2500

Note: A cleaning volume ranging from 50 to

9,999 microliters can be entered. Follow the

instructions on page Error! Bookmark not

defined. for refilling the wash container.

Select option

CLEAN

Opsys MW™ User’s Guide 37

Configuring the System

This page is intentionally left blank

38 Opsys MW™ User’s Guide

Wash Protocol Operations

Chapter 4 Wash Protocols

Wash Protocol Operations

A wash protocol consists of a series of Purge, Move, Soak, Aspirate,

Dispense and Fill operations.

Purge, Move and Soak can be carried out in any sequence. Aspirate,

Dispense and Fill can only be carried out within a Move operation, and

there cannot be a Move within a Move.

Each of these operations is described below:

Operation Description

Purge

Dispenses fluid from the dispense wash pins while

the wash head is positioned over the purge tray

Move Performs Aspirate, Dispense, Fill and/or Soak

operations on specified strips of the Microplate

Aspirate

Removes the contents of a well by positioning the

wash pins at the aspiration height in the well and

aspirating the liquid from the wells

A sweep may also be performed during Aspirate.

Note: Purge is usually

carried out at the beginning

of a wash protocol to rinse

the dispense wash pins and

remove air bubbles.

Note: The aspirate height

and sweep parameters for a

particular plate type are

specified during system

configuration (30).

If a sweep is specified during

configuration, the wash pins

are moved back and forth

during the aspiration cycle.

Opsys MW™ User’s Guide 39

Wash Protocol Operations

Operation Description

Dispense

Soak

Fill

Dispenses a specified amount of fluid into the wells

after aspirating the contents of the wells (i.e.

wherever a DISPENSE step is added to a protocol,

the OPSYS MW will automatically aspirate the

wells before dispensing more fluid in order to

prevent a well overflow). If a bottom wash is

specified, the wash head is then lowered to the

bottom wash position so that fluid will be aspirated

from the bottom of the wells while fluid is being

dispensed.

The contents of the wells are allowed to equilibrate

for the specified number of seconds.

The wells are filled with a specified amount of fluid.

Note: The dispense height

for a particular plate type is

specified during system

configuration (page 30).

40 Opsys MW™ User’s Guide

Creating a New Wash Protocol

Creating a New Wash Protocol

Specifying the Header

or

(or use keypad)

↓

PROGRAM Select PROGRAM from the main menu.

↓

(keypad) Enter a protocol name (up to 9 characters).

↓

(keypad) Enter an optional password.

↓

or

(or use keypad)

↓

Variable strips?

↓

Constant timing?

Select one of the 40 protocol numbers.

NOTE: If the password for a protocol is lost, the ability

to access the method and the method position are also

lost.

Select the plate type.

Specify whether the operator will be prompted at run

time to enter the number of strips to be washed (avoids

reprogramming the number of strips).

(If Variable strips? is YES). Specify whether the time

for washing any number of strips on a plate is constant.

NOTE: Pressing CANCEL while creating or

editing a protocol will bring you back to the

main menu without saving your changes.

Figure 8. Specifying the Wash Protocol Header

After the wash protocol header information is defined, the specific steps in

the wash protocol are specified.

The procedures for defining the wash protocol header are described in the

following pages. The procedures for specifying the steps in a wash protocol

are described beginning on page 45.

Opsys MW™ User’s Guide 41

Creating a New Wash Protocol

To create a new wash protocol header:

1. Display the main menu.

1: - - - - - - - - - -

SETUP PROGRAM

2. Use the up or down scroll keys to display the protocol number (or

use the keypad to enter the protocol number) that is to be

created:

6: - - - - - - - - - -

SETUP PROGRAM

3. Select PROGRAM. The name of the wash protocol is displayed

in the lower line:

4. Use the keypad to enter the protocol name (up to 9 characters)

and press ENTER. The display will read:

5. Select YES if the protocol is to be password protected. The

display will read:

Note: Dashes will be displayed if a protocol

has not yet been named.

Enter name

- - - - - - - - - -

Password?

YES NO

Note: Refer to page 24 for instructions on

entering alphanumeric characters.

Enter password

********

6. Enter the password, (up to eight numeric characters) and press

ENTER. The display will read:

Confirm password

********

42 Opsys MW™ User’s Guide

Note: If NO is selected, the Select plate

prompt (Step 7) will be displayed.

Creating a New Wash Protocol

7. Re-enter the password and press ENTER. The display will read:

Select plate

2: DYNEX_1

8. Use the up and down scroll keys to select the plate type (or enter

the number using the keypad) to be used and press ENTER. The

display will read:

Note: The plate name that is shown is an

example. The actual name will be the plate

name that is entered for that plate type during

system configuration (see page 30).

Variable strips?

YES NO

Note: “Variable Strips” is used to run an

established protocol on fewer strips than

originally specified in the “MOVE” cycle(s) of

an established protocol.

If YES is selected, the operator will be

prompted at run time to specify the number of

strips that are to be washed. Processing will

begin on the first strip selected in the “MOVE”

cycle and will end on the total number of strips

entered at run time (e.g. the protocol states:

“Move 3-12 1 cycle(s)” and at run time, 2

strips are entered, only strips 3 and 4 will be

processed).

9. If YES is selected, the display will read:

Constant timing?

YES NO

Opsys MW™ User’s Guide 43

Note: If NO is selected for Variable strips?,

the Select option prompt will be displayed

(see below).

Note: The Constant Timing prompt only

appears if you are using Variable Strips.

Creating a New Wash Protocol

10. Select YES if the total elapsed time for washing any number of

strips within a plate is to be constant. The display will read:

Select option

MOVE PURGE

The sequential steps in the wash protocol can now be specified,

as outlined on page 45.

44 Opsys MW™ User’s Guide

Creating a New Wash Protocol

Specifying Wash Cycle Operations

The final step in creating a wash protocol is to specify individual operations

within the wash protocol.

®

plate.

dispense

An example of a wash protocol is shown in 45. In this example, the

pin

wash

s are purged, and then a Dispense and Aspirate are carried out

twice on each of the 12 strips (columns) of a 96-well Microtiter

Finally, after all 12 strips have been washed twice, the contents of the

Microtiter plate are allowed to soak (equilibrate) for another 600 seconds.

PURGE Purge the dispense pins.

↓

MOVE

(2 Cycles)

↓

DISPENSE

(3 Times)

↓

Specify the starting strip and ending strip for each cycle

and the number of cycles to be performed.

For each strip, perform dispense three times.

ASPIRATE For each strip, perform one aspiration cycle.

↓

END LOOP End the cycle.

↓

SOAK

↓

After the two Move cycles have been completed, allow

the contents to equilibrate for 600 seconds.

END End the wash protocol.

Figure 9. Example of a Wash Protocol

The procedures for specifying the steps in this and other wash protocols are

described on the following pages.

Opsys MW™ User’s Guide 45

Creating a New Wash Protocol

To specify a Purge:

1. Display the header information for the selected wash protocol, as

outlined on page 41. The display will read:

2. Select PURGE. The display will read:

3. Use the keypad to enter the volume of fluid to be dispensed.

4. Press ENTER. The display will read:

Note: A purge must be performed outside of a

Move cycle.

Select option

MOVE PURGE

Fluid volume? 350

Note: A purge volume ranging from 50 to

9,999 microliters can be entered.

Select option

MOVE PURGE

46 Opsys MW™ User’s Guide

Creating a New Wash Protocol

To specify a Move cycle:

1. Display the header information for the selected wash protocol, as

outlined on page 41. The display will read:

Select option

MOVE PURGE

2. Select MOVE. The display will read:

Start strip? 1

3. Using the keypad, enter the strip number where the move cycle

should start.

4. Press ENTER. The display will read:

End strip? 12

5. Using the keypad, enter the strip number where the move cycle

should end.

6. Press ENTER. The display will read:

Cycles? 1

7. Using the keypad, enter the number of the specified move cycles

that are to be sequentially performed.

8. Press ENTER. The display will read:

9. Specify Aspirate, Dispense, Soak and Fill operations in the

sequence as they are to be carried out, as described in the

following sections.

10. When all of the operations for the Move cycle have been

sequentially specified, specify End Loop to designate the end of

the Move cycle.

Note: Between 1 and 9 Move cycles can be

specified.

Select option

ASPIRATE DISPENSE

Opsys MW™ User’s Guide 47

Creating a New Wash Protocol

To specify an Aspiration (within a Move):

1. Select ASPIRATE. The display will read:

2. Using the keypad, enter the number of aspiration cycles that are

to be to be performed within the MOVE cycle.

3. Press ENTER. The display will read:

Note: An Aspirate or Dispense must be

performed within a Move cycle.

Cycles? 1

Select option

ASPIRATE DISPENSE

48 Opsys MW™ User’s Guide

Creating a New Wash Protocol

To specify a Dispense (within a Move):

1. Select DISPENSE. The display will read:

2. Use the keypad to enter the volume of fluid to be dispensed.

3. Press ENTER. If a bottom wash is specified for the plate being

used, the display will read:

If a bottom wash is not specified for the plate being used or if NO

is selected for the Bottom Wash? prompt, the display will read:

Note: A Dispense or Aspirate must be

performed within a Move cycle.

Fluid volume? 350

Note: A volume ranging from 50 to 999

microliters can be entered.

Bottom Wash? NO

YES NO

Note: If the protocol requires bottom washing,

that must first be specified in the plate

definition used in the protocol.

Select option

ASPIRATE DISPENSE

4. Select YES if a bottom wash is to be included. The display will

read:

Fluid volume? 350

5. Use the keypad to enter the volume of fluid to be dispensed

during the bottom wash.

Note: A volume ranging from 50 to 999

microliters can be entered.

Opsys MW™ User’s Guide 49

Creating a New Wash Protocol

6. Press ENTER. The display will read:

Cycles? 1

7. Use the keypad to enter the number of bottom wash cycles to be

performed and press ENTER. The display will read:

Select option

ASPIRATE DISPENSE

50 Opsys MW™ User’s Guide

Creating a New Wash Protocol

To specify a Soak (within a Move):

1. Scroll right to display the next selection. The display will read:

2. Select SOAK. The display will read:

3. Enter the desired soak duration using the keypad.

4. Press ENTER The display will read:

Note: A Soak can be performed either within

or outside of a Move cycle. The procedure

below describes the procedure for specifying a

soak within a Move cycle.

The procedure for specifying a Soak outside

of a Move cycle is described on page 50.

Select option

SOAK FILL

Duration? 5

Note: A soak duration ranging from 1 to 999

seconds can be entered.

Select option

SOAK FILL

Opsys MW™ User’s Guide 51

Creating a New Wash Protocol

To specify a Fill (within a Move):

1. Scroll right to display the next selection. The display will read:

2. Select FILL. The display will read:

3. Use the keypad to enter the volume of fluid to be dispensed

during well filling.

4. Press ENTER. The display will read:

Note: A Fill must be performed within a Move

cycle.

Select option

SOAK FILL

Fluid volume? 50

Note: A volume ranging from 50 to 300

microliters can be entered.

Select option

SOAK FILL

52 Opsys MW™ User’s Guide

Creating a New Wash Protocol

Ending a MOVE Cycle

1. Scroll right to display the next selection. The display will read:

Select option

SOAK FILL

2. Scroll right to display the next selection. The display will read:

Select option

END LOOP

3. Select END LOOP. The display will read:

Select option

MOVE PURGE

Opsys MW™ User’s Guide 53

Creating a New Wash Protocol

To specify a Soak (outside of a Move):

1. Scroll right to display the next selection. The display will read:

2. Select SOAK. The display will read:

3. Enter the desired soak duration (1 to 999 seconds) using the

keypad.

Note: A Soak can be performed either within

or outside of a Move cycle. The procedure

below describes the procedure for specifying a

soak outside of a Move cycle.

The procedure for specifying a Soak within a

Move cycle is described on page 47.

Select option

SOAK END

Duration? 5

Note: A soak duration ranging from 1 to 999

seconds can be entered.

4. Press ENTER The display will read:

Select option

SOAK END

54 Opsys MW™ User’s Guide

Creating a New Wash Protocol

To specify the End of the wash protocol:

1. Scroll right to display the next selection. The display will read:

Select option

SOAK END

2. Select END. The display will read:

1: NAME_01

SETUP PROGRAM

Opsys MW™ User’s Guide 55

Modifying a Wash Protocol

Modifying a Wash Protocol

An existing wash protocol can be modified by using many of the same

commands that are used to create a wash protocol.

To modify a wash protocol:

1. Display the main menu:

1: NAME_01

SETUP PROGRAM

2. Use the up and down scroll keys to select the wash protocol to

be modified (or enter the number using the keypad). The display

will read:

4: NAME_04

SETUP PROGRAM

3. Select PROGRAM. If the wash protocol is password protected,

the display will read:

Enter password

4. Enter the Password using the keypad and press ENTER.

5. After a password is successfully entered (or if a password was

not specified for the selected protocol), the display will read:

Note: If a Password is not specified for the

selected wash protocol, the display will read

as shown in Step 5.

Note: If the Password is entered incorrectly an

error message is displayed. The operator is

allowed three attempts to enter the password.

After the third attempt, the main menu

(Step 1) will again be displayed.

Note: If the password for a protocol is lost, the

ability to access the method and the method

position are also lost.

Edit name

4: NAME_04 COPY

56 Opsys MW™ User’s Guide

Modifying a Wash Protocol

6. The cursor is positioned under the first character of the name. If

the name is to be changed, enter the name using the keypad and

press ENTER. The first step of the wash protocol will be

displayed:

MOVE 1-12 1 Cycles

DELETE EDIT

Note: The example above shows the MOVE

operation as the first step in the protocol. The

actual operation that is shown will depend

upon the protocol that is being modified.

Note: For each step that is displayed, the

operation being carried out and the value for

that operation are displayed. In the MOVE

example above, the Start Strip is 1, the End

Strip is 12, and the number of cycles is 1.

Opsys MW™ User’s Guide 57

Modifying a Wash Protocol

To modify a wash operation:

1. Select EDIT while the operation is displayed. The first step in the

operation is displayed:

Start strip? 1 Cycles

2. Modify the operation, using the same procedures as when

creating a new wash protocol.

3. Press ENTER to display the next step on the wash protocol.

Note: The actual step that is displayed

depends upon the operation being modified.

MOVE 1-10 1 Cycles

DELETE EDIT

Note: In the example above, the End Strip was

changed from 12 to 10. The actual values that

are displayed will depend upon the operation

being modified and the new value(s) entered.

Note: Once the move loop is modified, the

display will no longer read as shown above.

Instead, it will display the first command in the

move loop or End of Move.

58 Opsys MW™ User’s Guide

Modifying a Wash Protocol

To delete a wash operation:

1. Select DELETE while the operation is displayed. The operation is

removed from the wash protocol.

Note: If a MOVE operation is deleted, all

operations within the MOVE (i.e., Aspirate,

Dispense, Soak and Fill) are also removed.

Opsys MW™ User’s Guide 59

Modifying a Wash Protocol

To insert a wash operation:

1. Scroll right while the operation that the new operation is to

precede is displayed:

MOVE 1-10 1 Cycles

INSERT

2. Select INSERT. The display will read:

3. Select the option that is to be inserted, using the same procedure

as when creating a new wash protocol.

Note: The inserted operation will take place

immediately before the operation that is

displayed.

Select option

MOVE PURGE

60 Opsys MW™ User’s Guide

Copying a Wash Protocol

Copying a Wash Protocol

An existing wash protocol can be copied to another program number. If a

wash protocol is already in that location, it will be overwritten.

To copy a wash protocol:

1. Display the main menu:

1: NAME_01

SETUP PROGRAM

2. Use the up and down scroll keys to select the wash protocol to

be modified (or enter the protocol number using the keypad). The

display will read:

4: NAME_04

SETUP PROGRAM

3. Select PROGRAM. If the wash protocol is password protected,

the display will read:

Enter password

4. Enter the Password using the keypad and press ENTER.

5. After a password is successfully entered, the display will read:

6. Select COPY. The display will read:

Note: If the Password is entered incorrectly an

error message is displayed. The operator is

allowed three attempts to enter the password.

After the third attempt, the main menu will be

displayed.

Edit name

4: NAME_04 COPY

Copy to? 7

Note: The protocol number that is displayed

represents the first free protocol number, if any

are available.

Opsys MW™ User’s Guide 61

Copying a Wash Protocol

7. Using the keypad, enter the number of the wash protocol that the

commands are to be copied to. If a wash protocol already exists

at that location the display will read:

Overwrite test? NO

YES NO

8. Select YES. The display will read:

7: NAME_04

SETUP PROGRAM

62 Opsys MW™ User’s Guide

Preparation

Chapter 5 Washing a Plate

Once the parameters for at least one plate type and one wash protocol have

been set, the system can be used to wash a plate.

Preparation

The only preparation that is required is to check the fluid levels in the Wash

Container and the Waste Container. Service the containers if necessary.

To empty the waste container:

1. Unscrew the cap of the Waste Container. Lay the cap and level

sensor assembly on a paper towel.

2. Discard the waste in accordance with local regulations.

3. Rinse the waste container with deionized water. Discard the rinse

water.

4. Place the level sensor and tube back into the Waste Container

and screw the cap on.

Note: If desired, the waste container can be

disinfected with a 10% (v/v) solution of

household bleach in water.

Opsys MW™ User’s Guide 63

Preparation

To refill the wash container:

1. Separate the dispense line quick-connector in the cap of the

Wash Container.

2. Unscrew the cap of the Wash Container and lay it and the PickUp Filter on a clean paper towel.

3. Fill the Wash Container with the wash fluid that is being used.

4. Place the Pick-Up Filter into the Wash Container and screw the

cap on. Re-connect the dispense line quick-connector.

Note: If the wash solution is being changed,

discard the contents of the Wash Container

and thoroughly clean it before filling it with the

new wash solution.

64 Opsys MW™ User’s Guide

Washing a Plate

Washing a Plate

A plate is washed by positioning it on the carrier block, selecting the wash

protocol to be run, and pressing the START key.

To wash a plate:

1. (If needed) Turn on the instrument. The display will read:

1: TESTNAME

SETUP PROGRAM

2. Place the microplate on the plate carrier.

3. Select the desired wash program using the up or down scroll

keys or by entering the wash protocol number using the keypad.

4. Press the START key. The wash program will be automatically

carried out.

Note: Be sure that the plate position on the

carrier plate corresponds to the wash head

configuration that is being used. For example,

if a 1 x 8 head is used, be sure that the plate is

positioned with the columns aligned with the

wash head rather than perpendicular to the

wash head.

Note: Before starting the wash protocol, verify

that the correct wash protocol name is

displayed.

Note: If variable strips was specified for the

wash protocol, you will be prompted to enter

the strips that are to be washed before the

wash will commence.

Opsys MW™ User’s Guide 65

Washing a Plate

This page is intentionally left blank

66 Opsys MW™ User’s Guide

Routine Maintenance Procedures

Chapter 6 Routine Maintenance

Routine Maintenance Procedures

The Opsys MW™ Microplate Washer is constructed from materials that

resist chemical attack. If a spill occurs, it should be cleaned up as soon as

possible using a cloth moistened with a mild laboratory detergent (If needed,

dilute the laboratory detergent according to the manufacturer’s directions).

The following periodic maintenance procedures are required for the

Opsys MW:

Daily maintenance:

• Verify that the self-test passes, by observing Arm movement and the

absence of error messages.

• Clean the plate carrier, using a moist towel.

• Clean the external surfaces, using a moist towel.

Weekly maintenance:

• Empty the Wash Container and clean it.

The wash solution should be replaced at least once a week. The

Wash Bottle should be cleaned whenever fresh wash solution is

required.

To replace the wash solution:

1. Discard any wash solution that is left in the Wash Bottle.

2. Rinse the Wash Bottle with fresh solution.

3. Fill the Wash Bottle with wash solution.

4. Purge the system to ensure that all of the old solution is removed

from the tubing.

• Empty the Waste Container and clean it.

• Inspect the tubing between the Wash Bottle and the Wash Head.

Note: If particulate matter is observed in the

Wash Bottle, the wash solution should be

discarded at once.

• Inspect the tubing between the Wash Head and the Waste

Bottle.

• The tubing should be replaced if it has cracks, is cloudy,

remains pinched, or is otherwise defective.

Six month maintenance:

Opsys MW™ User’s Guide 67

Routine Maintenance Procedures

• Replace the dispense (Wash) tubing.

• Replace the aspirate (Waste) tubing.

• Replace the in-line hydrophobic filter.

If the system will not be used for a period of time, the system should

be flushed with de-ionized water so that buffers and/or reagents

used to wash the plates are not deposited on the Wash Head or

other components of the system.

Note: The dispense tubing and aspiration

tubing may need to be replaced more

frequently than every six months, depending

upon the frequency of use and the severity of

operating conditions.

Contact

replacement tubing.

DYNEX Technologies

for information on

As required maintenance:

• Pump Calibration (page 74)

68 Opsys MW™ User’s Guide

Cleaning and Decontamination

Cleaning and Decontamination

The Opsys MW™ is constructed from materials that resist chemical attack.

Spills should be cleaned as soon as possible. If you need to decontaminate

the Opsys MW™ instrument (for example, before servicing the instrument),

clean the system and then decontaminate it as described below.

To clean the system:

1. Clean external surfaces with a cloth moistened with mild

laboratory detergent.

To decontaminate the system:

1. Wipe the surfaces with a cloth moistened with 10% bleach or

70% alcohol.

CAUTION: Always disconnect the power cable

before cleaning the instrument.

Note: If needed, dilute the laboratory

detergent according to the manufacturer’s

instructions before using.

Opsys MW™ User’s Guide 69

Cleaning the Containers

Cleaning the Containers

Procedures for emptying, cleaning and refilling the Wash Container and the

Waste Container are described below.

To empty and clean the waste container:

1. Unscrew the cap of the Waste Container. Lay the cap and level

sensor assembly on a paper towel.

2. Discard the waste in accordance with local regulations.

3. Rinse the waste container with deionized water. Discard the rinse

water.

4. Place the level sensor and tube back into the Waste Container

and screw the cap on.

To refill the wash container:

1. Separate the dispense line quick-connector in the cap of the

Wash Container. Unscrew the cap and lay it and the Pick-Up

Filter on a clean paper towel.

2. Fill the Wash Container with the wash fluid that is being used.

3. Place the Pick-Up Filter into the Wash Container and screw the

cap on. Reconnect the dispense line quick-connector.

Note: If desired, the waste container can be

disinfected with a 10% (v/v) solution of

household bleach in water.

Note: If the wash solution is being changed,

discard the contents of the Wash Container

and thoroughly clean it before filling it with the

new wash solution.

70 Opsys MW™ User’s Guide

Replacing the Tubing

Replacing the Tubing

To replace the dispense tubing:

1. Separate the dispense line quick-connector in the cap of the

Wash Container. Unscrew the cap, lay it and the Pick-Up Filter

on a clean paper towel.

2. Discard the contents of the Wash Container. Thoroughly rinse

the container with deionized water and let it dry.

3. Disconnect and discard the Wash Container Internal Tube and

pick-up filter that is attached to the barb on the Quick Connect

Fitting in the Cap.

4. Replace the Wash Container Internal Tube and pick-up filter.

5. Remove the Quick Connect Fitting from the Pump Tube that is

attached to the Pump Inlet. Disconnect the tube from the pump

and discard.

6. Reattach the Quick Connect Fitting to a new length of Pump

Tube and attach the free end of the tube to the Pump Inlet.

7. Disconnect both ends of the Dispense Tube that is attached to

the Pump Outlet and the Wash Head, remove the tubing from the

dispense valve and discard.

8. Attach the short length of larger diameter tube to the Pump

Outlet and to the other end fit the larger barb of the Reducer

Fitting. To the small end of the Reducer fit the long length of

small diameter dispense tube and attach the free end to the

Wash Head

9. Route the dispense tubing through the upper slot in the front

corner of the instrument and through the routing clips at the front

of the instrument. Fit the dispense tubing in the dispense valve.

10. Fill the Wash Container with fresh wash fluid. Place the Wash

Container Internal Tube and pick-up filter back into the Wash

Container and screw the Cap on. Reconnect the dispense line

quick-connector.

Opsys MW™ User’s Guide 71

Replacing the Tubing

To replace the vacuum tubing:

1. Unscrew the Cap of the Waste Container, lay it and the level

sensor assembly on a clean paper towel.

2. Discard the contents of the Waste Container in accordance with

local regulations. Thoroughly rinse the container with deionized

water and let it dry.

3. Disconnect the vacuum tubing from the connector in the Cap and

from the connector in the Foam/Aerosol Trap. Discard the old

tube.

4. Obtain a new length of vacuum tubing.

5. Connect one end of the vacuum tubing to the connector in the

Waste Container Cap and the other end to the connector in the

Foam/Aerosol Trap.

Note: This procedure describes replacement

of the vacuum tubing connecting the Waste

Container to the Foam/Aerosol Trap. The

vacuum tubing connecting the Foam/Aerosol

Trap to the rear of the instrument should not

require changing.

6. Place the level sensor assembly back into the Waste Container

and screw the Cap on.

72 Opsys MW™ User’s Guide

Replacing the Tubing

To replace the waste tubing:

1. Unscrew the Cap of the Waste Container and lay it with the level

sensor assembly on a clean paper towel.

2. Discard the contents of the Waste Container in accordance with

local regulations. Thoroughly rinse the container with deionized

water and let it dry.

3. Disconnect the waste tubing from the connector on the Waste

Container cap and from the waste tubing connector on the wash

head.

4. Remove the waste tubing from the instrument.

5. Obtain a new length of waste tubing.

6. Route the waste tubing through the lower slot at the front corner

of the instrument and through the routing clips at the front of the

instrument.

7. Connect one end of the waste tubing to the waste tubing

connector on the wash head and connect the other end to the

connector in the Waste Container cap.

8. Place the level sensor assembly back into the Waste Container

and screw the Cap on.

Opsys MW™ User’s Guide 73

Pump Calibration

Pump Calibration

Each Opsys MW™ washer manifold, or head, (e.g., 1 x 8, 1 x 12) has three

calibration values stored in memory. These values are calculated and stored

during manufacture at DYNEX Technologies. When the Opsys MW

configuration is changed from one manifold to another, the corresponding

calibration settings will be recalled by correctly setting the head size using

the SETUP/HEAD feature (refer to page 28 for Specifying the Wash Head).

This calibration protocol may be used at any time to verify the performance

of the Opsys MW washer.

IMPORTANT! It is recommended that this protocol be completed if any

fluid-carrying component of the Opsys MW is replaced. This protocol may

also be used to recalibrate the Opsys MW if a new wash buffer with different

viscosity is used. Customize the protocol to emulate your assay, using the

appropriate dispense volume, pump speed and fluid density.

Calibration Protocol:

1. Define a flat bottom plate profile using the SETUP/PLATE

function (refer to page 30 for Specifying Plate Parameters).

2. Program an assay to dispense 200µl/well into columns 1-12

(refer to page 41 for Creating a New Wash Protocol).

3. Obtain a clean, dry flat bottom 96-well styrene plate.

4. Weigh the plate and record the empty plate weight in grams.

5. Run the assay programmed in Step 2. (This assay will dispense

200µl to all 96 wells in the plate.)

6. Weigh the plate and record the filled plate weight in grams.

7. Calculate the actual dispensed volume and % error using the

following formulas:

A. Actual Volume = [(Full weight – Empty weight) x 1000mg/g] /

(96 wells x fluid density)

B. %Error = 100 x (Actual Volume – Target Volume)/Target

Volume

Example:

Empty plate weight: 48.38g

Full plate weight: 67.42g

Density of water at 20°C = 0.998mg/µl

Actual Volume = [(67.42 – 48.38) x 1000]/(96 x 0.998) =

198.7µl/well

%Error = 100 x (198.7 – 200)/200 = -0.6%

74 Opsys MW™ User’s Guide

Pump Calibration

8. If the dispensed volume is too high, decrease the pump speed

using the SETUP/CAL function (refer to page 36).

• A pump speed change of -10 units roughly corresponds to a

well volume change of -10µl.

9. If the dispensed volume is too low, increase the pump speed

using the SETUP/CAL function (refer to page 36).

• A pump speed change of +10 units roughly corresponds to a

well volume change of +10µl.

10. Repeat Steps 3-9 until fluid is dispensed with the accuracy

required. (e.g., Error less than or equal to ±5%)

Opsys MW™ User’s Guide 75

Pump Calibration

This page is intentionally left blank

76 Opsys MW™ User’s Guide

Operational Problems

Chapter 7 Troubleshooting

Operational Problems

Problems that may occur during normal operation of the Opsys MW™ are

described below. For each problem, the symptom, probable cause and the

means for resolving the problem are shown.

Symptom Probable Cause Resolution

The instrument

fails to power up.

Verify that the electrical

The cord is not

connected.

Check that the cord is

plugged into the

instrument and into the

electrical outlet.

outlet is not controlled by

a switch or timer.

Verify that there is power

at the electrical outlet by

plugging in and checking

another device.

The powerstrip is

faulty.

The fuse is

blown.

The breaker is

tripped.

The power supply

is defective.

Liquid is not

dispensed from the

dispense pins.

The Wash

The dispense

pins are clogged.

Container is

empty.

Replace the powerstrip.

Service is required.

Service is required.

Reset the breaker.

Remove the wash head

assembly and clean it

using the manifold head

cleaning wire. Then run a

purge. Service is required

if problem persists.

Refill the Wash Container.

Opsys MW™ User’s Guide 77

Operational Problems

Symptom Probable Cause Resolution

Liquid is not

dispensed from the

dispense pins

(continued).

The dispense

The wash

protocol is

incorrectly

defined.

tubing or the

dispense pump

power supply is

not connected.

Check the system

configuration and wash

protocol for the number

fluids and fluid volume.

Verify that the dispense

tubing and the dispense

power supply are

connected (see page 20).

The dispense

tubing is sealed

shut at the

dispense valve.

Remove the tubing from

the dispense valve and

massage the tubing to

release it. Replace the

tubing into the dispense

valve at a different

location.

Purge the tubing more

frequently.

Replace the tubing.

The dispense

Service is required.

valve does not

open.

The wash head

manifold tubing is

blocked.

Remove the wash head

assembly and clean it

using the manifold head

cleaning wire. Then run a

purge. Service is required

if problem persists.

There is a

pressure leak.

Check the seals and

tubing for leaks.

Check for air leaks.

Reseat the tubing in the

The dispense

pump is faulty.

Liquid is dispensed

continuously from

the dispense pins

The dispense

tubing is not

inserted in the

dispense valve.

78 Opsys MW™ User’s Guide

dispense valve.

Service is required.

Insert the dispense tubing

into the dispense valve

(see page 20).

Operational Problems