Dynex MW 91000051 User Manual

Opsys MW

Please read carefully before using the Opsys MW

™

Microplate Washer

User’s Guide

IMPORTANT

Part No. 91000051, Revision B

This manual is published by DYNEX Technologies, Inc.

Questions or comments regarding the content of this manual can be

directed to the address below or to your DYNEX Technologies

representative.

DYNEX Technologies

14340 Sullyfield Circle

Chantilly, VA 20151-1683 USA

Tel. (703) 631-7800

(800) 288-2354

Fax. (703) 803-1441

TM

OPSYS MW

© 2006 This document is the copyright of DYNEX Technologies and must

not be copied or reproduced in any form without prior consent.

is a trademark of DYNEX Technologies, Inc.

DYNEX Technologies reserves the right to make technical improvements to

this equipment and documentation without prior notice as part of a

continuous program of product development. This manual supersedes all

previous editions.

Warranty and Special Provisions Limited Warranty

DYNEX Technologies products are fully guaranteed for one year against defects in

parts, materials, and workmanship. Defective parts and materials will be replaced

or, at the discretion of DYNEX Technologies, repaired at no charge for a period of

one year and labor required for such replacement or repair will be provided at no

charge for a period of one year, provided that the products are utilized and

maintained in accordance with the instructions in the applicable operating and

servicing manual, and provided further that the products have not, as determined

solely by DYNEX Technologies, been subject to misuse or abuse by the Customer

or other parties unrelated to DYNEX Technologies. DYNEX Technologies makes

no warranty, expressed or implied, as to the fitness of any product for any particular

purposes other than those purposes described in the applicable operating and

servicing manual, nor does DYNEX Technologies make any other warranty,

whether expressed or implied, including merchantability, other than those appearing

on the face hereof. Where DYNEX Technologies guarantees any product, whether

under this Warranty or as a matter of law, and there is a breach of such guarantee,

the Customer’s only and exclusive remedy shall be the replacement or repair of

defective parts and materials, as described above. This shall be the limit of DYNEX

Technologies’ liability. Furthermore, DYNEX Technologies shall not be liable for

incidental or consequential damages. Failure of the Customer to notify DYNEX

Technologies of a claimed defect by registered mail within thirty days of the

discovery thereof shall constitute a waiver of any claim for breach of warranty.

When a product is required by DYNEX Technologies to be installed by a DYNEX

Technologies engineer or technician, the period of this Warranty shall begin on the

date of such installation, provided however, that any use of the product prior to such

installation shall, at sole election of DYNEX Technologies, void this Warranty.

When installation by DYNEX Technologies personnel is not required, the period of

this Warranty shall begin on the date of shipment from DYNEX Technologies. The

period of this Warranty shall begin as described above whether or not the product

has been installed pursuant to a purchase order, and any trial period shall be

deducted from the Warranty period that would otherwise apply under a subsequent

placed purchase order for that product.

Limitation of Liability. Notwithstanding anything to the contrary contained herein,

the liability of Seller (whether by reason of breach of warranty, breach of contract,

tort, or otherwise), including without limitation under any indemnification provision

contained herein, shall be limited to replacement of goods returned to DYNEX

Technologies which are shown to DYNEX Technologies’ reasonable satisfaction to

have been nonconforming or to refund the purchase price, or, if not paid, to a credit

amount of the purchase price therefore.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND ARE GIVEN AND

ACCEPTED IN LIEU OF ANY AND ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING WITHOUT LIMITATION, THE IMPLIED WARRANTY OF

MECHANTABILITY AND THE IMPLIED WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE. NEITHER PARTY SHALL BE LIABLE TO THE OTHER

FOR ANY INCIDENTAL, INDIRECT, SPECIAL, OR CONSEQUENTIAL

DAMAGES.

Table of Contents

Table of Contents

About this Manual iii

Chapter 1 Introduction 1

Description 1

Programming 2

Wash Head 3

Wash Head Positions 4

Wash Fluid 5

Waste 5

Features 7

Specifications 9

Warning Labels 11

Chapter 2 Installation 13

Unpacking 13

Materials Provided 13

Hardware Components 15

Positioning the Instrument 18

Installing the Wash Head 19

Installing the Wash Container 20

Installing the Waste Container 21

Turning on the System 22

Chapter 3 Configuration 23

The Keypad 23

Menus 26

The SETUP Menu 27

The PROGRAM Menu 27

Configuring the System 28

Specifying the Wash Head 29

Specifying Plate Parameters 30

Displaying the Software Version 35

Specifying the Pump Parameters 36

Selecting Clean 37

Chapter 4 Wash Protocols 39

Wash Protocol Operations 39

Creating a New Wash Protocol 41

Specifying the Header 41

Specifying Wash Cycle Operations 45

Ending a MOVE Cycle 53

Modifying a Wash Protocol 56

Copying a Wash Protocol 61

Chapter 5 Washing a Plate 63

Preparation 63

Washing a Plate 65

Chapter 6 Routine Maintenance 67

Routine Maintenance Procedures 67

Opsys MW™ User’s Guide i

Table of Contents

Cleaning and Decontamination 69

Cleaning the Containers 70

Replacing the Tubing 71

Pump Calibration 74

Chapter 7 Troubleshooting 77

Operational Problems 77

Chapter 8 Service 81

Service Procedures 81

Spare Parts 82

Returning a Washer for Service 83

Contact DYNEX Technologies 85

Index 86

ii Opsys MW™ User’s Guide

About this Manual

About this Manual

This manual has been written for laboratory technicians and provides

detailed instructions for using the Opsys MW™ system.

This manual gives you the information needed to:

• Review safety precautions.

• Install the Opsys MW™ system.

• Understand the Opsys MW™ menus.

• Set the Opsys MW™ system up to suit your exact needs.

• Create or modify wash protocols.

• Run wash protocols using the Opsys MW™ system.

• Perform required preventive maintenance.

• Troubleshoot the system.

Opsys MW™ User’s Guide iii

About this Manual

This page is intentionally left blank

iv Opsys MW™ User’s Guide

Description

Chapter 1 Introduction

The Opsys MW™ is a microprocessor-controlled microplate washing system

that performs wash protocols that are defined by the user. It is designed to

wash all of the wells in one column or one row of a 96-well plate at once.

The washing protocol can be programmed so that all of the columns (or

rows) are washed in the same manner, or different wash cycles can be

applied to specified columns (or rows) on the plate.

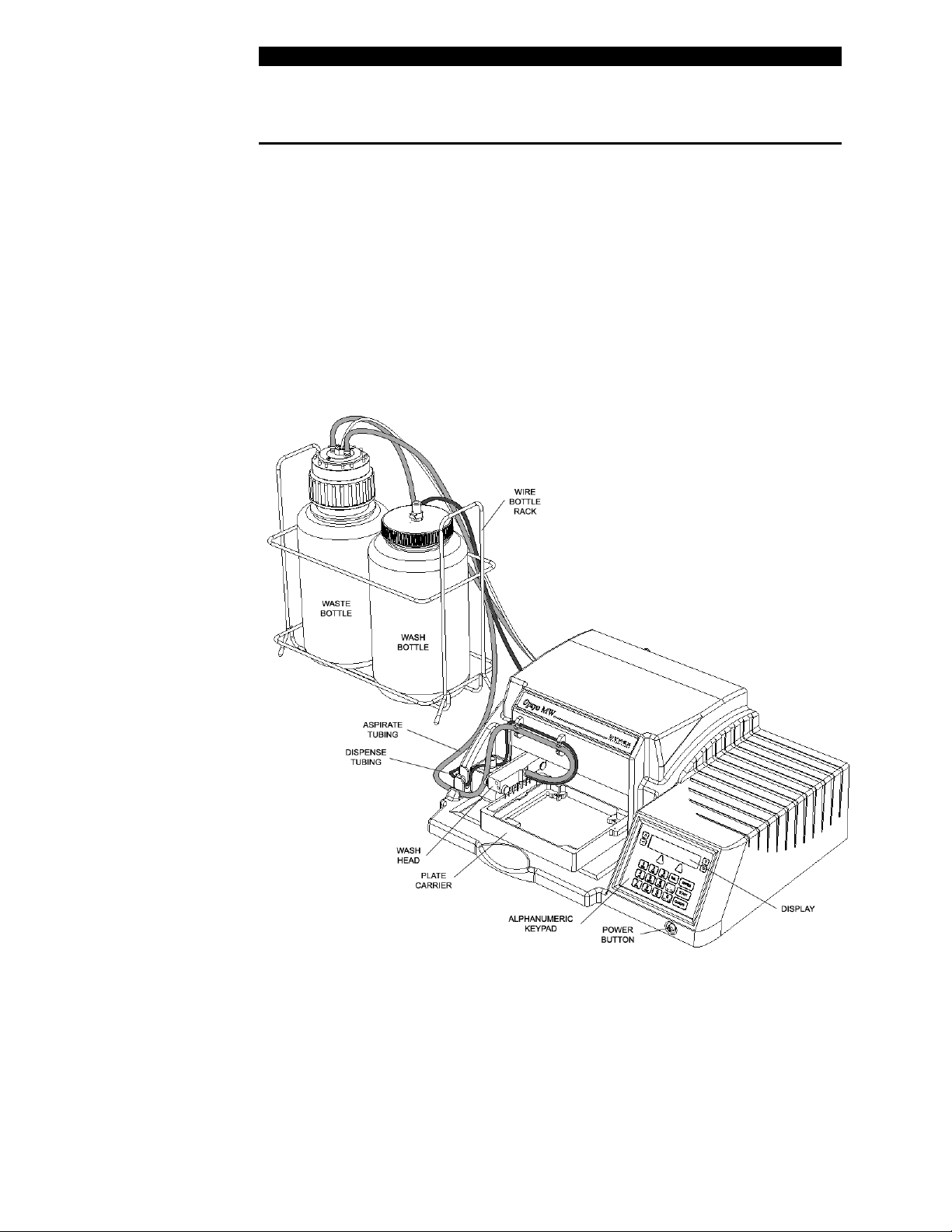

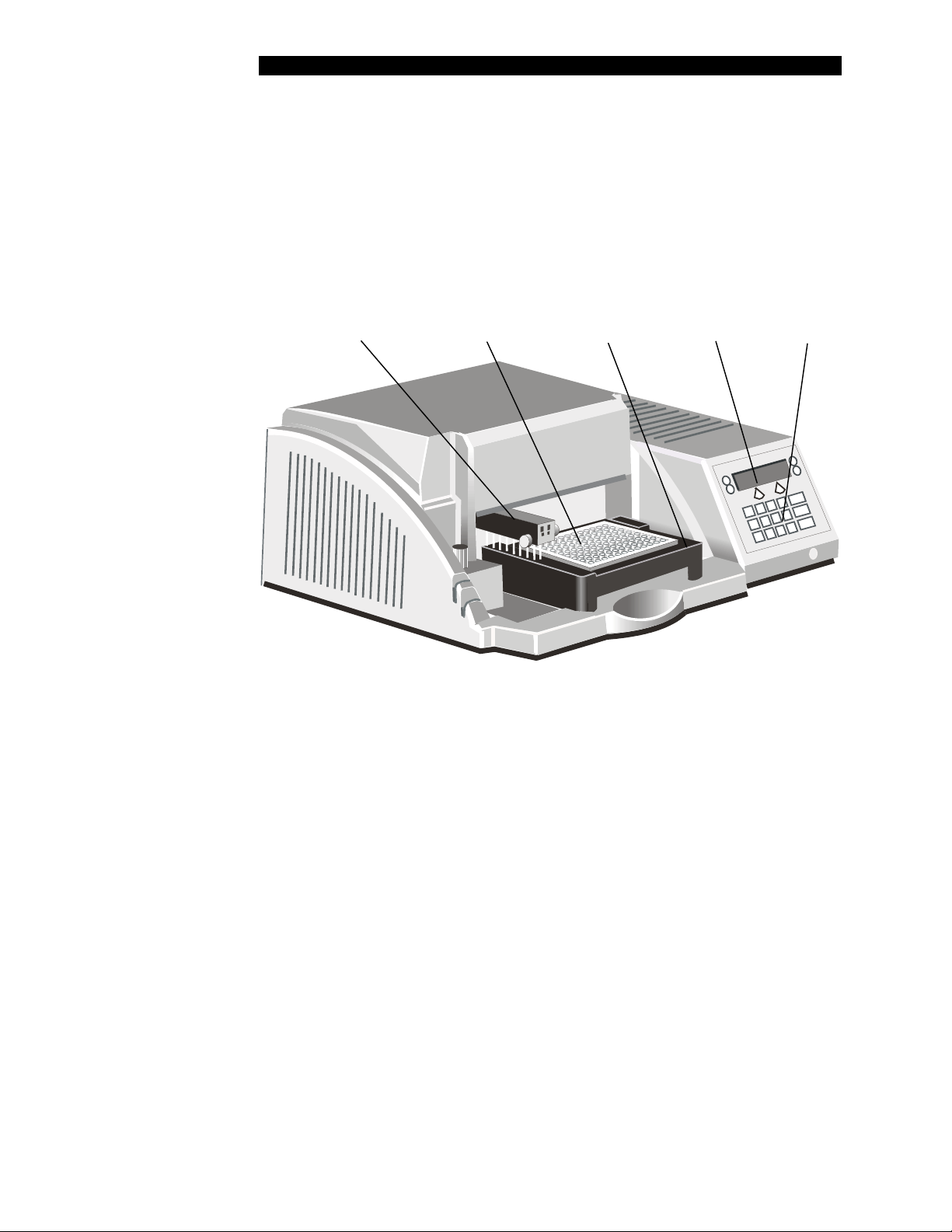

Description

The Opsys MW Microplate Washer is shown in Figure 1.

Figure 1. The Opsys MW™ Microplate Washing System

Opsys MW™ User’s Guide 1

Description

Programming

All wash protocols on the Opsys MW™ Microplate Washer are user-defined.

Up to 40 wash protocols can be contained on the system.

In addition, the system can be configured with up to ten different plate types

so that the wash head positions for each plate type can be specified.

Programming of a new wash protocol (or modifying an existing one) and

configuration of the system are carried out using the keypad and display.

Note: Memory limitations may restrict the size

and complexity of an individual wash protocol.

2 Opsys MW™ User’s Guide

Description

Wash Head

The wash head on the Opsys MW™ Microplate Washer contains multiple

sets of dual wash pins. Each set of dual wash pins consists of a

dispense pin and an aspirate pin that are closely spaced so that fluid can

be aspirated from and dispensed into a well simultaneously.

The following wash heads can be fitted on the Opsys MW™:

Wash Head Description

1 x 8

Eight sets of dual wash pins for washing a 96-well

microplate one column (8 wells) at a time.

1 x 12

If a wash head is installed to wash plates by columns, the plates are placed

on the instrument so that the columns of the plate are aligned with the wash

head. If a wash head is installed to wash plates by row, the plate is rotated

90 degrees and placed on the instrument so that the rows of the plate are

aligned with the wash head.

The wash pins are fixed to the wash head. During operation, the wash head

assembly is lowered to insert the wash pins into the wells or raised to

remove the wash pins from the wells. Lowering the wash head assembly

allows the well contents to be aspirated or a bottom wash to be performed.

Raising the wash head assembly allows the plate to be moved so another

column (or row) can be washed or so the wells can be filled.

Twelve sets of dual wash pins for washing a

96-well microplate one row (12 wells) at a time.

Opsys MW™ User’s Guide 3

Description

Wash Head Positions

The vertical positions that the wash head can assume are described below.

Each wash head position can be specified by the user to within 0.1 mm.

Wash Head Position Description

Dispense Height

Well Top

Aspiration Height

Sweep Height

Note: Procedures for specifying wash head

positions for various plate types are described

on page 30.

Positions the aspiration pins slightly

below the top of the well so that fluid can

be dispensed into the well up to a certain

level before it is aspirated.

Positions the aspiration pins so they are

aligned with the top of the well.

Positions the aspiration pins at the bottom

of the well so that the contents of the well

can be completely aspirated.

Raises the aspiration pins slightly above

the Aspiration Height (see above) so that

the aspiration pins can be moved back

and forth in the well while the fluid is

being aspirated.

Bottom Wash Height

In protocols with a bottom wash, lowers

the wash head during dispense so that

the force of the dispensed fluid can wash

the bottom of the wells.

4 Opsys MW™ User’s Guide

Description

Wash Fluid

A single wash fluid is used on the Opsys MW™ Microplate Washer. The

wash fluid is contained in the Wash Container and is dispensed into the

wells whenever a Dispense or Fill operation is specified in the wash

protocol. In addition, wash fluid is dispensed into the purge tray during a

Purge operation.

Dispensing of the fluid from the Wash Container is controlled by a pump

attached to the back of the Opsys MW™ Microplate Washer and a dispense

valve located near the wash head (Figure 1).

Waste

Fluid is removed from the wells during an Aspirate or Dispense operation

and collected in the Waste Container. The Waste Container contains a level

sensor to alert the operator when the container is full.

Removal of the fluid from wells is controlled by lowering the wash head so

that the aspiration pins are immersed into the well fluid (the aspiration

height). A vacuum is applied to the aspiration pins at all times during

operation so that the contents of a well are aspirated whenever the wash

head is lowered to the aspiration height.

Opsys MW™ User’s Guide 5

Description

This page is intentionally left blank

6 Opsys MW™ User’s Guide

Features

Features

The Opsys MW™ system has a number of performance and convenience

features. These are summarised below:

• Small footprint

• Up to 40 wash protocols can be programmed

• Up to ten plate types can be programmed

• Two wash head configurations (1 x 8 and 1 x 12)

• On-board self diagnostics

• SHOW function allows visual verification of wash head height

settings

• High-level alarm on Waste Container

Opsys MW™ User’s Guide 7

Features

This page is intentionally left blank

8 Opsys MW™ User’s Guide

Specifications

Specifications

Dimensions and Weight

Length 49 cm (19.3 in)

Width 38 cm (15.0 in)

Height 19 cm (7.5 in)

Weight 9.1 kg (20 lbs)

Operation

Dispense Range

Dispense Precision

Residual Aspirate Volumes

Washing Time Typical 5 cycle wash: 5 min 30 sec

Power < 100 W

Display 2 by 20 character back lit LCD

Keypad 21 key tactile membrane

Output Display, Printer, RS232

50 – 999 µL

5% CV (with 300 µL distilled water)

< 1 µL for U and V bottom plates

< 5 µL for flat bottom plates

Environmental

Operating Range 15° C to 30° C

15% to 85% relative humidity (non-condensing)

2000m altitude

Computer Interface

Port Serial RS-232 port (Service Access)

Baud Rate 19200. Character format

Character Format 7 data bits, 1 stop bit, no parity

Power Requirements

Voltage Power Frequency

Main Unit 100 - 240 V 200 VA 50/60 Hz

Line Voltage Variation

Line Frequency Variation

Opsys MW™ User’s Guide 9

±

10%

±

3 Hz

Specifications

Input Ranges

Assay Programming

Assay Name Up to 10 characters

Password Up to 8 characters

Move: Start Strip 1 - 8 for 1 x 8 heads and 1 - 12 for 1 x 12 heads (Increment: 1)

Move: End Strip 1 - 8 for 1 x 8 heads and 1 - 12 for 1 x 12 heads (Increment: 1)

Move: #Cycles 1 - 9 (Increment: 1)

Aspirate: Cycles 1 - 9 (Increment: 1)

Dispense

Purge

Fill

Soak 1 - 999 (Increment: 1 second)

50 - 999 (Increment: 1 µL)

50 - 9999 (Increment: 1 µL)

50 - 300 (Increment: 1 µL)

Plate Setup

Plate Name Up to 10 characters

Dispense Height 001 - 999 (Increment: 1)

Top of Well Height 001 - 999 (Increment: 1)

Aspirate Height 001 - 999 (Increment: 1)

Sweep Height 001 - 999 (Increment: 1)

Sweep Stroke 001 - 999 (Increment: 1)

Bottom Wash: Dispense

Height

001 - 999 (Increment: 1)

Standards

The instrument is designed in accordance with CSA 1010.1-92, UL 3101-1, EN61010-1

and EN61326.

10 Opsys MW™ User’s Guide

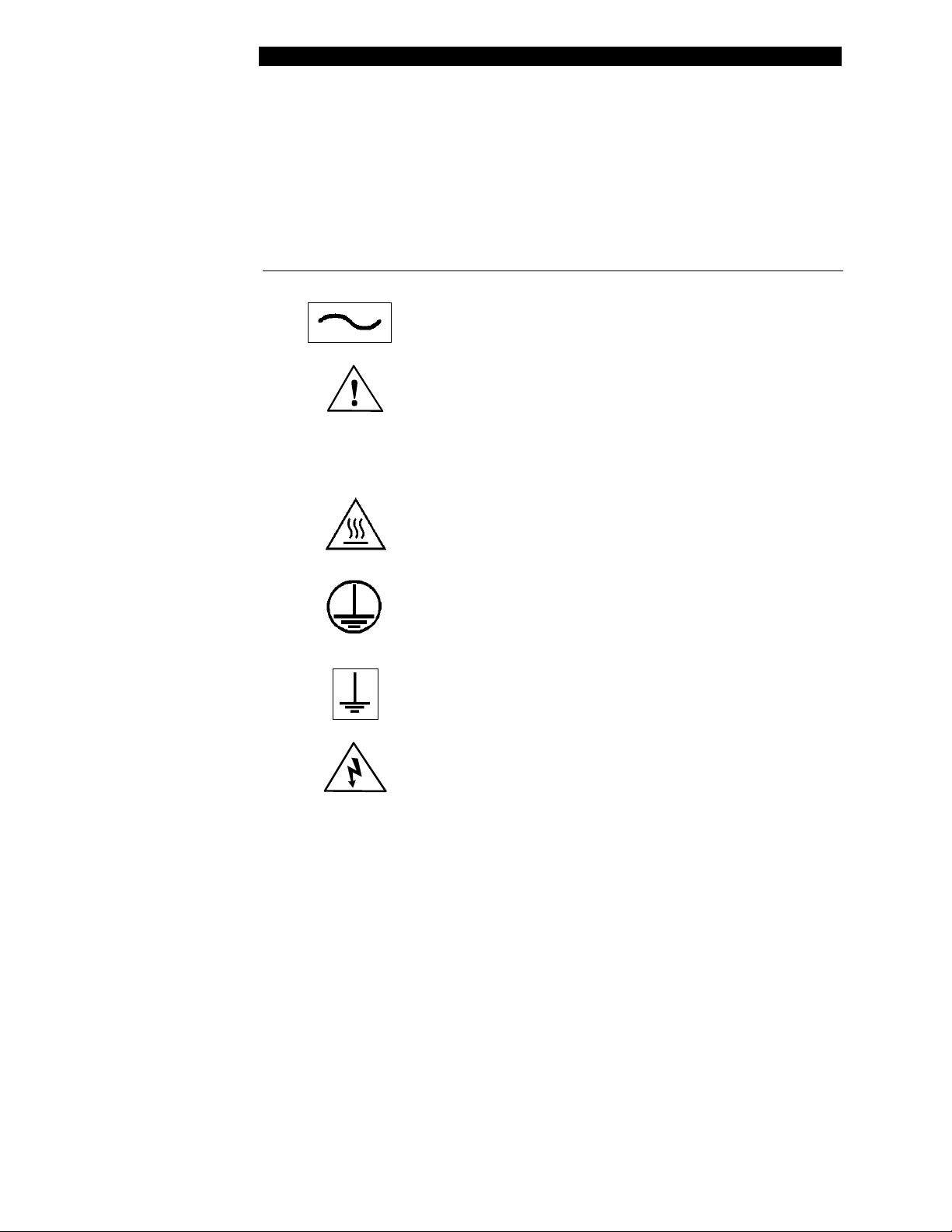

Warning Labels

Warning Labels

The Opsys MW™ or its components may contain certain labels that that

either warn the user of a hazard or note an electrical connection. The labels

that may be used on the Opsys MW™ system are described below.

Label Description

Alternating current is present.

(English) Caution symbol. Refer to the

Routine Maintenance chapter.

(French) Attention (voir documents

d’accompagnement).

(English) Caution, hot surface.

(French) Attention, surface chaude.

Protective conductor terminal.

Earth (ground) terminal.

(English) Caution, risk of electric shock.

(French) Attention, risque de choc électrique.

Opsys MW™ User’s Guide 11

Warning Labels

This page is intentionally left blank

12 Opsys MW™ User’s Guide

Unpacking

Chapter 2 Installation

Unpacking

Materials Provided

The main carton contains the instrument. The contents of this carton are

listed below:

Article Quantity

Opsys MW™ System 1

Instrument Power Cable 1

Cleaning Wire, Aspirate 1

Cleaning Wire, Dispense 1

Instrument Configuration Report 1

User’s Guide 1

Declaration of Conformity 1

Wash Head, 1 x 8 or 1 x12 1

Plate Holder 1

A sub-carton contains the wash container and waste container assemblies.

The contents of this carton are listed below:

Article Quantity

Wash Container Assembly 1

Waste Container Assembly 1

Opsys MW™ User’s Guide 13

Unpacking

To unpack the components:

1. Place the Opsys MW™ instrument in the position where it will be

located for use.

2. Place the Wash Container, Waste Container and Foam/Aerosol

Trap at the rear of the instrument.

3. Examine the packaging to be sure that the power cord and other

materials have been removed. Please save packaging material

for future use.

4. Verify that all of the materials listed above have been unpacked.

5. Inspect the components for damage. If damage is observed,

contact your shipper or service representative immediately.

14 Opsys MW™ User’s Guide

Hardware Components

Hardware Components

Hardware components of the Opsys MW™ instrument are shown in

Figure 2 and described below.

Wash Head Microtiter® Plate Plate Carrier Display Panel Keypad

Note: The Wash Container, Waste Container

and Foam/Aerosol Trap are external to the

instrument and are not shown in Figure 2.

Figure 2. The Opsys MW™ System

• Wash Head. The wash head contains sets (1 x 8 or 1 x 12) of dual

wash pins. Each set of wash pins consists of a dispense pin and

an aspirate pin, closely spaced so that fluid can be aspirated from a

well while fluid is being dispensed into the same well. The wash

head moves back and forth to wash each row (or column, depending

on the wash head that is used) of the plate by lowering the wash

pins into the corresponding wells.

• Plate Carrier. The plate carrier holds the plate in a fixed position so

that the wash pins can be precisely lowered to the correct height and

position in the wells during the washing procedure.

• Display Panel. The display panel is the means by which the system

communicates to the user. All messages, commands, and wash

parameters entered by the user are displayed.

Opsys MW™ User’s Guide 15

Hardware Components

• Keypad. The keypad is used by the operator to select commands

and enter wash parameters.

• RS232 Interface. The system includes an RS232 interface so that

an external computer can be connected for technical service

purposes.

• Wash Container. (Shown in Figure 1). The wash container contains

the wash fluid that is used for Dispense, Fill and Purge operations.

• Waste Container. (Shown in Figure 1). The waste container

contains the fluid that is aspirated from the wells. A level sensor is

contained inside of the waste container.

16 Opsys MW™ User’s Guide

Hardware Components

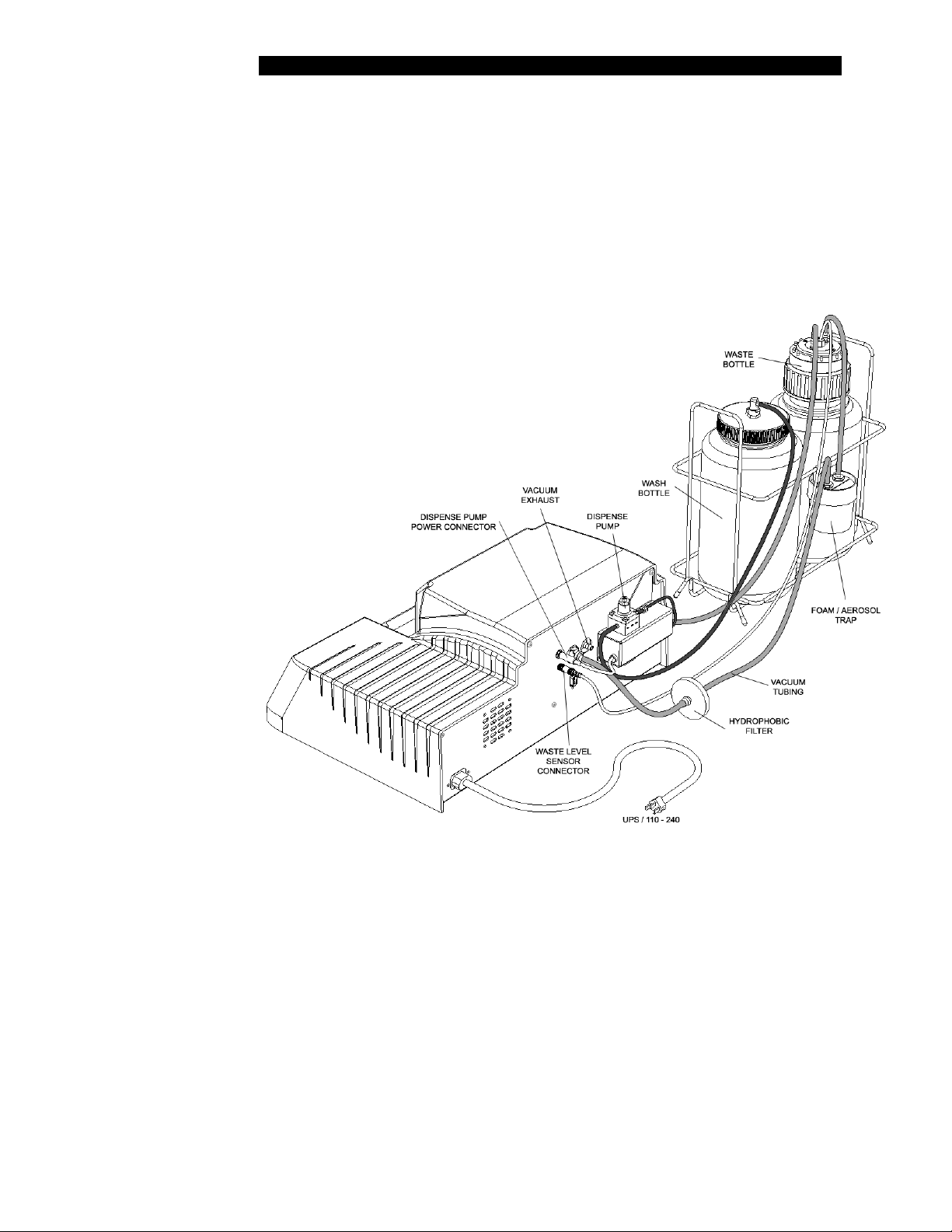

Connectors at the rear of the Opsys MW™ system are shown in Figure 3.

Connections for the power cord, dispense pump power, waste bottle level

sensor, waste bottle vacuum line and an external computer are made at the

rear of the system.

Important: Be sure that the vacuum exhaust

is not obstructed.

Figure 3. Rear View of the Opsys MW™ System

Opsys MW™ User’s Guide 17

Positioning the Instrument

Positioning the Instrument

Determine the area where the system will be located. You will need a firm

and level area that is approximately 51 cm (20 inches) wide, 62 cm (24

inches) deep, and 40 cm (16 inches) high for the Opsys MW™.

18 Opsys MW™ User’s Guide

Installing the Wash Head

Installing the Wash Head

The Wash Head must be located on the Wash Head Arm.

To install the Wash Head:

1. Position the Arm over the Purge Reservoir portion of the Plate

Holder.

2. Place the Wash Head on the two Arm Pins, being careful to

properly seat the Wash Head on the support pins.

3. Level the Wash Head in relation to the Plate Holder and tighten

the two thumbscrews at the front of the Wash Head / Arm

Assembly.

Opsys MW™ User’s Guide 19

Installing the Wash Container

Installing the Wash Container

The dispense tubing and dispense pump power cable must be connected.

To install the Wash Container:

1. Fill the Wash Container with the wash solution that is to be used.

2. Insert the Pick-Up Filter into the Wash Container and secure the

cap. Attach the Quick-Connector at the end of the pump tubing,

to the mating connector in the cap.

3. Route the dispense tubing through the upper slot at the front

corner of the instrument and through the routing clips at the front

of the instrument.

4. Connect the end of the dispense tubing to the wash tubing

connector on the wash head.

5. Thread the dispense tubing through the dispense valve.

(Figure 1).

6. Connect the dispense pump power cable to the dispense pump

power connector at the rear of the instrument (Figure 3).

Note: The Wash Container contains up to

4 liters.

Note: The tubing must be inserted fully into

the dispense valve opening to ensure proper

operation.

20 Opsys MW™ User’s Guide

Installing the Waste Container

Installing the Waste Container

To install the Waste Container and Foam/Aerosol Trap:

1. Insert the Quick-Connect end of the vacuum tubing on the

Foam/Aerosol Trap to the Quick-Connect vacuum connector at

the rear of the instrument Figure 3).

2. Screw on the Waste Container cap.

3. Route the waste tubing through the lower slot at the front corner

of the instrument and through the routing clips at the front of the

instrument.

4. Connect the end of the waste tubing to the waste tubing

connector on the wash head.

5. Connect the waste level sensor cable to the waste level sensor

connector at the rear of the instrument (Figure 3).

Opsys MW™ User’s Guide 21

Loading...

Loading...