DYNEX MP03-275-22, MP03-275-18, MP03-275-16, MP03-275-20 Datasheet

1/10

MP03 XXX 275 Series

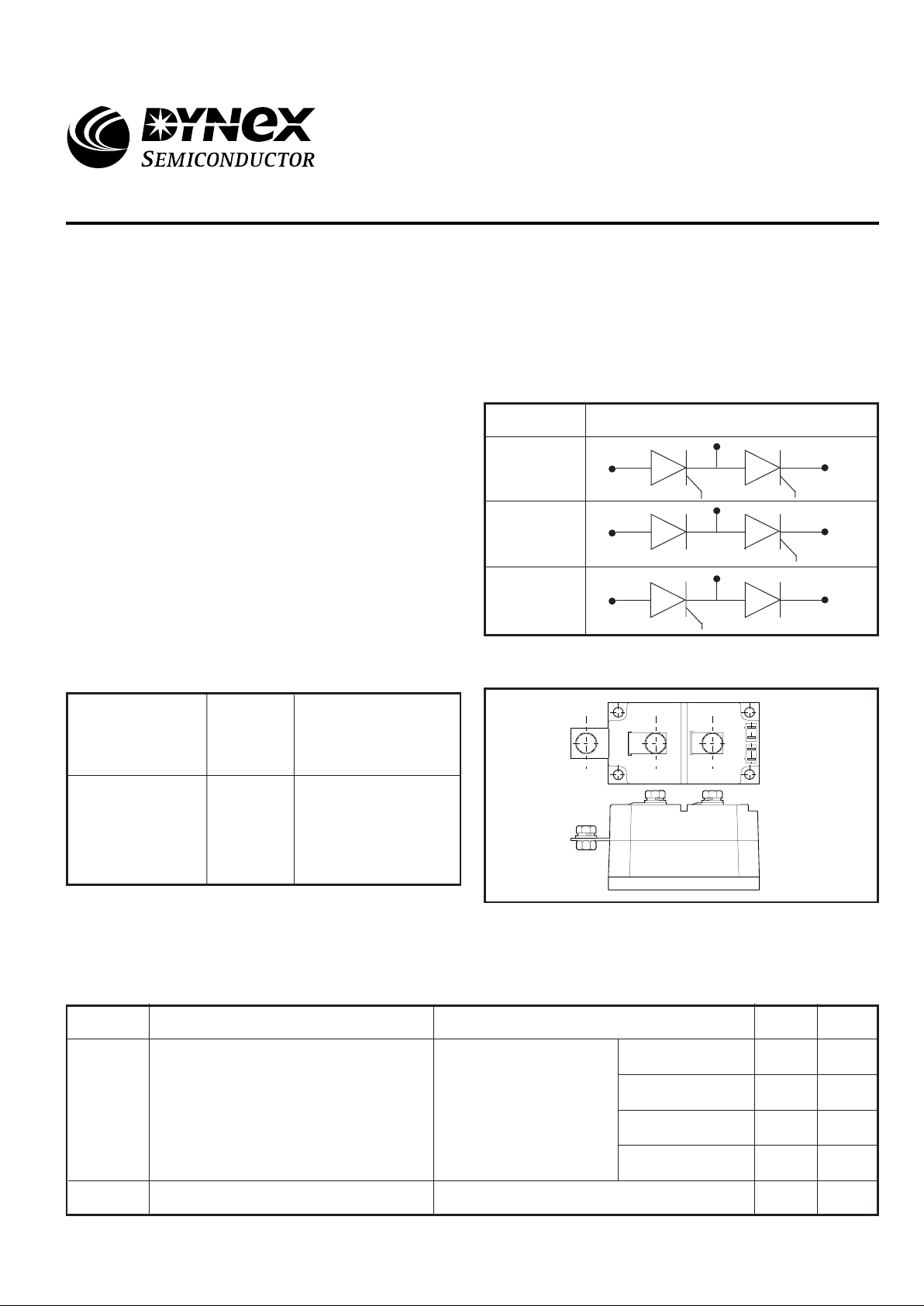

Code

Circuit

HBT

HBP

HBN

MP03/275 - 22

MP03/275 - 20

MP03/275 - 18

MP03/275 - 16

277

234

A

A

216

A

T

case

= 75oC

T

heatsink

= 75oC

T

heatsink

= 85oC

T

case

= 85oC

T

case

= 75oC

I

T(RMS)

RMS value

A181

A

430

Mean on-state current

Halfwave, resistive load

I

T(AV)

2200

2000

1800

1600

T

(vj)

= 125oC

I

DRM

= I

RRM

= 30mA

V

DSM

& V

RSM

=

V

DRM

& V

RRM

+ 100V

respectively

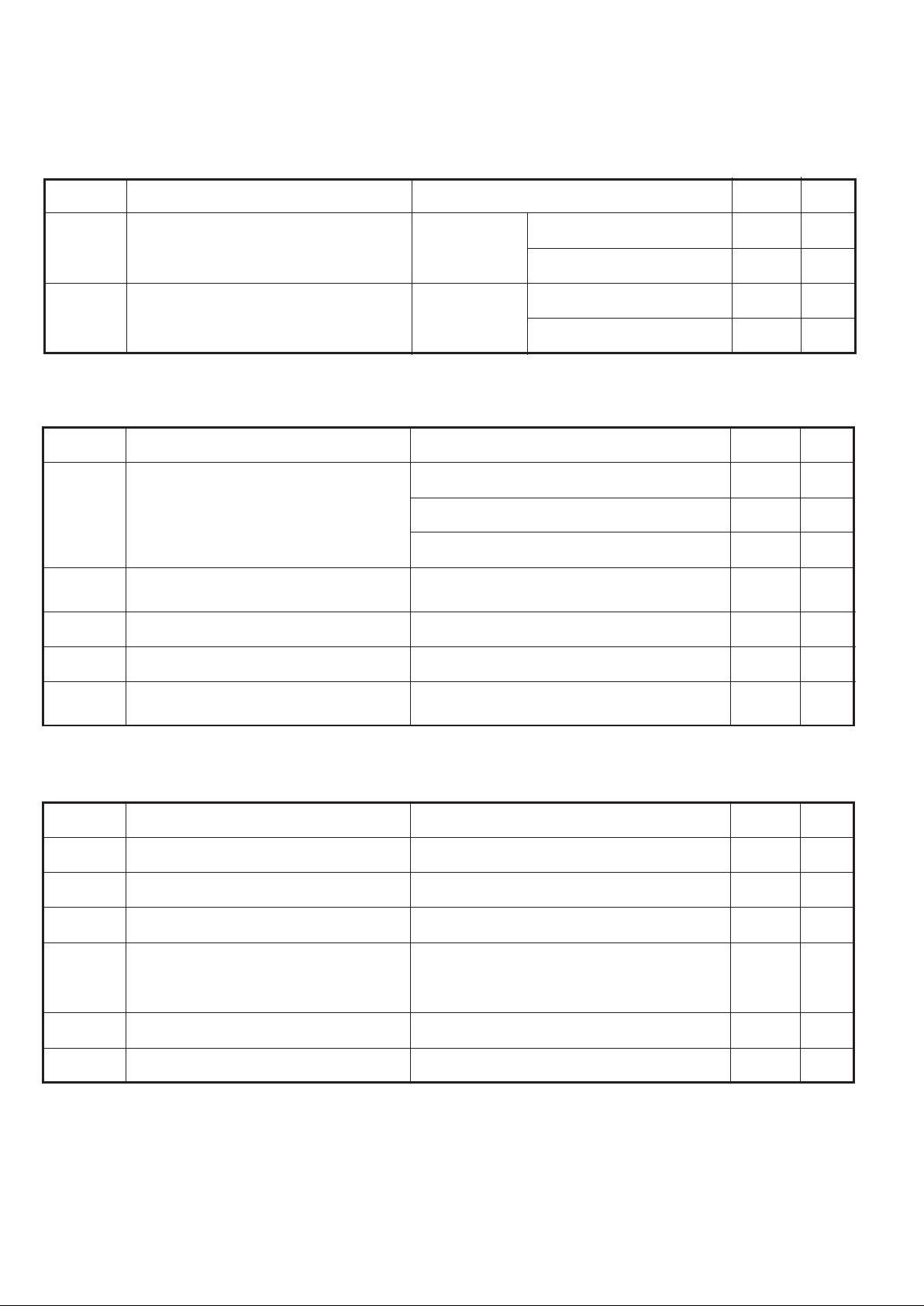

Module type code: MP03.

See Package Details for further information.

FEATURES

■ Dual Device Module

■ Electrically Isolated Package

■ Pressure Contact Construction

■ International Standard Footprint

■ Alumina (non-toxic) Isolation Medium

APPLICATIONS

■ Motor Control

■ Controlled Rectifier Bridges

■ Heater Control

■ AC Phase Control

CURRENT RATINGS - PER ARM

KEY PARAMETERS

V

DRM

2200V

I

TSM

8100A

I

T(AV)

(per arm) 277A

V

isol

2500V

PACKAGE OUTLINE

ParameterSymbol Conditions Max. Units

CIRCUIT OPTIONS

Lower voltage grades available.

For full description of part number see "Ordering instructions"

on page 3.

VOLTAGE RATINGS

Type

Number

Repetitive

Peak

Voltages

V

DRM VRRM

Conditions

MP03 XXX 275 Series

Phase Control Dual SCR, SCR/Diode Modules

Replaces December 1998 version, DS4481-4.0 DS4481-5.0 January 2000

2/10

MP03 XXX 275 Series

kA

VR = 0

VR = 50% V

RRM

VR = 0

VR = 50% V

RRM

A2s

8.1

Thermal resistance - case to heatsink

per thyristor or diode

3 phase

Peak reverse and off-state current

From 67% V

DRM

to 500A

Gate source 10V, 5Ω

Rise time 0.5µs, Tj =125oC

r

T

* Higher dV/dt values available, contact factory for particular requirements.

Note 1: The data given in this datasheet with regard to forward voltage drop is for calculation of the power dissipation in the

semiconductor elements only. Forward voltage drops measured at the power terminals of the module will be in excess of these

figures due to the impedance of the busbar from the terminal to the semiconductor.

kA

6.5

0.32 x 106A2s

0.21 x 10

6

10ms half sine;

Tj = 125˚C

10ms half sine;

Tj = 125˚C

Surge (non-repetitive) on-state current

I

TSM

I2t for fusing

I2t

dc

Thermal resistance - junction to case

per Thyristor or Diode

halfwave

R

th(j-c)

R

th(c-hs)

Mounting torque = 5Nm

with mounting compound

T

vj

Virtual junction temperature

Off-state (Blocking)

T

stg

Storage temperature range

Commoned terminals to base plate

AC RMS, 1min, 50Hz

Isolation voltageV

isol

0.12

o

C/W

o

C/W

0.13

2.5 kV

-40 to 125oC

o

C125

0.05

o

C/W

0.14

o

C/W

At 1000A, T

case

= 25oC - See Note 1 1.65 V

At V

RRM/VDRM

, Tj = 125oC30mA

To 67% V

DRM Tj

= 125oC 200* V/µs

100 A/µs

0.93 VAt Tvj = 125oC - See Note 1

0.67

mΩ

At Tvj = 125oC - See Note 1On-state slope resistance

V

T(TO)

Threshold voltage

Rate of rise of on-state current

dI/dt

Linear rate of rise of off-state voltagedV/dt

I

RRM/IDRM

On-state voltage

V

TM

Symbol Parameter Conditions Max. Units

Symbol Parameter Conditions Max. Units

Symbol Parameter Conditions Max. Units

SURGE RATINGS - PER ARM

THERMAL & MECHANICAL RATINGS

DYNAMIC CHARACTERISTICS- THYRISTOR

3/10

MP03 XXX 275 Series

Part number is made up of as follows:

MP03 HBT 275 - 20

MP = Pressure contact module

03 = Outline type

HBT = Circuit configuration code (see "circuit options" - front page)

275 = Nominal average current rating at T

case

= 75oC

20 = V

RRM

/100

NOTE: Diode ratings and characteristics are comparable with the SCR in types HBP or HBN

Types HBP or HBN can also be supplied with diode polarity reversed, to special order.

Gate non-trigger voltage

V

3.0

0.25

mA

V

V

GD

Gate trigger voltage

150

V

GT

I

GT

Gate trigger current

At V

DRM Tcase

= 25oC

V

DRM

= 5V, T

case

= 25oC

V

DRM

= 5V, T

case

= 25oC

-

-

-

V

30

0.25

V

V

RGM

Peak reverse gate voltage

V5.0

A

-

-

-

10

I

FGM

Peak forward gate current

Peak forward gate voltage

V

FGM

V

FGN

Peak forward gate voltage

Anode positive with respect to cathode

Anode negative with respect to cathode

Anode positive with respect to cathode

P

GM

P

G(AV)

Peak gate power

Mean gate power

tp = 25µs-

-

100

5

W

W

■ Adequate heatsinking is required to maintain the base temperature

at 75oC if full rated current is to be achieved. Power dissipation may

be calculated by use of V

T(TO)

and rT information in accordance with

standard formulae. We can provide assistance with calculations or

choice of heatsink if required.

■ The heatsink surface must be smooth and flat; a surface finish

of N6 (32µin) and a flatness within 0.05mm (0.002") are

recommended.

■ Immediately prior to mounting, the heatsink surface should be

lightly scrubbed with fine emery, Scotch Brite or a mild chemical

etchant and then cleaned with a solvent to remove oxide build up

and foreign material. Care should be taken to ensure no foreign

particles remain.

■ An even coating of thermal compound (eg. Unial) should be

applied to both the heatsink and module mounting surfaces. This

should ideally be 0.05mm (0.002") per surface to ensure optimum

thermal performance.

■ After application of thermal compound, place the module

squarely over the mounting holes, (or 'T' slots) in the heatsink.

Using a torque wrench, slowly tighten the recommended fixing

bolts at each end, rotating each in turn no more than 1/4 of a

revolution at a time. Continue until the required torque of 5Nm

(44lb.ins) is reached at both ends.

■ It is not acceptable to fully tighten one fixing bolt before starting

to tighten the others. Such action may DAMAGE the module.

Examples:

MP03 HBP275-16

MP03 HBN275-22

MP03 HBT275-18

ORDERING INSTRUCTIONS

MOUNTING RECOMMENDATIONS

Symbol Parameter Conditions UnitsMax.Typ.

GATE TRIGGER CHARACTERISTICS AND RATINGS

Loading...

Loading...