查询MA5114供应商

MA5114

MA5114

Radiation hard 1024x4 Bit Static RAM

Replaces June 1999 version, DS3591-4.0 DS3591-5.0 January 2000

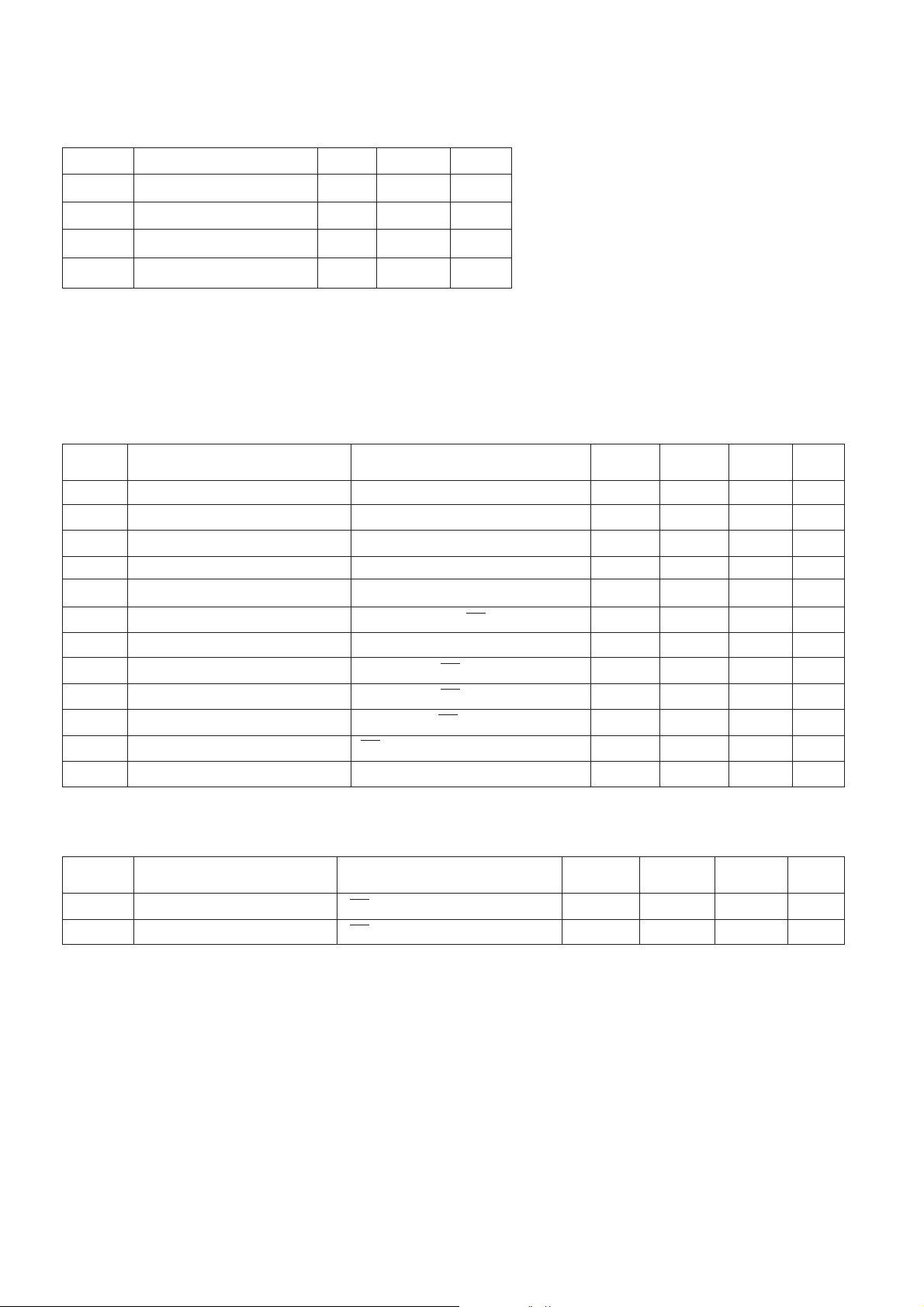

The MA5114 4k Static RAM is configured as 1024 x 4 bits and

manufactured using CMOS-SOS high performance, radiation hard,

3µm technology.

The design uses a 6 transistor cell and has full static operation with

no clock or timing strobe required. Address input buffers are deselected

when Chip Select is in the HIGH state.

Operation Mode CS WE I/O Power

Read L H D OUT ISB1

Write L L D IN

Standby H X High Z ISB2

Figure 1: Truth Table

FEATURES

■ 3µm CMOS-SOS Technology

■ Latch-up Free

■ Fast Access Time 90ns Typical

■ Total Dose 10

■ Transient Upset >10

■ SEU <10

■ Single 5V Supply

■ Three State Output

■ Low Standby Current 50µA Typical

■ -55°C to +125°C Operation

■ All Inputs and Outputs Fully TTL or CMOS

Compatible

■ Fully Static Operation

■ Data Retention at 2V Supply

6

Rad(Si)

-10

Errors/bitday

10

Rad(Si)/sec

Figure 2: Block Diagram

1/12

MA5114

CHARACTERISTICS AND RATINGS

Symbol Parameter Min. Max. Units

V

CC

V

T

A

T

S

Supply Voltage -0.5 7 V

Input Voltage -0.3 VDD+0.3 V

I

Operating Temperature -55 125 °C

Storage Temperature -65 150 °C

Stresses above those listed may cause permanent

damage to the device. This is a stress rating only and

functlonal operation of the device at these condltions,

or at any other condition above those indicated in the

operations section of this specification, is not Implied

Exposure to absolute maxlmum rating conditions for

extended perlods may affect device reliability.

Figure 3: Absolute Maximum Ratings

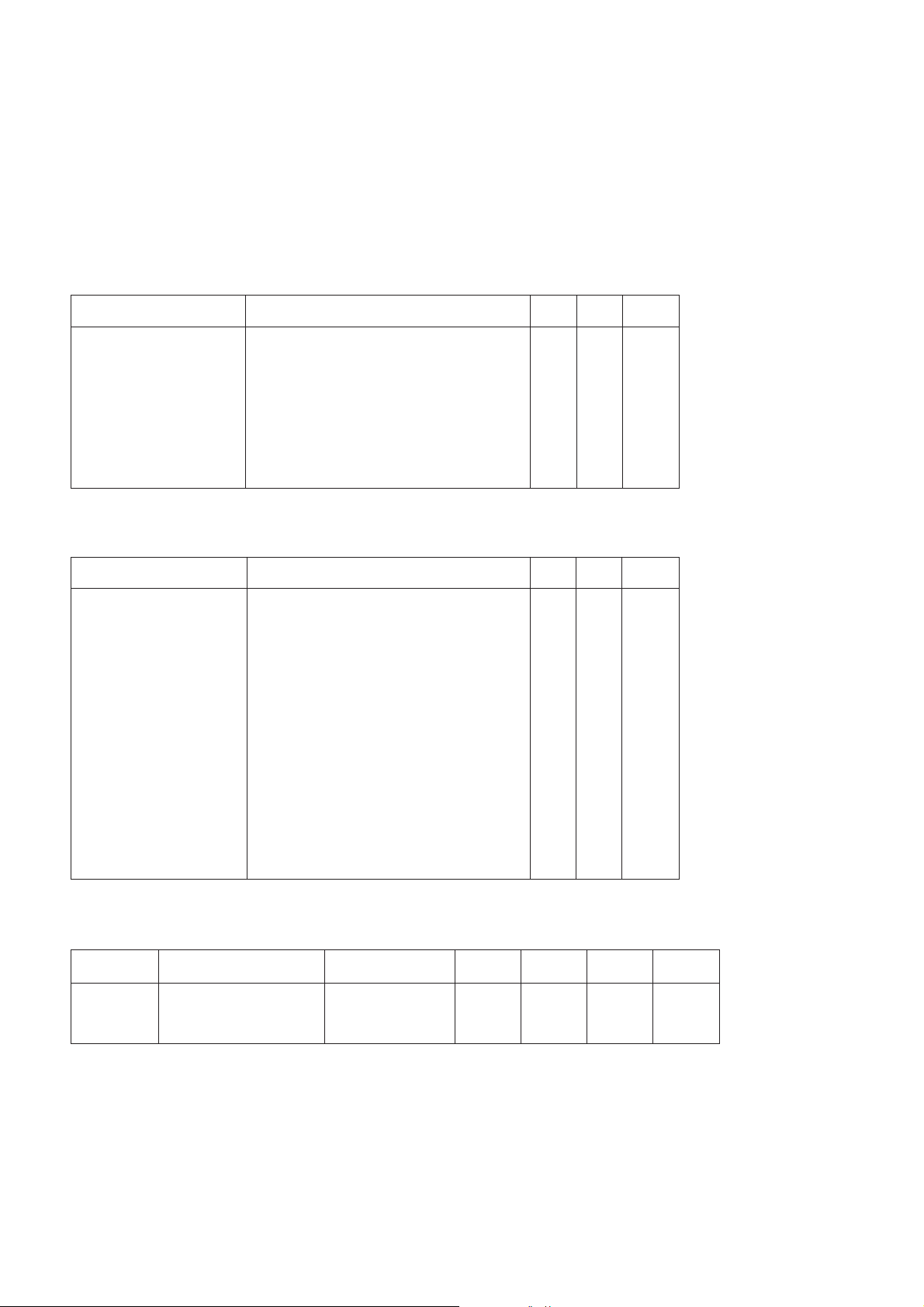

Notes for Tables 4 and 5:

1. Characteristics apply to pre radiation at T

= -55°C to +125°C with VDD = 5V ±10% and to post 100k Rad(Si) total dose

A

radiation at TA = 25°C with VDD = 5V ±10% (characteristics at higher radiation levels available on request).

2. Worst case at TA = +125°C, guaranteed but not tested at TA = -55°C.

GROUP A SUBGROUPS 1, 2, 3.

Symbol Parameter Conditions Min. Typ. Max. Units

V

V

V

V

V

I

I

LO

I

PUI

I

PDI

I

DD

I

SB1

I

SB2

Supply voltage - 4.5 5.0 5.5 V

DD

Input High Voltage - VDD/2 - V

lH

Input Low Voltage - V

lL

Output High Voltage I

OH

Output Low Voltage IOL = 2mA - - 0.4 V

OL

Input Leakage Current (note 2) All inputs except CS --±10 µA

LI

Output Leakage Current (note 2) Output disabled, V

= -1mA 2.4 - - V

OH1

= VSS or V

OUT

DD

SS

--±20 µA

- 0.8 V

Input Pull-Up Current VIN = VSS on CS input only - - -100 µA

Input Leakage Current VIN = VSS on CS input only - - 5 µA

Power Supply Current fRC = 1MHz, CS = 50% mark:space- 12 16 mA

Selected Supply Current CS = V

SS

-2535mA

Standby Supply Current Chip disabled - 50 3000 µA

DD

V

Figure 4: Electrical Characteristics

Symbol Parameter Conditions Min. Typ. Max. Units

V

I

DR

DDR

VCC for Data Retention CS = V

DR

2.0 - - V

Data Retention Current CS = VDR, VDR = 2.0V - 30 2000 µA

Figure 5: Data Retention Characteristics

2/12

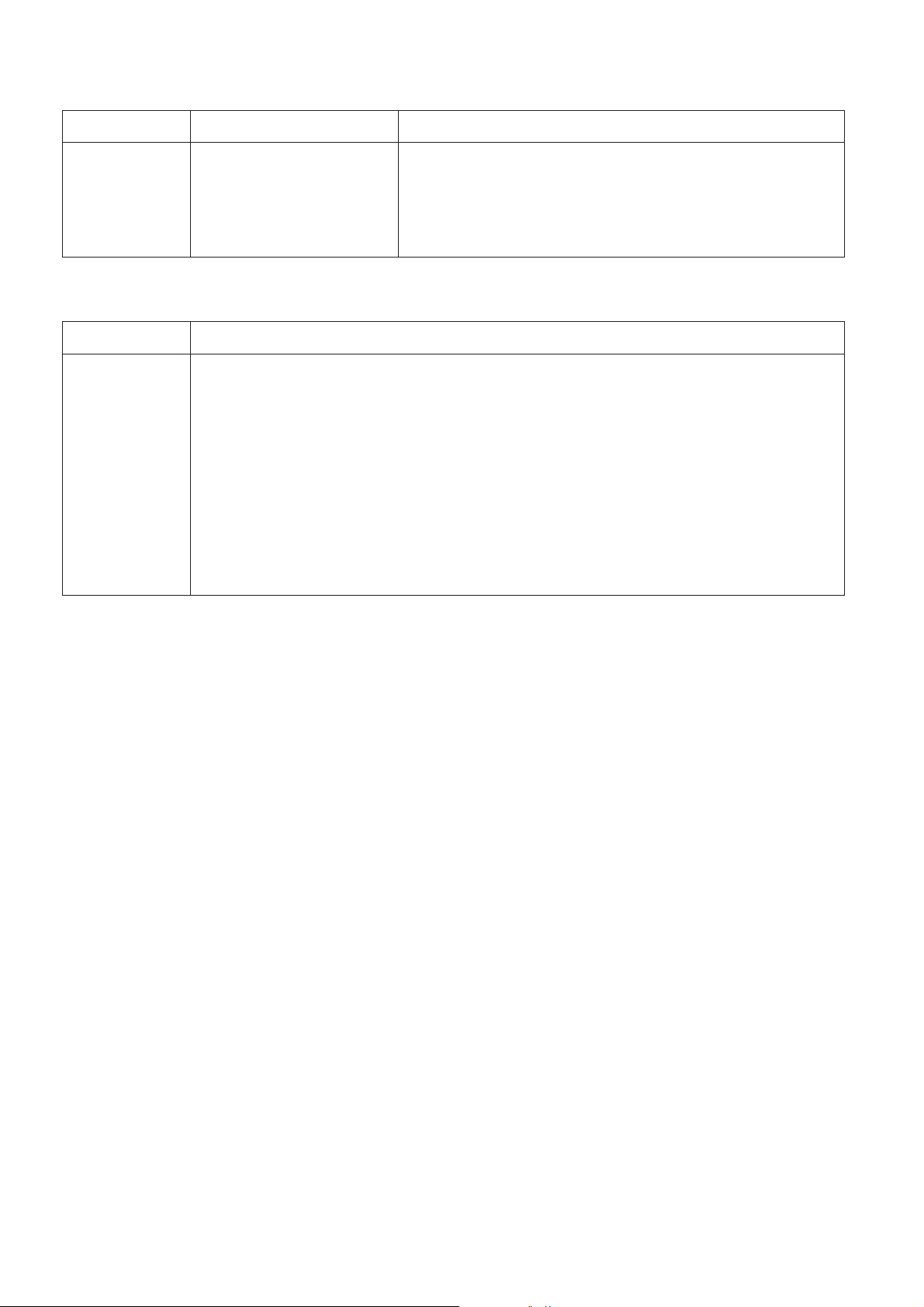

AC CHARACTERISTICS

Conditions of Test for Tables 5 and 6:

1. Input pulse = VSS to 3.0V.

2. Times measurement reference level = 1.5V.

3. Transition is measured at ±500mV from steady state.

4. This parameter is sampled and not 100% tested.

Notes for Tables 6 and 7:

Characteristics apply to pre-radiation at TA = -55°C to +125°C with V

at TA = 25°C with VDD = 5V ±10%. GROUP A SUBGROUPS 9, 10, 11.

Symbol Parameter Min Max Units

MA5114

= 5V±10% and to post 100k Rad(Si) total dose radiation

DD

T

AVAVR

T

AVQV

T

ELQV

T

(3,4) Chip Select to Output Active 10 - ns

ELQX

T

(3,4) Chip Select to Output Tri State 10 50 ns

ELQZ

T

AXQX

Read Cycle Time 135 - ns

Address Access Time - 135 ns

Chip Select to Output Valid - 135 ns

Output Hold from Address Change 10 - ns

Figure 6: Read Cycle AC Electrical Characteristics

Symbol Parameter Min Max Units

T

AVAVW

T

AVWL

T

WLWH

T

WHAV

T

DVWH

T

NHDX

T

(3,4) Write Enable to Output Tri State 10 50 ns

WLQZ

T

ELWL

T

ELWH

T

AVWH

T

(3,4) Output Active from End to Write 5 - ns

WHQX

Write Cycle Tlme 135 - ns

Address Set Up Time 10 - ns

Write Pulse Width 50 - ns

Write Recovery Time 5 - ns

Data Set Up Time 35 - ns

Data Hold Time 5 - ns

Chip Selection to Write Low 25 - ns

Chip Selection to End of Write 85 - ns

Address Valid to End of Write 80 - ns

Figure 7: Write Cycle AC Electrical Characteristics

Symbol Parameter Conditions Min. Typ. Max. Units

C

Note: T

C

IN

OUT

= 25°C and f = 1MHz. Data obtained by characterisation or analysis; not routinely measured.

A

Input Capacitance Vl = 0V - 6 10 pF

Output Capacitance VO = 0V - 8 12 pF

Figure 8: Capacitance

3/12

MA5114

Symbol Parameter Conditions

F

T

Basic Functionality VDD = 4.5V - 5.5V, FREQ = 1MHz

V

= VSS, VIH = VDD, VOL ≤ 1.5V, VOH ≥ 1.5V

IL

TEMP = -55°C to +125°C, GPS PATTERN SET

GROUP A SUBGROUPS 7, 8A, 8B

Figure 9: Functionality

Subgroup Definition

1 Static characteristics specified in Tables 4 and 5 at +25°C

2 Static characteristics specified in Tables 4 and 5 at +125°C

3 Static characteristics specified in Tables 4 and 5 at -55°C

7 Functional characteristics specified in Table 9 at +25°C

8A Functional characteristics specified in Table 9 at +125°C

8B Functional characteristics specified in Table 9 at -55°C

9 Switching characteristics specified in Tables 6 and 7 at +25°C

10 Switching characteristics specified in Tables 6 and 7 at +125°C

11 Switching characteristics specified in Tables 6 and 7 at -55°C

Figure 10: Definition of Subgroups

4/12

TIMING DIAGRAMS

ADDRESS

CS

T

T

ELQX

T

AVAVR

AVQV

T

ELQV

T

AXQX

T

MA5114

EHQZ

DATA OUT

1. WE is high for Read Cycle.

2. Address Vaild prior to or coincident with CS transition low.

HIGH

IMPEDANCE

Figure 11a: Read Cycle 1

T

AVAVR

ADDRESS

T

AVQV

DATA OUT

1. WE is high for Read Cycle.

2. Device is continually selected. CS low.

DATA VALID

T

AXQX

DATA VALID

Figure 11b: Read Cycle 2

5/12

MA5114

ADDRESS

T

AVWL

T

AVWH

T

AVAVW

T

WLWH (2)

T

WHAV (3)

ELWL

(7)

(4)

T

WLQZ

T

DVWH

T

WLQH

T

T

AXQX

WE

DATA OUT

T

HIGH

IMPEDANCE

DATA VALIDDATA IN

T

ELWH

CS

1. WE must be high during all address transitions.

2. A write occurs during the overlap (T

3. T

is measured from either CS or WE going high, whichever is the earlier, to the end of the write cycle.

WHAV

) of a low CS and a low WE.

WLWH

4. If the CS low transition occurs simultaneously with, or after, the WE low transition, the output remains in

the high impedance state.

5. DATA OUT is in the active state, so DATA IN must not be in opposing state.

6. DATA OUT is the write data of the current cycle, if selected.

7. DATA OUT is the read data of the next address, if selected.

8. T

must be met to prevent memory corruption.

ELWL

(5) (6)

WHDX

6/12

Figure 12: Write Cycle

OUTLINES AND PIN ASSIGNMENTS

D

MA5114

19

1810

W

Seating Plane

A

1

A

e b Z

Ref

A - - 5.715 - - 0.225

A1 0.38 - 1.53 0.015 - 0.060

b 0.35 - 0.59 0.014 - 0.023

c 0.20 - 0.36 0.008 - 0.014

D - - 23.11 - - 0.910

e - 2.54 Typ. - - 0.100 Typ. -

e1 - 8.13 Typ. - - 0.300 Typ. -

H 4.44 - 5.38 0.175 - 0.212

Me - - 8.28 - - 0.326

Z - - 1.27 - - 0.050

W - - 1.53 - - 0.060

Min. Nom. Max. Min. Nom. Max.

Millimetres Inches

XG406

M

E

A6

A5

A4

A3

A0

A1

A2

CS

Vss

C

e

1

1

2

3

4

5

6

7

8

9

Top

View

18 Vdd

17 A7

A8

16

15 A9

14 D1

D2

13

12 D3

11 D4

10

WE

H

15°

Figure 13: 18-Lead Ceramic DIL (Solder Seal) - Package Style C

7/12

MA5114

D

M

b

Z

e

L

A

c

M

E

A1

Pin 1

Ref

A - - 3.07 - - 0.121

A1 0.66 - - 0.026 - -

b 0.38 - 0.48 0.015 - 0.019

c 0.08 - 0.152 0.003 - 0.006

D 14.99 - 15.50 0.590 - 0.610

e - 2.54 - - 0.050 L 6.73 - 7.75 0.265 - 0.305

M 9.96 - 10.36 0.392 - 0.408

Me 7.6 - - 0.30 - -

Z 0.13 - 1.14 0.005 - 0.045

Millimetres Inches

Min. Nom. Max. Min. Nom. Max.

XG544

24Vdd

23A7

22A8

21A9

20NC

19NC

18D1

Bottom

View

17D2

16D3

15D4

14NC

13

WE

1NC

2A6

3A5

4A4

5A3

6NC

7A0

8A1

9A2

10 NC

11

CS

12 Vss

8/12

Figure 14: 24-Lead Ceramic Flatpack (Solder Seal) - Package Style F

D A

3

C

C

C

MA5114

Pad 1

Radius r

3 corners

Ref

e b

Bottom

View

Millimetres Inches

Min. Nom. Max. Min. Nom. Max.

1

A5

A6

E

N

Vdd

A7

A8

A - - 2.16 - - 0.096

b1 - 0.51 - - 0.020 -

D 8.76 - 9.14 0.345 - 0.360

E 8.76 - 9.14 0.345 - 0.360

e - 1.02 - - 0.040 -

r - 0.19 - - 0.0075 -

XG470

A4

A3

NCA0A1

2

1

24

23

22

A9

Bottom

View

NC

NC

D1

D2

A2

987654

10

N

11

CS

Vss

12

13

WE

14

N

15

161718192021

D4

D3

Figure 15: 24-Pad Leadless Chip Carrier - Package Style L

9/12

MA5114

Package Option Burnin

Function F C L Via Static 1 Static 2 Dynamic Radiation

A6 2 1 2 R 0V 5V F6 5V

A5 3 2 3 R 0V 5V F5 5V

A4 4 3 4 R 0V 5V F4 5V

A3 5 4 5 R 0V 5V F3 5V

A0 7 5 7 R 0V 5V F0 5V

A1 8 6 8 R 0V 5V F1 5V

A2 9 7 9 R 0V 5V F2 5V

NC S 11 8 11 R 0V 5V 0V 5V

VSS 12 9 12 Direct 0V 0V 0V 0V

NW E 13 10 13 R 0V 5V 5V 5V

D4 15 11 15 R 0V 5V LOAD 5V

D3 16 12 16 R 0V 5V LOAD 5V

D2 17 13 17 R 0V 5V LOAD 5V

D1 18 14 18 R 0V 5V LOAD 5V

A9 21 15 21 R 0V 5V F9 5V

A8 22 16 22 R 0V 5V F8 5V

A7 23 17 23 R 0V 5V F7 5V

VDD 24 18 24 Direct 5V 5V 5V 5V

1. F0=150KHz, F1=F0/2, F2=F0/4, F3=F0/8 etc.

2. Burnin R=1k

3. Radiation R=10k

Figure 16: Burnin and Radiation Configuration

10/12

MA5114

RADIATION TOLERANCE

Total Dose Radiation Testing

For product procured to guaranteed total dose radiation

levels, each wafer lot will be approved when all sample

devices from each lot pass the total dose radiation test.

The sample devices will be subjected to the total dose

radiation level (Cobalt-60 Source), defined by the ordering

code, and must continue to meet the electrical parameters

specified in the data sheet. Electrical tests, pre and post

irradiation, will be read and recorded.

GEC Plessey Semiconductors can provide radiation

testing compliant with MIL-STD-883 test method 1019,

Ionizing Radiation (Total Dose).

SINGLE EVENT UPSET CHARACTERISTICS

Total Dose (Function to specification)* 1x105 Rad(Si)

Transient Upset (Stored data loss) 5x10

10

Rad(Si)/sec

Transient Upset (Survivability) >1x1012 Rad(Si)/sec

Neutron Hardness (Function to specification) >1x1015 n/cm

2

Single Event Upset** 3.4x10-9 Errors/bit day

Latch Up Not possible

* Other total dose radiation levels available on request

** Worst case galactic cosmic ray upset - interplanetary/high altitude orbit

Figure 17: Radiation Hardness Parameters

UPSET BIT

CROSS-SECTION

(cm2/bit)

Ion LET (MeV.cm2/mg)

Figure 18: Typical Per-Bit Upset Cross-Section vs Ion LET

11/12

MA5114

ORDERING INFORMATION

Unique Circuit Designator

Radiation Tolerance

Radiation Hard Processing

S

30 kRads (Si) Guaranteed

L

50 kRads (Si) Guaranteed

C

100 kRads (Si) Guaranteed

R

MAx5114xxxxx

Package Type

C

Ceramic DIL (Solder Seal)

F

Flatpack (Solder Seal)

L

Leadless Chip Carrier

For details of reliability, QA/QC, test and assembly

options, see ‘Manufacturing Capability and Quality

Assurance Standards’ Section 9.

QA/QCI Process

(See Section 9 Part 4)

Test Process

(See Section 9 Part 3)

Assembly Process

(See Section 9 Part 2)

Reliability Level

Rel 0

L

Rel 1

C

Rel 2

D

Rel 3/4/5/STACK

E

Class B

B

Class S

S

http://www.dynexsemi.com

e-mail: power_solutions@dynexsemi.com

HEADQUARTERS OPERATIONS

DYNEX SEMICONDUCTOR LTD

Doddington Road, Lincoln.

Lincolnshire. LN6 3LF. United Kingdom.

Tel: 00-44-(0)1522-500500

Fax: 00-44-(0)1522-500550

DYNEX POWER INC.

Unit 7 - 58 Antares Drive,

Nepean, Ontario, Canada K2E 7W6.

Tel: 613.723.7035

Fax: 613.723.1518

Toll Free: 1.888.33.DYNEX (39639)

Datasheet Annotations:

Dynex Semiconductor annotate datasheets in the top right hard corner of the front page, to indicate product status. The annotations are as follows:-

Target Information: This is the most tentative form of information and represents a very preliminary specification. No actual design work on the product has been started.

Preliminary Information: The product is in design and development. The datasheet represents the product as it is understood but details may change.

Advance Information: The product design is complete and final characterisation for volume production is well in hand.

No Annotation: The product parameters are fixed and the product is available to datasheet specification.

This publication is issued to provide information only which (unless agreed by the Company in writing) may not be used, applied or reproduced for any purpose nor form part of any order or contract nor to be regarded

as a representation relating to the products or services concerned. No warranty or guarantee express or implied is made regarding the capability, performance or suitability of any product or service. The Company

reserves the right to alter without prior notice the specification, design or price of any product or service. Information concerning possible methods of use is provided as a guide only and does not constitute any

guarantee that such methods of use will be satisfactory in a specific piece of equipment. It is the user's responsibility to fully determine the performance and suitability of any equipment using such information and

to ensure that any publication or data used is up to date and has not been superseded. These products are not suitable for use in any medical products whose failure to perform may result in significant injury

or death to the user. All products and materials are sold and services provided subject to the Company's conditions of sale, which are available on request.

All brand names and product names used in this publication are trademarks, registered trademarks or trade names of their respective owners.

CUSTOMER SERVICE CENTRES

France, Benelux, Italy and Spain Tel: +33 (0)1 69 18 90 00. Fax: +33 (0)1 64 46 54 50

North America Tel: 011-800-5554-5554. Fax: 011-800-5444-5444

UK, Germany, Scandinavia & Rest Of World Tel: +44 (0)1522 500500. Fax: +44 (0)1522 500020

SALES OFFICES

France, Benelux, Italy and Spain Tel: +33 (0)1 69 18 90 00. Fax: +33 (0)1 64 46 54 50

Germany Tel: 07351 827723

North America Tel: (613) 723-7035. Fax: (613) 723-1518. Toll Free: 1.888.33.DYNEX (39639) /

Tel: (831) 440-1988. Fax: (831) 440-1989 / Tel: (949) 733-3005. Fax: (949) 733-2986.

UK, Germany, Scandinavia & Rest Of World Tel: +44 (0)1522 500500. Fax: +44 (0)1522 500020

These offices are supported by Representatives and Distributors in many countries world-wide.

© Dynex Semiconductor 2000 Publication No. DS3581-5 Issue No. 5.0 January 2000

TECHNICAL DOCUMENTATION – NOT FOR RESALE. PRINTED IN UNITED KINGDOM

12/12

Loading...

Loading...