Page 1

5450 NW 33rd Ave, Suite 104

Fort Lauderdale, FL 33309

3211 Fruitland Ave

Los Angeles, CA 90058

UM-600

6-Channel Monitor

Version 2

Installation and Operation Manual

Rev. G

P/N145F-12990

PCO – 00007462

(c) Copyright 2014, Dynalco Controls

All Rights Reserved

Published: April 22, 2014

Page 2

IMPORTANT - PLEASE READ BEFORE PROCEEDING!

This manual applies to all Version2 UM-600 Monitors.

The Dynalco model UM-600 is designed for reliable and rugged operation on engines,

turbines, pumps, compressors and other machinery for accurate process

measurement and protection. This product has been designed and tested to meet the

demands required in many industrial and hazardous locations meeting critical CSA

standards. The performance is directly related to the quality of the installation and

knowledge of the user in operating and maintaining the instrument. To ensure

continued operation to the design specifications, personnel should read this manual

thoroughly before proceeding with installation, operation and maintenance of this

instrument. If this product is used in a manner not specified by Dynalco, the protection

provided by it against hazards may be impaired.

WARNING

•

Failure to follow proper instructions may cause any one of the following

situations to occur: Loss of life; personal injury; property damage; damage to

this instrument; and warranty invalidation.

•

For clarification of instructions in this manual or assistance with your

application, contact Dynalco at (800) 368-6666 or (954) 739-4300 or send email to

customerservice@dynalco.com

•

Additional manuals and CSA certificates are available at www.dynalco.com

•

Follow all warnings, cautions, and instructions marked on and supplied with the

product.

•

Use only qualified personnel to install, operate, program and maintain the

product.

•

Educate your personnel in the proper installation, operation, and maintenance of

the product.

•

Install equipment as specified in the installation section of this manual. Follow

appropriate local and national codes. Only connect the product to power

sources and end devices specified in this manual.

•

Any repair is only to be performed by Dynalco using factory documented

components. Tampering or unauthorized substitution of parts and procedures

can affect the performance and cause unsafe operation of your process.

•

All equipment doors must be closed and protective covers must be in place

unless qualified personnel are performing maintenance.

•

Shutdown / alarms should be tested monthly for proper operation (see page 14)

•

Please see page 22 for CSA specific installation instructions.

1

Page 3

System Overview

The Dynalco model UM-600 is a universal monitor capable of reading up to 6 input channels,

calculating differential values, providing alarm / shutdown outputs as well as allowing all

parameters to be logged to an internal flash memory. An RS-485 Modbus link for

communications to a DCS or PLC is also provided.

Basic operation:

The UM-600 will be in “stopped” mode until a run indication is sensed. This is selectable as

either a contact closure or magnetic pickup input. Once “running” mode is sensed, the UM600 will read all inputs at a rate of 100 msec per channel. If any input crosses either an over

or under threshold, the unit will invoke a flashing red LED on the front panel as well as an

output trip (solid-state relay) that can be used for alarm or shutdown. Any trips will also cause

the UM-600 to date / time stamp whenever a trip threshold is crossed. The monitor will log

the last (10) alarm events for each channel input. These may be viewed on the front display.

Data Logging:

The UM-600 also allows data logging of any monitored values where they will be saved to an

internal flash memory. Memory is sufficient to hold up to 500,000 data values with date / time

stamp. When the UM-600 receives an engine run signal (either contact closure or mag pickup

signal) the unit begins monitoring all enabled inputs. Following that, the monitor will begin

logging data as configured. The logged data is temporarily saved to RAM memory which

holds 56 logged values. The logged values remain in RAM until any of (3) events occur:

1) The RAM is full.

2) The monitor receives an engine stop signal.

3) The user initiates a “Stop Logging” command.

Following any of the above events, the data in RAM is transferred to the non-volatile flash

memory. These values can be downloaded at any time to a PC using Dynalco’s download

cable and Log Reader software.

IMPORTANT - Input Power Requirements:

It is important that the input supply power be a reliable source with battery backup if needed.

If input power is interrupted or disconnected while the monitor is logging data, any data that

has not yet been stored to flash memory may be lost. This manual contains information on

page 14 that describes the steps required to safely disconnect power without risk of losing

data.

2

Page 4

Additional Features

• 5 - Digit Hourmeter Function (non-resettable)

• Engine RPM Display

• Fully programmable from front keypad

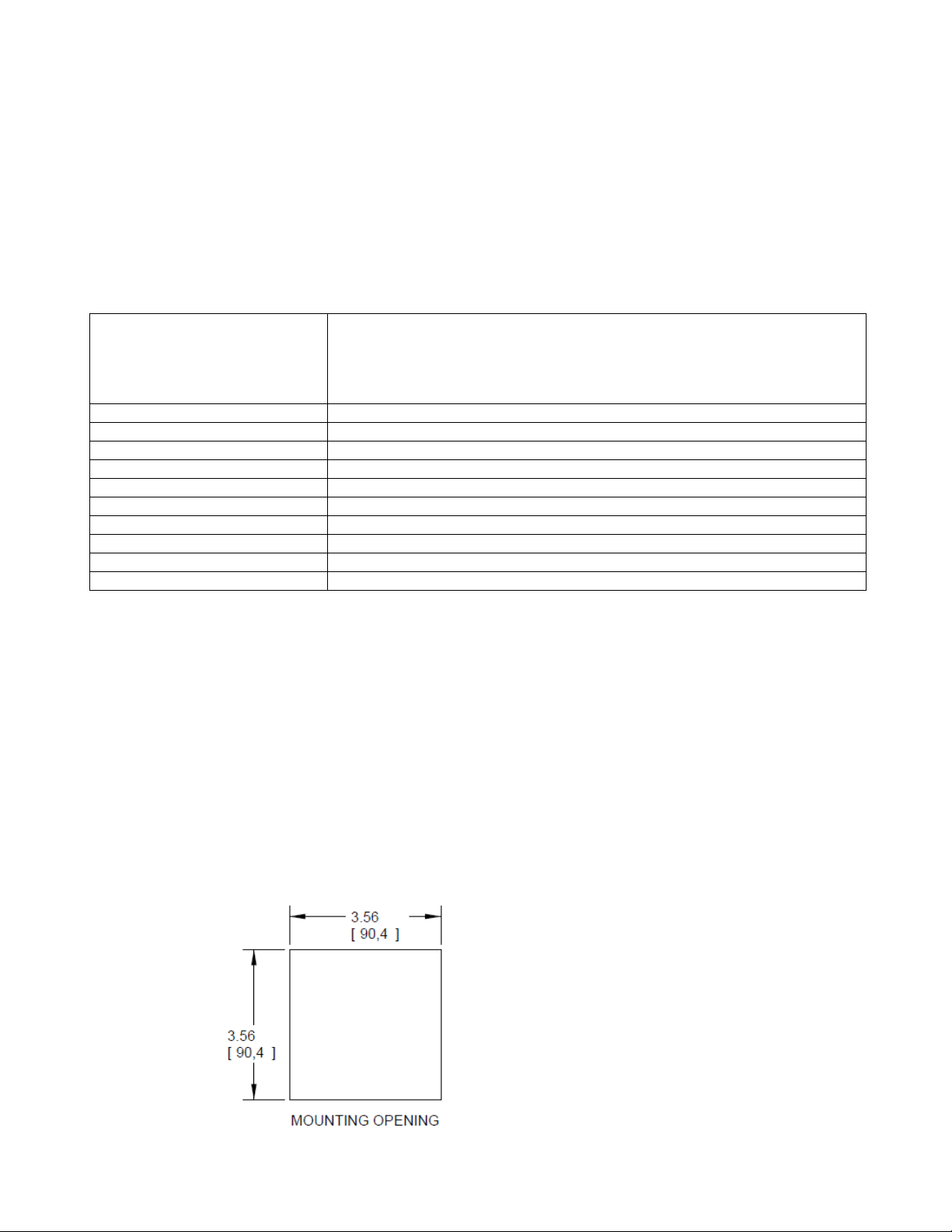

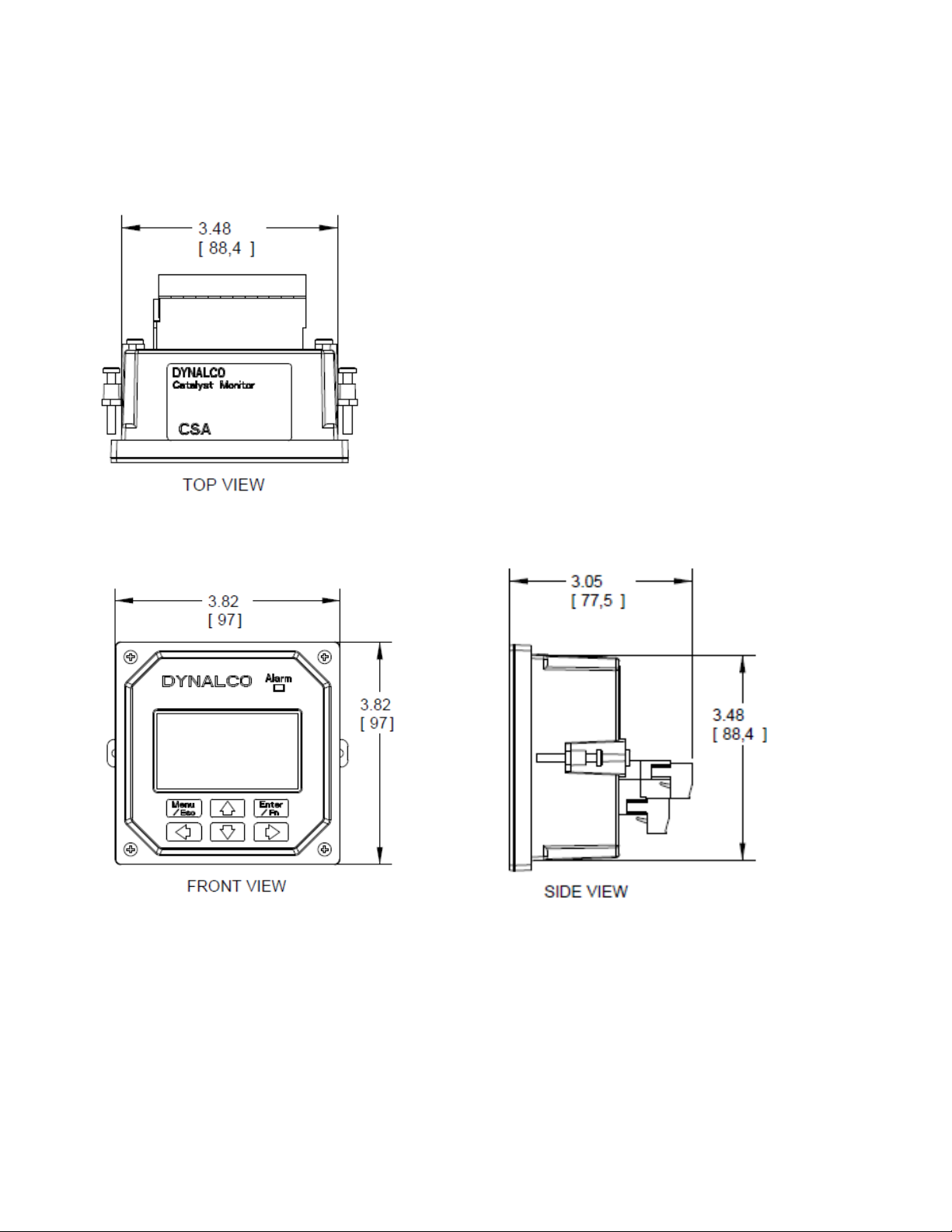

• ¼ DIN package (3 ½” width X 3 ½” height) for panel mount

Specifications

Input Types J or K type thermocouple (ungrounded)

4 - 20 mA

0 – 1 VDC

0 - 5 VDC

0 – 10 VDC

Digital Input Closure to ground indicates run condition (or use pulsed input)

Pulsed Input Magnetic pickup input for RPM display & to indicate run condition

Alarm Outputs 2 Digital Outputs rated @ 0.15 A / 48 VDC

Input Power 10 – 36 VDC

Display Backlit Graphic Display

Data Logging Internal Flash Memory to retain data logged values w/ date & time stamp

Communications Modbus

Connections Two-Part Terminal Blocks

Operating Temperature Range - 40 to + 70 Deg C

Certification CSA Class I, Division 2, Groups A, B, C, D

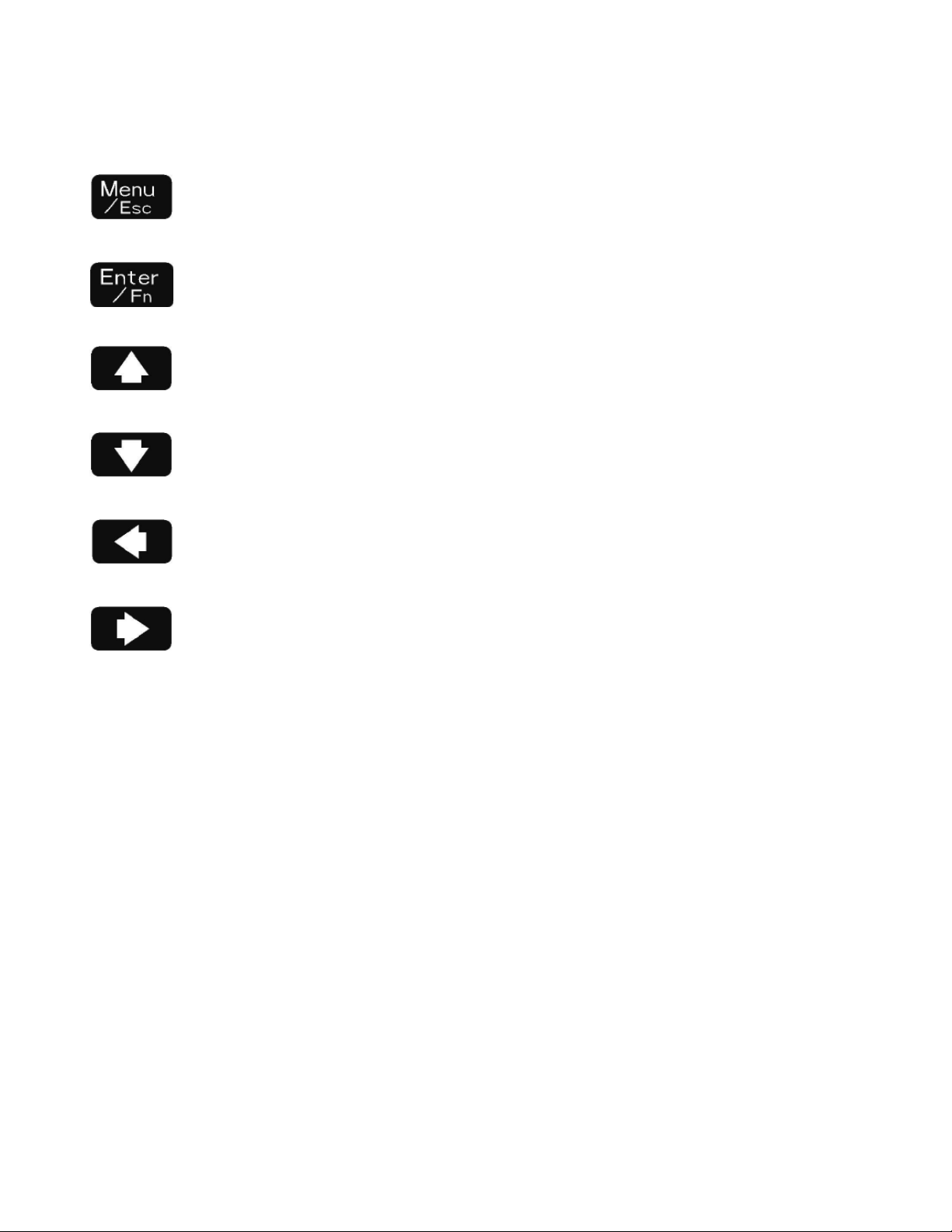

User Interface

The UM-600 is configured via the keypad on the front panel which includes a graphical backlit

LCD display capable of displaying alpha numeric values and custom engineering units of

measure. The keypad implements a menu system, which is navigated using the up, down,

left, right, enter and escape buttons. The backlight will turn off after ten minutes of inactivity

and will turn on when any of the keys are pressed.

Installation:

The UM-600 monitor is a standard ¼ DIN package, designed to be panel mounted. The

cutout dimensions are shown below.

3

Page 5

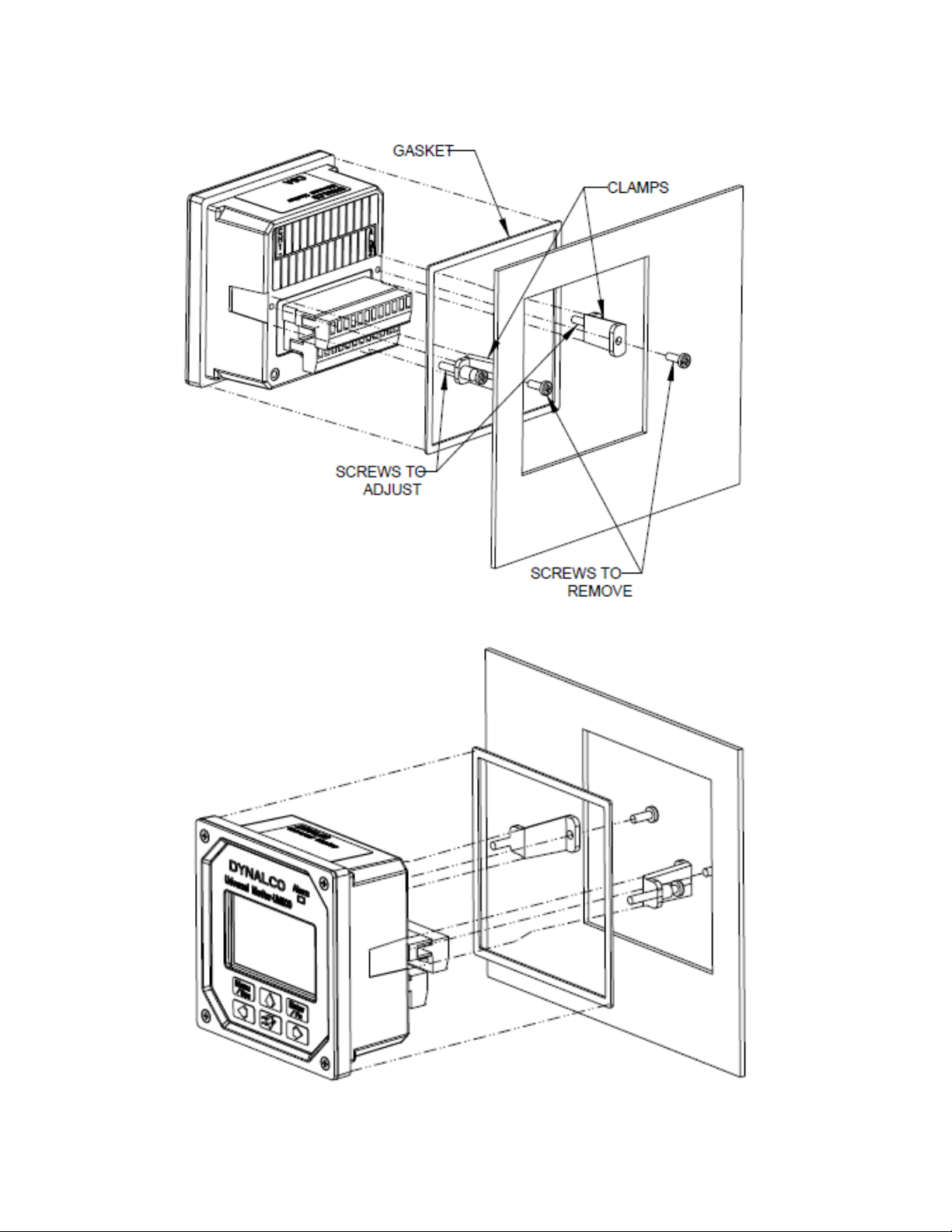

The UM-600 has integral mounting clips for securing into the panel. The following drawings

illustrate the mounting procedure.

4

Page 6

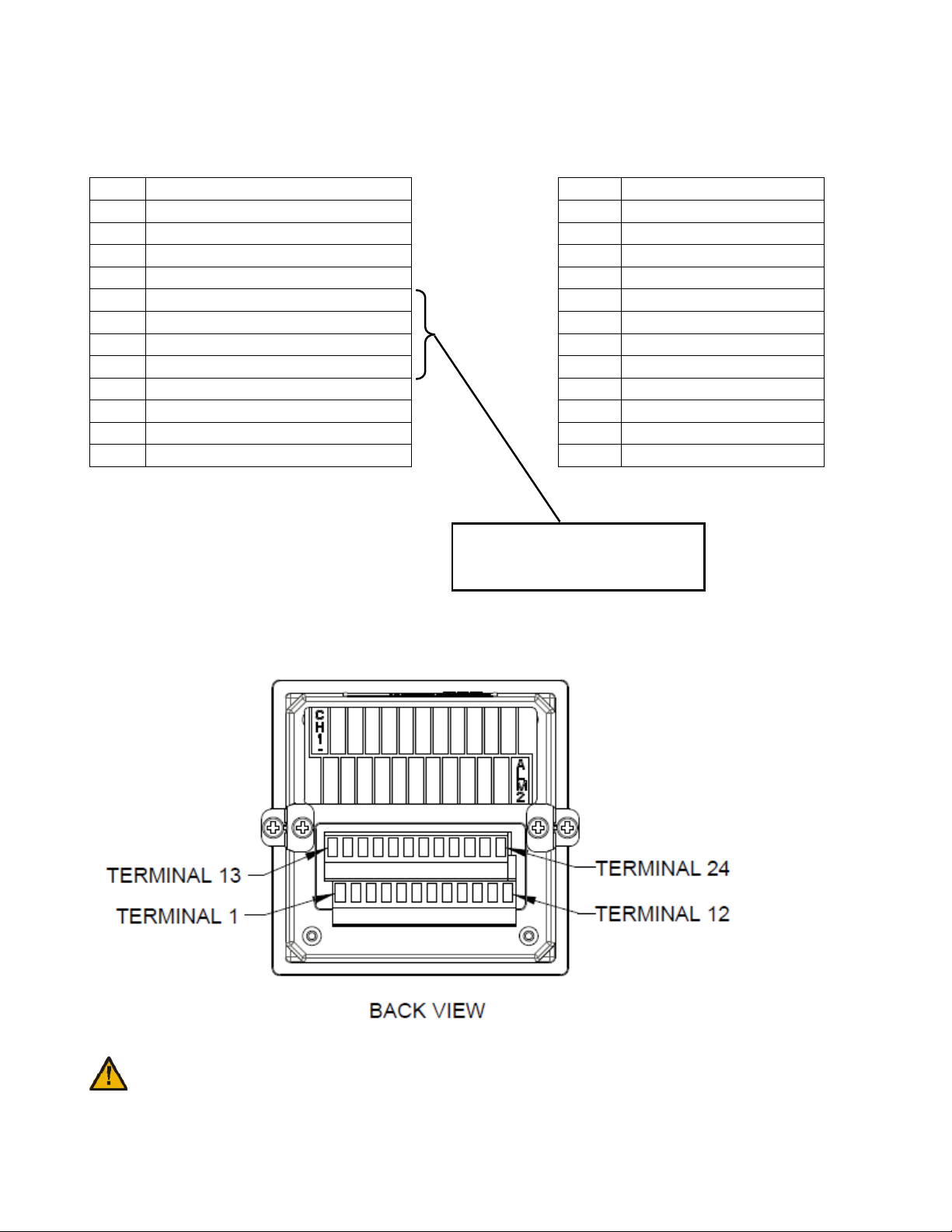

Terminal Connections

PIN

Description

PIN

Description

All connections are made via the removable connectors on the back of the unit.

1 GND (Power Gnd) 13 Channel 1 (-)

2 VIN (10 – 36 VDC input) 14 Channel 1 (+)

3 GND (mag pickup input) 15 Channel 2 (-)

4 RPM + (mag pickup input) 16 Channel 2 (+)

5 Receive Data (-) 17 Channel 3 (-)

6 Receive Data (+) 18 Channel 3 (+)

7 Transmit Data (-) 19 Channel 4 (-)

8 Transmit Data (+) 20 Channel 4 (+)

9 Alarm 1 21 Channel 5 (-)

10 Alarm 1 22 Channel 5 (+)

11 Alarm 2 23 Channel 6 (-)

12 Alarm 2 24 Channel 6 (+)

Also used for USB download

cable assembly p/n 270A-13020

(see page 15)

See page 21 for complete wiring information.

Terminal screws to be tightened to 4 inch-pounds torque.

5

Page 7

Outline Dimensions

6

Page 8

Programming Overview

All programming is accomplished through the front keypad. Below is a brief description of

each key.

Press to enter or exit the configuration screens

Press to enter or accept values

Select up

Select down

Go back one screen

Select and advance to next screen

Configuration consists of the following steps:

1) Setting current date / time

2) Enabling each input

3) Defining each input type

4) Defining min. & max. display values for any current or voltage inputs

5) Defining measurement display units (PSI, mV, F, C, H20, etc)

6) Setting over / under setpoint trips

7) Selecting either output 1 or output 2 (or both) for alarm trips

8) Setting either latching or non-latching for output trips

9) Defining data logging events

7

Page 9

Programming Instructions

Important: The UM-600 universal monitor must first be programmed prior to operation.

When first powering up the unit, the display will first indicate the firmware version and then go

to the operational mode. It may also display a screen warning that the time & date need to be

entered. This will be explained below.

To configure the UM-600 Monitor, first go to the main programming screen by pressing the

Menu / Escape key:

The following menu icons will appear from left to right:

Run Signal - defines run status input type (if any)

Channel - enables each channel type and alarm thresholds

Calibration - defines zero & span values for DCV & mA inputs

Alarm Settings - for setting high /low alarm thresholds

Alarm Logs - allows the user to view alarm status

Communication - Log Reader / Modbus setup

Data Logging - allows configuration of up to (10) different logging events

System - allows display customization & current date / time input

8

Page 10

A description of each menu item follows:

“Run Signal”

There are (3) run types available. The definitions are as follows:

None: No run indication required. Monitoring is always active.

RPM: Monitoring is active when signal received from magnetic pickup.

Digital: Monitoring is active when contact closure (connection to ground) is sensed.

To select run signal type, use the up / down arrows to select, then press the right arrow to

accept and advance to the next screen.

If “None” is selected, there is no other action required other than to select “escape.” After

selecting escape, you will be asked to select “yes” to save.

If “RPM” is selected, you will need to set the # gear teeth, RPM threshold and startup delay.

The RPM threshold is the speed above which monitoring will be active. The startup delay can

be configured to delay monitoring if desired, allowing time for all inputs to be at normal levels.

If no delay is required, set to 0 seconds. The magnetic pickup input terminals are indicated on

page 5.

If “Digital” is selected, you will only need to set the startup delay (if applicable). In this mode,

a run signal will be sensed with a contact closure (or short) between the magnetic pickup

input terminals indicated on page 5.

Pressing at any time during configuration will prompt you to save the changes.

Select “Yes” to save any changes made. Selecting “No” will not save changes.

“Channel”

Select the channel number to configure by pressing the up / down arrows, then pressing the

right arrow to navigate and select the following:

Enable Channel Yes / No

Channel Type 0-1 V, 0-5 V, 0-10 V, 4-20 mA, J Type, K Type

Description name input with up to 20 characters

Engineering Units up to 3 characters, for example: PSI, mV, F, C etc…

Note: For thermocouple inputs, you must enter either “F” or “C”

Differential calculations between channels 1&2, 3&4, 5&6 are also enabled by selecting the

“Channel” icon. Enable “Differential 1” for channels 1&2, “Differential 2” for channels 3&4 and

“Differential 3” for channels 5&6.

9

Page 11

10

”Calibration”

Select the channel number to configure by pressing the up / down arrows and

pressing the right arrow to select and continue.

The screens allow you to define the “Cal Zero” and “Cal Span” values for any channels that

are configured for 0-1 V, 0-5 V, 0-10 V or 4-20 mA inputs.

Example

A pressure transmitter is connected to channel # 1. The transmitter has a 4-20 mA

output representing a pressure input of 0 - 500 PSI. The “Cal Zero” and “Cal Span”

values would be defined as:

Cal Zero = 0

Cal Span = 500

Note that the “Engineering Units” would be input as PSI in “Channel” configuration

above.

“Alarm Settings”

Select the channel number to configure by pressing the up / down arrows, then pressing the

right arrow to navigate and select the following:

Enable alarms Yes / No

Alarm Type Latching / Non-Latching

Alarm Output None / Output 1 / Output 2 / Output 1 and 2

Alarm Low threshold for under-trip

Alarm High threshold for over-trip

Alarm Reset Points Set Defaults / Set Manually

If “Set Manually” is selected, 2 more screens follow:

Alarm Reset Low manually set reset hysteresis for low trip

Alarm Reset High manually set reset hysteresis for high trip

“Alarm Logs”

Selecting the “Alarm Logs” icon will allow you to view any active alarms as well as the history

log for each channel. Select any channel number by pressing the up / down arrows. Then

press the right arrow to view any active or logged alarms. Once an active alarm is

acknowledged, it will be placed into the history log. The history log will continuously store the

last 10 alarms for each channel as well as the time & date of each alarm occurrence.

“Communication”

This allows configuration for downloading data and Modbus communications.

Page 12

11

”Data Logging”

The UM-600 can be configured to log any of the parameters being monitored, at user defined

time intervals. The values are saved to an internal flash memory with sufficient memory to

hold up to 500,000 data values with date / time stamps. These values can be downloaded at

any time to a PC using Dynalco’s “Log Reader” software.

The logging of any parameter is configured as an event. The UM-600 will allow up to (10)

individual events to be defined.

Example # 1:

To configure data logging of an input value every 5 minutes:

Using the arrows on the keypad, select the “Data Logging” icon.

Next, select “Setup Log Events” and press the arrow.

The next screen will display a list of (10) events that can be configured. If this is the first event

to be programmed, select “Event 1” and press the arrow.

Next select “Enable” and press the arrow.

The next screen allows you to define an “On” condition. In most cases this will not be needed

since the “On” condition is normally defined by an “engine run” signal. See above (page 9) for

the procedure for configuring the “run” signal. In this example, select “No” and press the

arrow.

The next screen named “Input To Log” allows the user to select which parameter to log.

Using the up / down arrows, select the input channel that is to be logged. Press arrow.

The next screen named “Log Frequency” allows the configuration of how often (in minutes)

the value is to be logged. Press enter and edit for 5 minutes. Selecting escape will return

to the “Log Frequency” screen. Press the arrow and then select “Yes” to save the

changes. Pressing the escape key two times will escape to the normal monitoring mode.

Page 13

12

Example # 2:

To configure data logging of an input value following engine warm up:

(Note that this configuration will require an input signal from a magnetic pickup to indicate

engine running.)

Using the arrows on the keypad, select the “Data Logging” icon.

Next, select “Setup Log Events” and press the arrow.

The next screen will display a list of (10) events that can be configured. If this is the second

event to be programmed, select “Event 2” and press the arrow.

Next select “Enable” and press the arrow.

The next screen allows you to define an “On” condition. The configuration for logging this

value will require an “On” condition defined by an “engine run” signal. See above (page 9) for

the procedure for configuring the “run” signal. In this case, select “Yes” and press the

arrow.

Select “Edit Compare” on the next screen and press the arrow.

Select “Compare 1” on the next screen and press the arrow.

Select “RPM” on the next screen and press the arrow.

Select “Greater Than” on the next screen and press the arrow.

Select “A Value” on the next screen and press the arrow.

On the following screen, select an RPM value that will indicate engine running. This value

should be lower than the normal engine running speed and higher than the RPM defined as

the “run” signal in page 9.

The next screen will ask if you want to “Edit Another?” Select “no” and press the arrow.

Press the arrow (3) more times until the screen appears as “Enter ON Delay.” Enter this

number as the time delay (in seconds) following engine start when you would like to log the

input value. The maximum value configurable is 3600 seconds (60 minutes.) After entering

the time delay, press arrow.

The next screen allows you to define an “Off” condition. In this case, select “No” and press

the arrow.

The next screen named “Input To Log” allows the user to select which parameter to log.

Using the up / down arrows, select the input to log and press arrow.

The next screen named “Log Frequency” allows the configuration of how often (in minutes)

the value is to be logged. Entering 0 minutes will allow only (1) data log event following the

Page 14

13

start delay. If you wanted to continuously log the value, you would select the frequency in

minutes between data logs. Selecting escape will return to the “Log Frequency” screen.

Press the arrow and then select “Yes” to save the changes.

Pressing the escape key two times will escape to the normal monitoring mode.

“System”

“Display defaults” allows the selection of either single channel (absolute) or differential value

display. Note that regardless of this setting, pressing the right or left arrow during normal

operation will display the alternate display type.

“Digital output” allows the configuration of the solid state relay alarm outputs as either

“Normally Open” or “Normally Closed”

“Set date and time” is self-explanatory but is important for proper date / time stamps for both

alarm logs and data logging.

IMPORTANT NOTICE REGARDING CORRECT DATE / TIME SETTING:

The correct date / time is imperative for proper data logging.

Please note that the date and time may need to be re-programmed if the UM-600 Monitor

loses input power for over 1 week. This will be indicated by a warning upon powering up the

unit.

Note that only the date / time may be affected by extended loss of power. Any data logged to

the internal flash memory will be held indefinitely.

Page 15

14

Alarm Outputs

The UM-600 will alarm when channel values or differential values are above or below limits

as specified. Alarms can be configured as either latching or non-latching. If an alarm

condition is met, the red LED on the front panel will blink and the digital output(s) will trip. The

alarm point name (ch1, ch2, df1, df2) that caused the alarm will be stored in memory with

date/time stamp info. Non-latching alarms will reset the alarm if its value returns to normal.

Latching alarms require manual resetting via the front keypad.

WARNING:

The alarm / shutdown output should be tested monthly for proper operation, especially

if being used for engine overspeed shutdown or other critical function.

IMPORTANT NOTICE REGARDING POWER INTERRUPTION:

If input power to the UM-600 Monitor is disconnected or lost during a data log operation,

there is the possibility of losing data (see page 2).

To prevent this, it is important to turn off the data logging prior to power disconnect. This is

accomplished through the “Data Logging” icon on the main menu. When this is selected, the

first screen will allow you to select “Stop Logging.” Pressing the

arrow will provide

instructions for a safe power down.

The data logging will be enabled automatically when power is re-applied.

Page 16

15

Downloading logged values to PC:

The hardware connection from the UM-600 Monitor to a PC is via a USB cable assembly,

Dynalco p/n 270A-13020. The 6 ft cable length allows easy connection via a 4 pin Phoenix

plug to the lower connector (terminals 5, 6, 7, 8) on the back of the UM-600 Monitor. When

initially plugging the download cable into the PC’s USB port, the new device should be

recognized and the driver installed automatically.

Please call (954) 739-4300 if the driver is not installed properly or assistance is required.

The Dynalco host software “LogReader” is available as a free download from our website:

www.dynalco.com/downloads

There are (2) versions available:

LogReader Ver. 1 Use for Version 1 UM-600

LogReader ver. 2 Use for Version 2 UM-600

Following installation, you may click on the icon to open the application. This software will

allow date selectable log values to be downloaded to an excel spread sheet on the PC.

Page 17

16

Modbus Communication

PIN

Description

The unit also provides access to the internal registered values using the Modbus Protocol.

The diagram below shows the recommended connections to the removable connectors on

the back of the unit for either half-duplex or full-duplex (RS485).

Wiring is as follows:

5 TD(A) **

6 TD(B) **

7 Jumper to PIN 5

8 Jumper to PIN 6

** A 120 ohm termination resistor may need to be installed across pins 5 & 6.

Page 18

17

Modbus Address Registers:

Modicon

Modbus

Description

Min Value

Max

Data type

300001

0

Status Register, 0=not running,

0 1 16 bit signed integer

300002

1

Reserved

-32768

32768

16 bit signed integer

300003

2

Alarms

Bit mask

Bit 0

- Channel 1 Alarm

0 1

0001h

Bit 1

- Channel 2 Alarm

0 1

0002h

Bit 2

- Channel 3 Alarm

0 1

0004h

Bit 3

- Channel 4 Alarm

0 1

0008h

Bit 4

- Channel 5 Alarm

0 1

0010h

Bit 5

- Channel 6 Alarm

0 1

0020h

Bit 6

- Channel 1

-

2 Differential

0 1 0040h

Bit 7

- Channel 3

-

4 Differential

0 1 0080h

Bit 8

- Channel 5

-

6 Differential

0 1 0100h

Bit 9

- reserved

0 1

0200h

Bit 10

- reserved

0 1

0400h

Bit 11

- reserved

0 1

0800h

Bit 12

- reserved

0 1

1000h

Bit 13

– reserved

0 1

2000h

Bit 14

– reserved

0 1 4000h

Bit 14

– reserved

0 1

8000h

300004

3

Channel 1 Value

-32768

32767

16 bit signed integer

300005

4

Channel 2 Value

-32768

32767

16 bit signed integer

300006

5

Channel 3 Value

-32768

32767

16 bit signed integer

300007

6

Channel 4 Value

-32768

32767

16 bit signed integer

300008

7

Channel 5 Value

-32768

32767

16 bit signed integer

300009

8

Channel 6 Value

-32768

32767

16 bit signed integer

300010

9

Channel 1 and 2 Differential Value

-32768

32767

16 bit signed integer

300011

10

Channel 3 and 4 Di

fferential Value

-32768

32767

16 bit signed integer

300012

11

Channel 5 and 6 Differential Value

-32768

32767

16 bit signed integer

300013

12

Channel 1 High Alarm Limit

-32768

32767

16 bit signed integer

300014

13

Channel 2 High Alarm Limit

-32768

32767

16 bit signed integer

300015

14

Channel 3 High Alarm Limit

-32768

32767

16 bit signed integer

330016

15

Channel 4 High Alarm Limit

-32768

32767

16 bit signed integer

The Modbus address registers are defined in the tables below.

Input Register Table (table 1)

Address

Offset

Value

1=running.

Alarm

Alarm

Alarm

Page 19

18

300017

16

Channel 5 High Alarm Limit

-32768

32767

16 bit signed integer

300018

17

Cha

nnel 6 High Alarm Limit

-32768

32767

16 bit signed integer

330019

18

Channel 1 and 2 Differential High

Alarm Limit

-

32768

32767

16 bit signed integer

300020

19

Channel 3 and 4 Differential High

-

32768

32767

16 bit signed integer

300021

20 Channel 5 and 6 Differential High

-

32768

32767

16 bit signed integer

300022

21

Channel 1 Low Alarm Limit

-32768

32767

16 bit signed integer

300023

22

Channel 2 Low Alarm Limit

-32768

32767

16 bit signed integer

300024

23

Channel 3 Low Alarm Li

mit -

32768

32767

16 bit signed integer

300025

24

Channel 4 Low Alarm Limit

-32768

32767

16 bit signed integer

300026

25

Channel 5 Low Alarm Limit

-32768

32767

16 bit signed integer

300027

26

Channel 6 Low Alarm Limit

-32768

32767

16 bit signed integer

300028

27

Channel 1 and 2 Differential Low

-

32768

32767

16 bit signed integer

300029

28

Channel 3 and 4 Differential Low

-

32768

32767

16 bit signed integer

300030

29

Channel 5 and 6 Differential Low

-

32768

32767

16 bit

signed integer

300031

30

RPM

0

65535

16 bit unsigned integer

300032

31

Register Table Version

0

65535

16 bit unsigned integer

301002

-

1001

-

Log Buffer Entry #1

Custom (See table 4)

301006

-

1005

-

Log Buffer Entry #2

Custom (

See table 4)

301010

-

1009

-

Log Buffer Entry #3

Custom (See table 4)

301014

-

1013

-

Log Buffer Entry #4

Custom (See table 4)

301018

-

1017

-

Log Buffer Entry #5

Custom (See table 4)

301022

-

1021

-

Log Buff

er Entry #6

Custom (See table 4)

301026

-

1025

-

Log Buffer Entry #7

Custom (See table 4)

301030

-

1029

-

Log Buffer Entry #8

Custom (See table 4)

301034

-

1033

-

Log Buffer Entry #9

Custom (See table 4)

301038

-

1037

-

Log Buffer Entry #10

Custom (See table 4)

301042

-

1041

-

Log Buffer Entry #11

Custom (See table 4)

Alarm Limit

Alarm Limit

Alarm Limit

Alarm Limit

Alarm Limit

301005

301009

301013

301017

301021

301025

301029

301033

301037

301041

1004

1008

1012

1016

1020

1024

1028

1032

1036

1040

301045

1044

Page 20

19

301046

-

301049

1045

-

Log Buffer Entry #12

Custom (See table 4)

301050

-

1049

-

Log Buffer Entry #13

Custom (See table 4)

301054

-

1053

-

Log Buffer Entry #14

Custom (See table 4)

301058

-

1057

-

Log Buffer Entry #15

Custom (See table 4)

301062

-

1061

-

Log Buffer Entry #16

Custom (See table 4)

301066

-

1065

-

Log Buffer Entry #17

Custom (See table 4)

301070

-

1069

-

Log Buffer Entry #18

Custom (See table 4)

301074

-

1073

-

Log Buffer Entry #19

Custom (See table 4)

301078

-

1077

-

Log Buffer Entry #20

Custom (See table

4)

301082

-

1081

-

Log Buffer Entry #21

Custom (See table 4)

301086

-

1085

-

Log Buffer Entry #22

Custom (See table 4)

301090

-

1089

-

Log Buffer Entry #23

Custom (See table 4)

301094

-

1093

-

Log Buffer Ent

ry #24

Custom (See table 4)

301098

-

1097

-

Log Buffer Entry #25

Custom (See table 4)

301102

-

1101

-

Log Buffer Entry #26

Custom (See table 4)

301106

-

1105

-

Log Buffer Entry #27

Custom (See table 4)

301110

-

1109

-

Log Buffer Entry #28

Custom (See table 4)

301114

-

1113

-

Log Buffer Entry #29

Custom (See table 4)

301118

-

1117

-

Log Buffer Entry #30

Custom (See table 4)

302002

-

2001

-

Channel 1 Float Value

-9999.0

99999.0

32 bit Float(IEEE 754)

302004

-

2003

-

Channel 2 Float Value

-9999.0

99999.0

32 bit Float(IEEE 754)

1048

301053

301057

301061

301065

301069

301073

301077

301081

301085

301089

1052

1056

1060

1064

1068

1072

1076

1080

1084

1088

301093

301097

301101

301105

301109

301113

301117

301121

302003

302005

1092

1096

1100

1104

1108

1112

1116

1120

2002

2004

Page 21

20

302006

-

302007

2005

-

Channel 3 Float Value

-9999.0

99999.0

32 bit Float(IEEE 754)

302008

-

2007

-

Channel 4 Float Value

-9999

.0 99999.0

32 bit Float(IEEE 754)

302010

-

2009

-

Channel 5 Float Value

-9999.0

99999.0

32 bit Float(IEEE 754)

302012

-

2011

-

Channel 6 Float Value

-9999.0

99999.0

32 bit Float(IEEE 754)

302014

-

2013

-

Channel 1 and 2 Different

ial Value

-9999.0

99999.0

32 bit Float(IEEE 754)

302016

-

2015

-

Channel 3 and 4 Differential Value

-9999.0

99999.0

32 bit Float(IEEE 754)

302018

-

2017

-

Channel 5 and 6 Differential Value

-9999.0

99999.0

32 bit Float(IEEE 754)

302020

-

2019

-

Channel 1 High Alarm Limit

-9999.0

99999.0

32 bit Float(IEEE 754)

302022

-

2021

-

Channel 2 High Alarm Limit

-9999.0

99999.0

32 bit Float(IEEE 754)

302024

-

2023

-

Channel 3 High Alarm Limit

-9999.0

99999.0

32 bit Float(IE

EE 754)

302026

-

2025

-

Channel 4 High Alarm Limit

-9999.0

99999.0

32 bit Float(IEEE 754)

302028

-

2027

-

Channel 5 High Alarm Limit

-9999.0

99999.0

32 bit Float(IEEE 754)

302030

-

2029

-

Channel 6 High Alarm Limit

-9999.0

99999.

0 32 bit Float(IEEE 754)

302032

-

2031

-

Channel 1 and 2 Differential High

-

9999.0

99999.0

32 bit Float(IEEE 754)

302034

-

2033

-

Channel 3 and 4 Differential High

-

9999.0

99999.0

32 bit Float(IEEE 754)

302036

-

2035

-

Channel 5 and 6 Differential High

-

9999.0

99999.0

32 bit Float(IEEE 754)

302038

-

2037

-

Channel 1 High Low Limit

-9999.0

99999.0

32 bit Float(IEEE 754)

302040

-

2039

-

Channel 2 High Low Limit

-9999.0

99999.0

32

bit Float(IEEE 754)

302042

-

2041

-

Channel 3 High Low Limit

-9999.0

99999.0

32 bit Float(IEEE 754)

302044

-

2043

-

Channel 4 High Low Limit

-9999.0

99999.0

32 bit Float(IEEE 754)

302046

-

2045

-

Channel 5 High Low Limit

-9999.0

99999.0

32 bit Float(IEEE 754)

2006

302009

302011

302013

302015

302017

302019

302021

302023

302025

302027

2008

2010

2012

2014

2016

2018

2020

2022

2024

2026

302029

302031

302033

302035

302037

302039

302041

302043

302045

302047

2028

2030

2032

2034

2036

2038

2040

2042

2044

2046

Alarm Limit

Alarm Limit

Alarm Limit

Page 22

21

302048

-

302049

2047

-

Channel 6 High Low Limit

-9999.0

99999.0

32 bit Float(IEEE 754)

302050

-

2049

-

Channel 1 and 2 Differential Low

-

9999.0

99999.0

32 bit Float(IEEE 754)

302052

-

2051

-

C

hannel 3 and 4 Differential Low

-

9999.0

99999.0

32 bit Float(IEEE 754)

302054

-

2053

-

Channel 5 and 6 Differential Low

-

9999.0

99999.0

32 bit Float(IEEE 754)

302056

-

2055

-

RPM

0

99999.0

32 bit unsigned integer

302058

-

2057

-

Hourmeter

0

99999.0

32 bit unsigned integer

Modicon

Modbus

Description

Min

Max

Data type

401001

-

1000

-

1001

Log start date (upper 16 bits

Custom (See table 3)

32 bit Float(IEEE 754)

2048

302051

302053

302055

302057

302059

Holding Register Table (table 2)

Address

2050

2052

2054

2056

2058

Offset

Alarm Limit

Alarm Limit

Alarm Limit

Value

Value

401002

Date Format Table (table 3)

Second(MSB) Minute Hour

6

Bits

Value

range

0-59

Log Buffer Entry (table 4)

Length

Value

range

Datetime

32 bit unsigned

integer

See table 3

and lower 16 bits

respectively)

6

0-59

5

0-23

Event ID

16 bit unsigned

integer

1-10

Day

5

1-31

Value

-9999.0 – 99999.0

Month

4

1-12

Year(LSB)

6

0-63(relative to year

2000)

Page 23

22

Loading...

Loading...