Page 1

5450 NW 33rd Ave, Suite 104

Fort Lauderdale, FL 33309

3211 Fruitland Ave

Los Angeles, CA 90058

UM-200

2-Channel Monitor

Installation and Operation Manual

Rev. C

P/N145F-13019

(c) Copyright 2013, Dynalco Controls

All Rights Reserved

Published: March 28, 2013

Page 2

IMPORTANT - PLEASE READ BEFORE PROCEEDING!

The Dynalco model UM-200 is designed for reliable and rugged operation on engines,

turbines, pumps, compressors and other machinery for accurate process

measurement and protection. This product has been designed and tested to meet the

demands required in many industrial and hazardous locations meeting critical CSA

standards. The performance is directly related to the quality of the installation and

knowledge of the user in operating and maintaining the instrument. To ensure

continued operation to the design specifications, personnel should read this manual

thoroughly before proceeding with installation, operation and maintenance of this

instrument. If this product is used in a manner not specified by Dynalco, the protection

provided by it against hazards may be impaired.

WARNING

• Failure to follow proper instructions may cause any one of the following

situations to occur: Loss of life; personal injury; property damage; damage to

this instrument; and warranty invalidation.

• For clarification of instructions in this manual or assistance with your

application, contact Dynalco at (800) 368-6666 or (954) 739-4300 or send email to

customerservice@dynalco.com

•

Additional manuals and CSA certificates are available at www.dynalco.com

• Follow all warnings, cautions, and instructions marked on and supplied with the

product.

• Use only qualified personnel to install, operate, program and maintain the

product.

• Educate your personnel in the proper installation, operation, and maintenance of

the product.

• Install equipment as specified in the installation section of this manual. Follow

appropriate local and national codes. Only connect the product to power

sources and end devices specified in this manual.

• Any repair is only to be performed by Dynalco using factory documented

components. Tampering or unauthorized substitution of parts and procedures

can affect the performance and cause unsafe operation of your process.

• All equipment doors must be closed and protective covers must be in place

unless qualified personnel are performing maintenance.

•

Shutdown / alarms should be tested monthly for proper operation (see page 9)

•

Please see page 10 for CSA specific installation instructions.

1

Page 3

System Overview

The Dynalco UM-200 is capable of reading up to 2 input channels, calculating differential

value and providing an alarm / shutdown output.

Basic operation:

The UM-200 will be in “stopped” mode until a run indication is sensed. This is selectable as

either a contact closure or magnetic pickup input. Once “running” mode is sensed, the UM200 will read both inputs at a rate of 100 msec per channel. If any input crosses either an

over or under threshold, the unit will invoke a flashing red LED on the front panel as well as

an output trip (solid-state relay) that can be used for alarm or shutdown.

Additional Features

• 5 - Digit Hourmeter Function (non-resettable)

• Engine RPM Display

• Fully programmable from front keypad

• Standard SAE case size fits panels with 3-3/8 inch (86 mm) opening

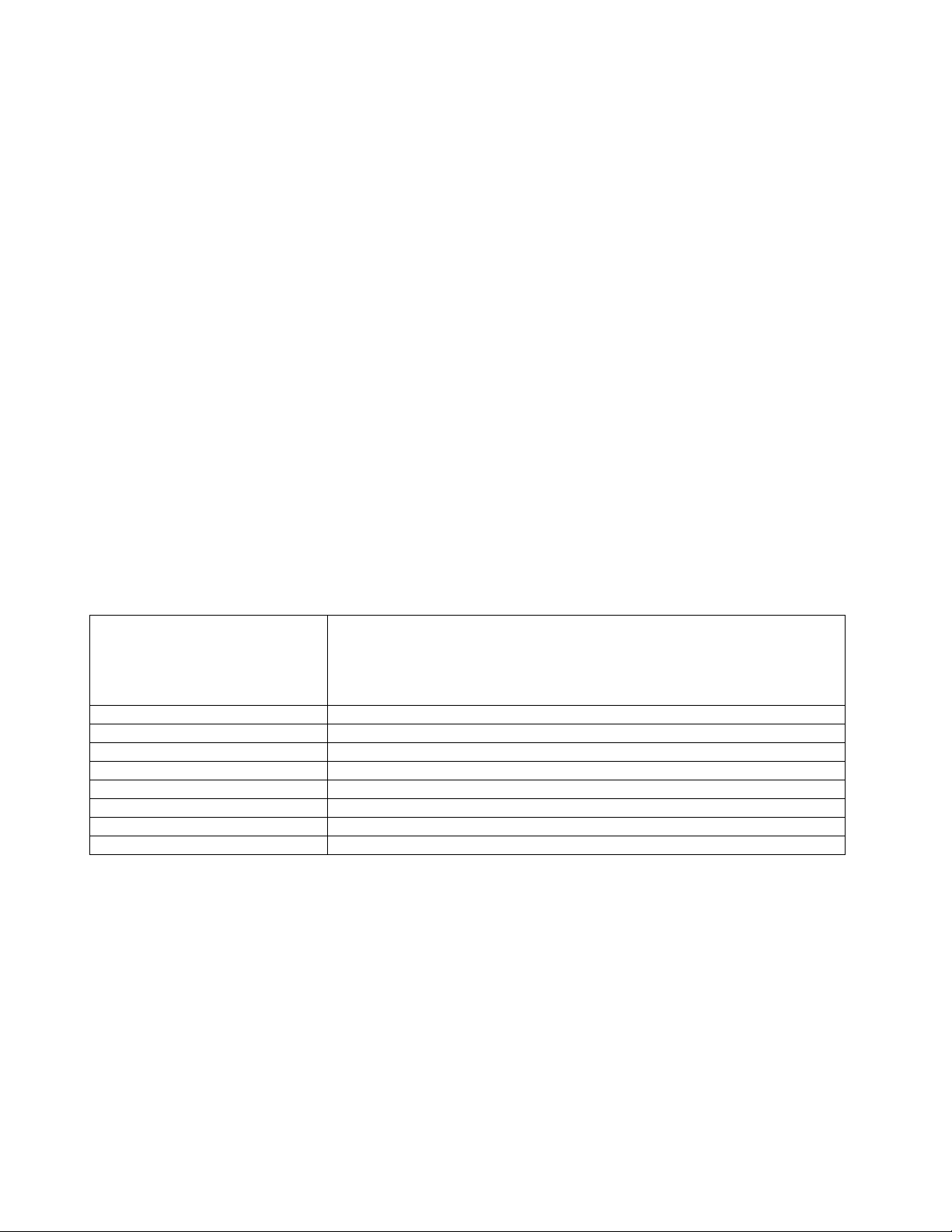

Specifications

Input Types J or K type thermocouple (ungrounded) accurate to +/- 0.2 %

4 - 20 mA

0 – 1 VDC

0 - 5 VDC

0 – 10 VDC

Digital Input Clo sure to ground in dicates run condition (or use pulsed input)

Pulsed Input Magnetic pickup input for RPM display & to indicate run condition

Relay Output Digital Output rated @ 0.15 A / 48 VDC

Input Power 10 – 36 VDC

Display Backlit Graphic Display

Connections Screw Terminals

Operating Temperature Range - 40 to + 70 Deg C

Certification CSA Class I, Division 2, Groups A, B, C, D

User Interface

The UM-200 is configured via the keypad on the front panel which includes a graphical backlit

LCD display capable of displaying alpha numeric values and custom engineering units of

measure. The keypad implements a menu system, which is navigated using the up, down,

left, right, enter and escape buttons. The backlight will turn off after five minutes of inactivity

and will turn on when any of the keys are pressed.

2

Page 4

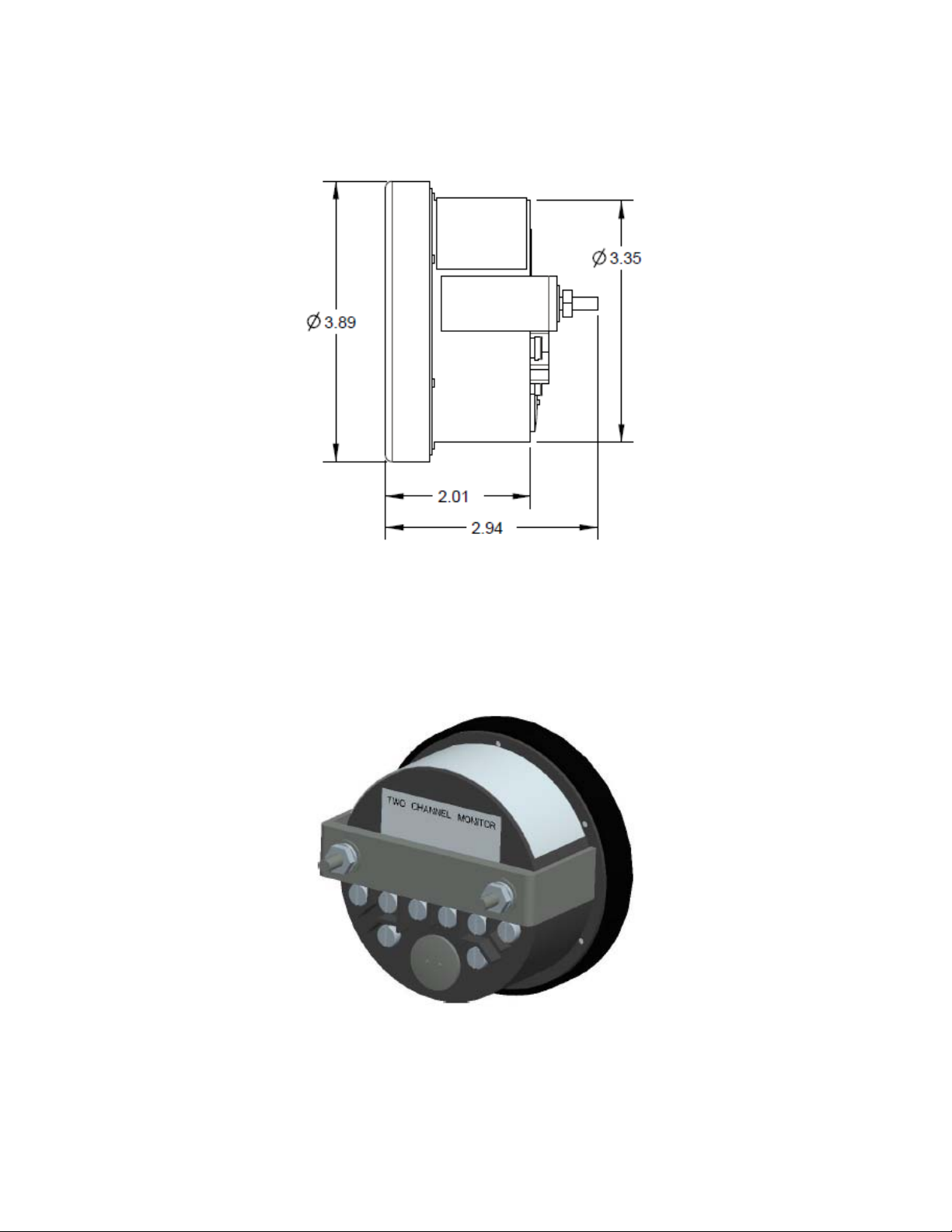

Installation

The UM-200 is designed to be panel mounted. The dimensions are shown below.

The UM-200 has a bracket for securing into the panel.

3

Page 5

Terminal Connections

All connections are made to terminals on the back of the unit.

Terminal screws to be tightened to 8 inch-pounds torque.

See page 10 for complete wiring information.

4

Page 6

Programming Overview

All programming is accomplished through the front keypad. Below is a brief description of

each key.

Press to enter or exit the configuration screens

Press to enter or accept values

Select up

Select down

Go back one screen

Select and advance to next screen

5

Page 7

Initial configuration consists of the following steps:

1) Enabling each input

2) Defining each input type

3) Defining min. & max. display values for any current or voltage inputs

4) Defining measurement display units (PSI, mV, F, C, H20, etc)

5) Setting over / under setpoint trips

6) Setting either latching or non-latching for output trip

Programming Instructions

Important: The UM-200 must first be programmed prior to operation.

When first powering up the unit, the display will first indicate the firmware version and then go

to the operational mode.

To configure each input, first go to the main programming screen by pressing the Menu /

Escape key:

The main configuration screen shows the following icons:

Run Signal – defines run status input type (if any)

Channel - enables each channel type and alarm thresholds

Calibration - defines zero & span values for DCV & mA inputs

System - allows display customization

6

Page 8

Configuration of “Run Signal”

Using the arrows on the keypad, select the “Run Signal” icon.

There are (3) run types available. The definitions are as follows:

None: No run indication required. Monitoring is always active.

RPM: Monitoring is active when signal received from magnetic pickup.

Digital: Monitoring is active when contact closure (connection to ground) is sensed.

To select run signal type, use the up / down arrows to select, then press enter.

If “None” is selected, there is no other action required other than to select “escape.” After

selecting escape, you will be asked to select “yes” to save.

If “RPM” is selected, you will need to set the # gear teeth, RPM threshold and startup delay.

The RPM threshold is the speed above which monitoring will be active. The startup delay

allows you to delay monitoring for as many as 300 seconds (5 minutes) to allow time for all

inputs to be at normal levels. If no delay is required, set to 0 seconds. The magnetic pickup

input terminals are indicated on page 3.

If “Digital” is selected, you will only need to set the startup delay (if applicable). In this mode,

a run signal will be sensed with a contact closure (or short) between the magnetic pickup

input terminals indicated on page 3.

Pressing at any time during configuration will prompt you to save the changes.

Select “Yes” to save any changes made. Selecting “No” will not save changes.

Configuration of each “Channel”

Using the arrows on the keypad, select the “Channel” icon.

Next, select the channel number to configure by pressing the up / down arrows and pressing

enter. Use the right

arrow to navigate and select the following:

Enable Channel Yes / No

Channel Type (0-1 V, 0-5 V, 0-10 V, 4-20 mA, J Type, K Type)

Description (name input with up to 20 characters)

Engineering Units (up to 3 characters for PSI, F, C etc…)

Note: For thermocouple inputs, you must enter either “F” or “C”

Enable alarms (read only or alarm?)

Alarm Type (latching or non-latching)

Alarm Output (select to enable output trip)

Alarm Low (select threshold for under-trip)

Alarm High (select threshold for over-trip)

Alarm Reset Points (select either the default reset value or manually set)

Alarm Reset Low (manually set reset hysteresis for low trip)

Alarm Reset High (manually set reset hysteresis for high trip)

7

Page 9

Differential calculations between channels 1 & 2 are also enabled by selecting the

“Channel” icon.

Configuration of “Calibration”

Using the arrows on the keypad, select the “Calibration” icon.

Next, select the channel number to configure by pressing the up / down arrows and pressing

enter.

The screens allow you to define the “Cal Zero” and “Cal Span” values for a channel that is

configured for 0-1 V, 0-5 V, 0-10 V or 4-20 mA input.

Example 1:

A pressure transmitter is connected to channel # 1. The transmitter has a 4-20 mA

output representing a pressure input of 0 - 500 PSI. The “Cal Zero” and “Cal Span”

values would be defined as:

Cal Zero = 0

Cal Span = 500

Note that the “Engineering Units” would be input as PSI in “Channel” configuration

above.

Example 2:

An oxygen sensor is connected to channel # 2. The output of the oxygen sensor is 0-1

VDC (0-1000 mV). The “Cal Zero” and “Cal Span” values would be defined as:

Cal Zero = 0

Cal Span = 1000

Note that the “Engineering Units” would be input as mV in “Channel” configuration

above.

System

Using the arrows on the keypad, select the “System” icon.

There are (2) display layouts available. Selecting layout A or B or will define the preferred

display type as follows:

Layout A: Displays both input channels plus differential

Also displays RPM & Hours if “Run Signal” configured for “RPM” input

Layout B: Displays each individual channel in large format

8

Page 10

Note that you are selecting the default layout type. You will be able to change the layout

during normal operation by pressing the left / right arrows.

Operation

Once programmed, the UM-200 will begin scanning the enabled channel inputs and will

initiate alarms based on over / under threshold values configured for each channel. It is not

necessary to define alarm threshold values for both channels as they may be for monitoring

only.

Alarm / Shutdown Output

The UM-200 will alarm when either channel value or differential value is above or below limits

as specified. Alarms can be configured as either latching or non-latching. If an alarm

condition is met, the red LED on the front panel will blink and the digital output (if enabled)

will trip. Non-latching alarms will reset the alarm if its value returns to normal. Latching alarms

require manual resetting via the front keypad.

WARNING:

Terminal connection screws to be tightened to 8 inch-pounds torque.

The alarm / shutdown output should be tested monthly for proper operation, especially

if being used for over / under pressure, over / under temperature shutdown or other

critical function.

Additional instructions for current users of Dynalco models TID-110 or STM-110 series

temperature monitors

The following products may be upgraded to the model UM-200 monitor:

TID110-11 J type thermocouple (displays in DegF)

TID110-12 J type thermocouple (displays in DegC)

TID110-13 K type thermocouple (displays in DegF)

TID110-14 K type thermocouple (displays in DegC)

STM110-11 J type thermocouple (displays in DegF)

STM110-12 J type thermocouple (displays in DegC)

STM110-13 K type thermocouple (displays in DegF)

STM110-14 K type thermocouple (displays in DegC)

Please see the programming steps in this manual for configuring the proper thermocouple

type and display in either DegF or DegC. Replacing the STM-110 series will also require

setting up the over temp alarm.

9

Page 11

10

Loading...

Loading...