Page 1

SWT-2000

Frequency Measurement and

Switching Instrument

Operating Manual

3690 NW 53

rd

Street • Fort Lauderdale, FL 33309 • Ph 954-739-4300 • Fax 954-486-4968 • www.dynalco.com

Page 2

TABLE OF CONTENTS

1. Product Features 1

2. Specifications 2

2.1 General 2

2.2 Inputs 2

2.2.1 Sensor Inputs 2

2.3 Binary Inputs 5

2.4 Outputs 5

2.4.1 Analog Outputs 5

2.4.2 Relays Outputs 6

2.4.3 Open Collector Outputs 7

2.5 Data Communication 7

2.5.1 Ethernet 7

2.6 Environment 7

2.6.1 Climatic Conditions 7

2.6.2 Electromagnetic Immunity 7

3. Principle of Operation 8

3.1 General 8

3.2 Machine Factor 8

4. Installation 9

5. Connections 9

5.1 Front View 9

5.1.1 Front View 9

5.1.2 Terminal A 10

5.1.3 Terminal B 11

6. Configuration via PC Software 12

6.1 Software Concept 12

6.2 PC Settings 12

6.3 Download Configuration Software 12

6.4 Configuration Software 13

6.4.2 Log in 13

6.4.3 Main Window and System Limit Matrix 13

6.4.4 Logging In and Out 13

6.5 Configuration File 13

6.5.1 ... creating new 13

6.5.2 ... resetting to factory default 14

6.5.3 ... loading 14

6.5.4 ... saving 14

6.5.5 ... printout 14

6.6 Communication with the SWT-2000 14

6.6.1 Read Measured Data 14

6.6.2 Reading Configuration from the SWT-2000 14

6.6.3 Writing a Configuration to the SWT-2000 15

6.6.4 Compare Data 15

6.7 Configuring 15

6.7.1 Speed Sensors 15

6.7.2 Binary Input Configuration 16

6.7.3 Set Measurement Interval 16

6.7.4 Sensor Alarm 16

6.7.5 Machine Factor 17

6.7.6 Dynamic Error 17

6.7.7 Math Function 18

6.7.8 System Limit 19

6.7.9 Relay Outputs 20

6.7.10 Open Collector Outputs 20

6.7.11 Analog Output 21

6.7.12 Copy Parameter Set 22

6.7.13 Change-Over Delay 22

6.8 Settings 22

6.8.1 Ethernet Interface 22

6.8.2 Changing the Password 23

6.9 Info 23

7. Behavior 24

7.1 Power On 24

7.1.1 Analog Output 24

7.1.2 Relay Output 24

7.1.3 Open Collector Output 24

7.2 Frequency Measurement 25

7.2.1 The Adaptive Trigger Level 25

Page 3

7.2.2 Signal Failure 26

7.3 Functions 26

7.3.1 "FUNC" Push Button 26

7.3.2 Parameter Sets A, B, C and D 26

7.3.3 Limits 26

7.3.4 Math Function 27

7.3.5 Frequency X2 and X4 28

7.3.6 Relay and Open Collector Latch Function 28

7.3.7 Analog Output 28

7.3.8 Interpretation of System Limit Inputs 29

7.4 Fault Behavior 29

7.4.1 Sensor Error 29

7.4.2 System Alarm 29

7.5 Power Failure 29

7.6 Behavior During Configuration 29

8. Mechanical Construction / Housing 30

8.2 Mounting 30

9. Accessories 31

Copyright © 2009 Dynalco. All rights reserved.

Part Number: SWT-2000

SWT-2000 Rev. 1, June 2009

Page 4

Page 5

Operating Instructions SWT-2000 DYNALCO

1. Product Features

The model SWT-2000 measures and monitors frequency signals (speed proportional values) in the

range 0.025Hz to 50,000Hz.

Available are:

• 2 Frequency Inputs (Speed sensors)

• 2 Analog outputs

• 2 Binary input

• 4 Relays

• 2 Open Collector Outputs

• 4 Parameter sets each having 6 System limits with 4 Limit values

• Sensor monitoring

• System monitoring

The SWT-2000 is configured via Computer (PC) using resident operating software.

2 models are available:

SWT-2000: 2 channel Speed Switch / Transmitter with 4 Relays and 2 Analog outputs 0/4-20mA

SWT-2000AC: (AC Version)

SWT-2000DC: (DC Version)

1

Page 6

Operating Instructions SWT-2000 DYNALCO

2. Specifications

2.1 General

Measurement time 2ms / 5ms / 10ms / 20ms / 50ms / 100ms / 200ms / 500ms / 1s / 2s / 5s

(Frequency measurements might take longer than the predefined measurement

time)

Supply voltage

Isolation

Power consumption

Power supply bridging

Weight

Sealing to DIN

EN 60529

AC Version

DC Version 18…36 VDC

AC Version 3000 VAC (from AC/DC power supply) Isolation voltage

DC Version 1500 VDC (from DC/DC converter)

Galvanic isolation between:

• Supply

• Sensor input incl. sensor supply

• Binary input 1

• Binary input 2

• Analog output 1

• Analog output 2

• Relay outputs

• Open Collector output 1

• Open Collector output 2

• Ethernet interface

P Min. (W) P Max. (W)

18 VDC

DC Version

AC Version

DC Version

AC Version

AC Version -25°C…+50°C Operating temperature

DC Version -40°C…+70°C

AC Version Storage temperature

DC Version

AC Version

DC Version

IP 20

24 VDC

36 VDC

110 VAC

230 VAC

18 VDC

24 VDC

36 VDC

110 VAC

230 VAC

90…264 VAC (47...63 Hz) / 120VDC … 370VDC

3.3 6.6

3.4 6.7

3.5 6.8

5.0 11.0

8.0 14.0

> 20ms

> 20ms

-40°C…+85°C

430g

390g

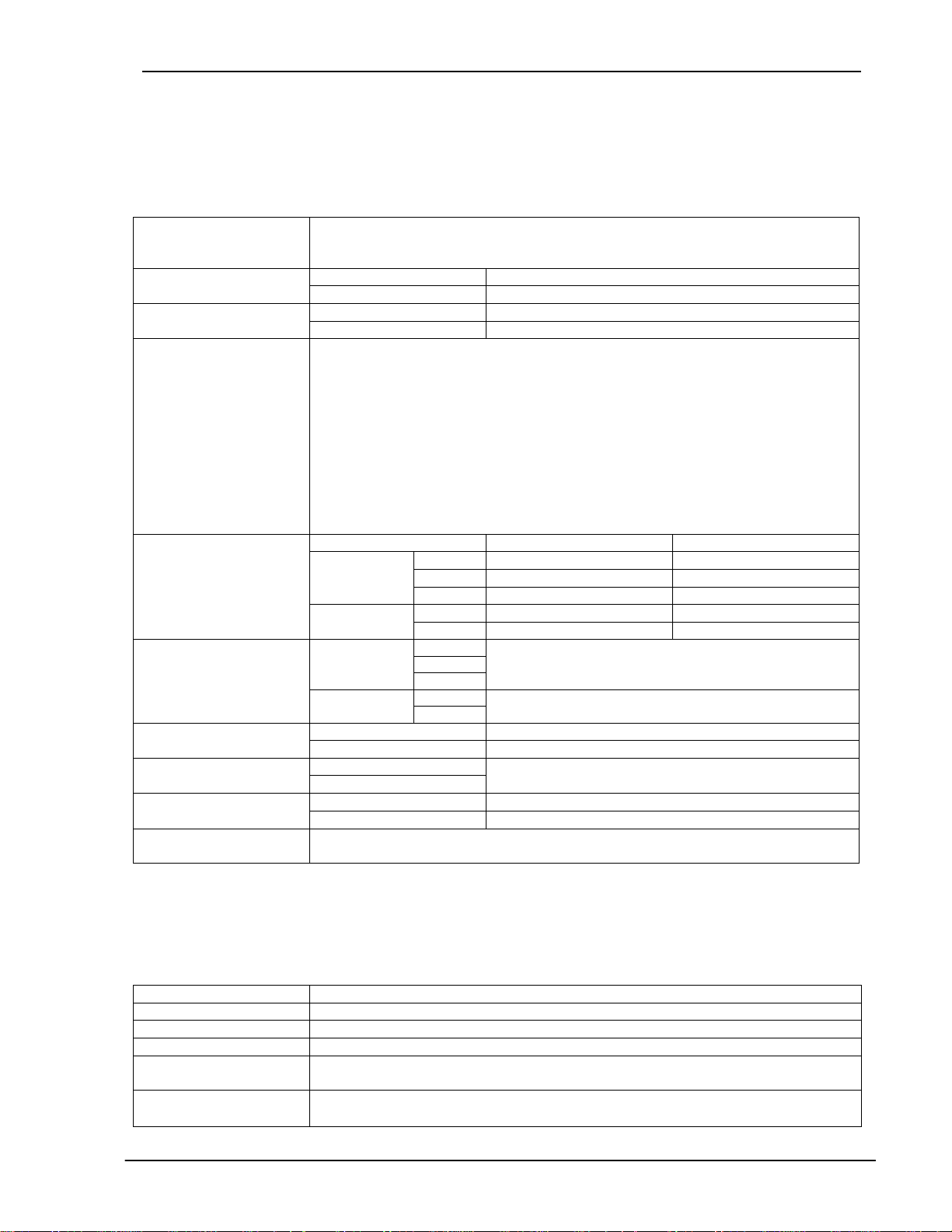

2.2 Inputs

2.2.1 Sensor Inputs

An overview how different sensor can be connected is in chapter 5.1.2 Terminal A

Number 2

Frequency range (-3dB) 0.025 Hz … 50 KHz

Measurement range Programmable within the frequency range

Measurement accuracy 0.002 %

Resolution

(Frequency)

Input impedance

10 ns

> 11.5 kΩ

(0.1 Hz

Æ

80 kΩ, 1 KHzÆ18.5 kΩ, 10 KHzÆ16 kΩ, 50 KHzÆ11.6 kΩ)

2

Page 7

Operating Instructions SWT-2000 DYNALCO

Input signal for fixed 3V

trigger (+/-15%)

• Max. Voltage: 80V

(226Vpp)

RMS

• Best suited to digital signals

• Schmitt Trigger Input (Hysteresis > 1V)

• „0“ = Low Level to 1.25V

• „1“ = High level from 3V (+/- 15%)

• Min. Pulse width: 5μs

• NO DC- decoupling

Input signal for adaptive

trigger min. 57mVpp

(+/-10%) 20mV

RMS

• Max. Voltage: 80V

• DC- decoupling

• The Trigger level automatically adapts itself to the input signal in the range

+28.5mV to +2V. The Adaptive Trigger improves the signal to noise immunity

(226Vpp)

RMS

e.g. where electromagnetic sensors are used.

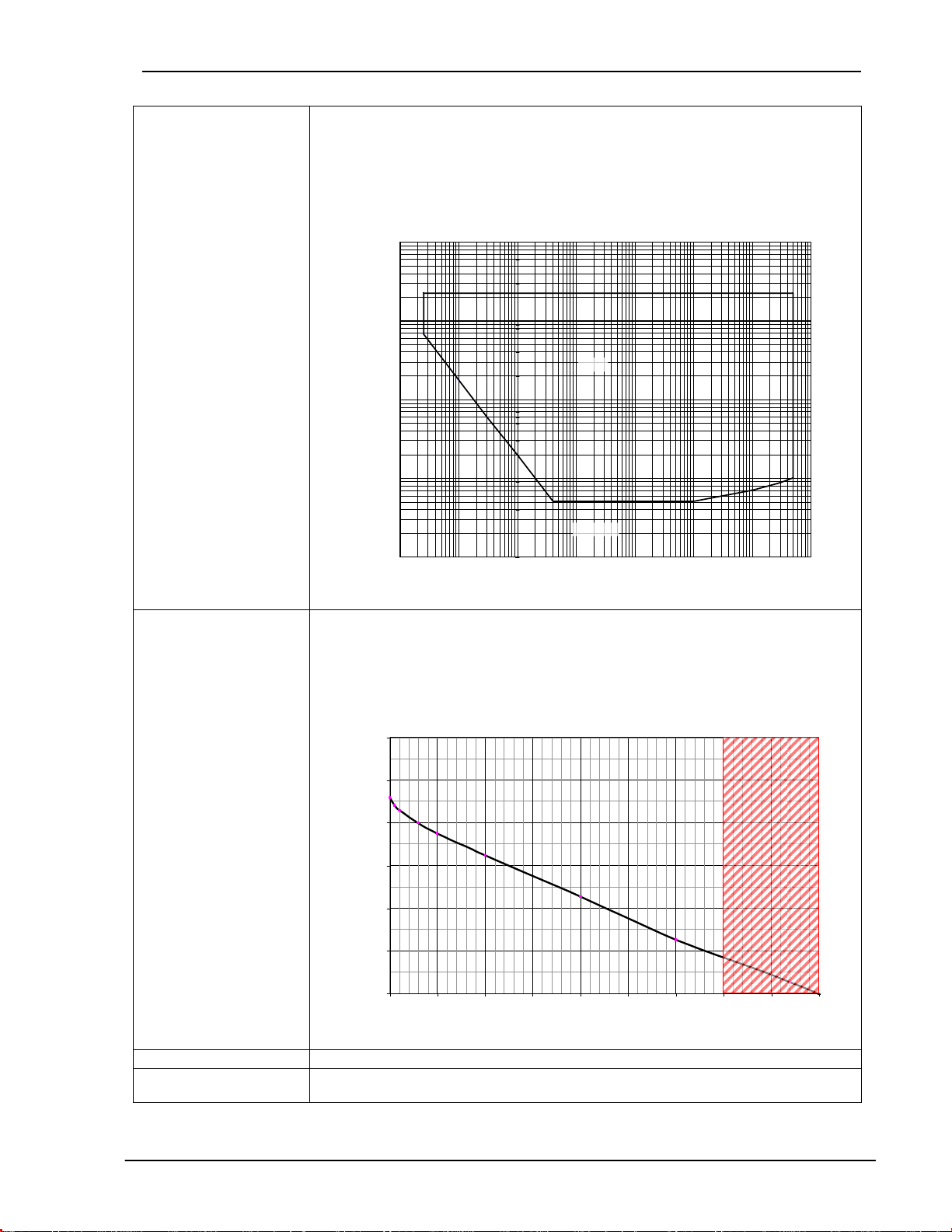

1000.00

100.00

10.00

Min. Trigger level: 57 mVpp +/-10% = 20 mV

+/-10% U min. = f(Frequency)

RMS

O.K

1.00

Sensor Signal (Vpp)

0.10

NOT O . K.

0.01

0.01

0.1

1

10

Frequency (Hz)

100

1000

10000

100000

3

Page 8

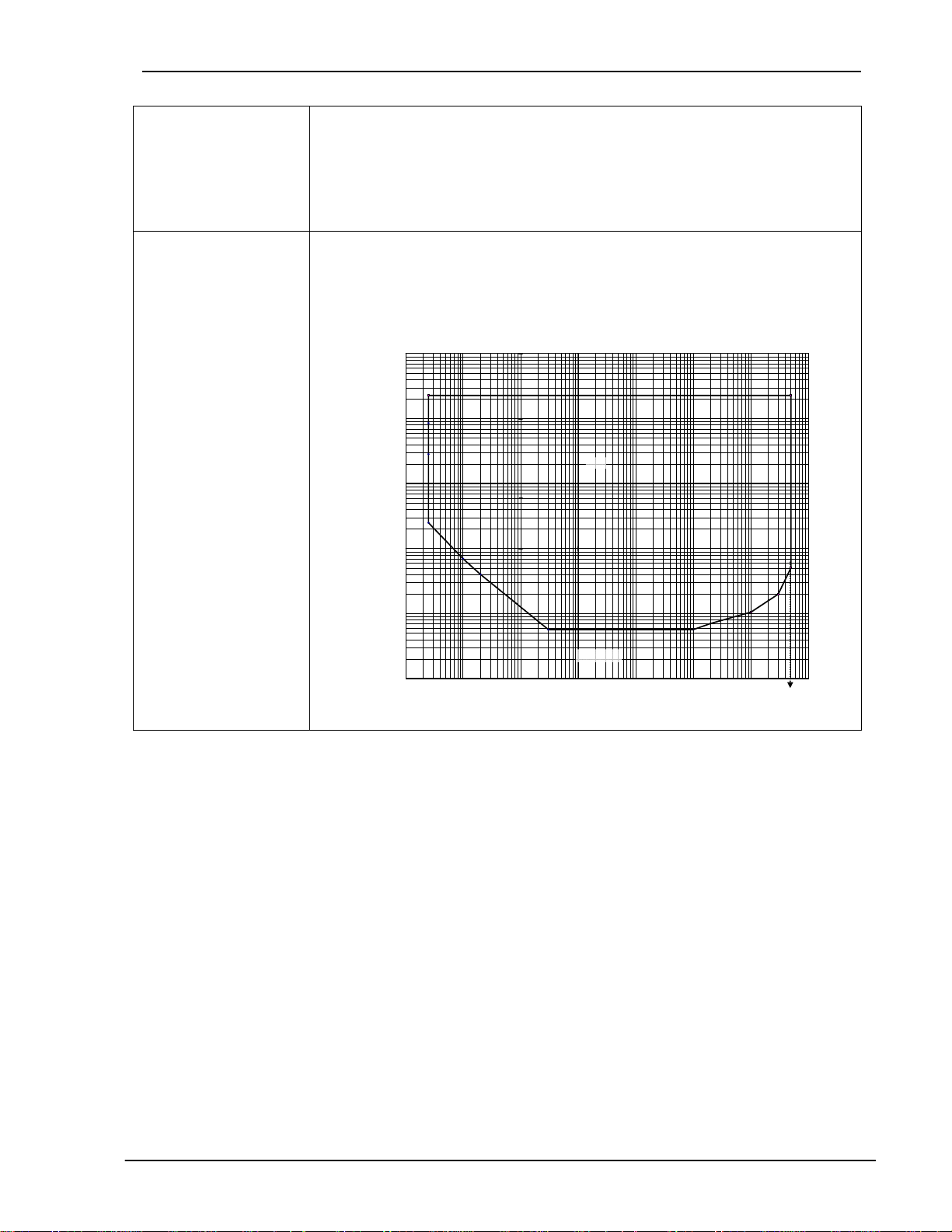

Operating Instructions SWT-2000 DYNALCO

Input signal for adaptive

trigger min. 500mVpp

(+/-10%) 180mV

RMS

• Max. Voltage: 80V

• DC- decoupling

• The Trigger level automatically adapts itself to the input signal in the range

(226Vpp)

RMS

+250mV to +2V. The Adaptive Trigger improves the signal to noise immunity

e.g. where electromagnetic sensors are used.

Min. Trigger level: 500 mVpp +/-10% = 180 mV

1000.0

100.0

10.0

Sensor Signal (V pp)

1.0

+/-10% U min. = f(Frequency)

RMS

O.K.

Sensor supply

NOT O . K.

0.1

0.01

0.1

1

10

Frequency (Hz)

100

1000

10000

• +14V +/- 0.5V, max. 35mA / Short circuit proof

• If the current limit has been activated, then the circuit needs to be

disconnected to reset the protection.

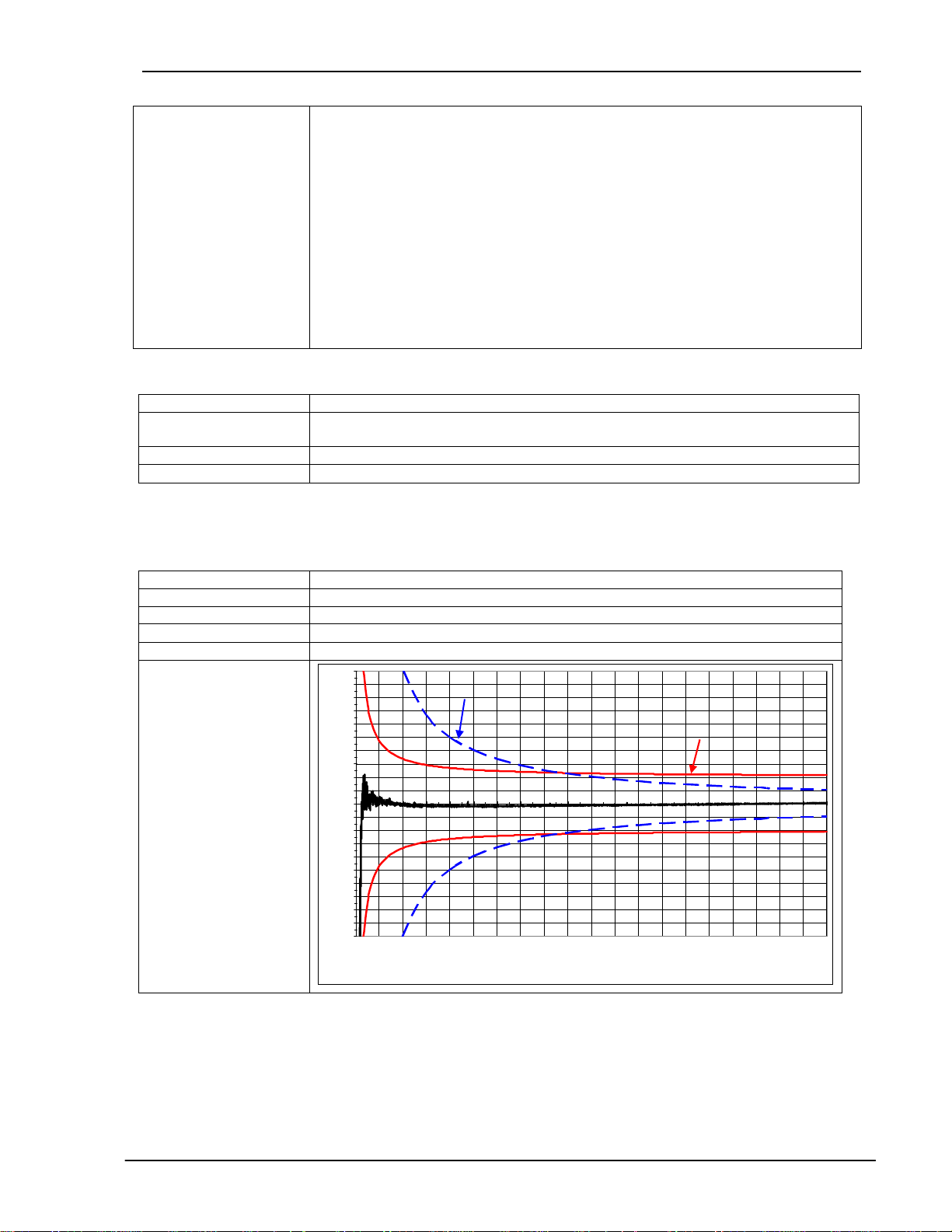

Typical voltage curve as a function of sensor current

14.8

14.6

14.4

14.2

Sensor voltage (V)

14.0

13.8

Sensor voltage = f (Sensor current)

100000

13.6

0 5 10 15 20 25 30 35 40 45

Sensor current (mA)

Integral pull up resistor

1000Ω to +14V (Only for 2 wire active e.g. NAMUR sensors)

Screen Terminals are provided for each sensor cable screen (Sh1 and Sh2). These

terminals are internally connected to the sensor input / supply 0V.

4

Page 9

Operating Instructions SWT-2000 DYNALCO

Sensor monitoring 3 sensor monitoring settings are available in the configuration software:

• No Sensor Monitoring

• Monitoring of supplied sensors (active Sensor Types)

[Also for 2 wire sensors that are supplied via the internal Pull-up resistor (1kΩ)

Æ Sensors drawing current outside of I

= 0.5…35mA

I

min

I

= 0.5…35mA

max

min

or I

are considered to be faulty.

max

• Monitoring of non powered sensors (passive Sensor Types)

[For 2 wire sensors such as electromagnetic sensors.]

Æ The sensor is considered to be faulty if the line is broken.

Here the sensor impedance is dynamically measured.

Z < 60 kΩ = OK

Z > 125 kΩ = NOT OK

2.3 Binary Inputs

Number 2 Active Binary Inputs and 1 push button (FUNC – logic OR with Binary input B1)

Level Logic 0 = 0V….+5V

Logic 1 = +15V….+36V

Isolation voltage 1500 V

Input resistance

R

min

RMS

= 8.2 kΩ

2.4 Outputs

2.4.1 Analog Outputs

Number 2 Analog outputs

Isolation voltage 1000 VDC

Output type Current (selectable 0…20 / 4…20mA)

Load

Open circuit voltage Max. 15V

Typical error curve

Max. 500Ω

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

-0.1

-0.2

-0.3

Measurement error (% )

-0.4

-0.5

-0.6

-0.7

-0.8

-0.9

-1

0.00E+00

CLASS 0.1 % (from End Value)

1.00E-03

2.00E-03

3.00E-03

4.00E-03

5.00E-03

6.00E-03

7.00E-03

8.00E-03

0.2 % (from measured value) + 2 LSB

9.00E-03

1.00E-02

1.10E-02

1.20E-02

1.30E-02

1.40E-02

I (A)

1.50E-02

1.60E-02

1.70E-02

1.80E-02

1.90E-02

2.00E-02

5

Page 10

Operating Instructions SWT-2000 DYNALCO

0

Mode

[mA]

21

20.5

2

12

Mode

4...20mA

Fai l ur e le vel

0 … 20mA

4

2

0

Startvalue Endvalue

0...20mA

Transfer Functions Start value < or > End value

Startvalue < Endvalue

Output

Outputvalue

Output

Resolution 14 Bit (16384 increments)

Max. Linearity error 2 LSB (Least Significant Bit) ca. 2.7uA

Measuring error Max. 0.15 % f.m.v. + 2 LSB (-25°C Æ +50°C)

Max. 0.20 % f.m.v. + 2 LSB (-40°C Æ +70°C)

Accuracy class 0.1 % of the end value

Damping Hardware time constant T = 4.1 ms

10% Æ90% = 8.6 ms (Hardware)

Actual time = Hardware time constant + Software setting (configuration)

Temperature Drift Typ.: 50 ppm/K, max. 120 ppm/K

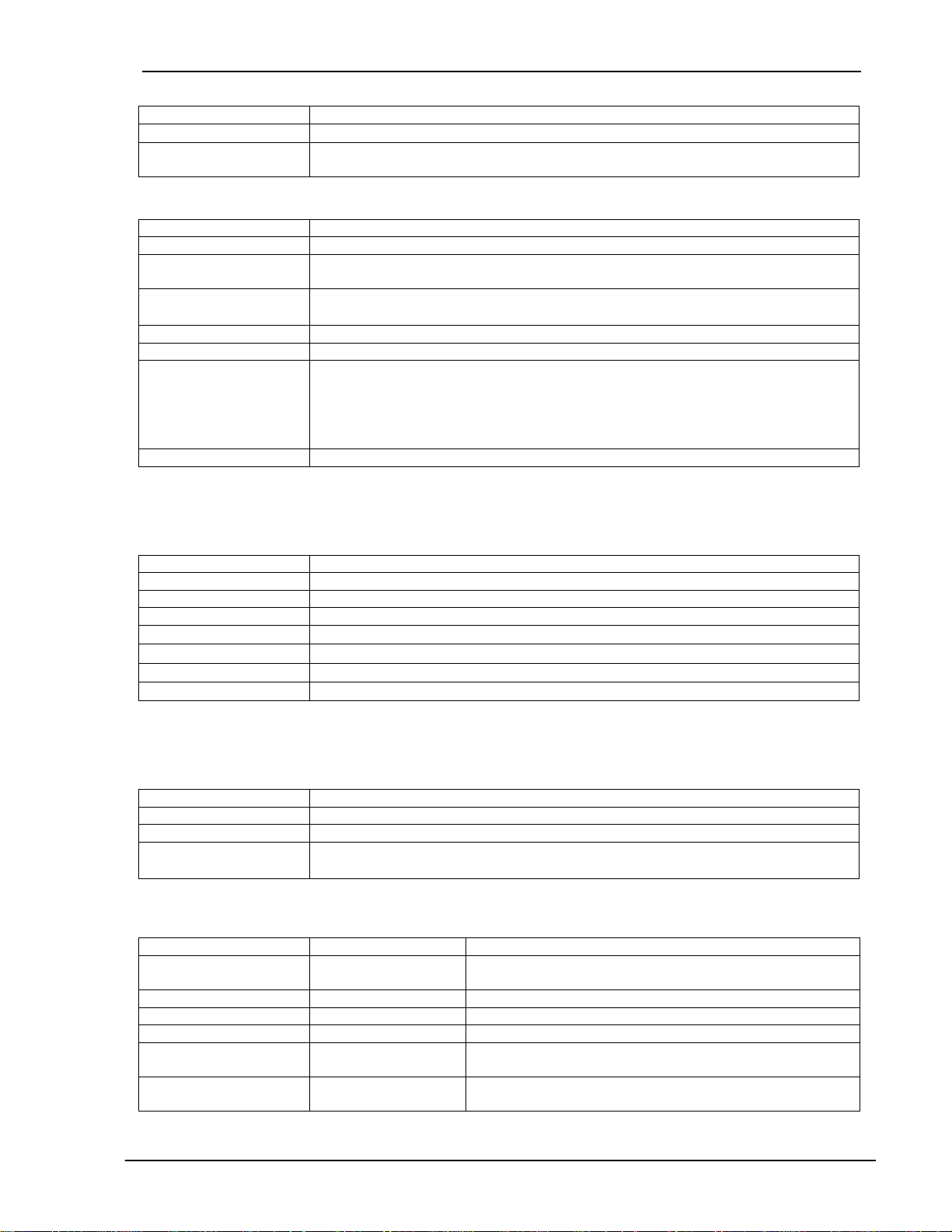

2.4.2 Rela ys Outputs

Number 4

Type Single Pole Double Throw (SPDT)

Functions

Relay - max. switching

current

• May be assigned to System Limit 1..6, Sensor Alarm, Static error Sensor 1 or

2, dynamic error, always on or off.

• With or without Hold function (Reset via Binary input)

• Fail Safe or Not Fail Safe

Startvalue > Endvalue

Outputvalue

Fe hler level

4 … 20mA

Output

Value

6

Page 11

Operating Instructions SWT-2000 DYNALCO

Reaction time Effective Measurement interval + max 6 ms

Contact resistance

Contact isolation 1500 VAC (coil to contact)

50 mΩ Max. (Initial contact)

1000 VAC (between open contacts)

2.4.3 Open Collector Outputs

Number 2 Open Collector outputs

Type Opto-coupler (passive)

External resistance IC nominal = 15mA (R

IC max. = 30mA

Reaction time

Load voltage V = 5VDC…36VDC

Isolation voltage 1500 VAC

Functions

Inverting Open collector output frequencies are in phase with the input signal.

• As Frequency output: <30 us

• Effective Measurement interval + max 30 us

• May be assigned to System Limit 1..6, Sensor Alarm, Static error Sensor 1 or

2, dynamic error, always on or off.

• With or without Hold function (Reset via Binary input)

• Frequency Sensor 1 or 2, Frequency x2, Frequency x4 (subject to phase shift)

• Fail Safe or Not Fail Safe

= V / I) Example: V = 24 V

Pull-up

Æ

R = 1.6 kΩ

2.5 Data Communication

2.5.1 Ethernet

Number 1

Physical Layer Ethernet 10Base-T, IEEE 802.3i

Max cable length 100 m

Transmission rate 10 MBit/s

Connection Front panel, 8P8C (RJ45)

Usage Configuration and measurement status

Protocol Peer to Peer

Connecting cable Use a crossover cable

2.6 Environment

2.6.1 Climatic Conditions

Standard DIN 40 040

Operating temperature See 2.1 General

Storage temperature See 2.1 General

Relative Humidity

2.6.2 Elec tromagnetic Immunity

Electrostatic discharge EN 61000-4-2 Contact 6 kV, air 8 kV

Electromagnetic fields

Fast transients EN 61000-4-4 2 kV, repeated 5 kHz duration 15 ms period 300 ms

Slow transients EN 61000-4-5 Line / line +/- 1kV, earth line +/- 2kV, 1 per minute

Conducted HF EN 61000-4-6 3 V eff (180 dBuV) 10 kHz – 80 MHz

Mains frequency

Magnetic field

Voltage dips

• 75% average over 1 year; to 90% for max. 30 days.

• Condensation to be avoided.

EN 61000-4-3

EN 61000-4-8 50 Hz, 100 A/m 2 minutes

EN 61000-4-11

30 V/m, not modulated and AM 80 % with 1000Hz Sinus

wave

Voltage dips, short interruptions and voltage variations

immunity tests

7

Page 12

Operating Instructions SWT-2000 DYNALCO

3. Principle of Operation

3.1 General

The model SWT-2000 is microprocessor controlled and operates in accordance with the period measurement

principle whereby the duration of the input period is measured during the measurement interval. The reciprocal

value based on the average input period corresponds to frequency and hence speed. The relationship

between frequency and speed is determined by the Machine Factor.

The status of System Limits is based on various inputs that can be logically combined AND or OR. System

Limit inputs may be: both speed inputs, a Math function based on the speed inputs and, the 2 binary inputs. A

hysteresis may be set for the speed inputs and Math function individually. The 6 System Limits in each of 4

parameter sets may be individually defined. Parameter sets may be selected via binary inputs. The 4 relays

and 2 open collector outputs may be assigned to any System Limit and will react accordingly. The 2 open

collectors may alternatively be assigned to frequency x1, x2 or x4. Relay and open collector status may be

latched and then reset via binary input.

The system permanently monitors itself. Sensors may in addition be monitored. Sensor error may be used in

the configuration to influence System Limits. System error would influence the relays, open collectors and

Analog outputs and the front panel LED would go out.

Frequency outputs (Open Collector Outputs) are not influenced by the Machine factor but correspond to the

input signal. For frequency X2 or X4 the 2 input signals should ideally be phase shifted by 90 degrees.

Parameter input is via resident PC software and the Ethernet Interface. This may also be used to interrogate

the unit, display measurement and unit status.

The Parameters are safely stored in EEPROM.

3.2 Machine Factor

The machine factor establishes the relationship between sensor frequency (Hz) and corresponding speed

(RPM).

Machine Factor = Frequency

RPM

If the # gear teeth and RPM are known, use the following formula to calculate corresponding frequency:

Signal Frequency (Hz) = (RPM) X (Teeth or Discontinuities)

60

Another way to calculate the machine factor is:

Machine Factor = (Teeth or Discontinuities)

60

Note: The above formulas are based on the gear or target turning at the same speed as the machine being

monitored, ie: no step up or step down gear ratios involved.

8

Page 13

Operating Instructions SWT-2000 DYNALCO

4. Installation

The SWT-2000 may only be installed by competent personnel. Only undamaged and correctly configured units

may be used.

Before switching on, check that the supply is within the permissible range.

The Sensor cable screens must be connected terminals „Sh1“ and „Sh2“ respectively so as to minimize the

effects of signal noise. These terminals are internally connected with 0V.

Attention: If the password has been changed, there is no way of returning to a factory setup. If the password

is forgotten, the unit will need to be returned to Dynalco for re-programming.

5. Connections

5.1 Front View

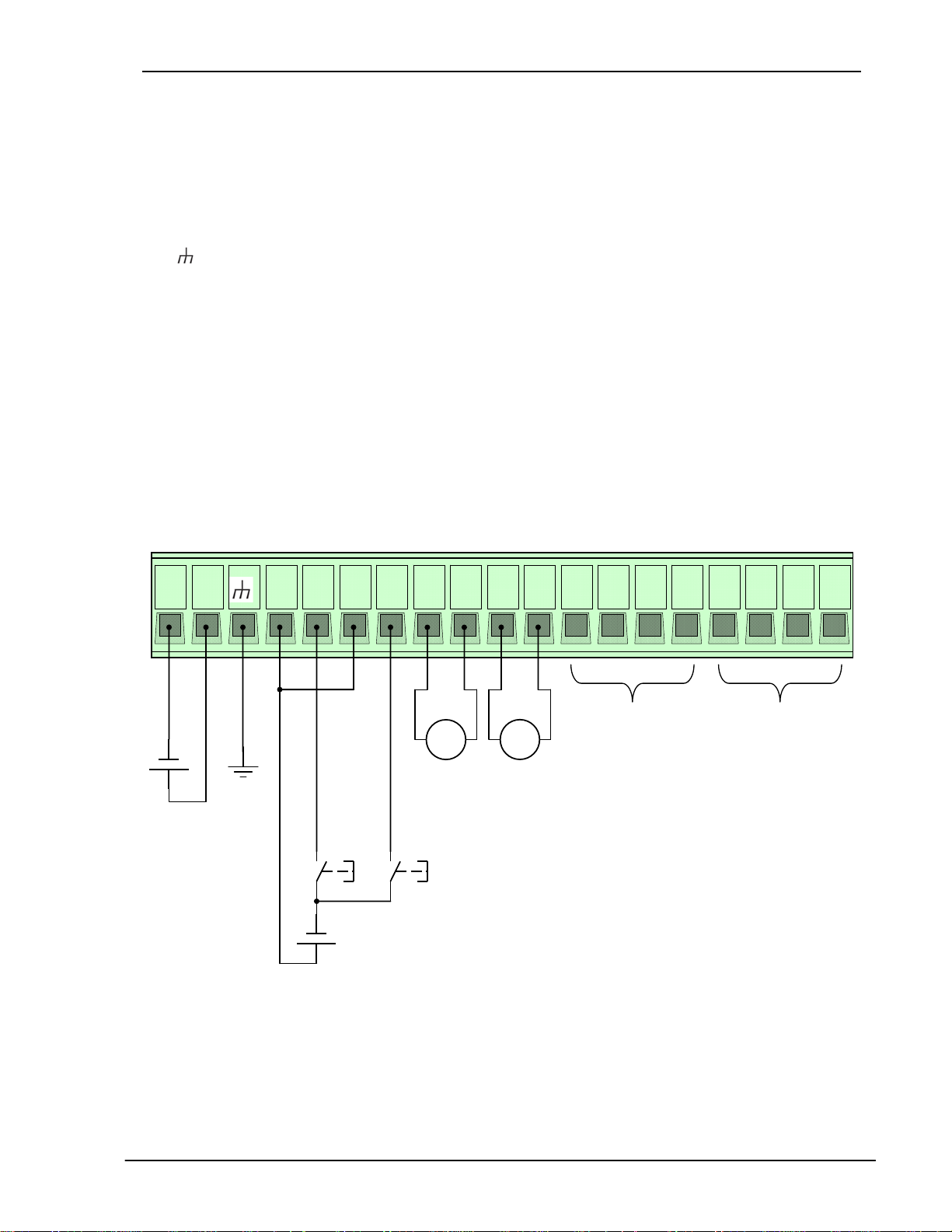

5.1.1 Front View SWT-2000

Terminal B

Terminal A

The Ethernet Interface, status LED along with the FUNC push button are located at the front. For

communications, see Paragraph 6 Configuration via PC Software

9

Page 14

Operating Instructions SWT-2000 DYNALCO

V

A

A

V

V

A

A

V

5.1.2 Terminal A

Supply

+ : Input Supply (+)

- : Input Supply (-)

: Earth

Sensor connections S1 / S2

S1 : Sensor input S1

Sh1 : Screen S1

V1+ : Sensor Supply S1

V1- : 0V S1

S2 : Sensor input S2

Sh2 : Screen S2

V2+ : Sensor Supply S2

V2- : 0V S2

+ -

B1 - B1

+

B2 - B2

O1

O1

-

+

+

Binary Inputs

B1+ : positive B1

B1- : negative B1

B2+ : positive B2

B2- : negative B2

Analog outputs

AO1+ : positive I1

AO1- : negative I1

AO2+ : positive I2

AO2- : negative I2

O2

O2+ Sh1

-

1- S1

Sh2

1

+

2

S2

-

2

+

+

-

Power supply

+

-

-

AO1 AO2

Current output

B2B1

Binary input

-

+

+

Sensor 1

Sensor 2

10

Page 15

Operating Instructions SWT-2000 DYNALCO

5.1.3 Terminal B

Open Collector Outputs Oc1 / Oc2

OC1+ : positive Open Collector 1 (Emitter)

OC1- : negative Open Collector 1 (Collector)

OC2+ : positive Open Collector 2 (Emitter)

OC2- : negative Open Collector 2 (Collector)

Relay output

Relay Outputs R1-R4

NC : Normally closed

NO : Normally open

Com : Common

com

R1

R1

no

R1

nc

R2

com

R2

no

com

R2

nc R3com

nc

no

R3

no R3nc

R4

comR4no R4nc

+

=

-

OC1- OC1+ OC2

-

Open Collector 1

Open Collector 2

OC2

+

11

Page 16

Operating Instructions SWT-2000 DYNALCO

6. Configuration via PC Software

6.1 Software Concept

The SWT-2000 Ethernet connection is used to configure or interrogate the unit. (see Paragraph 9

Accessories) The resident menu driven configuration software is used for unit set up.

Normal PC file handling procedures apply and the configuration file can be communicated between computer

and SWT-2000.

To run the Software you must have Java Runtime Environment (JRE) 1.5 or higher.

6.2 PC Settings

The PC Ethernet card must first be set correctly. SWT-2000’s cannot be used on a network.

Go to Desktop, Settings, Network connections and right click on <Properties>. Right click the Network card

you want to use for SWT-2000 comms and select <Properties>.

Select Internet protocol (TCP/IP) and select the Option <IP-Address automatically recognize>

6.3 Download Configuration Software

Connect the Tachometer to your PC using a cross over patch cable. Once connected open your browser and

enter the IP address 192.168.1.127/software

An HTML page will open with the Link <Download control program>

Click on the Link. Dependent upon your Internet Explorer configuration you will be asked whether you want to

<Open> (Run) or <Save> (Save as) the program.

Direct Execution

Select <Open> and the configuration will be read from the tachometer (can take a few seconds). Once loaded

the configuration software will open automatically.

Save As

Select <Save> to save the file in a path of your choice (can take a few seconds).

Open the file from your PC. The configuration software establishes a connection to the SWT-2000 and reads

the actual parameters.

12

Page 17

Operating Instructions SWT-2000 DYNALCO

6.4 Configuration Software

Configuration User and Process User

SWT-2000 parameters are divided into 2 groups, Configuration and Process parameters.

When the program is started, the window shows 3 log in levels, Config user, Process user or Guest. Process

and Configuration users require passwords.

As a Guest one only has the right to view measured data or print out actual parameters.

A Process user can perform Guest functions and view and change Process parameters.

The Configuration user has full access and control over all Parameters, Process as well as Configuration.

The factory settings are shown below Bold.

6.4.2 Log in

Here you can Log in on three different levels. The standart passwords for Config- and Process- User are:

Config user password

Process user password

1981

1977

6.4.3 Main Window an d System L imit Matrix

After successfully logging in you will see the main window used for displaying system and measurement

status.

On the left the various System Limit inputs are listed. In the middle the System Limit and alarm status are

shown and on the right all outputs and current levels can be seen.

In the middle is a bar called System limit Matrix. Click on this and an overview of the logical status of System

Limits, binary inputs and sensor error is shown.

6.4.4 Logging In and Out

To change user level log out via <File> and click on <Log out>, then log in again using the appropriate

password.

6.5 Configuration File

6.5.1 …cre ating new

To create a new configuration file go to <File>, <New> and click on OK. All parameters are then reset.

Note: If you have not saved the live parameters, they will be lost.

13

Page 18

Operating Instructions SWT-2000 DYNALCO

6.5.2 …resetting to factory default

To reset parameters to factory settings go to <Settings> <Back to factory setup> then click on OK.

Note: If you have not saved the live parameters, they will be lost.

6.5.3 …load ing

To load an existing file go to <File>, <Open> and select the required configuration file.

Note: If you have not saved the live parameters, they will be lost.

6.5.4 …saving

To save actual parameters go to <File>, <Save as> and choose the path and file name you want to use.

Please note that the file name ends in the format *. SWT-2000.

6.5.5 …printout

To print actual parameters go to <File>, <Print> and choose your printer. 9 pages will be printed.

6.6 Communication with the SWT-2000

6.6.1 Read Measured Data

To read actual measured data and unit status go to <Online>, <Start – read measure data>.

Measured data is updated in the Main window with interval defined under <Settings>, <Refresh Interval>.

¼ Second

½ Second

1 Second

2 ½ Seconds

5 Seconds

10 Seconds

To end the measured data display go to <Online>, <Stop – read measure data>.

6.6.2 Reading Configuration from the SWT-2000

When the configuration software is started the configuration file is automatically transferred to the PC. To up

load the file again go to <Online>, <Read parameters> and confirm with Enter.

Note: The live parameter data will be overwritten.

14

Page 19

Operating Instructions SWT-2000 DYNALCO

6.6.3 Writing a Configuration to the SWT-2000

When a new configuration file is ready it can be downloaded into the tachometer. Go to <Online>, <Write

Parameters> Enter. The new Parameters are then transferred to the Tachometer (can take 10s.). If no

connection can be established this will be aborted after 3 attempts.

Note: The actual file in the tachometer will be overwritten.

6.6.4 Comp are Data

If you would like to compare a PC configuration file with that in the SWT-2000, first open the file and then go

to <Online>, <Compare Data>.

The actual file is then uploaded from the SWT-2000 and compared with the software parameters. A dialogue

window will then appear showing whether the files are identical or not.

6.7 Configuring

The factory defaults are written in bold.

6.7.1 Speed Sens o rs

Go to <Configuration>, <Sensor>.

To connect the sensor see Paragraph 5 Connections.

5 Parameters are used to configure the sensor:

Type: powered / not powered

Resistor: activated / deactivated

Min. current: 0.5mA … 35mA

Max. current: 0.5mA … 35mA

Trigger level: fixed 3V / min 57mV

Sensor Type

Powered:

The sensor is supplied from the SWT-2000’s 14V (+/-0.5V) supply. To use static sensor

monitoring, the Min/Max current consumption must be defined.

Not powered:

The sensor is not powered by the SWT-2000 and no static monitoring is possible.

Internal pull up resistor

Deactivated:

The internal pull up is not in circuit.

Activated:

The internal pull up is in circuit.

/ min 500mV

pp

pp

Current monitoring

When the sensor is supplied from the tachometer upper and lower current limits must be entered. Current

consumption outside of the defined limits results in a static sensor error being signaled.

Trigger level

One of 3 modes may be selected. Fixed Trigger (fixed 3V) for digital sensors and two adaptive Triggers

(57 mV

/ 500 mVpp) for Analog speed sensors (electromagnetic).

pp

15

Page 20

Operating Instructions SWT-2000 DYNALCO

6.7.2 Binary Input Configuration

To configure binary inputs go to <Configuration>, <Binary>.

The following options are available for each binary input:

Logic level: Active high / Active low

Function of binary input: Input for System Limit / Selection of Control (A/B) (C/D) / Reset latch

Logic level definition

Active High:

Active Low:

Binary input for

System Limit input:

Binary input is a constituent part of System Limits.

Parameter set selection:

Binary inputs select the parameter set (PS), see Paragraph 7.3.2 Parameter sets A, B, C and D

Reset latch:

Binary input resets the relays and open collectors.

Logic 1 = binary input 15V …33V

Logic 1 = binary input 0V … 5V

6.7.3 Set Measuremen t Interval

Go to <Configuration>, <Measurement time>.

This time interval determines the period during which the speed, parameters, status and outputs are

recalculated and set accordingly.

Measurement time: 2ms / 5ms / 10ms / 20ms / 50ms /

100ms / 200ms / 500ms / 1s / 2s / 5s

6.7.4 Sensor Alarm

Go to <Configuration>, <Sensor alarm>.

There are 3 sources of errors which may be OR

Static error sensor 1: On / Off

Static error sensor 2: On / Off

Dynamic error: On / Off

Box checked = On, unchecked = Off

(see also Paragraph 6.7.1 Speed sensors).

Dynamic Error can only be used when 2 sensors are present. (see Paragraph 6.7.6 Dynamic Error).

ed together. Each error source may be included or excluded.

16

Page 21

Operating Instructions SWT-2000 DYNALCO

6.7.5 Machine Factor

Go to <Configuration>, <System>.

The Machine factor establishes the relationship between sensor frequency and associated machine speed.

(see Paragraph 3.2 Machine factor)

The Machine factor may also be set by means of the number of pulses per rev. The 2 parameters have a

fixed relationship of factor 60 (Pulses per rev. = Machine factor x 60)

Machine factor: 0.0001 … 1 … 999,999

Pulses per revolution: 0.006 … 60 … 59,999,940

Once the machine factor has been established all further entries such as speed limits are in machine units

e.g. rpm.

6.7.6 Dyna mic Error

Go to <Configuration>, <System>.

: Sensor 1 frequency

f

Difference

This function is only available when both sensor inputs are used. This function has influence only on Sensor

alarm.

Deviation: 0.0 … 100.0 … 999,999

If the speed difference is greater, then Dynamic error is signalled.

−=

ff

S1

: Sensor 2 frequency

f

S2

SS

21

17

Page 22

Operating Instructions SWT-2000 DYNALCO

6.7.7 Math Function

Go to <Configuration>, <Math>.

Math function is an additional input available for System Limit.

The following Math functions may be constructed.

S1 – S2

S2 – S1

S1 / S2

S2 / S1

100% x (S1-S2)/S2

100% x (S2-S1)/S1

Variance (S1)

Variance (S2)

Acceleration (S1)

Acceleration (S2)

S1

S2

Percentage difference

)12(100

nn −×

1

n

Variance

1

2

=

S j = 100

Acceleration

a

−

j

v

Δ

=

=

n: Speed

j

∑

ix

1

=

1

i

Δ

If the variance for S1, S2 or Analog input needs to be calculated, the measurement time must be set to 5ms

or higher.

Subtraction of speed values

Division of speed values

Percentage difference

Variance

Speed value acceleration

The speed values are fed through

e.g. for the Math function.

2

)(

−

xx

−

alt

11

ttnt

−

n: Speed

altFlankeSFlankeS

11

18

Page 23

Operating Instructions SWT-2000 DYNALCO

6.7.8 System Limit

Go to <Configuration>, <System Limits>.

Every System Limit has the same 5 logic inputs: Sensor 1, Sensor 2, Math function, Binary input 1, Binary

input 2. A hysteresis may be applied to the first 3. Each may be inverted or selected to form part of a logical

combination or disabled. The logical combination of inputs may be OR or AND.

Sensor alarm may be additionally combined OR with the System Limit result.

Sensor 1:

Limit low: 0.01 … 200.0 … 999,999

Limit high: 0.01 … 300.0 … 999,999

Sensor 2

Limit low: 0.01 … 400.0 … 999,999

Limit high: 0.01 … 500.0 … 999,999

Math Function

Limit low: -999,999 … 50.0 … 999,999

Limit high: -999,999 … 100.0 … 999,999

Inversion:

Sensor 1: Over speed / Under speed

Sensor 2: Over speed / Under speed

Math: Over-run / Under-run

Binary input 1: active / inactive

Binary input 2: active / inactive

Inclusion in logical combination:

Sensor 1: On / Off System Limit 1

Sensor 2: On / Off System Limit 2

Math: On / Off System Limit 3

Binary input 1: On / Off System Limit 4

Binary input 2: On / Off System Limit 4

Logical combination:

Combined OR / AND

Hysteresis

Hysteresis may be definined for the first 3 inputs via upper and lower limits. If the lower limit is set higher than

the upper limit, the hysteresis is inverted.

Inversion

Every input may be inverted.

Logical combination

The box must be ticked to include the input in the logical combination.

Sensor Alarm

To OR Sensor alarm with the System Limit result the box must be ticked.

19

Page 24

Operating Instructions SWT-2000 DYNALCO

6.7.9 Relay Outputs

To configure relay outputs go to <Configuration>, <Relay / Open Collector>.

Relay configuration consists of:

Assignment, the Latch Function and the Fail safe/Not fail safe mode.

Possible relay assignment:

Latch Function: Latched / not latched

Safety function: Fail safe / Not fail safe

Assignment selection

The selection box is used to choose relay assignment.

Latch Function

Defines whether a relay state should be held until reset.

Safety Function

Defines whether the relay is to operate in Fail safe (deactivate at limit) or not fail safe mode (activate at limit).

System limit 1

System limit 2

System limit 3

System limit 4

System limit 5 Always ON

System limit 6 Always OFF

Sensor Error

Static S1

Static S2

Dynamic error

6.7.10 Open Collector Outputs

To configure Open Collector outputs go to <Configuration>, <Relay / Open Collector>.

Open Collector configuration consists of:

Assignment, the Latch Function and the Fail safe/Not fail safe mode.

Possible Open Collector assignment:

System Limit 1 Static S2

System Limit 2 Dynamic error

System Limit 3 Always ON

System Limit 4 Always OFF

System Limit 5

System Limit 6

Sensor Error Frequency x2

Static S1 Frequency x4

Latch Function: Latched / not latched

Safety mode: Fail safe / Not fail safe

Assignmment selection

The selection box is used to choose Open Collector assignment.

Latch Function

Frequency S1

Frequency S2

20

Page 25

Operating Instructions SWT-2000 DYNALCO

Defines whether an Open Collector state should be held until reset.

Safety Function

Defines whether the Open Collector is to operate in Fail safe (deactivate at limit) or not fail safe mode

(activate at limit).

6.7.11 Analog Output

To configure Analog outputs go to <Configuration>, <Analog out>.

4 parameters are available: Assignment, Current range, Start and End values and the time constant.

Assignment possibilities:

Sensor 1

Sensor 2

Math value

Current range: 0 ..20mA / 4 .. 20mA

Start value: -999,999 … 0.0 … +999,999

End value: -999,999 … 2.000.0 … +999’999

Time constant 0 … 9.9 in 0.1 Second increments

Assignment selection

The selection box is used to choose Analog Output assignment.

Current range

0 … 20mA or 4 … 20mA

Start and End values

Enter the start and end values e.g.

0 (rpm) = 4mA

2000 (rpm) = 20mA

If the end value is lower than the start value, the output current follows a falling characteristic.

Time constant

Sets a time constant T. The target value is reached after 5xT.

The output current follows an e- Function.

Analog output 1

Analog output 2

21

Page 26

Operating Instructions SWT-2000 DYNALCO

6.7.12 Copy P arameter Set

Go to <Configuration>, <Copy from Control A>.

A Parameter set may only be copied from Parameter set A. The following Parameters will be copied:

- Machine factor 1 and 2

- Difference

- Math Function selection

- Upper and Lower Limits in System Limits

- System Limit inversion

- Inclusion of input in the logical combination

- Inclusion of Sensor alarm in the logical combination

- Relay / Open Collector assignment

- Relay / Open Collector latch mode

- Relay / Open Collector fail safe mode

- Analog output assignment

- 0..20mA or 4..20mA setting

- Start and End values

- Analog output time constant

6.7.13 Change-Over Delay

Go to <Configuration>, <Delay>.

One change-over delay may be set for the delay in switching from Parameter set B to Parameter set A only.

Delay time: 0 … 2000 Seconds

Only integer values can be used for the change-over delay.

6.8 Settings

6.8.1 Ethernet Interface

Go to <Settings>, <Interface …>.

No settings can be made. The PC- SWT-2000 connection is Peer to Peer

(PC to PC). SWT-2000’s cannot be connected to a network!

For technical data see Paragraph 2.5.1 Ethernet.

DHCP Server ON / OFF

TCP/IP Adresse 192.168.1.127

TCP/IP Maske 255.255.255.0

22

Page 27

Operating Instructions SWT-2000 DYNALCO

6.8.2 Changi n g the Password

Go to <Settings>, <Change Config user password> or <Change Process user password>.

Changing the password involves entering the old password and the new password twice. To save the

password click on <OK>.

The password is now stored in the configuration software.

To change it in the SWT-2000 the data must be downloaded.

A Configuration user may change the Process user password by entering the Configuration user password

first. Factory set passwords:

Config User:

Process User

Attention: If the password has been changed, there is no way of returning to a factory setup. If the password

is forgotten, the SWT-2000 will need to be returned to Dynalco to be reset.

1981

1977

6.9 Info

To gain information about the SWT-2000 or to enter a Process name <Info>, <Info about>.

An individual Process name may be entered into the text field to the right of <Process ID>, max. 16

characters. (Only alphanumeric characters).

Type: Tachometer type number

Java version: Java Version stored in the Tachometer

Firmware: SWT-2000 Firmware Version

Serial Nr: SWT-2000’s serial no.

Cal. Date: Calibration date

TCP/IP Address: SWT-2000’s IP Address

JRE Version: PC’s JAVA Runtime

23

Page 28

Operating Instructions SWT-2000 DYNALCO

7. Operating Behavior

7.1 Power On

The parameter set e.g. as defined by binary inputs is immediately valid.

7.1.1 Analog Output

Immediately after power on, the output corresponds to the lower range value set. Following the first

measurement interval the output corresponds to the measured value.

7.1.2 Relay Output

Up until the first measurement interval is completed, all relays are de-energiZed. Thereafter they assume the

defined condition.

If no input frequency is present then after measurement interval x 2, 0Hz is assumed.

7.1.3 Open Collector Output

Up until the first measurement interval is completed, all Open Collectors are inactive. Thereafter they assume

the defined condition.

If the Open Collector is assigned to a frequency, then it immediately assumes the corresponding status.

If no input frequency is present, then after measurement interval x 2, 0Hz is assumed.

24

Page 29

Operating Instructions SWT-2000 DYNALCO

7.2 Frequency Measurement

Every frequency measurement starts with the negative edge of the input signal. The last measured edge prior

the end of the measurement interval completes the running measurement and immediately starts the next.

An optimum measurement is achieved when the input period is shorter than the measurement interval.

Input signal

End of the measurement interval

Input period

Measurement

Time

If the input period is greater than the measurement interval, the frequency is calculated as follows:

f

=

1

n: Number of measurement intervals without input signal

nt

×

tMeasuremen

This continues until a second negative edge arrives.

End of the measurement interval

Input signal

Input period

Measurement

Time

The calculation and adjustment of outputs occurs immediately after the start of the next measurement interval.

If the input frequency is lower than the lower limit (0.025Hz), then the output will be zero. The measurement of

input frequencies above the upper limit (50kHz) is not guaranteed.

7.2.1 The Adaptive Trigger Level

The trigger level is continuously adjusted for

successive pulses. This guarantees that the trigger

level can follow a 50% reduction in speed from pulse

to pulse. DC offset, resonance and negative pulses

have no effect on the triggering

U

Old Triggerlevel

Triggerlevel

t

signal to

noise ratio

bad

Sensorsignal

25

Page 30

Operating Instructions SWT-2000 DYNALCO

7.2.2 Sign al Failur e

Signal failure is defined as the sudden transition from an input frequency to no further recognisable pulses.

The frequency is then calculated as follows:

f

=

The measured speed thereby follows an exponential function to the minimum frequency (0.025Hz) and then

falls to zero.

1

n: the number of measurement intervals without an input signal

nt

×

tMeasuremen

7.3 Functions

7.3.1 “FUNC ” Push Button

The front panel “FUNC“ button is ORed with binary input B1. Pushing this button executes the B1 function.

7.3.2 Parameter Sets A , B, C and D

The binary inputs must be used to change parameter sets. To configure binary inputs see paragraph 6.7.2.

Binary input configur.

Binary input configuration

Binary input 1 to <Selection of Control A/B>

Binary input 2 not to parameter set selection

Binary input 1 not to parameter set selection

Binary input 2 to <Selection of Control C/D>

Binary input 1 to <Parameter set selection A/B> and

Binary input 2 to <Parameter set selection C/D>

For delay in switching between Parameter sets B and A see Paragraph 6.7.13 Change-over delay.

Status

BIN 1

0 X A

1 X B

X 0 C

X 1 D

0 0 A

0 1 B

1 0 C

1 1 D

Status

BIN 2

Selected

Parameter set

7.3.3 Limits

User defined upper and lower limits allow wide or narrow hysteresis to be set. Unless otherwise required we

recommend a hysteresis of 10%.

26

Page 31

Operating Instructions SWT-2000 DYNALCO

7.3.4 Math Function

To set a Math function on a speed input please follow the steps below. (Example for Sensor 1):

1. Set the Math function to S1.

2. Set Math function and Sensor 1 hysteresis.

3. The Sensor – hysteresis gets the higher limit.

4. Math function must be set to under run.

5. All logic inputs must be switched off except Sensor 1 and Math function.

6. The two inputs must be combined OR.

System limit settings

27

Page 32

Operating Instructions SWT-2000 DYNALCO

7.3.5 Frequency X2 and X4

Prerequisites for the X2 and X4 function are that the input frequencies are synchronized, they exhibit

approximately 90 degrees phase shift and a Mark : Space ratio of approximately 1:1.

The X2 function is an EXOR combination of input frequencies S1 and S2. The X2 output frequency can reach

a max value of 35KHz.

The x4 function is based on doubling of the X2 frequency and generates a 10us output pulse each time a

positive or negative X2 edge is detected.

The Mark : Space ratio thereby changes with frequency. The x4 output frequency can reach a max value of

35KHz.

Frequency S1

90°

Frequency S2

Frequency X2

Frequency X4

10us

7.3.6 Rela y and Open Col lector Latch Function

Relays and Open Collectors can be assigned a latch function. If a signal arrives from the assigned function the

relay / OC is latched and remains latched until reset via binary input or the <FUNC> button.

Where fail safe mode is selected the deactivated Relay / Open Collector state is held.

7.3.7 Analog Output

If an analog time constant higher than zero is set, with measurement interval of 2ms, then the max.

frequency that can be measured is 35KHz.

To measure frequencies higher than 35KHz with time constant higher than zero, a min. measurement

interval of 5ms must be selected.

If Sensor Alarm is active that influences the analog output, which assumes the error condition:

Configuration Output current

0 .. 20mA 21mA

4 .. 20mA 4mA

28

Page 33

Operating Instructions SWT-2000 DYNALCO

7.3.8 Interpretation of System Limit Inputs

Upper and lower set points may be set for each of the 3 system limit inputs. In this way a hysteresis is defined.

If the upper set point is exceeded then this input assumes a status of 1. When the lower set point is then

passed, the status returns to 0. If the actual value lies between the 2 set points then the status is as before.

If a parameters set change takes place when the actual value lies between the set points, the status also

remains as before.

7.4 Fault Behavior

7.4.1 Sensor Error

The sensors may be monitored in 3 ways.

• Sensor powered by the SWT-2000 – Sensor supply current monitoring.

If the current falls outside of the defined range, a static error is signalled.

• Sensor not powered by the SWT-2000 – wire break detection.

Static error is signalled when wire breakage occurs. (Impedance measurement of 2 wire sensor)

• 2 speed sensors connected – Dynamic sensor monitoring, i.e. the 2 signals may be compared. If the

values differ by more than the defined tolerance, dynamic error is signalled.

The SWT-2000 behaviour in the event of a sensor fault is a function of the software configuration. If sensor

monitoring is selected, a fault causes the LED to go off and the analog output (both) go to error status. The

Relay and open collector behavior is a function of the configuration.

7.4.2 System Alarm

The microprocessor continuously monitors the following functions for errors: Supply, math functions of the

micro controller, RAM, EEPROM.

In the event of a fault the relays are de-activated, the current output goes to 2mA (4-20mA) or 21mA

respectively and the Open Collectors become high resistance if assigned to a function other than frequency

output. The SWT-2000 then initializes and attempts to run again.

7.5 Power Failure

If the power fails for longer than the bridging time, the outputs are de-activated, i.e. Analog outputs go to 0mA,

relays de-activate and the Open Collectors go to high resistance.

As soon as the supply returns to the minimum required, the SWT-2000 commences its initialization routine.

7.6 Behavior During Configuration

During the transmission of configuration or process parameters to the tachometer, it goes into a safe mode,

i.e. the outputs assume a defined state. For individual outputs that means:

• Relays: are no longer powered

• Open Collectors: become high resistance

• Analog outputs: assume the fault mode according to the configuration

29

Page 34

Operating Instructions SWT-2000 DYNALCO

8. Mechanical Construction / Housing

Dimensions

8.2 Mounting

Wall mounting Top hat rail mounting

(as delivered)

30

Page 35

Operating Instructions SWT-2000 DYNALCO

9. Accessories

Interface Cable PC – SWT-2000 (6 Ft crossover): Part No. 270A-105039

31

Loading...

Loading...