Page 1

SWT-1000

Speed Switch / Transmitter

Operating Manual

3690 NW 53rd Street • Fort Lauderdale, FL 33309 • Ph 954-739-4300 • Fax 954-4 86 -4968 • www.dynalco.com

Page 2

TABLE OF CONTENTS

1. Product Features 1

2. Specifications 2

2.1 General 2

2.2 Inputs 3

2.2.1 Analog Sensor Connection (Sign) 3

2.2.2 Digital Sensor Connection (IQ) 4

2.2.3 Binary Input and Push Button 4

2.3 Outputs 5

2.3.1 Analog Output 5

2.3.2 Relay 6

2.3.3 Open Collector Output 6

2.4 Data Communication 6

2.4.1 Serial Interface (RS 232) 6

2.5 Environment 6

2.5.1 Climatic Conditions 6

3. Principle of Operation 7

3.1 General 7

3.2 Machine Factor 8

4. Installation 9

5. Connections 9

6. Hardware Configuration 10

6.1 Analog Sensor Input (Sign) 10

6.2 Digital Sensor Input (IQ) 10

7. Configuration with PC Software 11

7.1 Software Concept 11

7.2 PC Communications 13

7.3 PC Software Settings 11

7.3.1 Interface (Settings Æ Interface) 11

7.3.2 Display Interval (Settings Æ Di splay Int erval) 11

7.4 Parameter List and Ranges 12

7.5 Parameters 14

7.5.1 System Parameters (Configuration Æ System) 13

7.5.2 Sensor Parameters (Configuration Æ Sensor) 13

7.5.3 Analog Output (Configuration Æ Anal og Output) 14

7.5.4 Limits (Configuration Æ Limits) 15

7.5.5 Relay Parameter and Selection of Parameter Set 15

8. Operating Behavior 17

8.1 Power On 17

8.1.1 Analog Output 17

8.1.2 Relay Output 17

8.2 Measurement 17

8.2.1 The Adaptive Trigger Level 17

8.2.2 Signal Failure 18

8.3 Functions 18

8.3.1 Limits and Window Function 18

8.3.2 Parameter Sets A and B 18

8.3.3 Relay Hold Function 18

8.3.4 Push-Button 18

8.3.5 Binary Input 19

8.4 Fault Behavior 19

8.4.1 Sensor Fault (Sensor monitoring) 19

8.4.2 System Alarm 19

8.4.3 Alarm 19

8.5 Power Supply Interruption 20

9. Mechanical Construction / Housing 20

10. Accessories 20

11. Outline Dimensions 20

Page 3

Operating Instructions SWT-1000 DYNALCO

1. Product Features

The model SWT-1000 speed switch / transmitter measures and monitors frequencies (speed

proportional values) in the range 0 to 35,000 Hz.

The following are available:

• 1 Current output

• 1 Sensor frequency output

• 1 Relay

• 2 Limits

• 2 Parameter sets – selectable via binary input

• Sensor monitoring

• System monitoring

The tachometers are configured via SWT -1000 PC configuration software.

All settings are in revolutions per minute (RPM).

Single channel tachometer, relay and 0/ 4-2 0mA current output

SWT-1000.r2.0609 1

Page 4

Operating Instructions SWT-1000 DYNALCO

2. Specifications

2.1 General

SWT-1000

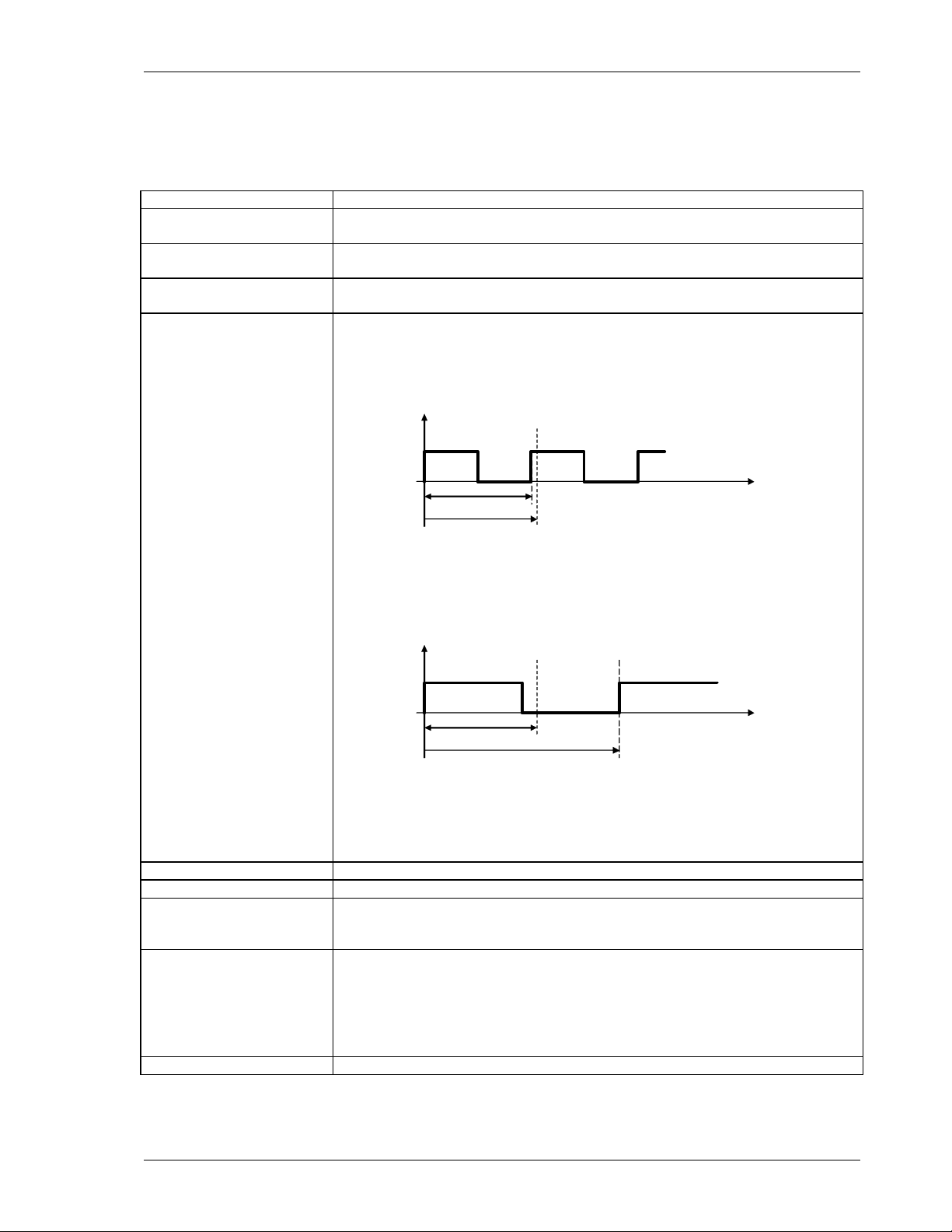

Lowest measuring

range

Highest measuring

range

Minimum response time

(Fix Time)

Effective Measuring

time

0.01 . . . 1.000 Hz

0.01 . . . 35.00 KHz

Selectable values: 2 / 5 / 10 / 20 / 50 / 100 / 200 / 500 ms

1 / 2 / 5 Seconds.

Is based on the minimum measuring time (Fix Time) and the measured

frequency.

• Input frequency period < Fix Time

Input

frequency

End of Fix Time

Input period

Fix Time

typically: t

max: t

= Fix Time

effective

= 2 x Fix Time

max

• Input frequency period > Fix Time

Input

frequency

End of Fix Time Ensuing edge

Fix Time time

Period of input signal

max: t

max

• In the event of sensor signal failure:

t

= Fix Time + (2 x last input frequency period)

effective

Resolution 0.05 %

Power supply range 10...36 VDC

Power consumption 10 V : 2.3 W

24 V : 2.6 W

36 V : 3.0 W

Isolation Galvanic isolation between:

• Power supply,

• Sensor input incl. sensor supply, Binary input, Seria l i n te rfa ce

• Analog output

• Relay output

• Open collector output

Isolation voltage 700 VDC / 500VAC

time

= 2 x input frequency period

SWT-1000.r2.0609 2

Page 5

Operating Instructions SWT-1000 DYNALCO

2.2 Inputs

2.2.1 Analog Sensor Connection (Sign)

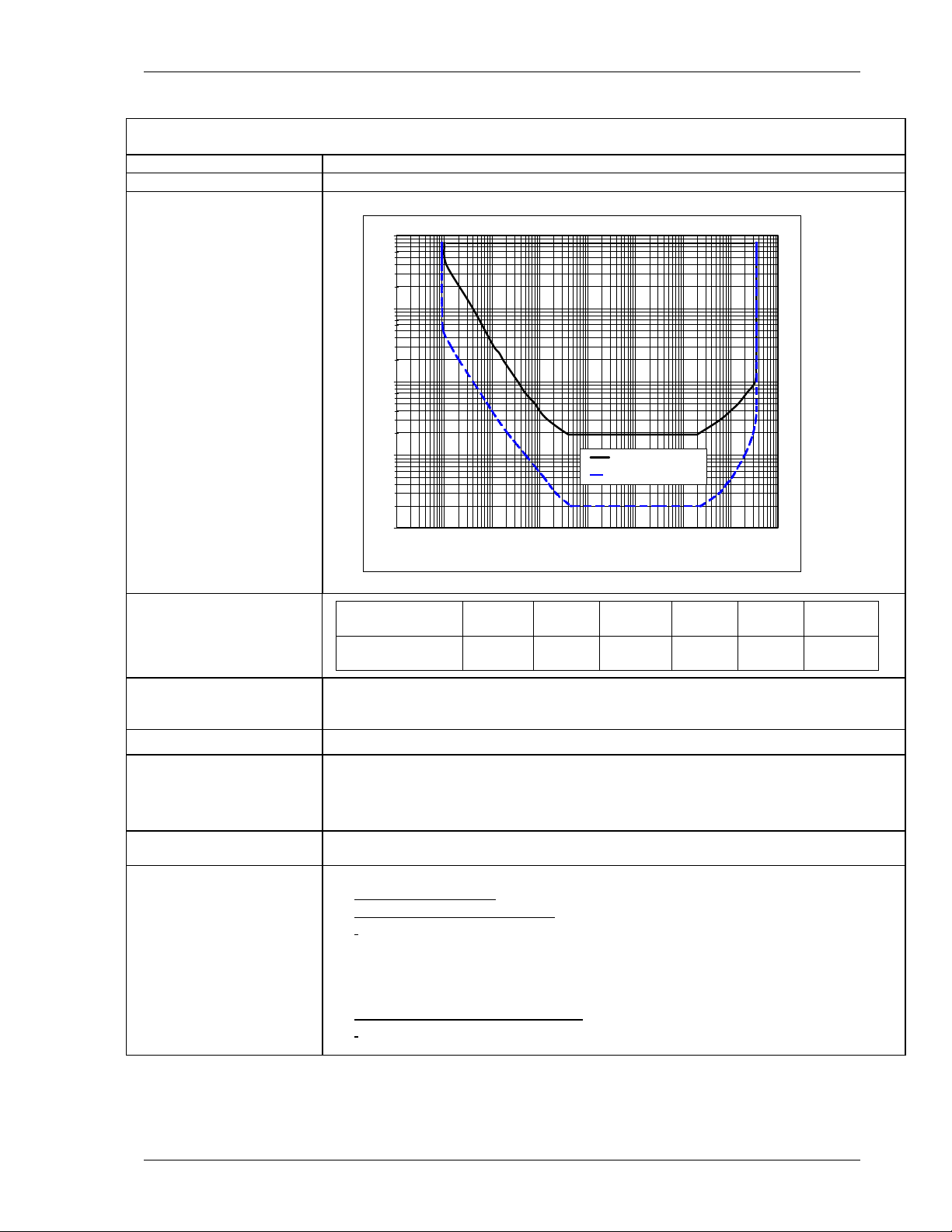

Frequency range (-3dB) 0.01 Hz / 35 kHz

Input impedance 30kOhm

Input voltage

• Max. 80V

•

100

10

Input voltage [Veff]

rms

Max. frequency against input voltage

O.K.

1

0.001

]

pp

NOT O.K.

0.01

0.1

1

10

Frequency [Hz]

Trigger: 500mVpp

Trigger: 20mVeff

100

1000

10000

100000

0.5 1 2.5 5 10 20

2000 667 333 200 166 125

Minimum positive pulse

width - digital signals

Input voltage

0.01

Signal

voltage [V

Min. Pulse

width [µs]

0.1

Sensor supply +14 V, max. 35 mA short circuit proof.

If the current limit activates, the sensor supply must be disconnected to reset the

protection.

Integrated pull-up 820 Ohm to +14V (configurable for 2 wire sensors with Jumper J1)

Trigger level Adaptive trigger level.

Configurable with Jumper J2:

• 250mV … 6.5V (>500mVpp) [Factory configuration]

• 28mV … 6.5V (>20mV

rms

)

Screen A terminal is provided for the sensor cable scre en. Th is terminal is connected to the

sensor supply 0V. (0VS)

Sensor monitoring 1 of 3 sett i ng s ma y be con figured via software:

• No Sensor Monitoring

• Monitoring of powered sensors

Also for 2 wire sensors supplied via the Pull-up resistor (Jumper J1)].

[

Æ The sensor is considered to be defectiv e if the sensor current consumption

falls outside of I

I

= 0.5…25mA

min.

= 0.5…25mA

I

max.

min

and I

• Monitoring of non powered sensors

For 2 wire sensors such as electromagnetic sensors.]

[

max

.

Æ The sensor is considered to be defective if the circuit is disconnected.

SWT-1000.r2.0609 3

Page 6

Operating Instructions SWT-1000 DYNALCO

2.2.2 Digital Sensor Connection (IQ)

Frequency range (-3dB) 0.01 Hz / 35 kHz

Input impedance 46 K

Input voltage Max. ± 36V peek

Minimum pulse width Min. pulse width 1.5 µs

Sensor supply +14 V, max. 35 mA short circuit proof.

If the current limit activates, the sensor supply must be disconnected to

reset the protection.

Trigger level

Screen A terminal is provided for the sensor cable screen. This terminal is

Sensor monitoring 1 of 2 settings may be configured via software:

• min.U

• max.U

low

high

= 1.6 V

= 4.5 V

connected to the sensor supply 0V. (0VS)

• No Sensor Monitoring

• Monitoring of powered sensors

Also for 2 wire sensors supplied via the Pull-up resistor (Jumper J1)

[

].

Æ The sensor is considered to be defective if the sensor cu rr ent

consumption falls outside of I

= 0.5…25mA

I

min.

I

= 0.5…25mA

max.

min

and I

max

.

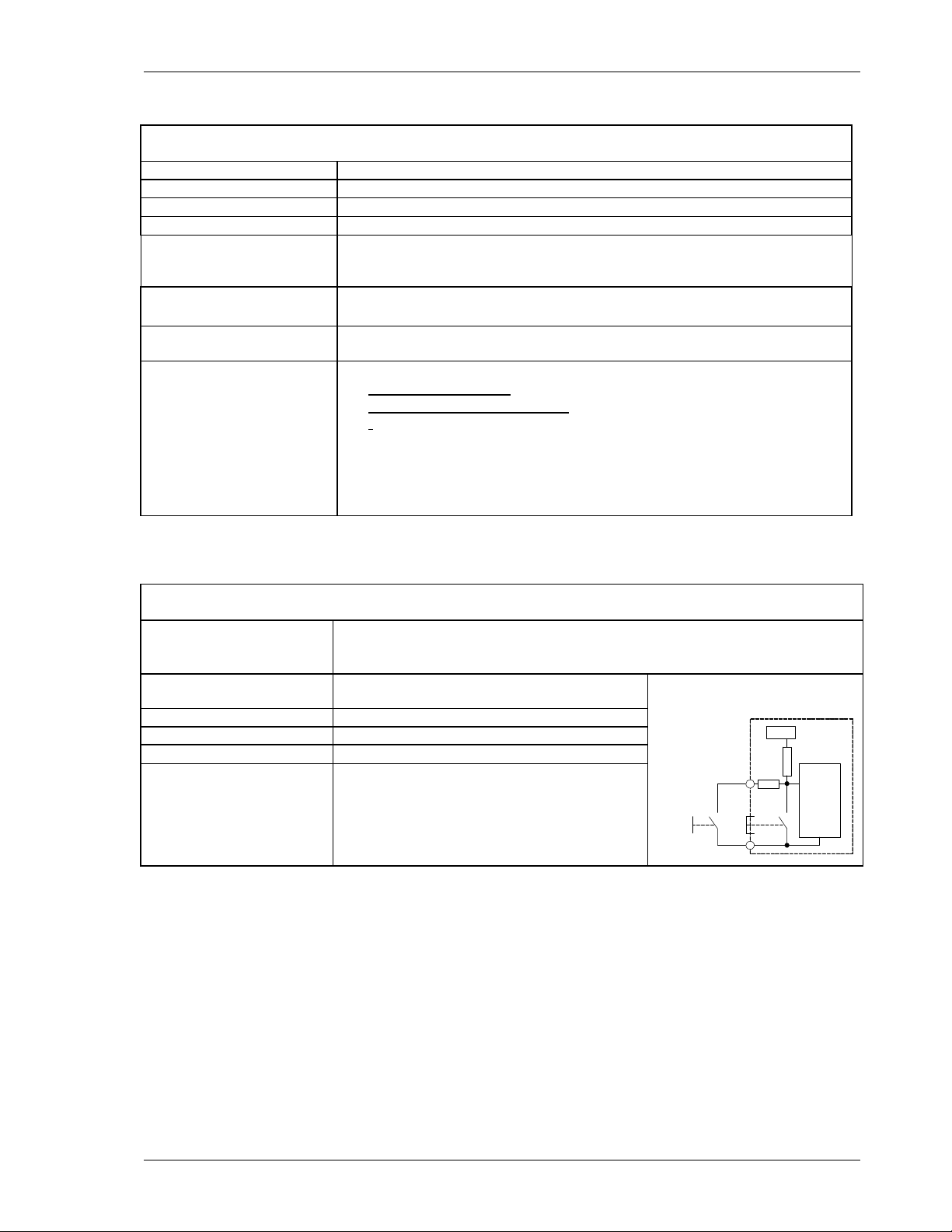

2.2.3 Binary Input and Push Button

Use For external selectio n of Parameter set A or B.

• Logic 1 = Parameter set A (Relay control A)

• Logic 0 = Parameter set B (Relay control B)

Levels Logic 1 = V > +3.5V

Logic 0 = V < +1.5V

Reference Sensor supply 0V

Max voltage 36V

Input resistance

Circuit Internal pull up resistance to 5V

R

= 10kΩ

min

Shorting the binary input to the sensor 0V

creates logic 0.

parameter set A B

+Bin

pushbutton

OVS

5 volts

SWT-1000

analysis

SWT-1000.r2.0609 4

Page 7

Operating Instructions SWT-1000 DYNALCO

2.3 Outputs

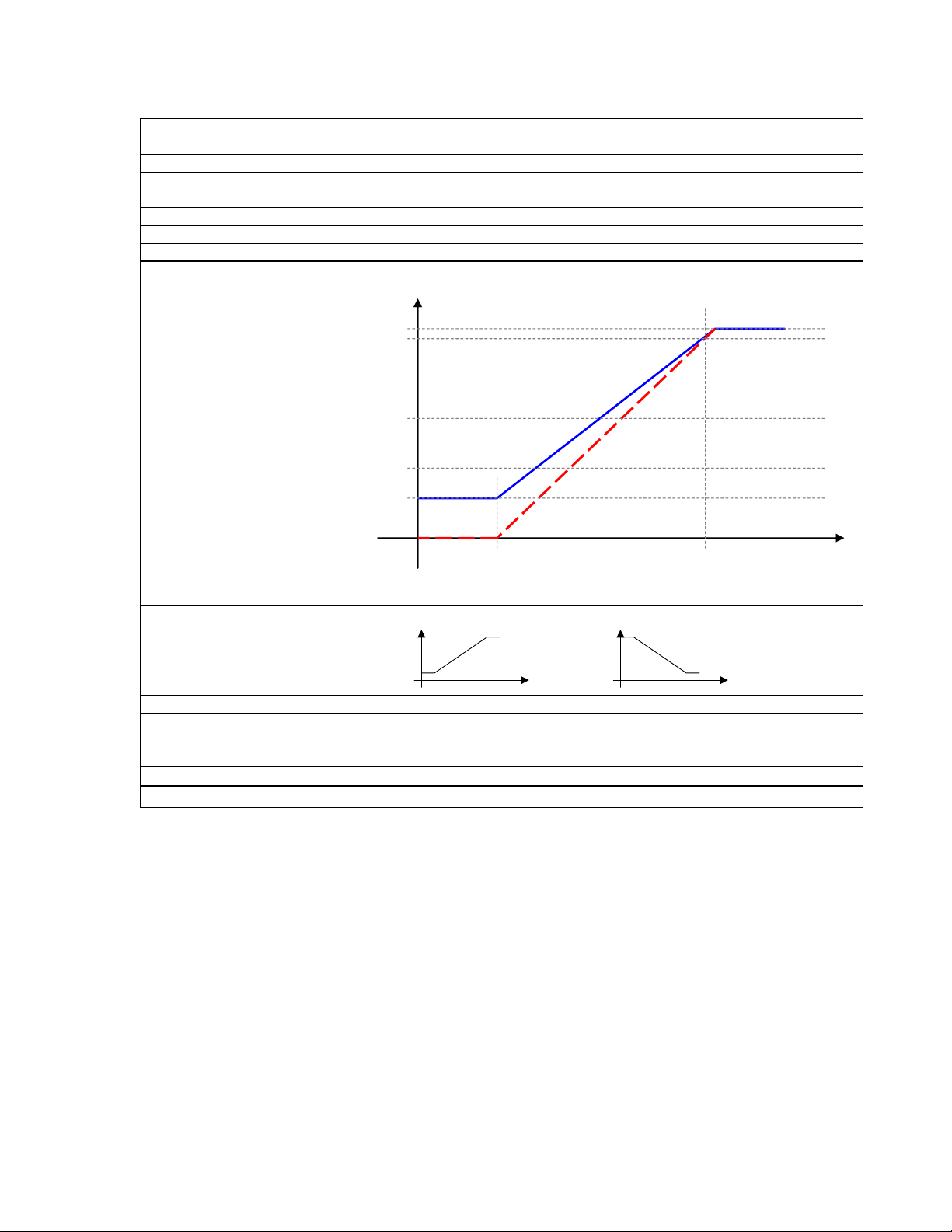

2.3.1 Analog Output

Type Current

Load Max. 500 ohms

Open circuit voltage Max. 12V

Operating Mode

SWT-1000

0…20 / 4…20mA

[mA]

21

20

12

4

0

4...20mA mode

0...20mA mode

initial value final value

Transfer functions Normal or Inverse (rising or falling characteristic)

output

„normal“

speed

output

„invers“

Resolution 12 Bit (4096 Steps)

Max Linear error 0.1 %

Accuracy 0.5 % of the full range value.

Damping Hardware 11 ms + Software setting (Configuration)

Temperature Drift

Typically ± 100 ppm/K, max. ± 300 ppm/K

Reaction time Effective measuring time + 7.5ms

(minimal measured

speed

value)

speed

[rpm]

SWT-1000.r2.0609 5

Page 8

Operating Instructions SWT-1000 DYNALCO

2.3.2 Relay

Type Single Pole Double Throw

Limit Hysteresis Programmable – 1 lower and 1 upper set point per limit.

Functions 2 programmable parameter sets select a ble via binary input

• Reaction to Alarm, Sensor fault, Limit, always on or off.

• “Normal“ or “Inverse“ (normally de-ene r gized or energized)

• With or without ‘Hold function’ (Reset via Binary input )

Accuracy 0.05% of the value set

Temperature tolerance

Reaction time Effective me asur ement time + 10.5ms

Contact rating AC: max. 250 VAC, 1250VA.

Contact isolation 1500 VAC

Max. ± 10ppm of the value set

DC:

2.3.3 Open Collector Output

Type Opto-coupler (passive)

External Pull-up R = 143 x V (Ic nominal = 7 mA)

R = 91 x V (Ic nominal = 11 mA)

Load voltage V = 5 – 30V

Max load current 25mA

Isolation 1500VAC

2.4 Data Communication

2.4.1 Serial Interface (RS 232)

Physical Layer Similar to EIA RS 232 but with +5V CMOS Level

Max cable length 2 m

Transmission rate 2400 Baud

Connection Front panel, 3.5mm jack plug

2.5 Environment

2.5.1 Climatic Conditions

Operating temperature - 40 ... + 85 °C

Storage temperature - 40 ... + 90 °C

Relative humidity 75% averaged over the year; up to 90% for max 30 da ys.

Condensation to be avoided.

SWT-1000.r2.0609 6

Page 9

Operating Instructions SWT-1000 DYNALCO

X

2

3. Principle of Operation

3.1 General

The SWT-1000 is controlled by a micropro ce ssor . It works according to the period measu rem ent

principle whereby the input period is measu r ed with subsequent computing of the reciprocal value

corresponding to the frequency or speed. The relationship between frequency and speed is

established with the Machine factor.

The current output and relay cont rol a re de te rmined from the speed. The relay function is defin ed

via 2 selectable parameter sets. Each parameter set can ac ce ss the 2 limit values, the alarm

definition, sensor monitoring and other process values. The 2 limits each have and upper and

lower set point (hysteresis setting). The selection of the valid parameter set is via the binary i np ut .

The relay status may be held until reset via the binary input

The system continuously monitors itself. In addition, the sensor may be moni tored. Dependent

upon the configuration, these co nditions can influence the relay and current output.

The alarm status is indicated via the front panel LED.

The frequency output (open colle ctor output) is not influenced by the machine factor and

corresponds to the input signal frequency.

The input of all parameters is via PC software and the RS232 interface. This may also be used to

interrogate the unit’s settings, measurement and general status.

Parameters are retained in an EEPROM.

binary

input

Analysis of the

binary input

Reset

Choice of the parameter set A/B

Push-Button

Sensor

connection

Sensor suppl y

Sensor control

Periodic time

measurement

EEPROM

RS 232

Frequency

calculation

Sensor failure

Frequency

System control

Machine

factor

System failure

Speed

Definition Alarm

Definition limit 1

Definition limit

Definition current output

Definition

Relay

LED

Relay

Current

output

Open

Collector

SWT-1000.r2.0609 7

Page 10

Operating Instructions SWT-1000 DYNALCO

3.2 Machine factor

The machine factor establishes the relati on sh ip between sensor frequency (Hz) and corresponding

speed (RPM).

Machine Factor = Frequency

RPM

If the # gear teeth and RPM are known, use the fol l o wing formula to calculate corresponding

frequency:

Signal Frequency (Hz) = (RPM) X (Teeth or Discontinuities)

60

Another way to calculate the machine f a cto r is :

Machine Factor = (Teeth or Discontinuities)

60

Note: The above formulas are base d on the gear or target turning at the same speed as t he

machine being monitored, ie: no step up or step down gear ratios involved.

SWT-1000.r2.0609 8

Page 11

Operating Instructions SWT-1000 DYNALCO

4. Installation

The SWT-1000 may only be installed by trained and comp e ten t pe r so nnel. An undamaged SWT1000, valid configuration and suitable in sta llation are required.

The power to the SWT-1000 should be capable of being disconnected via a switch or other

emergency means.

Before switching the equipment on, the power supply voltage should be verified t o be in the

permissible range.

The sensor cable screen must be connected to the terminal ‘Sh’ so as to minimize the influence of

noise. This terminal is directly connected int ern ally to 0VS.

5. Connections

Front view SWT-1000

Sensor connections

Sh : Screen - Sensor cable

0VS : Sensor reference voltage

+V Out : Sensor Supply

Ana. : Sensor signal analog

Dig. : Sensor signal digital

Pulsed Output

+ PO : Open Collector Output

- PO : Signal reference for the Open Collector

Relay output:

NC : Normally closed

NO : Normally open

COM : Common

Analog Output:

+ AO : Current positive

- AO : Current negative

Supply:

+24V : Power (10 ... 36 V)

GND : Power reference

: Earth

SWT-1000.r2.0609 9

Page 12

Operating Instructions SWT-1000 DYNALCO

6. Hardware Configuration

6.1 Analog Sensor Input (Sign)

Jumper

position

J1: Sensor type

2 wire sensors

(with 820Ohm Pull Up resistance)

J1

J2

J2: Adaptive trigger level

range

28mV to 6.5V (>20mV

rms

)

3 wire and electromagnetic sensors

(factory setting)

250mV to 6.5V

(>500mVpp)

[factory setting]

6.2 Digital Sensor Input (IQ)

No hardware configuration neces sary.

SWT-1000.r2.0609 10

Page 13

Operating Instructions SWT-1000 DYNALCO

7. Configuration with PC Software

7.1 Software Concept

All settings are written via PC to the SWT-1000 usin g t he RS232 interface and the aid of the user

friendly menu driven SWT-1000 software.

The parameter file may be stored, op en ed , printed and exchanged between the SWT- 100 0 a nd a

PC.

7.2 PC Communications

Communications with the SWT-1000 are init iat ed by the PC via the RS232 interface.

Prior to starting comms, Settings Æ Interface must be set to an appropriate serial interface.

The following settings also apply:

Transmission rate: 2400 Baud

Parity Bit: none

Data Bits: 8

Stop Bits: 2

Connector: 3.5mm jack plug

5 1

female

2

3

5

TXD

RXD

GND

TXD RXDGND

9

6

The diagram shows the stereo jack plug to D9 connections.

The tachometer RXD must be connected to t he PC’s TXD and vi ce ve rsa.

The SWT-1000 does not use a standard RS232 signal (-5V…+5V) but operates at 5V CMOS

levels, compatible with most PC’s as long as the cable is not longer than 2m.

A suitable cable may be ordered from DYNALCO – see sect ion 1 0 .

7.3 PC Software Settings

Interface (Settings Æ Interface)

In this menu the serial interface for comms with t he SWT-1000 is defined.

Display Interval (Settings Æ Display Interval)

The SWT-1000 measurement status may be inte rro gated and displayed on the PC via SWT-1000

Æ Start – Reading Measure Data.

The display update time may be set at intervals of ¼ to 10 seconds.

SWT-1000.r2.0609 11

Page 14

Operating Instructions SWT-1000 DYNALCO

7.4 Parameter List and Ranges

If you already have a configuration file you can open and view it using the SWT-1000 Wi nd ow s

Software menu

File Æ Open

You can also connect the SWT-1000 to a PC (see sect io n 7.2 ) an d r ea d ba c k t he parameters,

SWT-1000 Æ Read parameters

Once loaded into the software the parameter set may be printed via File Æ Print

Normal Windows file handling rules appl y .

7.5 Parameters

Parameters are changed in the sub menus fro m the d ro p do wn menu “Configuration“. Paramete r

list and ranges. Factory settings are shown in bold.

Configuration < System >

Machine factor 1.0000E-07 ... 1.0000 .. . 9.9 999E+07

Minimum Measuring time 2 / 5 / 10 / 20 / 50/ 100 / 200 / 500 ms / 1/ 2 / 5 Seconds

Min displayed measured value 1.0000E-12 ... 1 ... 1.0000E+12

Alarm definition Only System error System error OR Sensor Monitoring

Configuration < Sensor >

Sensor Type Active / Passive

Sensor input Analog (Sign) / Digital (IQ)

Sensor current minimum 0.5 ... 1.5 ... 25.0mA

Sensor current maximum 0.5 ... 25.0mA

Configuration < Analog output >

Measuring range start value 0.0000 ... 90% of the end value

Measuring range end value 1 … 2000.0 … 500000

Output range 0 ... 20mA / 4 ... 20mA

Time constant (Damping) 0.0 ... 9.9s

Configuration < Limits >

Status Limit 1 On / Off

Status Limit 2 On / Off

Mode Limit 1 Normal / Inverse

Mode Limit 2 Normal / Inverse

Lower Set point Limit 1 0.1 … 200.00 … 500000

Upper Set point Limit 1 0.1 … 300.00 … 500000

Lower Set point Limit 2 0.1 … 400.00 … 500000

Upper Set point Limit 2 0.1 … 500.00 … 500000

Configuration < Relay control >

Switching of control A/B

Selection of actuator None (always control A) / Binary Input B1

Delay time 0 ... 2.000 s

Relay Assignment

Control A Alarm / Sensor monitor / Limit 1 / Limit 2 / Window / On /

Off

Acknowledge A Without acknowledge (no hold function) /

Relay held when control active /

Relay held when control inactive

Acknowledge B Alarm / Sensor monitor / Limit 1 / Limit 2 / Window / On /

Off

Acknowledge B Without acknowledge (no hold function) /

Relay held when control active /

Relay held when control inactive

SWT-1000.r2.0609 12

Page 15

Operating Instructions SWT-1000 DYNALCO

Warning:

New configurations only become active af te r being d o wnl oad ed into the SWT-1000 via:

SWT-1000 Æ Write Parameters

7.5.1 System Parameters (Configuration Æ System)

Machine Factor

The machine factor establishes the relationship between s ensor frequency and associated speed.

Machine Factor = Frequency

RPM

See section

3.2 Machine factor.

Once the correct machine factor is enter ed, all ot her settings e.g limits are made in RPM.

Minimum Measuring Time

The minimum measuring time determines the ti me dur in g whi ch the input frequency is measured.

Once this time has lapsed, the calculation is made following the end of the running signal perio d.

The minimum measuring time may be increased to filter out frequency jitter so as to display a

stable reading but at the cost of increased reaction time.

Minimum Displayed Value

The minimum displayed value is a measured value under wh ich “0 0 00” is displayed.

Alarm Definition

This function defines the alarm. It may be only system error or a logical OR combination of

system error OR sensor monitoring. During an alarm the LED is off. In addition, the relay is

deactivated and the analog outpu t goes to 0mA irrespective of the output range.

7.5.2 Sensor Parameters (Configuration Æ Sensor)

Sensor Type

The type of sensor to be used is defined here.

<Sensor active>

supplied via the internal pull up resistor. (Jumper J1).

<Sensor passive>

See also section 8.4.1 Sensor Fault (Sensor monitoring).

Sensor Input

The sensor input “analog” (Sign) or “digital” (IQ) is defined here.

Sensor Current Minimum

As long as the sensor current consumption lies abov e the value <Current Minimum>, the sensor

is considered to be functioning correctly.

Sensor Current Maximum

As long as the sensor current consumption lies below the value <Current Maximum>, the sensor

is considered to be functioning correctly.

SWT-1000.r2.0609 13

is for monitoring sensors powered by SWT-1000 including 2 wire sensors

is for monitoring non powered sensors e.g. 2 wi re VR (pa ssive) sensors.

Page 16

Operating Instructions SWT-1000 DYNALCO

7.5.3 Analog Output (Configuration Æ Analog Output)

[mA]

21

20

4...20mA mode

12

(minimal measured

value)

4

0...20mA mode

0

initial value final value

speed

[RPM]

Measuring range – start value

Analog output start value 0 or 4mA

Measuring range – end value

Analog output end value 20mA

In the case of a negative transfer function the end value must be set smaller than the start value.

Output range

0…20mA or 4…20mA

Output time constant

The analog output signal may be smoothed by applying a software time constant. This damping is

deactivated when the time constant is 0. 0 seconds.

SWT-1000.r2.0609 14

Page 17

Operating Instructions SWT-1000 DYNALCO

t

7.5.4 Limits (Configuration Æ Limits)

The SWT-1000 series offers 2 independent limits Æ Limit 1 and 2.

Status

Limits are selected here. If the limit is deactivated, the other values such as set points and mode

have no further effect.

Mode

In Normal Mode the limit is active as soon as the High set po int is exceeded. In Inverse Mode the

limit is active from the start (zero speed) and deactivates when t he set point is reached (Fail Safe

operation)

Upper and Lower Setpoint

limi

activated

switching point

lower

upper

switching point

deactivated

As the speed increases, the limit switches when the High set point is rea che d a nd remains in that

condition until the speed reduces past the Low set point.

7.5.5 Relay Parameter and Selection of Parameter Set

(Configuration Æ Relay control)

Parameter set A / B selection

With standard factory setting, paramet e r set B may be acti v at ed via the binary input <Binary input

B1>. If parameter set B is to be deactivated, this setting should be none (always control A)

Delay time when switching A <- B

This value determines the delay from switching the binary input to the switching from parameter

set B to parameter set A.

Relay assignment with control A

Defines the relay behavior in parameter set A.

Relay assignment with control B

Defines the relay behavior in parameter set B.

Relay

Defines the source information for relay swit chin g.

Status

Relay dependency

register

Alarm (Common) Alarm [7.5.1 System Parameters (Configuration Æ

System)]

Sensor monitor Sensor status (7.5.2 Sensor Parameters (Configuration Æ

Sensor))

Limit 1/2 Selection of Limit ½ (

7.5.4 Limits (Configuration Æ Limits)

Window ExOR combination of both limits

On The relay is on

Off The relay is always off

Acknowledge

Acknowledge establishes if and under what conditions the relay status is held. A relay that is held

no longer reacts to the assigned signal a nd ca n only be reset via the binary input.

RPM

SWT-1000.r2.0609 15

Page 18

Operating Instructions SWT-1000 DYNALCO

SWT-1000.r2.0609 16

Page 19

Operating Instructions SWT-1000 DYNALCO

8. Operating Behavior

8.1 Power On

8.1.1 Analog Output

Following power on the output assume s t he out put range start value. Upon completion of the f i rst

measurement the output goes to the corresponding measured value.

Relay Output

The parameter set determined by the configur at io n an d bin ary input is valid from the start.

If the relay is assigned to a limit it remains deactivated until completion of the first measurement,

following which it assumes the status defined und er Li mit .

If the relay is assigned to any other item in the status regi ste r it immediately assumes the

corresponding status.

If no input frequency is present then after a period of 2 x Fixtime a measured value below the

lower set point is assumed.

8.2 Measurement

Every measurement begins with the positive edge of the input signal. Once the Fixtime has lapsed

the next positive edge ends the running measurement and starts the next.

The resulting effective measurement time is dependent upon whether the input sign a l peri od is

longer or shorter than the Fixtime.

Input signal period < Fixtime Input signal period > Fixtime

End of Fixtime Ensuing edge

Input

Frequency

Input period time

Fixtime

Effective measurement period

t

Measurement typically

t

Measurement max

= Fixtime

= 2 x Fixtime

The total measurement time has a resolution of ± 0.4 μs. The calcu lation and adaptation of

outputs follows immediately after the Fixtime. With inpu t frequencies outside of the measuring

range, the corresponding final values ar e assumed.

8.2.1 The Adaptive Trigger Level

After triggering, the trigger level is set for the

next pulse anew.

This guarantees that the trigger level can follow

a 50% reduction in speed from pulse to pulse.

DC offset, resonance and negative pu lses have

no influence on the triggering

Input

Frequency

t

Measurement max

U

End of Fixtime Ensuing edge

Fixtime time

Period of input signal

Effective measurement period

Fixtime

= 2 x Input signal period

old trigger level

trigger level

signal to

noise ration

bad sensor

signal

t

SWT-1000.r2.0609 17

Page 20

Operating Instructions SWT-1000 DYNALCO

8.2.2 Signal Failure

In the event of a sudden loss of a good signal, no po sit iv e edg e arrives to complete the

measurement or start a new one. Once the minimum measur e me nt time (Fixtime) has lapsed the

unit waits for twice the last measurement period f ollo wi ng whi ch h a l f th e last mea s ure d speed is

assumed. If the signal remains missing then the measurement approaches zero.

8.3 Functions

8.3.1 Limits and Window Function

Since the upper and lower sets points are freely selectable a large hysteresis may be set. If that is

not necessary we recommend setting a 10% hysteresis.

The Window function allows an Exclusive OR combin a tio n of Limit s 1 and 2, w hereby the status of

both limits is first determined (including any inv ersion) and a subsequent ExOR comparison

executed.

As soon as Relay assignment is <Window> the relay behaves as follows:

• With identical limit modes (both Normal or both Inverse) the relay is activated when the

measured value lies between the Limit 1 and 2 setti ng s.

• If different modes are set (one Normal and the other Inverse) the relay is deactivated when

the measured value is between Limts 1 and 2.

8.3.2 Parameter Sets A and B

The SWT-1000 has 2 parameter sets availab le th at d efine the relay assignment. Parameter set A

would normally be used. If another pa rameter set is needed, e.g. for test purposes, the binary

input may be used to change to parameter set B. Th e tran sfe r from parameter set B to parameter

set A may be delayed in the range 0 to 2000 seconds. Transferring from A to B is however

immediate and not affected by this setting.

To be able to select parameter sets using the binary input, Relay control - Selection of Actuator

must be appropriately set.

Binary input condition Selected Parameter set

High (5V) “normal“ A

Low (0V) “connected to 0V“ B

8.3.3 Relay Hold Function

A latch function may be assigned to the relay. By selecting <Relay is hold if control is active> the

relay is activated once the assigned limit is active and remains held even if the input frequency

would no longer cause a trip. By selecting <Relay is hold if contr o l is inacti ve>, the deactivared

state of the relay is held. The latched status ma y be re set by cycling power or via the binary input,

whereby the binary input must be activat ed as p er the configuration (0V or 5V) for between 0.1

and 0.3 seconds.

8.3.4 Push-Button

The front panel push button internally connects the binary input to 0VS thus generating a logic 0.

SWT-1000.r2.0609 18

Page 21

Operating Instructions SWT-1000 DYNALCO

8.3.5 Binary Input

2 functions are executable using the binary inp ut:

• Switching between parameter sets A and B. S ee 8. 3.2 Paramet e r Sets A and B.

• Resetting a latched relay. See 8.3.3 Rela.

The binary input has an internal pull up resistor to +5 V and is therefore normally logic High.

Shorting the binary input to the sensor supply 0V creates a logic 0.

5 Volt

SWT-1000

Switching the input for between 0.1 and 0. 3 seon ds r esets a

latched relay but does not influence para meter set selection, which

requires longer than 0.3 seconds.

parameter set A B

+Bin

pushbutton

OVS

10k

analysis

8.4 Fault Behavior

8.4.1 Sensor Fault (Sensor monitoring)

The sensor may be monitored in 2 ways. With sensor s powered by the SWT-1000 the sensor

supply current is monitored. If the curren t f alls out side t he permit ted range then sensor fault is

indicated.

If the sensor is not powered by the SWT-1000 then it may only be monit ored for disconnection. If

disconnected, sensor fault is indicated.

The SWT-1000 behavior in the event of a sensor fault is dependent on the configuration:

Alarm Configuration

Only System error

System error OR Sensor monitoring

Outputs in the event of a sensor fault

LED

Analog output

Current

On Measured value output per configuration

Off 0mA Deactivated

8.4.2 System Alarm

If the microprocessor detects a checksum faul t (RAM, ROM or EEPROM ) th e measured value is

set to 0 RPM, The analog output goes to 0/4mA and the relay is deactivated.

Alarm Configuration

Only System error

System error OR Sensor monitoring

Outputs in the event of a System alarm

LED

Analog output

Current

Off 0mA Deactivated

Relay

Relay

8.4.3 Alarm

As long as a combined alarm is present, no measuremen ts a re conducted and the outputs behave

as described above. Once the fault or alarm condition is removed the last correct measured value

is assumed. Eventual limit activation is not taken into acc ount .

SWT-1000.r2.0609 19

Page 22

Operating Instructions SWT-1000 DYNALCO

8.5 Power Supply Interruption

If input power remains off for longer than the permitted period the outputs deactivate i.e. the analog

output goes to 0mA, the relay deactivates and the “open collector“ output becomes high resistance.

Once the supply resumes in range the SWT-1000 begins its initialization routine.

9. Mechanical Construction / Housing

The housing features front plugab le te rminals that are protected from accidental cont a ct. The rear is

designed for mounting onto a DIN rail.

10. Accessories

Interface Cable PC – SWT-1000, Part No. PC-T400

SWT-1000.r2.0609 20

Loading...

Loading...