Page 1

3690 N.W. 53rd Street

Fort Lauderdale, FL 33309

SC-2124

SC-2124M

24 Channel Universal Scanner

Installation and Operation

Manual

P/N 145F-11902

Rev. 3.30

(c) Copyright 2000, Dynalco Controls

All Rights Reserved

Published: October 6, 2000

Revised: October 21, 2009

1

Page 2

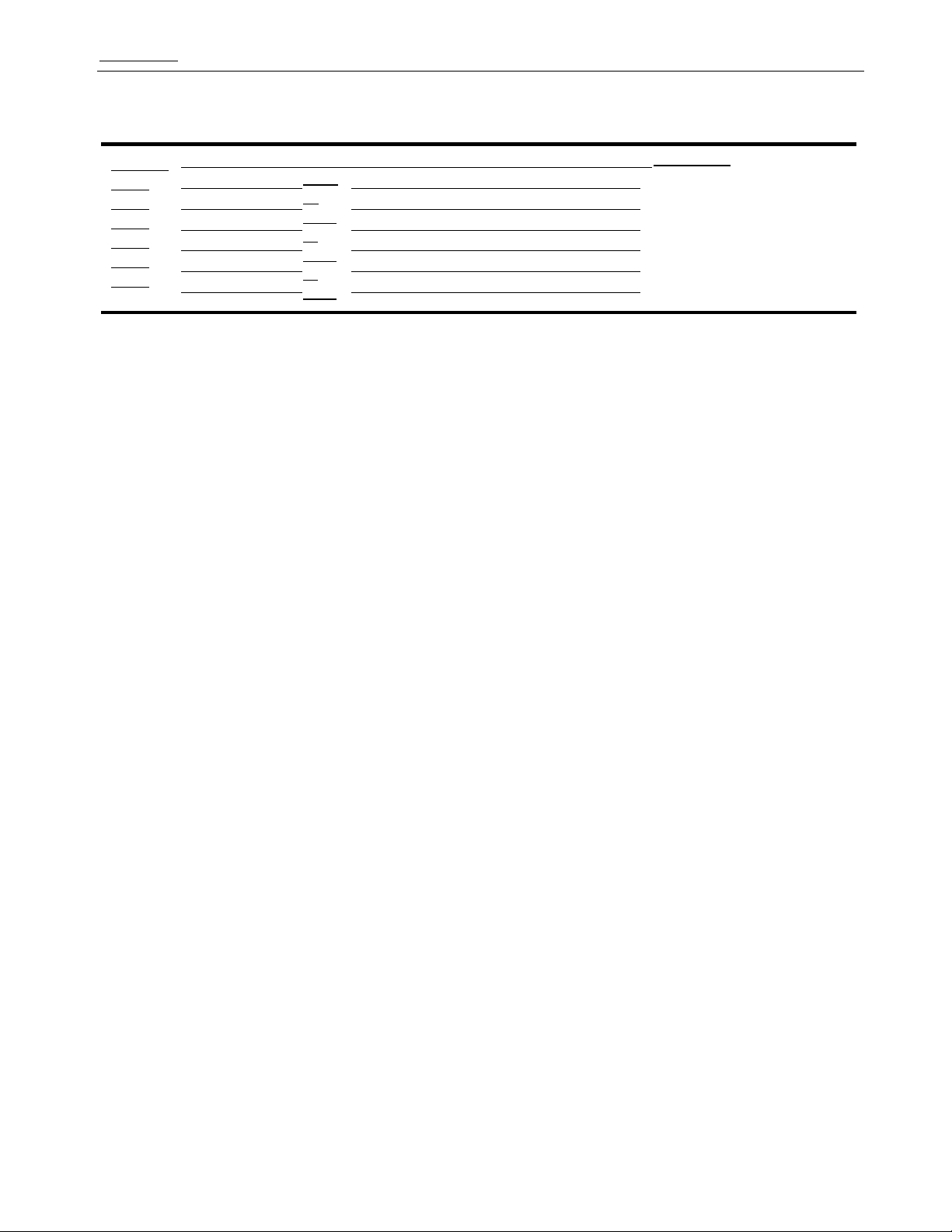

TABLE OF CONTENTS

1.0 Introduction 3

1.1 Ratings & Certification 6

2.0 Installation 7

2.1 Panel Cutout 7

2.2 Wiring 8

2.3 Mounting 10

3.0 Setup 13

3.1 HOST Software 13

3.1.1 Setup Screen 14

3.1.2 Configuration File 15

4.0 Standard Operation 16

4.1 RESET 17

4.2 START 17

4.3 ALARM 18

4.4 SHUTDOWN 18

5.0 User Interface 19

5.1 Navigation 19

5.2 Run Screens 21

5.2.1 Title Screen 21

5.2.2 Main Menu Screen 22

5.2.3 Main SCANNER Screen 22

5.2.4 SCAN Screen 23

5.2.5 Custom Screen(s) 23

5.2.6 Channel Screens 23

5.2.6.1 HELP Screens 24

5.2.7 SNAP Screen 24

5.2.7.1 First-Out Screen 24

FIGURES

Configuration Screen 14

1

2 Run Screens 20

APPENDICES

Appendix A Configuration Parameter List 25

Appendix B Example of a Configuration File 54

Appendix C Instructions for Downloading WinHost 67

Appendix D Modbus Addresses 68

Appendix E SC-RTD Module 69

2

Page 3

1.0 Introduction

The SC-2124 is a microprocessor-based universal scanner for continuous monitoring of up

to 24 channels measuring temperature from thermocouples, pressure or any other analog

signal that can be represented by either 0-5V or 4-20mA . Each scanner channel may be

configured for the following input types:

• J, K, E, or T thermocouple inputs

• 4-20 mA inputs (8 on-board resistors available via DIP switch)

• 0-5 V Inputs

The SC-2124 provides ALARM and SHUTDOWN capabilities via two dedicated on-board 5

Amp relays (plus 2 additional general-purpose relays) and automatically TRIPs should any

user-programmable threshold be exceeded.

The SC-2124 utilizes all DB-Style Connectors on the back of the unit for a cleaner wiring

arrangement. All wiring to the unit is done via separate DIN-RAIL type terminal modules and

then DB-25/15 cables connect to the unit.

The SC-2124 front panel includes a large-character, 4-row by 20-column, backlit LCD display

and application keypad. The display has several Run Screens: a SCAN Screen that displays

each enabled scanner channel, one channel screen at a time; one or more Custom Screens

to display up to four user-specified scanner channels per screen; and a SNAPSHOT Screen

that displays each enabled channel’s analog input reading at the time of the last

SHUTDOWN plus indication of the “First-Out” channel causing the shutdown.

Utilizing an on-board RS-232 communications port with a convenient DB-9 connector, the

SC-2124 provides powerful communications capabilities. Quick and easy configuration is

done from a laptop computer using the Dynalco DYNALINK software. The unit can also

switch protocols and talk Modbus RTU for continuous remote monitoring.

3

Page 4

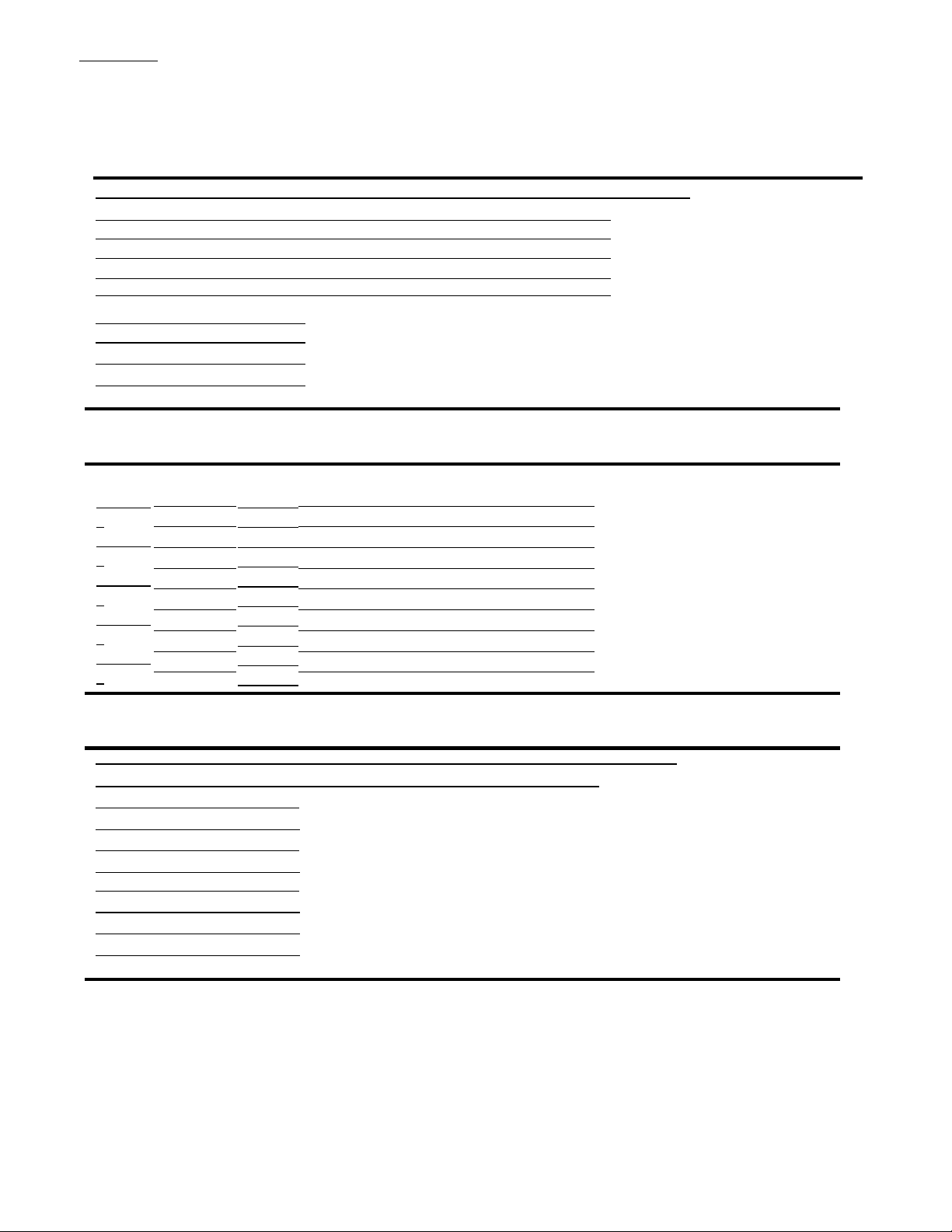

1.1 Packaging

Front View

6.55"

8.50"

4

Page 5

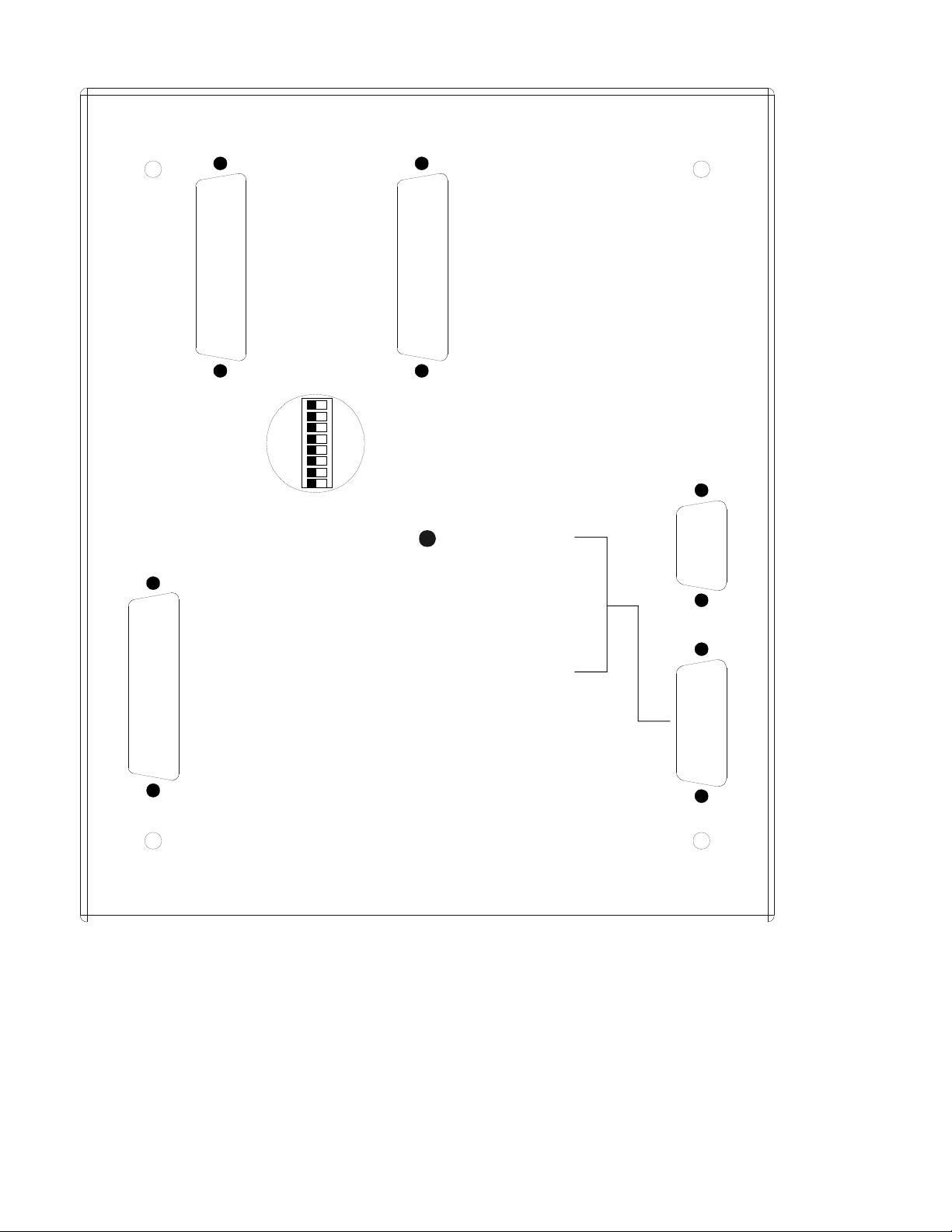

Rear View

CONN E

CHANNELS 1 - 8

4-20mA RESISTORS

CONN C

CONTACTS

(1) RLY 1 N/C

(3) RLY 1 COM.

(5) RLY 1 N/O

RELAY

ANALOG

INPUTS

13-24

OFF

CONN D

ANALOG

INPUTS

1-12

1

2

ON

3

4

5

6

7

8

DC POWER /

INSTRUMENTS

(1) CJC INPUT

(2) +5 VDC CJC POWER

(3) GND

(14) +DC POWER

(13, 15) DC POWER GND

RS232

COMMUNICATION

CONN B

CONN A

(7) RLY 2 N/C

(9) RLY 2 COM

(11) RLY 2 N/O

(15) RLY 3 N/C

(17) RLY 3 COM

(19) RLY 3 N/O

(21) RLY 4 COM

(23) RLY 4 COM

(25) RLY 4 N/O

5

Page 6

1.2 Specifications

1. Input Channels:24 Thermocouple (J,K,T, or E), 0 – 5V, or 4 – 20mA (On-Board 100

Ohm resistor provided on Channels 1 through 8).

Note: All Thermocouples have “Open-Thermocouple Detection”

2. Channel Scan Rate: Programmable (50mS Minimum)

3. Relay Outputs: 4 Relays, SPDT, rated @ 5A/24VDC, 1A/120VAC, and 0.5A/220VAC

4. Input Power: 9 – 38 VDC, 0.8A Max.

5. Sensor Power Out: +5VDC CJC Sensor Power, +8VDC RPM Sensor Power

6. Display: Backlit, 4 Line x 20 Character Alphanumeric Display with large 0.36”

Characters

7. Communications:

Hardware: RS-232

Software: Dynalink Laptop Configuration Software and Modbus RTU.

8. Rear Connections: All “DB - Style” Connectors on rear of unit. All field Wiring is done

via DIN-RAIL mounted Terminal Blocks.

9. Operating Temperature Range: -20 to +80C

10. Certification: CSA Class I, Div.2, Groups A, B, C, D

6

Page 7

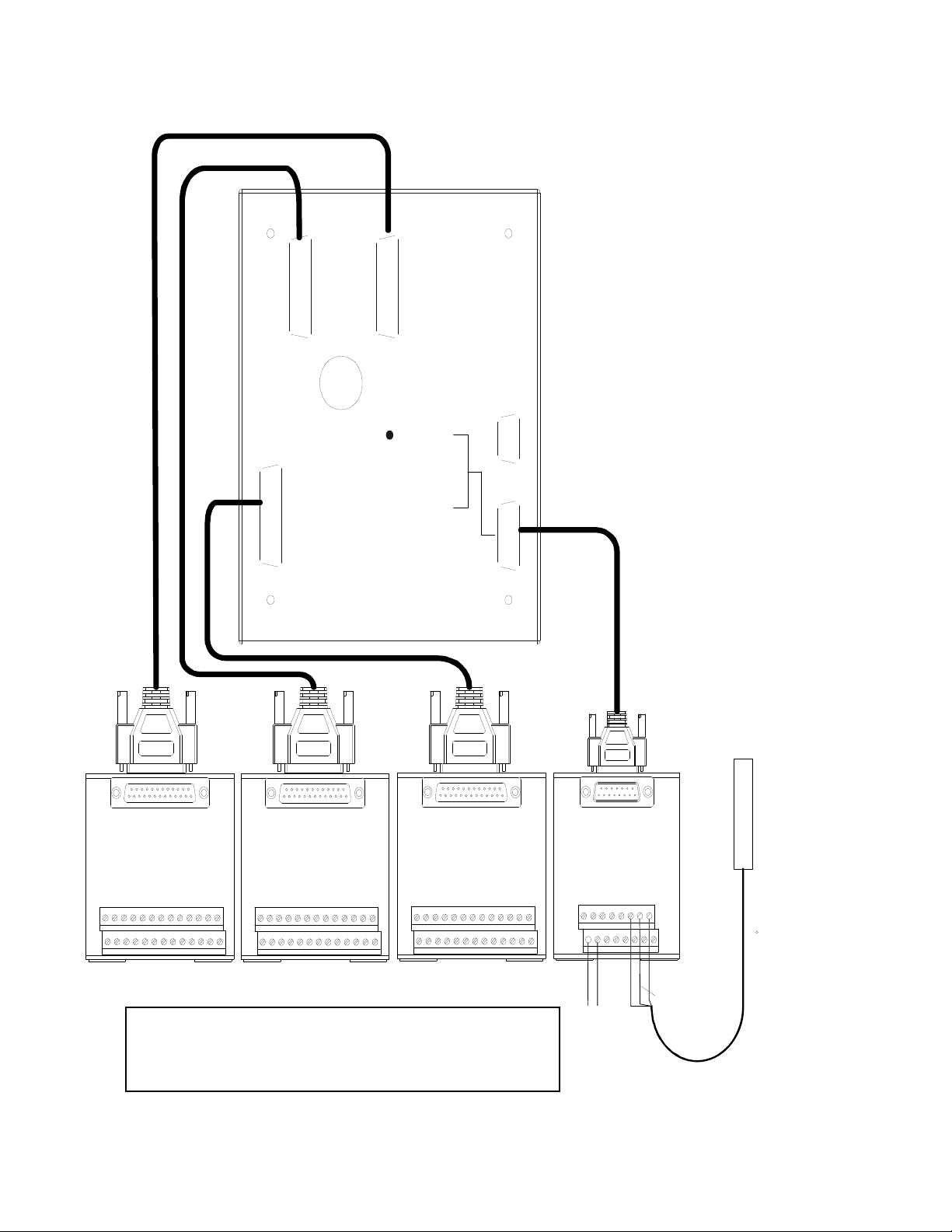

2.0 Installation

Installation requires a cutout as shown in section 2.1 along with four mounting holes. Once

the unit is mounted, a nearby (less than 6 feet away) location is needed for performing the

wiring to separate terminals. One method is to purchase the optional DB-to-Screw-Terminal

modules which are DIN-RAIL mounted. Also, the supplied Cold Junction Compensation

(CJC) Sensor is necessary if any thermocouples are to be used. The Dynalco ETS-202 CJC

sensor should be mounted as close as possible to the location where the thermocouple wires

are terminated.

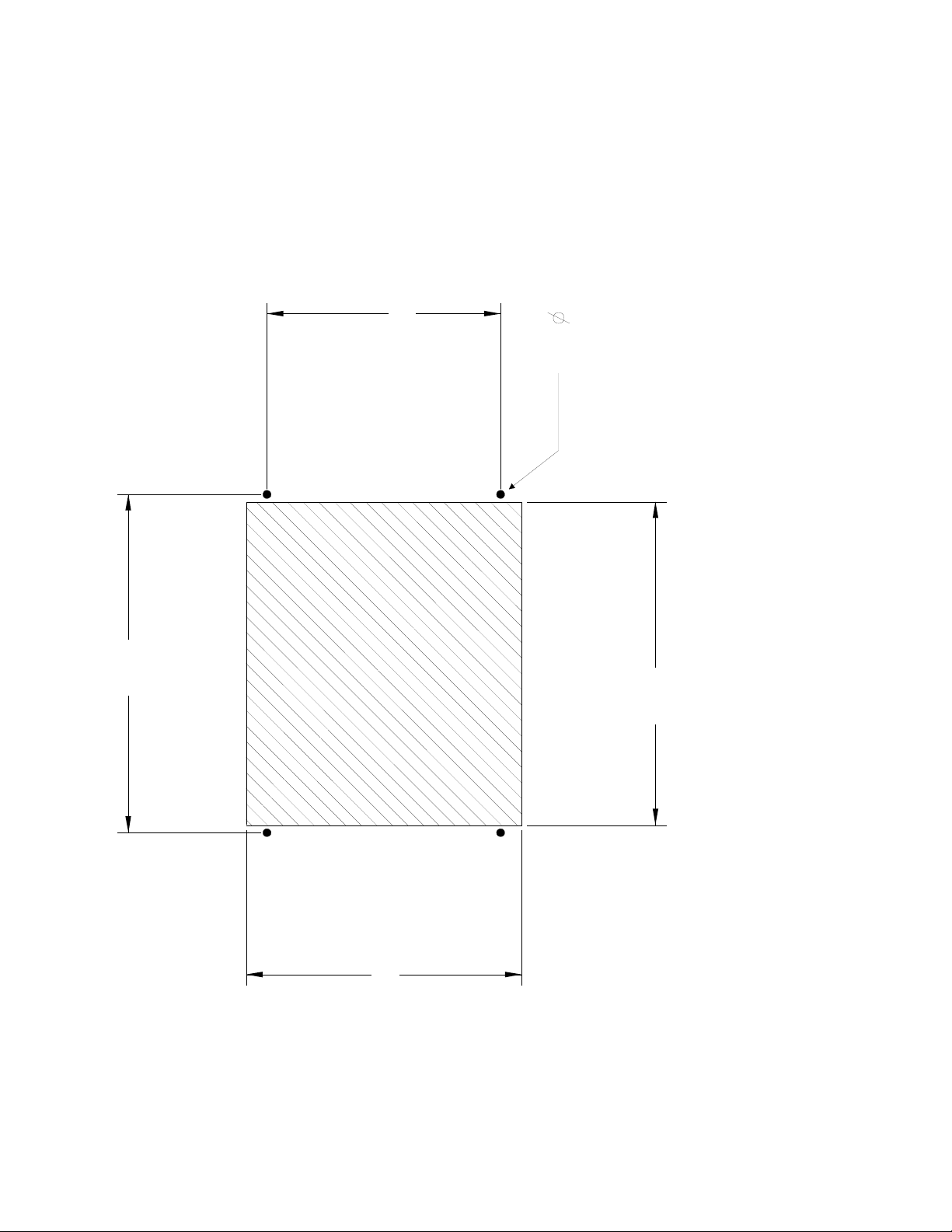

2.1 Panel Cutout

5.30

.1875

7.85

PANEL

CUTOUT

6.25

7.50

7

Page 8

2.2 Wiring

Connector A (DB-15M):

This Connector is used for the DC Power Input and the Cold Junction Compensation (CJC)

Sensor Input. In addition, depending upon the Scanner Model, it also contains Meter Bus

signals and an RPM Input.

Pinout: Pin#

Pin Name

1 CJC Sensor Input (WHT)

2 +5VDC CJC Sensor Power (RED)

3 CJC Sensor Common (BLK)

4 +8VDC RPM Sensor Power

5 RPM Input

6 RPM Common

7 NO CONNECTION

8 NO CONNECTION

9 Display (IIC Bus) Data

10 Display (IIC Bus) Clock

11 CAN Bus +

12 CAN Bus 13 Common

14 + DC Power In

15 DC Power Common

Connector B (DB-9F)

This Connector is used for RS-232 Communications to either a Laptop for Configuration or a

Modbus Communications Link.

Pinout: Pin# Pin Name

1 NO CONNECTION

2 Transmit Data Out

3 Receive Data In

4 NO CONNECTION

5 Common

6 NO CONNECTION

7 NO CONNECTION

8 NO CONNECTION

9 NO CONNECTION

8

Page 9

2.2 Wiring (Cont’d)

Connector C (DB-25M)

This Connector provides Contact Outputs for the 4 on-board relays.

Pinout: Pin# Pin Name

1 Relay 1 NC Contact

2 NO CONNECTION

3 Relay 1 Com

4 NO CONNECTION

5 Relay 1 NO Contact

6 NO CONNECTION

7 Relay 2 NC Contact

8 NO CONNECTION

9 Relay 2 Com

10 NO CONNECTION

11 Relay 2 NO Contact

12 NO CONNECTION

13 NO CONNECTION

14 NO CONNECTION

15 Relay 3 NC Contact

16 NO CONNECTION

17 Relay 3 Com

18 NO CONNECTION

19 Relay 3 NO Contact

20 NO CONNECTION

21 Relay 4 NC Contact

22 NO CONNECTION

23 Relay 4 Com

24 NO CONNECTION

25 Relay 4 NO Contact

2.2 DIP Switch (Rear of Unit)

Channels 1 – 8 have a 100 Ohm resistor available across their inputs for use with 4-20mA

inputs ONLY. Only move the appropriate DIP switch to the “ON” side if that channel is to be

configured as a 4-20mA input.

If any inputs besides channels # 1 – 8 are to be configured for 4 – 20 mA, a 100 ohm resistor

will need to be installed across the corresponding input channel terminations on the terminal

block.

NOTE: Setting the DIP switch to “ON” for either a 0-5V or thermocouple input will result in

faulty operation of the SC-2124.

9

Page 10

2.2 Wiring (Cont’d)

Connectors D and E are input terminals, each requiring p/n SC-CBLE25MM cable / terminal

block assembly.

Thermocouples can be connected to any input of either connector D or E.

For linear inputs (4 – 20 mA or 0 – 5 VDC) it is recommended to connect the wires to the

appropriate terminals for connector D. However, either connector D or E may be used. See

previous page for information on DIP switch settings for 4 – 20 mA inputs.

Any RTD inputs require the RTD module p/n SC-RTD, which includes the cable assembly. In

this case ,p/n SC-CBLE25MM will not be required. Note that (1) SC-RTD will handle up to 12

RTD inputs and can be connected to either connector D (Ch # 1 – 12) or connector E (Ch #

13 – 24).

Instructions for SC-RTD module configuration are in Appendix E.

Connector D (DB-25F)

This Connector provides the Analog Inputs for Channels 1 – 12.

Pinout:

Pin# Pin Name Pin# Pin Name

1 Channel 1 (+) 14 Channel 1 (-)

2 Channel 2 (+) 15 Channel 2 (-)

3 Channel 3 (+) 16 Channel 3 (-)

4 Channel 4 (+) 17 Channel 4 (-)

5 Channel 5 (+) 18 Channel 5 (-)

6 Channel 6 (+) 19 Channel 6 (-)

7 Channel 7 (+) 20 Channel 7 (-)

8 Channel 8 (+) 21 Channel 8 (-)

9 Channel 9 (+) 22 Channel 9 (-)

10 Channel 10 (+) 23 Channel 10 (-)

11 Channel 11 (+) 24 Channel 11 (-)

12 Channel 12 (+) 25 Channel 12 (-)

10

Page 11

Connector E (DB-25F)

This Connector provides the Analog Inputs for Channels 13 – 24.

Pinout:

Pin Name Pin# Pin Name

Pin#

1 Channel 13 (+) 14 Channel 13 (-)

2 Channel 14 (+) 15 Channel 14 (-)

3 Channel 15(+) 16 Channel 15 (-)

4 Channel 16 (+) 17 Channel 16 (-)

5 Channel 17 (+) 18 Channel 17 (-)

6 Channel 18 (+) 19 Channel 18 (-)

7 Channel 19 (+) 20 Channel 19 (-)

8 Channel 20 (+) 21 Channel 20 (-)

9 Channel 21 (+) 22 Channel 21 (-)

10 Channel 22 (+) 23 Channel 22 (-)

11 Channel 23 (+) 24 Channel 23 (-)

12 Channel 24 (+) 25 Channel 24 (-)

11

Page 12

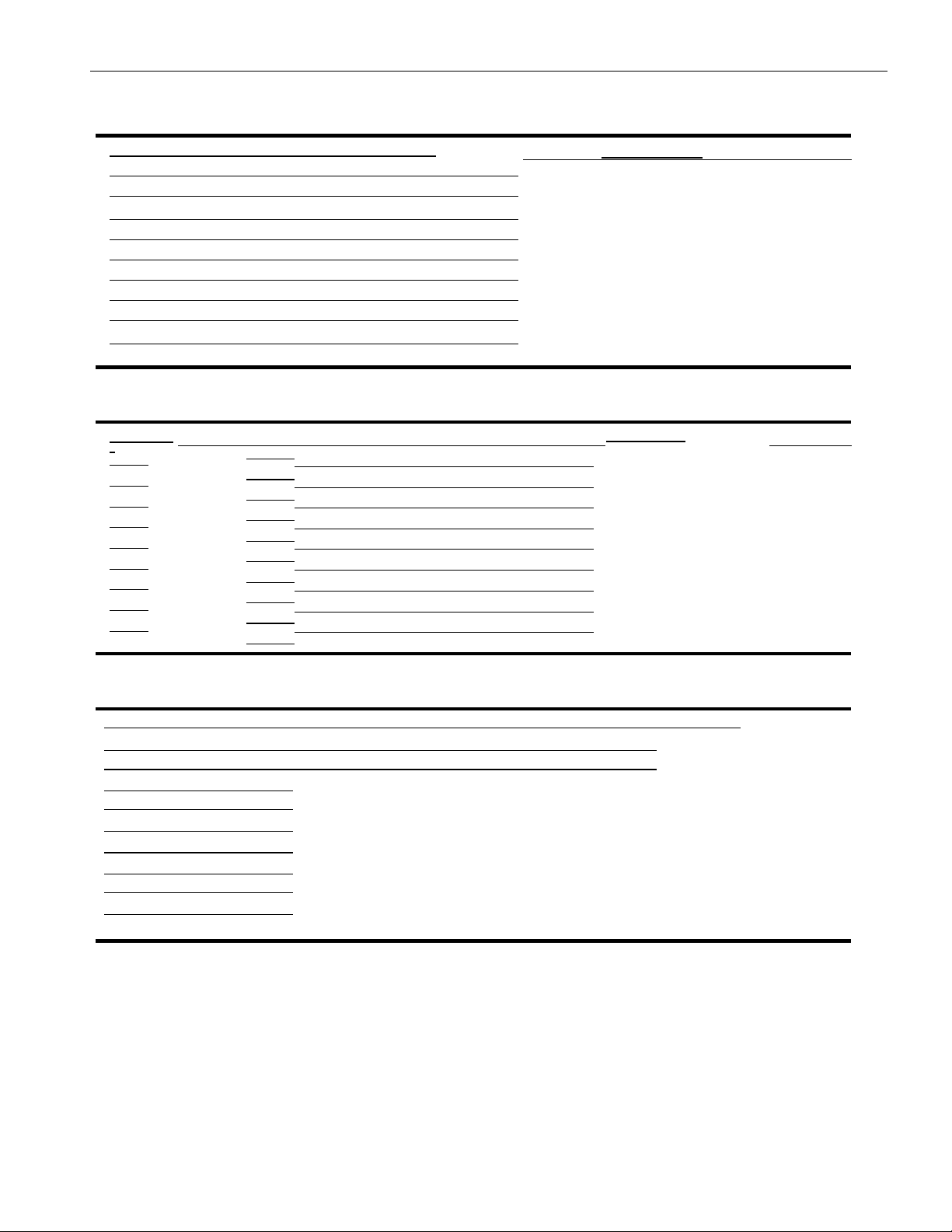

2.2 Wiring (Cont’d) Optional DB cables and

R

DB-to-Screw -Terminal DIN-RAIL Modules are available

CONN E

CONN D

ANALOG

INPUTS

13-24

ANALOG

INPUTS

1-12

4-20mA ENABLES

CHANNELS 1 - 8

OFF

ON

RS232

COMMUNICATION

CONN B

CONN C

RELAY

CONTACTS

(1) RLY 1 N/C

(3) RLY 1 COM.

(5) RLY 1 N/O

(7) RLY 2 N/C

(9) RLY 2 COM

(11) RLY 2 N/O

(15) RLY 3 N/C

(17) RLY 3 COM

(19) RLY 3 N/O

(21) RLY 4 COM

(23) RLY 4 COM

(25) RLY 4 N/O

DC POWER / CJC

(1) CJC INPUT

(2) +5 VDC CJC POWE

(3) GND

(14) +DC POWER

(13, 15) DC POWER GND

CONN A

(ANALOG INPUTS 13-24)

Note that terminal blocks for connectors A, C, D & E may

be different than illustration above, although terminal

designations on pages 8 – 11 are correct.

CJC

SENSOR

(ETS-202)

CONN ACONN CCONN E CONN D

(DC POWER/ CJC) (RELAYS)(ANALOG INPUTS 1-12)

12

Page 13

3.0 Setup

The SC-2124 requires the user to configure a variety of parameters: SCANNER channel

analog inputs; ALARM & SHUTDOWN TRIP conditions; Main SCAN Screen; and other

various other parameters. These parameters must be configured through the use of Dynalco

Controls HOST software. The user configures SCANNER parameters by either a useredited download file or individual parameter modification. The following sections details use

of the HOST software, download file, and parameter modification.

3.1 HOST Software

Dynalco Controls HOST software provides serial communication between a PC or laptop and

the SC-2124. WinHost is compatible with Windows 95, 98, 2000 & XP operating systems.

When communicating via WinHost software, the SCANNER must be connected via a

standard RS-232, 9-pin, male-female, serial communication cable. The HOST software

communicates to the SCANNER via Dynalink, Dynalco Control’s serial communication

protocol.

Each parameter has its own parameter number as listed in the spec file example in

Appendix B

When you open WinHost, you should see current parameters in the monitor screens. If you

see "??" instead of parameter values, check the serial link cable.

Any parameter value can be read by entering the parameter # in the "Command" line located

in the lower left corner of the monitor screen in WinHost. For example if you want to know

the value of parameter # 8001.1 (input type for channel 1) you would type 8001.1 in the

command line and hit enter. You will see the value of that parameter in the "Response" line

which is below the command line.

If you want to change the value of parameter 8001.1 so that channel 1 would be configured

for a K type thermocouple, you would then type in 8001.1=1 in the command line. After

hitting enter, you should see an "@" sign in the response line, indicating that the new value

was accepted.

Remember to always click on "Store" at the top of the screen after making changes.

Otherwise, the new values will be lost if you lose power to the SC2124.

In order to save any changes made to the scanner, you must store the new parameters as

follows:

Enter a letter "S" in the command line after making the changes. The response should be the

usual "@" sign.

During the store process, the SC2124 display will indicate "Configuration Parameter Store In

Progress." Make sure that the power is not removed during the "store" operation or you will

lose the saved data and all parameters will return to default values.

See Appendix B for instructions on downloading and installing WinHost software.

13

Page 14

3.1.1 Setup Screen

The SCANNER has the capability of communicating via Dynalink (point to point) using the

communications cable p/n CBLE-8509 or via Modbus (SC2124M only) through the serial

communications port CONN B. The user must setup the SCANNER to communicate via

Dynalink in order to configure the SCANNER with HOST software. A Configuration Screen

is available to switch between the Dynalink and Modbus protocols (See Figure 1).

Figure 1, Configuration Screen

COMMUNICATION

SETUP SCREEN

0

SELECT COMM PROTOCOL

>DYNALINK< MODBUS

D D M M

To enter Configuration Mode, the user must press the SETUP Key. The Communication

Setup Screen prompts the user to select a communication protocol. To communicate with

Dynalco Controls HOST software, the user must select the Dynalink protocol. To

communicate with an external device on a Modbus, the user must select the Modbus

protocol. To select either protocol, the user must press either of the Soft Keys located under

the corresponding protocol listed in the last row of the Configuration Screen. The currently

selected protocol is enclosed in brackets (‘>’ and ‘<’). The default SCANNER protocol is

Dynalink.

To exit Configuration Mode, the user must press and hold the ESC Key for one second.

14

Page 15

3.1.2 Configuration File

The easiest method for the user to configure the SC-2124 is by editing and downloading a

configuration file to the SCANNER. The configuration file is a template file that contains all

configurable parameters and an explanation for all parameter configuration settings. The

user must enter desired configuration values for all appropriate configuration parameters

before downloading the file to the SCANNER.

The configuration file can be edited with any text editor or word processor that can save files

in text format, such as Notepad or Wordpad available on Windows PCs.

The download file contains configuration comments and parameter configurations. The

comments for the configuration parameters explain the function for each parameter and the

programmable values associated for each parameter. The comments are any text or text

characters that follow a semicolon. General SCANNER configuration comments should not

be deleted. However, some comments, such as ‘<ANALOG INPUT CHANNEL #01>’, have

been included for the user to overwrite with application-specific descriptors, such as ‘Engine

Exhaust Temperature’.

The configuration file’s parameter configurations program the corresponding SC-2124

parameters when the file is downloaded to the SCANNER.

See Appendix A for an example of the standard SC2124.spc configuration file.

15

Page 16

4.0 Standard Operation

After power-up, the SC-2124 performs all standard SCANNER operations continually. These

operations include scanning all enabled analog input channels to update the channel

readings; monitoring channel inputs for Open Thermocouple, ALARM, or SHUTDOWN TRIP

conditions; performing Dynalink or Modbus communications to external devices.

To update all scanner channels, the SCANNER reads all enabled channels’ current analog

input readings. These readings are performed continuously and sequentially for all enabled

scanner channels. Current channel measurement readings are averaged with the previous

value to update the current analog input channel value.

The SCANNER then monitors each channel’s value compared to the channel’s configured

ALARM and SHUTDOWN thresholds. If any of the channel thresholds is exceeded, the

channels are considered to be in a fault state, and the SCANNER TRIPs an ALARM or

SHUTDOWN (See Sections 4.3 & 4.4). In addition, the SCANNER monitors all

thermocouple channels for Open Thermocouple detection. If any thermocouple channel is

open, the SCANNER labels that channel as open and displays ‘OPEN TC’ instead of that

channel’s current analog input reading. Detection of an open thermocouple on any scanner

channel may also result in an ALARM or SHUTDOWN (See Sections 4.3, 4.4, & 3.1.2.1).

Lastly, the SCANNER continually communicates with any external devices that initiate

communication and request SCANNER parameters. The SCANNER is capable of

communicating by Dynalink and Modbus. Only one serial communication port is available on

the SC-2124; thus, only one type of communication may occur on the port at any one time

(See Section 3.1). Dynalink would be used primarily while the SCANNER is being

configured using Dynalco Controls HOST software. Modbus communication would be used

to connect the SCANNER to other devices that communicate via Modbus.

16

Page 17

4.1 RESET

After power-up, the SC-2124 starts up in a RESET condition that assumes that all channels

are in a non-fault state, initializes the ALARM and SHUTDOWN TRIP conditions to a nonfault state, and forces all relays and discrete outputs to their non-fault states. After startup,

however, the user must manually RESET any TRIP conditions by a RESET key press from

the front panel or by setting the RESET parameter via HOST software (See Section 3.2.3).

This forces the user to actively acknowledge every SCANNER ALARM and SHUTDOWN.

When a RESET is manually triggered, the SCANNER clears the ALARM and SHUTDOWN

TRIP conditions and forces all relays and discrete outputs to their non-fault states. The

RESET is performed even if any scanner channels are in a fault state. If this is the case, the

SCANNER immediately TRIPs a new ALARM or SHUTDOWN (See Sections 4.3 & 4.4).

4.2 START

After RESET, the user may trigger specific SCANNER monitoring conditions via a START

request. To trigger a START request, the user must press the START key from the front

panel or set the START parameter via HOST software (See Section 3.2.3).

When a START is triggered, the SCANNER reloads the TRIP Class B timer with its initial

timer value, expressed in minutes. Once loaded, the timer ticks down until it expires,

whereupon all TRIP Class B channels become active. If any Class B channel is in a fault

state, no ALARM or SHUTDOWN is TRIPPED until the Class B timer is expired.

17

Page 18

4.3 ALARM

The SCANNER provides a precautionary ALARM warning to alert the user to potentially

hazardous or dangerous input conditions. The SCANNER monitors all enabled scanner

channels’ current analog input readings and compares each channel’s reading with a userconfigurable ALARM threshold. If any channel’s ALARM threshold is exceeded, the

SCANNER TRIPs an ALARM condition and blinks the ALARM indicator LED on the front

panel. A SCANNER ALARM is not latched and clears if no channel’s ALARM threshold is

faulted.

4.4 SHUTDOWN

The SCANNER provides a protective SHUTDOWN fault to guard against hazardous or

dangerous fault conditions. The SCANNER monitors all enabled scanner channels’ current

analog input readings and compares each channel’s reading with a user-configurable

SHUTDOWN threshold. If any channel’s SHUTDOWN threshold is exceeded, the

SCANNER TRIPs a SHUTDOWN condition and blinks the SHUTDOWN indicator LED on

the front panel.

When a SHUTDOWN occurs, the SCANNER saves the channel that caused the

SHUTDOWN to non-volatile memory as the First-Out channel. This First-Out channel is the

first channel that the SCANNER detects in a SHUTDOWN fault state. The SCANNER

displays the First-Out cause of the SHUTDOWN on the Main SCANNER Screen (See

Section 5.2.3). A SCANNER SHUTDOWN is latched and is not cancelled until

acknowledged by a RESET (See Section 4.1).

At the time of a SHUTDOWN, other scanner channels may be in a SHUTDOWN fault state.

Since several channels may be faulted, it is possible that another scanner channel besides

the First-Out channel caused the actual SHUTDOWN—the SCANNER merely detected and

labeled one faulted channel before the actual First-Out channel.

To aid the user in analyzing a SCANNER SHUTDOWN, the SCANNER also takes a Snap

Shot of all enabled scanner channels’ analog input readings at the time of the SHUTDOWN

and saves these Snap Shots to non-volatile memory. These Snap Shot values are displayed

on the SNAP Screen (See Section 5.2.7) and may be viewed after the user acknowledges

the SHUTDOWN condition via a SCANNER RESET. Only one set of SHUTDOWN Snap

Shot values is saved to memory at any one time. When a subsequent SHUTDOWN occurs,

the new Snap Shot values overwrite the old values in memory.

18

Page 19

5.0 User Interface

The SC-2124 user interface located on the front panel of the SCANNER consists of a largecharacter, 4-row by 20-column, backlit LCD display and an application keypad. The LCD

display is used to display SCANNER channel readings, SHUTDOWN First-Outs,

SHUTDOWN Snap Shot histories, and other informative statistics.

5.1 Navigation

The application keypad is used to navigate between Run Screens that display various

SCANNER readings and statistics. The keypad has the following keys used for navigation:

• UP, DOWN, LEFT, RIGHT Keys Navigate to screen in the desired direction

• Soft Keys Located directly under the LCD display,

these keys navigate to various screens as

indicated in the last line of the LCD display

• RESET Key RESET SCANNER

• START Key START SCANNER timers

• Setup Key Enter Configuration Mode

• ESC Key Navigate up one menu level; exit from

Configuration Mode

In addition to navigation, the user may execute specific key-press events from certain

screens. These screen-specific functions are typically labeled above corresponding Soft

Keys. To execute any screen-specific event function, the user must press and release the

corresponding Soft Key located below the labeled function. To repeatedly execute some

event functions, the user must press and hold the corresponding Soft Key. All SC-2124

screen-specific functions are described in the following sections that detail screen operation.

19

Page 20

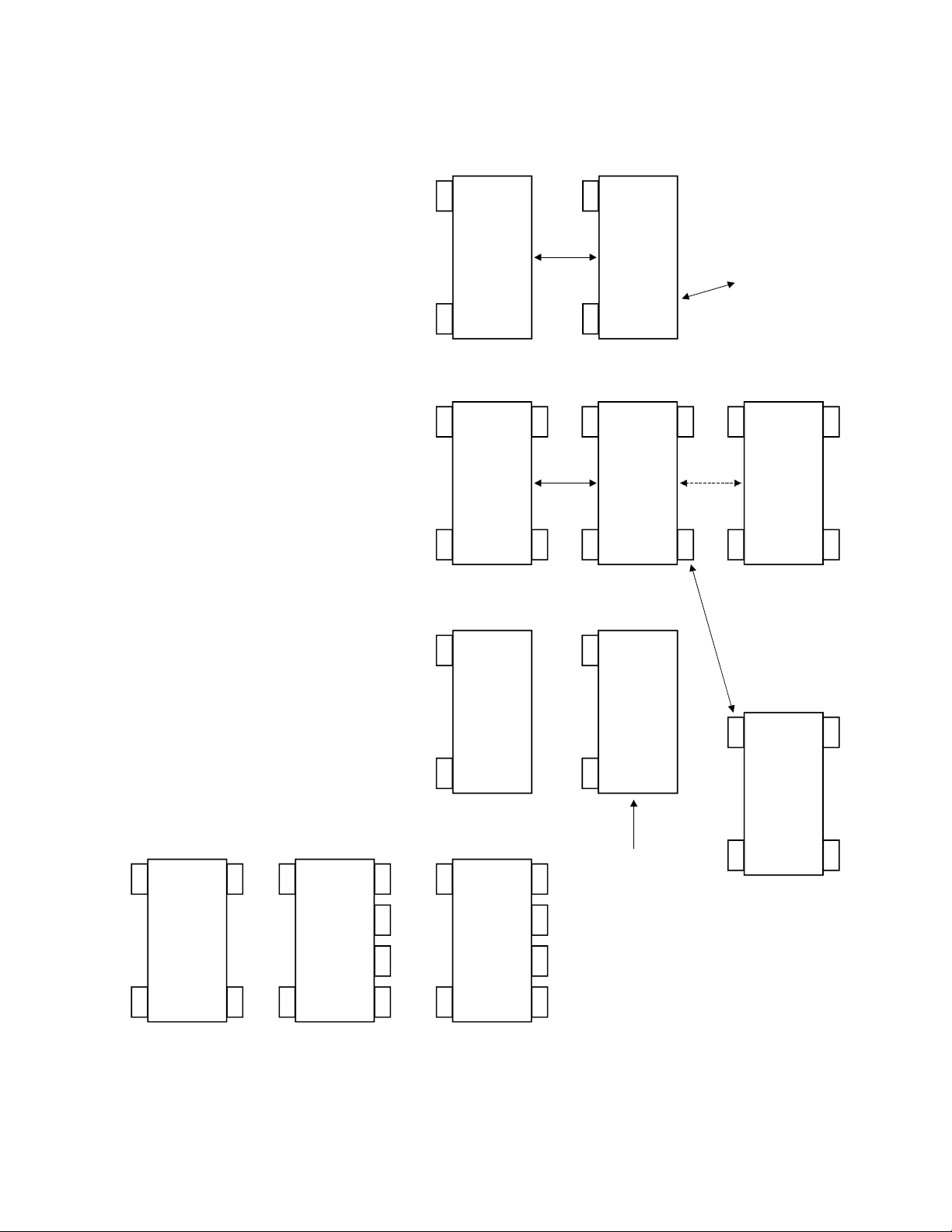

Figure 2, Run Screens

120 10

110 10

SCN CH02 PIST 1 PRES

In: 738 PSI

SCN CH01 ENG TEMP

In: 1452 °F

Th: 750 PSI

Th: 1800 °F

SNAP

150 +

HELP NEXT

125 10

FIRST-OUT SCREEN

SCN CH03 PIST 2 PRES

In: 755 PSI

Th: 750 PSI

FIRST-OUT SNAP

First Out Shutdown Channel on

SNAP Screen & First-Out Screen

will blink 'FIRST-OUT' in lower

left-hand corner of screen

110 10

SCN CH02 PIST 1 PRES

In: 689 PSI

Th: 750 PSI

150 +

HELP NEXT

110 10

SCN CH24

In: DISABLED

Th: 0 °F

150 +

HELP NEXT

SCAN-2 124 R u n Scr ee ns

TITLE SCREEN

0 10

DYNALCO CONTROLS

SCAN-2124

- +

V1.00

10 0

MAIN MENU SCREEN

MAIN

SCAN CUSTOM CH SNAP

200 10

ENG TEMP 1452

PIST 1 PRES 689

PIST 2 PRES 697

200 10

SCN Ch #05 1201

SCN Ch #06 1189

SCN Ch #09 DISABLED

HELP SCREENS

150 110

SCN CH02 PIST 1 PRES

Connector: CONN 4

SCAN SCREEN CUSTOM SCREEN(S) CHANNEL SCREENS SNAP SCREEN

100 200 110 120

100 10

SCN CH01 ENG TEMP

In: 1452 °F

10 200 110 120

Th: 1800 °F

MAIN CUSTOM CH SNAP

2nd Custom Screen

If available

110 +

+ Pin : PIN 02

- Pin : PIN 15

20

Page 21

5.2 Run Screens

The main purpose of the SC-2124 Run Screens is to allow the user to navigate to and from

screens that display current run-time values of scanner channels. Several screens are

available to display channel information in a few different formats (See Figure 1).

Each screen is shown with the following information: screen ID, screen text display,

navigational links, and possible screen event functions. This information is listed both in the

large, main text box area of the screen, as well as in the smaller informational boxes above

and below the main text box.

Listed in the upper, left-hand box is each screen’s navigational ID. Listed inside the main text

box is each screen’s text and run-time values display. Listed in the upper, right-hand box is

the navigational link to the next screen if the user presses the ESC Key. Listed in the boxes

below the main text box are the navigational links to other Run Screens or possible event

functions if the user presses any Soft Keys. If a navigational ID is listed, then the user

navigates to the specified screen if the user presses corresponding Soft Key. If a function is

listed by a ‘+’ or ‘-‘, then the user executes a screen-specific event function if the user

presses the corresponding Soft Key (See Section 5.1).

The following sections describe the behavior and functions available for each of the Run

Screens.

5.2.1 Title Screen

At startup, the SC-2124 displays the SCANNER Title Screen that includes the Dynalco

Controls banner, SCANNER name, and software version number. This Title Screen is

displayed for five seconds before navigating to the user-configured SCANNER Screen (See

Section 5.2.3).

In addition to the above information, this screen has two Soft Keys that increase or decrease

the LCD contrast. The left-most Soft Key decreases the LCD contrast by one step for every

key press or by one step every 200 milliseconds if the key is held. The right-most Soft Key

increases the LCD contrast by one step for every key press or by one step every 200

milliseconds if the key is held. The five second display timer is reset if any user key presses

are detected. This allows the user enough time to adjust the LCD contrast. If the user

modifies the LCD contrast, the SCANNER performs a CONFIGURATION Store to nonvolatile memory at screen exit to save the contrast setting.

21

Page 22

After startup, the user may navigate to the Title Screen from the Main Menu Screen. This

allows the user to adjust the LCD contrast at any time during the operation of the SC-2124.

The Title Screen is displayed for five seconds before navigating back to the Main Menu

Screen. The user may immediately navigate back to the Main Menu Screen by pressing the

ESC Key at any time.

5.2.2 Main Menu Screen

The Main Menu Screen allows fast navigation to all other Run Screens. To navigate to a

particular Run Screen, the user must press the Soft Key located directly under the

corresponding Screen Name listed on the Main Menu Screen: SCAN, Custom, Channel, or

SNAP. The user may also navigate to the Title Screen by pressing the ESC Key.

5.2.3 Main SCANNER Screen

One of the SC-2124 Run Screens is user-configured as the Main SCANNER Screen. This is

the main screen where the user views and monitors most of the information displayed by the

SCANNER. By default, the SCAN Screen is configured as the SCANNER Screen, but the

user may also configure the Custom Screen(s) as the SCANNER Screen.

For either configuration, the SCANNER Screen displays current measurement readings of

the analog input channels during normal operation. When a SHUTDOWN occurs, the

SCANNER automatically navigates† back to the Main SCANNER Screen to display the FirstOut SHUTDOWN channel, i.e. the cause of the SHUTDOWN (See Section 4.4). No

navigation may be performed until the First-Out SHUTDOWN is acknowledged by a

SCANNER RESET (See Section 4.1).

Since the Main SCANNER Screen is the default screen of primary interest to the user, the

SCANNER automatically navigates† back to the Main SCANNER Screen after 60 seconds of

user inactivity (delay is user-configurable).

†

Note: The SCANNER performs the automatic navigation only if the SC-2124

is in RUN Mode Screens, not in CONFIGURATION Mode. This allows the

user to enter CONFIGURATION Mode during a SHUTDOWN to modify

parameters that may cancel the SHUTDOWN condition.

22

Page 23

5.2.4 SCAN Screen

The SCAN Screen is the default SCANNER screen. The SCAN Screen displays each

enabled scanner channel for three seconds (delay is user-configurable) before displaying the

next enabled channel. Each channel display includes channel number, name, current

analog input reading (with units), and SHUTDOWN TRIP threshold (with units). If no

scanner channels are enabled, the SCAN Screen displays ‘ALL CHANNELS DISABLED’.

The SCAN Screen also contains fast navigation links back to the Main Menu Screen, as well

as to the Custom, Channel, and SNAP Screens. As from the Main Menu, to navigate to a

particular Run Screen, the user must press the Soft Key located directly under the

corresponding Screen Name listed in the last row of the SCAN Screen. In addition to the

fast navigational link, the user may also navigate back to the Main Menu by pressing the

ESC Key.

5.2.5 Custom Screen(s)

The Custom Screen(s) are user-configurable screens that display up to four scanner

channels per custom screen. The user may configure up to eight total scanner channels to

be displayed on two custom screens. If both custom screens are active, each custom screen

displays its configured scanner channels for three seconds (delay is user-configurable)

before displaying the next custom screen. If no custom screens are active, the Custom

Screen displays ‘NO CUSTOM SCREENS AVAILABLE’.

A custom screen is active if at least one scanner channel is configured to display on the

screen. Each scanner channel is displayed on its own row. If a user-configured channel

name is available, this channel name is displayed on the left-hand portion of the row.

Otherwise, the channel number is displayed on the left-hand portion of the row. The

channel’s current analog input reading is displayed on the right-hand portion of the row. If

the channel is disabled, the right-hand portion of the row displays ‘DISABLED’ instead of the

current analog input reading.

To navigate back to the Main Menu, the user must press the ESC Key.

5.2.6 Channel Screens

The Channel Screens display individual scanner channels. The display of each scanner

channel is identical to the format described for the SCAN Screen. Each channel displays

channel number, name, current analog input reading (with units), and SHUTDOWN TRIP

threshold (with units). Unlike the SCAN Screen, the SCANNER displays the individual

scanner channel without automatically displaying the next scanner channel after three

seconds. Note that the SCANNER returns to the Main SCANNER Screen after 60 seconds

of user inactivity (See Section 5.2.3).

To display the next scanner channel, the user must press the right-most Soft Key, labeled

‘NEXT’. In addition, the user may press the DOWN Key to display the next scanner channel

or the UP Key to display the previous scanner channel. To navigate back to the Main Menu,

the user must press the ESC Key.

23

Page 24

5.2.6.1 HELP Screens

In addition to viewing the channel’s current analog input reading, the Channel Screen

provides a link to channel HELP Screens. Each HELP Screen informs the user of the

specific Din Rail Connector and Pin-out for any scanner channel. To view the HELP Screen,

the user must press the left-most Soft Key, labeled ‘HELP’. This navigates to the desired

HELP Screen that displays the Connector number and +/- Pin Input numbers for the specific

scanner channel.

To return to the Channel Screen, the user must press either the ESC Key or the left-most

Soft Key. To view the next scanner channel’s HELP Screen, the user must press either the

right-most Soft Key or the DOWN Key, and to view the previous scanner channel’s HELP

Screen, the user must press the UP Key. To navigate back to the Main Menu, the user must

press the ESC Key.

5.2.7 SNAP Screen

The SNAP Screen displays a Snap Shot of all enabled scanner channels’ analog input

readings at the time of the last SHUTDOWN. The display of each scanner channel Snap

Shot is identical to the format described for the SCAN Screen. Each channel displays

channel number, name, Snap Shot analog input reading (with units), and SHUTDOWN TRIP

threshold (with units). To inform the user that the display values are a Snap Shot of the last

SHUTDOWN, the SNAP Screen displays ‘SNAP’ in the lower, right-hand corner of the

screen. In addition, to indicate the First-Out channel that caused the last SHUTDOWN (See

Section 4.4), the SNAP Screen blinks ‘FIRST-OUT’ in the lower, left-hand corner of the

screen whenever the First-Out channel is displayed.

Note that the values displayed are those saved from each channel’s analog input reading

and configuration at the time of the last SHUTDOWN. If any channel’s configuration

parameters have been modified since the last SHUTDOWN, it follows that these values will

differ from the current configuration settings.

To navigate to the First-Out Screen to display the First-Out channel, the user may press

either the UP or DOWN Key. To navigate back to the SNAP Screen, the user must again

press either the UP or DOWN Key. To navigate back to the Main Menu, the user must press

the ESC Key.

5.2.7.1 First-Out Screen

The First-Out Screen displays the First-Out channel that caused the last SHUTDOWN (See

Section 4.4). The display of the First-Out channel is identical to the format described for the

SCAN Screen. The First-Out Screen displays First-Out channel number, name, Snap Shot

analog input reading (with units), and SHUTDOWN TRIP threshold (with units). To indicate

to the user that the display value is the First-Out channel, the First-Out Screen blinks ‘FIRSTOUT’ in the lower, left-hand corner of the screen and displays ‘SNAP’ in the lower, right-hand

corner of the screen.

To navigate to the SNAP Screen, the user may press either the UP or DOWN Key. To

navigate back to the First-Out Screen, the user must again press either the UP or DOWN

Key. To navigate back to the Main Menu, the user must press the ESC Key.

24

Page 25

V

,

Appendix A

This appendix contains a table of all parameter numbers found in the

SCAN2124.SPC file.

Use this appendix to keep track of the values you assign to each parameter number. The

numbers in this table are in the same order as they appear in the SCAN2124.SPC file.

Password Settings

Parameter

6130=

6101= Change the time that the Configuration Password is active Minimum= 30 seconds

Description

Changes the Configuration Password

AFTER the user exits Configuration Mode Default= 60 seconds

alid Inputs

Default=1234

"8 characters of'1'

Maximum=540 seconds

Trip Relay Settings

Parameter Description Valid Inputs

136=

63102.1= Sets trip action for user relay 1.

63102.2= Sets trip action for user relay 2.

63102.3= Sets trip action for alarm relay.

63102.4= Sets trip action for shutdown relay.

149= Selects trip action for any open thermocouple

63050= Changes the Trip Class B timer triggered from

144= Changes the Trip Class B timer time remaining

Configure relays as inverted outputs or non-inverted

outputs

channel

front-panel 'Start' key press

before Class B faults are displayed

0= relay outputs non-inverted

1= relay outputs inverted (default)

0= normally energized

1= normally de-energized

2= normally energized latching

3= normally de-energized latching

0= disabled (default)

1= alarm

2= shutdown

0= 0 minutes

1=1 minute (default)

2= 2 minutes

3= 3 minutes

4= 4 minutes

5= 5 minutes

0= 0 seconds

1=15 seconds

2=30 seconds (default)

3=45 seconds

4=60 seconds

5=75 seconds

6=90 seconds

'2','3', or '4'"

25

Page 26

Scan Screen Settings

Parameter Description Valid Inputs

195= Selects type of scan screen to view (default or 0= displays default screen (enabled channels

custom) shown one at a time)

1= displays custom screen (shows up to 4

140= Define time between scan screens Minimum= 2 seconds

141= Change the time it takes to return to the main 0= off

scanner screen after no key press activity 1= 1 minute (default)

170= Select the scanner channel or node to display 0= display scanner channel number [‘CHXX’]

Custom Screen Settings

Parameter Defines the analog input channel to display on: Valid Input:

190.1= Screen 1, Line 1 0 = off (default)

190.2= Screen 1, Line 2

190.3= Screen 1, Line 3

190.4= S creen 1, Line 4

190.5= Screen 2, L ine 1

190.6= S creen 2, Line 2

190.7= Screen 2, Line 3

190.8= S creen 2, Line 4

190.9= Screen 3, L ine 1

190.10= Scr e en 3, Lin e 2

190.11= Screen 3, Line 3

190.12= Scr e en 3, Lin e 4

190.13= Scree n 4, Line 1

190.14= Scr e en 4, Lin e 2

190.15= Screen 4, Line 3

190.16= Scr e en 4, Lin e 4

190.17= Scree n 5, Line 1

190.18= Scr e en 5, Lin e 2

190.19= Screen 5, Line 3

190.20= Scr e en 5, Lin e 4

190.21= Screen 6, Line 1

190.22= Scr e en 6, Lin e 2

190.23= Screen 6, Line 3

190.24= Screen 6, Line 4

channels on one screen)

Default= 3 seconds

Maximum=10 seconds

2= 2 minutes 3= 3

minutes 4= 4

m i n u t es 5= 5

minutes

(default)

1= display scanner node number [‘N:XX’]

1 to 24= analog input channel

26

Page 27

Channel 1 Input Settings

Parameter Function Description Valid Inputs

110.1= Channel name for CH01

111.1= Units of measure for CH01

8001.1= Input type for CH01

8000.1= Enables CH01 for scanning

8017.1= Filter speed for CH01

8012.1= Display value for 0 V or 4 mA input Minimum=-999.0

8013.1= Display value for 5 V or 20 mA input

8015.1= Inverted resistance for 4-20mA source on CH01

8008.1= CH01 output offset to add to computed output value

63000.1= Shutdown trip class for CH01

63001.1= Shutdown threshold value for CH01 Numeric value

63002.1= Shutdown threshold hystersis for CH01

63003.1=

63000.25= Alarm trip class for CH01

63001.25= Alarm threshold value for CH01 Numeric value

63002.25= Alarm threshold hysteresis for CH01

63003.25=

Delay time between exceeded CH01 shutdown threshold and

CH01 shutdown

Delay time between exceeded CH01 alarm threshold and

CH01 alarm

Default=” “ (blank=CH01)

11 characters (including spaces)

0= deg F (default)

1= deg C

2= PSI

3= PSA

4= KPA

5= FTP

6= RPM

7= “ “ (blank)

0= J-TC (default)

1= K-TC

2= Nickel RTD

3= Platinum RTD

4= 4-20 mA (DIP 1 switch on)

5= 0-5 V

0= disabled (default)

1= enabled

Minimum=0.00 (none)

Default=0.05 (slow)

Maximum=1.00 (fast)

Default= 0.0

Maximum=9999.0

(in channel units)

Minimum=0.0 1/kohms

Default=10.0 1/kohms

Maximum=100.0 1 /kohms

Minimum=-1000.0

Default= 0.0

Maximum= 1000.0

(in channel units)

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

27

Page 28

Channel 2 Input Settings

Parameter Function Description Valid Inputs

110.2= Channel name for CH02

111.2= Units of measure for CH02

8001.2= Input type for CH02

8000.2= Enables CH02 for scanning

8017.2= Filter speed for CH02

8012.2= Display value for 0 V or 4 mA input Minimum=-999.0

8013.2= Display value for 5 V or 20 mA input

8015.2= Inverted resistance for 4-20mA source on CH02

8008.2= CH02 output offset to add to computed output value

63000.2= Shutdown trip class for CH02

63001.2= Shutdown threshold value for CH02 Numeric value

63002.2= Shutdown threshold hystersis for CH02

63003.2=

63000.26= Alarm trip class for CH02

63001.26= Alarm threshold value for CH02 Numeric value

63002.26= Alarm threshold hysteresis for CH02

63003.26=

Delay time between exceeded CH02 shutdown threshold and

CH02 shutdown

Delay time between exceeded CH02 alarm threshold and

CH02 alarm

Default=” “ (blank=CH02)

11 characters (including spaces)

0= deg F (default)

1= deg C

2= PSI

3= PSA

4= KPA

5= FTP

6= RPM

7= “ “ (blank)

0= J-TC (default)

1= K-TC

2= Nickel RTD

3= Platinum RTD

4= 4-20 mA (DIP 2 switch on)

5= 0-5 V

0= disabled (default)

1= enabled

Minimum=0.00 (none)

Default=0.05 (slow)

Maximum=1.00 (fast)

Default= 0.0

Maximum=9999.0

(in channel units)

Minimum=0.0 1/kohms

Default=10.0 1/kohms

Maximum=100.0 1 /kohms

Minimum=-1000.0

Default= 0.0

Maximum= 1000.0

(in channel units)

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

28

Page 29

Appendix C

Channel 3 Input Settings

Parameter Function Description Valid Inputs

110.3= Channel name for CH03

111.3= Units of measure for CH03

8001.3= Input type for CH03

8000.3= Enables CH03 for scanning

8017.3= Filter speed for CH03

8012.3= Display value for 0 V or 4 mA input Minimum=-999.0

8013.3= Display value for 5 V or 20 mA input

8015.3= Inverted resistance for 4-20mA source on CH03

8008.3= CH03 output offset to add to computed output value

63000.3= Shutdown trip class for CH03

63001.3= Shutdown threshold value for CH03

63002.3= Shutdown threshold hystersis for CH03

63003.3=

63000.27 Alarm trip class for CH03

63001.27= Alarm threshold value for CH03

63002.27= Alarm threshold hysteresis for CH03

63003.27=

Delay time between exceeded CH03 shutdown threshold and

CH03 shutdown

Delay time between exceeded CH03 alarm threshold and

CH03 alarm

Default=” “ (blank=CH03)

11 characters (including spaces)

0= deg F (default)

1= deg C

2= PSI

3= PSA

4= KPA

5= FTP

6= RPM

7= “ “ (blank)

0= J-TC (default)

1= K-TC

2= Nickel RTD

3= Platinum RTD

4= 4-20 mA (DIP 3 switch on)

5= 0-5 V

0= disabled (default)

1= enabled

Minimum=0.00 (none)

Default=0.05 (slow)

Maximum=1.00 (fast)

Default= 0.0

Maximum=9999.0

(in channel units)

Minimum=0.0 1/kohms

Default=10.0 1/kohms

Maximum=100.0 1 /kohms

Minimum=-1000.0

Default= 0.0

Maximum= 1000.0

(in channel units)

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

Numeric value

(channel units)

seconds

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

Numeric value

(channel units)

seconds

29

Page 30

Channel 4 Input Settings

Parameter Function Description Valid Inputs

110.4= Channel name for CH04

111.4= Units of measure for CH04

8001.4= Input type for CH04

8000.4= Enables CH04 for scanning

8017.4= Filter speed for CH04

8012.4= Display value for 0 V or 4 mA input Minimum=-999.0

8013.4= Display value for 5 V or 20 mA input

8015.4= Inverted resistance for 4-20mA source on CH04

8008.4= CH04 output offset to add to computed output value

63000.4= Shutdown trip class for CH04

63001.4= Shutdown threshold value for CH04 Numeric value

63002.4= Shutdown threshold hystersis for CH04

63003.4=

63000.28= Alarm trip class for CH04

63001.28= Alarm threshold value for CH04 Numeric value

63002.28= Alarm threshold hysteresis for CH04

63003.28=

Delay time between exceeded CH04 shutdown threshold and

CH04 shutdown

Delay time between exceeded CH04 alarm threshold and

CH04 alarm

Default=” “ (blank=CH04)

11 characters (including spaces)

0= deg F (default)

1= deg C

2= PSI

3= PSA

4= KPA

5= FTP

6= RPM

7= “ “ (blank)

0= J-TC (default)

1= K-TC

2= Nickel RTD

3= Platinum RTD

4= 4-20 mA (DIP 4 switch on)

5= 0-5 V

0= disabled (default)

1= enabled

Minimum=0.00 (none)

Default=0.05 (slow)

Maximum=1.00 (fast)

Default= 0.0

Maximum=9999.0

(in channel units)

Minimum=0.0 1/kohms

Default=10.0 1/kohms

Maximum=100.0 1 /kohms

Minimum=-1000.0

Default= 0.0

Maximum= 1000.0

(in channel units)

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

30

Page 31

Appendix C

Channel 5 Input Settings

Parameter Function Description Valid Inputs

110.5= Channel name for CH05

111.5= Units of measure for CH05

8001.5= Input type for CH05

8000.5= Enables CH05 for scanning

8017.5= Filter speed for CH05

8012.5= Display value for 0 V or 4 mA input Minimum=-999.0

8013.5= Display value for 5 V or 20 mA input

8015.5= Inverted resistance for 4-20mA source on CH05

8008.5= CH05 output offset to add to computed output value

63000.5= Shutdown trip class for CH05

63001.5= Shutdown threshold value for CH05 Numeric value

63002.5= Shutdown threshold hystersis for CH05

63003.5=

63000.29= Alarm trip class for CH05

63001.29= Alarm threshold value for CH05 Numeric value

63002.29= Alarm threshold hysteresis for CH05

63003.29=

Delay time between exceeded CH05 shutdown threshold and

CH05 shutdown

Delay time between exceeded CH05 alarm threshold and

CH05 alarm

Default=” “ (blank=CH05)

11 characters (including spaces)

0= deg F (default)

1= deg C

2= PSI

3= PSA

4= KPA

5= FTP

6= RPM

7= “ “ (blank)

0= J-TC (default)

1= K-TC

2= Nickel RTD

3= Platinum RTD

4= 4-20 mA (DIP 5 switch on)

5= 0-5 V

0= disabled (default)

1= enabled

Minimum=0.00 (none)

Default=0.05 (slow)

Maximum=1.00 (fast)

Default= 0.0

Maximum=9999.0

(in channel units)

Minimum=0.0 1/kohms

Default=10.0 1/kohms

Maximum=100.0 1 /kohms

Minimum=-1000.0

Default= 0.0

Maximum= 1000.0

(in channel units)

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

31

Page 32

Channel 6 Input Settings

Parameter Function Description Valid Inputs

110.6= Channel name for CH06

111.6= Units of measure for CH06

8001.6= Input type for CH06

8000.6= Enables CH06 for scanning

8017.6= Filter speed for CH06

8012.6= Display value for 0 V or 4 mA input Minimum=-999.0

8013.6= Display value for 5 V or 20 mA input

8015.6= Inverted resistance for 4-20mA source on CH06

8008.6= CH06 output offset to add to computed output value

63000.6= Shutdown trip class for CH06

63001.6= Shutdown threshold value for CH06 Numeric value

63002.6= Shutdown threshold hystersis for CH06

63003.6=

63000.30= Alarm trip class for CH06

63001.30= Alarm threshold value for CH06 Numeric value

63002.30= Alarm threshold hysteresis for CH06

63003.30=

Delay time between exceeded CH06 shutdown threshold and

CH06 shutdown

Delay time between exceeded CH06 alarm threshold and

CH06 alarm

Default=” “ (blank=CH06)

11 characters (including spaces)

0= deg F (default)

1= deg C

2= PSI

3= PSA

4= KPA

5= FTP

6= RPM

7= “ “ (blank)

0= J-TC (default)

1= K-TC

2= Nickel RTD

3= Platinum RTD

4= 4-20 mA (DIP 6 switch on)

5= 0-5 V

0= disabled (default)

1= enabled

Minimum=0.00 (none)

Default=0.05 (slow)

Maximum=1.00 (fast)

Default= 0.0

Maximum=9999.0

(in channel units)

Minimum=0.0 1/kohms

Default=10.0 1/kohms

Maximum=100.0 1 /kohms

Minimum=-1000.0

Default= 0.0

Maximum= 1000.0

(in channel units)

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

32

Page 33

Appendix C

Channel 7 Input Settings

Parameter Function Description Valid Inputs

110.7= Channel name for CH07

111.7= Units of measure for CH07

8001.7= Input type for CH07

8000.7= Enables CH07 for scanning

8017.7= Filter speed for CH07

8012.7= Display value for 0 V or 4 mA input Minimum=-999.0

8013.7= Display value for 5 V or 20 mA input

8015.7= Inverted resistance for 4-20mA source on CH07

8008.7= CH07 output offset to add to computed output value

63000.7= Shutdown trip class for CH07

63001.7= Shutdown threshold value for CH07 Numeric value

63002.7= Shutdown threshold hystersis for CH07

63003.7=

63000.31= Alarm trip class for CH07

63001.31= Alarm threshold value for CH07 Numeric value

63002.31= Alarm threshold hysteresis for CH07

63003.31=

Delay time between exceeded CH07 shutdown threshold and

CH07 shutdown

Delay time between exceeded CH07 alarm threshold and

CH07 alarm

Default=” “ (blank=CH07)

11 characters (including spaces)

0= deg F (default)

1= deg C

2= PSI

3= PSA

4= KPA

5= FTP

6= RPM

7= “ “ (blank)

0= J-TC (default)

1= K-TC

2= Nickel RTD

3= Platinum RTD

4= 4-20 mA (DIP 7 switch on))

5= 0-5 V

0= disabled (default)

1= enabled

Minimum=0.00 (none)

Default=0.05 (slow)

Maximum=1.00 (fast)

Default= 0.0

Maximum=9999.0

(in channel units)

Minimum=0.0 1/kohms

Default=10.0 1/kohms

Maximum=100.0 1 /kohms

Minimum=-1000.0

Default= 0.0

Maximum= 1000.0

(in channel units)

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

33

Page 34

Channel 8 Input Settings

Parameter Function Description Valid Inputs

110.8= Channel name for CH08

111.8= Units of measure for CH08

8001.8= Input type for CH08

8000.8= Enables CH08 for scanning

8017.8= Filter speed for CH08

8012.8= Display value for 0 V or 4 mA input Minimum=-999.0

8013.8= Display value for 5 V or 20 mA input

8015.8= Inverted resistance for 4-20mA source on CH08

8008.8= CH08 output offset to add to computed output value

63000.8= Shutdown trip class for CH08

63001.8= Shutdown threshold value for CH08 Numeric value

63002.8= Shutdown threshold hystersis for CH08

63003.8=

63000.32= Alarm trip class for CH08

63001.32= Alarm threshold value for CH08 Numeric value

63002.32= Alarm threshold hysteresis for CH08

63003.32=

Delay time between exceeded CH08 shutdown threshold and

CH08 shutdown

Delay time between exceeded CH08 alarm threshold and

CH08 alarm

Default=” “ (blank=CH08)

11 characters (including spaces)

0= deg F (default)

1= deg C

2= PSI

3= PSA

4= KPA

5= FTP

6= RPM

7= “ “ (blank)

0= J-TC (default)

1= K-TC

2= Nickel RTD

3= Platinum RTD

4= 4-20 mA (DIP 8 switch on)

5= 0-5 V

0= disabled (default)

1= enabled

Minimum=0.00 (none)

Default=0.05 (slow)

Maximum=1.00 (fast)

Default= 0.0

Maximum=9999.0

(in channel units)

Minimum=0.0 1/kohms

Default=10.0 1/kohms

Maximum=100.0 1 /kohms

Minimum=-1000.0

Default= 0.0

Maximum= 1000.0

(in channel units)

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

34

Page 35

Appendix C

Channel 9 Input Settings

Parameter Function Description Valid Inputs

110.9= Channel name for CH09

111.9= Units of measure for CH09

8001.9= Input type for CH09

8000.9= Enables CH09 for scanning

8017.9= Filter speed for CH09

8012.9= Display value for 0 V or 4 mA input Minimum=-999.0

8013.9= Display value for 5 V or 20 mA input

8015.9= Inverted resistance for 4-20mA source on CH09

8008.9= CH09 output offset to add to computed output value

63000.9= Shutdown trip class for CH09

63001.9= Shutdown threshold value for CH09 Numeric value

63002.9= Shutdown threshold hystersis for CH09

63003.9=

63000.33= Alarm trip class for CH09

63001.33= Alarm threshold value for CH09 Numeric value

63002.33= Alarm threshold hysteresis for CH09

63003.33=

Delay time between exceeded CH09 shutdown threshold and

CH09 shutdown

Delay time between exceeded CH09 alarm threshold and

CH09 alarm

Default=” “ (blank=CH09)

11 characters (including spaces)

0= deg F (default)

1= deg C

2= PSI

3= PSA

4= KPA

5= FTP

6= RPM

7= “ “ (blank)

0= J-TC (default)

1= K-TC

2= Nickel RTD

3= Platinum RTD

4= 4-20 mA (ext. resistor req’d)

5= 0-5 V

0= disabled (default)

1= enabled

Minimum=0.00 (none)

Default=0.05 (slow)

Maximum=1.00 (fast)

Default= 0.0

Maximum=9999.0

(in channel units)

Minimum=0.0 1/kohms

Default=10.0 1/kohms

Maximum=100.0 1 /kohms

Minimum=-1000.0

Default= 0.0

Maximum= 1000.0

(in channel units)

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

35

Page 36

Channel 10 Input Settings

Parameter Function Description Valid Inputs

110.10= Channel name for CH10

111.10= Units of measure for CH10

8001.10= Input type for CH10

8000.10= Enables CH10 for scanning

8017.10= Filter speed for CH10

8012.10= Display value for 0 V or 4 mA input Minimum=-999.0

8013.10= Display value for 5 V or 20 mA input

8015.10= Inverted resistance for 4-20mA source on CH10

8008.10= CH10 output offset to add to computed output value

63000.10= Shutdown trip class for CH10

63001.10= Shutdown threshold value for CH10 Numeric value

63002.10= Shutdown threshold hystersis for CH10

63003.10=

63000.34= Alarm trip class for CH10

63001.34= Alarm threshold value for CH10 Numeric value

63002.34= Alarm threshold hysteresis for CH10

63003.34=

Delay time between exceeded CH10 shutdown threshold and

CH10 shutdown

Delay time between exceeded CH10 alarm threshold and

CH10 alarm

Default=” “ (blank=CH10)

11 characters (including spaces)

0= deg F (default)

1= deg C

2= PSI

3= PSA

4= KPA

5= FTP

6= RPM

7= “ “ (blank)

0= J-TC (default)

1= K-TC

2= Nickel RTD

3= Platinum RTD

4= 4-20 mA (ext. resistor req’d)

5= 0-5 V

0= disabled (default)

1= enabled

Minimum=0.00 (none)

Default=0.05 (slow)

Maximum=1.00 (fast)

Default= 0.0

Maximum=9999.0

(in channel units)

Minimum=0.0 1/kohms

Default=10.0 1/kohms

Maximum=100.0 1 /kohms

Minimum=-1000.0

Default= 0.0

Maximum= 1000.0

(in channel units)

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

36

Page 37

Appendix C

Channel 11 Input Settings

Parameter Function Description Valid Inputs

110.11= Channel name for CH 11

111.11= Units of measure for CH11

8001.11= Input type for CH11

8000.11= Enables CH11 for scanning

8017.11= Filter speed for CH11

8012.11= Display value for 0 V or 4 mA input Minimum=-999.0

8013.11= Display value for 5 V or 20 mA input

8015.11= Inverted resistance for 4-20mA source on CH11

8008.11= CH11 output offset to add to computed output value

63000.11= Shutdown trip class for CH11

63001.11= Shutdown threshold value for CH11 Numeric value

63002.11= Shutdown threshold hystersis for CH11

63003.11=

63000.35= Alarm trip class for CH11

63001.35= Alarm threshold value for CH11 Numeric value

63002.35= Alarm threshold hysteresis for CH11

63003.35=

Delay time between exceeded CH11 shutdown threshold and

CH11 shutdown

Delay time between exceeded CH11 alarm threshold and

CH11 alarm

Default=” “ (blank=CH11)

11 characters (including spaces)

0= deg F (default)

1= deg C

2= PSI

3= PSA

4= KPA

5= FTP

6= RPM

7= “ “ (blank)

0= J-TC (default)

1= K-TC

2= Nickel RTD

3= Platinum RTD

4= 4-20 mA (ext. resistor req’d)

5= 0-5 V

0= disabled (default)

1= enabled

Minimum=0.00 (none)

Default=0.05 (slow)

Maximum=1.00 (fast)

Default= 0.0

Maximum=9999.0

(in channel units)

Minimum=0.0 1/kohms

Default=10.0 1/kohms

Maximum=100.0 1 /kohms

Minimum=-1000.0

Default= 0.0

Maximum= 1000.0

(in channel units)

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

37

Page 38

Channel 12 Input Settings

Parameter Function Description Valid Inputs

110.12= Channel name for CH12

111.12= Units of measure for CH12

8001.12= Input type for CH12

8000.12= Enables CH12 for scanning

8017.12= Filter speed for CH12

8012.12= Display value for 0 V or 4 mA input Minimum=-999.0

8013.12= Display value for 5 V or 20 mA input

8015.12= Inverted resistance for 4-20mA source on CH12

8008.12= CH12 output offset to add to computed output value

63000.12= Shutdown trip class for CH12

63001.12= Shutdown threshold value for CH12 Numeric value

63002.12= Shutdown threshold hystersis for CH12

63003.12=

63000.36= Alarm trip class for CH12

63001.36= Alarm threshold value for CH12 Numeric value

63002.36= Alarm threshold hysteresis for CH12

63003.36=

Delay time between exceeded CH12 shutdown threshold and

CH12shutdown

Delay time between exceeded CH12 alarm threshold and

CH12 alarm

Default=” “ (blank=CH12)

11 characters (including spaces)

0= deg F (default)

1= deg C

2= PSI

3= PSA

4= KPA

5= FTP

6= RPM

7= “ “ (blank)

0= J-TC (default)

1= K-TC

2= Nickel RTD

3= Platinum RTD

4= 4-20 mA (ext. resistor req’d)

5= 0-5 V

0= disabled (default)

1= enabled

Minimum=0.00 (none)

Default=0.05 (slow)

Maximum=1.00 (fast)

Default= 0.0

Maximum=9999.0

(in channel units)

Minimum=0.0 1/kohms

Default=10.0 1/kohms

Maximum=100.0 1 /kohms

Minimum=-1000.0

Default= 0.0

Maximum= 1000.0

(in channel units)

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

38

Page 39

Appendix C

Channel 13 Input Settings

Parameter Function Description Valid Inputs

110.13= Channel name for CH13

111.13= Units of measure for CH13

8001.13= Input type for CH13

8000.13= Enables CH13 for scanning

8017.13= Filter speed for CH13

8012.13= Display value for 0 V or 4 mA input Minimum=-999.0

8013.13= Display value for 5 V or 20 mA input

8015.13= Inverted resistance for 4-20mA source on CH13

8008.13= CH13 output offset to add to computed output value

63000.13= Shutdown trip class for CH13

63001.13= Shutdown threshold value for CH13 Numeric value

63002.13= Shutdown threshold hystersis for CH13

63003.13=

63000.37= Alarm trip class for CH13

63001.37= Alarm threshold value for CH13 Numeric value

63002.37= Alarm threshold hysteresis for CH13

63003.37=

Delay time between exceeded CH13 shutdown threshold and

CH13shutdown

Delay time between exceeded CH13 alarm threshold and

CH13 alarm

Default=” “ (blank=CH13)

11 characters (including spaces)

0= deg F (default)

1= deg C

2= PSI

3= PSA

4= KPA

5= FTP

6= RPM

7= “ “ (blank)

0= J-TC (default)

1= K-TC

2= Nickel RTD

3= Platinum RTD

4= 4-20 mA (ext. resistor req’d)

5= 0-5 V

0= disabled (default)

1= enabled

Minimum=0.00 (none)

Default=0.05 (slow)

Maximum=1.00 (fast)

Default= 0.0

Maximum=9999.0

(in channel units)

Minimum=0.0 1/kohms

Default=10.0 1/kohms

Maximum=100.0 1 /kohms

Minimum=-1000.0

Default= 0.0

Maximum= 1000.0

(in channel units)

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

39

Page 40

Channel 14 Input Settings

Parameter Function Description Valid Inputs

110.14= Channel name for CH14

111.14= Units of measure for CH14

8001.14= Input type for CH14

8000.14= Enables CH14 for scanning

8017.14= Filter speed for CH14

8012.14= Display value for 0 V or 4 mA input Minimum=-999.0

8013.14= Display value for 5 V or 20 mA input

8015.14= Inverted resistance for 4-20mA source on CH14

8008.14= CH14 output offset to add to computed output value

63000.14= Shutdown trip class for CH14

63001.14= Shutdown threshold value for CH14 Numeric value

63002.14= Shutdown threshold hystersis for CH14

63003.14=

63000.38= Alarm trip class for CH14

63001.38= Alarm threshold value for CH14 Numeric value

63002.38= Alarm threshold hysteresis for CH14

63003.38=

Delay time between exceeded CH14 shutdown threshold and

CH14shutdown

Delay time between exceeded CH14 alarm threshold and

CH14 alarm

Default=” “ (blank=CH14)

11 characters (including spaces)

0= deg F (default)

1= deg C

2= PSI

3= PSA

4= KPA

5= FTP

6= RPM

7= “ “ (blank)

0= J-TC (default)

1= K-TC

2= Nickel RTD

3= Platinum RTD

4= 4-20 mA (ext. resistor req’d)

5= 0-5 V

0= disabled (default)

1= enabled

Minimum=0.00 (none)

Default=0.05 (slow)

Maximum=1.00 (fast)

Default= 0.0

Maximum=9999.0

(in channel units)

Minimum=0.0 1/kohms

Default=10.0 1/kohms

Maximum=100.0 1 /kohms

Minimum=-1000.0

Default= 0.0

Maximum= 1000.0

(in channel units)

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

40

Page 41

Appendix C

Channel 15 Input Settings

Parameter Function Description Valid Inputs

110.15= Channel name for CH15

111.15= Units of measure for CH15

8001.15= Input type for CH15

8000.15= Enables CH15 for scanning

8017.15= Filter speed for CH15

8012.15= Display value for 0 V or 4 mA input Minimum=-999.0

8013.15= Display value for 5 V or 20 mA input

8015.15= Inverted resistance for 4-20mA source on CH15

8008.15= CH15 output offset to add to computed output value

63000.15= Shutdown trip class for CH15

63001.15= Shutdown threshold value for CH15 Numeric value

63002.15= Shutdown threshold hystersis for CH15

63003.15=

63000.38= Alarm trip class for CH15

63001.38= Alarm threshold value for CH15 Numeric value

63002.38= Alarm threshold hysteresis for CH15

63003.38=

Delay time between exceeded CH15 shutdown threshold and

CH15shutdown

Delay time between exceeded CH15 alarm threshold and

CH15 alarm

Default=” “ (blank=CH15)

11 characters (including spaces)

0= deg F (default)

1= deg C

2= PSI

3= PSA

4= KPA

5= FTP

6= RPM

7= “ “ (blank)

0= J-TC (default)

1= K-TC

2= Nickel RTD

3= Platinum RTD

4= 4-20 mA (ext. resistor req’d)

5= 0-5 V

0= disabled (default)

1= enabled

Minimum=0.00 (none)

Default=0.05 (slow)

Maximum=1.00 (fast)

Default= 0.0

Maximum=9999.0

(in channel units)

Minimum=0.0 1/kohms

Default=10.0 1/kohms

Maximum=100.0 1 /kohms

Minimum=-1000.0

Default= 0.0

Maximum= 1000.0

(in channel units)

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

41

Page 42

Channel 16 Input Settings

Parameter Function Description Valid Inputs

110.16= Channel name for CH16

111.16= Units of measure for CH16

8001.16= Input type for CH16

8000.16= Enables CH16 for scanning

8017.16= Filter speed for CH16

8012.16= Display value for 0 V or 4 mA input Minimum=-999.0

8013.16= Display value for 5 V or 20 mA input

8015.16= Inverted resistance for 4-20mA source on CH16

8008.16= CH16 output offset to add to computed output value

63000.16= Shutdown trip class for CH16

63001.16= Shutdown threshold value for CH16 Numeric value

63002.16= Shutdown threshold hystersis for CH16

63003.16=

63000.40= Alarm trip class for CH16

63001.40= Alarm threshold value for CH16 Numeric value

63002.40= Alarm threshold hysteresis for CH16

63003.40=

Delay time between exceeded CH16 shutdown threshold and

CH16shutdown

Delay time between exceeded CH16 alarm threshold and

CH16 alarm

Default=” “ (blank=CH16)

11 characters (including spaces)

0= deg F (default)

1= deg C

2= PSI

3= PSA

4= KPA

5= FTP

6= RPM

7= “ “ (blank)

0= J-TC (default)

1= K-TC

2= Nickel RTD

3= Platinum RTD

4= 4-20 mA (ext. resistor req’d)

5= 0-5 V

0= disabled (default)

1= enabled

Minimum=0.00 (none)

Default=0.05 (slow)

Maximum=1.00 (fast)

Default= 0.0

Maximum=9999.0

(in channel units)

Minimum=0.0 1/kohms

Default=10.0 1/kohms

Maximum=100.0 1 /kohms

Minimum=-1000.0

Default= 0.0

Maximum= 1000.0

(in channel units)

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

42

Page 43

Appendix C

Channel 17 Input Settings

Parameter Function Description Valid Inputs

110.17= Channel name for CH17

111.17= Units of measure for CH17

8001.17= Input type for CH17

8000.17= Enables CH17 for scanning

8017.17= Filter speed for CH17

8012.17= Display value for 0 V or 4 mA input Minimum=-999.0

8013.17= Display value for 5 V or 20 mA input

8015.17= Inverted resistance for 4-20mA source on CH17

8008.17= CH17 output offset to add to computed output value

63000.17= Shutdown trip class for CH17

63001.17= Shutdown threshold value for CH17 Numeric value

63002.17= Shutdown threshold hystersis for CH17

63003.17=

63000.41= Alarm trip class for CH17

63001.41= Alarm threshold value for CH17 Numeric value

63002.41= Alarm threshold hysteresis for CH17

63003.41=

Delay time between exceeded CH17 shutdown threshold and

CH17shutdown

Delay time between exceeded CH17 alarm threshold and

CH17 alarm

Default=” “ (blank=CH17)

11 characters (including spaces)

0= deg F (default)

1= deg C

2= PSI

3= PSA

4= KPA

5= FTP

6= RPM

7= “ “ (blank)

0= J-TC (default)

1= K-TC

2= Nickel RTD

3= Platinum RTD

4= 4-20 mA (ext. resistor req’d)

5= 0-5 V

0= disabled (default)

1= enabled

Minimum=0.00 (none)

Default=0.05 (slow)

Maximum=1.00 (fast)

Default= 0.0

Maximum=9999.0

(in channel units)

Minimum=0.0 1/kohms

Default=10.0 1/kohms

Maximum=100.0 1 /kohms

Minimum=-1000.0

Default= 0.0

Maximum= 1000.0

(in channel units)

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

0= Off

1= Class A over (default)

2= Class B over

3= Class C over

4= Class A under

5= Class B under

6= Class C under

(channel units)

seconds

43

Page 44

Channel 18 Input Settings

Parameter Function Description Valid Inputs

110.18= Channel name for CH18

111.18= Units of measure for CH18

8001.18= Input type for CH18

8000.18= Enables CH18 for scanning

8017.18= Filter speed for CH18

8012.18= Display value for 0 V or 4 mA input Minimum=-999.0

8013.18= Display value for 5 V or 20 mA input

8015.18= Inverted resistance for 4-20mA source on CH18

8008.18= CH18 output offset to add to computed output value

63000.18= Shutdown trip class for CH18

63001.18= Shutdown threshold value for CH18 Numeric value

63002.18= Shutdown threshold hystersis for CH18

63003.18=

63000.42= Alarm trip class for CH18

63001.42= Alarm threshold value for CH18 Numeric value

63002.42= Alarm threshold hysteresis for CH18

63003.42=

Delay time between exceeded CH18 shutdown threshold and

CH18shutdown

Delay time between exceeded CH18 alarm threshold and

CH18 alarm

Default=” “ (blank=CH18)

11 characters (including spaces)

0= deg F (default)

1= deg C

2= PSI

3= PSA

4= KPA

5= FTP

6= RPM

7= “ “ (blank)

0= J-TC (default)

1= K-TC

2= Nickel RTD

3= Platinum RTD

4= 4-20 mA (ext. resistor req’d)

5= 0-5 V

0= disabled (default)

1= enabled

Minimum=0.00 (none)

Default=0.05 (slow)

Maximum=1.00 (fast)

Default= 0.0

Maximum=9999.0

(in channel units)

Minimum=0.0 1/kohms

Default=10.0 1/kohms