Page 1

AF900PC

Air/Fuel Ratio Control System

Installation and Operating Guide

(c) Copyright 2003, Dynalco Controls

All Rights Reserved.

Revision E 01/30/2012

Page 2

Specifications and information herin are subject to change without notice. Dynalco

reserves the right to make changes to the equipment described herin to improve

function or design. Although the information contained in this manual has been

carefully reviewed and is believed to be reliable, Dynalco does not assume any

liability for special, indirect, incidental, or consequential damages arising out of the

application or use of the equipment described herein. Warranty is limited and

cannot exceed the price paid for the product upon which the warranty is based.

Trademarks

AF900PC, Dynahost, Dynatrend and Dynalink are trademarks of Dynalco.

Windows and Windows XP are registered trademarks of Microsoft Corporation.

Dynalco

5450 N.W. 33

Fort Lauderdale, FL 33309 U.S.A.

Phone (954) 739-4300

Fax (954) 486-4968

www.dynalco.com

P/N 145F-11993

Rev. E

Dated: January 30, 2012

rd

Avenue, Suite 104

1

Page 3

CONTENTS

1. Introduction to the AF900PC Pg. 3

2. Theory of Operation Pg. 3

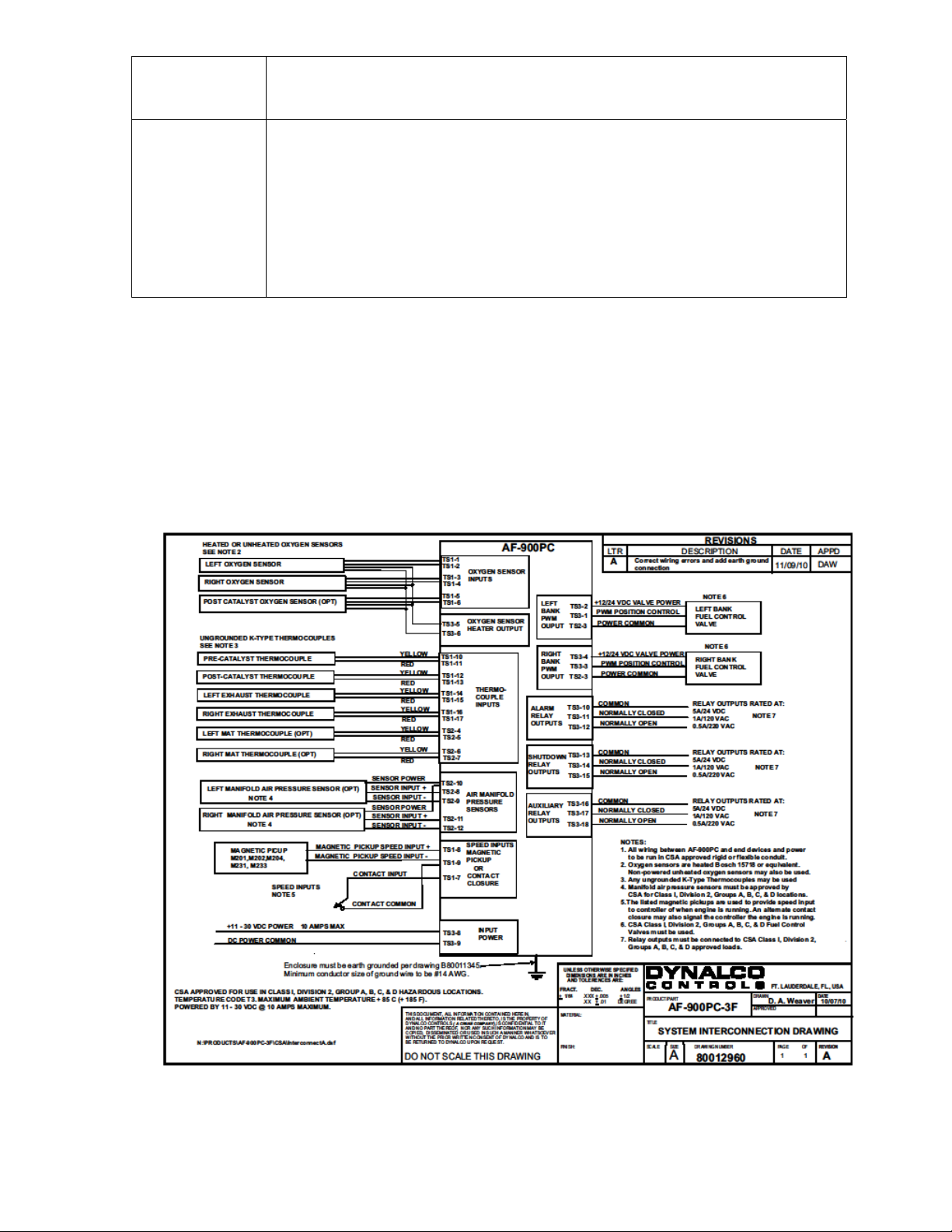

3. System Diagram Pg. 4

4. Specifications Pg. 5

5. Components/Installation Summary Pg. 6

5.1 System Components Pg. 6

5.2 Installation Summary Pg. 6

6. Installation Details Pg. 7

6.1 Mounting the AF900PC Controller Pg. 7

6.2 Mounting the Heated Oxygen Sensor(s) Pg. 8

6.3 Installation of the K type thermocouple Pg. 8

6.4 Installation of M201 Magnetic Pickup for Speed Sensing Pg. 8

6.5 Installation of full-authority fuel valves Pg. 9

7. Wiring the AF900PC Controller Pg. 9

8. Electrical Connections Pg. 9

9. Front Panel Display User Interface Pg. 12

9.1 Front Panel Configuration Scree ns Pg. 12

9.2 FPD Keypad Pg. 13

9.3 FPD Screens Pg. 14

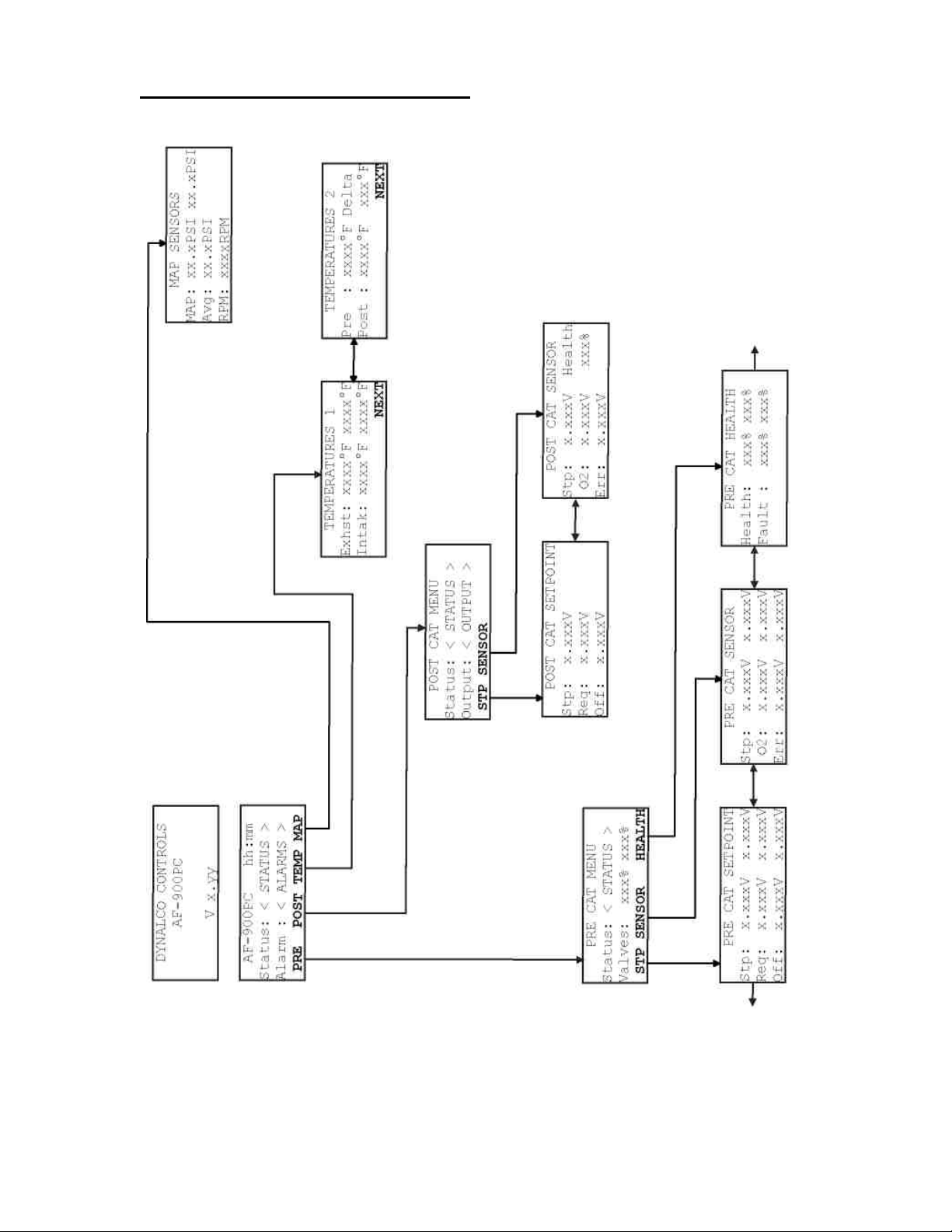

9.4 Navigational Map of RUN Screens Pg. 15

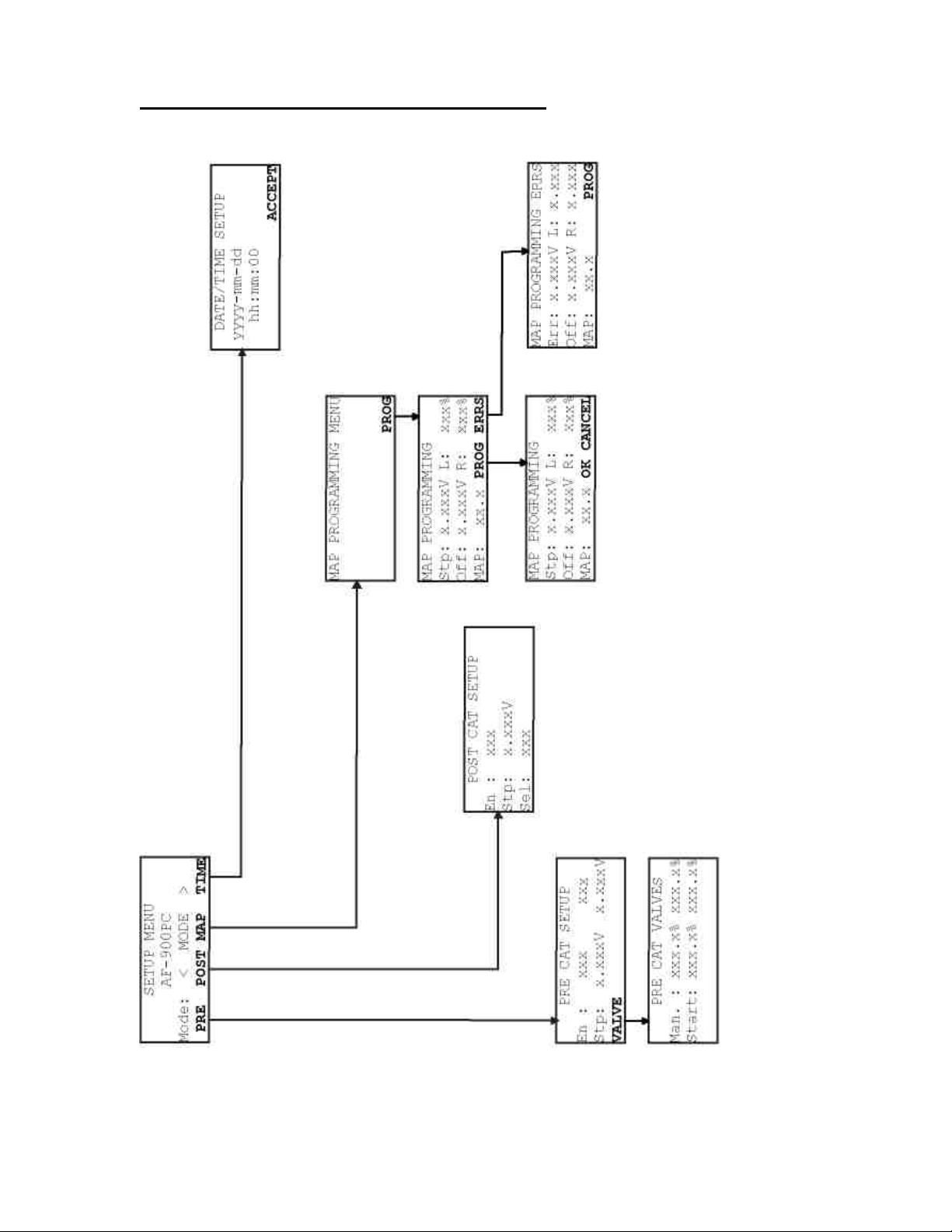

9.5 Navigational Map of SETUP Mode Screens Pg. 16

9.6 FPD SETUP Mode Pg. 17

10. Computer Interface using DynaHost Software Pg. 19

10.1 Control Panel Specifications Pg. 19

10.2 Screen Navigation Pg. 20

10.3 Main Screen Specifications Pg. 23

10.4 Communication Settings Dialogue Pg. 37

11. Computer Interface using Configuration File Pg. 38

11.1 Downloading a Configuration File Pg. 39

11.2 Uploading Configuration to an .spc file Pg. 40

12. Software Operation Pg. 41

12.1 AUTO Mode Pg. 41

12.2 MANUAL Mode Pg. 42

13. Control Software Pg. 42

14. Manifold Air Pressure (MAP) Load Compensation Pg. 43

15. Catalytic Converter Delta Temperature Pg. 45

16. Data Logging Pg. 45

17. Setup Pg. 46

18. Transfer Pg. 47

19. Start Up Procedure Pg. 49

20. Diagnostics Pg. 50

21. Appendix A. - Example of a Configuration File Pg 52

22. Modbus Addresses Pg. 104

2

Page 4

1. Introduction to the AF900PC

The AF-900PC is a state-of-the-art air/fuel ratio control system for single/dual bank,

spark-ignited, natural gas fueled carbureted engines. The AF-900PC incorporates

an extensive suite of advanced features that intelligently compensate for real-world

sensor and engine conditions.

This sophisticated system maintains the percentage of oxygen (O2) in the engine’s

exhaust gas stream by adjusting the amount of fuel to the carburetor(s). Fuel

valves mounted between the regulator and carburetor adjust the fuel pressure

applied to the carburetor to maintain the desired air/fuel ratio. The AF900PC is

designed to work with rich-burn engine systems using 3-way or NSCR type

catalytic converters.

In these applications it is very important to maintain air/fuel ratio to avoid damage

to the converter, prevent engine damage when fuel BTU content variations cause

the engine to run very rich or lean, and ultimately enable the engine to reduce

emissions.

2. Theory of Operation

Utilizing heated O2 sensor(s) in the exhaust stream (one per bank), the AF-900PC

provides PWM outputs to full-authority fuel valves in order to accurately control

air/fuel ratio over a wide load range. The O2 sensor operates best slightly rich or

lean of a point called stoichiometric, which is an A/F ratio of 16.09:1 for natural gas.

Engines with catalytic converters should be run slightly rich of stoichiometric for

lowest emissions.

The AF900PC implements compensation through an intelligent closed-loop

algorithm which provides smooth control behavior that is adaptable to changing

engine load, speed, fuel quality, ambient temperature and catalytic converter

conditions.

In addition, the AF900PC offers optional intake manifold pressure sensor(s)

capability for further adjustment of the post-catalytic setpoints, allowing the catalytic

converter to maintain emissions over an even wider range of engine loads and

operating conditions.

The AF900PC system monitors the proper operation of all sensor inputs and

controller outputs, flagging errors and changing its operating mode when a fault is

detected.

Equipped with a powerful onboard data logging feature and real-time clock, the

AF900PC has the ability to log controller conditions at either pre-determined times

of day or on a time interval basis. This allows users to automatically capture and

store diagnostic errors and overall system performance internally over any given

period of time. It also aids in troubleshooting hard to catch intermittent system

problems.

Page 5

The MODBUS communications capability allows remote monitoring of system

performance and status.

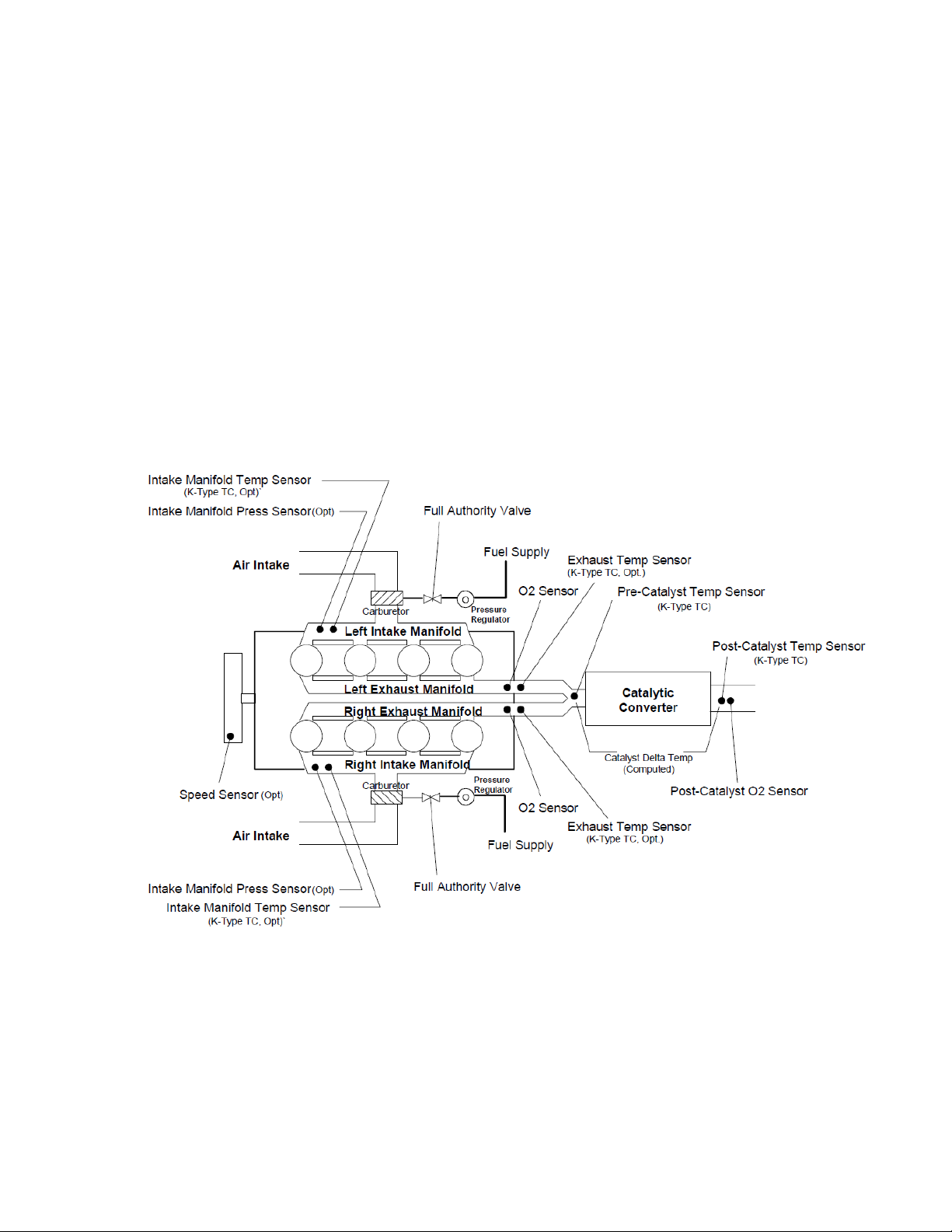

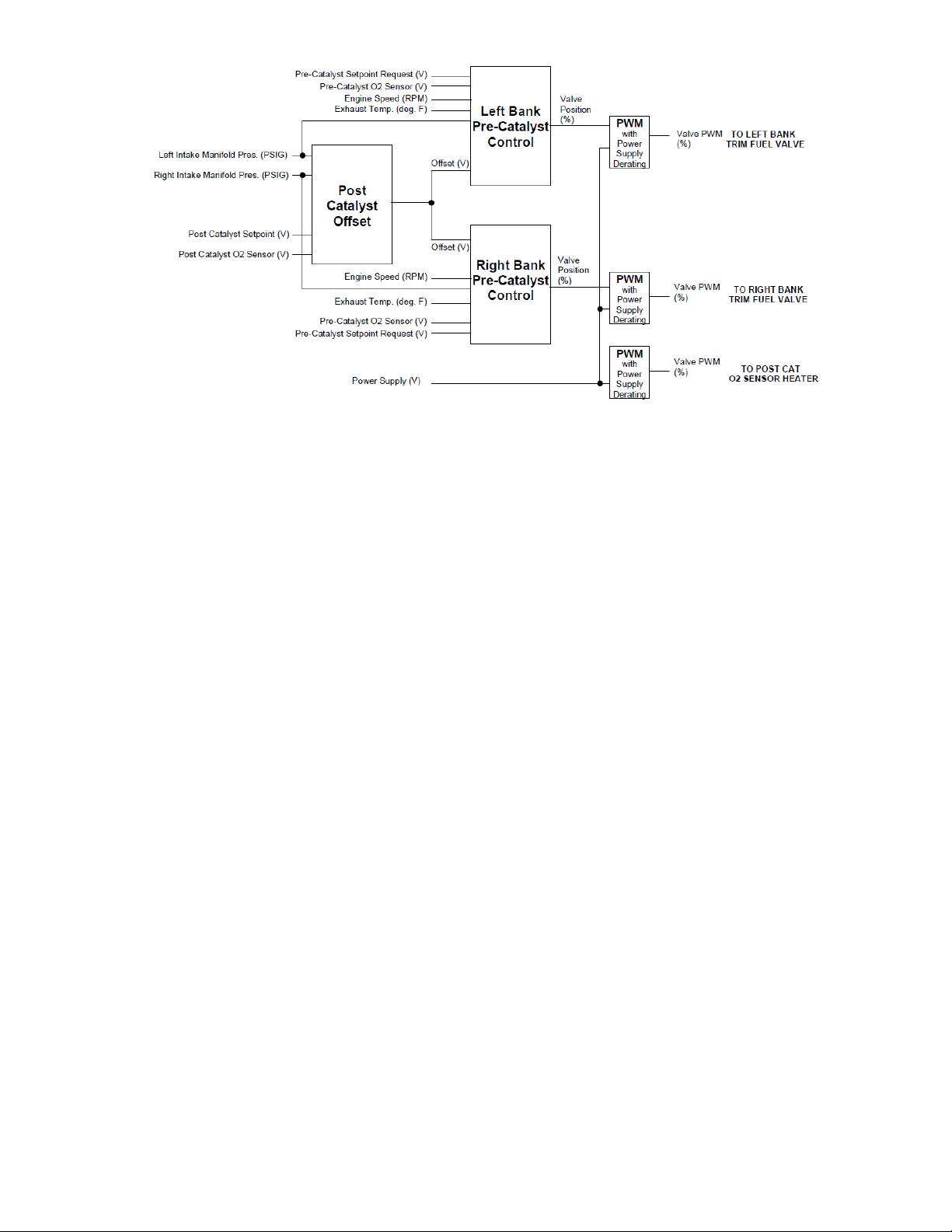

3. System Diagram

AF900PC

Engine Diagram

4

Page 6

4. Specifications

Inputs

Controller

Outputs

Relay

Outputs

Input Power

Sensor Power Out

Display

Data Logging

Communications

Connections

Operating Temperature

Range

Certification

Left Bank O2 Sensor (heated)

Right Bank O

RPM Input (Magnetic Pickup)

RPM Status (Contact Closure)

Left Bank Output (PWM)

Right Bank Output (PWM)

3 Relays, SPDT, rated @ 5A/24VDC, 1A/120VAC, and

0.5A/220VAC

10 – 30 VDC @ 70 Watts Input Power to AF900PC controller

+ 8 VDC Active Magnetic Pickup Sensor Power

Backlit, 4 Line x 20 Character Alphanumeric Display with large

0.36” Characters

Internal 64M Flash Memory and Windows Based DynaTrend

Software to transfer the data to a laptop for viewing and graphing

Hardware: RS-232 / RS-485

Software: DynaHost Laptop Configuration

Modbus

All Two-Part Terminal Blocks

- 30 to + 80 Deg C

CSA Class I, Division 2, Groups A, B, C, D

Sensor (heated)

2

5

Page 7

5. Components/Installation Summary

5.1 System Components

Included

Single Bank Dual Bank

AF-900PC-3F Air/Fuel Ratio Controller (1) (1)

400A-12959 Pre-Cat O2 Sensor Cable Ass’y (50 ft) (1) (2)

400A-12064 Post-Cat O2 Sensor Cable Ass’y (100 ft) (1) (1)

External Components (purchase separately)

Heated Pre-Cat Oxygen Sensor (Bosch p/n 15718) (1) (2)

Full-Authority Fuel Valve (1) (2)

Optional External Components (purchase separately)

M201 Magnetic Pickup for speed sensing (1) (1)

C101-XX Pickup Cable for M201 (1) (1)

Heated Post-Cat Oxygen Sensor (Bosch p/n 15718) (1) (1)

K type thermocouples (ungrounded) (2) (2)

5.2 Installation Summary

1. Mount AF900PC Controller

2. Install Oxygen Sensor(s) in each engine exhaust bank

3. Run cables for Oxygen Sensors to controller (conduit must be used for Division 2

certification).

4. Install full-authority fuel valve(s)

5. Wire power to controller (10-30 VDC)

6. Install pickup for engine run signal and wire to controller. (Note: A contact closure run

signal may be used instead of the magnetic pickup).

7. Wire controller Alarm, Shutdown, and Auxiliary relay outputs to engine panel

shutdown and warning devices as required.

6

Page 8

6. Installation Details

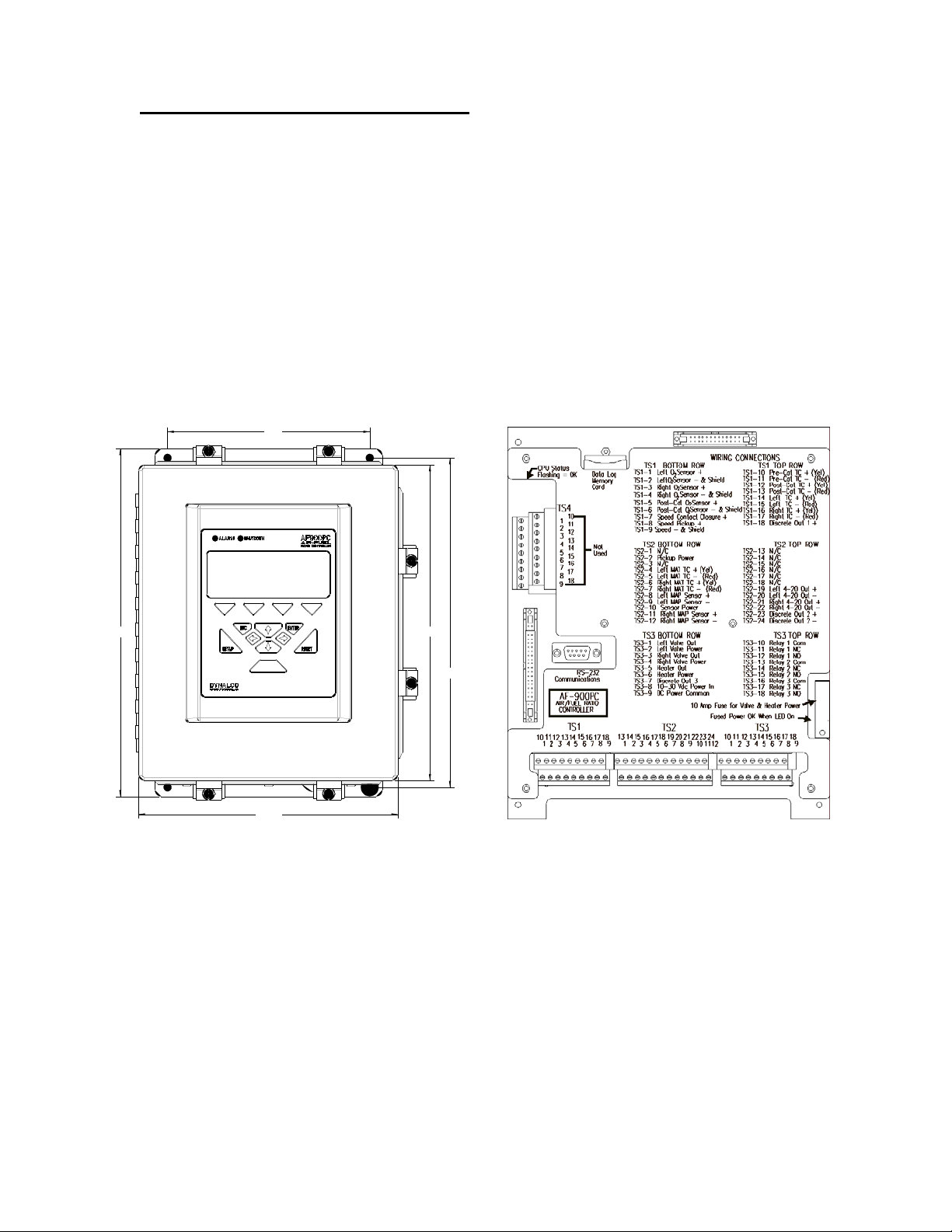

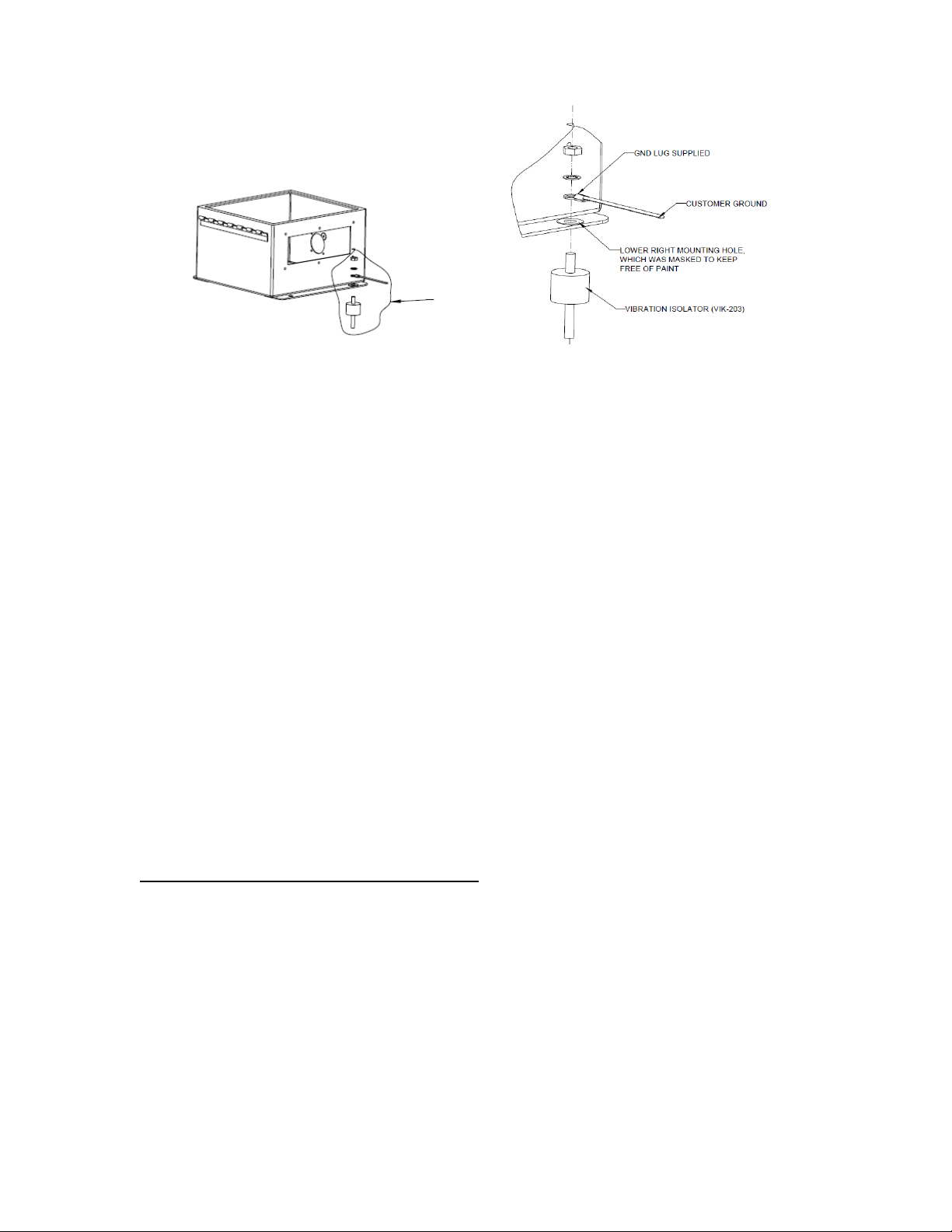

6.1 Mounting the AF900PC Controller

The AF900PC Controller (Fig. 1) should be mounted at “eye level” in an accessible

location for easy display and keypad interface. The controller must be mounted in

surroundings where vibration is minimal and the ambient temperature does not

exceed 80 Deg C. A typical mounting location is on the side of the engine control

panel. A shock mount kit should always be used while mounting. All wiring enters

the controller through the bottom of the enclosure. There are three holes for ½”

conduit entry. All wiring is connected to the main board using removable terminal

blocks for ease of wiring and controller replacement.

NOTE: Installation requires four mounting holes.

8.0

13.5

10.25

12.25

12.8

Front View Inside View

Air/Fuel Ratio Control System

AF900PC

Fig. 1

7

Page 9

6.2 Mounting the Heated Oxygen Sensor(s)

The heated oxygen sensor(s) should be mounted in the exhaust pipe as close to

the engine exhaust manifold as possible. A single bank engine requires only one

sensor. For dual bank “V” engines, the left and right bank sensors should be

mounted as close to the engine exhaust manifold as possible to eliminate cross

talk between the two banks.

CAUTION: The sensor(s) must be mounted where the temperature on the

outer shell does not exceed 400O F (204O C).

Above 400oF, sensor life will deteriorate rapidly and output voltage will be affected.

The sensor(s) should be mounted on a horizontal plane or above horizontal to keep

water from accumulating on the sensor tip. The sensor(s) should also be mounted

where they are accessible as sensor replacement is recommended every 2000

hours. It is recommended a fitting with 18mm x 1 ½ internal threads be welded into

the exhaust pipe for each sensor to be mounted. This will provide a flat mounting

surface for the sensor to avoid exhaust leaks. Sensors should be mounted with an

anti-seize compound on the threads.

NOTE: Recommended torque for mounting the sensors is 28 – 38 ft-lbs.

The conduit for the oxygen sensor should be routed to avoid close proximity to high

tensions ignition cables and coils to minimize potential EMI interference. Ignition,

flow control valve, and power wiring must not be placed in the same conduit with

oxygen sensor wiring. The conduit should also be routed where temperature does

not exceed 200oF.

6.3 Mounting the K type thermocouples (ungrounded must be used)

Optional thermocouples may be installed in the exhaust pipe to monitor pre and

post catalyst temperatures. The AF900PC will also calculate the differential (or

delta) temperature to help ensure proper catalyst operation. An NPT tap should be

used to tap the hole for the thermocouple. An adjustable fitting on most

thermocouple probes will allow proper insertion depth into the exhaust stream. The

thermocouples should be connected to the AF900PC terminal block using

thermocouple extension wire to eliminate erroneous readings.

6.4 Installation of M-201 Magnetic Pickup for Speed Sensing

The M201 magnetic pickup detects engine speed by sensing flywheel gear teeth as

they pass by. The pickup must be mounted on a bracket or flywheel cover so that it

is perpendicular to the face of the flywheel teeth it is sensing. The M201 requires a

5/8-18 UNF thread for mounting. The gap between the pickup pole piece and the

gear teeth should be set to 0.020” to 0.030”. Once the gap has been set, the pickup

should be secured with the lock nut. The M201 should be connected to the

AF900PC with a C101 pickup cable/connector.

8

Page 10

6.5 Installation of the full-authority fuel valves (one per bank)

The full-authority fuel valves are to be mounted between the fuel regulator and

carburetor fuel inlet, as close to the carburetor inlet as possible.

7. Wiring the AF900PC Controller

All wiring to the AF900PC enters the controller through three (3) conduit openings

in the bottom and connects to three (3) double row terminal strips on the bottom of

the controller main board. The terminal strips unplug from the main board for ease

of controller wiring and replacement. The main board cover plate shows the

location of the terminal strips.

Wiring for terminal strip TS1 should enter through the left conduit opening.

Wiring for terminal strip TS2 should enter through the center conduit opening.

Wiring for terminal strip TS3 should enter through the right conduit opening. This

will separate the millivolt signal levels on TS1 and TS2 from the power, output, and

relay wiring on TS3.

8. Electrical Connections

The Fuel Valves must be configured for single demand, PWM control, and low side

drive.

Terminal Strip

TS1

Bottom Row

TS1-1

TS1-2

TS1-3

TS1-4

TS1-5

TS1-6

TS1-7

TS1-8

TS1-9

Left Bank Oxygen Sensor Output +

Left O2 Sensor Cable - (Black and Shield)

Right Bank Oxygen Sensor Output +

Right O2 Sensor Cable - (Black and Shield) (DB only)

Post-Catalyst Sensor Cable + (White)

Post-Catalyst Sensor Cable – [Black (paired with white) and shield]

Speed Contact Closure + (Required if speed magnetic pickup is not used)

Speed Magnetic Pickup +

Speed Magnetic Pickup - and shield (for speed contact closure if used)

Description

9

Page 11

Terminal Strip

TS1

Top Row

TS1-10

TS1-11

TS1-12

TS1-13

TS1-14

TS1-15

TS1-16

TS1-17

TS1-18

Pre-Catalyst Thermocouple + (Yellow)

Pre-Catalyst Thermocouple - (Red)

Post-Catalyst Thermocouple + (Yellow)

Post-Catalyst Thermocouple - (Red)

Left Exhaust Thermocouple + (Yellow)

Left Exhaust Thermocouple - (Red)

Right Exhaust Thermocouple + (Yellow) (DB only)

Right Exhaust Thermocouple - (Red) (DB only)

Not Used

Terminal Strip

TS2

Bottom Row

TS2-1

TS2-2

TS2-3

TS2-4

TS2-5

TS2-6

TS2-7

TS2-8

TS2-9

TS2-10

TS2-11

TS2-12

Not Used

+8 VDC Pickup Power for Active Speed Pickup (Optional)

Left & Right Bank Valve Power Common

Left Manifold Air Temperature (MAT) Thermocouple + (Yellow) (Optional)

Left Manifold Air Temperature (MAT) Thermocouple - (Red) (Optional)

Right Manifold Air Temperature (MAT) Thermocouple + (Yellow) (Optional)

Right Manifold Air Temperature (MAT) Thermocouple - (Red) (Optional)

Left Manifold Air Pressure (MAP) Sensor Input (+)

Left Manifold Air Pressure (MAP) Sensor Input (-)

DC Power for Left and Right Manifold Air Pressure (MAP) Sensors

(Factory set to Input Supply Voltage but jumper selectable to 5.0 VDC)

Right Manifold Air Pressure (MAP) Sensor Input (+)

Right Manifold Air Pressure (MAP) Sensor Input (-)

Terminal Strip TS2, Top Row

No Connections Currently Used

Terminal Strip

TS3

Bottom Row

TS3-1

TS3-2

TS3-3

TS3-4

TS3-5

TS3-6

TS3-7

TS3-8

TS3-9

Left Bank + PWM Valve Position Control

Left Bank Valve +12/24 DC Power

Right Bank + PWM Valve Position Control

Right Bank Valve +12/24 DC Power / Right Bank Oxygen Sensor Heater Left & Right Bank Oxygen Sensor Heater Left & Right Bank Oxygen Sensor Heater +

Not Used

+10 to 30 VDC System Power In @ 70 Watts (#16 AWG wire required)

DC Power Common (#16 AWG wire required)

Description

Description

Description

10

Page 12

Terminal Strip

TS3

Top Row

TS3-10

TS3-11

TS3-12

TS3-13

TS3-14

TS3-15

TS3-16

TS3-17

TS3-18

NOTE: Relay contacts are shown in the de-energized state.

Alarm Relay Common

Alarm Relay Normally Closed

Alarm Relay Normally Open

Shutdown Relay Common

Shutdown Relay Normally Closed

Shutdown Relay Normally Open

Auxiliary Relay Common

Auxiliary Relay Normally Closed

Auxiliary Relay Normally Open

Description

This terminal strip contains the contacts for the alarm, shutdown, and auxiliary

relays. These contacts are isolated and may be connected to engine shutdown

devices (such as the panel annunciator) or warning devices as required. Any of the

AF900PC thirty-nine trip channels may be programmed to energize one of the

three relays. The SPDT relay contacts are rated @ 5A/24VDC, 1A/120VAC, and

0.5A/220VAC.

11

Page 13

9. Front Panel Display User Interface

The AF900PC requires the user to configure a variety of parameters. By

performing one of three procedures below, parameters may be configured.

1) Using interface via the SETUP key (password required), keypad, and a 4x20

display.

NOTE: A limited number of parameters are available in the setup screens

of the AF900PC. Using a laptop to configure the AF900PC is

recommended.

2) Using DynaHost multiple laptop configuration screens via a laptop or PC.

3) Using DynaHost, a text editor (Windows Wordpad) and editing the

downloaded file (AF900PC.SPC) via a laptop or PC.

9.1 Front Panel Configuration Screens

The AF900PC Front Panel Display (FPD) user-interface consists of a 4-row by 20column LCD display (LCD); a 13-key custom keypad; and two LEDs to indicate

ALARM and SHUTDOWN.

12

Page 14

9.2 FPD Keypad

The custom keypad consists of the following keys:

Four screen-specific Soft Keys are located

directly under the LCD. These keys navigate to

other screens or perform specific actions as

indicated in the last line of the LCD.

SETUP Key enters SETUP Mode.

ESC Key navigates up one menu-level; exits

SETUP Mode; returns to the Main Title Screen;

or cancels certain actions. (Note: To exit SETUP

Mode or return to Title Screen, the customer

must press and hold the ESC Key for three or

more seconds.)

UP, DOWN, LEFT, and RIGHT Keys select or

modify values in SETUP Mode.

ENTER Key accepts modified values changed in

SETUP Mode.

RESET Key resets AF900PC fault conditions

.

13

Page 15

9.3 FPD Screens

The LCD displays information to the user, grouping the information into screens.

Each screen displays a specific set of information to the user. To change screens,

the user must navigate to the desired screen using the indicated Soft Keys.

The AF900PC will display a title screen upon power up.

DYNALCO CONTROLS

AF900PC

V x.yy

The title screen displays a banner and indicates the current software version for

five seconds before displaying a main status screen. To return to the title screen,

the user must press and hold the ESC key for three seconds.

The main user screens are the Main Status Screen, Pre-Cat Status Screens, PostCat Status Screens, Temperature Screens, and MAP Screen. The main status

screen displays the current engine/air-fuel control status (STOPPED, START,

MANUAL, AUTO, etc.) and any current ALARM or SHUTDOWN fault conditions.

The pre-cat status screens display the current pre-cat status and fuel valve

opening percentage. The post-cat status screen displays the current post-cat

status. The temperature screens display all measured engine temperatures. The

MAP screen displays the manifold air pressure(s) and engine RPM.

The SETUP mode screens allow authorized operators to view and/or adjust

software setpoints.

NOTE: Title Screen is not accessible in SETUP Mode.

A navigational screen map layout for the user RUN screens is shown on page 14.

A navigational screen map layout for the SETUP mode screens is shown on page

15.

14

Page 16

9.4 Navigational Map of RUN Screens

15

Page 17

9.5 Navigational Map of SETUP Mode Screens

16

Page 18

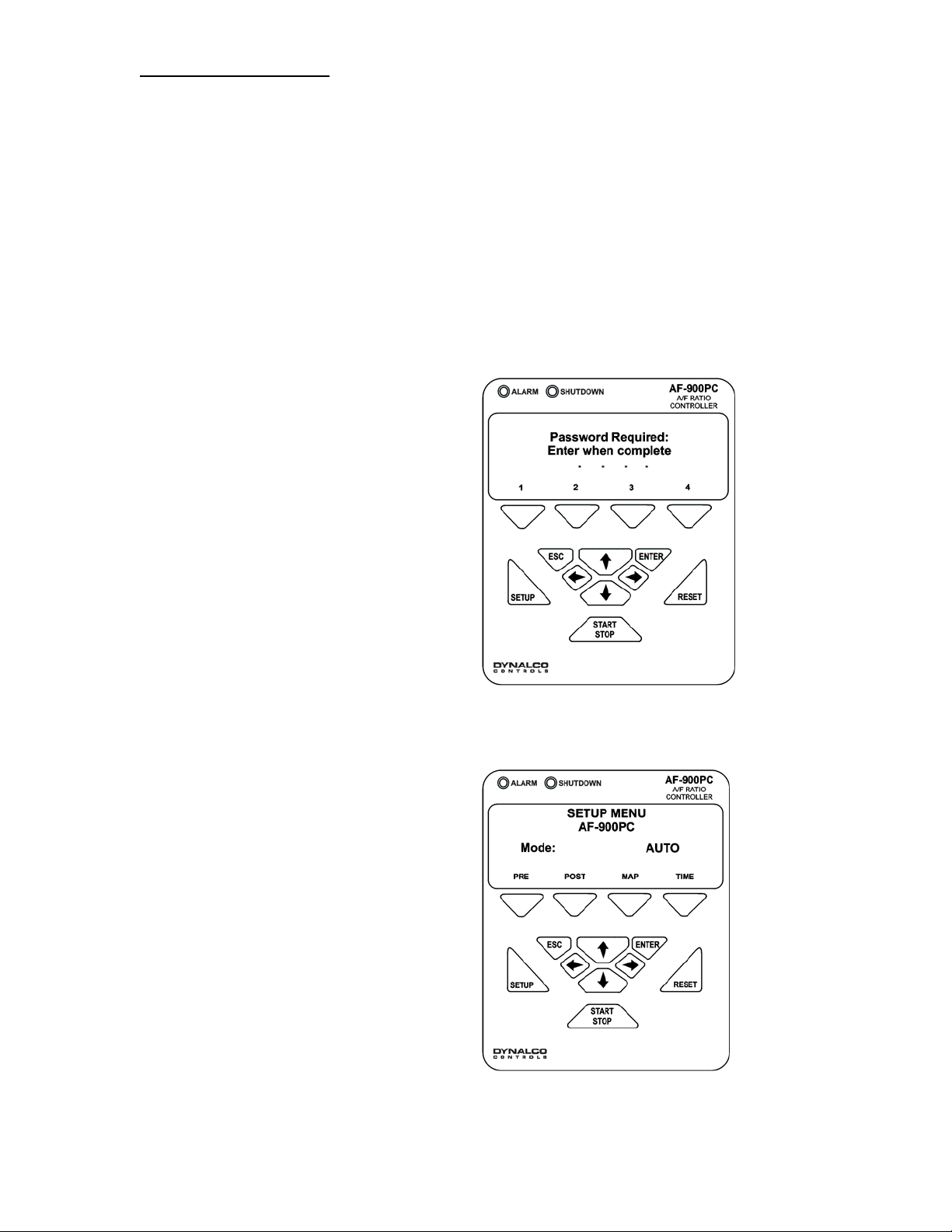

9.6 FPD SETUP Mode

1) To enter SETUP mode, press the SETUP key on the FPD.

2) Enter current SETUP password.

NOTE: A four character default password “1 2 3 4” is pre-assigned prior to

shipping. This password may be changed using the DynaHost software to

change parameter 6112.0, if desired. Passwords may be up to eight

characters in length using the digits 1, 2, 3, or 4 only.

3) Enter password using the Soft Keys labeled “1 2 3 4”. A solid asterisk (*) will

appear for each entered character, while a blinking asterisk (*) indicates additional

characters may be entered.

4) Press ENTER for SETUP Mode.

17

Page 19

From the SETUP menu the user may navigate to setpoint screens (screens that

allow you to change values) by using the Soft Keys. The user may view and/or

modify setpoint values as follows:

1. Navigate to the desired setpoint screen.

2. Press the ENTER key to enter setpoint select mode. The first setpoint

on the screen is now enclosed in angle brackets, i.e. >SETPOINT<.

3. Press the UP/DOWN keys to select the setpoint to modify. The angle

brackets will move from one setpoint to the next for each UP/DOWN key

press.

4. Press the ENTER key to enter setpoint modify mode. The bracketed

setpoint will blink indicating that the operator may now modify its value.

5. Press the UP/DOWN keys to increment or decrement the setpoint value.

The increment/decrement rate may be changed by selecting the desired

rate displayed above the appropriate Soft Key.

6. Press the ENTER key to save the modified setpoint value; press the

ESC key to cancel the modified setpoint value and restore the original

value.

7. Press the ESC key to exit setpoint select mode and return to SETUP

mode screen navigation.

To exit SETUP mode, user must press and hold the ESC key for three seconds. All

modified setpoint values will be stored to memory while display shows the

following:

CONFIGURATION

PARAMETER STORE

IN PROGRESS

Once the SETUP configuration is stored to memory, the AF900PC returns to the

operator screens.

CAUTION: Power must remain normal during the storing process. A failure of

power during “In Process” memory storing will result in the loss of all data

storage and will bring the AF900PC back to factory defaults.

18

Page 20

10. Computer Interface using DynaHost Software

DynaHost software provides serial communication between a PC or laptop and the

AF900PC. DynaHost will run on a PC with 133MHz Intel Pentium processor, 32

MB of RAM, and a minimum of 100MB of hard disk space. DynaHost is compatible

with Windows 95/NT/98/2000/XP.

The AF900PC must be connected via a standard RS-232, 9-pin, male-female,

serial communication cable. The HOST software communicates

to the AF900PC via Dynalink, Dynalco Control’s ASCII-based serial communication

protocol.

When the program is running there are two major sections: the Control Panel and

the Current Screen.

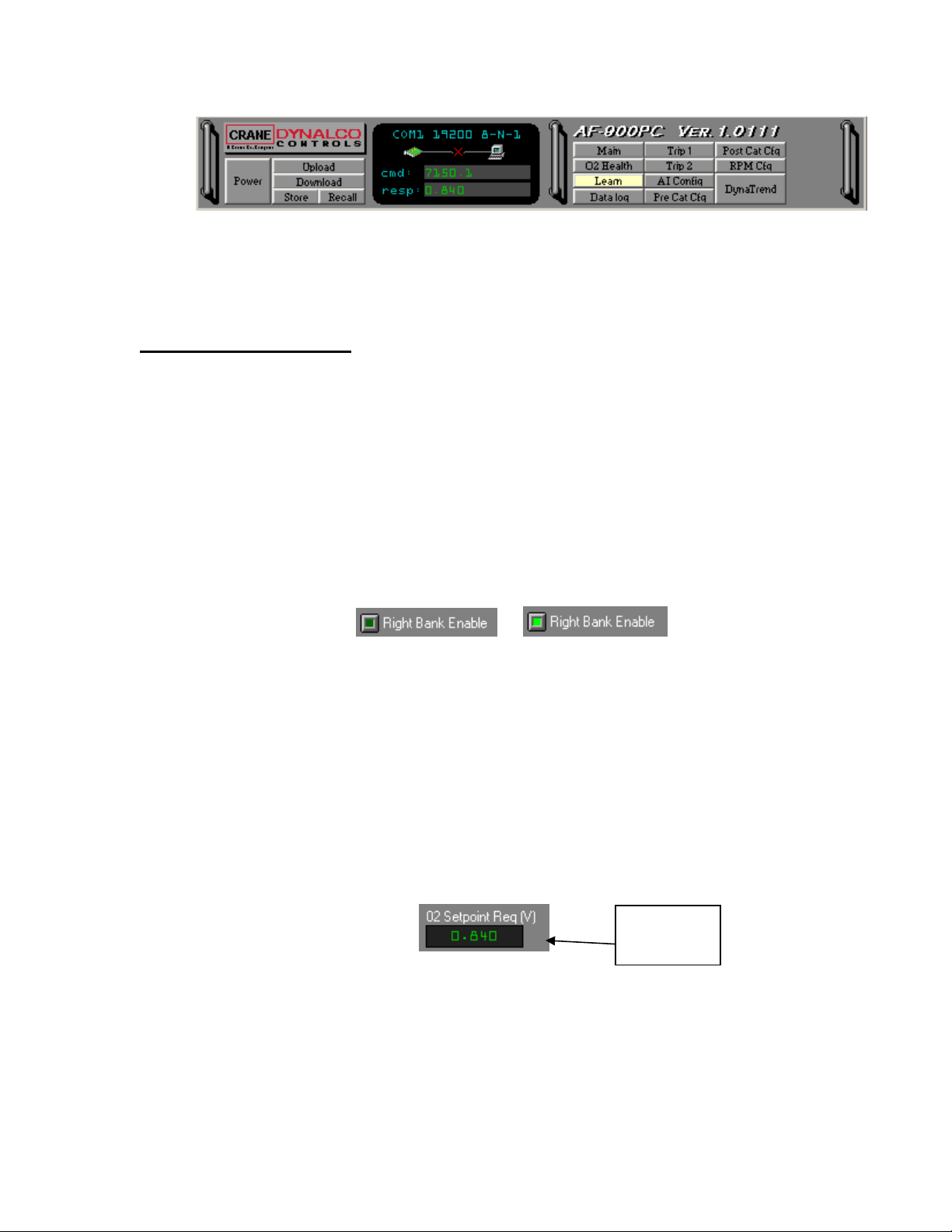

10.1 Control Panel Specifications

The Control Panel is located at the top of the application screen on the laptop or

PC and allows the user to view the status of the host application, showing the

communication settings and status.

Control Panel (Connected)

Figure 1A

The Control Panel above (Fig. 1A) shows an active communication which allows

the user to navigate through the multiple screens (Main, O2 Health, Learn, Data

log, Trip 1, Trip 2, AI Config, Pre-Cat Cfg, Post-Cat Cfg, RPM Cfg and DynaTrend).

The Control Panel also contains the basic commands:

• Power: Closes the host application.

• Upload: Uploads the current configuration of the AF900PC to a configuration file

(.spc).

• Download: Downloads a configuration file (.spc) to the AF900PC.

• Store: Stores the current configuration.

• Recall: Recalls the last configuration stored.

• Cmd: Sends a command to the AF900PC.

• Resp: Shows the response to a command sent to the AF900PC.

• Screen Buttons: Show the current screen being displayed and allows you to

switch to other screens.

19

Page 21

The Control Panel in Fig. B shows an inactive communication by displaying a red

“X” across the communication line.

Control Panel (Disconnected)

Figure 1B

10.2 Screen Description

A yellow highlighted button, as shown in Fig. 1B, displays the current screen you

are in. Within each screen you can display information by using the following

controls:

Toggle Button: Represents 2-state parameters. Place the mouse over the button

to the left of text (Figure 2) to see the current state and click on the button to toggle

the state. The button will be green when enabled, black when disabled.

NOTE: The parameter number is displayed when you place the mouse over

the label.

(Disabled) (Enabled)

Toggle Button

Figure 2

Read/Write Green Display: A parameter (Figure 3) which may be modified by

typing a value and pressing ENTER.

NOTE: The parameter number is displayed when you place the mouse over

the label.

Type in value

Green Display

Figure 3

and press

<enter>.

20

Page 22

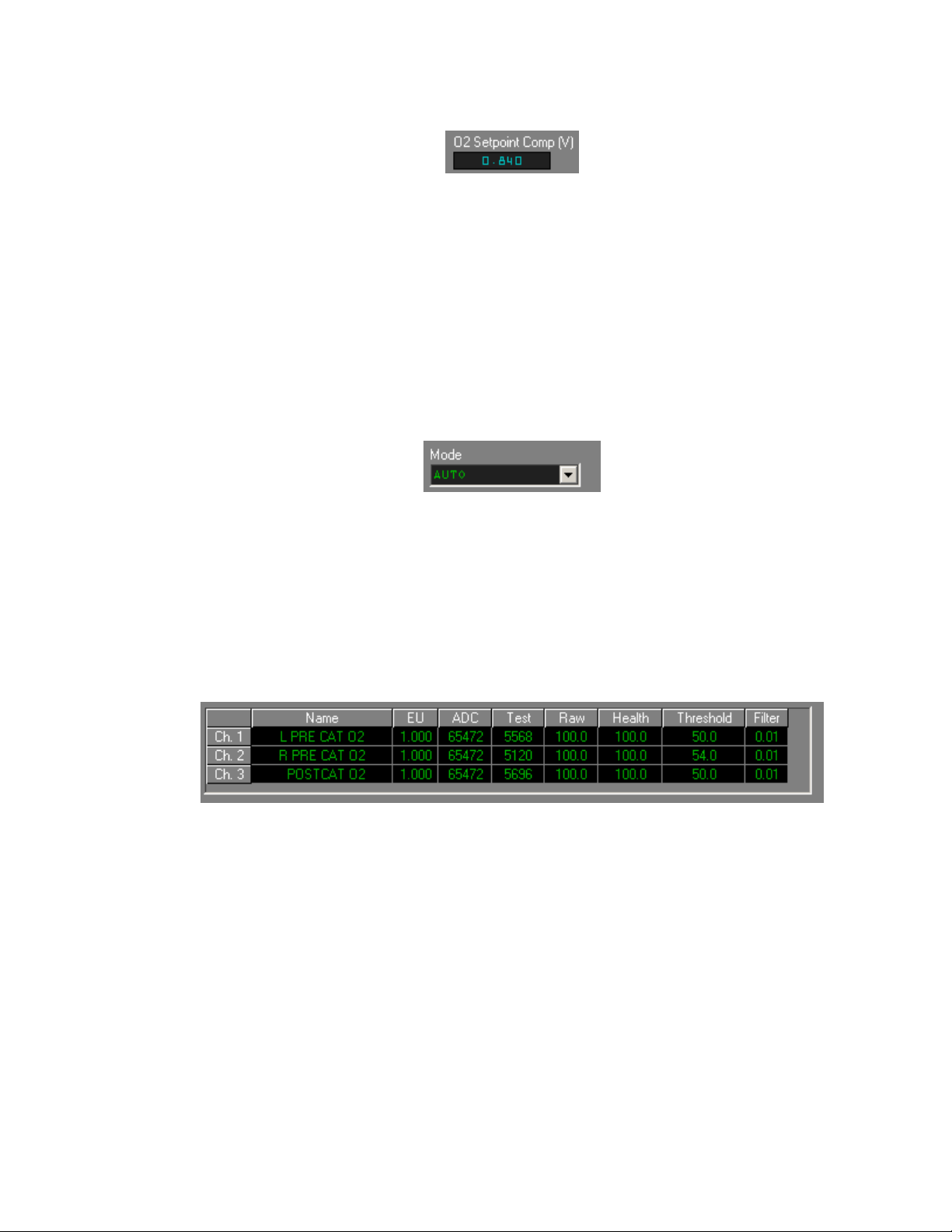

Read Only Blue Display: A parameter (Fig. 4) that can only be read.

Blue Display

Figure 4

Combo Box Display: A parameter (Figure 5) modified by selecting one of the

options displayed when you click on the drop-down button.

NOTE: The parameter number is displayed when you place the mouse over

the label.

Combo Box Display

Figure 5

Grid Display: A matrix of green displays (Fig. 6). Some parameters may be

modified by typing in the value and pressing ENTER (press backspace to delete

the current value).

Grid Display

Figure 6

21

Page 23

Scope: Traces the value of up to two numeric parameters in real time domain. The

user may select parameters to trace by dragging the probe (Figure 7) and dropping

it in the display (blue or green). Minimum and maximum ranges and the

time/division may also be changed. The scope may be enlarged to occupy the

entire screen by clicking on the zoom in button on the scope. The scope will update

much faster when zoomed in because the communications link will request only the

two parameters displayed on the scope.

Take the probe

and Drag and

Dropt it on a

display…

Scope

Figure 7

22

Page 24

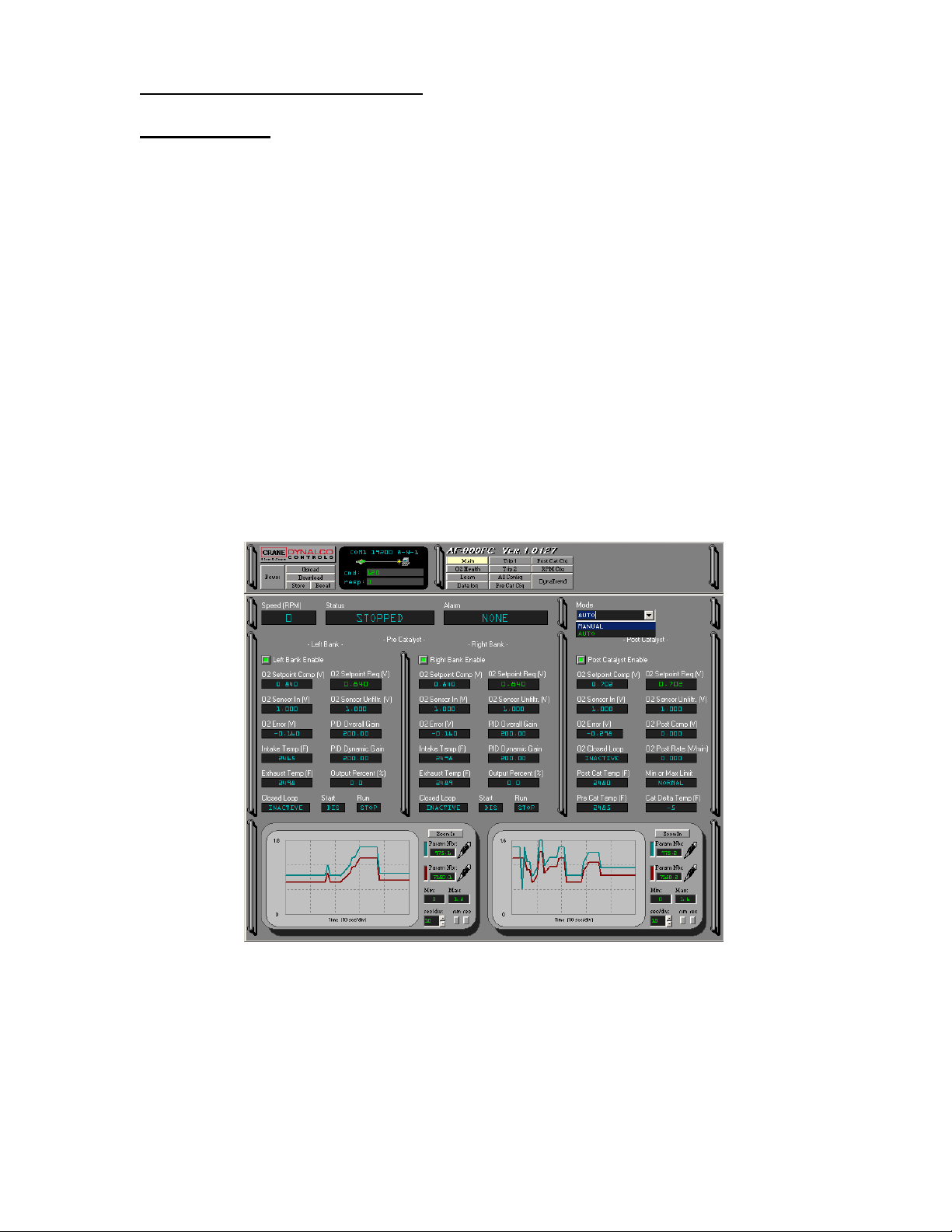

10.3 Main Screen Specifications

MAIN SCREEN

Shows the system and alarm status, the current speed and the main parameters of

the pre-catalyst (left and right banks) and post-catalyst

(Fig. 8). There are also two scopes to plot up to 4 parameters in real time.

In addition, the following parameters may also be changed from the main screen:

Mode: The controller may be changed between AUTO and MANUAL mode by

clicking on the drop down MODE menu and selecting the desired operating mode.

Left and Right Bank O2 Setpoint Req. (V): The pre-catalyst O2 initial setpoint

request voltage may be changed by clicking into the value, deleting the old value,

and entering the new value. Typical operating range is 0.700 to 0.900V.

Post-Catalyst O

Setpoint Req. (V): The post-catalyst O2 initial setpoint request

2

voltage may be changed by clicking into the value, deleting the old value, and

entering the new value. Typical operating range is 0.650 to 0.850V

Left Bank, Right Bank, and Post-Catalyst Enable: Left bank, right bank, and

post-catalyst control may be enabled or disabled by clicking the ENABLE button. If

the button is green, the control is enabled.

Main Screen

Figure 8

23

Page 25

OXYGEN SENSOR HEALTH SCREEN

The O2 Health Screen (Fig. 9) shows parameters related to sensor health

measurement.

Descriptions of the parameters are as follows:

EU: Displays the current voltage input from each O2 sensor.

ADC: Displays the A/D converter counts from the last sensor input measurement.

Test: Displays the A/D converter counts from the last sensor test measurement.

Raw: Displays the last calculated sensor health for each sensor.

Health: Displays the filtered sensor health for each sensor.

Filter: Programmable parameter sets the filter time constant for the sensor health.

With the maximum value of 1.0, there is no filtering and each sensor test becomes

the new Health value. With the default filter value of 0.01, each new sensor reading

becomes 1/100th of the Health value. In other words, a smaller filter value means

more filtering.

Time (sec): Determines time interval (in seconds) at which sensor health test will

be performed. Sensor Health test is performed every 60 seconds with the default

value of 60.

Oxygen Sensor Health Screen

Figure 9

24

Page 26

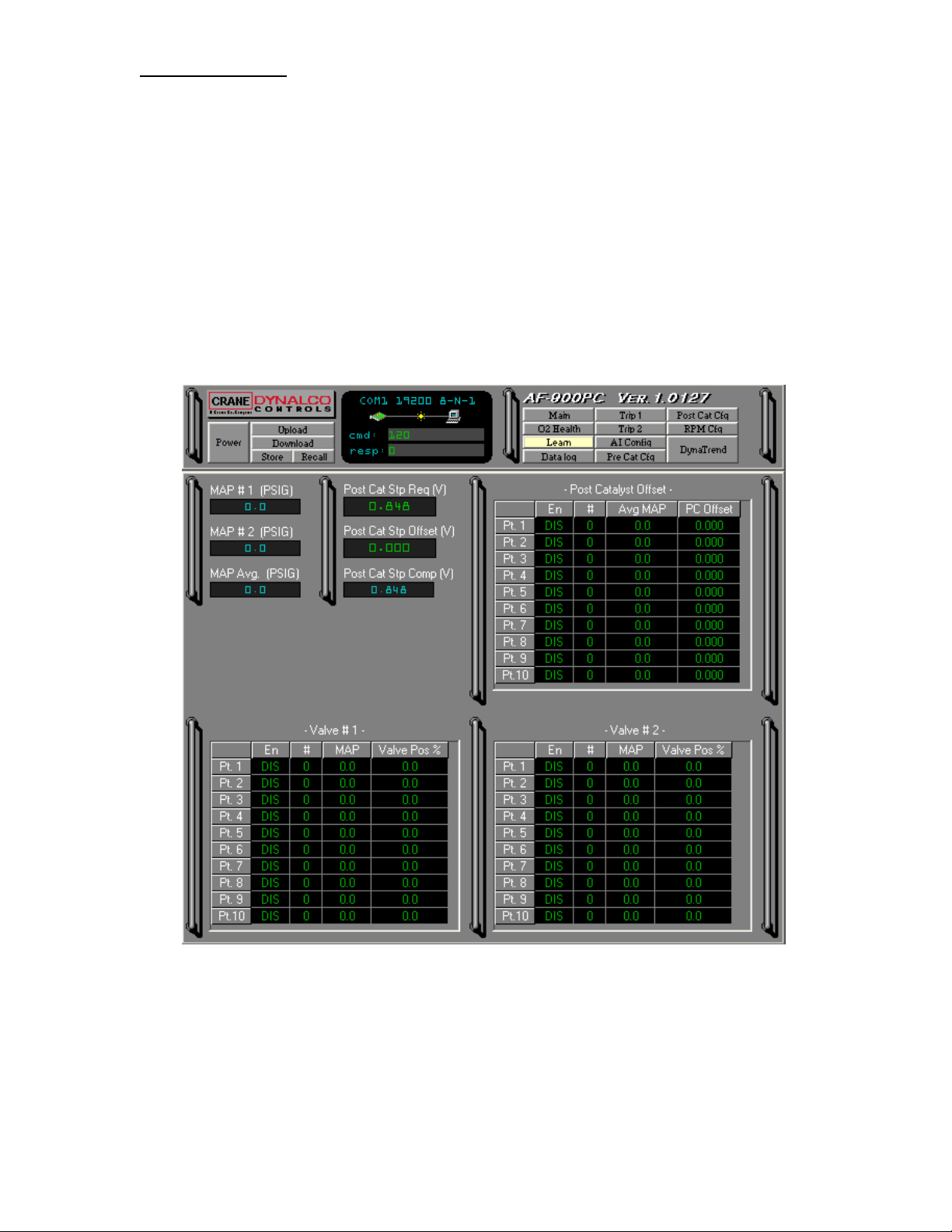

LEARN SCREEN

The Learn Screen (Fig. 10) displays the post-catalyst offset and valve learn tables

created during the MAP programming procedure. MAP pressure and post-catalyst

setpoint values are also shown on this screen. MAP programming may only be

initiated from the AF900PC front panel and will be discussed later in the manual.

Each new point programmed will be entered into the proper place on the table

according to the MAP pressure. The PC offset and valve pos % will change linearly

between points on the table. A point may be deleted from the table by clicking into

the En for that point, deleting the En with the backspace key, and entering DIS.

The PC offset and valve pos % for any point may be changed by deleting the old

value and entering a new value. The MAP values in the tables cannot be altered.

Learn Screen

Figure 10

25

Page 27

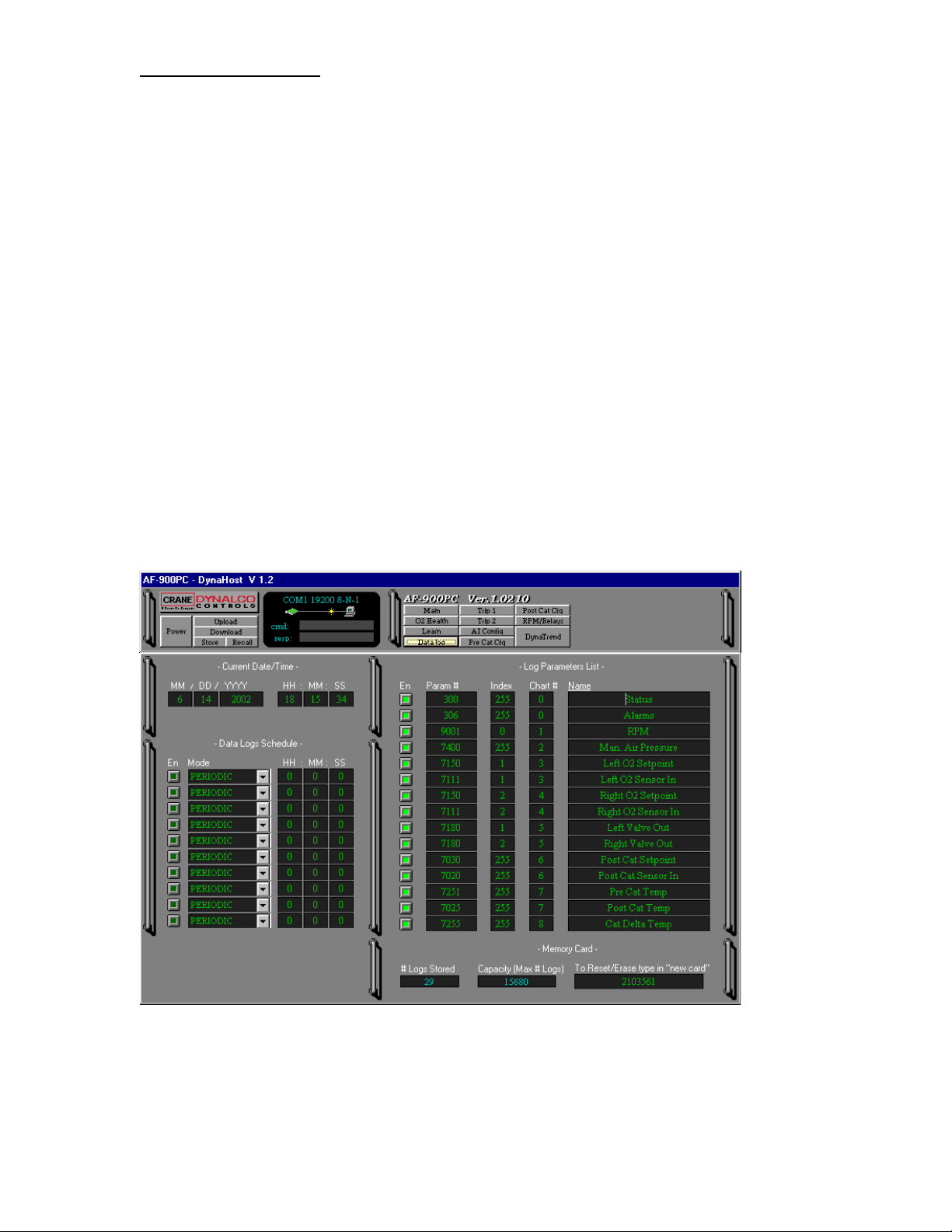

DATA LOG SCREEN

This screen (Fig. 11) sets up the data log system and current date/time.

Data log parameters may be modified as follows:

Current Date/Time: The time and date may be changed by deleting the old value

and entering a new value as required.

Data Log Schedule: Up to ten (10) daily data log times or a periodic data log

interval may be used. The unit may also be set up for one (1) periodic interval time

and up to nine (9) daily log times.

To enable periodic mode data logging:

1. Enter the desired data log interval.

2. Select PERIODIC mode from the drop down menu.

3. Click the EN button for that channel.

To enable daily data logging:

1. Enter the desired data log time.

2. Select DAILY mode from the drop down menu.

3. Click the En button on that channel.

NOTE: Data Log may occur as often as once per second.

Data Log Screen

Figure 11

26

Page 28

Log Parameter List: The Log Parameter List (Fig. 11) shows the most important

controller parameters being data logged. Disable by clicking the En buttons for any

parameters you do not wish to data log. Enter “0” for the Chart # for any

parameters where an excel chart is not required.

NOTE: Parameters having no numerical value (such as Status) must be

assigned to chart # 0.

NAME shows the parameter name as it appears on the header on the excel

spreadsheet and on the excel charts. The names may be edited if desired.

If you wish to log a parameter not shown:

1. Enter the parameter number and index.

2. Enter the parameter chart #.

3. Enter the parameter name.

The parameter number and index may be found by placing the cursor over the

name of the parameter. The index is the decimal value of the parameter.

NOTE: Enter 255 for the index if the parameter does not have a decimal value.

Flash Memory: This section, shown at the bottom of Fig. 11 of the data log screen,

shows the status of the Onboard Flash Memory. “# Logs Stored” indicates the

number of data logs which have occurred since the last memory reset. “Capacity”

shows the maximum number of data logs required to fill the memory. To “reset”

memory, type “new card” in the Reset box and press enter. The flash memory will

be reset when the next data log occurs. All previously recorded data on the flash

memory will be lost upon reset.

27

Page 29

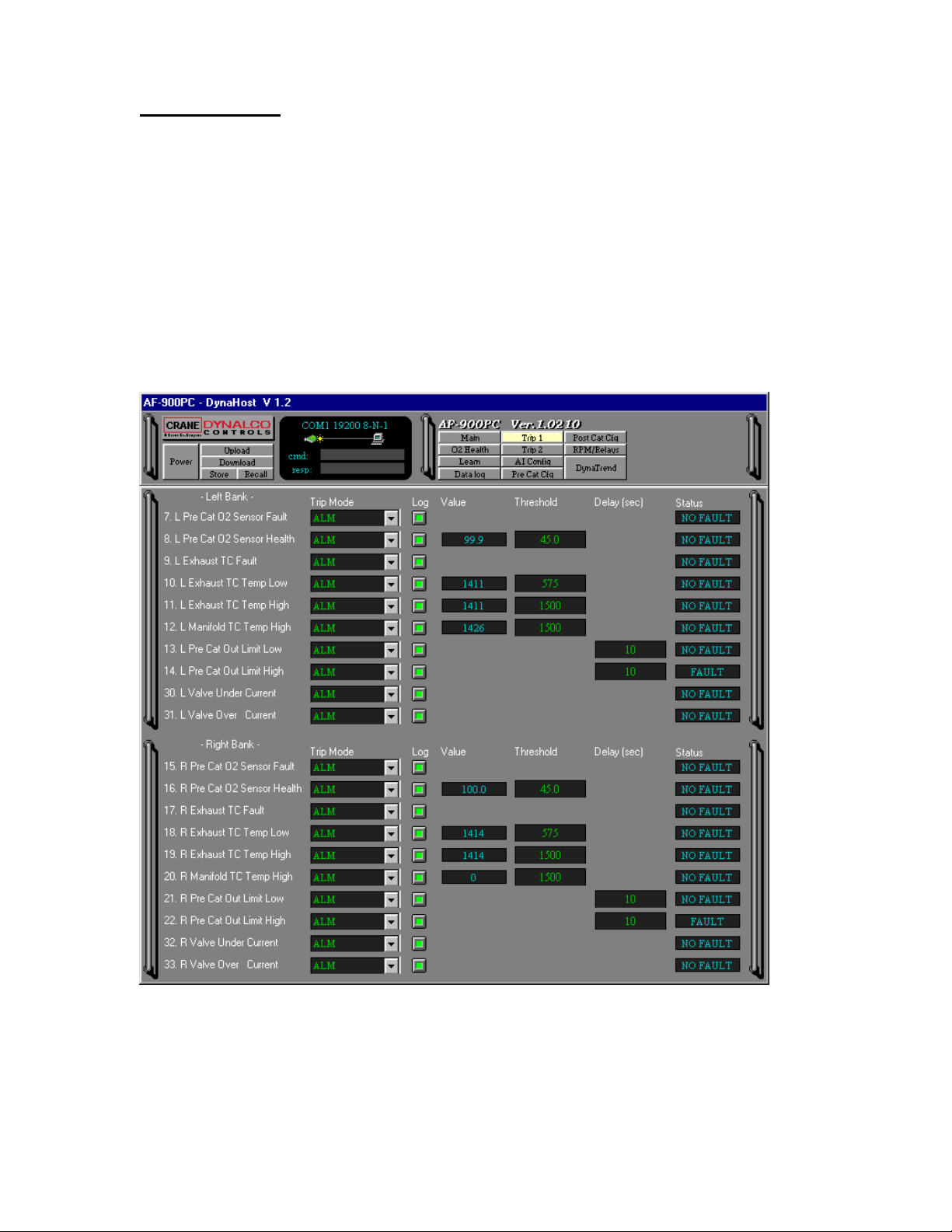

NOTE: The following descriptions apply to the Trip 1 and Trip 2 Screens

TRIP SCREEN 1

A screen (Fig. 12) used to setup the trip action for pre-catalyst system faults. The

screen shows all faults set to Alarm and Data Log.

Trip Mode: Selects the action, from the drop down menu, which will be taken by

the controller when the fault occurs. To make best use of the system diagnostics, it

is recommended that all trips be programmed to Alarm or Shutdown so the

operator will be alerted if a fault occurs. Faults that are critical to the engines

health, such as high catalyst temperature, should be configured to Shutdown so

the shutdown relay contacts may be used to trip the panel annunciator.

Disabled (DIS): The trip is disabled and no action will be taken.

Alarm (ALM): Trips the Alarm Relay, flashes the Alarm LED, and shows the fault

on the LCD display.

Trip Screen 1

Figure 12

Shutdown (SD): Trips the shutdown relay, flashes the shutdown LED, and shows

the fault on the LCD display.

Auxiliary (AUX): Trips the auxiliary alarm when fault occurs.

28

Page 30

Log: Click the Log button “ON” to force a data log to internal flash memory when

the fault occurs.

Value: This column displays the current value of all trips that have a numeric value.

The value displayed is after the appropriate filters have been applied.

Threshold: This column displays the trip threshold value for all trips that have a

numeric value. To change a threshold value, click into the parameter and edit it.

Delay: This column indicates the delay time in seconds or minutes between the

fault occurring and the trip being actuated. All delay times may be edited and have

a range of 0 to 240.

Status: Indicates whether each trip is in the “Fault “ or “No Fault” condition.

TRIP SCREEN 2

This screen (Fig. 13) is used to setup the trip action for post-catalyst and catalytic

converter system faults.

Trip Screen 2

29

Figure 13

Page 31

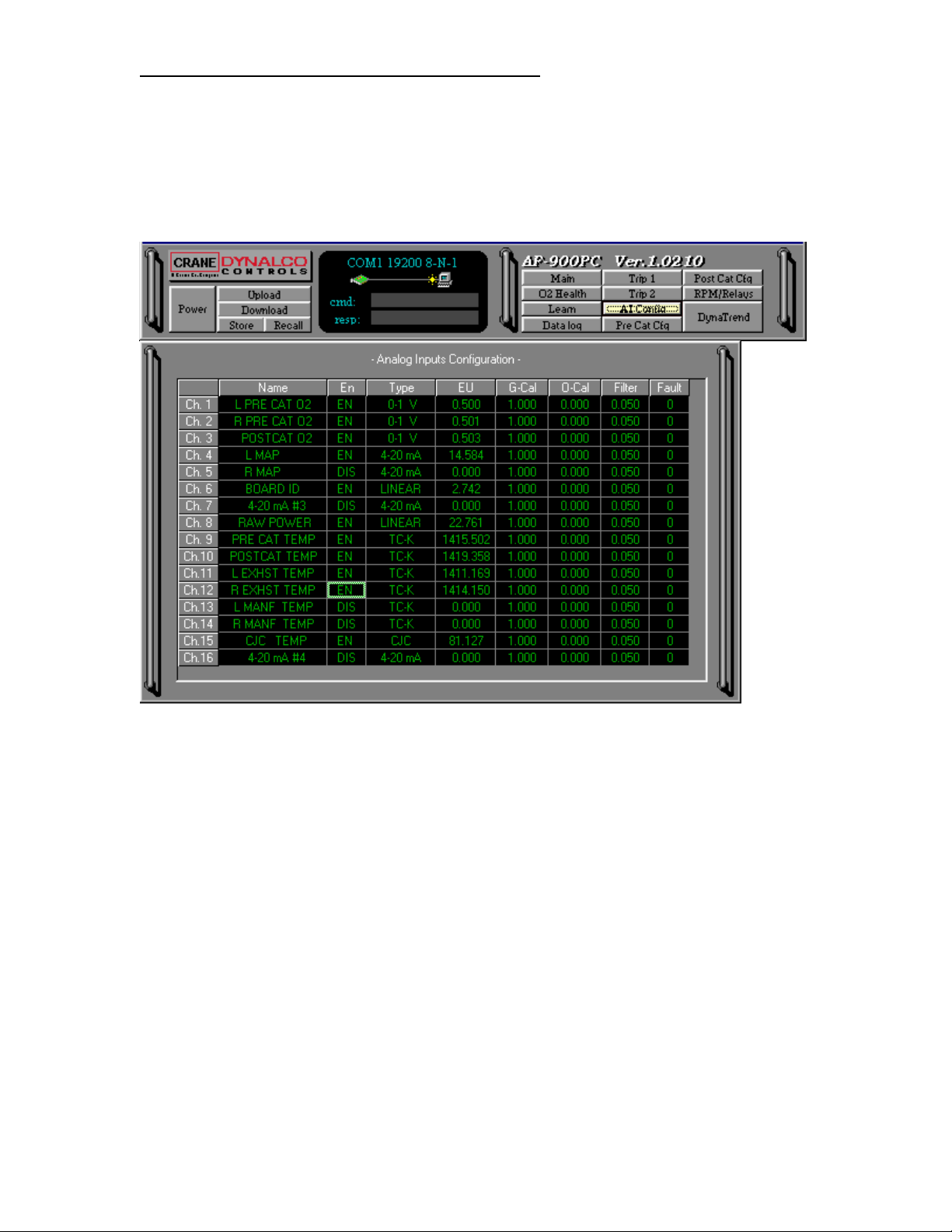

ANALOG INPUTS CONFIGURATION SCREEN

This screen (Fig. 14) is used to set up the analog input system. It also shows the

current status of every channel.

NOTE: Specialized personnel should use this screen primarily to enable and

disable inputs for the application.

Analog Inputs Configuration Screen

Figure 14

Name: Name of each analog input channel. Channel names cannot be changed.

Type: Shows input type for each analog input channel. Type cannot be changed.

EU: Displays current measurement value for each analog input channel.

G-Cal: Factory gain calibration setting that should not be changed.

O-Cal: Factory offset calibration setting that should not be used.

Filter: Filter value applied to each input channel. The minimum value of 0.001

provides maximum filtering while the maximum value of 1.000 provides no filtering.

Fault: This column indicates each input channel’s fault status. All channels should

show “0” if there are no faults. Inputs faults are latching and must be cleared by

pressing the Reset button on the front panel.

En: This column is used to enable the required input channels. Entering EN

enables the channel, while entering DIS disables the channel. Enable the input

channels listed below:

30

Page 32

Single or Dual Bank Dual Bank Only

L PRE-CAT O2 R PRE-CAT O2

POST-CAT O2 R EXHST TEMP

BOARD ID

RAW POWER For MAP Programming

PRE-CAT TEMP L MAP

POST-CAT TEMP R MAP (Optional)

L EXHST TEMP

CJC TEMP For Intake Manifold Temperature

L MANF TEMP

R MANF TEMP

NOTE: 4/20 #3 and 4/20 #4 are not used by the AF900PC.

PRE-CATALYST CONFIGURATION SCREEN

This screen (Fig. 15) is used to set up the left and right bank pre-catalyst system.

The following section describes the function of every parameters located on this

screen. The parameters for the left and right bank are identical so they will be

discussed only once.

31

Page 33

Pre-Catalyst Configuration Screen

Figure 15

Output Enable: This button enables or disables the left or right bank PI control

loop. One bank must be enabled for the controller to function.

O

Setpoint Req (V): Sets the initial target voltage for the left and right bank

2

Pre-Cat O2 sensors. Typically set between 0.700 and 0.900 Volts.

Start Percent (%): Sets the fuel valve opening when the controller is in the START

mode.

Manual Percent (%): Sets the fuel valve opening when the controller is in the

MANUAL mode.

Fault Percent (%): Sets the fuel valve opening when a pre-cat O2 sensor fault

occurs if the sensor fault select is set to FAULT.

32

Page 34

Sensor Fault Select: Determines what control action will be taken if the pre-cat O2

sensor has a fault. Options are chosen from a drop down menu and are as follows:

Opposite: Sets the fuel valve opening the same as the opposite bank.

Fault: Sets the fuel valve opening to the value configured in the “fault percent

(%)” parameter.

MAP: Sets the fuel valve opening from the learn table based on current

manifold air pressure reading.

Start Temp (F): Controller changes from SENSOR WARM UP mode to AUTO

mode when exhaust temperature exceeds this threshold.

Off (Exhst Low) Temp (F): Controller returns to SENSOR WARM UP mode when

the exhaust temperature on either bank drops below this threshold. This parameter

is also used for “Exhaust TC Temp Low” trip.

Prop Gain: The pre-catalyst proportional gain parameter determines the gain of

the PI control loop. The larger the gain, the more aggressive the output changes in

response to errors. A typical of 0.020 is a good place to start.

Reset Time: The pre-catalyst reset time parameter determines the integration rate

of the PI control loop. The smaller the reset time parameter the faster the control

loop will integrate and increase or decrease the output while there is error. A typical

value of 5.0 is a good starting point.

Fast Dynamics: This button enables or disables the fast dynamic control function.

Fast dynamics are used to boost the proportional gain when a large error occurs.

Gain @ Fast +: Sets the proportional gain multiplier when in fast dynamics with a

Pre-Cat O2 sensor reading greater than the “O2 Setpoint Comp (V)”. A starting

value of 3.0 is suggested.

Gain @ Fast -: Sets the proportional gain multiplier when in fast dynamics with a

Pre-Cat O2 sensor reading less than the “O2 Setpoint Comp (V)”. A starting value of

3.0 is suggested.

Error for Slow: Sets the error voltage at which the PI loop will return to slow

dynamics. A starting value of 0.025 is suggested.

Error for Fast: Sets the error voltage at which the PI loop will go into fast

dynamics. A starting value of 0.050 is suggested.

33

Page 35

POST-CATALYST CONFIGURATION SCREEN

This screen (Fig. 16) sets up the post-catalyst system. All parameters that are

green may be changed.

Post-Catalyst Configuration Screen

Figure 16

Post-Cat Enable: This button allows the post-catalyst control to be enabled and

disabled.

Setpoint Selector: Selects the source for the final post-cat sensor target voltage.

When set to REQ, the final target voltage will be the O2 Setpoint Req (V) voltage.

When set to MAP, the final target voltage becomes the O

Setpoint Req (V)

2

modified by the MAP table.

O2 Setpoint Req (V): Sets the initial target voltage for the post-cat O2 sensor.

Typical range for this parameter is 0.650 to 0.850 V.

Max Pre-Cat Error Left: Sets the maximum allowable left bank pre-cat error for

the post-cat control to be active. Post-cat integration is frozen when the error

exceeds this value. Typically set to 0.020

Max Pre-Cat Error Right: Sets the maximum allowable right bank pre-cat error for

the post-cat control to be active. Post-cat integration is frozen when the error

exceeds this value. Typically set to 0.020.

Post-Cat Start Temp: Sets the minimum catalytic converter outlet temperature to

enable post-catalyst control. This temperature should be set high enough to allow

proper catalytic converter action before post-catalyst control is attempted.

34

Page 36

Min Post-Cat Comp: Sets the maximum allowable negative post-cat

compensation in millivolts. Post-cat integration will be frozen when this level is

reached. Typically set to –100.

Max Post-Cat Comp: Sets the maximum allowable positive Post-cat

compensation in millivolts. Post-cat integration will be frozen when this level is

reached. Typically set to 100.

Post-Cat Temp (F): Displays the current post-catalyst temperature value.

Pre-Cat Temp (F): Displays the current pre-catalyst temperature value.

Cat Delta Temp (F): Displays the current temperature differential across the

catalytic converter.

Filtered Delta Temp (F): Displays the temperature differential across the catalytic

converter after the time filter has been applied.

Filter Time (hours): Select the desired filter time for the FILTERED DELTA TEMP

from the drop down menu. Filter time is defined as the time required to reach 100%

of the new value when a change in delta temperature occurs. The filter is not linear.

Listed below is an example of the % new value reached at different points of the

filter time:

1/8 time ~ 37% 1/4 time ~ 60%

1/2 time ~ 85% 1 time ~ 100%

The following 4 parameters work together to establish the post-catalyst control

integration rate for pre-cat setpoint compensation when an error exists. The

association between these parameters is shown in the drawing on the configuration

screen on the following page.

Min Error (mV): Sets the minimum post-cat error voltage. No post-cat control will

occur when the error is less than this value. Set to 2.000 as a starting point.

Max Error (mV): Sets the post-catalyst error voltage for max rate post-cat

integration will begin. Set to 50.000 as a starting point.

Min Rate (mV/min): Sets the minimum post-cat integration control rate. Set to

1.000 as a starting point.

Max Rate (mV/min): Sets the maximum post-cat integration control rate. Set to

5.000 as a starting point.

35

Page 37

RPM/RELAY CONFIGURATION SCREEN

This screen (Fig. 17) sets up the RPM channel and the action of the relays.

RPM/Relays Configuration Screen

Figure 17

RPM Configuration:

Current RPM: Displays the current running speed of the engine.

Number of Teeth: Enter the number of teeth on the flywheel when using a

magnetic pickup for speed input indication.

RPM Filter: Sets the amount of filtering for the RPM display. With a minimum

setting of 0.01, the RPM display will be averaged over 100 readings. There is no

filtering with a maximum setting of 1.00. Typically set at 0.1.

RPM Start Delay (sec): Sets the time interval for the controller and will remain in

the START mode when the engine is started. When in START mode, the fuel

valves are forced to START % allowing the engine to stabilize before attempting

automatic control. The minimum time is 0, maximum time is 300 seconds.

RPM Start Threshold: Sets the minimum engine speed on start for the engine to

be considered running. Minimum setting is 30 RPM. This parameter is used only

when using a magnetic pickup for speed sensing.

36

Page 38

Pickup Threshold (mV): Selects the speed input voltage sensitivity from the drop

down menu. A setting of 1000 mV will work for most applications. At this setting a

minimum pickup input voltage of 1.000 peak ( 0.707 VAC RMS) is required. Used

only when magnetic pickup is used for speed input.

RPM Selector: Selects which speed input source will be used to determine that the

engine is running. When clicked ON, the speed contact closure will be used to

signal a run condition.

NOTE: Engine RPM cannot be displayed when using the contact closure

speed input.

When clicked OFF the magnetic pickup speed input will be used to determine

engine speed.

Relay Action Configuration:

The three drop down menus in this section determine the control action for the

Alarm, Shutdown, and Auxiliary Relays. Select the desired control action for each

relay from the description below:

NE: The relay is normally energized and will de-energize while in the tripped state.

ND: The relay is normally de-energized and will energize while in the tripped state.

LNE: The relay is normally energized and will latch in the de-energized state when

a trip occurs. The latched relay trip condition may be cleared by pushing the front

panel RESET key.

LND: The relay is normally de-energized and will latch in the energized state when

a trip occurs. The latched relay trip condition may be cleared by pushing the front

panel RESET key.

10.4 Communication Settings Dialog

This dialog (Fig. 18) is displayed when you click on the communication settings

label in the control panel.

The AF900PC is configured by default with the settings shown in Figure 18. The

settings can be recalled at any time by pressing the Defaults button.

Use this screen to change the COM port number to match the serial port being

used by your computer.

NOTE: All other parameters are fixed by the AF900PC firmware and changing

them will cause a communication failure.

37

Page 39

Communication Settings

Figure 18

11. Computer Interface Using Configuration File

Another method used to configure the AF900PC is to edit and download a

configuration file to the AF900PC. The configuration file is a template file that

contains all configurable parameters and an explanation for all parameter

configuration settings. The user must enter desired configuration values for all

appropriate configuration parameters before downloading the file to the AF900PC.

The configuration file can be edited with any text editor or word processor that can

save files in text format, such as Wordpad available on Windows PCs.

The download file contains configuration comments and parameter configurations.

The comments for the configuration parameters explain the function for each

parameter and the programmable values associated for each parameter. The

comments are any text or text characters that follow a semicolon.

General AF900PC configuration comments should not be deleted. However, some

comments, such as ‘<ANALOG INPUT CHANNEL #01>’, have been included for

the user to overwrite with application-specific descriptors, such as ‘Engine Exhaust

Temperature’. Once the file has been edited, it should be saved under a different

name so that the original factory .spc file remains intact.

The configuration file’s parameter configurations program the corresponding

AF900PC parameters when the file is downloaded to the AF900PC.

38

Page 40

11.1 Downloading a Configuration File

A list of parameters along with their values can be downloaded to the

AF900PC. The configuration file has a .spc file extension and is a plain ASCII text

file.

NOTE: An example of a configuration file is shown in Appendix A.

A semicolon character indicates the start of a comment. A comment can start

anywhere on a line. The end of line terminates the comment.

Parameters and their values are specified using the following format:

param_number = value ; comment

The parameter is specified by the ‘param_number’ argument, followed by an equal

sign and then the actual desired parameter value in the ‘value’ argument. An

optional comment can be added to describe what the parameter number

represents. The last line of the configuration file should contain a single ‘S’

character that must be sent to the controller. This command tells the controller to

store the parameters just downloaded.

CAUTION: DynaHost sends only the commands found in the configuration

file. If the ‘S’ is not present in the file, it will not be sent to the controller.

;************************************************************

*****************

DYNALCO CONTROLS

; 3690 N.W. 53rd Street

; Fort Lauderdale, FL 33309

;

; AF900PC

;

; Filename : AF900PC.SU

; Date : March 16, 2002

;************************************************************

*****************

;

1=50 ; Set the number of teeth

2=16 ; Set the number of cylinders

3=4 ; Set the number of strokes

4=100

6=0

39

Page 41

8=1

9=2000

11=9

12=0

77=33.5

86=0

105=0

106=3500

107=0

110=30

111=350

112=30

S ; Store parameter to non-volatile memory

A configuration file (AF900PC.spc) is provided with the DynaHost program. Use

this file to edit or when you want to go back to the factory defaults.

A report is presented (Fig. 19) when downloading the configuration file. A

successful response to a command sent is represented with an ampersand ‘@’.

Download Report

Figure 19

11.2 Uploading Configuration to an .spc file

It is recommended that a configuration file (.spc) with the current configuration of

your system be saved once the controller has been optimized for the installation.

This will provide a download file for other controllers used on similar engine types.

To upload a file, click the Upload button on the control panel of any DynaHost

screen. You will be presented with two dialog boxes; the first one is going to ask for

the ‘Source File’, which could be the AF900PC.spc file provided from factory. The

second dialog box is going to ask for the ‘Target File’ where you are going to save

40

Page 42

the configuration. A file name such as the engine name may be used for the target,

but the name must end in “.spc”.

An upload report (Fig. 20) will open showing each parameter and it’s corresponding

value once data transfer begins.

Upload Report

Figure 20

12. Software Operation

12.1 AUTO Mode

After power-up, the AF900PC will begin operation in STOPPED mode

since most likely the RPM input will be zero. In this state, the controller completely

closes both the left and right bank fuel valves.

Once the AF900PC measures sufficient engine RPM (RPM>Startup RPM

parameter) or it detects the speed contact closure input present, it positions the left

and right bank fuel valves to their startup positions. This is now the START mode.

In the START mode the AF900PC waits for a timer to expire before changing into

the SENS WARMUP mode. Once in the SENS WARMUP mode the AF900PC

waits for the O2 sensors to warm up with the engine exhaust. During SENS

WARMUP mode the valves are held in the startup position until the left and right

bank exhaust temperatures are both above the threshold for the controller to go

into AUTO mode.

NOTE: If using heated O2 sensors, the threshold will be set to 0 Deg F,

enabling “AUTO” mode immediately following timer duration.

The delay timer in the START mode is setup in case a running engine shuts down,

then quickly re-starts while the exhaust is still hot. In this case, the delay timer will

allow conditions to stabilize before the controller further opens the fuel valves in

AUTO mode.

41

Page 43

Once in AUTO mode, the controller waits for both pre-catalyst control loops to

stabilize and the pre-catalyst O2 setpoints to be within a small error before

introducing post-catalyst compensation. At that point the controller will be in its

final mode, AUTO/POST which is automatic with post-catalyst compensation.

12.2 MANUAL Mode

In MANUAL mode, the controller operates entirely in accordance with manually

entered parameter numbers, via DynaHost by the user. MANUAL mode may be

entered and exited only from DynaHost.

In MANUAL mode, the PWM output is determined strictly by the Manual Percent

(%) parameter(s). No automatic control takes place.

Note: It is recommended this mode only be used for troubleshooting by an

experienced user.

13. Control Software

The AF-900PC control software consists of two independent, identical left and right

bank pre-catalyst PI control loops. In addition, a separate post-catalyst offset

control section adjusts both the pre-catalyst loop setpoints in order to compensate

for actual catalytic converter behavior.

During initial system setup, the post-catalyst offset compensation is turned OFF

and the two pre-catalyst setpoints are adjusted until a separate emissions analyzer

shows that exhaust emissions are in compliance. At that point the post-catalyst O

sensor voltage is noted and used as the post- catalyst O2 setpoint. This way the

behavior of the catalytic converter is "captured" in the post-catalyst O2 setpoint.

Then the post-catalyst offset compensation is turned ON.

During normal operation, both the pre-catalyst loops will react faster to engine

changes and the slower post -catalyst offset loop will adjust the two pre-catalyst

loops based on factors which affect just the catalytic converter performance such

as fuel BTU content, temperature, load, etc...

2

42

Page 44

Simplified Control Software Block Diagram

AF900PC

14. Manifold Air Pressure Sensor (MAP) Load

Compensation (Option)

The AF-900PC is capable of accepting an input from a MAP sensor

in order to determine engine load. This option is needed for engines that operate

over a very wide load range and thus, one fixed post-catalyst setpoint does not

maintain emissions over the entire load range. If this option is used, the postcatalyst O2 setpoint is "offset" according to the engine load, which is proportional to

the MAP sensor output.

Up to ten offset points can be created for precise compensation in the high load

range. In the low load range, the base post-catalyst O

any offset. Only loads above "point zero" engine load (MAP) have any offset

added to the base post-catalyst O

catalyst O

load compensation begins.

In order to add MAP offsets, the user must enter SETUP mode by pressing the

SETUP key. When prompted for a Password, enter "1 2 3 4 " (or the correct

password if it has been changed from the factory default), and press ENTER.

A "Zero Point" must first be entered. Point zero is the starting point for MAP offset

compensation to begin. The "Zero Point" is the largest MAP load where the engine

remains in compliance with zero post-cat offset. To program "Zero Point" proceed

as follows:

setpoint never changes, but offsets are added to it once high engine

2

setpoint. At all engine loads the base post-

2

setpoint is used exclusive of

2

43

Page 45

1. From the Setpoint menu, press the MAP Soft Key.

2. From the Map Programming menu screen, press the MAP Soft Key.

3. Once in the Map Programming screen, observe that the Offset is 0.000. If the

Offset is zero, proceed to step 5.

4. Press the Enter button and note the "Off" value is bracketed. Press Enter again

and note that "Off" is flashing. Use the Up and Down keys to set the value to

zero, then press Enter again.

5. To program the "Zero Point", press the MAP Soft Key, then the OK Soft Key.

The zero point is now programmed and will appear as Pt 1 in the post-catalyst

offset table in the DynaHost learn screen. Also note that Pt 1 was also entered

in the Valve #1 and Valve #2 learn tables.

The next step is to enter the full load MAP offset. Run the engine at 100% load for

a minimum of 15 minutes before entering the full load offset.

Proceed to enter the full load offset as follows:

1. Press the Enter button twice and note that the "Off" value is flashing.

2. Use the Up and Down keys to add or subtract post-cat offset. This offset is

immediately added to the Post-Cat Setpoint Req. When adjusting offset, allow

ample time for the AF-900 and catalytic converter to react to the changes.

Remember, the post-catalyst control loop is very slow.

3. Once full load emissions compliance has been satisfied, press the Enter key to

except the offset value followed by the Escape key. Next press the OK Soft

Key. The full load offset value has now been saved and may be viewed as Pt 2

on the post-catalyst offset table on the DynaHost learn screen. Also note that Pt

2 has also been entered in the Valve #1 and Valve #2 learn tables.

Additional points may be entered, one at a time, if the engine does not meet

emissions compliance at loads between the zero point and full load. Each point will

then have an offset amount and a corresponding MAP load amount stored in nonvolatile memory.

Using DynaHost, the offsets at these points may be altered, but not the

corresponding MAP load amount at this point. The point must be deleted entirely in

order to alter the MAP load amount, in which case an entirely new point may be

added. No matter how many points are created, the points are connected in a

linear manner to provide a continuous offset amount.

44

Page 46

15. Catalytic Converter Delta Temperature

The logic diagram below shows the operation of the catalytic converter differential

temperature measurement function. The pre-cat temperature is subtracted from the

post-cat temperature to obtain delta temperature. The "Filter Time" set on the PostCat Cfg screen is then applied to the delta temperature used for the trips. A trip will

occur if either the Delta Temp High or Delta Temp Low thresholds are exceeded,

provided the start timer shown at the bottom of the diagram has expired.

Catalytic Delta Temperature

AF900PC

16. Data Logging

The AF900PC has powerful data logging capabilities through the use of on-board

Flash Memory, providing up to 64 Megabytes of capacity.

Up to 15 parameters can be logged as fast as every 1 second. Additionally,

ALARMS can be chosen for data logging as well as the AF900PC status

(MANUAL, START, AUTO, AUTO).

Using Dynalco’s Windows-based DynaTrend software, the user can transfer the

logged data to a laptop and view or graph the data. Dynalco’s DynaTrend software

can automatically and seamlessly open Excel to view and graph the data. Each

parameter logged is identified with a label and also a time/date stamp. Once the

data has been transferred to a laptop using DynaTrend, the file can be saved and

assigned a file name that can be the engine name/number/date, etc. with Windows

standard long filenames.

45

Page 47

17. Setup

Using DynaHost and the data logging screen file (Fig. 21), the user can decide

which parameters are to be logged and how often or at what time of day. The set

up of this screen has been described in Section 10 of the manual.

Data Log Screen

Figure 21

46

Page 48

18. Transfer

To transfer the data to a laptop, connect the RS232 DB9 connector to the

AF900PC and start the DynaHost software.

DynaTrend is the tool used to upload the data log information stored in memory.

The information is uploaded into a text file in the comma-separated values format

(.csv). DynaTrend also allows you to export the .csv file to Microsoft Excel.

DynaTrend software is initiated by clicking on the DynaTrend button at the top of

any screen. The steps to follow, which are shown in Figures 22 & 23, appear on

the computer screen. Once complete, the user is prompted to go to Excel for

presentation of the data.

All the information stored in the memory may be uploaded, or only the information

stored since the last time you uploaded.

DynaTrend (uploading data)

Figure 22

DynaTrend (exporting data to Excel)

Figure 23

47

Page 49

The figures below shows an example of what the data log table and chart look like

after exporting to Microsoft Excel:

Data Log Spreadsheet

Figure 24

Data Log Chart

Figure 25

48

Page 50

19. Start Up Procedure

1) Before starting the engine, make sure the AF900PC is powered up.

2) The following AF900PC parameters need to be set prior to starting engine. It

is recommended to use the DynaHost user software main screen

configuration (see section 10.3) for setting the following:

• Manual Mode

• Valve output = 100%

• Gain = 50%

• Reset = 50%

• Post O2 sensor off

3) Since the AF900PC is in “Manual” mode and valve outputs are set to 100%

or full open positions, the fuel pressure will be the same as it was before the

AF900PC was installed.

4) Start the engine and allow to warm up to normal operating temperature.

5) Next, increase engine load to 100% or normal operating load.

6) Check the O2 sensor output voltage on each bank using either the front

display or using the DynaHost user software. This will give an indication of

where the engine has historically been running.

7) Set the O2 sensor setpoints to the same voltage read above.

8) Adjust the power screw adjustments on the carburetor(s) to full rich position.

The O2 sensor output voltages should increase.

9) Decrease the manual output settings slowly by 5% decrements until the O2

sensor output voltages match close to the readings taken in step 6 above. Be

careful not to lean the A/F too far as this could cause engine damage.

10) Switch to AF900PC AUTO mode. The AF900PC will now be controlling the

output fuel valves so that the actual O2 sensor outputs match the setpoints.

11) Install an emissions analyzer in the exhaust and fine-tune the LEFT BANK

SP and RIGHT BANK SP for the desired air/ fuel ratio. It is best to make

small adjustments (no more than 10 mV at a time) and allow engine time to

adjust before re-checking emissions.

12) The AF900PC will now control the air/fuel ratio to maintain the O2 sensor

output voltage established by by tuning the LEFT BANK SP and RIGHT

BANK SP.

49

Page 51

When CONTROL LIMIT comes on during operation, it indicates that the AF900PC

cannot apply sufficient valve movement to obtain the desired air/fuel ratio under the

existing operating conditions. In this case, the engine’s fuel pressure regulator

spring or carburetor will have to be adjusted. If CONTROL LIMIT and LEAN are

on, the AF900PC output fuel valve is wide open and cannot increase fuel flow to

meet the O2 sensor setpoint. In this case the fuel pressure regulator spring

pressure must be increased or the carburetor enriched. If CONTROL LIMIT and

RICH are on, the AF900PC cannot decrease fuel flow enough to meet the O2

sensor setpoint. This would be unlikely and could be caused by a fuel valve

malfunction.

20. Diagnostics

The AF900PC has powerful self-diagnostics to detect and properly deal with

system and sensor faults. Below is a list of possible faults for which trips can be

enabled:

Post-Catalyst O2 Sensor Fault

Param #7093

Post-Catalyst O2 Sensor Health

Param #950

Post-Catalyst Thermocouple Fault

Param #7094

Post-Catalyst Temperature Low

Param #7025

Post-Catalyst Compensation Limit

Param #7096

Left Bank Pre-Catalyst O2 Sensor Fault

Param #7232.1

Left Bank Pre-Catalyst O2 Sensor Health

Param #950.1

Sensor reading is outside normal range of 0 – 1V

Sensor health is degraded – time to replace

Thermocouple open or reading is outside valid range

Temperature after the catalytic converter is too low

The post-catalyst compensation is at its maximum

Sensor reading is outside normal range of 0 – 1V.

Sensor health is degraded – time to replace.

Left Bank Pre-Catalyst Thermocouple Fault

Param #7233.1

Left Bank Pre-Catalyst Temperature Low

Param #7120.1

Thermocouple open or reading is outside valid range.

Temperature before the catalytic converter on left

bank is too low

50

Page 52

Left Bank Pre-Catalyst Output Low

Param #7241.1

The left bank pre-catalyst control output is at its low

limit.

Left Bank Pre-Catalyst Output High

Param #7243

Right Bank Pre-Catalyst O2 Sensor Fault

Param #7232.2

Right Bank Pre-Catalyst O2 Sensor Health

Param #950.2

Right Bank Pre-Catalyst Thermocouple

Fault Param #7233.2

Right Bank Pre-Catalyst Temperature Low

Param #7120.2

Right Bank Pre-Catalyst Output Low

Param #7241.2

Right Bank Pre-Catalyst Output High

Param #7243.2

The left bank pre-catalyst control output is at its

minimum limit

Sensor reading is outside normal range of 0 – 1V

Sensor health is degraded – time to replace

Thermocouple open or reading is outside valid range

Temperature before the catalytic converter on right

bank is too low

The right bank pre-catalyst control output is at its low

limit

The right bank pre-catalyst control output is at its

minimum limit

Pre-Catalyst Thermocouple Fault

Param #7265

Pre- Catalyst Temperature Low

Param #7251

Left Bank Intake Manifold Temperature

Sensor Fault, Param #7407.1

Right Bank Intake Manifold Temperature

Sensor Fault, Param #7407.2

Catalytic Converter Temperature

Difference Too Low, Param #7267

Catalytic Converter Temperature

Difference Too High, Param #7268

Thermocouple open or reading is outside valid range

Temperature after the catalytic converter is too low

Left bank sensor reading is outside normal range of 4

– 20mA

Right bank sensor reading is outside normal range of

4 – 20mA

The temperature difference between the inlet and

outlet of the ctalytic converter is too small, indicating

that the catalyst is not working properly to reduce

emissions

The temperature difference between the inlet and

outlet of the catalytic converter is too large, indicating

something is wrong with the catalytic converter such

as it might be plugged.

51

Page 53

21. APPENDIX A.

lExample of a Configuration File (AF900PC.SPC)

; Filename : AF900PC.SPC

; Date : 2002/03/11

;*****************************************************************************

; (1) This template download file is used to configure a Dynalco AF900PC.

; Copies of this file may be downloaded from the Dynalco Controls website

; (www.dynalco.com).

; (2) Desired configuration values should be entered in all appropriate

; fields before downloading to the AF900PC. The default value for

; each configuration variable is set as the initial download value.

; (3) Comments are included for each configuration variable to explain the

; purpose and programmable values associated with each variable.

;**************************************************

; *************************************************

; ******************* PASSWORD ********************

; *************************************************

; SETUP PASSWORD **********************************

; Selects the password for entering front; panel AF900PC SETUP Mode.

;

; The password may be up to eight (8)

; characters in length. The password must

; contain ONLY the digit characters '1',

; '2', '3', or '4'. If any other characters

; are used, no user will be able to enter

; front-panel AF900PC SETUP Mode.

;

; This password is ONLY required to

; configure the AF900PC through the

; front-panel. NO password is required

; to download a configuration file to

; the AF900PC.

6112.0=1234

; SETUP PASSWORD ACTIVE TIME **********************

; Selects the active time for the front; panel SETUP Password. This is the time

; that the password remains active AFTER

; a user has exited front-panel AF900PC

; SETUP Mode. This allows a user to re; enter SETUP Mode WITHOUT having to re; enter the password.

;

; Min Val Max Val

; 30 -> 60 (default) -> 300 (in seconds)

6101=60

Page 54

/*$PAGE*/

; *************************************************

; ******************** RELAYS *********************

; *************************************************

; TRIP RELAY ACTION *******************************

; 0 Normally Energized (default)

; 1 Normally Deenergized

63102.1=1 ; ALARM RELAY

63102.2=1 ; SHUTDOWN RELAY

63102.3=1 ; AUX RELAY

; *************************************************

; ********************* RPM ***********************

; *************************************************

; RPM NUMBER TEETH ********************************

; Number teeth/holes on flywheel.

;

; Min Val Max Val

; 4 -> 60 (default) -> 500 (in teeth)

9004.0=60

; RPM AVERAGING FILTER ****************************

; Averages new RPM readings into current

; RPM value by the following equation:

;

; RPM = [RPM_previous * (1 - filter)] + [RPM_read * filter]

;

; Filter values near to 1.00 pass new

; readings very quickly. Filter values

; near to 0.00 pass new readings very

; slowly. A filter value of 0.00 does

; NOT pass new RPM readings at all.

;

; Slower filter values take longer to

; settle to the current RPM but have a

; high noise rejection and stability.

; Faster filter values settle quickly but

; have low noise rejection and stability.

;

; Min Val Max Val

; 0.00 -> 0.10 (default) -> 1.00 (no units)

9003.0=0.10

; RPM INPUT SELECT ********************************

; Select RPM Input Source.

; 0 Magnetic Pickup (default)

; 1 Run Contacts

155=0

; START RPM ***************************************

; Maximum RPM allowed while making changes

; to RPM Tooth number.

;

;

53

Page 55

; Min Val Max Val

; 25 -> 50 (default) -> 9999 (in RPM)

151=50

; START RPM HYSTERESIS ****************************

; Start RPM hysteresis to re-enable RPM Tooth number

; changes once Start RPM is reached.

;

; Min Val Max Val

; 0 -> 25 (default) (in RPM)

;

; Example:

; If Start RPM = 50 RPM &

; Start Hyst = 20 RPM

; then RPM tooth changes DISABLED > 50 RPM

; but re-ENABLED < 30 RPM

; (50 - 20 = 30 RPM)

152=25

; START DELAY *************************************

; Delay, after Start RPM reached or Run Contacts

; CLOSED, before RUN state.

;

; Min Val Max Val

; 0 -> 30 (default) -> 300 (in seconds)

153=30

;

54

Page 56

/*$PAGE*/

; *************************************************

; ************* OXYGEN SENSOR HEALTH **************

; *************************************************

; SENSOR HEALTH FAULT PERCENTAGE ******************

; Minimum Sensor Health Percentage before fault.

;

; Min Val Max Val

; 0.0 -> 100.0 (default) (in health %)

952.1=100.0 ; <LEFT BANK O2 SENSOR>

952.2=100.0 ; <RIGHT BANK O2 SENSOR>

952.3=100.0 ; <POSTCAT O2 SENSOR>

; SENSOR HEALTH AVERAGING FILTER ******************

; Averages new Sensor Health readings into

; current Sensor Health value by the following

; equation:

;

; SensorHealth = [SensorHealth_previous * (1 - filter)] +

; [SensorHealth_read * filter]

;

; Filter values near to 1.00 pass new

; readings very quickly. Filter values

; near to 0.00 pass new readings very

; slowly. A filter value of 0.00 does

; NOT pass new Sensor Health readings at

; all.

;

; Slower filter values take longer to

; settle to the current Sensor Health

; but have a high noise rejection and

; stability. Faster filter values settle

; quickly but have low noise rejection

; and stability.

;

; Min Val Max Val

; 0.00 -> 0.01 (default) -> 1.00 (no units)

957.1=0.01 ; <LEFT BANK O2 SENSOR>

957.2=0.01 ; <RIGHT BANK O2 SENSOR>

957.3=0.01 ; <POSTCAT O2 SENSOR>

; SENSOR HEALTH TEST TIME *************************

; Time between Oxygen Sensor Health tests.

;

; Min Val Max Val

; 10 -> 60 (default) -> 300 (in seconds)

970=60

;

55

Page 57

/*$PAGE*/

; *************************************************

; ************* ANALOG INPUT CHANNELS *************

; *************************************************

; ***************** AI CHANNEL #01 ****************

; L PRE CAT O2 ************************************

; AI CHANNEL ENABLE *******************************

; 0 DISABLED

; 1 ENABLED (default)

5500.1=1

; AI CHANNEL FILTER *******************************

; Averages new AI channel readings into

; current AI channel value by the following

; equation:

;

; Value = [Value_previous * (1 - filter)] + [Value_read * filter]

;

; Filter values near to 1.00 pass new

; readings very quickly. Filter values

; near to 0.00 pass new readings very

; slowly. A filter value of 0.00 does

; NOT pass new RPM readings at all.

;

; Slower filter values take longer to

; settle to the current RPM but have a

; high noise rejection and stability.

; Faster filter values settle quickly but

; have low noise rejection and stability.

;

; Min Val Max Val

; 0.00 -> 0.05 (default) -> 1.00 (no units)

5516.1=0.05

56

Page 58

; ***************** AI CHANNEL #02 ****************

; R PRE CAT O2 ************************************

; AI CHANNEL ENABLE *******************************

; 0 DISABLED

; 1 ENABLED (default)

5500.2=1

; AI CHANNEL FILTER *******************************

; Averages new AI channel readings into

; current AI channel value by the following

; equation:

;

; Value = [Value_previous * (1 - filter)] + [Value_read * filter]

;

; Filter values near to 1.00 pass new

; readings very quickly. Filter values

; near to 0.00 pass new readings very

; slowly. A filter value of 0.00 does

; NOT pass new RPM readings at all.

;

; Slower filter values take longer to

; settle to the current RPM but have a

; high noise rejection and stability.

; Faster filter values settle quickly but

; have low noise rejection and stability.

;

; Min Val Max Val

; 0.00 -> 0.05 (default) -> 1.00 (no units)

5516.2=0.05

;

57

Page 59

/*$PAGE*/

; ***************** AI CHANNEL #03 ****************

; POSTCAT O2 **************************************

; AI CHANNEL ENABLE *******************************

; 0 DISABLED

; 1 ENABLED (default)

5500.3=1

; AI CHANNEL FILTER *******************************

; Averages new AI channel readings into

; current AI channel value by the following

; equation:

;

; Value = [Value_previous * (1 - filter)] + [Value_read * filter]

;

; Filter values near to 1.00 pass new

; readings very quickly. Filter values

; near to 0.00 pass new readings very

; slowly. A filter value of 0.00 does

; NOT pass new RPM readings at all.

;