Page 1

OWNER’S MANUAL

Page 2

DSP 260

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

DSP 260 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

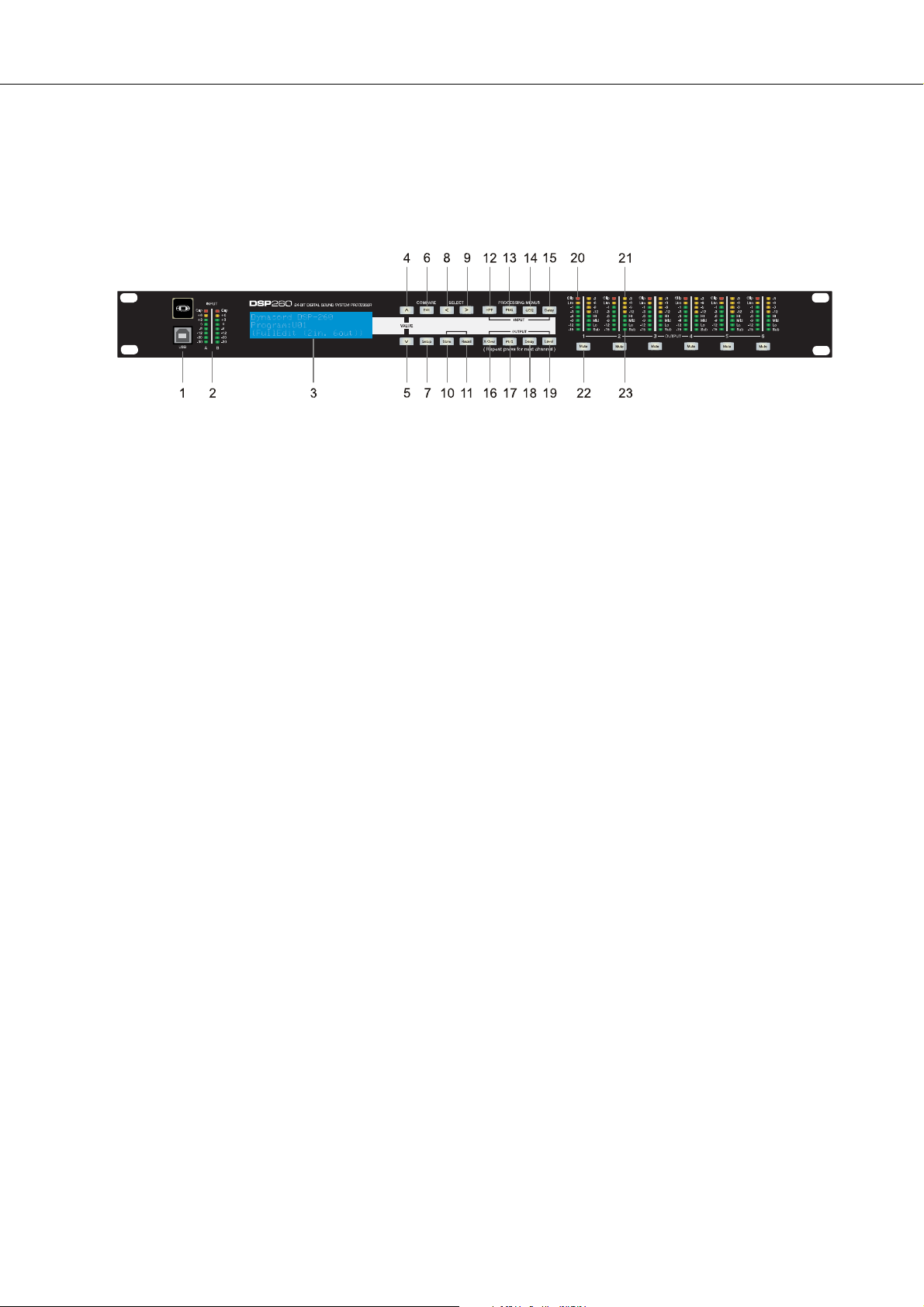

Controls & Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

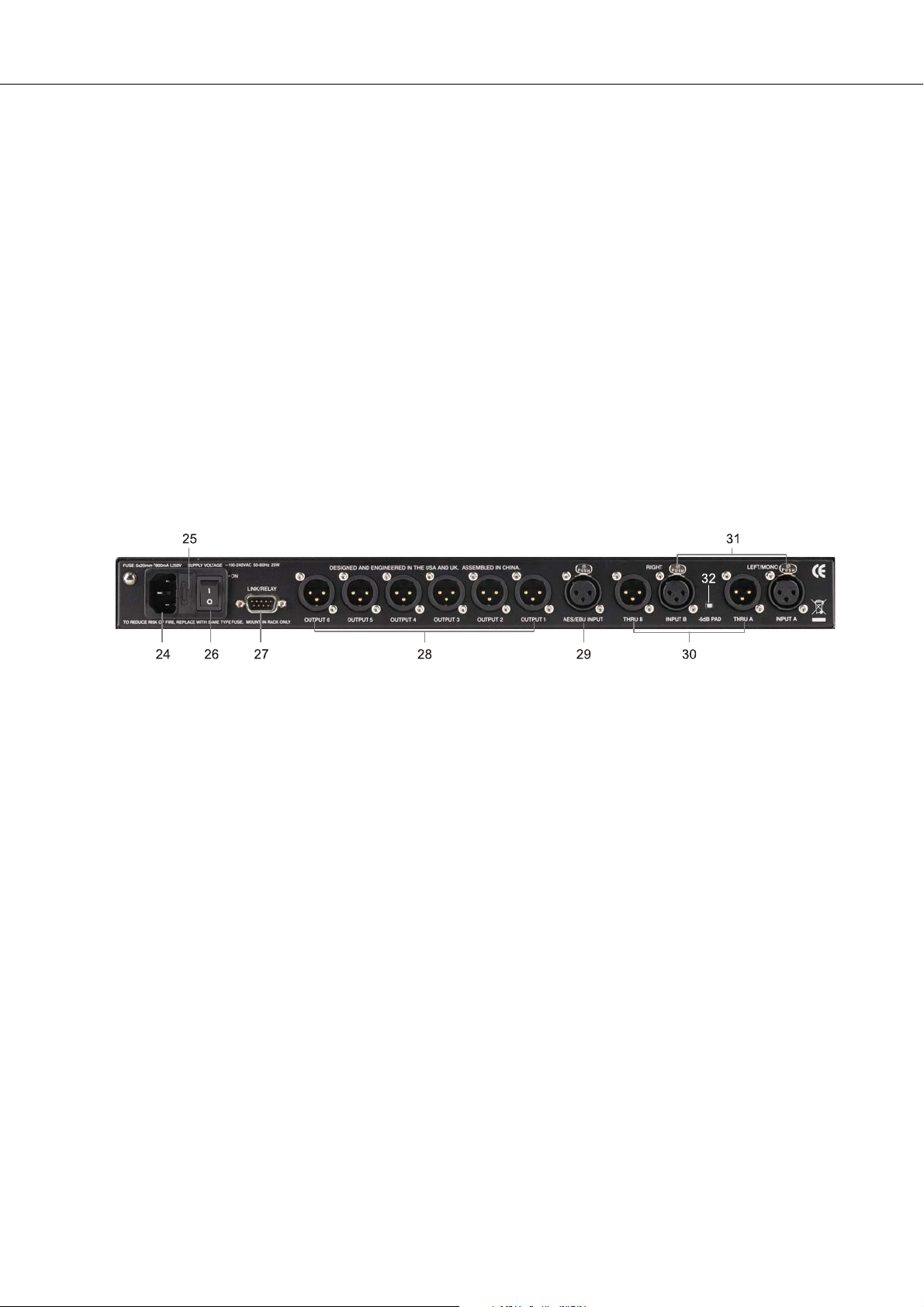

Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Editing & Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Factory Presets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

User Presets – Standard Editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

User Preset – Full Editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Unpacking & Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Run-time Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Input Level Meters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Output Level Meters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Output Gain Reduction Meters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Output Channel Mute Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Output Channel Function Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Preset Recall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Preset Store . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Edit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Setup Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Configurations of the DSP 260 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2-Way Stereo + Full Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3-Way Stereo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4-Way + FR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5-Way + FR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Free Configuration - Full Edit 2 In 6 Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3-Way Stereo-MonoSub+FR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4-Way Stereo-MonoSub/LF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Operation Modes & Presets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

EQ Plot Images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6 dB PEQ Cuts Q Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6 dB-Oct Shelves at 200 Hz and 2 kHz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

12 dB PEQ Cuts Q Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

12dB-Oct Shelves at 200 Hz and 2 kHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Bessel Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Butterworth Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Hi Lo Pass Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Linkwitz-Riley Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

PEQ Gains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2 Owner‘s Manual

Page 3

DSP 260

IMPORTANT SAFETY INSTRUCTIONS

The lightning flash with arrowhead symbol, within

an equilateral triangle is intended to alert the user

to the presence of uninsulated “dangerous voltage“ within the product’s enclosure that may be

of sufficent magnitude to constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is intended to alert the user to the presence

of important operating and maintenance (servicing) instructions in the literature accompanying

the product.

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all inst ruc t io n s .

5. Do not use this apparatus near water.

6. Clean only with a dry cloth.

7. Do not block any ventilation openings. Install in accordance with the manufacture’s instructions.

8. Do not install near heat sources such as radiators, heat registers, stoves, or other apparatu s (including am p lifiers) that produce hea t.

9. Do not defeat the safety purpose of the polarized or the grounding-type plug. A polarized plug has two blade s with one wider than the other. A

grounding type plug has two blades and a third grounding prong. The w ide blade o r the third pron g are provided for your safety. If the provided plug

does not fit into your outlet, consult an electrician for replacement of the obsolete outlet.

10. Protect the power cord from being walked on or pinched p articularly at plugs, conve nience recep t ac les , and the po int where th ey exit from the

apparatus.

11. Only use attachments/accessories specified by the ma nufac turer.

12. Use only with the cart, stand, tripod, bracket, or table specified by th e man ufacturer, or sold with the apparatus. Wh en a cart is used, use cau tion when

moving the cart/apparatus combination to avoid injury from tip-over.

13. Unplug this apparatus during lightning storms or when unuse d for a lo ng period of time .

14. Refer all servicing to qualified service personnel. Servicing is required when the app ar atus has been dam aged in any wa y, such as power-supply cord

or plug is damaged, liquid has been spilled or objects have fallen into the appara tus, the apparatus has been exposed to rain or moisture, does not

operate normally, or has been dropped.

15. Do not expose this equipment to dripping or splashing and ensure that no objects filled with liquids, such as vases, are placed on the equipm e nt.

16. To completely disconnect this equipment from the AC Mains, disconnect the power supply cord plug from the AC recep t a cle.

17. The mains plug of the power supply cord shall remain readily operable.

18. No naked flame sources, such as lighted candles, should be placed on the appa ratus .

19. This is an CLASS I apparatus and shall be connected to a main socket outlet with a protective earth connection.

WEEE Recycling/Disposal Instructions

The Wheelie Bin symbol found on the product or in the manual indicates that this product must not be disposed of with other waste. It is in our category the manufacturer’s responsibility to properly dispose of their

waste electrical and electronic equipment (WEEE) at the end of its life. Due to the differences in each EU

country’s management of WEEE, please contact your local distributor. We are committed to facilit ate our own

electronic-waste-management-system, for the free of charge return of all EVI Audio GmbH products: Telex,

Dynacord, ElectroVoice, Midas Consoles, KlarkTeknik and RTS. Arrangements are made with the dealer

where you purchased the equipment from, for the returning of all unusable equipment at no cost, to the factory in Straubing, for environmental protective disposal.

IMPORTANT SERVICE INSTRUCTIONS

CAUTION: These servicing instructions are for use by qualified personnel only. To reduce the risk of electric shock, do not perform any servicing

other than that contained in the Operating Instructions unless you are qualified to do so. Refer all servicing to qualified service personnel.

1. Security regulations as stated in the EN 60065 (VDE 0860 / IEC 65) and the CSA E65 - 94 hav e to be obeye d wh en se rvicing the app liance .

2. Use of a mains separator transformer is mandatory during m a intenan ce wh ile the applian ce is open ed , need s to be ope rated and is connected to the

mains.

3. Switch off the power before retrofitting any extensions, changing the mains voltage or the o utput volt a ge.

4. The minimum distance between p art s carrying m ains voltag e and any accessible met al piece (m etal en closure), respectively between the mains poles

has to be 3 mm and needs to be minded at all times. The minimum dist anc e between parts carrying mains voltage and any switches or breakers that

are not connected to the mains (secondary parts) has to be 6 mm and needs to be minded at all times.

5. Replacing special components that are marked in the circuit diagram using the secu rity symbo l (N ote) is only perm issible w he n using or iginal p arts.

6. Altering the circuitry without prior consent or advice is not legitimate.

7. Any work security regulations that are applicable at the locations where the appliance is being serviced have to be strictly obeyed. This applies also to

any regulations about the work place itself.

8. All instructions concerning the handling of MOS-circuits have to be observed.

NOTE: SAFETY COMPONENT (MUST BE REPLACED BY ORIGINAL PART)

Owner‘s Manual 3

Page 4

DSP 260

1 Overview

4 Owner‘s Manual

Page 5

DSP 260

Owner‘s Manual 5

Page 6

DSP 260

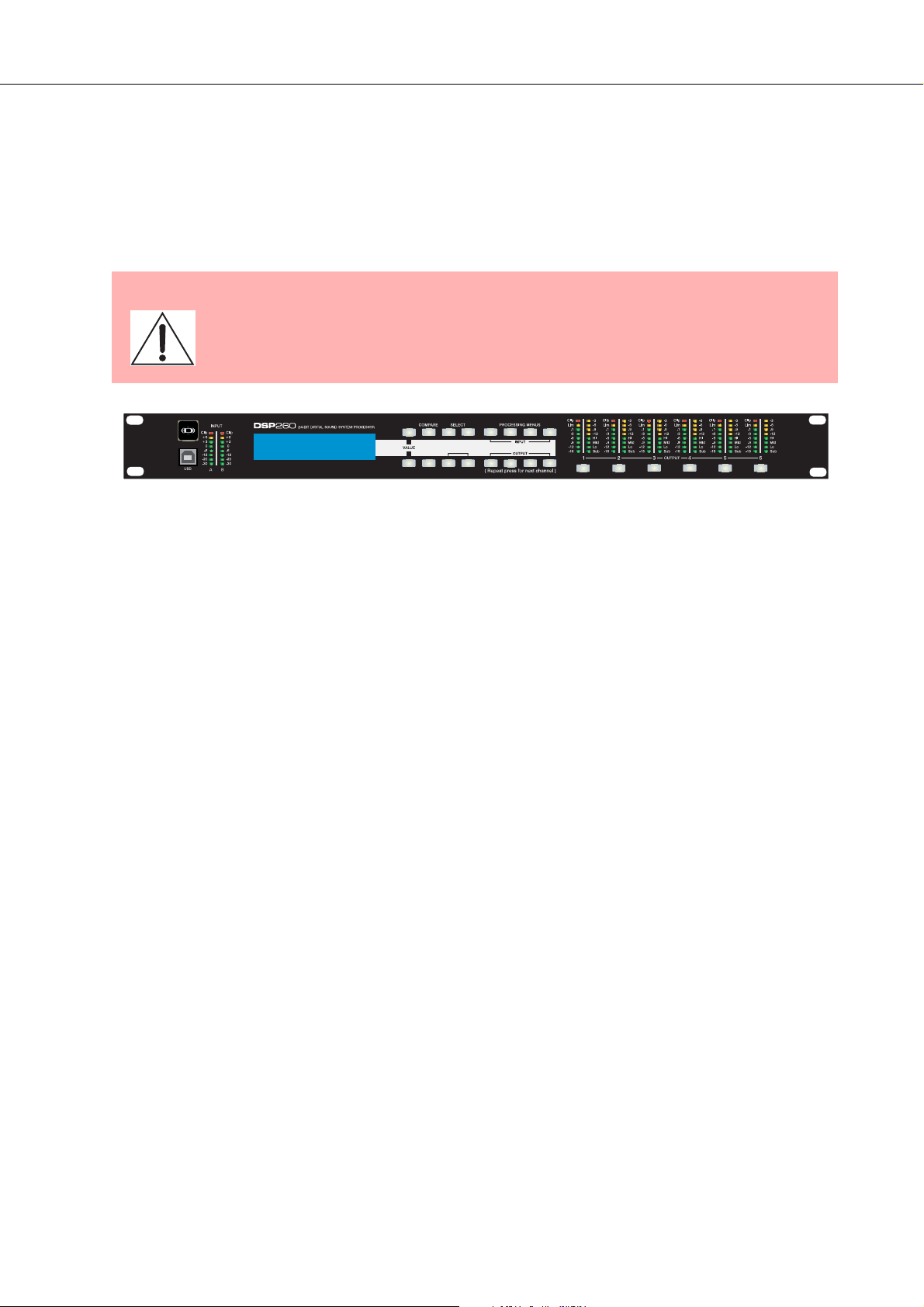

2 Introduction

Thank you for purchasing the Dynacord DSP 260 Digital Signal Processor. The Dynacord DSP 260 Digital

System Processor is a universal two-input, six-output digital signal processor with the flexibility of

configuration to handle a multitude of audio system needs and applications; installed sound, house of

worship, convention & meeting facilities, concert touring, club, portable sound reinforcement and more.

IMPORTANT NOTE:

To achieve optimum performance and guard against damage to the processor, your sound system or yourself, please read, understand and follow all of

the directions contained in this Owner’s Manual. Failure to do so may result

in improper performance, loss or injury.

Dynacord DSP-260

Program:U01

(FullEdit (2in. 6out))

Edit

>

<

>

Setup

PEQ

HPF

>

X-OverRecallStore

DelayGEQ

Level

Delay

PEQ

Mute

Mute Mute

Mute

Mute

Mute

2.1 DSP 260 Features

The internal routing matrix can be configured as 2-way stereo + full-range, 3-way stereo, 4-way mono +

full-range, 5-way mono + full range, 3-way stereo with a mono sub + full-range, 4-way stereo with mono

sub and low frequency and finally as a freely assignable 2 x 6 matrix router.

The DSP 260 replaces entire racks of signal processors previously needed to properly configure and

control sound reinforcement systems with a single Analog Devices® SHARC™ DSP processor. The

substantial advantages of the DSP 260 over discrete signal processing racks include:

• 24-bit, 48 kHz digital signal path

• No patch cables to fail or add noise

• Optimal gain structure throughout all stages of signal processing; no gain matching from processor to

processor.

• Recallable factory and user presets; instant system reconfiguration for differing applications and performances.

• Easy, intuitive operation and editing with a PC and the DSP 260 Graphic User Interface Application.

Each DSP 260 Digital System Processor includes the following signal processing blocks:

• Input VU Metering

• Analog or AES/EBU inputs

• 24-bit, 48 kHz A/D converters

• Stereo Hi-pass filters

• Stereo 9-band parametric equalizer

• Stereo 31-band graphic equalizer

• Stereo delay

6 Owner‘s Manual

Page 7

Matrix Router / Mixer

• Two inputs (stereo)

• Summed left / right (mono) input

• Six assignable outputs

Outputs (each)

• Cross-over (hi-pass / low-pass filters), with selectable filter types

• 5-band parametric equalizer

•Delay

•Polarity

• Peak RMS detecting limiter

• Level & Mute

• 24-bit, 48 kHz D/A converters

DSP 260

Additional features include:

• Electronically balanced XLR inputs and outputs

• -6 dB switchable input level pad

• Contact closure interface for recall of up to eight selectable presets

• Front-panel USB port for connection to PC; preset editing and real time parameter control and monitoring.

• Firmware updates

• FLASH memory for preset storage and in-field firmware upgrades

• Input level meters

• 192 x 32 back-lit graphic LCD display

• LCD navigation / editing controls

• DSP block navigation short-cut controls

• Output level meters

• Output gain reduction meters

• Output assignment display LEDs; sub, low, mid & high

• Output channel Mute controls

• Auto-ranging internal power supply; 100-240 V AC, 50-60 Hz

• Standard IEC A.C. inlet with external, replaceable fuse

Owner‘s Manual 7

Page 8

DSP 260

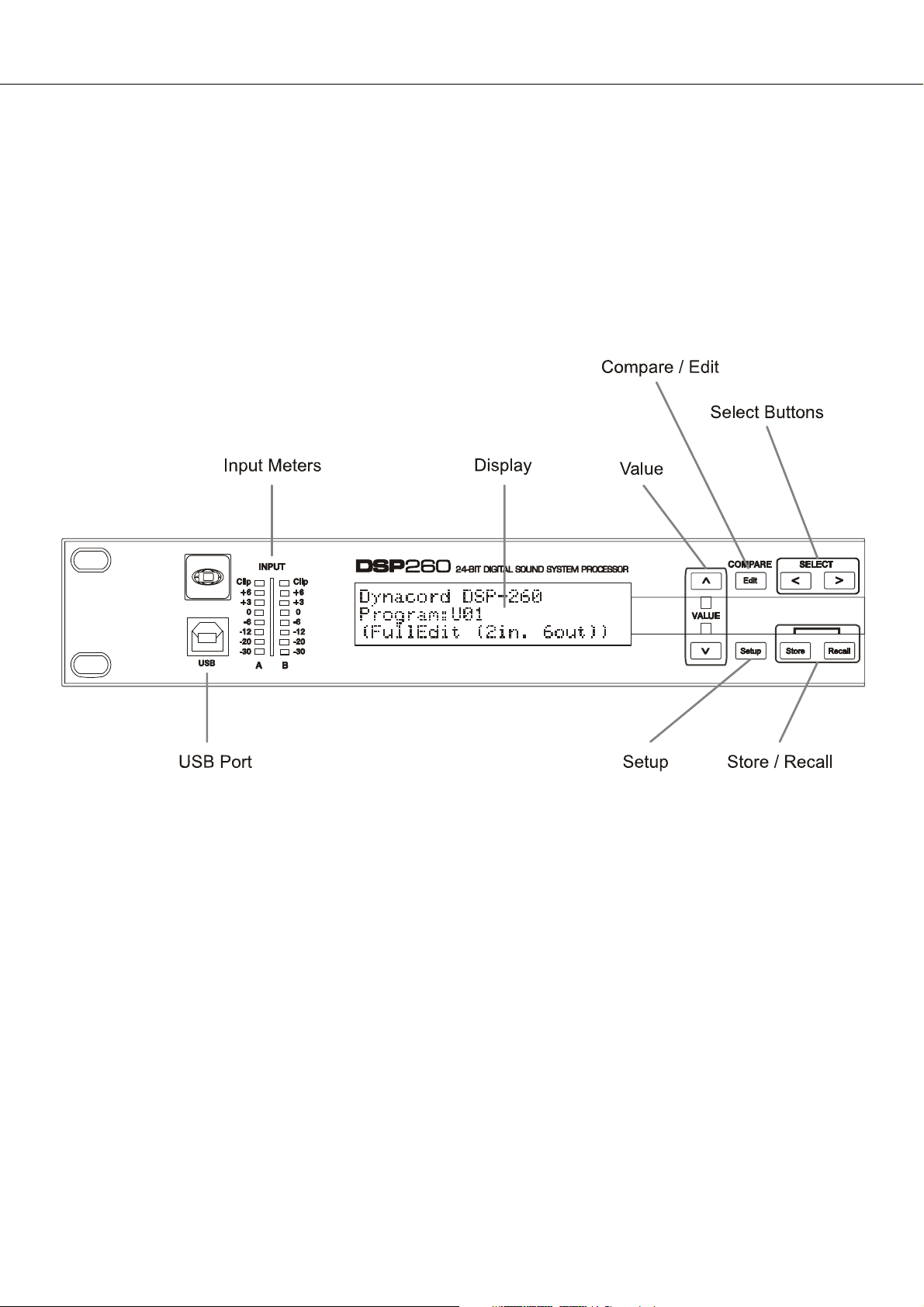

3 Controls & Connection

3.1 Front Panel

1 – USB Connector

USB 1.1 port for connection to a PC running Windows XP or Vista. With a connected PC you may run the

DSP 260 Editor Graphic User Interface Application. The DSP 260 can be operated, edited and configured

for installation with an easy to use, intuitive interface. Any available firmware updates downloadable from

www.dynacord.com can be loaded via the USB port as well; allowing for easy in-field updates.

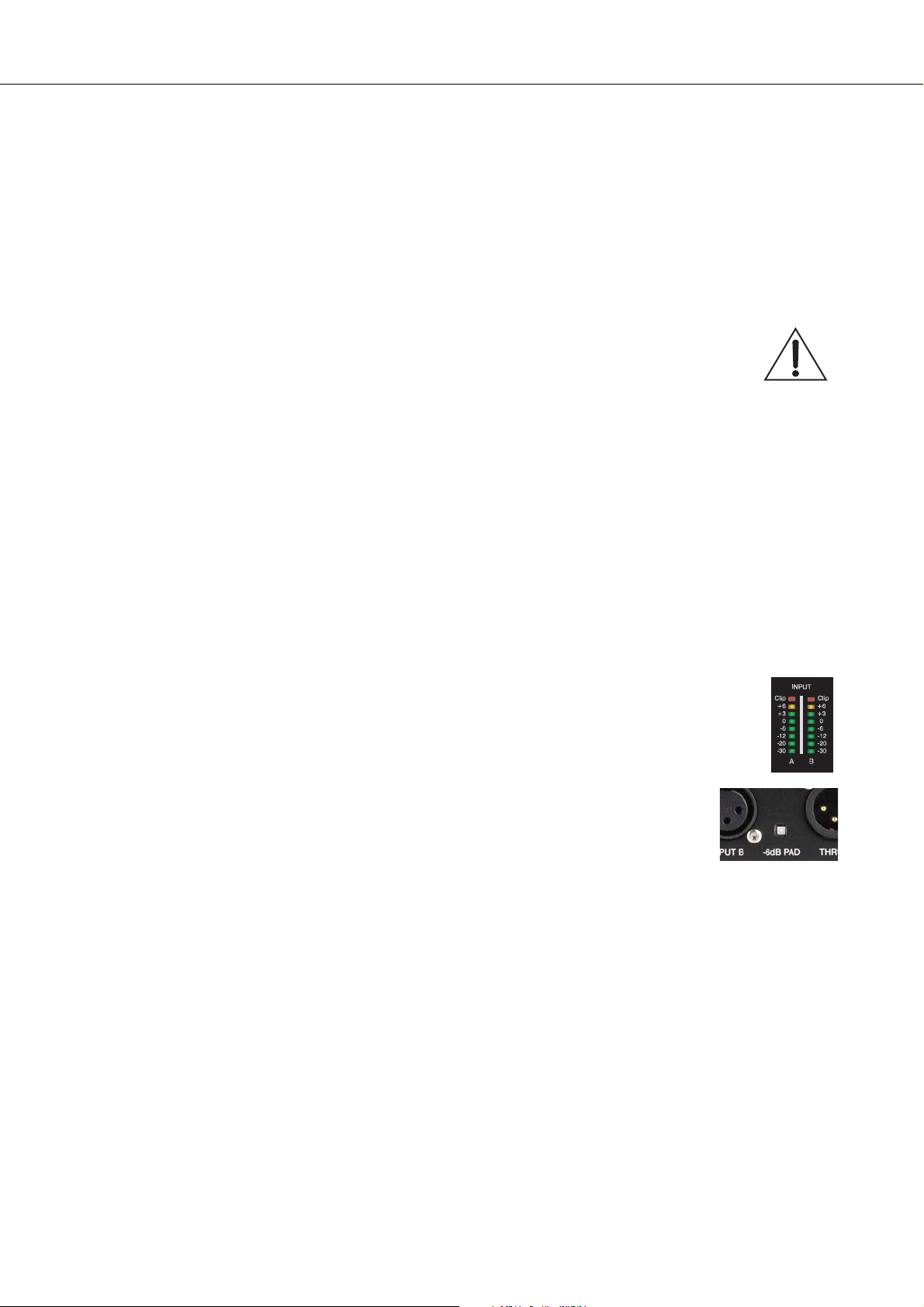

2 – Input Level Meters

The DSP 260 does not itself have input level controls. Proper input level adjustment is accomplished by

setting the output level from the (L / R) bus outputs from the connected mixer (or other audio output

device), as the vast majority of today’s mixer-outputs are dBu calibrated. When the mixer is operating at

optimal levels, so is the DSP 260. The input meters monitor the input level of either analog or AES-EBU

inputs, depending on the input mode selection set in the Setup Menu.

Optimal signal-to-noise performance is obtained when the nominal (average), input level consistently lights

the +3dBu (green) and / or +6dBu (Yellow) LED indicators. As the DSP 260 is a digital audio device – and

digital clipping produces very unpleasant results, the Clip (red) LED should not light. If the DSP 260’s input

does clip, reduce the output level of the connected mixer. The -6dB PAD button at the rear panel can be

used for adjusting the input level also.

3 – LCD Display

The back-lit, 192 x 32 graphic LCD display allows for operation and editing of the DSP 260 without the

need for an attached PC. The contrast can be set in the Setup Menu for varying lighting conditions and

viewing angles.

The LCD display works in conjunction with Menu buttons, Select buttons and Value buttons - to operate,

navigate and edit the DSP 260’s parameters.

In Run mode, the LCD displays the number and name of the currently selected factory or user preset.

Pressing the Recall or Store buttons switches to their respective menus. Pressing the Edit or Setup menu

buttons switches the display to the last edited parameter.

8 Owner‘s Manual

Page 9

DSP 260

In Edit and Setup mode, the top line of the LCD display shows the currently selected parameter edit

screen. Use the Select buttons to activate the top line of the display, and the value buttons to scroll through

available parameter edit screens.

4/5 – Value Up/Down Buttons

Depending on the current LCD screen, the Value Up/Down Buttons performs the following function:

• Recall – Select forwards/backwards through the stored preset list to select a preset to be recalled to

current memory.

• Store – Select User Preset destinations forwards/backwards to select a destination for the currently

edited preset, scroll forwards through ANSI character set to name preset.

• Edit / Setup – Scroll forwards/backwards through Edit / Setup screens when the top line of the LCD

screen is active. Scroll forwards through values for the selected parameter in an Edit / Setup screen.

6 – Edit / Compare Button

Pressing the Edit button while in Run mode places the current preset in Edit mode and the Edit button

lights. The LCD display shows the last edit screen that was selected. From this point, any edit screen can

be displayed and altered.

Pressing the Edit button again “compares” the edited preset, if parameters have been altered, to the

original un-edited preset. This compare function will audibly switch between the altered parameters and

the previously stored settings, allowing you to hear the effect of any DSP changes that have been made.

Use this feature to monitor progress in editing or creating presets.

Subsequently recalling a new preset will prompt you to save changes, which you may do or not.

7 – Setup Button

Pressing the Setup button while in Run mode displays the Setup menus in the LCD display and the Setup

button lights. In this mode, any Setup menu can be displayed and altered. Changes made to Setup menu

items are saved automatically.

To exit Setup mode, press the Setup button again. The LCD display will revert to Run mode.

8 – Select < Button

The Select < button is pressed to navigate backwards through Edit, Setup and / or Recall menu displayed.

The button cycles through all available value fields in a screen and wraps around from first to last.

9 – Select > Button

The Select > button is pressed to navigate forwards through Edit, Setup and / or Recall menu displayed.

The button cycles through all available value fields in a screen and wraps around from last to first.

Owner‘s Manual 9

Page 10

DSP 260

10 – Store Button

Pressing the Store button while in Run mode displays the Store Preset screen in the LCD display and the

Store button lights. In this screen edited presets can be named and saved to a user preset location.

Pressing the Store button again completes the preset save operation.

To exit without storing the current preset, press the Edit or Setup buttons to return to the Run mode

screen.

11 – Recall Button

Pressing the Recall button while in Run mode displays the Recall Preset screen in the LCD display and the

Recall button lights. In this screen, any of the 60 factory and 20 user presets can be recalled into current

memory. Pressing the Recall button again completes the preset load operation and returns the LCD

display to Run mode.

To exit without storing the current preset, press the Edit or Setup buttons to return to the Run mode

screen.

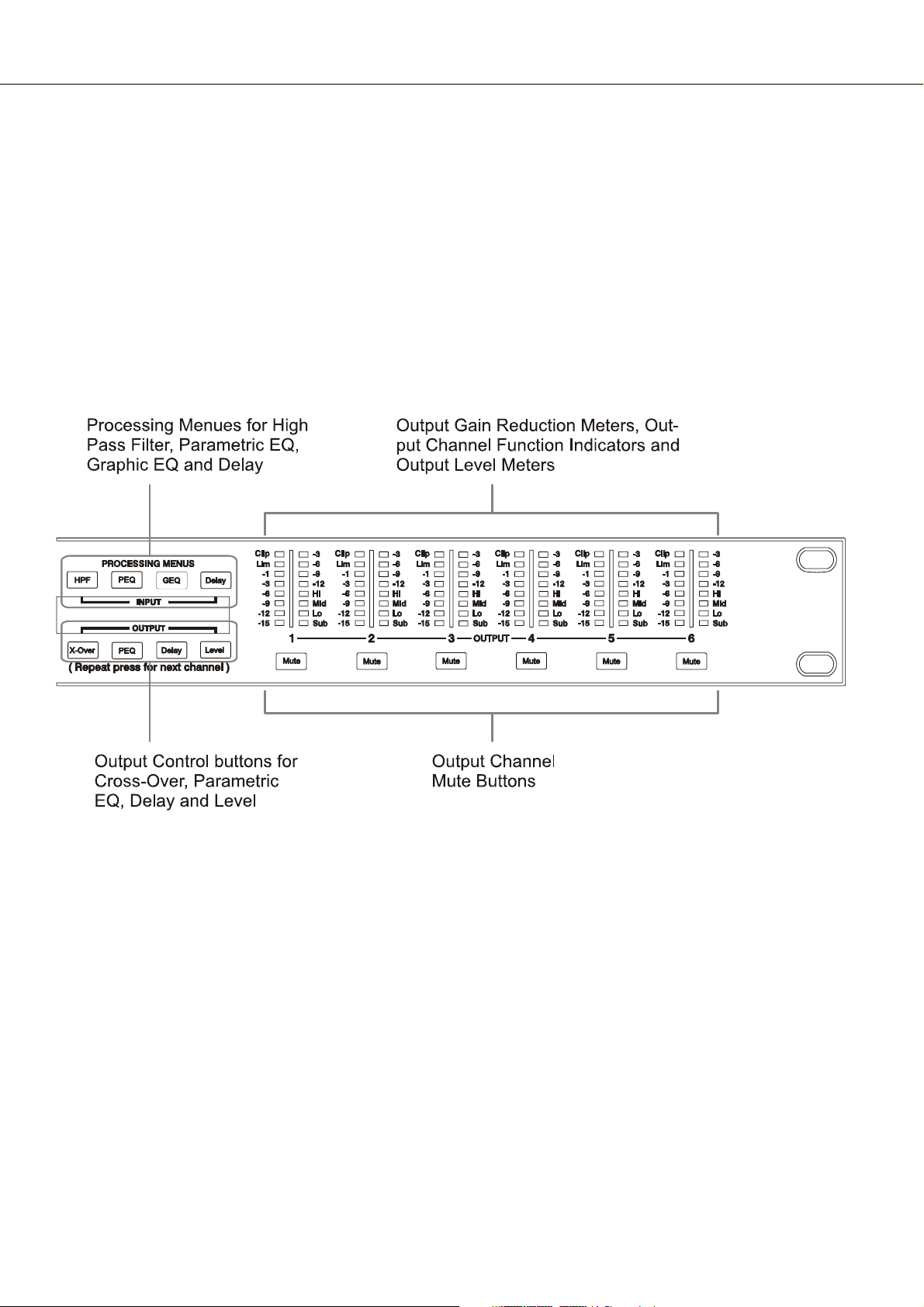

12 – Input HPF Button

Pressing the HPF button places the current preset in Edit mode and jumps to the Hi-Pass Filter screen of

Input A. Subsequent button presses toggle the display between Input A and Input B.

13 – Input PEQ Button

Pressing the PEQ button places the current preset in Edit mode and jumps to the first screen of the Input

Parametric Equalizer. Subsequent button presses toggle the display between Input A and Input B.

14 – Input GEQ Button

Pressing the GEQ button places the current preset in Edit mode and jumps to the the Input Graphic

Equalizer screen. Subsequent button presses toggle the display between Input A and Input B.

15 – Input Delay Button

Pressing the Delay button places the current preset in Edit mode and jumps to the Input Delay screen.

Subsequent button presses toggle the display between Input A and Input B.

10 Owner‘s Manual

Page 11

DSP 260

16 – Output X-Over Button

Pressing the X-Over button places the current preset in Edit mode and jumps to the first Output Channel

Cross-Over screen. Subsequent button presses step through the available output channels (depending on

configuration).

17 – Output PEQ Button

Pressing the PEQ button places the current preset in Edit mode and jumps to the first Output Parametric

Equalizer screen. Subsequent button presses step through the available output channels (depending on

configuration).

18 – Output Delay Button

Pressing the Delay button places the current preset in Edit mode and jumps to the Output Channel Delay

screen. Subsequent button presses step through the available output channels (depending on

configuration).

19 – Output Level Button

Pressing the Level button places the current preset in Edit mode and jumps to the Output Channel Level

screen. Subsequent button presses step through the available output channels (depending on

configuration).

20 – Output Level Meters

Each output channel has an eight-segment output level VU meter. Meter response characteristics can be

selected in the Setup menu: Normal Fast, Peak-Hold Slow Decay. The yellow segment indicates that

limiting is being applied to the output channel. The red segments indicates clipping of the D/A converters

and should be avoided by adjusting the Output Level of the output channel. It is important to understand

how the meters work and what they are displaying. The Output Meters are displayed as “dB to Limiter

Threshold”. In other words, these meters will display the headroom between the output level and the limiter

threshold. When viewed in conjunction with the Gain Reduction meters, this provides a complete display of

level and headroom before and after limiting has been engaged to allow system levels to be optimized.

This also means that the output metering will be displayed differently depending on the limiter threshold

setting.

21 – Output Gain Reduction Meters

Each output channel has a four-segment gain reduction meter that shows the effect of the output channel

Limiter on output level; from 0dB to -12dB.

Owner‘s Manual 11

Page 12

DSP 260

22 – Output Channel Mute Buttons

Each output channel has a lighted Mute button. Pressing the Mute button turns off the output of that

channel. The button lights red as an alert. Press the Mute button again to restore the output channel’s

signal.

Output channels may also be muted from the DSP 260 Graphic User Interface Application, if the unit is

connected to a PC. Muting a channel in any window of the application will light the channel Mute button on

the front panel of the unit as well.

23 – Output Channel Function Indicators

Each output channel has a four-segment function display for informational purposes only. For any given

configuration possible with the DSP 260, an output channel may be identified as a sub, low, low/mid, mid,

mid/hi, hi or full range output. One or two adjacent LED are displayed to indicate all possible output

bandpasses. (Full range is indicated by all lit LED’s.)

3.2 Rear Panel

24- A.C. Inlet

The DSP 260 features a standard IEC A.C. inlet that will accept universal power cords. The DSP 260

power supply is auto-ranging and can accept voltages from 100 - 240 V AC, 50 – 60 Hz. Only A.C. cords

approved for use in your country should be connected to the DSP 260.

25 – A.C. Fuse

The A.C. inlet includes a fuse holder that contains the mains fuse as well as a spare fuse. If necessary,

replace the fuse only with a specified 5x20mm, T800 mA, L250 V replacement. Disconnect A.C. power

before replacing a fuse. Before turning the unit back on, assess the condition of the A.C. receptacle

powering the DSP 260. If fuses continue to blow, refer servicing of the DSP 260 only to qualified service

personnel.

12 Owner‘s Manual

Page 13

DSP 260

26 – A.C. Power Switch

The A.C. power switch turns power to the DSP 260 On and Off.

27 – Link/Relay Interface

The operating mode of this dual purpose interface is selected in the Setup menu. Operating modes are:

• RS-232 Interface - Used to link two DSP 260s together in a Master/Slave setup. Connection is made

via a standard 9-pin null-modem serial interface cable with female connectors.

• Contact Closure Port - Eight contact closure pins plus ground for interfacing to 5 V contact closure

systems. Each pin can be assigned a preset that is recalled when voltage on that pin is detected. The

lowest pin number takes priority in multiple controller systems.

28 – Balanced XLR Outputs

Each output channel has an electronically balanced XLR connector for connection to system amplifiers.

Each output channel can output different frequency ranges depending on its assignment and cross-over

settings.

Care must be taken to assure that each output is connected to an appropriate

amplifier and loudspeaker to avoid damage or unexpected results. Note that

a new preset may change the assignment of channel and its frequency range.

For instance an output assigned to Hi frequency speakers in one preset, may

be assigned as a sub output in another. See “Configurations of the DSP 260”.

29 – AES/EBU Digital Input

In addition to the analog audio inputs, an AES/EBU digital stereo input is provided and selectable in the

Setup menu. The input conforms to IEC standard 60958 Type I. Connections must be made with threeconductor, 110-Ohm, twisted pair cabling and an XLR connector.

30 – Balanced XLR Thru

Each analog audio input is connected to an electronically buffered and balanced output as a through

connector. The signal does not undergo any digital conversion or processing. These connectors are used

to pass input audio to a second DSP 260 used as a slave or to other audio inputs in the system.

31 – Balanced XLR Inputs

Each input has an electronically balanced, locking XLR connector. In stereo or dual modes, connections to

both inputs must be made. In mono modes, only one connection need be made, typically to Input A.

Owner‘s Manual 13

Page 14

DSP 260

32 – 6dB Pad

Input levels to the DSP 260 can be reduced 6dB prior to the A/D converter to compensate for higher-level

output from mixers and other audio devices. For ideal signal to noise performance when connecting the

DSP 260 to high output level devices engage the 6dB pad rather than turning down the output of the

connected device. The DSP 260‘s Input level Meters (2) will indicate incoming signal level and whether

attenuation is required.

3.3 Installation

For proper operation, all directions regarding installation and connection must be followed.

Mounting

The DSP 260 should be mounted in a rack-mount enclosure or rack rails. The unit is 1RU tall by 14”

(353mm) deep. Proper clearance for air circulation around the unit must be provided. Do not block any

vent holes on the unit. All four mounting points provided by the rack ears must be secured.

Power Connection

The DSP 260 must be connected to A.C. power only by means of the provided IEC A.C. cable or by a

power cable provided by the dealer / installer to match the configuration of your country or region. The

DSP 260 must only be connected to a properly wired, three pin, grounded A.C. outlet. A.C. power must

range from 100 – 240VAC, 50 – 60Hz. The DSP 260 internal power supply is an auto-ranging design; no

adjustments are necessary to configure it for proper A.C. power.

Audio Cables

Always use correctly shielded audio cables when connecting to the DSP 260.

Balanced Input / Output Connections

To minimize induced noise caused by audio cables and to maximize the length of cables used, balanced

connections are strongly advised for both Inputs and Outputs. The XLR jacks provided on the DSP 260 are

configured as pin 1 ground, pin 2 hot (+), pin 3 cold (-). Cable shielding must be connected to pin 1. XLR –

XLR cables or ¼” tip-ring-sleeve – XLR cables can both be used for balanced connections to the DSP 260.

14 Owner‘s Manual

Page 15

DSP 260

Un-balanced Input / Output Connections

Un-balanced connections can be made to the DSP 260, although induced noise from cabling may be

increased. Cables should also be less than 15” (5m) in length. Unbalanced connections can be 6dB lower

in level as well. To match the audio level obtained with a balanced connection, it is necessary to tie pin 3 to

ground at the XLR connector. This may increase noise.

RS-232

Two DSP 260s can be used in combination as a Master / Slave for managing larger

sound reinforcement systems. A 9-pin D-Sub connector is provided on the rear of

each unit for data line connections. A standard female-to-female RS-232 cable that

conforms to the null modem wiring convention is used to connect the two units. Cable

length should be kept to less than 45 feet (15 m) for the most reliable operation.

These cables are readily available at local computer dealers.

Operation of the DSP 260 9-pin port for RS-232 connections is selected in the Setup

menu.

Relay Contact Closure

The same 9-pin port used for RS-232 connection to another DSP 260

can alternately be used to recall presets from relay contact closures.

Pins 1 – 4 and pins 5 – 9 are the input lines and pin 5 provides the

ground reference. When the DSP 260 detects a connection between

pin-5 ground and input pins, as completed by an external relay, a

preset assigned by the user to input pins is recalled into memory and

the DSP 260 returns to run-time mode.

Owner‘s Manual 15

Page 16

DSP 260

USB

Connecting the DSP 260 to a PC for operation via the DSP 260 Graphic User Interface application is

accomplished via the front panel USB port. The port conforms to the USB 1.1 Type B specification. Type B

USB cables are readily available at computer dealers.

Connection to Amplifiers

It is very important to confirm correct connection to all amplifiers. DSP 260 has the ability to

configure each output for a specific frequency range; sub, low freq. mid freq, high freq. You

must make sure that each output is connected to the correct amplifier and loudspeaker(s).

Incorrect connections could lead to unexpected results or damage to loudspeaker

components.

Note also that each preset in the DSP 260 includes DSP and bandpass parameters for the

output channels. It is possible for a new preset to change an output from Hi to Sub, for

instance. Make sure that connections to amplifiers and loudspeakers are correct before

using a new preset.

Input Level Adjustment

The final step in setting up, installing and connecting the DSP 260 is to set proper input levels to the unit.

The DSP 260 does not itself have input level controls. Proper input level setting is accomplished by setting

the output level from the (L / R) bus outputs from the connected mixer (or other audio output device). The

input meters monitor the input level of either analog or AES/EBU inputs, depending on the input mode

selection set in the Setup Menu.

Optimal signal-to-noise performance is obtained when the nominal (average), input level

consistently lights the +3dBu (green) and / or +6dBu (Yellow) LED indicators. As the

DSP 260 is a digital audio device – and digital clipping produces very unpleasant results –

the Clip (red) LED should never light. If it does, reduce the output level of the connected

mixer.

Input levels to the DSP 260 can be reduced 6dB with the rear panel pad switch to

compensate for higher-level output from mixers and other audio devices. For ideal

signal to noise performance when connecting the DSP 260 to high output level

devices, engage the 6dB pad rather than turning down the output of the connected

device.

16 Owner‘s Manual

Page 17

DSP 260

4 Editing & Operation

4.1 Factory Presets

The DSP 260 comes with 60 factory presets to configure and manage typical sound reinforcement

systems. Factory presets can be recalled at will. Limited editing can be performed from the front-panel

LCD user interface such as output level, mute and limiter threshold setting. Installers can identify factory

presets with system configurations that are not appropriate for the given installation and lock-out and hide

them from the operator.

4.2 User Presets – Standard Editing

The DSP 260 uniquely allows for limited access to and visibility of

parameters. Via the DSP 260 Graphic User Interface Application,

the installer can determine which parameters may be accessed.

4.3 User Preset – Full Editing

The DSP 260 can also be configured in full-edit mode. All matrix

routing presets are available including 2 x 6 Full Edit. All DSP

parameters are accessible and adjustable. Resulting settings can be

saved into 20 User Preset locations for later recall. Editing can be

performed from the front-panel LCD display or on a PC with the

DSP 260 Editor Graphic User Interface Application. Full editing is

recommended only for experienced installers / operators.

4.4 Unpacking & Warranty

Carefully remove the DSP 260 from its packaging and packaging materials. Please save all packing

materials and box, should you ever need to return the DSP 260 for warranty service.

Included with the DSP 260 is this Owner’s Manual, Warranty card and A.C. power cable. Contact your

distributor, dealer or installer if any of these items is not included.

Fill out the warranty card in its entirety and return it to the address noted. Only products for which

completed warranty cards have been received will be covered fully under warranty.

for your DSP 260 is 36 months (3 years), from the date of purchase. Please save the warranty certificate

and receipt; which must be presented at the time of warranty service for the factory warrantee to be valid.

1) Warranty coverage rights vary by state and country. Your warranty rights may vary. Consult your distributor, dealer or installer for your warranty rights.

1

The factory warranty

Owner‘s Manual 17

Page 18

DSP 260

5 Run-time Mode

5.1 LCD Display

On power-up, the DSP 260 boots and displays the run-time screen.

The current preset memory location and name are displayed as well

as the configuration on which the preset is based.

CAUTION

Before operating the sound reinforcement system, and any time a new preset

is recalled, check the configuration display to make sure that it is appropriate

for your system and that connections to your system are correct for the current configuration. Failure to do so could cause unexpected results or damage to the system or its components.

The LCD display‘s contrast can be adjusted in the Setup Menu to

accommodate different viewing angles.

5.2 Input Level Meters

During operation, the left and right input level meters display the signal present at the

DSP 260’s analog and Digital inputs. The DSP 260 does not itself have input level controls.

Proper input level setting is accomplished by setting the output level from the (L / R) bus

outputs from the connected mixer or other audio source.

Optimal signal-to-noise performance is obtained when the nominal (average), input level

consistently lights the +3dBu (green) and / or +6dBu (yellow) LED indicators. As the

DSP 260 is a digital audio device – and digital clipping produces very unpleasant results –

the Clip (red) LED should never light. If it does, reduce the output level of the connected

mixer. The -6dB PAD button at the rear panel can be used for adjusting the input level also.

5.3 Output Level Meters

Each output channel has an eight-segment

output level VU meter. Meter response

characteristics can be selected in the Setup

menu: Normal Fast, Peak-Hold or Slow

Decay. The yellow segment indicates that

limiting is being applied to the output channel.

It is important to understand how the meters

work and what they are displaying. The Output Meters are displayed as “dB to Limiter Threshold”. In other

words, these meters will display the headroom between the output level and the limiter threshold. When

viewed in conjunction with the Gain Reduction meters, this provides a complete display of level and

headroom before and after limiting has been engaged to allow system levels to be optimized. This also

18 Owner‘s Manual

Page 19

DSP 260

means that the output metering will be displayed differently depending on the limiter threshold setting.

The red segments indicates clipping of the D/A converters and should be avoided by adjusting the Output

Level setting of the output channel.

5.4 Output Gain Reduction Meters

Each output channel has a four-segment gain reduction meter that shows the effect of the

output channel Limiter on output level; from 0dB to -12dB. Output limiting can be bypassed

by entering Edit mode, selecting Output Channel Limiter and selecting a limiter threshold of

+21 dBu (8.691V) or turning the Bypass parameter to “On”.

5.5 Output Channel Mute Buttons

Each output channel has a lighted Mute button. Pressing the Mute button turns off the output of that

channel. The button lights red as an alert. Press the Mute button again to restore the output channel’s

signal.

5.6 Output Channel Function Indicators

Each output channel has a four-segment function display for informational purposes only. For

any given configuration possible with the DSP 260, an output channel may be identified as a

sub, low, low/mid, mid, mid/hi, hi or full range output. One or two adjacent LED’s are

displayed to indicate all possible output bandpasses. (Full range is indicated by all lit LED’s.)

5.7 Preset Recall

The DSP 260 preset memory provides 60 factory

program presets and can store up to 20 user presets.

(F01-F60, U01–U20) Factory presets have been

designed to represent common system configurations

utilizing Dynacord loudspeaker systems. User presets

allow you to accommodate other system configurations

and / or loudspeaker systems.

To recall a preset, press the front panel Recall button. The display

switches to the Recall Preset screen and displays the next in a list of

available presets in memory. Using the Value Up and Down buttons,

select the preset to be recalled. Valid presets will display the preset

name. Empty presets will display a “?”.

Select a valid preset and press Recall again. The display will

prompt, “Recall Preset? Press Recall”. Press Recall a third time to confirm and load the new preset.

Recall

Owner‘s Manual 19

Page 20

DSP 260

If the preset you are recalling is based on a configuration different

from that of the current preset, the display will prompt, “Changing

config can damage speakers”, to remind you that the new preset

may not be appropriate for your system as it is currently connected.

Press Recall again to confirm and load the new preset.

Make sure that the new preset is appropriate for your system, and that connections to your system are correct for the current configuration. Failure to

do so could cause unexpected results or damage to the system or its components.

To exit the Recall process without loading a new preset, press the Edit, Setup or any of the DSP block

buttons. (Edit or Setup buttons will return the display to run-time mode. DSP block buttons will display the

corresponding DSP block edit screen.)

5.8 Preset Store

Edited presets can be stored in one of 20 User Preset

locations. (U01 – U20) To store a preset, press the

Store button. The LCD display will switch to the Store

Program screen. Use the Value Up and Down buttons

to select the user destination. Locations that already

have presets saved in them will display a preset name.

Empty locations will display “?” in the name field. You may select an empty location, or a location of a

preset that will be over-written.

Press the < Select > buttons to navigate

down to the preset name field. Use the

Value Up and Down buttons to select the

field for each letter / symbol character. The

DSP 260 provides the complete ANSI

character set, including lower-case &

upper-case letters, numerals and symbols. Pressing and holding the Value Up and Down buttons will scroll

rapidly through the character set. Press the < Select > buttons to move to the next or previous character

position.

When the preset is named, press

Store again. If the preset location

was previously empty, the display

will prompt “Are you sure? Press

Store”. If you are overwriting an

existing preset the display will

prompt “Overwrite Preset? Press Store”. In either case, press Store again to proceed and store the new

preset.

To Exit Store without saving the edited preset, press the Edit, Setup

or any of the DSP block buttons. (Edit or Setup buttons will return

the display to run-time mode. DSP block buttons will display the

corresponding DSP block edit screen.)

Store

20 Owner‘s Manual

Page 21

DSP 260

5.9 Edit

Both Factory and User preset can be edited, but edited presets can only be stored in User preset locations.

Standard Edit Mode

The DSP 260 defaults to Standard Edit mode wherein, input and output channel parameters are

appropriately linked. (Refer to “Configurations” illustrations to see which channels are parameter-linked for

each configuration.

Linked parameters are always identical in value. For instance, setting a graphic eq curve for Input A, sets

the same curve for Input B, if the configuration has linked stereo inputs. Either input channel can be edited;

changes will be reflected in both. The same is true for parameters of linked output channels. The only

exception to the linking of parameters is the Mute buttons. Output channels can be individually muted at

any time, either from the DSP 260 front panel or the Graphic User Interface application.

Full Edit Mode

In the Setup menu, the edit mode can be changed to Full Edit. In Full

Edit, no parameter links are enforced, regardless of the

configuration selected. Any parameter can be changed without any

effect on other parameter values.

Regardless of the edit mode selected, there are two means to enter

edit mode: pressing the Edit button or pressing any DSP block button.

Use the < Select > buttons to navigate to the top line of any edit screen, and

the Value Up and Down buttons to navigate to any other Edit screen. As a

short-cut, press a DSP block button to jump to the last selected screen of

said block and navigate as above to reach the desired screen.

5.10 Parameters

The following section is a detailed description of every DSP parameter available in the DSP 260; grouped

by DSP block, in order of the signal flow of the DSP 260.

Input A&B DSP Block

Output 1-6 DSP Block

Not all parameters may be accessible in every preset and, depending on the configurations set by the

Owner‘s Manual 21

Page 22

DSP 260

contractor/installer, not all presets and/or preset values may be available for editing. Changes to preset

availability, parameter availability and preset value ranges can only be set using the DSP 260 Editor PC

application.

Input Channel Hi-Pass Filter

Use the < Select > buttons to make the top line of the Edit screen active and the

Value Up and Down buttons to navigate to the Input Hi-Pass screen.

The first DSP block in the DSP 260’s signal flow is the stereo Hi-Pass Filter. In any sound

reinforcement system, the Hi-Pass filter is crucial for maximizing the efficiency and performance

of the PA system. Both analog and digital audio sources can include significant sub-sonic (infra-sonic)

program material and artifacts. Audio frequencies below the threshold of human hearing can still be

present at the amplifier inputs, and the amplifiers and loudspeakers will do all they can to reproduce them;

at a great cost of power and efficiency.

Hi-Pass filters can set a frequency, below which, signals will be attenuated or reduced. The cut-off

frequency selected for the hi-pass filter – below which the frequencies will be attenuated - will vary

depending on the program material and connected loudspeaker system. For example, full range music can

produce frequencies down to the theoretical limit of human hearing (20 Hz), some acoustic music can be

limited to frequencies above 60 Hz, and voice-only reproduction is limited to much higher frequencies. Hipass filter applications and settings will be determined by the needs of the given

for the program material and sound reinforcement system.

The DSP 260 Hi-pass filter offers several response curves, or slopes, to suit the needs of the given

application. Select the curve that best meets the needs of your particular situation:

DSP 260

preset selected

Freq

The cut-off frequency for the Hi-Pass filter. The frequency range is

from 20 Hz to 200 Hz and is adjustable in 1 Hz increments. Select

the frequency setting that is appropriate for the attenuation slope

selected and type of program material.

Bypass

No sub-sonic or low-frequency filtering is applied. Use this to bypass the Hi-Pass filter.

Slp

Slope or degree of attenuation.

• 6dB/Oct - A very gentle attenuation of frequencies below the selected cut-off frequency; good for acou-

stic music that is generally within known frequencies, but may drop below; without much energy.

• 12dB/Oct - Steeper attenuation of frequencies below the selected cut-off frequency; useful when un-

expected low-frequency material may be encountered. When 12dB/Oct is selected, Q band is available - from 0.4 Oct to 2.0 Oct.

Input Channel Parametric EQ

Use the < Select > buttons to make the top line of the Edit screen active and the

Value Up and Down buttons to navigate to the Input PEQ screen.

The DSP 260 provides a stereo nine-band multi-mode filter generically referred to as the Input

PEQ (Parametric Equalizer). The Input PEQ is a very powerful and complex set of multi-mode

22 Owner‘s Manual

Page 23

DSP 260

filters. Care must be given configuring these filter bands, as they interact and can produce unexpected

results. Using the DSP 260 Editor PC application is strongly recommended to set all but the most simple

eq curves.

Each band of the Input PEQ can be configured for a specific filter mode, frequency, slope or Q and gain

setting. Attention must be paid to the ultimate output gain through the rest of the DSP 260’s audio path, as

it is possible to boost frequency ranges to the point where the internal or external audio paths of the

system may be clipped. Monitoring the output VU meters of the DSP 260’s output channels will indicate

internal clipping; the input meters of connected amplifiers should do the same.

To bypass any band of the DSP 260’s Input PEQ multi-mode filter

bank, set the desired band’s gain to 0.0 dB. This will have the effect

of bypassing the selected filter band.

The following section details the type of filters that can be selected

for each of the Input PEQ’s 9 bands and their parameters:

Low-shelf

The Low-shelf filter is a “hinge” type; in that frequencies below its frequency setting can be

boosted or cut; hinging on the cut-off Frequency. The amount of boost or cut (Gain), and

the extent of width of the filter’s transition band (Slope), are determined by the low-shelf filter’s settings.

(See Response/Q and Gain.)

Use the < Select > buttons to navigate to the filter setting you wish to adjust, and the Value Up and Down

buttons to alter these settings. Press the Value Up and Down buttons once to increment values by one

unit, or press and hold to scroll rapidly through available values. (Values do not wrap around.)

Hi-shelf

The Hi-shelf filter is a “hinge” type; in that frequencies above its frequency setting can be

boosted or cut; hinging on the cut-off Frequency. The amount of boost or cut (Gain), and

the width of the filter’s transition band (Slope), are determined by the hi-shelf filter’s settings. (See

Response/Q and Gain.)

Use the < Select > buttons to navigate to the filter setting you wish to adjust, and the Value Up and Down

buttons to alter these settings. Press the Value Up and Down buttons once to increment values by one

unit, or press and hold to scroll rapidly through available values. (Values do not wrap-around.)

PEQ

PEQ is shorthand for Parametric Equalizer. A parametric equalizer has three parameters that

determine the frequencies that are affected by it; Center Frequency, Q (filter-width) and

Gain. Parametric filters are ideal for identifying, isolating and correcting problematic frequency ranges.

The Frequency parameter determines the center of a range of frequencies that will be adjusted by the

PEQ. The Q parameter will determine the range of frequencies adjacent to the center frequency that will

also be effected; the greater the value, the smaller the range of adjacent frequencies that will be effected.

The gain parameter determines the amount of boost or cut that is applied to the frequencies that are

affected by the filter.

Use the < Select > buttons to navigate to the filter setting you wish to adjust, and the Value Up and Down

buttons to alter these settings. Press the Value Up and Down buttons once to increment values by one

unit, or press and hold to scroll rapidly through available values. (Values do not wrap-around.)

Low-pass

The Low-Pass filter determines the ultimate high frequency that your sound reinforcement

system is allowed to reproduce; given the capabilities of amplifiers, speakers and

transducers. The low-pass filter is useful for reducing excessive high frequency energy that can create

stress on high frequency transducers and listener fatigue.

Available parameters are Frequency and Slope. The frequency parameter determines the frequency

above which frequencies will be attenuated. The slope determines how quickly frequencies above the cut-

Owner‘s Manual 23

Page 24

DSP 260

off frequency will be attenuated. (See response curve.)

Use the < Select > buttons to navigate to the filter setting you wish to adjust, and the Value Up and Down

buttons to alter these settings. Press the Value Up and Down buttons once to increment values by one

unit, or press and hold to scroll rapidly through available values. (Values do not wrap-around.)

Hi-pass

The Hi-Pass filter determines the ultimate low frequency that your sound reinforcement

system is allowed to reproduce; given the capabilities of amplifiers, speakers and

transducers. Keep in mind that the DSP 260 signal path already includes a hi-pass filter prior to the Input

PEQ DSP block. Settings to this filter in most configurations may be redundant or interactive with the initial

Hi-Pass filter.

Available parameters are Frequency and Slope. The frequency parameter determines the frequency

below which frequencies will be attenuated. The slope determines how quickly frequencies below that will

be attenuated. (See response curve.)

Use the < Select > buttons to navigate to the filter setting you wish to adjust, and the Value Up and Down

buttons to alter these settings. Press the Value Up and Down buttons once to increment values by one

unit, or press and hold to scroll rapidly through available values. (Values do not wrap-around.)

Input A/B Parametric EQ

Band Type Frequency Slope Resp / Q Gain

HIPASS HIP ASS 20 Hz...20000 Hz

PARA EQ BAND 1-9 LOSLV 20 Hz...20000 Hz

HISL V 20 Hz...20000 Hz

PEQ 20 Hz...20000 Hz 0.40 to 20 -15.0dB to +15.0dB

LOPASS 20 Hz...20000 Hz

HIP ASS 20 Hz...20000 Hz

6dB/oct.

12dB/oct. 0.40 to 2.00

6dB/oct.

12dB/oct.

6dB/oct.

12dB/oct.

6dB/oct.

12dB/oct. 0.40 to 2.00

6dB/oct.

12dB/oct. 0.40 to 2.00

-15.0dB to +15.0dB

-15.0dB to +15.0dB

Input Channel GEQ (Graphic Equalizer) (available soon)

Use the < Select > buttons to make the top line of the Edit screen active and the Value Up and Down

buttons to navigate to the Input GEQ screen.

The DSP 260’s input signal path includes a stereo 31-band graphic equalizer after the stereo 9-band PEQ

in the signal path. This DSP block can be used for very precisely identifying, isolating and correcting

problematic frequency ranges.

Keep in mind that changes to the Input GEQ will be interactive with adjustments made in the Input PEQ.

Unexpected results can occur.

Press the < Select > buttons to move the cursor down into the GEQ frequency adjustment field.

Subsequent presses of the < Select > buttons will move the cursor forward or backwards through the

frequency adjustment field; from band to band. The selected frequency’s “fader” is highlighted in the

display. As each band is selected, its center frequency and current cut/boost setting is displayed on the top

line of the LCD display.

To adjust the amount of boost or cut for a selected frequency band, select the band with the < Select >

buttons and press the Value Up or Down buttons as required. The LCD display will reflect your changes by

24 Owner‘s Manual

Page 25

DSP 260

moving the selected frequency band’s “fader” up or down.

To exit the Input GEQ edit screen, press the Input GEQ button, use the < Select > buttons to again

highlight the top line of the edit screen display or press any other DSP block button.

Input Delay

DSP 260 offers an input delay that is useful for compensating for different arrival times of sound

originating from loudspeakers that are closer or further away from the listener than others. A

technique known as the Haas Effect allows the operator to create the illusion that all of the

sound has originated from the stage even though additional speakers have been placed around

the room.

Available Input Delay parameters are

determine the Delay time values (-200.00ms to +700.00ms.) and the Bypass parameter simply toggles

between On/Off.

To access the Input Delay, press the Delay button found on the input processing menu. Subsequent button

presses will toggle the display between Input A and Input B. Input delay parameters are accessed using

the <SELECT> button to navigate between Delay and Bypass using the VALUE up/down keys to adjust

values.

Delay, Units

and

Bypass

. The Delay parameter allows the user to

Illustration 5.1: Input B Delay is set to 75 feet. In this illustration, speaker array B is said to b 75 feet in front

of Main speaker array A. The effect of air temperature is also automatically calculated for the total delay time

using the Temperature value entered in the Setup Menu.

Routing

Input selections (In-A, In-B or In-A+B) can be applied to any or all of

DSP 260’s six outputs. Choose a desired output channel from the

output menu and press the Edit button to scroll to the Routing

window using the Value up/down arrows.

Using the <SELECT> key to navigate to the Source parameter,

apply a desired input selection to a selected output channel using

the VALUE up/down keys to choose between inputs (In-A, In-B or In-A+B).

Cross-Over (Output Channels)

The DSP 260’s crossover is an advanced frequency

division process that is accomplished by applying a

variety of high-pass and low-pass filters to a

predetermined set of crossover points.

Speaker systems are generally made up of several

drivers that are dedicated to a specific range of frequencies that

result in the efficient reproduction of the audio spectrum and a smooth sound. The DSP 260 crossover

routes frequencies to the appropriate drivers to accurately reproduce sound. The crossover network can

Owner‘s Manual 25

Page 26

DSP 260

also be used to insure that low-frequency energy is not accidently routed to the mid-range or tweeter

drivers that may result in potential damage.

Available DSP 260 crossover parameters are Type and Frequency.

To access the Crossover screen, press the X-Over button found on the output processing menu.

Subsequent button presses will toggle the display between OUT1 to OUT6. Use the <SELECT>

button to navigate between the Low Pass/parameters. Adjust the values of each parameter using

the up/down VALUE arrows.

The DSP 260 Crossover offers a variety of HiPass and LoPass filters depending on the configuration

output selected along with a variety of selectable filters and frequency ranges that are adjustable using the

up/down VALUE arrows.

Type

Type offers list of selectable slopes/response Q’s

•Thru

•6dB

• 12dB/ 0.5Q - 2.0Q

• Bessel: 12 dB, 18 dB or 24 dB

• Butterworth: 12dB, 18dB or 24 dB

• Linkwitz-Riley: 12dB or 24 dB

Frequency

Frequency offers a selectable frequency range from 20.0 Hz to 20,000Hz.

Hi-Pass/Lo Pass

The DSP 260 Hi-Pass and Lo-Pass filters are determined by selecting the Type from the list of

parameters, (see list above) and by choosing a frequency range between 20.0 Hz to 20,000Hz. (See

above)

Illustration 5.2: Here the HiPass Output 2 Crossover is set to Linkwitz-Riley 24dB with the frequency set to

60.0Hz

The crossover filter generally consists of a low pass filter in one channel and a high pass filter in the

adjacent channel. This is where the frequency x-over filter’s Hi-Pass parameters are set. The Hi-Pass

frequency parameters are linked to the corresponding Lo-Pass frequency parameter unless in Full Edit

Mode or using the Configuration option. Please refer to the Configuration section of this manual for details

on the effect different Configurations have on channel linking.

The Type parameter defines the filter characteristics of the crossover Hi-Pass filter. Different slopes and filter

responses (6dB, 12dB with different

can be bypassed. Again, the Hi-Pass frequency parameters are linked to the corresponding Lo-Pass

frequency parameter depending on the Configuration that is currently being used. High pass frequencies are

set with a pre-determined frequency that attenuates frequencies below (the crossover point). On the contrary,

a Low Pass filter passes frequencies below the crossover point and attenuates those above.

Q

values, Bessel, Butterworth, Linkwitz-Riley) are available and the filter

26 Owner‘s Manual

Page 27

DSP 260

Crossover Alignment Delay

To access the Crossover Delay screen, press the X-Over button

found on the output processing menu. Subsequent button presses

will toggle the display between OUT1 to OUT6. Use the <SELECT>

button to navigate between the Crossover parameters. Adjust the

values of each parameter using the up/down VALUE arrows.

• Delay - Use this parameter to compensate for physical offsets of the acoustic centers of transducers

within a loudspeaker cabinet. For example, due to cabinet construction, the acoustic center of a high

frequency transducer may be mounted behind or in front of the acoustic center of the low frequency

transducer. The Delay parameter can align the audio signal between the multiple transducers within

the loudspeaker.

•

Polarity

•

Unit

delay times. This calulation also includes the influence of the environmental temperature

Temperature parameter in the Setup Menu.

•

Bypass

-

The polarity of the audio signal can be inverted using this control.

- The user may select betwen time and distance display. Distances are automatically converted into

based on the

- Setting this to On disables the Crossover Delay.

Parametric EQ (Output Channels)

Pressing the PEQ button places the current preset in Edit

mode and jumps the LCD screen to a pre-selected

parametric EQ (bands 1-5). Subsequent button presses

advances the display to the next output channel (OUT1 to

OUT6). Use the <SELECT > key to navigate between the PARA EQ

BAND (1-5), Type, Frequency, Q and Gain parameters. Adjust the

values of each parameter using the up/down VALUE arrows.

Output 1-6 Parametric EQ

Band Type Frequency Slope Resp / Q Gain

PARA EQ BAND 1-5 LOSLV 20 Hz...20000 Hz

HISL V 20 Hz...20000 Hz

PEQ 20 Hz...20000 Hz 0.40 to 20 -15.0dB to +15.0dB

LOPASS 20 Hz...20000 Hz

HIP ASS 20 Hz...20000 Hz

ALLPS1 20 Hz...20000 Hz

ALLPS2 20 Hz...20000 Hz 0.40 to 2.00

Delay (Output Channels)

DSP 260’s output delays can be applied to output channels OUT1 - OUT6 and can be used to

compensate for the positioning of cabinets or speaker arrays relative to each other or the

original sound source.

The Delay parameter determines the delay time of the corresponding channel or the distance

6dB/oct.

12dB/oct.

6dB/oct.

12dB/oct.

6dB/oct.

12dB/oct. 0.40 to 2.00

6dB/oct.

12dB/oct. 0.40 to 2.00

-15.0dB to +15.0dB

-15.0dB to +15.0dB

Owner‘s Manual 27

Page 28

DSP 260

between different loudspeaker clusters. The delay time or physical distance is displayed in milliseconds,

microseconds, feet, inches, meters, or centimeters.

To access the Delay screen, press the Delay button found on the output processing menu. Subsequent

button presses will toggle the display between OUT1 to OUT6. Use the <SELECT> key to navigate

between Delay (-200.00ms to 680.00ms) and Bypass (on/off). The values for each parameter can be

adjusted using the up/down VALUE arrows.

Illustration 5.3: Here Output 5 and 6 are linked and their delay is set to 200 feet. Output 3 and 4 are also

linked and set to 100 feet. In this configuration, speaker outputs 5 and 6 are said to be 200 feet in front of

Main speaker output array 1 and 2. The effect of air temperature on the actual delay time will also be auto-

matically calculated based on the Temperature Parameter in the Setup Menu. See Output Linking.

Channel Level (Output Channels)

The Channel Level is used to adjust master output levels.

To access the Channel Level screen, press the Level

button found on the output processing menu. Subsequent

button presses will toggle the display between OUT1 to

OUT6. Use the <SELECT> button to navigate between the

selectable Level parameters (-100.0dB to +6.0dB). Adjust the value

by using the up/down VALUE arrows.

Channel Limiter (Output Channels)

DSP 260‘s output channel limiters prevent audio signals

from exceeding a set level. Press the Level button to

change the output channel. Hold-down the Level button

for some seconds - you will then be presented with the

Limiter screen. Use the < SELECT> key to navigate

between Threshold (-9.0 dBu to + 21.0 dBu), Release (50.0ms to

300.0 ms), Amp (preset values for specific power amplifiers) and

Bypass (on/off). Adjust the values of each parameter using the up/

down VALUE arrows.

28 Owner‘s Manual

Page 29

DSP 260

Limiter threshold values are determined by the amplifiers and

loudspeakers that are used in the system. One important

consideration in setting the limiter threshold value is the input

sensitivity and gain of the connected amplifiers. Because

different amplifiers can have different sensitivities, it is common

to need to calculate the limiter offset to a factory preset based

on the amplifier sensitivity. The DSP 260 offers a unique

solution to this problem with the Amp parameter. All DSP 260

Factory Presets include limiter threshold values. You may use

the Amp parameter to select the model of Dynacord amplifier

that you are using and the limiter threshold offset will be

automatically calculated based on the amplifier gain and

sensitivity. When an amplifier is selected from the list, the

actual Threshold parameter will be locked to ensure that

proper settings are maintained. It is very important to ensure that the proper amplifier is selected from the

list, as an improper selection can result in incorrect Limiter settings for your system and may result in

system damage. If a non-Dynacord amplifier is used in the system, selecting “Other” from the amp list will

allow the Threshold setting to be directly edited, however, the amplifier documentation should be consulted

so you can calculate you limiter offset (if any) as needed. The Amp parameter is only available when using

a Factory Preset.

Amp Type

S900

S1200

CL800

CL1200

CL1600

LX1600

LX2200

LX3000

L1000 (0dBu, +6dBu, +26dB)

L1600 (0dBu, +6dBu, +26dB)

L2400 (0dBu, +6dBu, +26dB)

H2500 (0dBu, +32dB, +35dB)

H5000 (0dBu, +32dB, +35dB)

Owner‘s Manual 29

Page 30

DSP 260

6 Setup

The Setup menu allows access DSP 260’s global parameters on the LCD screen. This is where

preferences for many functions can be set or adjusted. Pressing the Setup button brings up the first Setup

window. Use the VALUE up/down arrows to scroll through the Setup menu: Use the <SELECT> buttons to

scroll to Setup parameters to make adjustments using the VALUE up/down buttons.

IMPORTANT NOTE

To achieve optimum performance and guard against damage to the processor, your sound system or yourself, please read, understand and follow all of

the directions contained in this Owner’s Manual. Failure to do so may result

in improper performance, loss or injury.

6.1 Setup Menus

Configuration

Configuration window is where you can select the desired setup for

your system. Use the <SELECT> key to navigate to the Mode

parameter to choose the best setup for your system. Use the up/

down VALUE arrows to choose between:

1. 2 Way Stereo + FR

2. 3 Way Stereo

3. 4 Way + FR

4. 5 Way + FR

5. Free Configuration

6. 3 Way Stereo-Mono Sub+FR

7. 4 Way Stereo-Mono Sub+LR

For more on Configuration Setup, see page 34.

Caution

Before operating the sound reinforcement system, and any time a new preset

is recalled, check the configuration display to make sure that it is appropriate

for your system and that connections to your system are correct for the current configuration. Failure to do so could cause unexpected results or damage to the system or its components.

30 Owner‘s Manual

Page 31

Input

This window is where the global input mode is set. Use the

<SELECT> key to navigate to the MODE parameter. Use the up/

down VALUE arrows to choose between Analog and Digital input.

LCD

LCD settings allow the user to adjust the contrast preferences of the

LCD screen to compensate for different lighting conditions that may

be encountered within different venues. Use the <SELECT> key to

navigate to the CONTRAST parameter to choose the best setup for

your system. Use the up/down VALUE arrows to choose between: 10 to + 10 LCD contrast.

Limiter Units

DSP 260

In this window you can select between dBu and Volt for Limiter

units. Use the <SELECT> key to navigate to the UNITS parameter.

Metering

Users can set their VU metering preferences here.

Use the <SELECT> key to navigate to the MODE

parameter. Use the up/down VALUE arrows to

choose between Normal Fast, Peak Hold and Slow

Decay.

Temperature

This parameter is used to calculate the speed of sound for

converting delay times into distance. Use SETUP Temperature to

adjust number of degrees and type of temperature base. Use the

<SELECT> key to navigate to the TEMP and UNITS parameters.

Use the up/down VALUE arrows to choose between – 4.0 F to

140.0 F. The UNITS parameter lets the user choose between

Fahrenheit and Celsius.

Owner‘s Manual 31

Page 32

DSP 260

Note: Sound travels at different speeds depending on the density of the surrounding air it is traveling

through. Cold air is denser than warm air thus, travels slower than it would if the air was warmer.

Temperature can have a major influence with greater distances, particularly with respect to widely

separated speaker arrays surrounding the audience for example. Temperatures might vary wildly

between an indoor environment and an outdoor evening environment for example.

V = 331m/s + (0.6m/s/C) * T

The speed of sound at room temperature is 346 meters per second. At freezing temperatures sound

travels at 331 meters per second. V is the speed of sound and T is the temperature of the air. This

formula finds the average speed of sound for any given temperature (celcius). The speed of sound is

also affected by other factors such as humidity and air pressure.

Editing

Editing mode is where the Edit Mode (Standard Edit or Full Edit) is

set. The DSP 260 defaults to Standard Edit mode wherein, input

and output channel parameters are appropriately linked. (See

page 42 for more.) In Full Edit mode, no parameter links are

enforced, regardless of the configuration selected. Use the

<SELECT> key to navigate to the EDITING parameter to choose

your editing preferences.

Lock - Front Panel Access

A lockout mode has been provided for the installer to protect the system settings from being modified by a

user. This can be set from the front panel or from the GUI software.

From the front panel

Use the <SELECT> key to navigate to the Lock menu. Use the

VALUE key to choose your four digit code. Then use the <SELECT>

key navigate to the Store parameter, to lock or unlock front panel

editing.

From the GUI

Open the DSP 260’s GUI and choose Front Panel

Access from the Window pull-down menu. Doing so

will bring up the Front Panel Access GUI that will

present the unit’s currently loaded state including

preset (U## or F##), DSP Blocks and Parameters. Any or all of the DSP 260’s DSP Blocks and/or

individual parameters within the DSP blocks can be locked or hidden from this window by selecting the

corresponding box to engage the lock icon. For example, an installer may chose to lock and hide all Limiter

parameters, lock all Crossover parameters but leave them visible, and lock the last 5 Input PEQ filters,

leaving the first 4 available for the user to edit and modify.

32 Owner‘s Manual

Page 33

System

This window displays the firmware version currently running on the

DSP 260.

RS-232 Port

An RS-232 (DB-9 or ‘D-Sub’) connection is provided on the back

panel to link to another DSP 260 to enable Master/Slave operation.

Use the <SELECT> key to navigate to the MODE parameter and

use the up/down VALUE arrows to choose between RS-232 and

Contacts.

Contacts allow control messages to select

individual presets (per pin 1-9) using a remote

device. The additional CONTACTS parameter

is used as a display only and corresponds to

the binary values of individual pins, ie - on/off.

DSP 260

For more on this see Relay Contact Closure on page 15.

Owner‘s Manual 33

Page 34

DSP 260

7 Configurations of the DSP 260

The DSP 260 offers 7 pre-defined configurations. A configuration is a basic setting that includes the

routing of inputs and outputs, the function of the outputs (Sub, Lo, Mid, Hi, Full Range) including basic xover filter settings, and different channel/parameter linking schemes.

The active configuration is defined by the selected program i. e., each program is based on a specific

configuration which is also displayed next to the program number and program name.

Each output employs two X-Over filters that can be assigned to a variety of filter types and slopes. Each

output channel provides 5 additional filters which can be used as parametric EQs, Low- / High-shelving

filters, or Lo-Pass and Hi-Pass filters, and also as All-Pass filters. In addition to a gain control for adjusting

the output level and a polarity switch, each output is monitored by a digital limiter with adjustable threshold,

attack and release.

List and Detailed Description

•2 Way Stereo + FR

•3 Way Stereo

•4 Way + FR

•5 Way + FR

• Free Configuration - Full Edit 2 in 6 Out

• 3 Way Stereo - Mono Sub + FR

• 4 Way Stereo - Mono Sub + LF

Please use caution when changing configurations.

34 Owner‘s Manual

Note:

Not all parameters may be accessible in every preset and, depending on the

configurations set by the contractor/installer, not all presets and/or preset

values may be available for editing. Changes to preset availability, parameter

availability and preset value ranges can only be set using the DSP 260 Editor

PC application.

Page 35

DSP 260

7.1 2-Way Stereo + Full Range

This configuration generally represents a 2-way stereo frequency

crossover, where IN A serves as the left input channel and IN B as

the right input channel. OUT 1 is the left Low-frequency output and

OUT 2 is the left High-frequency output. OUT 4 and OUT 5 are the

corresponding right Low-frequency and High-frequency output

channels

Note: On Input channels, all Parametric EQ and Graphic EQ parameters are linked. For Output channels,

linking applies to Crossovers, EQ, Delay Level and Limiter.

Owner‘s Manual 35

Page 36

DSP 260

7.2 3-Way Stereo

This configuration represents a 3-way frequency crossover where IN

A serves as the left input channel and IN B as the right input

channel. OUTs 1 & 4 L/R are the Sub frequency channel, OUT 2 &5

L/R are Low and Mid-frequency channels, 3 & 6 L/R are the Highfrequency channels.

Note: On Input channels, all Parametric EQ and Graphic EQ parameters are linked. For Output channels,

linking applies to Crossovers, EQ, Delay Level and Limiter.

36 Owner‘s Manual

Page 37

DSP 260

7.3 4-Way + FR