Page 1

DPM 8016

en | Operation manual

Page 2

Page 3

Table of contents

1

Safety notes 4

2

Brief description 7

3

System description 8

4

Scope of delivery and warranty 12

5

Installation 13

5.1 Front 13

5.2 Back 14

5.3 Installation 15

6

Connections 17

6.1 Power supply voltage 18

6.2 Ethernet 18

6.3 REMOTE CAN BUS 19

6.4 Control port 22

7

Configuration 25

7.1 Installing extension cards 25

7.2 Network configuration 26

8

Operation 28

9

Maintenance 29

10

Technical data 30

10.1 Power consumption 31

10.2 Block diagram 33

10.3 Dimensions 34

10.4 Standards 34

11

Appendix 35

11.1 Ethernet basics 35

11.2 Table of IP addresses 37

DPM 8016 Table of Contents | en 3

Operation manual 16-Dec-13 | 02 | F01U259190

Page 4

Safety notes

Danger!

The lightning symbol inside a triangle notifies the user of high-voltage, uninsulated lines and

contacts inside the devices that could result in fatal electrocution if touched.

!

Warning!

An exclamation mark inside a triangle refers the user to important operating and service

instructions in the documentation for the equipment.

1. Read these safety notes.

2. Keep these safety notes in a safe place.

3. Heed all warnings.

4. Observe all instructions.

5. Do not operate the device in close proximity to water.

6. Use only a dry cloth to clean the unit.

7. Do not cover any ventilation slots. Always refer to the manufacturer's instructions when

installing the device.

8. Do not install the device close to heaters, ovens, or other heat sources.

9. Note: The device must only be operated via the mains power supply with a safety ground

connector. Do not disable the safety ground connection function of the supplied power

cable. If the plug of the supplied cable does not fit your mains socket, please contact

your electrician.

10. Ensure that it is not possible to stand on the mains cable. Take precautions to ensure the

mains cable cannot become crushed, particularly near the device connector and mains

plug.

11. Only use accessories/extensions for the device that have been approved by the

manufacturer.

12. Unplug the device if there is risk of lightning strike or in the event of long periods of

inactivity. However, this does not apply if the device is to be used as part of an

evacuation system!

13. Have all service work and repairs performed by a trained customer service technician

only. Service work must be carried out immediately following any damage such as

damage to the mains cable or plug, if fluid or any object enters the device, if the device

has been used in rain or become wet, or if the device has been dropped or no longer

works correctly.

1

4 en | Safety notes DPM 8016

16-Dec-13 | 02 | F01U259190 Operation manual

Page 5

14. Please ensure that no dripping water or spray can penetrate the inside of the device. Do

not place any objects filled with fluids, such as vases or drinking vessels, on top of the

device.

15. To ensure the device is completely free of voltage, unplug the device from the power

supply.

16. When installing the device, ensure that the plug is freely accessible.

17. Do not place any sources of open flame, such as lit candles, on top of the device.

18. This PROTECTION CLASS I device must be connected to a MAINS socket with a safety

ground connection.

Caution!

Use only manufacturer-approved carts, stands, brackets, or tables that you acquired together

with the device. When using carts to move the device, make sure the transported equipment

and the cart itself cannot tip over or cause injury or material damage.

IMPORTANT SERVICE INFORMATION

!

Caution!

This service information is for use by qualified service personnel only. To avoid the risk of

electric shock, do not perform any maintenance work that is not described in the operating

instructions unless you are qualified to do so. Have all service work and repairs performed by

a trained customer service technician.

1. Repair work on the device must comply with the safety standards specified in EN 60065

(VDE 0860).

2. A mains isolating transformer must be used during any work for which the opened device

is connected to and operated with mains voltage.

3. The device must be free of any voltage before performing any alterations with upgrade

sets, switching the mains voltage, or performing any other modifications.

4. The minimum distance between voltage-carrying parts and metal parts that can be

touched (such as the metal housing) or between mains poles is 3 mm, and must be

observed at all times.

5. The minimum distance between voltage-carrying parts and circuit parts that are not

connected to the mains (secondary) is 6 mm, and must be observed at all times.

6. Special components that are marked with the safety symbol in the circuit diagram (note)

must only be replaced with original parts.

7. Unauthorized changes to the circuitry are prohibited.

8. The protective measures issued by the relevant trade organizations and applicable at the

place of repair must be observed. This includes the properties and configuration of the

workplace.

9. Observe the guidelines with respect to handling MOS components.

Danger!

SAFETY COMPONENT (MUST BE REPLACED BY ORIGINAL PART)

DPM 8016 Safety notes | en 5

Operation manual 16-Dec-13 | 02 | F01U259190

Page 6

!

Caution!

Risk of explosion if battery is not replaced correctly. Must be replaced only with the same or

equivalent type of battery.

6 en | Safety notes DPM 8016

16-Dec-13 | 02 | F01U259190 Operation manual

Page 7

Brief description

The DPM 8016 is the modular, network-capable central unit of the PROMATRIX 8000 system.

The system can be adjusted to requirements via the eight slots for audio input, audio output

or message manager modules. The DPM 8016 contains all necessary audio functions and is

responsible for controlling and monitoring the complete PROMATRIX 8000 system. A single

DPM 8016 can manage up to 16 call stations and up to 500 loudspeaker circuits; in larger

systems, up to ten DPM 8016 controllers can be linked with each other via a digital audio and

control bus.

2

DPM 8016 Brief description | en 7

Operation manual 16-Dec-13 | 02 | F01U259190

Page 8

System description

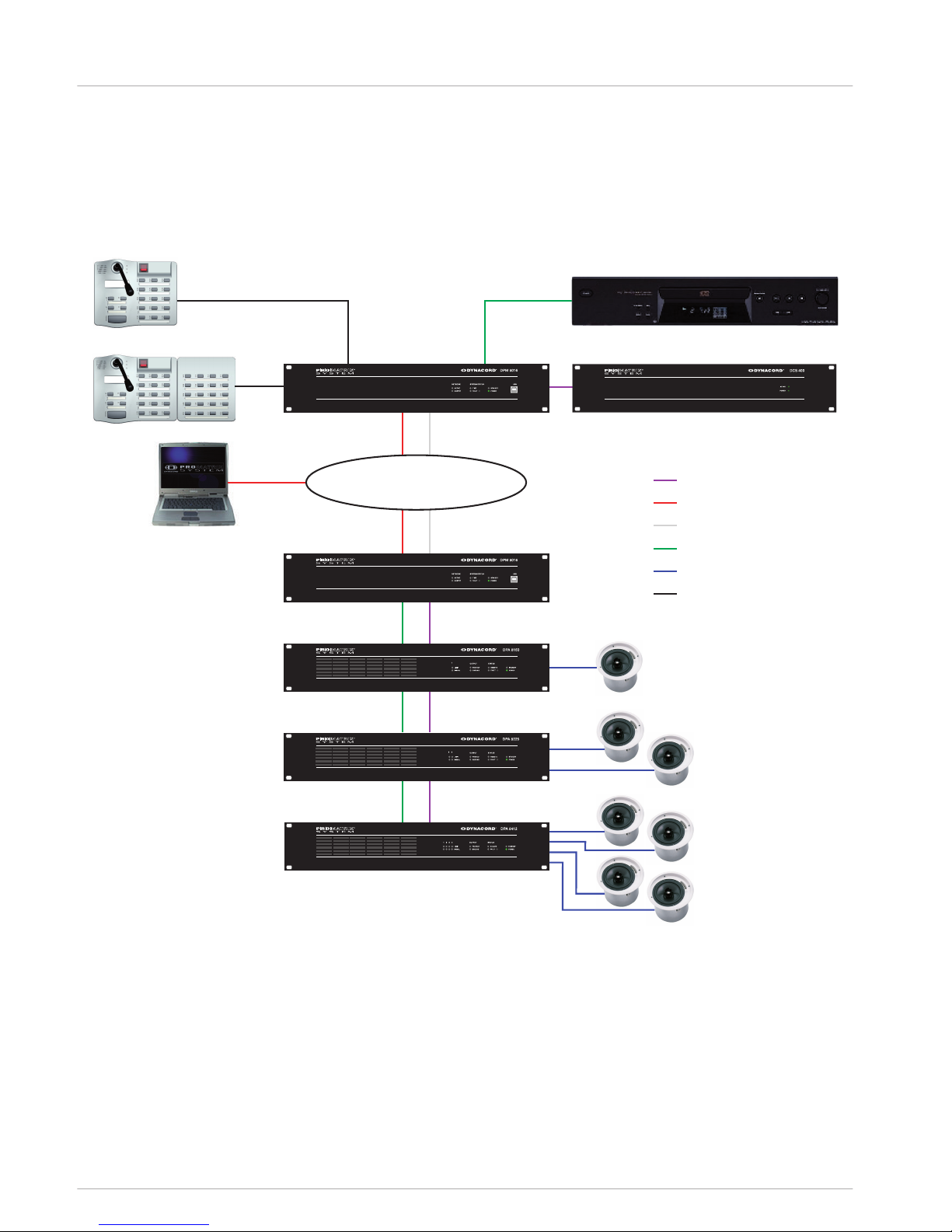

This chapter explains the basic configuration of the PROMATRIX 8000 system and its most

important functions. The following block diagram shows a PROMATRIX system with DPM 8016

central unit, call stations, audio equipment, amplifiers, a power supply, relay cards and

loudspeaker circuits, as well as control cards for external signals.

ETHERNET

PC

DPM 8016

DPM 8016

DPC 8120

DCS 400

DPC 8015

AUDIO SOURCE

ETHERNET

REMOTE CAN BUS

COBRA NET

AUDIO (LINE LEVEL)

AUDIO (100 V)

PCA

DPA 8225

DPA 8412

DPA 8150

Figure 3.1: PROMATRIX 8000

General overview

The DPM 8016 is the modular, network-capable central unit of the PROMATRIX 8000 system.

The system can be adjusted to system requirements via the 8 slots for audio input, audio

output or message manager modules. The DPM 8016 contains all necessary audio functions

and is responsible for controlling and monitoring the complete PROMATRIX 8000 system. The

type and number of connected audio sources, amplifiers, and relay cards are extremely

variable, and can be adjusted to individual requirements. A single DPM 8016 can manage up to

16 call stations and up to 500 zones; in larger systems, up to 10 DPM 8016 controllers can be

linked with each other via a digital audio and control bus. Control inputs and outputs can be

3

8 en | System description DPM 8016

16-Dec-13 | 02 | F01U259190 Operation manual

Page 9

used for controlling and monitoring functions, and allow both the logic level and the analog

level to be processed and generated. Configuration is performed on a PC using the IRIS-Net

software, which also provides access to system documentation and the required user

interface. A configuration can be changed at any time, and adjusted to new circumstances

without having to modify the system installation. A PC is required only for loading or changing

the configuration; it does not need to be connected during live operation. In many cases,

however, a permanently connected PC is helpful; for example, to provide detailed status

displays and log reports, real-time loudspeaker and sound control, or for remote diagnosis and

maintenance via the network. The user interface can be individually tailored, and up to 32

password levels can be assigned.

Audio routing

A digital 36 x 16 audio matrix is integrated into the DPM 8016. Up to 16 local audio inputs, 4

internal generators, and 16 optional CobraNet network inputs are available. The 16 matrix

outputs can be used as local audio outputs, or optionally provided via the CobraNet network.

This means 16 audio channels can be used in parallel, and connected to the amplifiers. Each

loudspeaker circuit can be connected with amplifier outputs via a relay matrix, which allows

for 500 loudspeaker zones. The DPM 8016 manages the audio signals, and distributes them

according to priority. In addition to the call stations, other audio sources can also be

connected to the audio inputs such as microphones, mixing desks, CD players, MP3 players,

tuners, and so on. A number of different connections are available for optimum adjustment.

Audio processing

The DPM 8016 provides separate volume controls with a mute function for each audio input

and audio output. Each audio input has a 3-band equalizer and a compressor for optimal

sound adjustment of the audio sources. All outputs are fitted with a 5-band equalizer and a

limiter. For the equalizers, the operator can select from six different filter types for each band

filter (peak, low-shelving, high-shelving, high pass, low pass, all pass). Volume levels, filter

parameters, and so on are set on the PC during configuration. However, these can also be

changed in real-time during operation using the graphical user interface, the special keys for

the call stations, or external operating controls.

Signal generators

The DPM 8016 provides four signal generators: Two independent generators for generating

alarm signals and two independent generators for generating gong signals. Operators can

choose between 24 alarm types and six gong types that are available ex-works.

Call stations

The call stations of the DPC 8000 series are used mainly for announcements, but are also used

for manual control of the PROMATRIX 8000 system. Possible call station functions include

circuit/group selection, announcements, program allocation, triggering gong and alarm signals,

and voice mail playback. However, special commands such as volume control, monitor

selection, preset switching, light control, function displays, and much more are also possible.

The call stations can therefore also be configured for general control tasks. If an

announcement is to be routed through a loudspeaker circuit that is already occupied, the

system issues an occupied notification (i.e., the BUSY-LED flashes). If the call station

concerned has a higher priority, it can interrupt the lower-priority call from the other call

station/signals. The system naturally includes safeguards relating to this: The user is notified

that the system is occupied when selecting the circuit (before the interruption) by the flashing

BUSY-LED. The user can now decide whether to interrupt the signal immediately, or whether

to wait until the end of the active announcement. Each zone selection key has two LEDs: A

DPM 8016

System description | en 9

Operation manual 16-Dec-13 | 02 | F01U259190

Page 10

green LED shows the current selection, and a yellow LED shows the current status of the zone

(occupied, free, alarm active). System information or error messages can be displayed on the

call station's illuminated graphic display.

Control inputs and outputs

The PROMATRIX 8000 system has analog and digital control inputs and outputs. The control

inputs allow a connection to be established to fire alarm systems, intruder alarm systems, or a

control desk. However, it is also possible to connect external switches, controllers, or rotary

encoders, or to retrieve output messages from external equipment (power supply, power

amplifiers, and so on). The control outputs allow the user to activate/deactivate external

devices, trigger signals and events, remotely control doors, gates, and roller blinds, generate

an analog level for media control, and much more.

Automatic control

The DPM 8016 contains a quartz-controlled real-time clock that can be switched to DCF77

radio clock operation via an optional antenna (radio receiver NRS 90193). The system clock

automatically recognizes leap years; in DCF77 mode, it also automatically switches to daylightsaving time. Up to 40 external slave clocks can be controlled by the system clock. A special

output for polarity switch impulses, which is protected against short circuits, is integrated in

the DPM 8016 for this purpose. Slave clocks are automatically adjusted if a time difference

between the slave clocks and the system clock is detected, for example after a power failure

or in the event of manual input. Together with the calendar function, the system clock can be

used to execute functions such as a break gong, music, gate control, light control, and so on.

These functions can be programmed for specific days, but can also be implemented on an

hourly, daily, weekly, monthly, and annual basis. Up to 500 time-controlled events can be

entered. Functions and parameters can be connected in an internal sequence. The TaskEngine

in the DPM 8016 provides a graphic display that allows the user to combine processes

individually. One example would be a gong signal to be transmitted at a certain volume and

with a specific priority in specific call groups, and which simultaneously activates a control

output. In this case, the process consists of the “gong” and “analog output” function blocks

combined with the parameters of gong type, volume, priority number, call group number, as

well as the type and number of the control output. The processes can be triggered via special

function keys on the call stations or via control inputs, but can also be linked to clock or

calendar dates.

Interfaces

In addition to the control inputs and outputs, the PROMATRIX 8000 system also includes other

interfaces. The call stations are connected to the DPM 8016 via the PCA bus (CAN bus

standard). Up to four call stations can be connected via one PCA bus. The power amplifiers

and the DCS 400 control system are controlled and monitored by the DPM 8016 via an

additional, independent CAN bus interface. The connection to a PC is established via an

Ethernet interface. The Ethernet interface is used to connect several DPM 8016 controllers.

The redundant, optional CobraNet interface is used to transmit audio data.

Security features

The DPM 8016 monitors all internal functions itself, and the connected call stations and power

amplifiers including their connection lines are also monitored by polling and pilot tone. When

using the DPA 8000 POWER AMPLIFIER, loudspeaker lines can be monitored by end-of-line

modules installed at the ends of the lines. The PROMATRIX 8000 system also supports

emergency power operation – in the event of a power failure, the DPM 8016 can assume all

power management functions, that is, all unnecessary internal and external consumers switch

to standby mode, or are deactivated and only reactivated again when required. This greatly

10

en | System description DPM 8016

16-Dec-13 | 02 | F01U259190 Operation manual

Page 11

reduces power consumption, and ensures maximum operating time on battery power. Error

messages can be displayed on the call station displays in plain text. A potential-free contact is

used on the DPM 8016 for batch messages.

Operating Instructions

In accordance with the specified and technical details for this product, the DPM 8016 can be

used to control and monitor public address and call systems within the building installation,

as well as for professional audio systems.

The DPM 8016 is not a stand-alone device. The following are the minimum requirements for

operation:

1. A mains adapter (24 V) sufficiently configured for the system’s power demands.

2. If the device is to be operated with call stations: The required number of call stations

from the DPC 8000 series (max. 16) and the corresponding connecting cables.

3. If the audio element of the device is to be used: Power amplifier, preferably from the

DPA 8000 series incl. cabling and loudspeaker with cabling.

4. If the internal real-time clock is to be synchronized to the DCF77 time signal: An active

DCF77 reception antenna (NRS 90193) incl. cabling. (This feature can be used only in

regions in which the DCF77 signal can be received with sufficient strength, or if

converters from different time information to DCF77 are used.)

5. If slave clocks are to be controlled: The required number of slave clocks (max. 40) incl.

cabling

6. If line relays and/or control inputs or outputs are to be used: A DCS system consisting of

a DCS 801R and the required types of DCS cards

DPM 8016

System description | en 11

Operation manual 16-Dec-13 | 02 | F01U259190

Page 12

Scope of delivery and warranty

Number Component

1 DPM 8016

1 Operating manual

2 CAN terminating resistor (120 Ω)

1 2-pole connector for 24 V DC input (Phoenix PC 5/2-STF1-7.62 – 1777833)

2 12-pole connector for GPIO (Phoenix MC 1.5/12-STF-3.81 – 1827800)

1 Warranty card with safety notes

Table 4.1: Scope of delivery

Warranty

For information regarding the warranty, see www.dynacord.com

4

12 en | Scope of delivery and warranty DPM 8016

16-Dec-13 | 02 | F01U259190 Operation manual

Page 13

Installation

Front

Number Element Description

1 ACTIVE LED Illuminates green when the digital audio network is

in operation.

2 TIME LED The green TIME LED indicates the operating status

of the DCF77 radio clock receiver. The following

statuses are possible:

• Off: No radio clock signal is being received, or

no radio clock antenna is connected. The

system clock is quartz-controlled.

• On: The radio clock signal is functioning

correctly. The system clock is synchronized via

DCF77.

3 STANDBY LED Illuminates yellow when the device is in standby

mode.

4 MASTER LED Illuminates green if this DPM 8016 controller is in

the digital audio network of the master.

5 FAULT LED This LED illuminates yellow during a reset or in the

event of a watchdog error in the DPM 8016. It also

indicates faults in external system components (end

levels, call stations, relay cards, etc.). The LED is

coupled with the READY contact (see Section

Control port, page 22) on the rear of the device,

which allows any faulty system behavior to be

reported externally.

6 FAULT key Press the FAULT key to confirm a fault in the system

and deactivate the signal tone.

5

5.1

DPM 8016 Installation | en 13

Operation manual 16-Dec-13 | 02 | F01U259190

Page 14

Number Element Description

7 POWER LED This LED illuminates green when the voltage supply

of the DPM 8016 (24 V) is connected. The LED

switches off when the DPM 8016 is disconnected

from the voltage supply or if the voltage supply is

switched off or fails.

8 USB interface Used to connect the DPM 8016 to a PC. For future

applications. See the Section Connections, page 17

Back

Figure 5.1:

Number

Element Description

1 Power supply input (DC INPUT

24/48V)

Connection for 24 V DC voltage. See

Section Power supply voltage, page 18

2 CONTROL PORT See Section Control port, page 22

3 STATUS LED See Section REMOTE CAN BUS, page

19

4 REMOTE CAN BUS interfaces

5 RS-232 interfaces See Section Connections, page 17

6 ETHERNET interface with status

LEDs

The orange LED illuminates when an

Ethernet connection has been

established with another device. The

green LED illuminates briefly whenever

data is transferred. See Section

Ethernet, page 18

7 RESET key Briefly press the RESET key to restart

the DPM 8016. Press the RESET key for

at least 3 seconds to enter service

mode.

8 Network module slot See Section Installing extension cards,

page 25

9 Extension slots

5.2

14 en | Installation DPM 8016

16-Dec-13 | 02 | F01U259190 Operation manual

Page 15

Installation

The DPM 8016 has been developed for horizontal installation in a conventional 19" rack

cabinet. As a rule, the DPM 8016 must be mounted in such a way that the ventilation slots are

not blocked on either side.

Figure 5.2: Air supply and ventilation of the DPM 8016

The ventilation direction runs from left to right when the device is observed from the front. If

possible, devices with the opposite ventilation feed should not be mounted in the same rack/

cabinet. When installing the device in the housing and rack cabinet, ensure there is a free

channel of air between the sides of the DPM 8016 device and the side walls of the cabinet/

rack up to the level of the upper rack or cabinet vent so that the devices are sufficiently

ventilated. There should be free space of at least 100 mm above the cabinet for ventilation.

!

Warning!

The maximum ambient temperature of +45 °C should not be exceeded.

When installing in a cabinet or transport rack, standard installation rails should be used to

prevent the front panel distorting.

The DPM 8016 must be protected from:

• Dripping water or spray

• Direct sunlight

• High ambient temperatures or immediate sources of heat

• High humidity

• Large dust deposits

• Strong vibrations

If these requirements cannot be guaranteed, the device must be regularly serviced to prevent

any outages that could occur as a result of negative ambient conditions. If the DPM 8016 is

moved directly from a cold to a hot location, there is a possibility of condensation forming

inside the device. The device must only be commissioned once it has warmed up to the new

temperature (after around one hour). If a solid object or fluid enters the housing, immediately

disconnect the device from the voltage supply, and have it serviced by an authorized call

station before it is recommissioned.

Front bracket

Attach the DPM 8016 on the front side with four screws and washers as shown in the

following figure.

5.3

DPM 8016 Installation | en 15

Operation manual 16-Dec-13 | 02 | F01U259190

Page 16

Figure 5.3: Attachment on the front panel

When installing in cabinet racks, installation rails should always be used to prevent the front

panel distorting.

16 en | Installation DPM 8016

16-Dec-13 | 02 | F01U259190 Operation manual

Page 17

Connections

USB and RS-232 interface

These interfaces are used for servicing.

Audio interfaces

For the analog audio connection, use a symmetrical cable configuration (2 signal wires +

shielded braiding) with XLR socket. For connection purposes, 3-pole connectors are included

with the audio extension cards. Conductor cross-sections of 0.14 mm² (AWG26) to 1.5 mm²

(AWG16) can be used. Recommended connecting line: Symmetrical cable configuration with

flexible 2 x 0.14 mm² shielding. Although all analog inputs and outputs of the DPM 8016 can

also have asymmetrical configurations, a symmetrical audio connection cable is a better

alternative. With a symmetrical signal design, the shielding in the cable connects all metal

housings, which prevents external disruption signals from entering the audio signal path,

especially buzzing.

Interface to call stations (PCA BUS)

The PROMATRIX CAN Audio (PCA) BUS interface (of a UI-1 universal input module) connects a

DPC 8015 call station with the DPM 8016. This is an 8-pole RJ-45 connector that integrates

the power supply, control interface (CAN bus), and audio interface. The following image

shows the allocation of the PCA BUS jack and the corresponding RJ-45 connector.

Notice!

For CAN (4, 5), AUDIO IN (3, 6), and AUDIO OUT (7, 8), the leads must be twisted as pairs.

8: AUDIO OUT -

2: CAN_GND

4: CAN_H (+)

5: CAN_L (-)

1 8

7: AUDIO OUT +

1: +24V DC

3: AUDIO IN +

6: AUDIO IN -

Figure 6.1: Allocation of the PCA bus interface

Figure 6.2: Allocation of the PCA bus connector

For the PCA BUS interface, the same requirements apply for the used line (length, cross

section, etc.) as for the REMOTE CAN BUS interface (See Section REMOTE CAN BUS, page

19).

6

DPM 8016 Connections | en 17

Operation manual 16-Dec-13 | 02 | F01U259190

Page 18

Notice!

The terminating of the PCA BUS in the UI-1 universal input module is configured via IRIS-Net

during system configuration.

Power supply voltage

The DPM 8016 requires a DC 24 V voltage supply. The scope of delivery includes a 2-pole

connector. Conductor cross-sections of 0.2 mm² (AWG24) to 6 mm² (AWG10) can be used.

Recommended connecting cable: Flexible CU strand, LiY, 1.5 mm².

The maximum power consumed depends on the extension cards inserted into the DPM 8016

and any connected peripheral equipment (e.g., call stations). We recommend using a system

mains adapter from our catalog. The “Power Calculator” tool can be used to calculate the

overall power requirements of a DPM 8016 or a complete PROMATRIX system. The latest

version can be found in the Tools directory on the IRIS-Net CD, or you can request the tool

from our Support department.

Ethernet

Connecting the DPM 8016 system controller via the Ethernet interface allows the DPM 8016 to

communicate with one or more PCs. This not only allows simple configuration of the DPM

8016 using the delivered IRIS-Net software, but it also allows you to operate and monitor the

entire PROMATRIX 8000 system. Providing that you use the necessary network hardware, the

DPM 8016 can also be operated via a wireless network (WLAN). The Ethernet interface is

provided as an RJ-45 jack (8P8C). Both the 10Base-T and 100Base-TX Ethernet standards are

supported. For the Ethernet interface assignment, see the following diagram and table.

Figure 6.3: Ethernet interface assignment

Pin

Name Description Pair Cable color according to

T568A T568B

1 Tx+ Transmit+ 2 Green stripes Orange

stripes

2 Tx- Transmit- Green Orange

3 Rx+ Receive+ 3 Orange

stripes

Green stripes

6 Rx- Receive- Orange Green

Table 6.1: Ethernet interface assignment

6.1

6.2

18 en | Connections DPM 8016

16-Dec-13 | 02 | F01U259190 Operation manual

Page 19

The following diagram shows the assignment of the Ethernet connector. The diagram shows

the connector from the contact side.

Figure 6.4: Assignment of the Ethernet connector

In both Ethernet standards, the maximum length of a connected cable is 100 meters, with two

twisted wire pairs used in each cable. For 10Base-T, a category 3 cable (unshielded, CAT-3)

must be used, and for 100Base-TX, a category 5 cable (shielded, CAT-5) must be used. When

connecting the DPM 8016 using a patch cable in conjunction with a hub/switch, the cable

wiring must be one to one, i.e., the wire of the cable at pin 1 for one connector is connected

with pin 1 on the other connector; the same process applies to the other pins. The two

standards T568A and T568B are used for the colors of the cable wires, although standard

T568B is more widely used.

LED status lights

The Ethernet interface of the DPM 8016 controller has an orange and a green LED to display

the status of the Ethernet connection. If no network cable is connected, both LEDs remain

unlit. The orange connectivity LED on the left side of the Ethernet interface illuminates once

the DPM 8016 controller has established an Ethernet connection with another device (e.g.,

another DPM 8016 controller or an Ethernet switch). The green network traffic LED on the

right side of the Ethernet interface briefly illuminates each time Ethernet data is transferred.

Crossover cable

When using a crossover cable to connect a DPM 8016 controller with a PC directly, wire-pair 2

must be swapped with wire-pair 3. This creates the necessary switch of sending and receiving

lines; with a hub/switch, this exchange is performed internally.

REMOTE CAN BUS

The DPM 8016 controller has two RJ-45 jacks for the REMOTE CAN BUS. The jacks are

switched in parallel, and act as an input and for looping the remote network. Standard RJ-45

network cables can be used for cabling within the rack.

For longer cable lengths, observe the CAN guidelines. The CAN bus requires a 120 Ω

connecting jack at both ends. The CAN bus allows different data rates to be used, where the

data rate is indirectly proportional to the bus length. If the network has only a minimal extent,

data rates of up to 500 kbit/s are possible. In larger networks, the data rate will be decreased

(down to the minimum data rate of 10 kbit/s).

Notice!

The data rate is preset to 10 kbit/s.

The following table explains the relationship between data rates and bus lengths/network

size. Bus lengths of over 1000 meters should be implemented only with CAN repeaters.

Data rate (in kbit/s) Bus length (in meters)

500 100

250 250

6.3

DPM 8016 Connections | en 19

Operation manual 16-Dec-13 | 02 | F01U259190

Page 20

Data rate (in kbit/s) Bus length (in meters)

125 500

62.5 1000

20 2500

10 5000

Table 6.2: Data rate and bus length of the REMOTE CAN BUS

The following diagrams show the assignment of the CAN jack / CAN connector.

Figure 6.5: Assignment of the CAN jack

Figure 6.6: Assignment of the CAN connector

Pin

Designation Cable color

T568A T568B

2 CAN_GND Green Orange

4 CAN_H (+) Blue

5 CAN_L (-) Blue stripes

7 MONITOR BUS + Brown stripes

8 MONITOR BUS - Brown

Table 6.3: Assignment of the REMOTE CAN BUS interface

Cable specification

In accordance with the ISO 11898-2 standard, shielded or unshielded twisted pair cables with

an impedance of 120 Ω should preferably be used as the data transfer cable for the CAN bus.

Terminating resistance of 120 Ω must be provided at both ends as the line. The maximum bus

length depends on the data transmission rate, the type of data transmission cable, and the

number of bus participants.

20

en | Connections DPM 8016

16-Dec-13 | 02 | F01U259190 Operation manual

Page 21

Bus length (inm)Data transmission cable Connection

resistance (in

mΩ)

Maximum data

transmission

rate

Resistance per unit

(in mΩ/m)

Cable crosssection

0 to 40 < 70 0.25 to 0.34 mm²

AWG23, AWG22

124 1000 kbit/s at

40 m

40 to 300 < 60 0.34 to 0.6 mm²

AWG22, AWG20

127 500 kbit/s at

100 m

300 to 600 < 40 0.5 to 0.6 mm²

AWG20

150 to 300 100 kbit/s at

500 m

600 to 1000 < 26 0.75 to 0.8 mm²

AWG18

150 to 300 62.5 kbit/s at

1000 m

Table 6.4: Relationships for CAN networks with up to 64 participants

In the event of long cables and several devices on the CAN bus, terminating resistors with ohm

ratings higher than the specified 120 Ω are recommended in order to reduce the resistive load

for the interface drivers, which in turn reduces the voltage loss from one line end to another.

The following table allows an initial estimate to be made for the required cable cross-section

for different bus lengths and a different number of bus participants.

Bus length (in m)

Number of devices on the CAN Bus

32 64 100

100 0.25 mm² or AWG24 0.34 mm² or AWG22 0.34 mm² or AWG22

250 0.34 mm² or AWG22 0.5 mm² or AWG20 0.5 mm² or AWG20

500 0.75 mm² or AWG18 0.75 mm² or AWG18 1.0 mm² or AWG17

Table 6.5: REMOTE CAN BUS cable cross-section

If a participant cannot be directly connected to the CAN bus, a stub line (branch line) must be

used. Since there must always be precisely two terminating resistors on a CAN bus, a stub line

cannot be terminated. This creates reflections, which impair the rest of the bus. To minimize

these reflections, these stub lines should not exceed a maximum individual length of 2 meters

at data transmission rates of up to 125 kbit/s, or a maximum length of 0.3 meters at higher bit

rates. The overall length of all branch lines should not exceed 30 meters.

The following applies:

• Standard RJ-45 patch cables with 100 Ω impedance (AWG 24 / AWG 26) can be used for

short distances (up to 10 meters).

• The guidelines specified above for the network cabling must be used when wiring the

racks with each other and for the building installation.

STATUS LED

The STATUS LED is used to check communication across the REMOTE CAN BUS. If the CAN

interface is not in operation, the LED is deactivated. In normal operation, the LED flashes in 2second intervals. The duration for which the LED is illuminated within these 2-second cycles

corresponds to the bus load, i.e., at higher loads, the LED is illuminated for longer during the

2 seconds than at lower bus loads.

DPM 8016

Connections | en 21

Operation manual 16-Dec-13 | 02 | F01U259190

Page 22

Control port

The control port on the rear of the DPM 8016 controller is split into two halves. The upper half

has eight freely configurable control inputs, and a DCF77 receiver can also be connected. The

lower half has six freely configurable control outputs and a ready contact, and slave clocks can

also be connected. The scope of delivery includes two 12-pole connectors. Conductor crosssections of 0.14 mm² (AWG26) to 1.5 mm² (AWG16) can be used. Recommended connecting

cable: Flexible CU strand, LiY, 0.25 mm². The control port is configured in IRIS-Net.

Control inputs (CONTROL INPUTS 0-10V)

The upper half of the control port has eight freely programmable control inputs for voltages of

between 0 volts and 10 volts. The inputs are numbered 1 through 8. The DPM 8016 controller

provides its own voltage supply for externally connected control elements, e.g., a

potentiometer. The voltage supply is available at the control port connections for 10V REF and

ground; see the following diagram.

Figure 6.7: Sample application of a control input and use of an analog input signal

The control inputs can also be used as digital control inputs. Internally, the control inputs are

connected to ground via a resistor. If an input is created to the 10 V REF connection or

another, external voltage, the input switches to the active status (On).

!

Caution!

The maximum permissible voltage on a control input is 48 V.

6.4

22 en | Connections DPM 8016

16-Dec-13 | 02 | F01U259190 Operation manual

Page 23

Figure 6.8: Sample application of a control input and use of 2 digital inputs signals

Control outputs (CONTROL OUTPUTS)

The lower half of the control port has six freely programmable control outputs numbered 1

through 6. In inactive mode (Off), these control outputs are open, while in active mode (On),

they are closed to ground. To operate the externally connected elements, a voltage source is

available on the connection 24/48V/200mA; see also the following diagram.

Notice!

The voltage value used as the supply voltage for the DPM 8016 controller is always present on

the 24/48V output.

!

Caution!

The maximum permissible power on the 24/48V output is 200 mA.

Figure 6.9: Sample application of a control output

Ready contact (READY)

The lower half has a potential-free READY changeover contact. This changeover contact signals

to other devices that the DPM 8016 is ready for operation or indicates faults in the system.

The following table shows the possible statuses of the ready contact.

DPM 8016 Connections | en 23

Operation manual 16-Dec-13 | 02 | F01U259190

Page 24

Status Switch position Description

Ready for operation (=

ready)

The voltage supply is functioning,

the boot process of the device has

completed, and there are no faults

in the system. The relay has been

activated.

Not ready The voltage supply is off/interrupted

or the boot process of the device

has not yet completed, or there is a

fault in the system. The relay has

dropped/is without power.

Table 6.6: READY contact

The changeover contact position for the status “ready” is displayed on the device. The IRISNet software allows the user to configure the fault types for which the changeover contact

should switch over and signal the status “Not ready”. To integrate the DPM 8016 into the

hazard alert systems, a normally-closed contact (standby current principle) is recommended,

i.e., the left and middle pin.

!

Caution!

The maximum load of the ready contact is 30 V/1 amp.

Radio clock input (DCF77)

The top half of the control port has an input for the radio receiver of the DCF77 signal. We

recommend using the DYNACORD NRS 90193 receiver. Observe the delivered documentation

when connecting the receiver to the DPM 8016.

Slave clock output (SC OUT)

The lower half of the control port has a special, short-circuit-proof output for polarity switch

impulses. Slave clocks connected here are automatically adjusted if a time difference is

detected between the slave clocks and the system clock, for example after a power failure or

in the event of manual input. Ensure that all slave clocks are connected with the same polarity.

Notice!

The maximum permissible number of slave clocks on the SC OUT output depends on the

power consumption of the slave clock type used. Example: When using a slave clocks type

with a power consumption of 12 mA up to 80 slave clocks can be connected.

24 en | Connections DPM 8016

16-Dec-13 | 02 | F01U259190 Operation manual

Page 25

Configuration

IRIS-Net

IRIS-Net PC software (Intelligent Remote & Integrated Supervision) is used to configure and

operate the DPM 8016. It enables the overall configuration of the DPM 8016 to be performed

off-line using a PC (i.e., without establishing a connection between the PC and DPM 8016).

The configuration can then be transferred by establishing a connection between the PC and

DPM 8016 via Ethernet. In addition to configurations, IRIS-Net can also be used for

comprehensive checking and monitoring of a PROMATRIX 8000 system. For more information

about installing IRIS-Net on your PC, see the file “iris_readme.pdf”. During the installation, the

IRIS-Net user manual is automatically copied to the PC.

Set-up process

1. Install the extension cards. If you have acquired extension cards (e.g., UI-1, AO-1, CM-1,

PMX-MM-2) for your DPM 8016, install these. See the Section Installing extension cards,

page 25.

2. If extension cards with inputs or outputs (UI-1, AO-1 or CM-1) were installed in step 1,

connect the devices to be used. Follow the documentation for the extension cards and

the devices used.

3. Connect the Ethernet interface of the DPM 8016 controller with the PC via a suitable

Ethernet cable. See the Section Ethernet, page 18.

4. If your application includes CAN devices such as DPA amplifiers or a DCS system, connect

the REMOTE CAN BUS interface of the DPM 8016 with the CAN devices. See the Section

REMOTE CAN BUS, page 19.

5. Connect the voltage supply of the DPM 8016.

6. Activate the voltage supply of the DPM 8016, and activate the additional connected

devices if applicable.

7. Install the IRIS-Net (Intelligent Remote & Integrated Supervision) program on the PC. See

the installation instructions for IRIS-Net in the file iris_readme.pdf.

8. Start IRIS-Net on your PC.

Installing extension cards

This chapter describes the options for expanding the DPM 8016 with extension cards. The

DPM 8016 can be assigned extension cards in various ways:

• 8 slots (extension slots) for enhancing the system with analog audio inputs (UI-1), analog

audio outputs (AO-1) or one message manager (PMX-MM-2)

• 1 network module slot for installing an audio network module (e.g., CM-1 CobraNet

module)

!

Caution!

The DPM 8016 must always be isolated from the supply voltage if you intend to install a

module. For precise installation instructions, see the description of the respective module.

Extension slots

Eight slots, which are numbered 1 through 8, are available on the rear panel of the DPM 8016

for extending the system. These slots allow any combination of extension cards of the

following types:

• DPM UI-1 universal input module with 2 analog audio inputs

• DPM AO-1 analog output module with 2 analog audio outputs

• PMX-MM-2 message manager module

7

7.1

DPM 8016 Configuration | en 25

Operation manual 16-Dec-13 | 02 | F01U259190

Page 26

Notice!

Only one PMX-MM-2 can be used in the DPM 8016.

Any of these slots can be used to install the extension cards; once they are installed, they are

automatically recognized by the DPM 8016.

Figure 7.1: Installation of an audio extension card

Network module slot

The network module slot on the rear panel of the DPM 8016 can be used to retrofit an audio

network interface to a CobraNet network. The CM-1 module used here has two Ethernet

connections to set up a redundant network.

Network configuration

The DPM 8016 can be connected to a TCP/IP network via the Ethernet interface on the rear

panel. For information regarding the basics of Ethernet and TCP/IP, see the Appendix, page

35 to this document. The DPM 8016 has the following network configuration by default:

Parameter Value

IP address 192.168.1.100

Subnet mask 255.255.255.0

Gateway 192.168.1.1

DHCP Disabled

Table 7.1: Factory setting for Ethernet interface

An IP address must be unique, i.e., it must only be assigned to one device (host) in a network.

If a new Ethernet is established for operating the DPM 8016, we recommend retaining the

default network ID and subnet mask. When integrating the DPM 8016 into an existing

Ethernet, the network configuration of the DPM 8016 must be adjusted. The default IP

address of the DPM 8016 can be retained if

• only one single DPM 8016 is connected with the default network configuration via

Ethernet, and

7.2

26 en | Configuration DPM 8016

16-Dec-13 | 02 | F01U259190 Operation manual

Page 27

• the network ID 192.168.1 can be retained, and

• no other device has the host ID 100.

If at least one of these three conditions is not met, the default IP address of the DPM 8016

must be changed.

Example:

The following diagram shows a sample application with four DPM 8016 controllers in a

connected Ethernet. These are connected to a PC via a central Ethernet switch. This means

the default IP address 192.168.1.100 would occur several times in the network. The default IP

addresses of at least three DPM 8016 controllers must therefore be changed to create unique

addresses for the devices in the network.

Figure 7.2: IP addresses of several DPM 8016 controllers

To change the default IP addresses of the DPM 8016 controller, it is helpful to create a list of

all devices and IP addresses used in the Ethernet connection. An example of such a list for the

system described in the above diagram is given below. The Appendix contains a blank form.

For each device used in the network, enter the name of the device, a unique description, and

the IP address to be assigned. If the device is shown in IRIS-Net, you can enter the description

used here in the table.

Device

Name in IRIS-Net Location/Description IP address

DPM 8016 Head office Head office 2.C03 192.168.1.100

PC - Head office 2.C03 192.168.1.1

DPM 8016 Administration Administration

building

192.168.1.101

DPM 8016 Production Production building 192.168.1.102

DPM 8016 Multipurpose Multipurpose hall 192.168.1.103

When commissioning this sample system, the IP addresses specified in the overview table

would have to be assigned to the individual devices. The IP address is changed via IRIS-Net

and the connection is established via the Ethernet interface of the DPM 8016 controller. For

information about the precise procedure, see the online help in IRIS-Net.

DPM 8016

Configuration | en 27

Operation manual 16-Dec-13 | 02 | F01U259190

Page 28

Operation

To operate the DPM 8016, see the IRIS-Net documentation.

8

28 en | Operation DPM 8016

16-Dec-13 | 02 | F01U259190 Operation manual

Page 29

Maintenance

The DPM 8016 does not require any maintenance.

9

DPM 8016 Maintenance | en 29

Operation manual 16-Dec-13 | 02 | F01U259190

Page 30

Technical data

DPM 8016 System Controller Modular PROMATRIX 8000 controller including signal

processing, routing, system control and supervision

Audio 16 audio channels

8 audio slots, modular

2-channel input and output cards

Networking Module slot for optional CobraNet interface

16 I/O audio

Safety/redundancy Internal supervision, system monitoring, watchdog, fault

output

Redundant audio network possible

PC configuration and control

software

IRIS-Net - Intelligent Remote & Integrated Supervision

Integration of DPM 8016, amplifiers, call stations, and

peripheral control

Configuration, control, and supervision for complete

audio systems

Programmable user control panels and access levels

Audio input specifications See technical specifications of used input module

Audio output specifications See technical specifications of used output module

Frequency response 20 Hz to 20 kHz (-0.5 dB)

Signal to noise ratio (A-weighted) DPM 8016 analog in to analog out: 106 dB typical

THD+N < 0.01%

Crosstalk < 100 dB @ 1 kHz

Sample rate 48 kHz

DSP processing resolution 24 bit linear A/D and D/A conversion, 48 bit processing

Signal processing 3 DSPs (480 MIPS) internal, DSP extension module

optional

Ethernet 10 / 100 MB, RJ-45 (PC control)

CAN 10 to 500 kbit/s, 2 x RJ-45 (remote amp control)

RS-232 2 ports, 9 pin DSUB female (remote control)

USB USB type B on front panel (PC control)

10

30 en | Technical data DPM 8016

16-Dec-13 | 02 | F01U259190 Operation manual

Page 31

Control port 2 x 12-pole connector

1 slave clock output (max. 1 A)

1 time sync input (DCF-77 standard, for receiver NRS

90193)

8 control inputs (analog 0-10 V / logic control)

6 control outputs (open collector, max. 60 V/1 A)

1 ready/fault output (NO/NC relay contacts, max. 30 V/1

A)

3 reference outputs (+10V, 100 mA / +24V, 200 mA /

GND)

Power supply +24 V DC (wide range tolerance: 18 V to 58 V DC)

Power consumption 6 to 550 W (depending on installed modules and

periphery)

Supply current See table below

Cooling Fan, left-to-right

Operating temperature range -5 °C to +45 °C (-40°F to +158°F)

Electromagnetic environment E1, E2, E3

Dimensions (W x H x D) 19”, 2 HU, 483 x 88 x 376 mm

Weight DPM 8016 (without optional modules): 7.25 kg

DPM UI-1 Universal Input Module: 100 g

DPM AO-1 Analog Output Module: 100 g

PMX-MM-2 Message Manager Module: 85 g

CM-1 CobraNet Module: 75 g

DPM Universal Input Module DPM UI-1 (part number: PDC-121856), 2 analog audio

inputs, 1 x mic/line level, 1 x line level, electronically

symmetric, 1 PCA input

DPM Analog Output Module DPM AO-1 (part number: PDC-121857), 2 analog audio

outputs, line level, electronically symmetric

Message Manager Module PMX-MM-2 (part number: PMX-MM-2), two playback

channels, up to 32 two minute records in CD quality

CobraNet Module CM-1 (part number: D170327), 16 digital audio inputs

and outputs, 2 CobraNet ports (primary/secondary) for

network redundancy

Power consumption

DPM 8016 DPM UI-1 DPM AO-1 PMX-MM-2 CM-1

Standby 0.165 A 0.050 A 0.050 A 0.060 A 0.170 A

Idle (no

audio)

0.165 A 0.080 A 0.050 A 0.060 A 0.170 A

10.1

DPM 8016 Technical data | en 31

Operation manual 16-Dec-13 | 02 | F01U259190

Page 32

DPM 8016 DPM UI-1 DPM AO-1 PMX-MM-2 CM-1

Normal mode

(-10 dB)

0.300 A 0.080 A 0.050 A 0.060 A 0.170 A

Alert (alarm)

mode (-3 dB)

0.300 A 0.080 A 0.050 A 0.060 A 0.170 A

Table 10.1: DPM 8016 power consumption at 24 V DC

Power consumption of call stations

For each DPC 8015 call station: 0.080 A (with active loudspeaker: 0.190 A)

For each DPC 8120 call station extension: 0.020 A

32 en | Technical data DPM 8016

16-Dec-13 | 02 | F01U259190 Operation manual

Page 33

Block diagram

SIGNAL

PROCESSING

CLOCK

CIRCUIT

12.288 MHz

FLASH

(16 MByte)

SDRAM

(32 MByte)

DC

POWER

SUPPLY

REAL TIME

CLOCK &

Watchdog

AUDIO

SLOT 1

2 Ch.

In / Out

GPIO

8 Analog Inputs

6 Logic Outputs

FRONT PANEL

Display / Control

Clocks

MCLK, WCLK, BCLK

FRAM

(64 Kbyte)

RS-232

Port 1

RS-232

Port 2

USB Device

Interface

Ethernet

Transceiver

RJ-45

USB-Controller

Ethernet-Controller

UART2

UART1

SPI

Watchdog

HOST CPU

SYSTEM

USB Port

(Typ B)

9-pin D-SUB

Internal

Expansion

Slot

CAN

Host Bus

Audio Out (16 Channels)

Audio In (16 Channels)

9-pin D-SUB

AUDIO NETWORK

PORT

2 x 12-pin

Phoenix

Remote CAN

Interface

2 x RJ-45

AUDIO

MODULES

2 - 8 Channels

Analog I/O

Digital I/O

AUDIO NETWORK

MODULES

16 Inputs / 16 Outputs

SPI Bus

24 V / 48 V =

DCF77

Slave Clocks

Ready/Fault Out

I/O

D

A

AUDIO

SLOT 2

2 Ch.

In / Out

AUDIO

SLOT 3

2 Ch.

In / Out

AUDIO

SLOT 4

2 Ch.

In / Out

AUDIO

SLOT 5

2 / 8 Ch.

In / Out

AUDIO

SLOT 6

2 / 8 Ch.

In / Out

AUDIO

SLOT 7

2 / 8 Ch.

In / Out

AUDIO

SLOT 8

2 / 8 Ch.

In / Out

Audio

Monitoring

Monitor Bus

16 Channels

16 Channels

10.2

DPM 8016 Technical data | en 33

Operation manual 16-Dec-13 | 02 | F01U259190

Page 34

Dimensions

Standards

The DPM 8016 meets the following standards (correct as of July 2012):

• EN 54-16

• EN 55103-1

• EN 55103-2

• EN 55022

• EN 55024

• EN 60945

10.3

10.4

34 en | Technical data DPM 8016

16-Dec-13 | 02 | F01U259190 Operation manual

Page 35

Appendix

Ethernet basics

The DPM 8016 system controller can be connected to an Ethernet connection via the Ethernet

interface (RJ-45) on the rear panel. Ethernet is a computer networking technology for local

networks. If two devices (hosts) are to be connected, they can be connected via a crossed

Ethernet cable (crossover cable). If more than two devices are to be connected, they are

connected via a normal Ethernet cable (patch cable) and a central node (hub or switch). The

central node has one connection (port) for each participant on the network. The Ethernet

interface of the DPM 8016 is compatible with the following Ethernet standards:

• 10Base-T (IEEE 802.3i): With this standard, four wires (two twisted pairs) of a CAT-3 or

CAT-5 cable are used for the connection. The transfer rate is 10 Mbit/s, and the maximum

length of a segment is 100 meters.

• 100Base-TX (IEEE 802.3u): As with 10Base-T, two twisted cable pairs are used, but a

CAT-5 cable must be used. 100Base-TX with a transfer rate of 100 Mbit/s is the standard

Ethernet implementation.

IP address

Different network protocols can be used for communication between the devices connected

to the Ethernet. The DPM 8016 uses the TCP/IP protocol, which means this is an IP network.

In an IP network, IP addresses are used for the logical address assignment of devices. The

DPM 8016 uses version IPv4 (Internet Protocol Version 4) for address assignment, which

means an IP address is 32 bits (= 4 bytes) long. Using this system, around 4.3 billion unique

addresses are possible in theory. IPv4 addresses are usually represented using dotted decimal

notation, i.e., the four bytes are written as four decimal numbers separated by decimal points.

The general format of an IPv4 address is therefore AAA.BBB.CCC.DDD, for example

130.009.122.195. Leading zeros can also be omitted, so that the above example can also be

written as 130.9.122.195. The following table shows address ranges that should be used in

private networks. Private IP addresses are particularly useful in networks that are connected

to the Internet. Private IP addresses are not routed in the Internet, which means that an

address conversion with NAT (Network Address Translation) or PAT (Port Address Translation

= NAT and additional change of the port number) is necessary to access the Internet. This

means that several devices can be connected to the Internet via a router even if only one IP

address has been assigned by the Internet provider. It also means that the real IP addresses of

the devices can be hidden from hackers by NAT/PAT (security through obscurity).

Subnet mask

An IP address is always subdivided into a network element (network address/ID) and a host

element (host address/ID or device address). Devices are in the same IP network if the

network elements of their addresses are identical. If devices are in the same IP network, they

can communicate with each other directly. In order for devices in different networks to

communicate, additional equipment (such as a router) is required. Host addresses may not be

duplicated within a network. For example, a network could split the 4 bytes (32 bits) of an IP

address into a 3 byte network element and a 1 byte host element. The precise split between

the network element and host element is given in the form of a subnet mask. In this case, the

subnet mask 255.255.255.0 would mean the IP address was split into the first 24 bits or last 8

bits. The CIDR notation for displaying a subnet mask was an alternative to dotted decimal

notation. In CIDR notation, suffixes are used. The suffix specifies the number of 1-bits in the

subnet mask. The subnet mask 255.255.255.0 in dotted decimal notation would therefore

11

11.1

DPM 8016 Appendix | en 35

Operation manual 16-Dec-13 | 02 | F01U259190

Page 36

correspond to the suffix /24, because with the subnet mask 255.255.255.0, the first 24 places

of an IP address are selected as the network address (binary format). The choice of subnet

mask and the resulting different split of the IP address into network element and host element

have an effect on the maximum number of addressable devices within a network. For the

specific number, however, the host element must neither be composed entirely of zeros or

entirely of ones in binary form.

Example:

In the example IP address of 130.9.122.195 with a subnet mask of 255.255.255.0 given above,

the network element would be 130.9.122.0. Each device (or interface) in the network would

therefore use an IP address of 130.9.122.DDD. Since it is not possible to use the binary values

00000000 or 11111111 for the host element DDD, the decimal values 1 through 254 are

permissible for DDD. This means that a maximum of 254 different devices are addressable in

the network, with possible IP addresses from 130.9.122.1 through 130.9.122.254.

36 en | Appendix DPM 8016

16-Dec-13 | 02 | F01U259190 Operation manual

Page 37

Table of IP addresses

Project: ________________________________________

Subnet mask Gateway

Device Name in IRIS-Net Location/Description IP address

11.2

DPM 8016 Appendix | en 37

Operation manual 16-Dec-13 | 02 | F01U259190

Page 38

Page 39

Page 40

Bosch Sicherheitssysteme GmbH

Robert-Bosch-Ring 5

85630 Grasbrunn

Germany

www.dynacord.com

© Bosch Sicherheitssysteme GmbH, 2013

Loading...

Loading...