Page 1

Bulletin E-90-DL8

Series DL8 Process Data Logger

Specifications - Installation and Operating Instructions

Temperature

Sensor

GENERAL

Eliminate traditional paper chart recorders with the Series

DL8 Process Data Logger. This versatile, mulit-channel data

logger monitors and stores up to 32,768 process readings

for later download to IBM compatible computers. Seven

external input channels easily interface with commom

transducer and transmitter outputs. Internal thermistor

measures ambient temperature conditions. The DL200

Windows

(sold separately) makes programming the data logger simple and easy. The Series DL8 Process Data Logger is ideal

for monitoring temperature, relative humidity, pressure,

wind speed, current, voltage and power.

GENERAL INSTALLATION (for all DL Loggers)

The Trendreader software must be installed on your computer prior to the use of any data logger described in this

reference.

NOTE: For additional information on graph manipulation,

custom equations, modern setup, and sample rate tables,

consult the Trendreader software manual.

™

(Trendreader) software and connecting cable

Input Jack for Interface Cable

PHYSICAL DATA

No. of Channels: Eight; One

for internal thermistor and

seven for external analog

inputs.

Accuracy: ±1% of full scale.

Internal Thermistor Range:

-40 to 158°F (-40 to 70°C).

Memory Size: 32,768 readings.

Sampling Methods:

Continuous (First-in, First-out)

or Stop when full (Fill-thenstop).

Sampling Rates: Selectable

from 8 seconds to once every

5 days.

Resolution: 8 bits (1 in 256).

Power: Built-in 3.6V Lithium

battery.

Power Consumption: 5-10

µA.

Clock Accuracy: ±8 seconds per day plus one sampling interval.

Security

Eyelet

2.95

[75]

0.656

[17]

Input Impedance:

0 to 200 mV: > 20MΩ.

0 to 2.5 V: > 20MΩ

0 to 5.0 V: 20KΩ

0 to 10.0 V: 40.9KΩ

0 to 25 mA: 100Ω

Maximum Input Voltage: All

Voltage channels: ±40 V,

reverse polarity protected. All

Current channels: ±7 V,

reverse polarity protected.

Ambient Operating Temp:

-50 to 160°F (-45 to 70°C), 0

to 95% RH, non-condensing.

Connection: Removable

screw terminal.

Computer Requirements:

IBM compatible 386 or above

and Windows

with 2 mB RAM and 2 mB

hard drive disk space, one serial port.

Housing: Noryl

Weight: 5 oz. (110 g).

3.375

[9.5]

™

3.1 or later

™

Magnetic

Strip

0.45

[12]

Setup

To setup your datalogger you must first have Trendreader

software installed and running on your computer. You can

then configure your logger with various options by plugging

into your computer via the interface cable. From the

Communicate menu, choose Preferred Logger SR+. To

access the logger window, double click on the logger icon

or click Communicate on the menu bar and choose the

highlighted Open COM from the menu.

DWYER INSTRUMENTS, INC.

P.O. Box 373 • Michigan City, IN 46361-0373, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

SERIES DL8 PROCESS DATA LOGGER MODELS & EQNS

Model No.

DL8

DL81

Input Type

0 to 2.5 VDC

0 to5 VDC (2 channels)

0 to 10 VDC

0 to 200 mV DC

0 to 25 mA DC (2 channels)

All channels 0 to 25 mA.

Equation #

7

18

17

19

6

6

Table 1

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

If more than one logger icon appears on the screen or more

than one Open COM is highlighted on the Communicate

menu, this means you have more than one COM port available on your computer. Choose the port that the particular

logger is connected to.

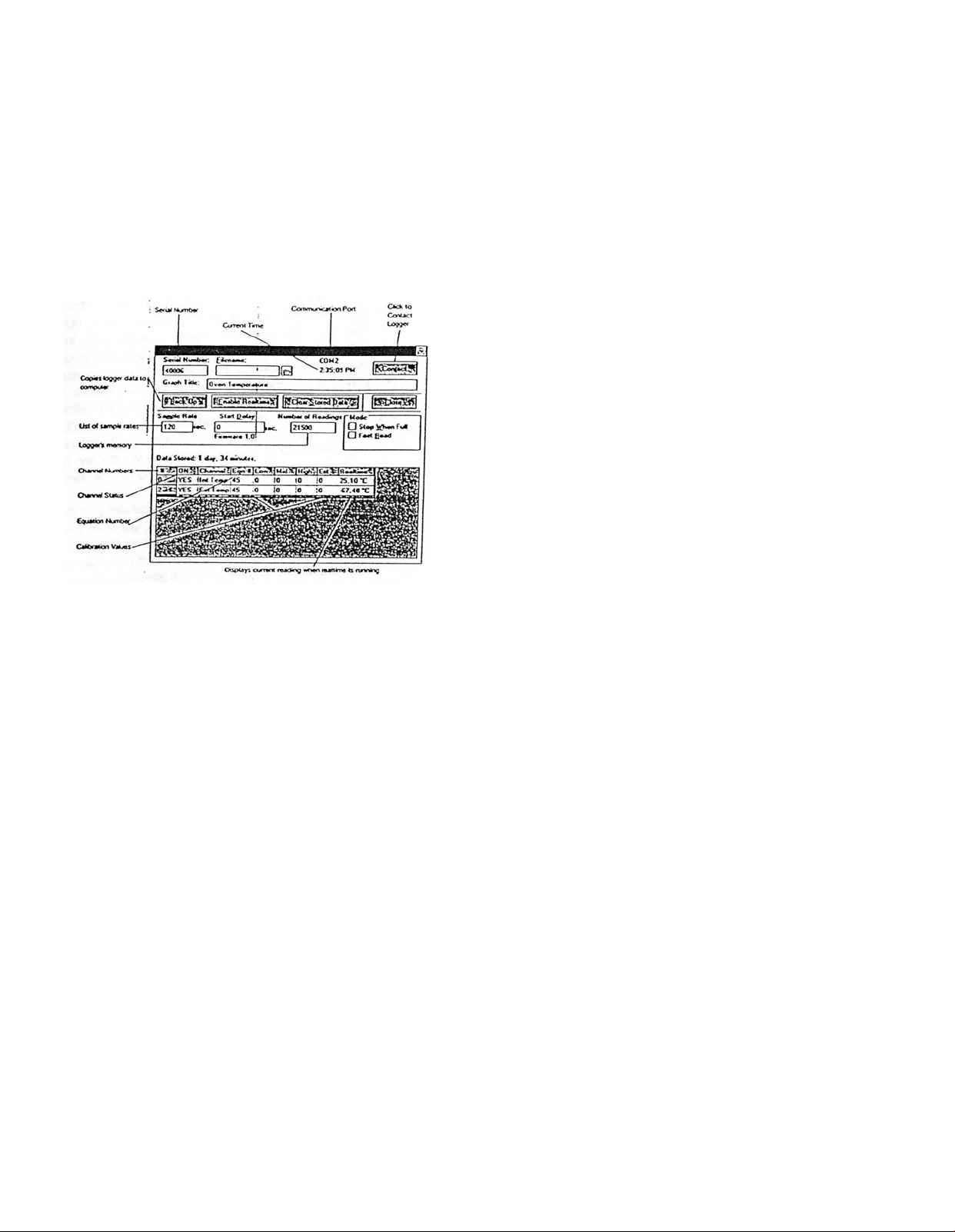

The logger window will display the serial number of the logger Trendreader software is communicating with. See

Figure 1. To contact another logger connected to the compute. 1. Double-click the serial number displayed to highlight it. 2. Type the serial number of the logger you want to

contact. 3. Click the Contact button.

Enabling and Disabling Channels

Enabling a channel activates that channel and it will continually record and store readings in memory. In the channel

ON column, Yes means the channel is active, No means it

is not. Click on the channel being changed to toggle

between yes and no. Disable any channels not required to

conserve memory space.

Equation Numbers

Equations are calculations the software uses to convert raw

logger data to understandable units. Refer to page one

(Table 1) for the appropriate equation number.

To see a list of standard equations available, double click

one of the equation numbers in the Eqn column. The Select

an Equation dialog box will appear, enabling you to scroll

through the standard equations. If you want to choose one

of the equations on the list, click it to highlight, and click

Accept (or Enter). You can also choose an equation by typing the number in the selected Equation Number box and

clicking Accept (or Enter).

Custom equations can be created and assigned to specific

logger channels. For additional information on creating custom equations, please refer to the instruction manual included with the Trendreader software.

Figure 1

Filename

You cannot name the file during setup. Name the file when

you are backing up the logger.

Current Time

Make sure the current time is correct. To change the time,

access the Program manager on your computer and follow

instructions in your computer setup manual.

Stop When Full and Continuous Mode

The logger can be set to stop taking readings when the

memory is full, or to continue to take readings when the

memory is full. To choose the first option, click the box in

front of Stop When Full so that there is an “X” in it. To

choose the continuous mode, click the box in front of Stop

When Full so there is no “X” in it. The logger will continue to

take readings when the memory is full, discarding the oldest reading as it records new readings.

Stopping Realtime

When the logger window is opened, the logger is operating

in realtime mode, which means current readings are being

displayed in the window. Before changing any settings, click

Edit Setup.

Clearing Stored Data

To empty stored data, click Clear Stored Data.

Calibrations

The calibration values displayed in the low, med, high

columns are factory set and match the sensor applied.

Viewing Realtime Readings

The realtime function allows the user to view measurements

as they are being recorded. Viewing current readings can

be useful when monitoring remote loggers by modem. In

realtime mode, the logger reads and displays the variable

every 8 seconds. If the sample rate is greater than 8-seconds, the average value for the sample interval is stored

(based on 8-second readings).

Do not leave realtime running if you want to perform other

tasks in Trendreader or if you want to switch to another

Windows™application. The operation of Trendreader of

other Windows™program will be slowed considerably with

realtime running. To stop or start realtime, click the Edit

Setup button. Stopping realtime has no effect on the logger’s information gathering.

Units of Measure

The units of measure can be changed to fit your particular

needs. To change the units displayed in Realtime and on the

logged data choose the Options menu, highlight the parameter being measured. The units appropriate for that particular parameter will be displayed in the units window.

Select the box corresponding to the desired units of measure and press Enter.

Page 3

When viewing in realtime, the new units will be displayed at

the next update interval. The standard unit of measure will

be designated with a 1 in the Scale column. When selecting a different unit of measure, make sure the conversion

from the standard is correct.

Choosing a Sample Rate

The sample rate is the frequency that the logger takes readings. The current sample rate is always displayed. to

change the sample rate: 1. Click the current rate. The sample rate dialog box appears. The dialog box displays current

sample rate, the number of active channels, and the length

of time it will take to fill the memory using the number of

active channels and rate. (To determine the loggers capacity, enable the number of channels required before choosing

a sample rate). 2. Click the down arrow to see available

sample rates from 8 seconds to 8 hours in Continuous and

Stop When Full modes. Scroll if necessary, and click on the

desired rate. In Fast Read mode, sample rates less than 8

seconds are available. 3. Click Accept. The new sample

rate will apply to all active channels. If you do not want to

change the sample rate, click cancel.

Delaying Starting Time

Make sure the correct time is displayed in the logger window before using this function. Once the logger has been

setup, click Save Setup, and the logger will start gathering

data. To delay the start time: 1. Double click in the Start

Delay box to open the Select a Time dialog box. 2. Set the

time and/or date for the logger to start taking readings. 3.

Click Accept. The logger can be set for a delayed start time

of up to two years.

Number of Readings

The maximum number of readings the DL8 logger can store

is 32,768. If fewer readings are desired, change the number

(in increments of 500).

Fast Read Mode

Choose Fast Read Mode when:

1. You need a sample rate of less than 8-seconds, and /or

2. You want to delay the logger’s start time but do not want

to specify the start time until after the logger has been

setup.

Fast Read Mode allows you to choose sample rates from

0.04 seconds (25 readings per second) to 2 minutes. The

sample rate must be in increments of 0.04 seconds. NOTE:

A separate power source is required when using Fast Read

Mode. Power can be supplied from the computer the logger is connected to or a separate battery pack (BP-100). If

using the battery pack, the logger will start taking reading as

soon as the battery is connected.

The logger cannot work in continuous Mode when using

Fast Read Mode. The logger will stop taking readings as

soon as the memory is full. The logger will also interrupt

readings when it is connected to Trendreader software.

To delay start in Fast Read Mode:

1. Set the delay time in seconds in the Start Delay box. Use

this method when the logger will remain connected to a

computer or battery pack.

2. If the battery pack will be connected at a later time, follow this procedure before disconnecting the logger from the

computer: Before clicking Save Setup, set that Delay for

long enough that you can save the setup and disconnect

the logger while it is asleep. The logger must be asleep (on

start delay) when it is disconnected to be able to start taking readings when the battery is connected to it. NOTE: You

must set a minimum start delay of 16 seconds before you

disconnect the logger from the computer. the logger must

be disconnected from the computer within 8-seconds of

setting the delay. If these steps are omitted, the logger will

not start when the battery is connected.

To calculate the number of readings a particular time span

will need, divide the time span by the sample rate (making

sure both are in seconds or minutes). If you are taking readings at 8-second intervals for 24-hours, and need to know

the number of readings, convert 24-hours to seconds

(86400) and divide by the sample rate of 8-seconds to get

10,800 readings. When backing up the logger, it will stop at

the specified number of readings.

Saving Changes

When you have finished setting up your logger, click Save

Setup. A dialog box will appear asking to clear the logger

and save setup. (Setting up a logger erases all the previously gathered data). Click OK.

Do not contact a logger in Fast Read Mode until you are

going to back it up. Contacting the logger will stop it from

taking readings. You can contact a logger by clicking

Contact or by opening the window once it has been closed.

BACKING UP A LOGGER

Copying data from a logger to your computer requires an

IC-100 or IC-200 Interface cable. to backup a single logger

use the IC-100 Interface Module. The IC-200 Interface

Module can be used to backup several loggers. Backing up

a logger can take a number of minutes depending on the

speed of your computer and the amount of data being

transferred.

Page 4

The process can be speed up by selecting the Set Baud

rate, Fastest Available from the Communicate menu. (If you

have problems backing up a logger, try a slower baud rate.

On some computers, choosing the fastest available baud

rate causes timing conflicts. NOTE: The IC-200 module

automatically transmits at 1200 baud and cannot be adjusted.

Backing Up a Logger

From the Communicate menu, choose Preferred Logger

SR+. To access the logger window, double click on the logger icon or click Communicate on the menu bar and choose

the highlighted Open COM from the menu. To backup a logger, click Backup in the logger window. A dialog box

appears showing the baud rate, the serial number of the

logger, and the progress of the backup. (You may cancel

the backup procedure by clicking Cancel).

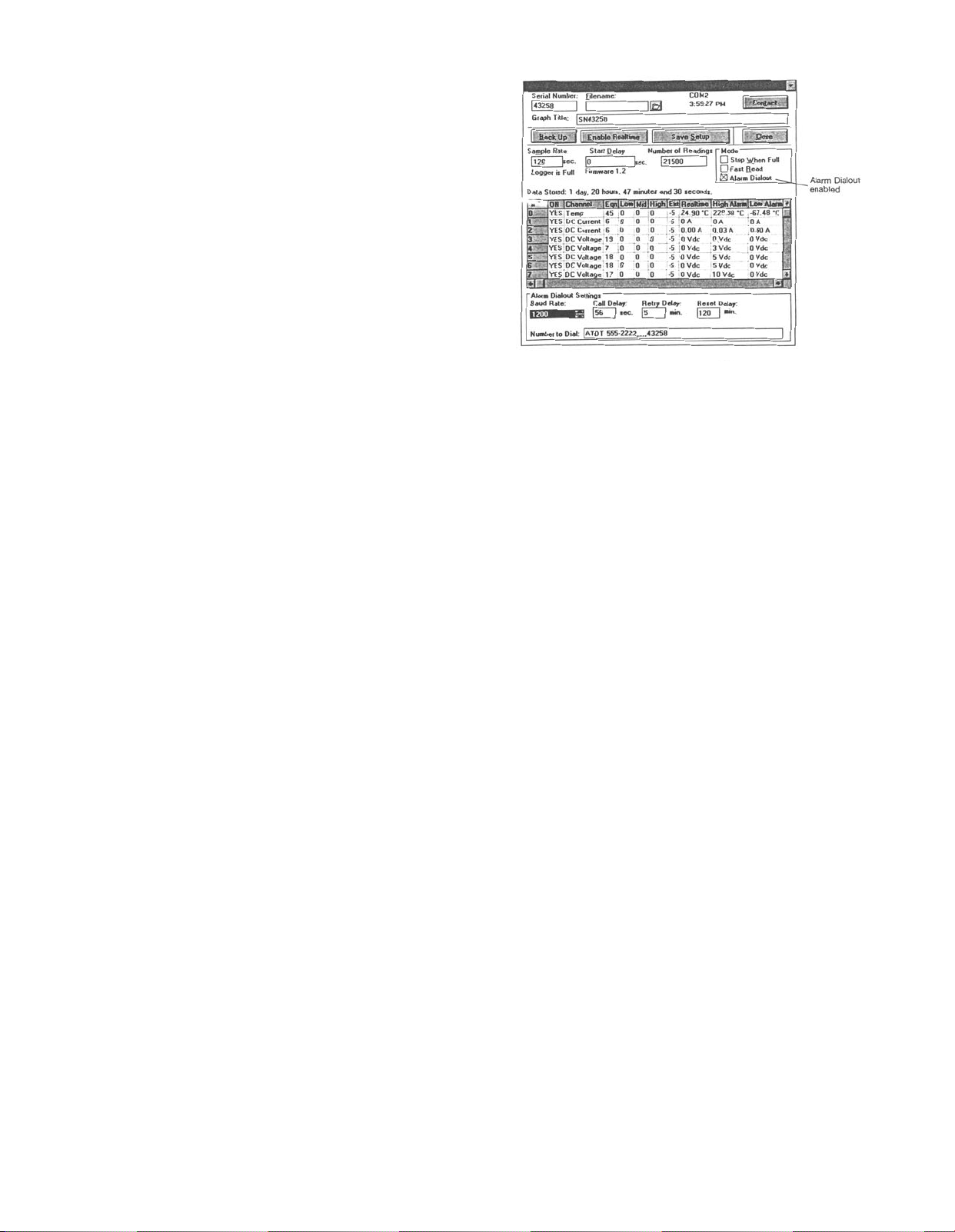

Figure 2

Opening a Graph after Backup

If you want to view the transferred information as a graph

immediately after backup, open the Options menu in the

main window and make sure a check mark is in front of

Open Graph after Backup. NOTE: See the Trendreader software manual for details on manipulating graphs.

Naming a File

When backup is completed, the Save As dialog box

appears to enable you to name the file. The default name is

always the serial number of the logger. If you want to keep

the logger’s serial number as the filename, click OK. If you

want to give the file a different name, type the new name

and click OK. NOTE: You cannot type anything after the dot

in the Trendreader filename. The three letter extension, is

automatically assigned.

Backing Up Additional Loggers

You can daisy-chain the DL8 loggers together and back

them up one by one. You may want to disable the opening

a graph after backup function when you are backing up

several loggers. If this function is not disabled, a graph will

be opened after backing up each logger, increasing the total

backup time. To disable this function, open the Options

menu and make sure there is no check mark in front of

Open Graph After Backup.

Alarm Dialout is enabled by setting high and low alarm

thresholds, entering the number that is to receive the alarm

call, and sending the setup to the logger. When an alarm

condition occurs, the logger will dial out and leave the

remote site number on the receiver’s telephone caller ID or

on the pager’s display. (Alarm Dialout does not leave a verbal message). To activate Alarm dialout, click Alarm Dialout

in the logger window so that there is a check in the Alarm

Dialout box. A dialog box will appear at the bottom of the

window. See Figure 2.

Setting High and Low Alarm Thresholds

Set high and low alarm thresholds for each active channel

on the logger. Any reading lower than the low alarm threshold or higher than the high alarm threshold will cause the

logger to dial out from the remote site. Set the high alarm to

the highest possible value and low alarm to the lowest possible value if you do not want the alarm activated on that

channel.

Choosing a Baud Rate

Baud rate is a measure of the transmission speed of the dial

commands that the logger sends to the modem. The

default baud rate is 1200, which is reliable and accurate for

most situations. Higher baud rates are available in the baud

rate box.

ALARM DIALOUT

Alarm Dialout enables you to setup the logger at a remote

site so that it will dial a phone number when readings have

exceeded preset alarm thresholds. It can be setup to dial a

telephone or pager. The receiving telephone requires caller

ID to use this feature.

If sending the alarm to a pager, the pager system must

accept touch-tone codes that can be displayed on the

pager.

Entering the Number to Dial

A. Calling a telephone: Remember the telephone must

have caller ID to receive the alarm.

1. Type a dial command in the Number to Dial box.

If the phone line at the remote site has tone dial, type ATDT.

If pulse dial, type ATDP.

2. After the dial command, type the number of the

telephone that is to receive the alarm call.

Page 5

B. Calling a pager: The pager system must accept

touch-tone codes that can be displayed on the pager.

1. Type the dial command ATDT in the Number to

Dial box.

2. After the dial command, type the number of the

pager that is to receive the alarm call.

3. After the pager number and before the identifying code there must be a pause to allow the receiving station to answer. Enter this pause by typing commas. (For

most modems, each comma causes a pause of two seconds).

4. Type a code that will identify the logger. For

example: ATDT 555-2222,,,,,40167, would instruct the logger to dial the pager number and pause for ten seconds,

and then send the serial number of the logger.

Setting Call Delay

Call delay is the length of time that a logger will wait before

dialing out once an alarm condition has occurred. If you do

not want the remote logger to dial out immediately when

one or more of the channels goes into alarm condition, you

can set the Call delay to designate the number of seconds

the logger will wait before dialing.

If the alarm condition does not exist for the entire delay period, the logger will not dial out. If the logger comes out of an

alarm condition during the call delay period, the delay timer

will stop and will start again from zero at the next alarm

event.

Setting Retry Delay

If a remote logger dials out an alarm but cannot get through

(line is busy), it will continue to dial out until connection is

made. Retry delay is the length of time the logger will wait

between unsuccessful attempts. It is recommended to set

the retry dial to 5 minutes. The logger will continue to dial

out after every retry delay time and as long as the alarm

condition exists and has not been acknowledged.

Setting Reset Delay

Reset Delay begins when you acknowledge the alarm by

backing up the logger that has dialed out. Reset Delay

deactivates Alarm Dialout to give time to fix the problem that

caused the alarm. When Reset Delay period has elapsed,

Alarm Dialout will reactivate, and if an alarm condition exists,

the logger will dial out again.

IMPORTANT: If an alarm condition occurs and Reset Delay

has been initiated by the last backup, the logger will wait

until the Reset Delay period is over before dialing out. To

bypass the Reset Delay period (if you have fixed the alarm

problem but time remains on the Reset Delay), click the

Clear Stored Data button and follow the subsequent

prompts.

Sending the Setup to the Logger

After choosing Alarm Dialout settings, setup logger by clicking the Save Setup/Clear Stored Data button and follow the

subsequent prompts.

Responding to Alarm Call

1. When the logger dials out to warn of alarm condition, dial

into the site and backup the logger.

2. Fix the problem that caused the alarm.

3. Reactivate Alarm Dialout by contacting the logger and

clicking Clear Stored Data.

NOTE: Test Alarm Dialout regularly to ensure proper operation.

Fast Read Mode Disabled

Alarm Dialout is not designed to operate in Fast Read

Mode. When Alarm Dialout is enabled, fast Read Mode is

disabled; when Fast Read Mode is enabled, Alarm Dialout

is disabled.

Cold or Humid Environments

The environment the logger will be placed in must be suitable, please refer to the physical data section. If conditions

are not acceptable, consider using a protective enclosure.

For humid environments, the logger can be protected by

placing it in a ziplock plastic bag.

If the logger is used in a cold environment, make sure condensation will not settle on the logger when it is brought

back into a warmer environment. The best way to prevent

condensation is to place the logger in a plastic ziplock bag

and include a dessicant. When you bring the logger back

into the warmer climate, leave the logger in the bag with the

dessicant until the logger has come to equilibrium with the

environment.

Label

If working with more than one logger, label each, identifying

the task and location before you distribute them throughout

a building or system. To do this, simply use shipping tags.

Later, when you retrieve them to graph their data, you will

know what each graph refers to.

Mounting

Use the magnetic backing to conveniently mount the logger

on metal surfaces like ductwork or electrical control cabinets. If concerned about theft, make sure to lock the logger

to a permanent fixture using the special locking tab.

Special mounting methods (using Velcro®fasteners) to

secure the loggers to other surfaces may be used. NOTE:

Do not rely on the logger’s magnetic strip for secure mounting if the surface is uneven, unstable, or above 150°F

(65°C).

Page 6

Keep Track

Be sure to keep record of the locations of each logger. This

will save time in looking for them when the data-gathering is

completed. Also, keep track of when the loggers were put

into service. This will help when producing graphs.

Retrieval

After sufficient time has passed to obtain a representative

profile of data, retrieve the logger and bring it back immediately for analysis. Make sure the logger has a label so it can

be properly identified and differentiated.

Analysis

To analyze the logger, you must first transfer a copy of its

data into your computer. To do this, plug the logger into the

Trendreader interface cable and choose Logger,

Communicate, Backup. After describing the information to

the computer, the data is automatically copied to disk, time

and date stamped, and converted into the appropriate

measurement units. A portion or the entire data set can be

copied.

Each file will initially have the same descriptive title, but you

can use Files, Revise Logger to alter these accordingly. To

view graphs, choose Draw, New and select the appropriate

file. A detailed description of all software functions can be

found in the Trendreader Reference Guide.

4. Connect the power supply adapter to the gender changer.

5. Connect the 6VDC power supply to the adapter.

NOTE: The cable length between the IC-200 and the computer or modem can be extended. Maximum length should

be 500 feet (150 m). Use 22-gauge stranded wire, with two

conductors and a shield.

Identifying Loggers on a Network

Before you can contact a network group of loggers at a site

for the first time, you must name the site and list serial numbers so they can be identified.

1 From the Communicate menu in the main Trendreader

window, choose SR+ Network so that a check mark exists

in front of it.

2. Choose the COM port that the loggers are connected to.

The Logger List dialog box will appear. Site name and logger serial numbers will be entered in this dialog box. See

Figure 3 below.

OPERATING A LOGGER NETWORK

The Series DL8 Dataloggers can be networked to enhance

the monitoring and backup capabilities. Use model IC-200

Interface Module to connect as many as 8 loggers to your

computer simultaneously. The IC-200 Module will allow

backup of a 8 loggers, one after the other, with one command. Realtime data from up to 64 channels (8 loggers with

8 channels) can be displayed on a single screen.

Connecting an IC-200 to the Computer

1. Connect the serial port extension cable’s female end to

the computer’s 25-pin serial port. Use the 9-pin connector

if the computer has a 9-pin port).

2. Connect the cable’s other end to the IC-200 connection

maked “PC”.

3. Connect the power supply adapter to the other end of

the IC-200 (the end marked “modem”).

4. Connect the 6VDC power supply to the adapter.

Connecting an IC-200 to a Modem at a Remote Site

1. Connect the serial port extension cable to the modem.

2. Connect the cable’s other end to the IC-200 connection

marked “modem”.

3. Connect the gender changer to the other end of the IC200 (marked “PC”).

Figure 3

3. In the Site Name box type a unique name for the site and

press Enter.

4. Click in the Serial # Column, type the serial number of

one of the loggers, and press Enter. (The order does not

matter, however, if you click Show All to view realtime readings, the readings will be displayed in the order they were

entered.)

5. If desired, add a description in the Description column

and press Enter.

6. Repeat steps 4 and 5 until all the loggers at the site are

listed.

7. Click Save Changes.

You can now contact any of the loggers listed.

Deleting a Site and its Loggers

1. Highlight the site to be deleted in the Site Name box. To

scroll between sites, click the down arrow.

2. Click Delete. The site name serial numbers and descriptions will be deleted.

3. Click Save Changes.

Deleting One Logger from a List

1. Click in the loggers serial number box to highlight the

number.

2. Click Delete. The serial number and description will be

deleted.

3. Click Save Changes.

Page 7

Viewing Realtime Readings of All Loggers

1. From the Communicate menu in the main Trendreader

window, click SR+ Network until a check mark appears in

the box.

2. Choose the COM port the network is connected to. The

Logger List dialog box will appear.

3. Click Show All. The Network Realtime window will open

displaying each logger’s realtime readings. See figure 4

below. When finished viewing the realtime readings, either

click Close to close the window, or double-click a logger’s

serial number to open that logger’s window.

Figure 4

Contacting a Network Logger

There are three ways to contact a logger on a network:

1. From the Logger List dialog box

2. From the Network Realtime window

3. From the Logger window

SETUP (specifically for the DL8)

This section provides guidelines to follow to get you started

with your DL8.

1. The first step in using your DL8 is to decide what information, or parameters, you want to log. For example, you

may simply wish to replace an existing hard-wired 4-20 mA

chart recorder or, instead, monitor from a special multipletransducer circuit that you have assembled.

2. Determine what sensors, transducers, or transmitters

you need to do the job (if not already present).

3. Modify the channels, externally (using resistors), if

required for maximum resolution (see Customizing Input

ranges).

4. Write an equation to convert the raw readings from the

transducer or circuit you want to monitor into the proper

engineering units you require (for example: converting 4-20

mA signal from a relative humidity transmitter to 0 to 100%

R.H.). For help in writing these equations refer to your

Trendreader Software manual.

Contacting a Logger from the Logger List

Double-click the logger’s serial number (or click the logger’s

serial number and click Contact Logger). The loggers main

window will open.

Contacting a Logger from the Network Realtime

When you have contacted a logger by one of the previous

two methods and you have that logger’s window open, you

can contact another logger on the network by taking the following steps:

1. Click Edit Setup. (See figure 5).

2. Double-click the serial number in the Serial Number box.

3. Type the number of the logger you want to contact.

4. Click the Contact button to open that logger’s window.

NOTE: DO NOT setup networked loggers in the Fast Read

Mode. Any networked logger that is setup in Fast Read

Mode will stop logging as soon as it or any other logger on

the network is contacted.

Figure 5

Figure 6: Using Transducers with Power Supply

5. Decide how you are going to power your transducers (if

required). You can either use a standard power supply and

create a circuit like that shown in Figure 6 or use batteries

(see External Battery Operation) and produce your own selfcontained logging assembly (Figure 7). For this application,

you must activate the internal battery switch.

Figure 7: Using Transducers with a Battery

6. Connect your transducers or transmitters and check

operation through the Logger, Communicate, Realtime

function in the Trendreader Software.

Page 8

Avoiding Ground Loop Problems

Take special care to avoid ground loop problems when you

use your DL8 Process Data Logger. A ground loop can

occur when there is more than one path to ground in your

logger-transducer circuit. Ground loops can damage your

DL8 Process Data Logger as well as your transducers. To

avoid ground-loop problems your DL8 circuit:

• Do not use more than one grounded power sup

ply to power your transducers.

• Do not connect your logger to your computer in

real time readings unless:

• your computer is battery-operated (i.e. not

grounded); or

• your transducer power supply is not grounded.

If you must use more than one grounded power supply in

your circuit, each transducer you use must be isolated. If

you must use non-isolated transducers, then you must use

a Signal Repeater/Loop Isolator between the transducer

output and the DL8 input.

Wiring Notes and Considerations

1. The Series DL8 Process Data Logger has two common

inputs (labeled “-Common”). These are not isolated from

each other and can be used as the “-” connection for the

power supply (or battery) and any of the transducers being

logged by the Series DL8.

2. For permanent applications, wiring connections can first

be made to the Series DL8 removable terminal block. The

terminal block can then be attached (with glue, for example)

to a permanent fixture. When it comes time to analyze data,

the data logger can simply be unplugged from the terminal

block and brought back to your computer. After backing up

the data, the logger can be returned and plugged back into

the terminal block. Logging will then automatically continue.

3. The 2.5 V and 200 mV channels “float” when no connections are made to them. They can thus be expected to

read a positive voltage when left both active and unconnected. When connected, however, they will read the correct input voltage.

4. The “25 mA” channels read positive current only. Make

sure to observe polarity. If you are using both channels

simultaneously, ensure that both 4-20 mA transmitters

source a positive current through the logger to a common

(-).

CHOOSING INPUT CHANNELS

To choose which of the DL8’s seven external input channels

to use for your particular applications and understanding of

resolution is required.

Maximizing Resolution

The resolution of your DL8 Logger is eight bits. This means

that it can resolve analog signals, with a defined range, to

256 discrete steps (2 to the power of 8). When logging from

the 2.5V channel, for example, the DL8 will record digital

values in increments of 2.5 volts divided by 256, or approximately 10 millivolts.

Resolution is usually not a significant factor until you have

logging applications that will produce input signals far less

than that of the range of the logger’s channel itself.

The 2.5V channel will have a resolution of 0.4% over a

range of 0 to 2.5 volts (.01/2.5 x 100) which should be more

than adequate for most applications. If, however, you are

intending to measure signals ranging from 50 to 150 millivolts (with the same 2.5V channel), resolution will be much

coarser (10%). By switching the 50 to 150 millivolt input to

the 200mV channel, resolution can be improved to approximately 1%.

Choosing Input Channels

It is important to maximize resolution when measuring and

recording from the DL8’s current and voltage channels.

Usually you can do this simply by choosing the channels

that match or approximate the input signals you will be

using. The table below lists several possible input signal

ranges and the recommended channels to use. It also lists

alternative channels that can be used to add additional

simultaneous monitoring capability. These alternative channels will, however, require the addition of external resistors

(see Customizing Input Ranges).

Range

of Input

0 to 500 mV

0 to 1.0 V

0 to 2.0 V

0 to 3.0 V

0 to 6.0 V

0 to 20 V

0 to 2.0 mA

4 to 20 mA

0 to 50 mA

0 to 100 mA

In the above table, the Range of Input column lists examples of input signals that you may wish to monitor using

your logger. The Standard Solution column lists the channel

you would normally choose to monitor that particular signal.

In this table, 200 refers to the 200mV channel, 2.5 the 0 to

2.5V channel, 5 to either of the two 0 to 5V channels, 10 to

the 0 to 10V channel, and 25 to either of the two 0 to 25mA

channels. The Alternative Solution column lists other channels that can be used to monitor the same input signals. In

most cases, these channels will need to be fitted with external resistors.

Standard

Solution

2.5

2.5

2.5

5

10

N/A

25

25

N/A

N/A

Alternative

Solution(s)

200

200

200

200

5, 2.5, 200

10, 5, 2.5, 200

200

2.5, 200

25, 5

25, 10

Page 9

Non-Standard Ranges

You may want to use a special transducer or tie in an existing process signal loop that does not match the DL8’s standard input ranges. The following step-by-step procedure

will help you choose which channel is best.

1. Determine the maximum output signal (M) and the zero

offset signal (Z) of the transmitter or circuit you wish to tie

into. For example, a transducer with a specified range of 1

to 6 volts DC will have a maximum output signal of 6 volts

and a zero offset signal of 1 volt. A 4 to 20 milliamp transmitter will have a maximum output signal of 20 mA and a

zero offset signal of 4 mA.

5. To find out in what actual steps (S) your logger will collect

data, first determine the input (I) of your transducer or transmitter. You can do this by subtracting the lowest level input

from the high. A thermocouple transmitter, for example, with

a range of -20° to 600° will have an input span of 620° (600(-20)). A pressure transducer with a range of 0 to 100 psi will

have an input span of 100 psi.

6. To calculate S, measured in the same units as the input

span (I) above, use this equations:

R x 1

S =

100

2. Determine the transducer’s full scale output (F). You can

do this simply by subtracting Z from M. The full scale output of the 1 to 6 volt transducer is 5 volts. The full scale output of the 4-20 mA transmitter is 16 mA.

3. Compare M with the channels available on the logger and

choose a channel with an input equal or greater to this value

(if available). If no such channel exists, then modify one to

suit by referring to the Customizing Input Ranges section.

4. Determine the resolution (R) of the channel you chose in

Step # 2 will be adequate. You can determine this, in percent, by using the following equation:

C x 0.4

R =

Where:

C = the input range of the channel to use (in either

millivolts, volts or milliamps).

F = the full scale output of your transducer (M-Z)

measured in the same units as for C.

R = the resolution expressed in a percentage (%)

of full scale output.

For example, a 0.5 to 2.5 volt transducer connected to the

2.5V channel will be logged with a resolution of 0.5%. A 4

to 20 mA transducer hooked up to the 25 mA channel will

log with a resolution of 0.6%.

F

For example, a 4 to 20 mA Relative Humidity transmitter

with an input span (I) of 90% R.H. and a calculated resolution (R) of 0.6% will record data in steps of 0.54% R.H.

CUSTOMIZING INPUT RANGES

The standard input ranges on the DL8 should be suitable for

most process signal applications, but occasionally you may

require measurement of non-standard input levels where

resolution is a primary concern (see the Choosing Input

Channels section). Ranges can be adapted easily by using

either one or two external resistors. Trendreader Software’s

Expert, Equations function can then be used to scale the

data to the new input levels.

The resistor value that you will require to modify each logger’s input channel is selected by inserting your special

input requirements into a simple equation. The following

sections detail these equations and the method of tying in

these resistors.

10 Volt Channel

The 10 volt channel can be modified to span higher ranges

(greater than 0 volts DC) by adding a single resistor to the

“10V” terminal shown in Figure 8. The value of the resistor

R must be calculated by the following formula based on the

desired voltage input range Ein:

R = (4,090 x Ein) - 40,900

Generally, it is good practice to keep resolution to within 1%

for most applications. However, you may be able to accept

far coarser resolution in some applications and, in others,

require far better. You’ll be able to determine your own

requirements after you’d be become familiar with the results

you can expect with different arrangements. If your requirements demand greater resolution than what you calculated,

then you should set up your inputs with resistors as

described in the Customizing Input Ranges section.

For example, if you wish to measure up to 20 volts, the

resistor value should be:

(4,090 x 20) - 40,900 = 40,900 ohms.

Since you won’t always be able to get the exact resistor

value that you calculated, you can determine the logger’s

actual input range by plugging the value of the resistor (R)

you obtain back into the equation. For example, if the closest resistor you could obtain was 42K ohms, then the actual voltage input range would be:

42,000 + 40,900

Ein=

4,090

= 20.27 volts

Page 10

This value will be needed when it comes time to create your

own custom equation using Trendreader Software’s Expert,

Equations function.

Figure 8: Modifying the 10 volt channel for extended range

You can also easily convert the 10V channel to measure 0

to 100 mA current simply by putting a 100 ohm resistor

(minimum rating: 2 watts) between the “10V” and

“-Common” terminals.

5 Volt Channels

The two 5 volt channels can be modified to span higher

ranges (greater than 5V DC) by adding a single resistor, in

the same way as shown for the 10V channel in Figure 8, to

either, or both, of the two “5V” terminals. The value of the

resistor R must be calculated by the following equation

based on the desired voltage input range Ein:

R = (4,000 x Ein) - 20,000

For example, if you wish to measure up to 20 Volts, the

resistor value should be:

(4,000 x 20) - 10,000 = 70,000 ohms.

Figure 9: Modifying the 2.5 volt channel

Since you won’t always be able to get the exact resistor

value that you calculated, you can determine the actual

input range you’ll have by plugging the value of the resistor

back into the formula:

R + 10,000

Ein=

4,000

This value will be needed when it comes time to create your

own custom equation using Trendreader software’s Expert,

Equations function.

For example, if you wish to measure up to 20 volts, the

resistor value should be:

(4,000 x 20) - 20,000 = 60,000 ohms.

Since you won’t be able to get the exact resistor value that

you calculated, you can determine the actual input range

you’ll have by plugging the value of the resistor back into

the formula:

R + 20,000

Ein =

4,000

You can easily convert either of both 5V channels to measure 0 to 50 mA current by wiring a 100 ohm resistor (minimum rating: 0.5 watts) from the “5V” terminals to common.

2.5 Volt Channel

The 2.5 volt channel can be modified to span higher ranges

(greater than 2.5V DC) by adding two resistors to the input

terminals as shown in Figure 9. The value of the resistor

marked “10K” must be 10,000 ohms ±1%. The value of the

resistor marked “R” must be calculated by the following

equation based on the desired voltage input range (E

in

):

R = (4,000 x Ein) - 10,000

You can easily convert the 2.5V channel to measure 0 to 25

mA current by wiring a 100 ohm resistor from the “2.5V” terminal to common.

200 millivolt Channel

The 200 millivolt channel can be modified to span higher

ranges (greater than 200 mV DC) by also adding two resis-

tors, in the same way as shown for the 2.5V channel in

Figure 9. The value of the resistor marked “10K” must be

10,000 ohms ±1%. The value of the resistor marked “R”

must be calculated by the following formula based on the

desired voltage input range (Ein):

R = (50,000 x Ein) - 10,000

You can also modify the 200mV channel to log current loop

signals with greater sensitivity than the two 25 mA channels. To do this, put a 100 ohm resistor across the “200mV”

and “-Common” terminals and you will be able to log currents from 0 to 2.0 mA with approximately ten times the resolution of the 25mA channels. The equation to use to

determine other current (Iin) ranges, in milliamps is:

200

S =

in

I

Page 11

25 milliamp Channel

The 25 milliamp channel can be modified to span higher

ranges (greater than 25 mA DC) by also adding a single

resistor across the input terminals as shown in Figure 10.

The value of the resistor “R” must be calculated by the following formula based on the desired current input range (Iin):

The internal switch can be activated during exit from setup

session by choosing “Yes” as answer to “Activate the

Logger’s external battery switch?” The battery switch status can be checked in setup menu. If the battery switch is

activated Hi Cal for channel 1 (25mA) reads -5. If the switch

is not activated, this value is 0.

2,500

R =

Iin- 25

Make sure the resistor can withstand at least twice the

power you will be sending it. To calculate this, use the following equation:

2

P = 2 * I

in

* R

Where:

P = Minimum Power Rating of resistor (in watts)

Iin= Maximum amperage expected through resistor

(in Amps).

R = Resistance of Resistor (in ohms).

For example, a 50 ohm resistor calculated to measure currents up to 75mA will require a power rating greater or equal

to 0.56 watts. Therefore, a one watt resistor will be fine.

The switch works by closing eight seconds prior to a reading, remaining closed until the reading is taken, then immediately opening again before repeating the cycle.

It extends battery life by only drawing power, when necessary, to meet the input requirements of the transducer or

transmitter circuit that you want to monitor.

To use the battery switch, the battery’s positive (+) terminal

must be wired to the “+ Battery In” terminal on the data logger (refer to Figure 11). The power to your external transducers will then be available from the “+ Power Out” terminal. The battery’s negative (-) terminal can then be wired to

either of the “-Common” terminals.

Figure 10: Modifying a 25 mA channel

For increased sensitivity at lower current ranges down to

2.5 milliamps, refer to the section for modifying the 200 mV

channel.

External Battery Operation

You can activate a special function on the DL8 designed to

optimize the use of power from external batteries while out

in the field. The battery-saving contacts can provide switching capability to draw power from the battery only when

needed, thus maximizing its life for extended field applications.

The internal battery switch allow you to power external

transducers with a separate battery pack. This capability

makes it easy for you to assemble your own self-contained

data logging kit for long-term in-field use where there is no

convenient power supply receptacle.

Figure 11: Using the Battery Switch

Maximum current that the battery switch can source is

100mA. Battery supply voltage can be from 9 to 25 volts.

Short circuit protection is continuous at 9 volts, but only one

second at higher voltages.

Things you should know about batteries

When using batteries for power your external sensors and

transducers, you should keep in mind a few key points.

1. The rated voltage of a battery only applies to initial use.

Once under load, the voltage will decrease gradually until

completely drained. By knowing how the battery voltage is

affected through use you can make sure that the voltage

requirements of your external transducers will be met. A

good rule of thumb to follow is to exceed the minimum

required input voltage for your transducers by at least two

times (where acceptable).

2. Nickel-Cadmium batteries (rechargeable) self-drain themselves at a rate approximately 1% of their remaining capacity per day. This should be taken into account for extended

logging sessions.

Page 12

Determining how long your batteries will last

To estimate how long your batteries will successfully power

your external sensors and transducers, you will need to

know both the capacity of the batteries as well as the proposed resistance presented to them by the load (your own

transducers).

Battery capacity, usually expressed in milliamperes hours

(mAh), is the total amount of electrical charge a cell can

store or deliver. Unfortunately, most commercially-available

batteries are sold without this information.

As a general guide, most good quality nine volt batteries

have a capacity of approximately 500 mAh. This means, at

an average continuous current draw of 50 mA it will deliver

approximately ten hours of service.

The load you impose on your battery will depend on how

many transducers you intend to have in your logging circuit.

The greater the number of transducers, the greater the

power draw from the battery. If you are logging from a 4 to

20mA transducer, the maximum current it will draw will be

approximately 20mA. If you power it continuously, your 500

mAh battery should not run out until you’d had at least

twenty-five hours of service. Since your transducer probably will not always draw maximum current (12mA might be

a more reasonable figure), you can probably expect up to

forty-two hours of service.

Regulated Voltages

The unstable voltage characteristics of batteries makes

them, by themselves, incompatible for use with transducers

that required a regulated voltage supply. You can, however,

add your own voltage regulator to your transducer circuit to

compensate for this instability (see Figure 12). Voltage regulators are readily available at most electronic parts supply

stores (such as Radio Shack).

Figure 12: Regulating Battery Supply Voltage

Make sure that your supply voltage to your regulator is at

least two volts higher than the level to which you want to

regulate to. To do this, you can easily increase the voltage

of your batteries by hooking them up in series as shown in

Figure 12.

The battery-saving switch contacts can increase the lifetime

of your external batteries significantly. Since the batteries

will be powered only for eight seconds out of every logging

interval, the power draw on the battery will be reduced considerably.

Example

Problem: You want to log pressure once every thirty minutes from a 0 to 300 psig transducer. The output of the

transducer is 4 to 20mA. The excitation voltage is listed at

between 9 and 40 volts DC.

Solution: From this information we know that a 4 mA signal will represent 0 psig and a 20 mA signal will represent

300 psig. Since the minimum excitation voltage is 9 volts,

we should supply at least 18 volts initially from our batteries.

We can do this by simply connecting two nine volt 500 mAh

batteries in series.

Without the battery-saving switch enabled, our minimum

expected battery life would be approximately twenty-five

hours. With the switch enabled, and thus closing only eight

out of every 1,800 seconds (or thirty minutes), the life will be

extended by a factor of 225 (or 1800/8). This means that we

should be able to log from this transducer for over 5,625

If the wires between the voltage regulator, batteries, and

transducers are long (more than a few inches) the regulator

may oscillate and produce an unstable voltage. You can

correct this by connecting one 0.1 microfarad capacitor to

each of the regulator’s outside pins then wiring them to the

regulator’s center pin. Make sure to keep the capacitor

leads as short as possible.

MAINTENANCE

No routine maintenance is required on the Series DL data

loggers. Periodic checks of connections and mounting is

recommended. Please contact Dwyer Instruments, Inc.

before returning unit for repair to review information relative

to your application and obtain a return authorization number. When returning a product to the factory, carefully package and ship freight prepaid. Be sure to include a complete

description of the application and problem and identify any

hazardous material used with the product.

©Copyright 1999 Dwyer Instruments, Inc Printed in U.S.A. 2/99 FR R1-443087-00

DWYER INSTRUMENTS, INC.

P.O. Box 373 • Michigan City, IN 46361-0373, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...