Page 1

Bulletin B-30

Series DH3 Digihelic®Differential Pressure Controller

Specifications - Installation and Operating Instructions

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, IN 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

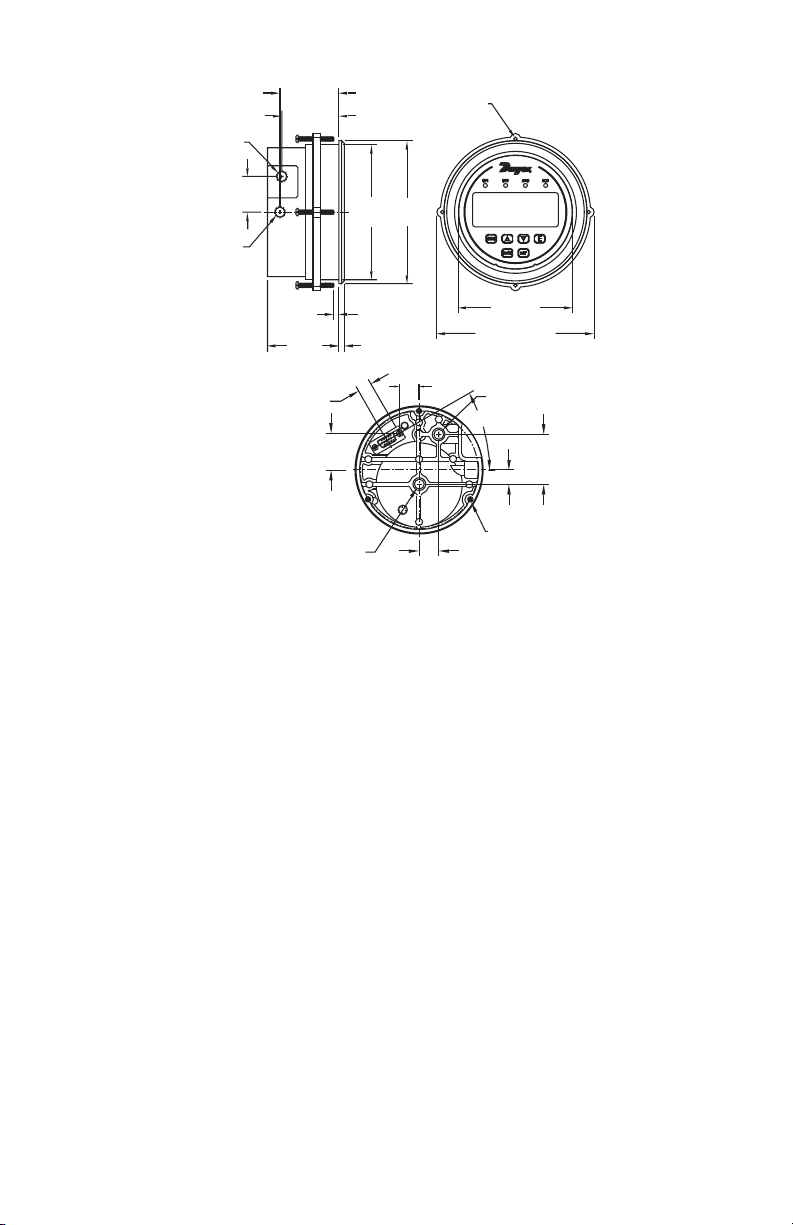

DIMENSIONS

(4) 6-32 HOLES

EQUALLY SPACED ON A

5-1/8 (130.18) B.C.

PANEL MOUNTING

1/8 FEMALE NPT LOW

PRESSURE CONNECTION

1/8 FEMALE NPT HIGH

PRESSURE CONNECTION

2-1/16

(52.39)

2

(50.80)

1-1/4

(31.75)

ø4-47/64

(120.25)

Ø5

(127.00)

Ø4 (101.60)

FACE

5-1/2 (139.70) O.D.

MOUNTING RING

5/8 (15.88)

PANEL MAX

2-1/2

(63.50)

3/16

(4.76)

1/8 FEMALE NPT HIGH

PRESSURE CONNECTION

1/2

(

12.70)

1-9/32

(32.54)

1

1/16

(17.46)

30°

1-3/4

(44.45)

1/2 (12.70)

11/16

(17.46)

1/8 FEMALE NPT LOW

PRESSURE CONNECTION

(3) Ø3/16 (4.77) HOLES EQUALLY

SPACED ON A 4-1/8 (104.78) B.C.

SURFACE MOUNTING

SPECIFICATIONS

Service: Air and non-combustible, compat-

ible gases.

Wetted Materials: Consult factory.

Housing Material: Die cast aluminum

case and bezel.

Accuracy: ±1.5% for 0.25˝ and ±0.25˝ w.c.

ranges. Ranges 0.5˝ to 5˝ w.c. and corresponding bi-directional (except ±2.5˝ w.c.):

±1%; All other ranges: ±0.5% @ 77°F

(25°C) including hysteresis and repeatability (after 1 hour warm-up).

Stability: < ±1% per year.

Pressure Limits: Ranges

≤ 2.5˝ w.c.: 25 psi; ±2.5˝, 5˝ w.c.: 5 psi;

10˝: w.c. 5 psi; 25˝ w.c.: 5 psi; 50˝ w.c.: 5

psi; 100˝ w.c.: 9 psi.

Temperature Limits: 32 to 140°F (0 to

60°C).

Compensated Temperature Limits: 32 to

140°F (0 to 60°C).

Thermal Effects: 0.020%/°F (0.036/°C)

from 77°F (25°C). For 0.25˝ and ±0.25˝

w.c. ranges: ±0.03%/°F (±0.054%/°C).

Power Requirements: 12-24 VAC/VDC.

Power Consumption: 3 VA max.

Output Signal: 4-20 mA DC into 900

ohms max.

Zero & Span Adjustments: Accessible via

menus.

Response Time: 250 ms (dampening set

to 1).

Display: Backlit 4 digit LCD 0.4˝ height

LED indicators for set point and alarm status.

Electrical Connections: 15 pin male high

density D-Sub connection. 18˝ (46 cm)

cable with 10 conductors included.

Process Connections: 1/8˝ female NPT.

Side or back connections.

Mounting Orientation: Mount unit in vertical plane.

Size: 5˝ (127 mm) O.D. x 3-1/8˝ (79.38

mm).

Weight: 1.75 lbs. (794 g).

Agency Approvals: CE.

SWITCH SPECIFICATIONS

Switch Type: 2 SPDT relays.

Electrical Rating: 1 amp @ 30 VAC/VDC.

Set Point Adjustment: Adjustable via key-

pad on face.

2

Page 3

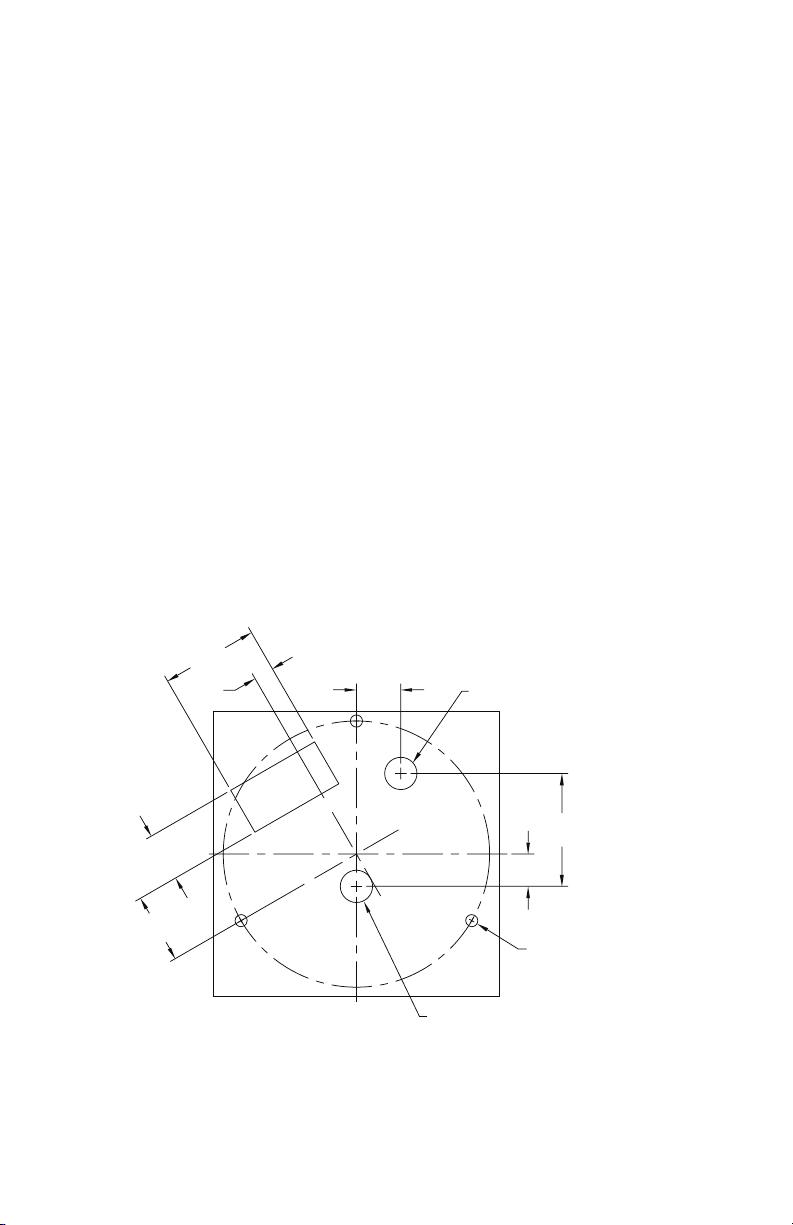

INSTALLATION

1-1/2

[38.1]

5/16

[7.94]

11/16

[17.46]

3/4

[19.05]

1-3/32

[27.78]

1-3/4

[44.45]

1/2 [12.70]

(3) Ø3/16 [4.77] HOLES EQUALLY

SPACED ON A 4-1/8 [104.78] B.C.

Ø1/2 [12.70] HOLE FOR

LOW PRESSURE CONNECTION

Ø1/2 [12.70] HOLE FOR

HIGH PRESSURE CONNECTION

LOCATION: Select a clean, dry location free from shock and vibration where temperature

limits will not be exceeded. Distance from the transmitter to the receiver is limited only by

total loop resistance. See ELECTRICAL CONNECTIONS. Tubing feeding pressure to the

instrument can be practically any length required, but long lengths will increase response

time slightly.

POSITION: All standard models are calibrated for use in a vertical mounting position.

Higher range models will perform properly at other angles but should be spanned and

zeroed in the position in which they will be used. Because of their sensitivity to gravitational forces, models with ranges under 1˝ w.c. (25.4 mm w.c.) must always be mounted vertically.

PRESSURE CONNECTIONS: For installation convenience two sets of 1/8˝ female NPT

pressure ports are supplied. Be sure to seal the unused ports with pipe plugs included.

Positive Pressure - Connect tubing to HIGH PRESSURE port and vent LOW PRESSURE

port to atmosphere.

Negative (Vacuum) Pressure - Connect tubing to LOW PRESSURE port and vent HIGH

PRESSURE port to atmosphere. (When operating this device in a dusty environment,

install an optional A-331 Filter Vent Plug in the vented port to keep interior clean.)

Differential Pressure - Connect tubing from the higher source to HIGH PRESSURE port

and from the lower source to LOW PRESSURE port.

Fig. A

3

Page 4

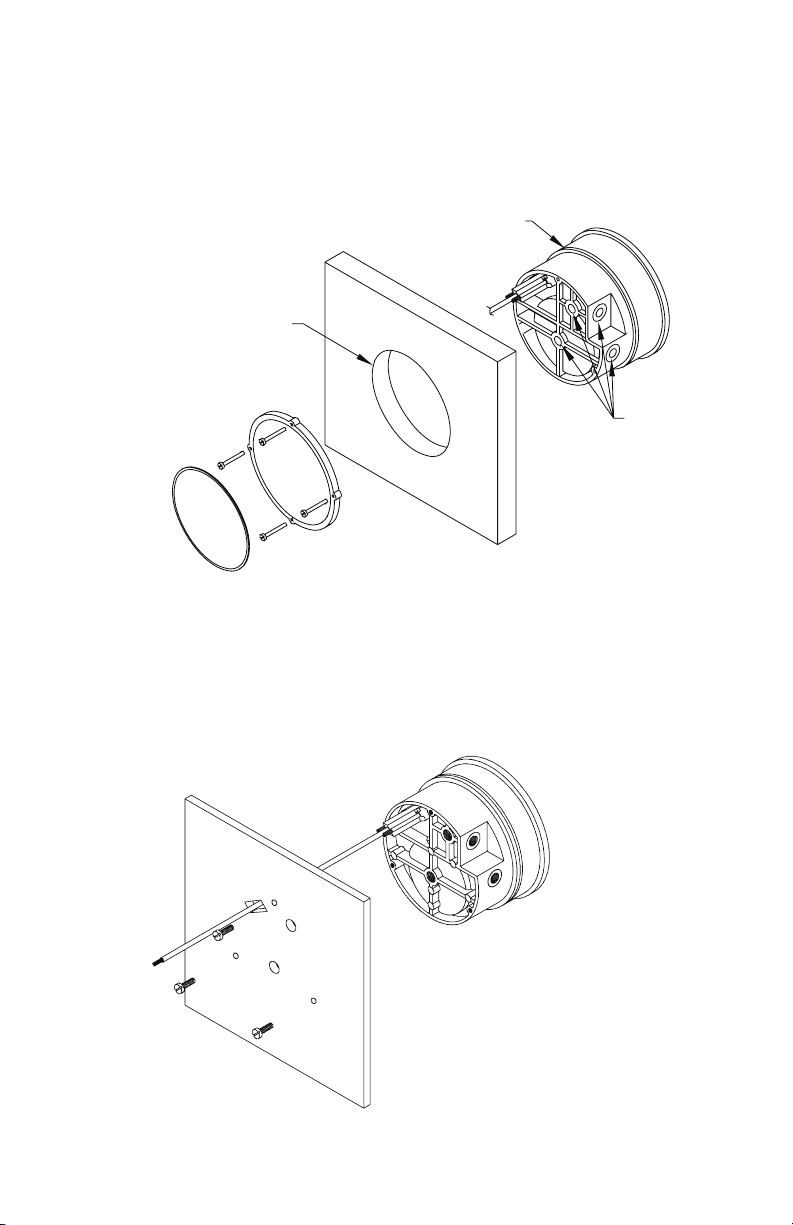

MOUNTING: The DH 3 may be either panel (flush) mounted or surface mounted.

Ø4-3/4 [120.65] HOLE

PNEUMATIC

PRESSURE TAPS

SNAP RING

GROOVE

Panel Mounting - Cut a 4-13/16˝ or 122 mm diameter hole in the panel and insert the unit

from the front. Slip on the mounting ring with the stepped side facing rear. Next, fit the snap

ring into the narrow groove at back edge of bezel. Thread four (6) 32 x 1-1/4˝ mounting

screws into tapped holes in mounting ring and set it against snap ring. Tighten screws

against rear of panel. See Fig. B.

Fig. B

Surface Mounting - Drill (3) 3/16˝ (4.76 mm) diameter holes for mounting and cut a 9/16˝

x 1-1/2˝ (14.3 x 38.1 mm) opening for access to terminal block as indicated in Fig. B. If rear

pressure connections are to be used, also provide 1/2˝ diameter holes as shown in Figs.

A and C. Insert 6-32 machine screws from rear of mounting surface, thread into tapped

holes on back of transmitter and tighten.

Fig. C

4

Page 5

WIRING

The DH 3 uses a standard 15 pin male high density D-Sub connector available from

most electronic distributors. A pre-wired 18˝ cable is included with each unit.

See below table for cable color wiring information.

Function

15 PIN Connector

Cable Color

Terminal

12-24 VAC/VDC Power

12-24 VAC/VDC Power

4-20mA XMTR Output 4-20mA XMTR Output +

SP1 Relay N/O

SP1 Relay Com

SP1 RELAY N/C

SP2 or ALarm Relay N/O

SP2 or ALarm Relay Com

SP2 or ALarm Relay N/C

1. If 12-24 VDC power is used, the polairty is unimportant.

2. Wire in accordance with an equivalent national standard or code. Use copper conductors only rated for 60°C.

3. All terminals are rated CLASS 2.

4. ISOLATION: All inputs and outputs to each other: 500 VAC.

5. 4-20 mA Transmitter – Check the specifications for the device receiving this signal for

input resistance. Typical 250 to 600 OHMS, 600 OHMS maximum.

1

6

2

11

12

13

14

15

10

5

NOTES:

Brown

Yellow

Black

Red

Vilolet

Grey

White

Blue

Green

Orange

5

Page 6

SP/ALSP/AL

M

ENUMENU

EE

RSTRST

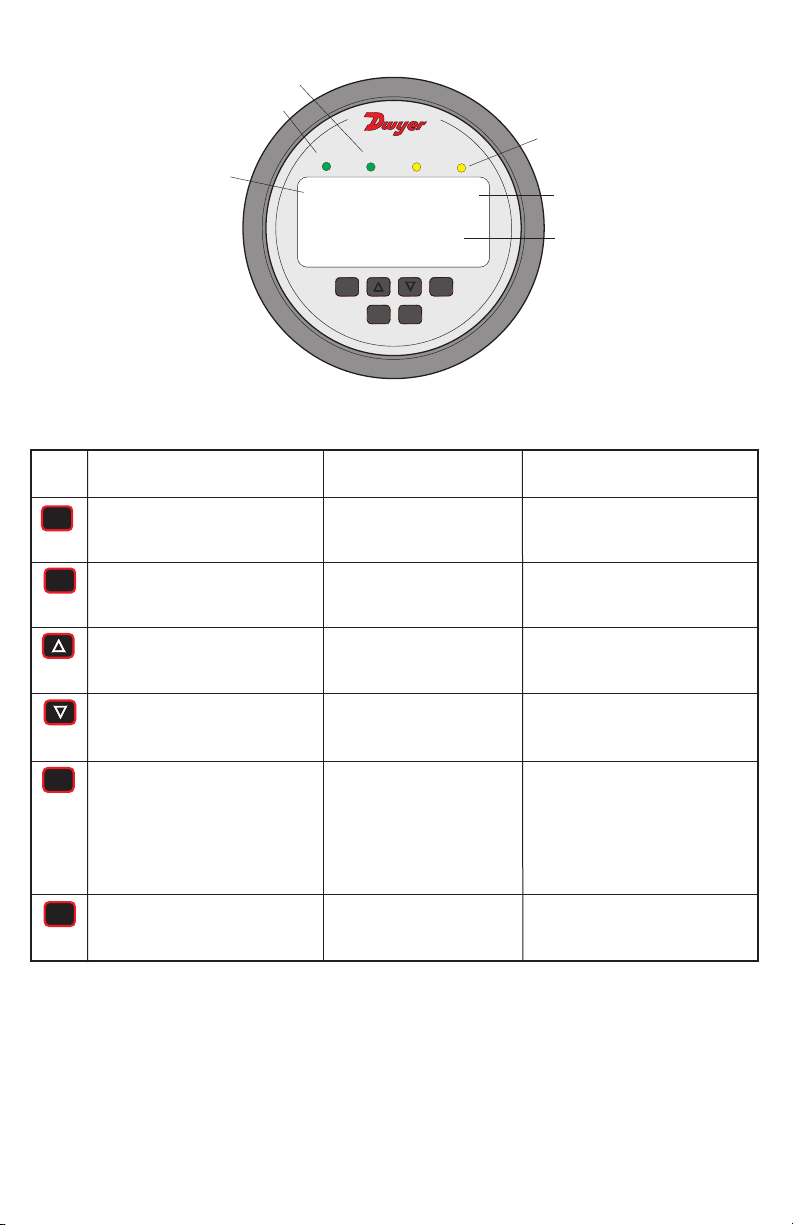

KEY FUNCTIONS

INWCINWC

1.0001.000

SP1SP1

SP2SP2

ALHIALHI

ALLOALLO

SP/ALSP/AL

RSTRST

MENUMENU

EE

X1KX1K

FRONT PANEL

ALARM

DESCRIPTOR

UNITS

I

NPUT VALU E

MULTIPLIER

DESCRIPTOR

VISABLE WITH

SOME VELOCITY

A

ND FLOW

RANGES

SP2 DESCRIPTOR

SP1 DESCRIPTOR

SP/AL

MENU

UP

ARROW

DOWN

ARROW

ENTER

RESET

Home

Position Function

Sequences the display

through SET POINT and

ALARM settings

Allows access to the menus

Displays full scale

range of unit

Clears or resets an Alarm

(alarm set for manual reset)

Main Menu Function

Return to home

position

Return to home

position

Sequences through

menus

Sequences through

menus

Enter into SUB MENU

6

Sub Menu Function

Return to home position

Return to previous menu

Increments a value

Decrements a value

Changes a value or

setting. Press ENTER and

display will blink. Adjust

with UP or DOWN arrows.

Press ENTER to store.

Display will stop blinking.

Peak/Valley SUB

MENU resets display to

present value.

Page 7

SETTING SET POINTS AND ALARMS

S

P/ALSP/AL

S

P/ALSP/AL

S

P/ALSP/AL

SP/ALSP/AL SP/ALSP/AL

S

P/ALSP/AL

S

P/ALSP/AL

SP/ALSP/AL

SP/ALSP/AL SP/ALSP/AL

SP/ALSP/AL

S

P/ALSP/AL

S

P/ALSP/AL

Visible whenVisible when

Visible whenVisible when

Visible whenVisible when

mode =mode =

mode =mode =

mode =mode =

CONTROL MODECONTROL MODE

CONTROL MODECONTROL MODE

CONTROL MODECONTROL MODE

PRES

SURE

PRESSURE

00

00

TIMETIME

0.20.2

0.40.4

0.60.6

0.80.8

1.0

(in. w.c.)

SP/ALSP/AL

The hot key provides direct access to the Set Point and Alarm MENU. The Set

Point and Alarm MENUS that are displayed are based upon the Control (CtrL) SUB

MENU.

SET POINT ADJUSTMENT

Adjusting the DH

band, simply adjust

or

SP2L

for the desired relay turn off point.

In the above graph, an instrument with a 1.0˝ range would have the SP1 relay turn on at

0.8˝ and off at 0.4˝.

The relays outputs normally function in the direct acting mode, which means the relays turn

on with an increase in pressure. SP1 may be configured to act as a reverse acting relay

(refer to the 1SP SUB MENU setting, page 15). When set for reverse acting,

relay turn OFF point, and

®

3 Set Points is quick and simple. Instead of setting a set point and dead-

SP1H

or

SP2H

for the desired relay turn on point, and then adjust

SP1H

sets the relay turn on point, and

SP1L

sets the relay turn off point.

SP1L

sets the relay turn ON point. SP2 is always direct acting.

7

SP1H

SP1L

sets the

Page 8

MENU MAPMENU MAP

CONTINUED

CONTINUED

SETTINGSSETTINGS

MAIN MENUS SUB MENUS

MENUS

UNAVAILABLE

FOR

BI-DIRECTIONAL

RANGES AND

RANGES ABOVE

25 IN. W.C.

EE

MENUMENU

8

Page 9

CONTINUEDCONTINUED

SETTINGSSETTINGS

MAIN MENUS SUB MENUS

0PEn

EE

MENUMENU

9

Page 10

MAIN MENUS SUB MENUS

SETTINGS

EE

MENUMENU

Menus present only

in pressure operation

10

Page 11

ain Menu Selections (Upper Right Display Reads

M

M

ENU

)

SECr

all settings.

OPEr

units.

OUt

mode of operation.

d.S

lution, % output and dampening.

AdU

scaling, Maintenance Set Point settings and calibration.

Security - Lock out access to Set Point and Alarm settings, or lock out access to

Operation - Selection of Pressure, Velocity or Flow and corresponding engineering

Output - Select a Single Set Point, 2 Set Points, or a Set Point and an Alarm

Display - Monitor and adjust display related settings: Peak, Valley, display reso-

Advanced functions - Modify advanced function parameters, transmitter output

11

Page 12

MAIN MENUS and SUB MENUS

Units visible, so unit

is presently set to

measure pressure

is presently set to

measure pressure

Units not visibleUnits not visible Units not visibleUnits not visible

SECr

(Security) MAIN MENU

SECr

is the only SUB MENU in the security MENU. When the security SUB MENU

is selected, the present security level is displayed in the upper right hand display. To

change the security level, adjust the number displayed to the number shown in the

following table for the desired security level.

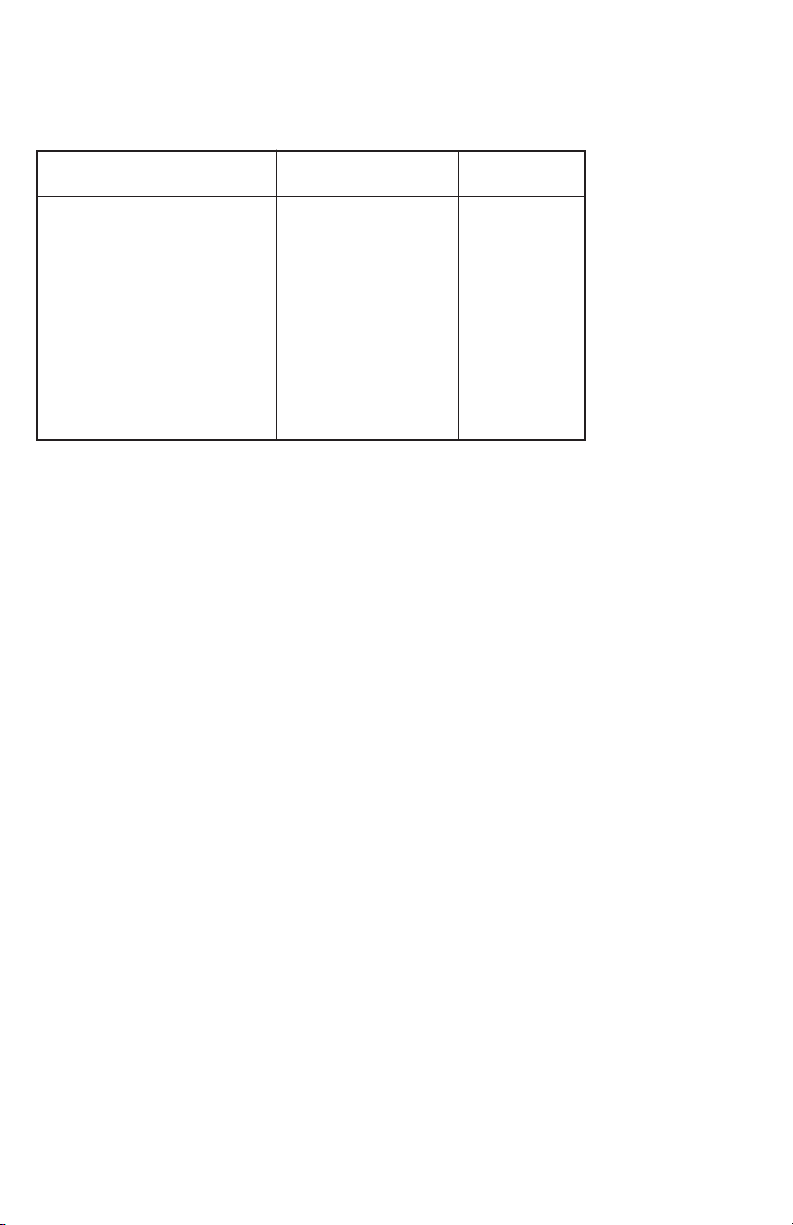

Security Level

Displayed

Access

All menus access

Password Value

to Enter

10

1

2

Menu Access

70

SP/AL Locked

3

SP/AL Access

90

Menus Locked

4

All settings locked

111

The password values shown in the table cannot be altered, so retain a copy

of these pages for future reference.

OPEr

(Operation) MAIN MENU

The

OPEr

MENU selects the measurement type of the instrument.

The SUB MENUS are:

PrES

- Pressure

UEL

- Velocity

FLO

- Flow

If the instrument is set for Velocity, the

MENU. If the instrument is set for Flow, the

ArEA

SUB MENUS. These will be discussed under Velocity and Flow. When scrolling

through the

OPEr

SUB MENUS, the measurement type the unit is currently set for will

KFAC

ArEA

DIA

- Diameter

- K Factor

- Area

OPEr

XDIM

- X Dimension

YDIM

- Y Dimension

MENU will have an additional

OPEr

MENU will have additional

KFAC

KFAC

SUB

and

show the units in the upper right display. The other measurement types will have a blank

upper right display.

12

Page 13

PrES

(Pressure) SUB MENU

For pressure measurement, the following units are available:

INWC

- Inches of water column

FTWC

- Feet of water column

MMWC

- Millimeters of water column

CMWC

- Centimeters of water column

PSI

- Pounds per square inch

INHG

- Inches of mercury

Table 1 Pressure Range vs. Available Units

INHG

MMWC

FTWC

INWC

.2083

.4167

.8333

2.083

4.167

8.333

OVFL

(over flow) or

2.540

6.350

12.70

25.40

63.50

127.0

254.0

635.0

1270

2540

.1000

.2500

.5000

1.000

2.500

5.000

10.00

25.00

50.00

100.0

NOTE:

exceeded above or below full scale by 2%.

CMWC

.2540

.6350

1.270

2.540

6.350

12.70

25.40

63.50

127.0

254.0

PSI

.1839

.3678

.1806

.7356

.3613

1.839

.9032

3.678

1.806

7.356

3.613

UnFL

(under flow) will appear when the ranges have been

MMHG

- Millimeters of mercury

MBAR

- Millibar

PA

- Pascal

KPA

- Kilopascals

HPA

- Hectopascals

OZIN

- Ounce inches

MMHG

.1868

.4671

.9342

1.868

4.671

9.342

18.68

46.71

93.42

186.8

MBAR

.2491

.6227

1.245

2.491

6.227

12.45

24.91

62.27

124.5

249.1

PA

24.91

62.27

124.5

249.1

622.7

1245

2491

6227

KPA

.1245

.2491

.6227

1.245

2.491

6.227

12.45

24.91

HPA

.2491

.6227

1.245

2.491

6.227

12.45

24.91

62.27

124.5

249.1

OZIN

.1445

.2890

.5780

1.445

2.890

5.780

14.45

28.90

57.80

UEL

(Velocity) SUB MENU

For velocity measurement, the following units are available:

SFPM

- Standard feet per minute

M/S

- Meters per second

Table 2 Available Velocity Ranges

INPUT RANGE

INWC

0 - 0.1

0 - 0.25

0 - 0.5

0 - 1

0 - 2.5

0 - 5

0 - 10

0 - 25

NOTE: Air velocity and flow readings are based upon standard dry air conditions with an

ambient temperature of 70°F and a barometric pressure of 29.92 INHG.

SFPM

RANGE

0 - 1266

0 - 2002

0 - 2832

0 - 4004

0 - 6332

0 - 8954

0 - 12.66 x IK

0 - 20.02 x IK

M/S RANGE

0 - 6.431

0 - 10.17

0 - 14.39

0 - 20.35

0 - 32.17

0 - 45.48

0 - 64.33

0 - 101.7

13

Page 14

LO

Flow) SUB MENU

F

(

For flow measurements the following units are available:

SCFM

- Standard cubic feet per minute

M^3H

- Cubic meters per hour

FLO r

(Flow Range) SUB MENU

LO

- 99.99 x 1K flow range

HI

- 999.9 x 1K flow range

Tables 3-6 show the flow ranges available, and the maximum duct size that can be set

for each input range.

Table 3

FLOr = LO

RANGE

IN WC

0.1

0.25

0.5

1

2.5

5

10

25

Table 5

FLOr = LO

RANGE

IN WC

0.1

0.25

0.5

1

2.5

5

10

25

Maximum Duct Size (English)

SCFM

RANGE

MAX. DUCT

SIZE, SQ.

FT.

99.99 x 1K

99.99 x 1K

99.99 x 1K

99.99 x 1K

99.99 x 1K

99.99 x 1K

99.99 x 1K

99.99 x 1K

78.9

49.9

35.3

24.9

15.7

11.1

7.8

4.9

Maximum Duct Size (Metric)

Mˆ3/Hr

RANGE

99.99 x 1K

99.99 x 1K

99.99 x 1K

99.99 x 1K

99.99 x 1K

99.99 x 1K

99.99 x 1K

99.99 x 1K

MAX. DUCT

SIZE Mˆ2

4.32

2.73

1.93

1.37

0.86

0.61

0.43

0.27

Table 4

FLOr = HI

RANGE

IN WC

0.1

0.25

0.5

1

2.5

5

10

25

Table 6

FLOr = HI

RANGE

IN WC

0.1

0.25

0.5

1

2.5

5

10

25

Maximum Duct Size (English)

SCFM

RANGE

MAX. DUCT

SIZE, SQ.

FT.

999.9 x 1K

999.9 x 1K

999.9 x 1K

999.9 x 1K

999.9 x 1K

999.9 x 1K

999.9 x 1K

999.9 x 1K

789.8

499.5

353.1

249.7

157.9

111.7

78.9

49.9

Maximum Duct Size (Metric)

3

M

/Hr

Range

999.9 x 1K

999.9 x 1K

999.9 x 1K

999.9 x 1K

999.9 x 1K

999.9 x 1K

999.9 x 1K

999.9 x 1K

MAX. DUCT

SIZE, M

2

43.19

27.31

19.3

13.64

8.63

6.10

4.31

2.73

KFAC

SUB MENU

KFAC

K Factor - becomes accessible if the instrument is set for Velocity or Flow.

When the DH3

®

is used with a Pitot tube, the manufacturer may specify a K

Factor. The adjustment range is 0.01 to 2.00. The factory setting is 1.

14

Page 15

rEA

IA

DIM

nd

DIM

A

,

D

,

X

a

These SUB MENUS become accessible if the instrument is set for flow. When measuring

flow, the area of the duct must be specified. Tables 3 and 4 show the input range vs maximum flow and duct size. For a rectangular duct the maximum size is specified in square

feet or meters. For a circular duct the maximum size is specified as the diameter. X, Y and

circular dimensions are entered in feet with 0.01 foot resolution for

resolution for

ArEA

circular duct is selected, the

is selected, the

DIA

XDIM

YDIM

FLOr = HI

- Area, select

- Diameter, enter the diameter of a duct

- Enter the “X” dimension of a duct

- Enter the “Y” dimension of a duct

UB MENUS

Y

S

FLOr = LO

, or entered in millimeters with 1 millimeter resolution.

CIR

XDIM

for a circular duct or

DIA

SUB MENU will be activated. If a rectangular duct

and

YDIM

SUB MENUS will be activated.

RECT

for a rectangular duct. If a

and 0.1 foot

Y

X

OUt

(Output) MAIN MENU

The

OUt

MENU selects the output type of the instrument. The SUB

MENUS are:

CtrL

- Control type

ISP

- SP1 reverse or direct acting

AL

- Alarm type

ALrE

- Alarm reset, manual or auto

AL.H

- Alarm inhibit

ALDL

- Alarm delay

15

Page 16

0

100

Process

R

ever

se A

ct

ing

Tim

e

SPH

SPL

Relay Inactive

Relay Active

trL(Control) SUB MENU

0

100

Process

Dire

ct

Actin

g

T

im

e

SPH

SPL

Relay Inactive

Relay Active

C

1SP

- Single set point

2SP

- Two fully independent set points

SPAL

- Single set point and alarm

1SP

(SP1 Reverse or Direct Acting) SUB MENU

DIR

- Direct. Relay turns on with increasing pressure

REV

- Reverse. Relay turns on with decreasing pressure

16

Page 17

he following alarm function SUB MENUS are activated when

MIN. PRESSURE

MAX. PRESSURE

ALHI

Relay OFF Relay ON

HIGH AL AR M FUNCTION

MIN. PRESSURE

MAX. PRESSURE

ALLO

Relay ON Relay OFF

LOW ALA RM FUNCTION

MIN. PRESSURE

MAX. PRESSURE

ALLO

Relay ON Relay OFF Relay ON

HIGH/L OW ALARM

FUNCTION

ALHI

T

AL

(Alarm Type) SUB MENU

HI

- High alarm

LO

- Low alarm

HILO

- For a high/low guardband type alarm

C

trL

s set to

i

S

PAL

:

ALARM ADJUSTMENT

Alarm settings are dependent upon the selected alarm mode. The DH3

®

differential pressure controller alarm may be configured as a High Alarm, Low Alarm, or High/Low Alarm.

Alarm settings are all absolute and may be set to anywhere within the range of the instrument. The dead bands of the alarms are fixed at 1% of full scale.

17

Page 18

L0S

A

ALrE

AL.H

ALDL

d.S

Alarm Output State) SUB MENU

(

CL0S

- Alarm relay contacts close upon alarm condition

0PEN

- Alarm relay contacts open upon alarm condition

(Alarm Reset) SUB MENU

ONOF

- Automatic reset

HOLD

- Manual reset. An alarm is reset by the RESET key on the front

panel, or an external reset switch.

(Low Alarm Inhibit) SUB MENU

ON

- Alarm inhibit is on

OFF

- Alarm inhibit is off

If

AL.H

is selected ON, a low alarm condition is suspended upon power up until the

process value passes through the alarm set point once.

(Alarm Delay) SUB MENU

Sets the amount of time an alarm condition must be continuously met before

the alarm condition is recognized. The alarm delay is adjustable from 0-3600

seconds.

(Display) MAIN MENU

PEAK

- Peak value

VALy

- Valley value

ZERO

- Zero

PEAK

(Peak) SUB MENU

The Peak feature stores the highest pressure reading the instrument has measured

since the last reset or power up. At power up

reading. To manually reset the

SUB MENU.

VALy

(Valley) SUB MENU

The valley feature stores the lowest pressure reading the instrument has measured

since the last reset or power up. At power up

reading. To manually reset the

VALy

SUB MENU.

rESO

- Resolution

Pd.S

- Process display

DAMP

- Dampening level

PEAK

is reset to the present pressure

PEAK

value, press the RESET key while in the

VALy

is reset to the present pressure

VALy

value, press the RESET key while in the

18

PEAK

Page 19

ESO

Resolution) SUB MENU

r

(

The DH 3 is capable of displaying four digits of resolution. However, at very low

pressures the instability of the pressure may cause fluctuations in the least

significant digit causing the least significant digit to be of little value.

Three digit resolution (

right of a decimal.

3DIG

- Set display for 3 digit resolution

4DIG

- Set display for 4 digit resolution

Pd.S

(Process Display) SUB MENU

STD

- Display reads pressure, velocity, or flow values

PCT

- Display reads % of full scale value

3DIG

) can only be active when there is at least one digit to the

When the display is reading percent,

display. The percent display is only available in pressure operation.

DAMP

(Dampening) SUB MENU

Adjust from 1-16

Dampening stabilizes the display from instabilities due to things such as vibration and

excessive pressure fluctuations. The dampening setting adjusts the amount of

readings that are averaged for each display update. Adjust the dampening value until

the display reads a stable value for the application.

AdU

(Advanced) MAIN MENU

POL

- Process output low

POH

- Process output high

MSP1

- Maintenance set point 1

MSP2

- Maintenance set point 2

POL

and

POH

(Process Output Low and High) SUB MENUS

This feature is used in pressure operation only.

Process output low and high are used to scale the 4-20 mA output. Set

desired display reading for 4mA output, and set

for 20 mA output.

minimum scale up to

scale.

POH

must be higher than

POH. POH

may be adjusted from

PCT

is displayed in the upper right of the

ZERO

- Zero calibration

SPAN

- Span calibration

POH

to the desired display reading

POL. POL

may be adjusted 2% BELOW

POL

to 2% ABOVE maximum

POL

to the

19

Page 20

SP1

SP/ALSP/AL

nd

SP2

M

a

Maintenance Set Point 1 & 2) SUB MENUS

M

(

Adjust for the desired maintenance set points when the unit is placed in the

maintenance mode. The deadband is fixed at 2% of full scale. To enter or

leave the maintenance mode, press and hold the for 8 seconds.

ZERO

and

SPAN

(Calibration of Zero and Span) SUB MENUS

The lower display reads

ZERO

Calibration

CAL

in this mode.

NOTE: For accurate calibration, DO NOT apply any pressure when

performing this function.

With the display reading

ZERO

, press the ENTER key. The upper display will

blink. Press ENTER again to complete the zeroing of the instrument or press

the

MENU

key to cancel.

SPAN

Calibration

With the display set to

SPAN

, apply full scale pressure to the unit. Press the

ENTER key. The upper display will blink. Press ENTER again to complete the

calibration or press the

MENU

key to cancel.

©Copyright 2012 Dwyer Instruments, Inc.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, IN 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Printed in U.S.A. 2/12

Phone: 219/879-8000 www.dwyer-inst.com

FR# 443555-00 Rev.3

Loading...

Loading...