Page 1

Bulletin B-32

Series DH Digihelic®Differential Pressure Controller

Specifications - Installation and Operating Instructions

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, IN 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

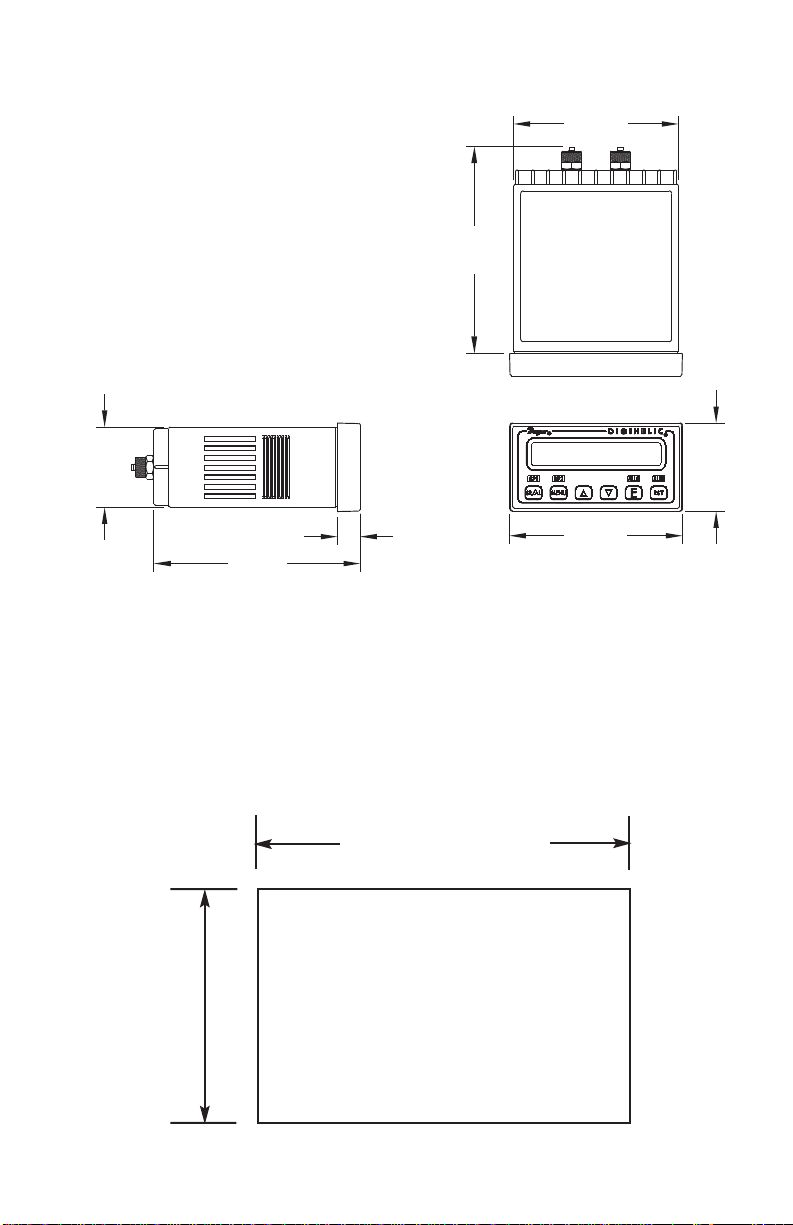

DIMENSIONS

3-19/32

[91.28]

4-1/2

[114.30]

1-3/4

[44.45]

1/2

4-1/2

[114.30]

[12.70]

Face Designed to Meet NEMA 4X (IP66)

PANEL CUT OUTS

Horizontal

3.620 in. + 0.032 - 0.0

(92.00 mm + 0.8 - 0.0)

1.772 in. + 0.024 - 0.0

(45.00 mm + 0.6 - 0.0)

1-15/16

[49.21]

3-25/32

[96.04]

1

Page 3

SPECIFICATIONS

Service: Air and non-combustible, compatible gases.

Wetted Materials: Consult factory.

Housing Material: ABS plastic, UL approved 94-V-0.

Accuracy: ±0.5% at 77°F (25°C) including hysteresis and repeatability (after 1 hour

warm-up).

Stability: < ±1% per year.

Pressure Limits: Ranges ≤ 2.5 in. w.c. = 2 psi

5˝: 5 psi; 10˝: 5 psi; 25˝: 5 psi; 50˝: 5 psi; 100˝: 9 psi.

Temperature Limits: 32 to 140°F (0 to 60°C).

Compensated Temperature Limits: 32 to 140°F (0 to 60°C).

Thermal Effects: 0.020%/°F (0.036/°C) from 77°F (25°C).

Power Requirements:

High Voltage Power = 100 to 240 VAC, 50 to 400 Hz or 132 to 240 VDC.

Low Voltage Power = 24 VDC ±20%.

Power Consumption:

Low Voltage Power = 24 VDC - 130 mA max.

High Voltage Power = 100 to 240 VAC, 132 to 240 VDC - 7VA max.

Output Signal: 4-20 mA DC into 900 ohms max.

Zero & Span Adjustments: Accessible via menus.

Response Time: 250 ms (dampening set to 1).

Display: 4 digit LCD 0.4˝ height LED indicators for set point and alarm status.

Electrical Connections: Screw terminals.

Process Connections: Compression fitting for use with 1/8˝ ID tubing x 1/4˝ OD

tubing (3.175 mm ID x 6.35 mm OD).

Enclosure Rating: Face designed to meet NEMA 4X (IP66).

Mounting Orientation: Mount unit in horizontal plane.

Size: 1/8 DIN. Panel Cutout: 1.772 x 3.620 in (45 x 92 mm).

Weight: 14.4 oz (408 g).

Serial Communications: Modbus® Protocol RTU, RS485, 9600 Baud.

Agency Approvals: UL Listed, CUL Listed File No. E83725

CE EMC and Low Voltage Directives:

EN61000-4-2

EN61000-4-3*

EN61000-4-4

EN61000-4-5

EN61000-4-6

EN61000-4-11

EN55011

EN601010

* Models DH-001 through DH-004, DH-011 through DH-014 pass criteria B. All others pass criteria A.

Switch SPECIFICATIONS

Switch Type: 2 SPDT relays.

Electrical Rating: 8 Amps at 240 VAC resistive.

Set Point Adjustment: Adjustable via keypad on face.

2

Page 4

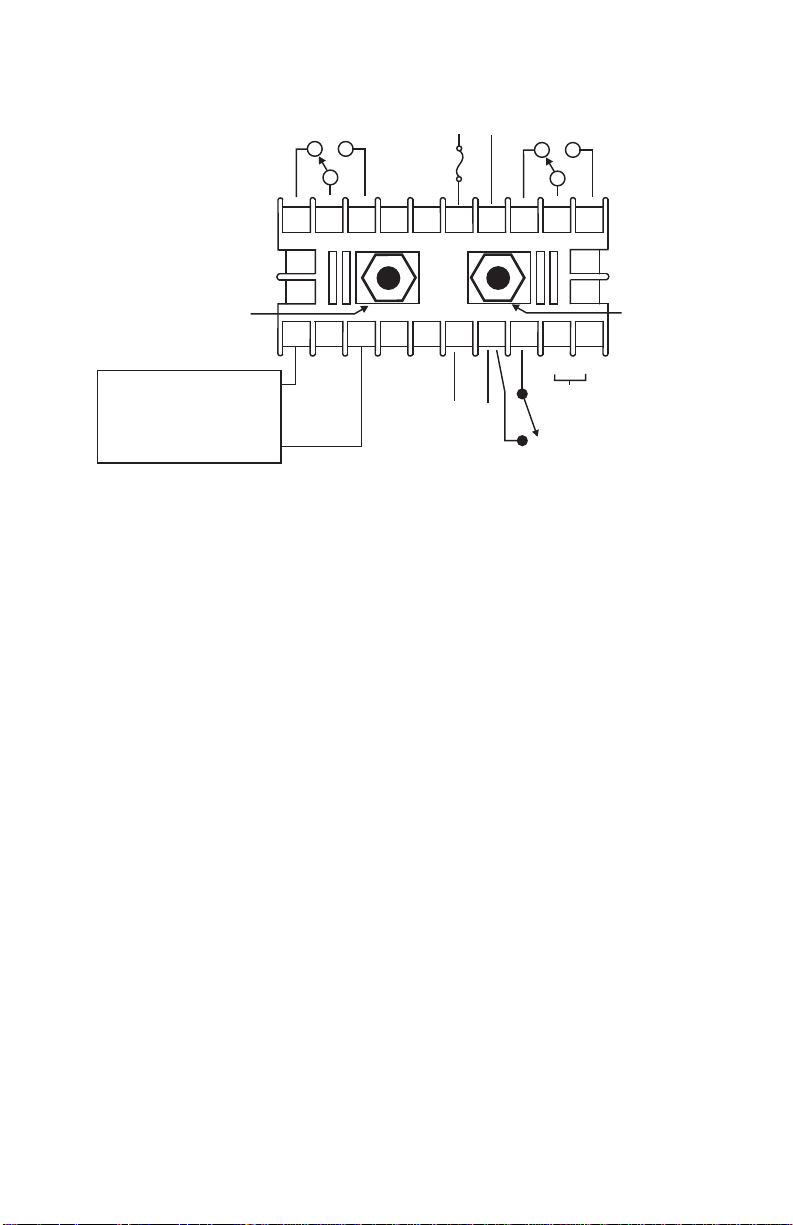

WIRING

2020

1919

1818

1717

1616

1515

1414

1313

1111

1212

1010

9 8

7

6

5

4

3

2

1

21

21

2222

2323

2424

C

C

N/CN/C

N/CN/C

N/ON/O

N/O

N/O

SP1

RELAY

SP1

RELAY

SP2 OR

ALARM

RELAY

SP2 OR

ALARM

RELAY

3/8A 250VAC

MEDIUM LAG

3/8A 250VAC

MEDIUM LAG

100-240 VAC or

132-240 VDC POWER

100-240 VAC or

132-240 VDC POWER

NOTE1NOTE1

A

B

_

+

RS485 SERIAL

COMMUNICATION

RS485 SERIAL

COMMUNICATION

_

+

24 VDC POWER24 VDC POWER

REMOTE RESET

SWITCH

REMOTE RESET

SWITCH

NOTE 1

NOTE 1

4-20mA

transmitter

output

4-20mA

transmitter

output

Device receiving 4-20mA

signal. Check specifications

of this device for input load

resistance. Typical 250 to

600 OHMS, 900 OHMS

maximum

signal. Check specifications

of this device for input load

resistance. T

600 OHMS, 900 OHMS

maximum

_

_

+

+

_

+

High Pressure PortHigh Pressure Port

Low

Pressure

Port

Low

Pressure

Port

WIRING

NOTES:

WARNING

If Digihelic®is powered by 24 VDC, the device receiving the 4-20 mA transmitter

output MUST NOT share a common ground with the 24 VDC supply or damage

to the Digihelic®will result.

1. The instrument may be powered from the AC line or 24 VDC. Do not wire AC

line terminals 4-5 and 24 VDC terminals 14-15 at the same time or damage to

the unit will result.

2. For supply connections, wire in accordance with an equivalent national standard

or code. Use copper conductors only rated for at least 75°C.

3. Terminals 11-15, 18 and 20 are rated CLASS 2.

4. ISOLATION:

Relays - 1500 VAC to all other inputs and outputs.

AC Line Power (terminals 4-5) - 1500 VAC to all other inputs and outputs.

RS485 output - 500 VAC to all other CLASS 2 wiring.

The 24 VDC Power, 4-20 mA transmitter, and Remote Reset Switch share

a common ground.

5. The Remote Reset Switch must be a dry contact switch.

6. Shielded cable is required for RS485 wiring.

3

Page 5

It is not necessary to remove the control chassis from the housing for

20

19

18

17

16

15

14

13

12

10

9 8

7

6

543

2

1

21

22

23

24

20

19

18

17

16

15

14

13

12

10

9 8

7

6

543

2

1

21

22

23

24

20

19

18

17

16

15

14

13

12

10

9 8

7

6

543

2

1

21

22

23

24

_

_

_

+

+

+

SHIELD

SHIELD

TIE SHIELD TO EARTH GROUND

TO RS232 TO

RS485 CONVERTER

120 OHM

RESISTOR

LAST UNIT ON RS485 BUSS

WIRE NUT

THE 120 OHM RESISTOR

IS USUALLY ONLY

NECESSARY FOR LONG

WIRE RUNS.

installation. If the control chassis is removed from the housing, you

must follow industry standard practice for control and protection

against Electro-Static Discharge (ESD). Failure to exercise good ESD

C

practices may cause damage to the control.

Wiring to housing terminals while chassis is removed may cause distortion of the internal connector and possible damage to the connector when the chassis is reinstalled. It is strongly recommended that

the control housing be wired with the chassis installed.

INSTALLATION

Mount the instrument in a location that will not be subject to excessive temperature,

shock or vibration. All models are designed for mounting in an enclosed panel.

Select the position desired for the instrument on the panel. Prepare the panel by cutting and deburring the required opening.

From the front of the panel, slide the instrument through the cut out. The housing

gasket should be against the housing flange before installing.

From the rear of the panel slide the mounting collar over the housing. Hold the housing with one hand and using the other hand, push the collar evenly against the panel

until the springs are compressed. The ratchets will hold the mounting collar and

housing in place.

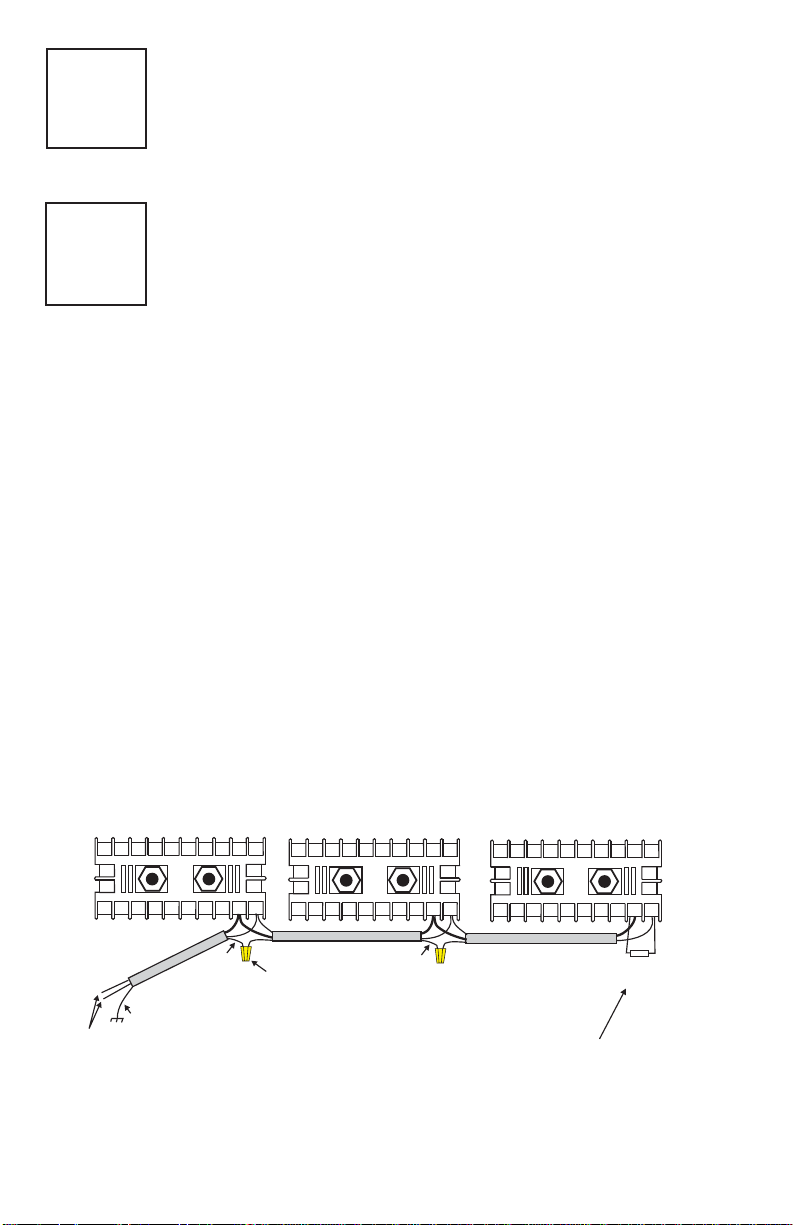

DIGIHELIC® CONTROLER RS485 WIRING

- RS485 WIRING TO DAISY CHAIN INSTRUMENTS ON THE

UP TO 128 UNITS MAY BE DAISY CHAINED

TO RS232 TO

RS485 CONVERTER

10

23

24

19

16

17

18

TIE SHIELD TO EARTH GROUND

20

15

14

SHIELD

13

21

22

111112

WIRE NUT

10

23

24

19

20

18

RS485 BUSS

LAST UNIT ON RS485 BUSS

10

21

23

22

16

17

15

13

14

SHIELD

4

24

111112

19

20

16

17

15

18

THE 120 OHM RESISTOR

IS USUALLY ONLY

NECESSARY FOR LONG

WIRE RUNS.

14

13

120 OHM

RESISTOR

21

22

111112

Page 6

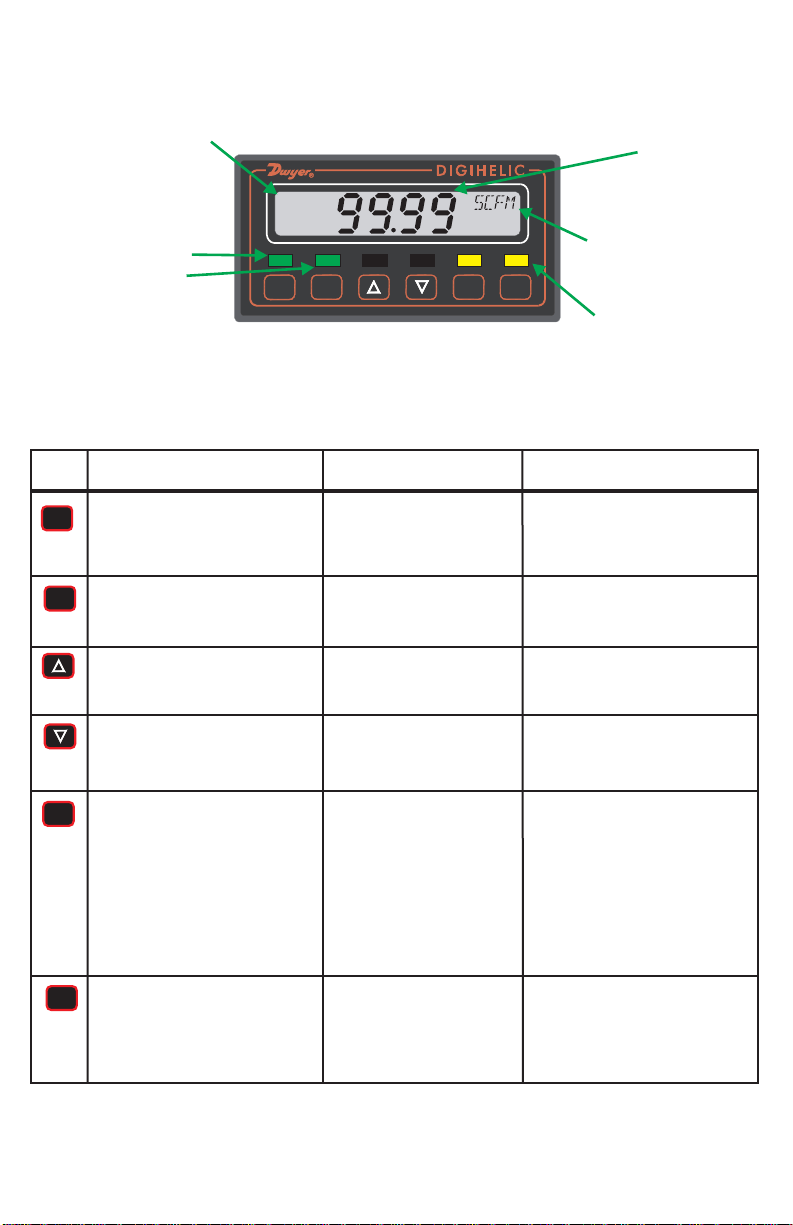

SP1

SP2

ALHI

ALLO

SP/AL

RST

MENU

E

X1K

MULTIPLIER DESCRIPTOR

MULTIPLIER DESCRIPTOR

VISIBLE WITH SO

ME VELOCITY

AND FLOW RANGE

FRONT PANEL

PRESSURE

VALUE

UNITS

ALARM

DESCRIPTOR

SP2

DESCRIPTOR

SP1

DESCRIPTOR

SP/ALSP/AL

SP/AL

MENUMENU

SP/AL

MENU

SP/AL

MENU

SP/AL

MENU

E

SP/AL

MENU

E

RSTRST

VISIBLE WITH S

ME VELOCITY

AND FLOW RANGE

SP1

DESCRIPTOR

SP2

DESCRIPTOR

FRONT PANEL

X1K

SP1

SP2

SP/AL

MENU

KEY FUNCTIONS

ALLO

ALHI

RST

PRESSURE

VALUE

UNITS

ALARM

DESCRIPTOR

HOME POSITION FUNCTION

Sequences the display

SP/AL

through SET POINT and

ALARM settings

Allows access to the

MENU

UP

ARROW

DOWN

ARROW

ENTER

RESET

Clears or resets an Alarm

(alarm set for manual

menus

Displays full scale

range of unit

reset)

MAIN MENU FUNCTION

Return to home

position

Return to home

position

Sequences through

menus

Sequences through

menus

Enter into SUB MENU

5

SUB MENU FUNCTION

Return to home position

Return to previous menu

Increments a value

Decrements a value

Changes a value or

setting. Press ENTER

and display will blink.

Adjust with UP or DOWN

arrows. Press ENTER to

store. Display will stop

blinking.

Peak/Valley SUB

MENU resets display to

present value.

Page 7

SETTING SET POINTS AND ALARMS

SP/AL

SP/AL

SP/AL

SP/AL

SP/AL

SP/AL

SP/AL

SP/AL

SP/AL

SP/AL

SP/AL

SP/AL

SP/AL

Visible when

Visible when

Visible when

mode =

mode =

mode =

CONTROL MODE

CONTROL MODE

CONTROL MODE

PRESSUREPRESSURE

0

0

TIME

TIME

0.20.2

0.40.4

0.60.6

0.80.8

1.0

(in. w.c.)

SP/ALSP/AL

The hot key provides direct access to the Set Point and Alarm MENU. The

Set Point and Alarm MENUS that are displayed are based upon the Control (CtrL)

SUB MENU.

CONTROL MODE

SP/AL

SP/AL

SP/AL

CONTROL MODE

SP/AL

SP/AL

SP/AL

SP/AL

SP/AL

CONTROL MODE

SP/AL

SP/AL

SP/AL

SP/AL

SP/AL

Visible when

Visible when

Visible when

mode =

mode =

mode =

SET POINT ADJUSTMENT

Adjusting the Digihelic®Controller Set Points is quick and simple. Instead of setting

a set point and deadband, simply adjust

SP1L

on point, and then adjust

or

SP2L

SP1H

or

SP2H

for the desired relay turn

for the desired relay turn off point.

In the above graph, an instrument with a 1.0˝ range would have the SP1 relay turn

on at 0.8˝ and off at 0.4˝.

turn off point. The relays outputs normally function in the direct acting mode, which

means the relays turn on with an increase in pressure. SP1 may be configur ed to act

as a reverse acting relay (refer to the 1SP SUB MENU setting, page 15). When set

for reverse acting,

ON point. SP2 is always direct acting.

SP1H

SP1H

sets the relay turn on point, and

sets the relay turn OFF point, and

6

SP1L

SP1L

sets the relay turn

sets the relay

Page 8

MENU MAP

MENU MAP

CONTINUED

SETTINGS

SP/AL

MENU

SP/AL

MENU

SP/AL

MENU

E

SP/AL

MENUMENU

MAIN MENUS SUB MENUS

SETTINGS

MENUS

UNAVAILABLE

FOR

BI-DIRECTIONAL

RANGES AND

RANGES ABOVE

25 IN. W.C.

CONTINUED

7

Page 9

CONTINUED

SETTINGS

MAIN MENUS SUB MENUS

SP/AL

MENU

SP/AL

MENU

SP/AL

MENU

E

SP/AL

MENUMENU

SETTINGS

CONTINUED

8

Page 10

MAIN MENUS SUB MENUS

SETTINGS

SP/AL

MENU

SP/AL

MENU

SP/AL

MENU

E

SP/AL

MENUMENU

Menus present only

in pressure operation

9

Page 11

Main Menu Selections (Upper Right Display Reads

MENU

)

SECr

OPEr

OUt

d.S

AdU

Security - Lock out access to Set Point and Alarm settings, or lock out

access to all settings.

Operation - Selection of Pressure, Velocity or Flow and corresponding

engineering units.

Output - Select a Single Set Point, 2 Set Points, or a Set Point and an

Alarm mode of operation.

Display - Monitor and adjust display related settings: Peak, Valley, display

resolution, % output and dampening.

Advanced functions - Modify advanced function parameters, transmitter

output scaling, Modbus

Maintenance Set Point settings and calibration.

®

Protocol communication settings,

10

Page 12

MAIN MENUS and SUB MENUS

Units visible, so unit

is presently set to

measure pressure

is presently set to

measure pressure

Units not visibleUnits not visible Units not visibleUnits not visible

SECr

OPEr

The

The SUB MENUS are:

(Security) MAIN MENU

SECr

The password values shown in the table cannot be altered, so retain a copy

of these pages for future reference.

is the only SUB MENU in the security MENU. When the security

SUB MENU is selected, the present security level is displayed in the

upper right hand display. To change the security level, adjust the

number displayed to the number shown in the following table for the

desired security level.

Security Level

Displayed

1

2

3

4

Access

All menus access

Menu Access

SP/AL Locked

SP/AL Access

Menus Locked

All settings locked

Password

Value to Enter

10

70

90

111

(Operation) MAIN MENU

OPEr

MENU selects the measurement type of the instrument.

PrES

UEL

FLO

If the instrument is set for Velocity, the

SUB MENU. If the instrument is set for Flow, the

KFAC

When scrolling through the

currently set for will show the units in the upper right display. The other measure-

ment types will have a blank upper right display.

- Velocity

- Flow

and

- Pressure

ArEA

SUB MENUS. These will be discussed under Velocity and Flow.

KFAC

ArEA

DIA

OPEr

- K Factor

- Area

- Diameter

OPEr

MENU will have an additional

OPEr

SUB MENUS, the measurement type the unit is

11

XDIM

YDIM

MENU will have additional

- X Dimension

- Y Dimension

KFAC

Page 13

PrES

(Pressure) SUB MENU

For pressure measurement, the following units are available:

INWC

- Inches of water column

FTWC

MMWC

CMWC

PSI

INHG

- Feet of water column

- Millimeters of water column

- Centimeters of water column

- Pounds per square inch

- Inches of mercury

MMHG

MBAR

PA

KPA

HPA

OZIN

- Millimeters of mercury

- Millibar

- Pascal

- Kilopascals

- Hectopascals

- Ounce inches

Table 1 Pressure Range vs. Available Units

INWC

FTWC

MMWC

.1000

.2500

.5000

1.000

2.500

.2083

5.000

.4167

10.00

.8333

25.00

2.083

50.00

4.167

100.0

8.333

NOTE:

exceeded above or below full scale by 2%.

OVFL

2.540

6.350

12.70

25.40

63.50

127.0

254.0

635.0

1270

2540

(over flow) or

CMWC

.2540

.6350

1.270

2.540

6.350

12.70

25.40

63.50

127.0

254.0

UnFL

PSI

INHG

MMHG

.1868

.4671

.9342

1.868

.1839

.3678

.1806

.7356

.3613

1.839

.9032

3.678

1.806

7.356

3.613

(under flow) will appear when the ranges have been

4.671

9.342

18.68

46.71

93.42

186.8

MBAR

.2491

.6227

1.245

2.491

6.227

12.45

24.91

62.27

124.5

249.1

PA

24.91

62.27

124.5

249.1

622.7

1245

2491

6227

KPA

.1245

.2491

.6227

1.245

2.491

6.227

12.45

24.91

HPA

.2491

.6227

1.245

2.491

6.227

12.45

24.91

62.27

124.5

249.1

OZIN

.1445

.2890

.5780

1.445

2.890

5.780

14.45

28.90

57.80

UEL

(Velocity) SUB MENU

For velocity measurement, the following units are available:

SFPM

M/S

- Standard feet per minute

- Meters per second

Table 2 Available Velocity Ranges

INPUT RANGE INWC

0 - 0.1

0 - 0.25

0 - 0.5

0 - 1

0 - 2.5

0 - 5

0 - 10

0 - 25

NOTE: Air velocity and flow readings are based upon standard dry air conditions with an

ambient temperature of 70°F and a barometric pressure of 29.92 INHG.

SFPM RANGE

0 - 1266

0 - 2002

0 - 2832

0 - 4004

0 - 6332

0 - 8954

0 - 12.66 x IK

0 - 20.02 x IK

M/S RANGE

0 - 6.431

0 - 10.17

0 - 14.39

0 - 20.35

0 - 32.17

0 - 45.48

0 - 64.33

0 - 101.7

12

Page 14

FLO

(Flow) SUB MENU

For flow measurements the following units are available:

SCFM

M^3H

- Standard cubic feet per minute

- Cubic meters per hour

FLO r

(Flow Range) SUB MENU

LO

- 99.99 x 1K flow range

HI

- 999.9 x 1K flow range

Tables 3 -6 show the flow ranges available, and the maximum duct size that can

be set for each input range.

Table 3

FLOr = LO

RANGE

IN WC

0.1

0.25

0.5

1

2.5

5

10

25

Table 5

FLOr = LO

RANGE

IN WC

0.1

0.25

0.5

1

2.5

5

10

25

Maximum Duct Size (English)

SCFM

RANGE

99.99 x 1K

99.99 x 1K

99.99 x 1K

99.99 x 1K

99.99 x 1K

99.99 x 1K

99.99 x 1K

99.99 x 1K

Maximum Duct Size (Metric)

Mˆ3/Hr

RANGE

99.99 x 1K

99.99 x 1K

99.99 x 1K

99.99 x 1K

99.99 x 1K

99.99 x 1K

99.99 x 1K

99.99 x 1K

MAX. DUCT

SIZE, SQ. FT.

78.9

49.9

35.3

24.9

15.7

11.1

7.8

4.9

MAX. DUCT

SIZE Mˆ2

4.32

2.73

1.93

1.37

0.86

0.61

0.43

0.27

Table 4

FLOr = HI

RANGE

IN WC

0.1

0.25

0.5

1

2.5

5

10

25

Table 6

FLOr = HI

RANGE

IN WC

0.1

0.25

0.5

1

2.5

5

10

25

Maximum Duct Size (English)

SCFM

RANGE

999.9 x 1K

999.9 x 1K

999.9 x 1K

999.9 x 1K

999.9 x 1K

999.9 x 1K

999.9 x 1K

999.9 x 1K

Maximum Duct Size (Metric)

Mˆ3/Hr

Range

999.9 x 1K

999.9 x 1K

999.9 x 1K

999.9 x 1K

999.9 x 1K

999.9 x 1K

999.9 x 1K

999.9 x 1K

MAX. DUCT

SIZE, SQ. FT.

789.8

499.5

353.1

249.7

157.9

111.7

78.9

49.9

MAX. DUCT

SIZE, Mˆ2

43.19

27.31

19.3

13.64

8.63

6.10

4.31

2.73

KFAC

KFAC

SUB MENU

K Factor - becomes accessible if the instrument is set for Velocity or Flow.

When the Digihelic

may specify a K Factor. The adjustment range is 0.01 to 2.00. The factory

setting is 1.

®

Controller is used with a pitot tube, the manufacturer

13

Page 15

ArEA, DIA, XDIM

These SUB MENUS become accessible if the instrument is set for flow. When measuring flow, the area of the duct must be specified. Tables 3 and 4 show the input

range vs maximum flow and duct size. For a rectangular duct the maximum size is

specified in square feet or meters. For a circular duct the maximum size is specified

as the diameter. X, Y and circular dimensions are entered in feet with 0.01 foot res-

olution for

with 1 millimeter resolution.

FLOr = LO

and

YDIM

SUB MENUS

and 0.1 foot resolution for

FLOr = HI

, or entered in millimeters

ArEA

duct. If a circular duct is selected, the

rectangular duct is selected, the

vated.

DIA

XDIM

YDIM

OUt

The

MENUS are:

CtrL

ISP

AL

- Area, select

CIR

for a circular duct or

XDIM

- Diameter, enter the diameter of a duct

- Enter the “X” dimension of a duct

- Enter the “Y” dimension of a duct

(Output) MAIN MENU

OUt

MENU selects the output type of the instrument. The SUB

- Control type

- SP1 reverse or direct acting

- Alarm type

RECT

DIA

SUB MENU will be activated. If a

and

YDIM

ALrE

AL.H

ALDL

- Alarm reset, manual or auto

- Alarm inhibit

- Alarm delay

for a rectangular

SUB MENUS will be acti-

X

Y

14

Page 16

0

100

Process

Reverse Acting

Time

SPH

SPL

Relay Inactive

Relay Active

CtrL

(Control) SUB MENU

1SP

- Single set point

2SP

- Two fully independent set points

SPAL

1SP

(SP1 Reverse or Direct Acting) SUB MENU

DIR

REV

- Single set point and alarm

- Direct. Relay turns on with increasing pressure

- Reverse. Relay turns on with decreasing pressure

100

Process

0

Relay Inactive

Relay Active

Direct Acting

SPH

SPL

Time

15

Page 17

The following alarm function SUB MENUS are activated when

SPAL

:

AL

(Alarm Type) SUB MENU

HI

- High alarm

LO

- Low alarm

HILO

- For a high/low guardband type alarm

CtrL

is set to

ALARM ADJUSTMENT

Alarm settings are dependent upon the selected alarm mode. The Digihelic

Controller alarm may be configured as a High Alarm, Low Alarm, or High/Low Alarm.

Alarm settings are all absolute and may be set to anywhere within the range of the

instrument. The dead bands of the alarms are fixed at 1% of full scale.

®

HIGH ALARM FUNCTION

MIN. PRESSURE

MIN. PRESSURE

Relay ON Relay OFF

MIN. PRESSURE

ALLO

ALLO

ALHI

Relay OFF Relay ON

LOW ALARM FUNCTION

ALHI

MAX. PRESSURE

MAX. PRESSURE

HIGH/LOW ALARM

FUNCTION

MAX. PRESSURE

Relay ON Relay OFF Relay ON

16

Page 18

ALrE

(Alarm Reset) SUB MENU

ONOF

HOLD

AL.H

(Low Alarm Inhibit) SUB MENU

ON

OFF

If

up until the process value passes through the alarm set point once.

ALDL

Sets the amount of time an alarm condition must be continuously met before

the alarm condition is recognized. The alarm delay is adjustable from 0-3600

seconds.

d.S

(Display) MAIN MENU

PEAK

VALy

ZERO

- Automatic reset

- Manual reset. An alarm is reset by the RESET key on the front

panel, or an external reset switch.

- Alarm inhibit is on

- Alarm inhibit is off

AL.H

is selected ON, a low alarm condition is suspended upon power

(Alarm Delay) SUB MENU

- Peak value

- Valley value

- Zero

rESO

Pd.S

DAMP

- Resolution

- Process display

- Dampening level

PEAK

(Peak) SUB MENU

The Peak feature stores the highest pressure reading the instrument has

measured since the last reset or power up. At power up

to the present pressure reading. To manually reset the

press the RESET key while in the

VALy

(Valley) SUB MENU

The valley feature stores the lowest pressure reading the instrument has

measured since the last reset or power up. At power up

the present pressure reading. To manually reset the

RESET key while in the

VALy

PEAK

SUB MENU.

SUB MENU.

17

PEAK

VALy

PEAK

VALy

value, press the

is reset

value,

is reset to

Page 19

rESO

(Resolution) SUB MENU

The Digihelic®Controller is capable of displaying four digits of resolution.

However, at very low pressures the instability of the pressure may cause

fluctuations in the least significant digit causing the least significant digit to be

of little value. Three digit resolution (

least one digit to the right of a decimal.

3DIG

- Set display for 3 digit resolution

4DIG

- Set display for 4 digit resolution

Pd.S

(Process Display) SUB MENU

STD

- Display reads pressure, velocity, or flow values

PCT

- Display reads % of full scale value

3DIG

) can only be active when there is at

When the display is reading percent,

the display. The percent display is only available in pressure operation.

DAMP

(Dampening) SUB MENU

Adjust from 1-16

Dampening stabilizes the display from instabilities due to things such as

vibration and excessive pressure fluctuations. The dampening setting adjusts

the amount of readings that are averaged for each display update. Adjust

the dampening value until the display reads a stable value for the application.

AdU

(Advanced) MAIN MENU

POL

- Process output low

POH

- Process output high WR- Modbus®Protocol write enable/disable

MSP1

- Maintenance set point 1

MSP2

POL

- Maintenance set point 2

and

POH

(Process Output Low and High) SUB MENUS

This feature is used in pressure operation only.

Process output low and high are used to scale the 4-20 mA output. Set

POL

to the desired display reading for 4mA output, and set

desired display reading for 20 mA output.

POL

may be adjusted 2% BELOW minimum scale up to

POL

be adjusted from

to 2% ABOVE maximum scale.

ADDR

ZERO

SPAN

PCT

is displayed in the upper right of

- Modbus® Protocol address

- Zero calibration

- Span calibration

POH

POH

must be higher than

POH. POH

to the

POL

may

.

18

Page 20

MSP1

SP/ALSP/AL

and

MSP2

(Maintenance Set Point 1 & 2) SUB MENUS

Adjust for the desired maintenance set points when the unit is placed in the

maintenance mode. The deadband is fixed at 2% of full scale. To enter or

leave the maintenance mode, press and hold the for 8 seconds.

ADDR

(Modbus® Protocol Address ) SUB MENU

Modbus®communication instrument address. Set from 1 to 247. This number must match the address number used by the host computer.

To obtain the Digihelic®Controller Modbus®register list please visit

www.dwyer-inst.com

See page 4 for wiring diagram.

WR

(Modbus® Write Protect) SUB MENU

d.S

- Disables write commands from Modbus®. Protocol can only read

information from the instrument.

En

- Enable write commands from Modbus® Protocol. Modbus®can read

information from and write information to the instrument.

ZERO

and

SPAN

(Calibration of Zero and Span) SUB MENUS

The lower display reads

ZERO

Calibration

NOTE: For accurate calibration, DO NOT apply any pressure when

performing this function.

With the display reading

blink. Press ENTER again to complete the zeroing of the instrument or press

MENU

the

SPAN

With the display set to

ENTER key. The upper display will blink. Press ENTER again to complete the

calibration or press the

©Copyright 2009 Dwyer Instruments, Inc.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, IN 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

key to cancel.

Calibration

CAL

in this mode.

ZERO

, press the ENTER key. The upper display will

SPAN

, apply full scale pressure to the unit. Press the

MENU

key to cancel.

Modbus®is a registered trademark of Schnieder Automation and Company.

Printed in U.S.A. 7/09

Phone: 219/879-8000 www.dwyer-inst.com

FR# 443246-00 Rev. 4

Loading...

Loading...