Page 1

Bulletin V-21

5

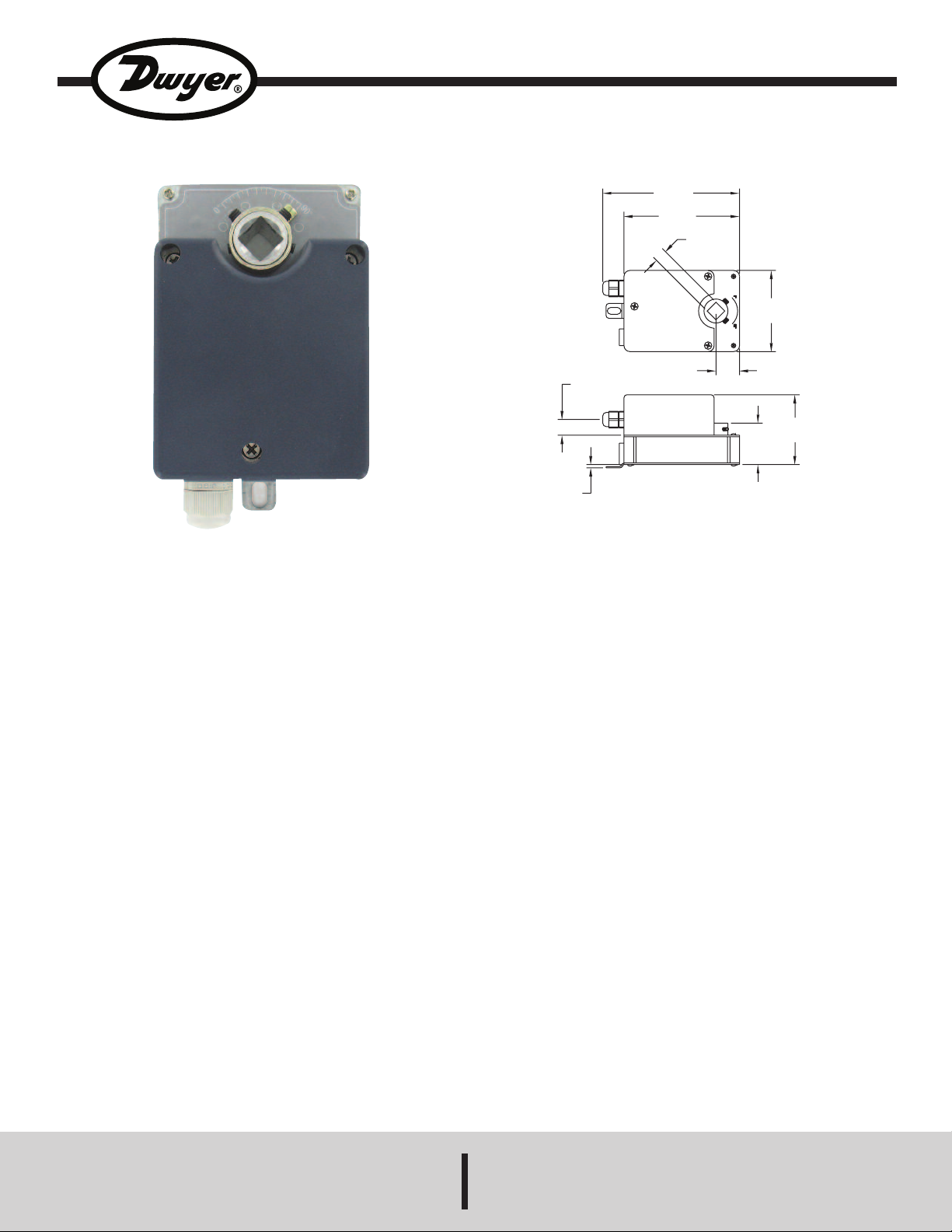

-23/32

(

145.26)

4-53/64

(122.63)

1

7/32 SQ

(

13.49)

3

-25/64

(

86.12)

63/64

(25.00)

2-59/64

(74.22)

1

-47/64

(

44.05)

9/64

(3.57)

2

1/32

(

16.67)

Series DDC 17, 35, 53, 70 in-lb Modulating Damper Actuator

Specifications - Installation and Operating Instructions

Series DDC Direct Coupled Actuators are non-spring return actuators

that are perfect for positioning of dampers and valves in HVAC Systems.

Actuators are designed to accept 4 to 20 mA or 0 to 10 VDC modulating

control signals and are 24 VAC powered. Actuators produce 17 to 70 inlb (2 to 8 Nm) of torque. Unit features a 0 to 100 VDC feedback signal of

damper position.

Features

• Direct mount.

• Actuator travel indicator.

• Overload protection.

• Manual override.

• Modulating 4 to 20 mA or 0 to 10 VDC control signal.

• Position feedback signal.

• 60,000 cycles nominal.

FUNCTION TESTING

Press the manual button on the back of the actuator. The gearing inside

the actuator will break away. The damper can be operated manually

while pressing the manual button. DO NOT OPERATE WHEN POWER

IS ON!

SPECIFICATIONS

Power Requirements: 24 VAC, ±10%, 50/60 Hz, single phase.

Power Consumption: 4 VA.

Control Input: 4-20 mA or 0-10 VDC.

Overload Protection: Magnetic clutch.

Angle of Rotation: 95° (mechanically adjustable).

Accuracy: ±5%.

Fits Shaft Diameter: 0.4˝ (10 mm) or 0.5˝ (13 mm).

Position Indication: Visual indicator.

Direction of rotation: CW/CCW.

Running Time: 17 in-lb, 35 in-lb, 53 in-lb: 72 sec.; 70 in-lb:160 sec.

Electrical Connection: Terminal block, 18 AWG.

Manual Override: Push button.

Temperature Limit: -22 to 122°F (-30 to 50°C).

Sound: <45 dB.

Life Expectancy: 60000 full cycles.

Housing: NEMA 2 (IP40).

Wiring Connection: Terminal block.

Standard Accessories: (2) imitative baffles, (2) baffle setscrews, (1)

actuator body setscrew, and (1) aluminum gasket.

Weight: 1.72 lb (0.78 kg).

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

Page 2

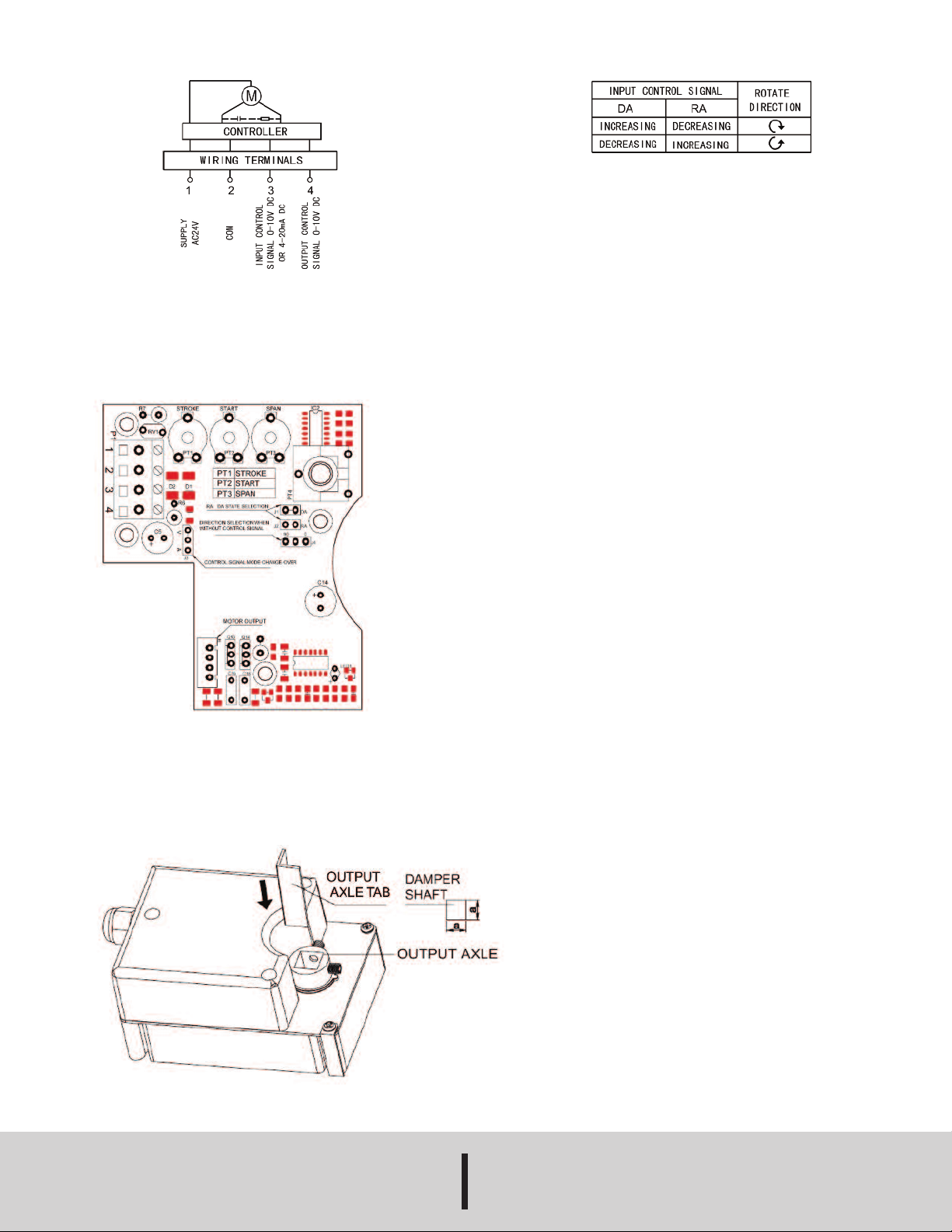

WIRING DIAGRAM

Set Up

• Set jumper J1 or J2 to proper selection for reverse or direct acting. See

Chart 1: Actuator Action above for more detail.

• Set jumper J3 for Voltage or Current input control signal.

• Set jumper J4 for actuator direction on loss of control signal.

• Potentiometer PT1 adjusts the stroke of the actuator.

CHART 1: ACTUATOR ACTION

MAINTENANCE

Upon final installation of the Series DDC Non-Spring Return Direct

Coupled Actuator, no routine maintenance is required. A periodic check

of the system calibration is recommended. The Series DDC is not field

serviceable and should be returned if repair is needed (field repair

should not be attempted and may void warranty). Be sure to include a

brief description of the problem plus any relevant application notes.

Contact customer service to receive a return good authorization number

before shipping.

Square shaft installation

Before installation, the aluminum gasket should be put into the hole of

Output Axle. Fix with square damper shaft. The rotating angle of the

actuator can be set by internal potentiometer. The match between

working range and feedback signal is automatically done by the actuator.

a = .4˝ (10 mm)

or

.5˝ (13 mm)

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 5/14 FR# R3-443451-40 Rev. 2

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

Loading...

Loading...