Page 1

Series DCT600 Timer Controller

Specifications – Installation & Operating Instructions

4-1/4

[107.95]

4-7/8

[123.8]

BULLETIN E-99

1/2

[12.7]

1/16

[1.59]

[1.59]

1-23/64

[34.53]

[12.7]

1/16

1/2

1-3/16

[30.16]

[158.75]

8-1/4

[209.55]

6-1/4

[171.45]

8-3/4

[222.55]

6-3/4

6-1/4

[156.75]

6-7/8

[174.62]

Introduction

The Series DCT600 Timer Controller is a timing system for pulse-jet type dust collectors or pneumatic conveying systems in either continuous or on-demand cleaning

applications. It provides either 4, 6,10, 22 or 32 channels. The DCT600 was designed

for ease of installation in your dust collector system. For installations requiring fewer

channels than available on the board, a shorting plug (DCT610) or dip switches

(DCT632) allows selection of the last used channel. Time-on and time-off settings are

selected using two potentiometers. High-limit and low-limit control inputs are provided for use with on-demand systems. When used in a continuous mode the high-limit

input is jumpered. For safety, the control circuitry including the control inputs and the

last channel jumper, is isolated from the power line.

DWYER INSTRUMENTS, INC.

SPECIFICATIONS

Output Channels: 4, 6, 10, 22 & 32 channels.

Voltage Requirements: 85 to 270 VAC (~) 50 or 60 Hz.

Power Consumption: 1.8 W.

Input Power: 302 VA max.

Load: 300 VA max, pilot rating C300.

Fuse: Type 3 AG, 3A @ 250 VAC (~).

Ambient Operation Temperature: -40 to 149°F (-40 to 65°C).

Storage Temperature: -40 to 176°F (-40 to 80°C).

Humidity Conditions: 5 to 95% noncondensing.

On Time: 50 to 500 msec.

On Time Accuracy: ±5% of setting.

On Time Repeatability: ±1 msec.

Off Time: 1 to 180 seconds.

Off Time Accuracy: 5% of setting.

Pollution Degree: 2.

Altitude: 6560 ft (2000 m) max.

Environment: Indoor use, must be installed in a weather-proof enclosure for out-

side applications.

Weight: 9 oz (255 g).

Agency Approvals: UL, cUL, CE.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

Installation

Warning: Always install and service this device with the power off

and a lockout installed if required. Line voltages are exposed on the

board. As a result, this device is not intended to be installed in any open

location. It must be installed within an enclosure that meets appropriate

safety and local code requirements. Follow applicable safety procedures when installing or servicing this product.

Warning: Always replace the fuse with the proper type and rating.

The fuse is Type 3 AG fast acting 3 Amp @ 250V. DO NOT use slowblow type fuses. Failure to comply with this requirement will pose a serious safety risk and will void manufacturer’s warranty.

As a permanently installed piece of equipment, a power disconnect

switch, circuit breaker, or other approved disconnect device must be

installed in close proximity to the installed board and within easy reach

of the operator. This disconnect device must include a label indicating

its function as a mains disconnect.

Power Requirements

The controller is designed for operation on either 120 VAC or 240 VAC 50/60 Hz

power. The input voltage must be between 85 VAC and 270 VAC either 50 or 60 Hz.

The solenoid loads must be rated for the line voltage.

Location

The system must be located in an enclosure that meets relevant safety standards and

electrical codes. There are no other special orientation requirements. Mount it using

the four mounting holes in the baseplate. The baseplate back is flush, so no special

spacers are needed to accommodate obstructions except for those imposed by the

location itself.

Installed screws and other mounting hardware must maintain a spacing of 0.250 in

(6.35 mm) from the circuit board.

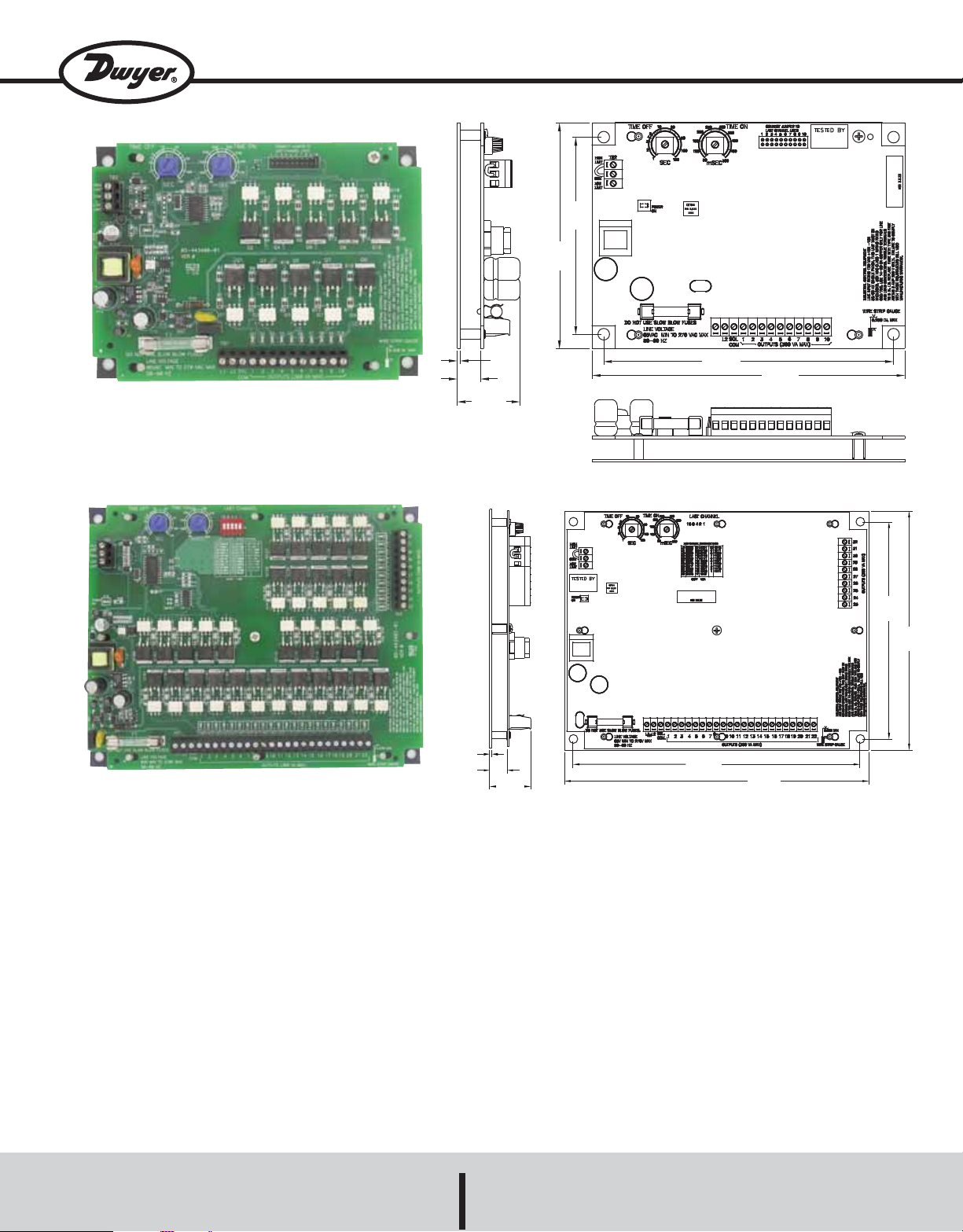

Figure 2-1 Wiring Connections DCT622, DCT632

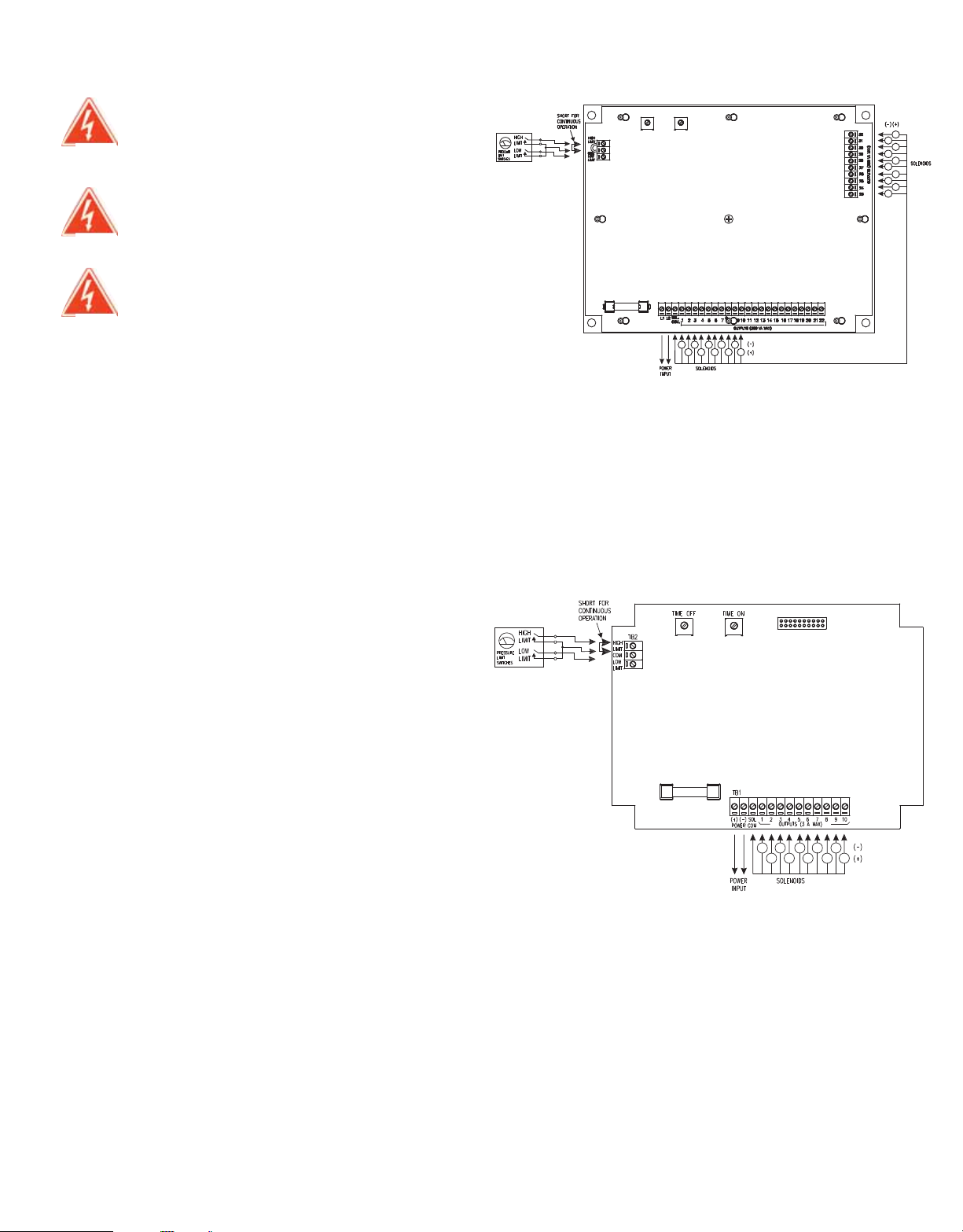

Connections

The line and solenoid connections are located at the lower edge of the board. The

terminal block is a “Euro” style connector system that clamps the wire within the connector body. The connector will accept wire sizes from 14 to 22 gages. Wire must be

copper only with at least 60°C or 60/75°C rated insulation. These terminals should be

torqued to 5 in. lb. The connectors are specified for single connection but multiple

wires may be connected to a single lug provided local codes allow this and good

workmanship practices are followed. When using stranded wire, make sure that there

are no “stray” strands. These pose safety hazards and may cause system failure or

damage. Connect the line power to L1 and L2. Connect the solenoids between the

selected output and the solenoid common. Solenoid common and L2 are internally

connected. Refer to Figure 2-1 or Figure 2-2 depending on model.

The wire should be stripped to no more than 0.25 in. A strip gauge is provided at the

lower right corner of the board. Longer than this may cause shorts or expose line voltages to possible contact.

Switches connected to the control inputs at the top of the board must be isolated normally open contacts connected only to the relevant terminal and to the common terminals. These switches should be rated for low voltage and low current operation.

The following subparagraphs describe the external switch connections. Refer to figure 2-1 or Figure 2-2 depending on model for switch connection illustration.

Figure 2-2 Wiring Connections DCT604, DCT606, DCT610

Page 3

External Limit Switch Connection

0.31 TYP [7.87]

4 PLACES

7.73

[196.3]

8.88

[225.6]

4.00 TYP

[101.6]

5.74

[145.8]

4.45

[113.0]

4.00

[101.6]

The controller may be used with an external pressure limit switch or sensor to provide

demand-cleaning operation. A three pin terminal block provides connection for external high and low limit switches. A simple on-off system can be established with a single pressure switch connected to the high limit input. Better control can be achieved

with a high and low limit switch/gage such as the Dwyer Photohelic

The switches must be isolated contacts between the high or low limit input and the

common connection. The wiring from the switches must be two or three wires with no

other connections made to these. The common line must not be connected to equipment ground or protective ground, since these may introduce electrical noise and

cause improper operation or possible damage to the control board. The operation of

these inputs is summarized as follows:

Operating Modes

Current

Operation

Hold

Hold or Run

Hold

Hold

Run

Hold

Run

Ø – Transition from open to closed

≠ – Transition closed to open

X – Either open or closed

Continuous Cycle Mode

The DCT600 has two operating modes available for different applications. Starting

with the most basic mode, it is capable of operating in a continuous cleaning cycle.

This can be initiated by placing a jumper between the high limit input and the common connection. Two setup parameters control operation: time off, time on. Time on

and time off specifically deal with the solenoid on time and the time interval between

the end of the on pulse and the start of the next.

Low Limit

Switch

Open

X

Ø

Closed

Closed

Closed

≠

High Limit

Switch

Open

Closed

Open

Ø

≠

Ø

Open

®

pressure gage.

Next

Operation

Hold

Run

Hold

Run

Run

Run

Hold

Last Channel Selection DCT622, DCT632

The DCT622 and DCT632 use a set of 5 switches to select the last channel. If the

selected last channel is greater than the number of channels available then the controller will cycle through only the available channels. The following table defines the

switch settings for each of the last channel selections. For convenience this table is

also provided on the board below the switch.

Time Off and Time On Setup

Channel

32

31

30

29

28

27

26

25

24

23

22

0 = Off, 1 = On

Time off defines the period of time between solenoid activations when no channels

are enabled. This value may be set between 1 second and 200 seconds with a resolution of 1 second. Time on defines the solenoid on time. The value may be set

between 50 msec and 500 msec with a resolution of 10 msec. If adjustments are

made while the system is in operation, the new setting will take effect in the following

solenoid cycle. Do not use excessive force to turn the potentiometers. This will damage the unit. A factory installed option is available for a time on range of 0.05 to 10

seconds.

Switch

00000

00001

00010

00011

00100

00101

00110

00111

01000

01001

01010

Channel

21

20

19

18

17

16

15

14

13

12

11

Switch

01011

01100

01101

01110

01111

10000

10001

10010

10011

10100

10101

Channel

10

9

8

7

6

5

4

3

2

1

Switch

10110

10111

11000

11001

11010

11011

11100

11101

11110

11111

Demand Mode

Demand mode operation can be configured using the high limit and low limit inputs.

A simple on-off system can be setup with a single pressure switch connected to the

high limit input. Better control can be achieved with a high and low limit switch set

such as is provided in the Photohelic

on and time off may be programmed to define the cleaning cycle. When the cleaning

cycle is completed, the controller will continue the cycle until the last channel is

pulsed. The next cleaning cycle will always start on channel 1. A factory installed

option is available. A factory installed option is available that will not clean to the end

of a cycle, but rather stop where the cleaning cycle ended. The next demand for

cleaning will start where the last cleaning cycle left off.

System Setup

Last Channel Selection DCT604, DCT606, DCT610

A jumper connector is provided on the DCT610, DCT606, and DCT604 to select the

last channel used. Place the jumper on the two pins corresponding to the last channel used in the installation.

®

pressure gage. In this on-demand mode, time

Weatherproof Enclosure Option

DCT604, DCT606, DCT610

Page 4

13-3/16

(338.14)

11-19/64

(285.94)

5-19/32

(142.08)

Weatherproof Enclosure Option

Explanation of Symbols:

DescriptionSymbol

Caution: Risk of electric shock

Caution: Risk of danger, refer to user’s manual for further

information

DCT622, DCT632

~

Agency Approvals and Test Standards:

UL: UL508: 2008

CE: IEC 61000-4-2: 2001

©Copyright 2009 Dwyer Instruments, Inc Printed in U.S.A. 7/09 FR# 05-443494-00 Rev.3

DWYER INSTRUMENTS, INC.

IEC 61010-1: 2001-02

IEC 61000-4-3: 2006

IEC 61000-4-4: 2004

IEC 61000-4-5: 2005

IEC 61000-4-6: 2006

IEC 61000-4-11: 2004

CENELEC EN 55022: 2007

FCC Part 15 CFR Title 47: 2007

ICES-003: 2004 Digital Apparatus (Industry Canada)

ANSI 63.4-2003

CENELEC EN 61326-1: 2006

2004/108/EC EMC Directive

Alternating current

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...