Page 1

Bulletin E-97-M

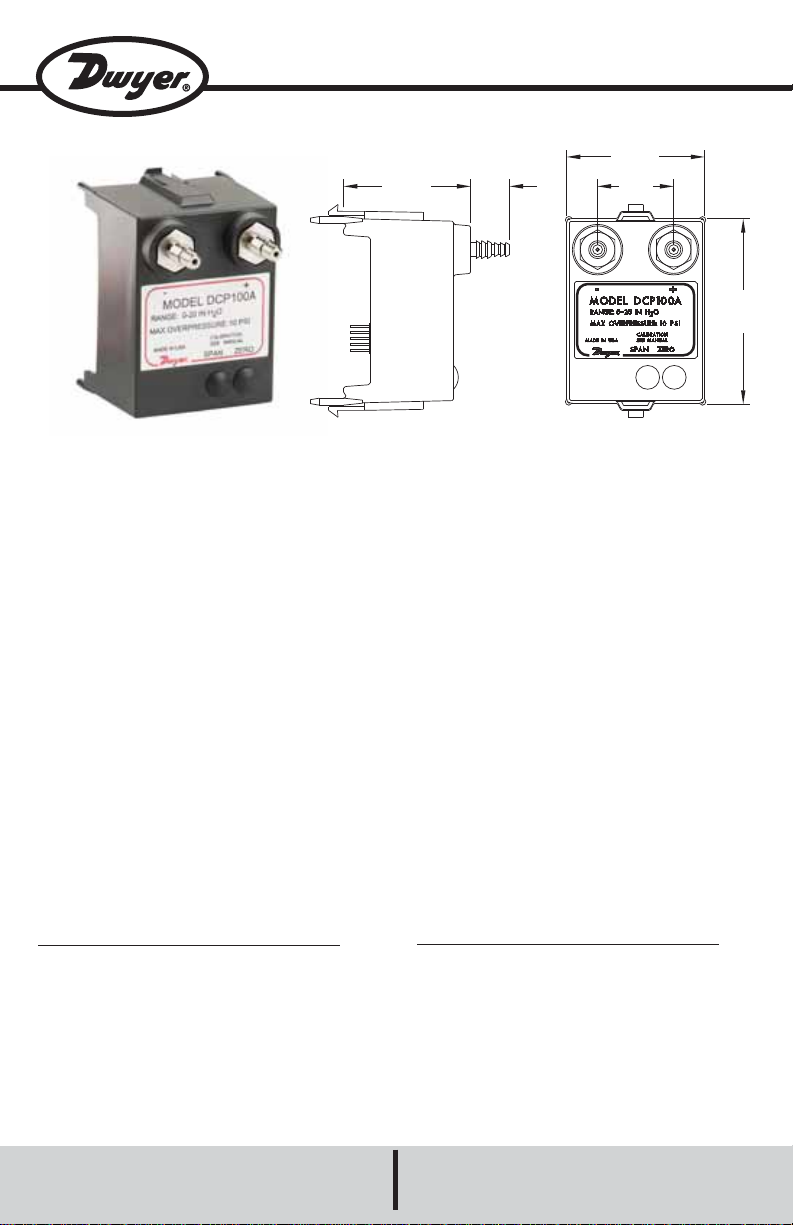

Series DCP100A/200A Pressure Modules

Specifications – Installation & Operating Instructions

1-13/16

[46.04]

1-11/16

[42.86]

1/2

[12.70]

1

[25.40]

2-7/16

[61.91]

The DCP100A or DCP200A pressure modules are designed exclusively for use with

the Dwyer

®

DCT1000 Dust Collector Timer

Controller boards for on-demand cleaning

requirements. These series of modules are

available in 10″ w.c. [2.49 kPa] or 20″ w.c.

[4.98 kPa] ranges, which allow for differential

process pressure measurement as indicated on the display of the master controller.

An isolated 4-20 mA readout channel is provided for remote pressure display. The 4-20

mA output may be wired either for use with

an external power supply and indicator or

using the isolated on-board 24 volt power

supply to power the loop.

Table of Contents Page No.

1.0 Installation . . . . . . . . . . . . . . . . .2

1.1 Location . . . . . . . . . . . . . . . . . . . .2

1.2 Connections . . . . . . . . . . . . . . . . .2

1.3 Pressure Module Installation . . .2-3

1.3.1 Alarm Mode Switch Connection . .3

1.3.2 Alarm Reset Switch Connection . .3

1.3.3 Connecting the 4-20 mA loop . . .3

1.3.4 Connecting the Alarm Relay . . . . .3

SPECIFICA T IONS

Pressure Ranges: 10˝ w.c. or 20˝ w.c.

Temperature Limits: -40 to 140°F

(-40 to 60°C).

Pressure Limit: 10 psi (68.95 kPa).

Pressure Limit (differential): 10 psi

(68.95 kPa).

Accuracy: ±1.5% F.S. @ 73°F (22.8°C).

Output Signal: 4-20 mA.

Alarm Contacts: 1.5A inductive load, 3A

resistive load @ 30 VAC or 40 VDC.

Process Connections: Two barbed connections for use with 1/8˝ (3.18 mm) or

3/16˝ (4.76 mm) I.D. tubing.

Weight: 5.5 oz (155.9 g).

Table of Contents Page No.

2.0 Demand Mode using a

DCP100A/200A Pressure

Module . . . . . . . . . . . . . . . . . . . .3

2.1 High Limit Setup . . . . . . . . . . . . . .4

2.2 Low Limit Setup . . . . . . . . . . . . . .4

2.3 High Alarm Setup . . . . . . . . . . . . .4

2.4 Low Alarm Setup . . . . . . . . . . . . .4

2.5 Auto Alarm Reset Setup . . . . . . . .4

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361,U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

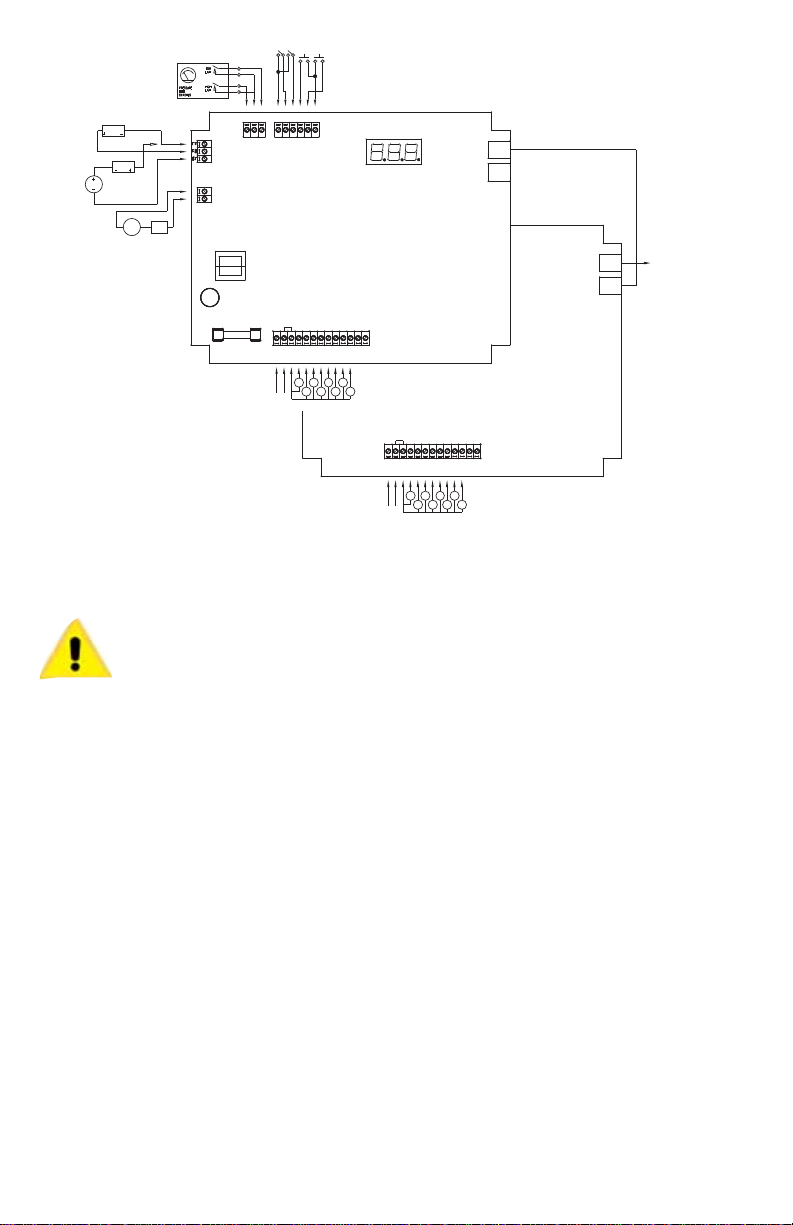

4-20 mA CONNECTIONS

RECEIVER

USING DCT1000

24V SUPPLY

RECEIVER

OPTIONAL

CONNECTION

SUPPLY

USING EXTERNAL

POWER SUPPLY

SUPPLY

NORMALLY OPEN CONTRACTS

MAN

ALARM

D1

ALARM

LOW

HIGH

OVR

MODE

CLN

RESET

LIMIT

COM

COM

TB3

(INTERNALLY CONNECTED)

TB1

L1

L2

SOL

COM

COM

TB2

MASTER CONTROLLER

(10 CHANNEL SHOWN)

5

8

6

7

34

9

12

OUT

DAISY

CHAIN

MASTER CONTROLLER

IN

INPUT MUST NOT BE

DAISY

CHAIN

CONNECTED

OUT

CHAIN

IN

CHAIN

TO ADDITIONAL

EXPANDER MODULES

DAISY

DAISY

10

LIMIT

4-20 MA

OUTPUT

4-20 MA

SOURCE

EXTERNAL

INTERNAL ALARM

TB4

CONTACTS

TB5

ALARM

LOAD

C3Ø4

F1

LINE

INPUT

SOLENOIDS

Fig. 1 - Switch

Connections

3.0 Pressure Module Maintenance 4

1.0 Installation

Caution: Prior to installing the

DCP100A/200A please review the

operating specifications carefully.

Some operating systems, especially in

pneumatic conveying applications, may see

static pressure or vacuum conditions that

exceed the capability of the

DCP100A/200A pressure module. For

these conditions there are a number of

alternate Dwyer Instruments, Inc. pressure

products that can be used to meet your

application requirements, all of which can

be terminated to the Dwyer

®

DCT1000 Dust

Collector Timer Controller. For more information on these and other Dwyer

®

products, please call us at (219) 879-8000, or

visit us on the web at www.dwyer-inst.com

or www.dust-controls.com.

1.1 Location

The system should be located in an enclosure that meets relevant safety standards

and electrical codes. There are no other

special orientation requirements as the

pressure module is not orientation sensitive.

SLAVE CHANNEL EXPANDER

(INTERNALLY CONNECTED)

SOL

L2

COM

34

12

SOLENOIDS

5

(10 CHANNEL SHOWN)

6

7

8

10

9

TB1

L1

LINE

INPUT

Care should be observed when routing the

air hoses to ensure that any potential condensation or moisture will not drain into the

sensor. Where heavy condensation is present, a drip loop or an in-line filter should be

installed to ensure long term operation.

1.2 Connections

When a pressure module is installed, the 420 mA process signal and the alarm relay

contacts are available. The circuit may be

used with the internal 24-volt power source

or with an external source. In either case,

the 4-20 mA circuit is isolated from ground

and other signals. The alarm relay contacts

are isolated, normally open contacts.

Pressure connections may be made to the

stepped hose barbs with either 1/8″ or

3/16″ I.D. tubing. The following subparagraphs describe the external switch connections. Refer to Figure 1 (above) for

switch connection illustration.

1.3 Pressure Module Installation

The pressure module is attached to the

Master Controller using integral connectors

on both units. The insertion ports for the

pressure module are located in the upper

2

Page 3

left quadrant of the DCT1000 Master

Controller. The pressure module can be

removed by compressing the retaining clips

on each end of the module, then gently

pulling the module out of the master controller board.

When inserting the module, the following

procedure should be adhered to insure

proper installation:

• Examine the bottom of the pressure module and note the orientation of the connectors.

• Align the module so that these connectors

match the connector receptacles on the

controller board.

• Orient the module with the four alignment

pins over their respective mounting holes.

• Gently press the module into the connectors and snap the retaining clips on either

end of the module into their slots.

• Always install and service this device with

the power off and a lockout installed if

required. “Hot” plugging the pressure module into an operating system may damage

the system or cause the calibration parameters to be erased.

Caution: Do not force the module

into the connectors. Forcing the

insertion may damage the connectors. Properly aligned, the module

should snap into place.

PRESSURE

ALIGNMENT

PINS

LOCKING PINS

INSERTED FROM

UNDERNEATH

MODULE ONLY

INSERT LOCKING PINS UNTIL THEY SNAP FIRMLY IN PLACE

MODULE

CIRCUIT

BOARD

LOCKING PINS INSERTED

ALL THE WAY INTO THE

CHANNEL

1.3.1 Alarm Mode Switch Connection

The auto alarm reset is controlled by the

alarm mode switch connection. To enable

the auto alarm reset the alarm mode input

must be connected to a common connection. A jumper may be used when auto

alarm reset is always active. A switch may

be used if there are times that the auto

alarm reset must be disabled. The switch

must be an isolated contact and wired such

that no connection is made between either

of the wires and ground.

1.3.2 Alarm Reset Switch Connection

The alarm may be reset either by pressing

the Alarm Reset button on the control panel

or by an external switch connected

between the alarm-reset terminal and one of

the common terminals. The alarm reset will

only operate if the pressure module is

installed and the pressure has returned to a

normal condition.

1.3.3 Connecting the 4-20 mA loop

The pressure module provides an isolated

4-20 mA output, which may be used to

remotely monitor the differential pressure

across the dust bags or cartridges. The

connection is made on the master control

module at the terminal block designated for

this signal. The connection is a 2-wire configuration with the option of using either an

external 15 to 35 VDC power source or

using the internal 24 VDC source.

1.3.4 Connecting the Alarm Relay

With the pressure module installed, a relay

contact is provided for controlling an external alarm. This relay is a single form-A contact. It is activated when either the high

alarm threshold is exceeded, or the pressure drops below the low alarm threshold.

The connection is made at the two-pin connector TB5.

2.0 Demand Mode using a

DCP100A/200A Pressure

Module

The DCT1000 system may be configured to

be a self-contained on-demand control system with the installation of the DCP100A

/200A pressure module. When this module

is installed, the master controller detects it

and automatically sets the system to an ondemand mode, enabling features associated with the pressure sensor. The following

subparagraphs describe the setup and

operation of these pressure related features.

3

Page 4

2.1 High Limit Setup

The High Limit Setup sets the pressure at

which the cleaning cycle will begin. This

value may be between zero and the pressure module calibration pressure. Normally,

the High Limit should be above the Low

Limit. If, however, the High Limit pressure is

set below the Low Limit, the cleaning cycle

will begin when the High Limit is exceeded

and stop when the pressure falls below the

High Limit. The Low Limit in this case will

have no effect. Pressing both Up and Down

buttons simultaneously and holding for

about four seconds will restore the factory

setting for High Limit to 5.0″ w.c. [1.24 kPa].

2.2 Low Limit Setup

The operation of the Low Limit mode is

identical to the High Limit mode except that

the default Low Limit pressure is 3.0″ w.c.

[0.75 kPa]. The upper setable value is the

calibration pressure of the pressure module

and the lower limit is zero. Press the Select

button until the Low Limit indicator is illuminated. Use the Up and Down controls to set

the limit to the desired setting. Pressing both

Up and Down buttons simultaneously and

holding for about four seconds will restore

the factory default.

2.3 High Alarm Setup

The operation of the High Alarm Setup is

identical to the High and Low Limit Setup.

The High Alarm default is 0.0″ w.c. The

upper setable value is the calibration pressure of the pressure module and the lower

limit is zero. Press the Select button until the

High Alarm indicator is illuminated. Use the

Up and Down controls to set the limit to the

desired setting. Pressing both Up and Down

buttons simultaneously and holding for

about four seconds will restore the factory

default.

2.4 Low Alarm Setup

The operation of the Low Alarm Setup is

identical to the High and Low Limit Setup.

The Low Alarm default is 0.0″ w.c. The

upper setable value is the calibration pressure of the pressure module and the lower

limit is zero. Press the Select button until the

Low Alarm indicator is illuminated. Use the

Up and Down controls to set the limit to the

desired setting. Pressing both Up and

Down buttons simultaneously and holding

for about four seconds will restore the factory default.

2.5 Auto Alarm Reset Setup

The Auto Alarm Reset Setup mode allows

the auto alarm reset time to be selected.

This value may be set between zero and

255 seconds. The factory default value is

five seconds. When the auto alarm reset is

enabled by shorting the auto alarm reset terminal to a common terminal, the alarm will

be reset after the pressure returns to the

normal range and the selected timeout period has expired.

3.0 Pressure Module

Maintenance

The pressure module should require very little maintenance under normal operational

conditions. However, periodic calibration

may be desirable to assure accuracy of the

readings. The module may be removed and

returned to the factory for calibration.

Still need help? Please feel free to contact one of our customer service representatives at 219879-8000 or visit us on the web at www.dwyer -inst.com or www.dust-controls.com. Thank you

for choosing Dwyer Instruments.

©Copyright 2009 Dwyer Instruments, Inc Printed in U.S.A. 8/09 FR# 443123-01 Rev. 2

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361,U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...