Page 1

911

CNC-controlled sewing unit with large

sewing area

Operating Instructions

Installation Instructions

Service Instructions

1

2

3

Postfach 17 03 51, D-33703 Bielefeld Potsdamer Straße 190, D-33719 Bielefeld

Telefon +49 (0) 5 21/ 59 25-00 Telefax +49 (0) 5 21/ 9 25 24 35 www.duerkopp-adler.com

Ausgabe / Edition: Änderungsindex Teile-Nr./Part.-No.:

08/2010 Rev. index: 00.0 Printed in Federal Republic of Germany 0791 911001

Page 2

All rights reser ved.

Property of Dürkopp Adler AG and copyrighted. Reproduction or publication of the content in any

manner, even in extracts, without prior written permission of Dürkopp Adler AG, is prohibited.

Copyright ©

Dürkopp Adler AG - 2010

Page 3

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruction manual contains important information on how to

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and life of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruction manual must always be available at the machine/sewing

unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

– Operation, including equipping, troubleshooting during the work

cycle, removing of fabric waste,

– Service (maintenance, inspection, repair) and/or

– Transport.

The user also has to assure that only authorized personnel work on the

machine.

The user is obliged to check the machine at least once per shift for

apparent damages and to immediatly report any changes (including the

performance in service), which impair the safety.

The user company must ensure that the machine is only operated in

perfect working order.

Never remove or disable any safety devices.

If safety devices need to be removed for equipping, repairing or

maintaining, the safety devices must be remounted directly after

completion of the maintenance and repair work.

Unauthorized modification of the machine rules out liability of the

manufacturer for damage resulting from this.

Observe all safety and danger recommendations on the machine/unit!

The yellow-and-black striped surfaces designate permanend danger

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

Page 4

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

2. Before putting into service also read the safety rules and

3. The machine must be used only for the purpose intended. Use of

4. When gauge parts are exchanged (e.g. needle, presser foot, needle

5. Daily servicing work must be carried out only by appropriately

instruction book and operated by persons with appropriate training.

instructions of the motor supplier.

the machine without the safety devices is not permitted. Observe all

the relevant safety regulations.

plate, feed dog and bobbin) when threading, when the workplace is

left, and during service work, the machine must be disconnected

from the mains by switching off the master switch or disconnecting

the mains plug.

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance unit.

Exceptions to this are only adjustments and functions checks made

by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as

the entire sewing unit is found to comply with EC directives.

13. The line cord should be equipped with a country-specific mains

plug. This work must be carried out by appropriately trained

technicians (see paragraph 8).

It is absolutely necessary to respect the safety

instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Page 5

Contents Page:

Preface and General Safety Instructions

Part 1: Operating Instructions Cl. 911 - Original Instructions

(Edition 08/2010)

1 Product Description ..............................................3

2 Designated Use .................................................5

3 Subclasses ....................................................5

4 Optional Equipment ...............................................6

1

5 Technical Data ..................................................7

6 Operation

6.1 Switchingon-Switchingoff-Safestop-Quickstop...........................8

6.2 Raisingthemachinehead...........................................11

6.3 Changingtheneedle..............................................12

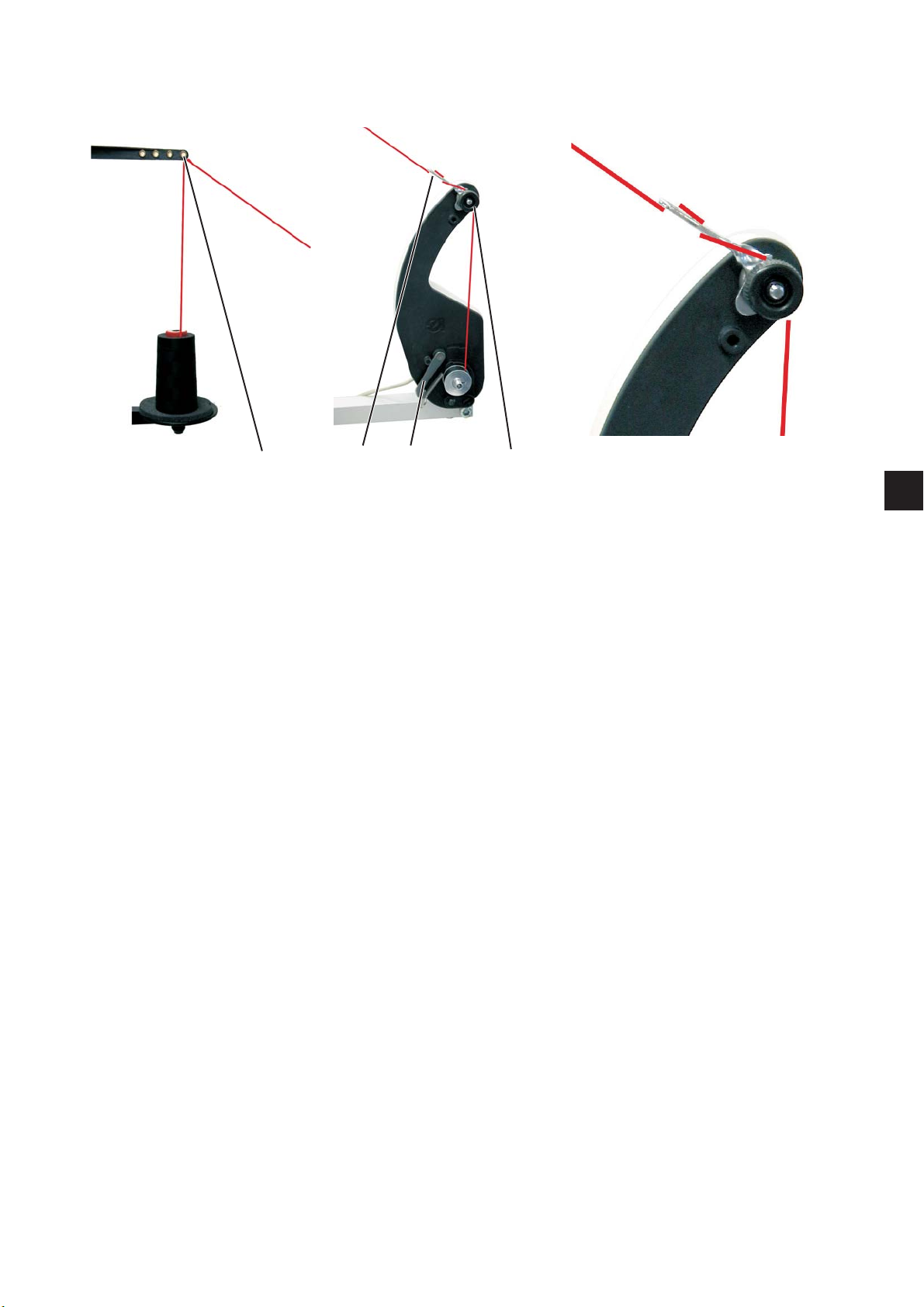

6.4 Threadingtheneedlethread .........................................13

6.5 Adjustingthethreadregulator ........................................14

6.6 Winding on the hook thread ..........................................15

6.7 Changing the hook-thread bobbin ......................................16

6.8 Setting the hook thread tension .......................................17

7 Operating the control unit of the 911

7.1 Thecontrolpanel................................................18

7.2 Operatingthetouchscreenpanel......................................18

7.3 Thestartscreen.................................................22

7.4 Themainscreen.................................................23

7.5 Popupmenustructure.............................................24

7.6 Menuitem“File”.................................................25

7.7 Menuitem“Edit” ................................................29

7.8 Menuitem“Extras”...............................................41

7.9 Menuitem“Correction” ............................................49

7.10 Menuitem“?”..................................................50

7.11 Teach-in ......................................................51

7.12 Repairmode...................................................55

7.13 Thread breakage ................................................56

8 DA-CAD 5000 ..................................................57

Page 6

Contents Page:

9 Error messages/Information messages

9.1 Errormessages.................................................59

9.2 Informationmessages.............................................63

10 Maintenance

10.1 Cleaning and Checking ............................................64

10.2 OilLubrication..................................................65

Page 7

1 Product Description

CNC-controlled sewing unit based on the class 867 with large sewing

area (sewing field size 300 x 200 mm) and a DAC III control unit with

special software.

For technical textiles manufacturers, motor vehicle equipment

manufacturers, seat manufacturers (automotive), bag, case and

backpack manufacturers (leather/textile), shoe manufacturers.

For the following applications:

Bartacks on load-bearing straps, lowering harnesses, safety

harnesses, lashing straps; Attaching of labels and facing pieces;

Decorative seams on shoes and legs of boots, decorative seams in

special applications.

Material:

Straps, ropes, leather, webbing, airbag materials, leather cut, foam

laminate, leather- laminate- and textile plastics

Double-lockstitch machine equipped with:

Automatic sewing foot and clamp lifting, sewing stroke adjustment,

thread trimmer, needle thread monitoring, thread pulling device and

multiple thread tension.

1

Technical specifications

The sewing unit is driven by a positioning drive.

With the control unit DACIII are operated apart from the sewing drive

also two step motors needed for the X and Y motions of the seam

geometry and a Z axis for the adjustment of the sewing foot.

The arm shaft of the sewing unit is directly driven by a brushless DC

motor.

Max. speed 3,000 U/min.

·

Stitch length up to 12.7 mm.

·

99 program memory locations are available.

·

The programs can be sewn individually or in sequences.

·

Motor driven sewing foot lifting.

·

Pneumatic driven clamp opening/closing.

·

The maximum size of the sewing field is 300 mm in X direction and

·

200 mm in Y direction.

Central oil wick lubricating for the machine head and the hook.

·

Equipped with a vertical hook

·

The BFT graphical control panel OP 7000 serves as control

·

element.

3

Page 8

With electronic needle thread monitor.

In order to generate a clean seam pattern, the sewing unit is equipped

with a multiple thread tension device, permitting to assign to various

thread pulling directions the according tension value previously saved

in the sewing program.

The thread pulling device allows pulling the needle thread under the

sewing material during the first stitch.

The sewing unit is equipped with a programmable stitch counter for

the hook thread monitoring and a piece counter.

Integrated test and check program for service and maintenance

works. In addition to the monitoring of the sewing process, it is also

possible to check the motor functions, the inputs and outputs for the

reference switches, the v alves and the feeding motors. The program

also serves for the adjustment of machine functions and the preparing

of sewing programs by the teach-in method.

Individual stitch parameter per stitch in order to control external units

like:

The stroke position of the presser foot, thread trimmer, thread

·

clamp,

Speed, thread tension etc.

·

The height of the stand can be adjusted with the telescoping feet from

a minimum work height of 760 mm to a maximum work height of 910

mm for stand-up working.

The foot pedal needed to operate the sewing unit can be shifted to

allow an ergonomic adaption to the operator.

4

Page 9

2 Designated Use

The class 911 is a sewing unit that is designated for the sewing of

light to medium-heavy material. Such material is generally made of

textile fibers, composite materials but it may also consist of leather.

Suchlike material is used in the clothing industry and for domestic and

motor-vehicle upholstery.

This sewing unit can also be used to produce so-called technical

seams. In this case however, the operator must assess the possible

dangers which may arise (DÜRKOPP ADLER AG will be happy to offer

its assistance), since such applications are relatively rare and at the

same time can be so varied that no single set of criteria can cover

them all. The outcome of this assessment may require appropriate

safety measures to be taken.

Generally only dry material may be sewn with this sewing unit. The

material may be no thicker than 4 mm when compressed by the

lowered workclamp. The material may not contain any hard objects.

The seam is generally produced with textile-fibre s ewing thread

(cotton threads, synthetic yarns of covering yarns) with the following

dimensions:

Class 911 thread thickness 15/3 - 120/3

Before using any other thread the possible dangers arising have to be

assessed and appropriate safety measures if necessary taken.

This sewing unit may be set up and operated only in dry,

well-maintained premises. If the sewing unit is used in

premises which are not dry and well-maintained it may be

necessary to take further precautions which should be agreed in

advance (see EN 60204-31:1999).

As manufacturers of industrial sewing machines we proceed on the

assumption that personnel who work on our products will have

received training at least sufficient to acquaint them with all normal

operations and with any hazards which these may involve.

1

3 Subclasses

Cl. 911-210 CNC-controlled sewing unit based on the class 867 with large sewing

area (sewing field size 300 x 200 mm) and a DAC III control unit with

special software.

5

Page 10

4 Optional Equipment

For the sewing unit 911 the following optional equipment is available:

Optional equipment Order-No. Remark

Reception P.-Clamp 0911 457554 Kit for the reception of the parallel

clamp actuation

Bow f. P.- Clamp 0911 457604 Bow holding fixture for the clamping plate

P.-set of clamps HF 0911 417604 parallel set of clamps HF (bow bracket)

P.-set of clamps prg.1 0911 417634 Finished set of clamps f. parallel

clamp act. prg.1

P.-set of clamps prg.2 0911 417644 Finished set of clamps f. parallel

clamp act. prg.2

P.-set of clamps prg.3 0911 417654 Finished set of clamps f. parallel

clamp act. prg.3

L-bracket f. P.-Clamp 0911 457614 Kit L-bracket for reception of the divided

clamp (parallel)

P.-set of clamps HF div. 0911 417614 P.-set of clamps HF, divided, fastening with L-bracket

P.-set of clamps div. prg.1 0911 417664 Finished P.-set of clamps for divided clamp pgr.1

P.-set of clamps div. prg.2 0911 417674 Finished P.-set of clamps for divided clamp pgr.2

P.-set of clamps div. prg.3 0911 417684 Finished P.-set of clamps for divided clamp pgr.3

P.-set of clamps HF div. 0911 417624 P.-set of clamps HF, divided, fastening w. L-bracket

closed frame

P.-set of clamps div. prg.1 0911 417694 Finished P.-set of clamps, div., with

closed frame prg.1

P.-set of clamps div. prg.2 0911 417704 Finished P.-set of clamps, div., with

closed frame prg.2

P.-set of clamps div. prg.3 0911 417714 Finished P.-set of clamps, div., with

closed frame prg.3

Reception f. change-over clamp 0911 457564 Kit for the reception of the change-over clamp

C.-set of clamps HF 0911 417524 Change-over s et of clamps HF

C.-set of clamps prg.1 0911 417554 Finished change-over set of clamps prg.1

C.-set of clamps prg.2 0911 417564 Finished change-over set of clamps prg.2

C.-set of clamps prg.3 0911 417574 Finished change-over set of clamps prg.3

Kit reduced pressure 0911 597544

Kit barcode reader 0911 597554

Set throat plate 0911 597504 Throat plate for processing thin materials

Set presser foot 0911 597514 Presser foot

Jumping foot 0467 220283 For thin material

Sewing lamp complete 9822 510026

Table clamp 9822 510027

Pneumatic connection package 0797 003031

Height adjustment 0911 407524 Table top height adjustable from 800mm to 1050mm

6

Page 11

5 Technical Data

Type of stitch 301

Hook type Vertical hook

Needle system 134/35

Needle size [Nm] 80 until 180

Number of needles 1

Stitch length (programmable) [mm] depending on the seam pattern up to 12.7

max. speed [min

Clamp stroke [mm] 20

Foot lifting [mm] 20

Sewing field size [mm] 300 x 200

Number of free contour programs 99

Operating pressure [bar] 6

Air consumption [NL] 4

-1

] max. 3000 1/min

Table height (adjustable

manually via spindle)

-min [mm] 760

-max [mm] 910

Length, Width, Height [mm] 1200 x 1200 x 1150 (+120mm spindle length)

Weight (mounted) [kg] 225

Rated voltage [V] 230

Frequency [Hz] 50 / 60

Rated load [W] 450

Noise:

Lc = dB (A)

Workplace-related emission value in accordance with DIN 45635-48-A-1-KL-2

Sewing length: __ mm

Stitch: __

Speed: _____ min

-1

1

Material: G1 DIN 23328 2 plies

Sewing cycle: 1.3 sec. on and 1.0 sec. off

7

Page 12

6 Operation

6.1 Switching on - Switching off - Safe stop - Quick stop

6.1.1 Switching on

6.1.2 Switching off

1

–

Turn on the main switch 1.

The following request occurs on the display:

“Push Pedal backwards for referencing”

–

Step the pedal backwards to start the reference r un of the sewing

unit.

The main menu appears in the display.

–

Turn off the main switch 1.

All the drives and the control unit are immediately separated from

the mains.

8

Page 13

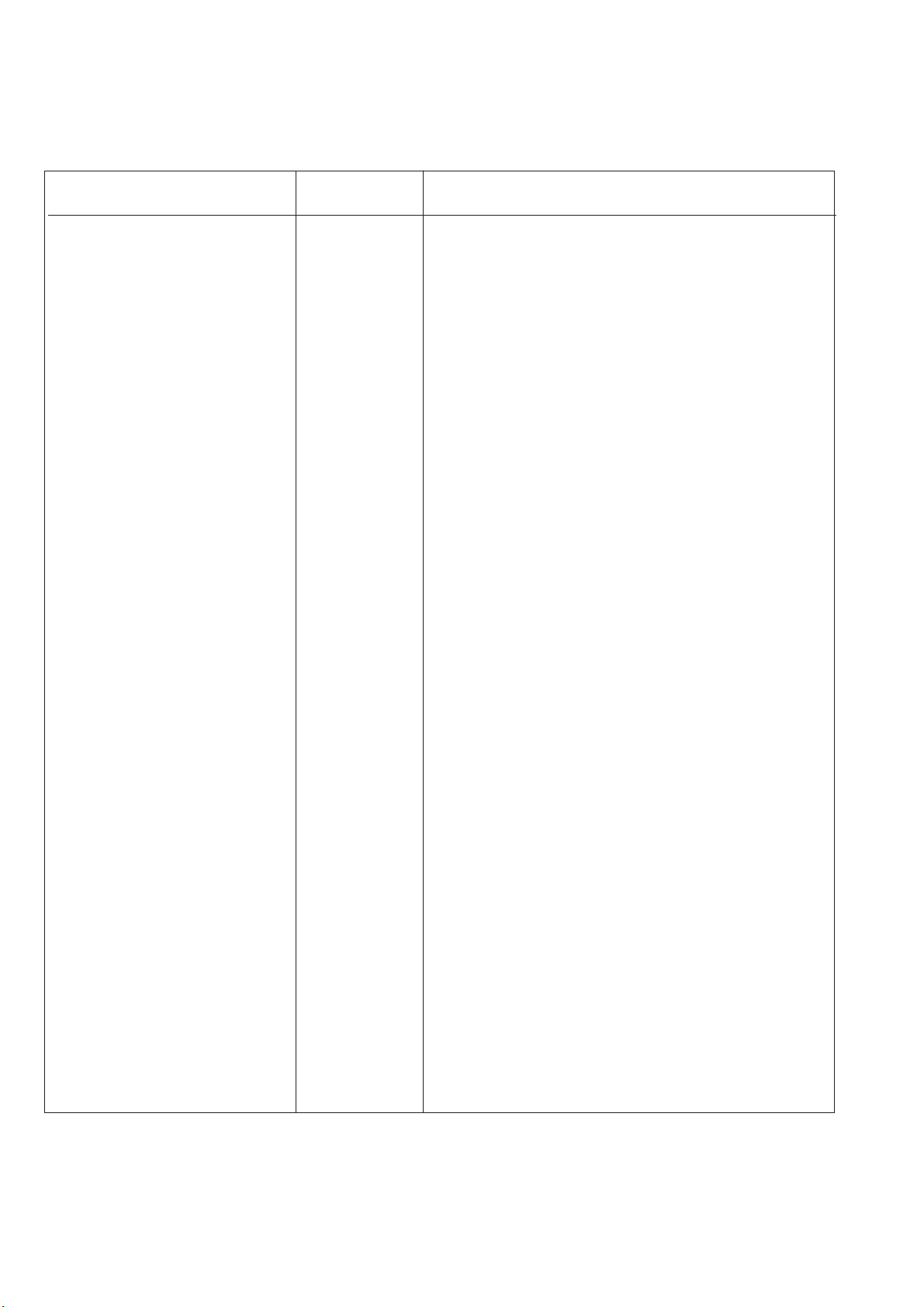

43 2

6.1.3 Safe Stop

Caution: Risk of injury!

The sewing unit has to be switched off or switched to “safe stop”

before carrying out any work on it.

Only work in the hook area with “safe stop” activated when it is

illuminated.

Switching on “safe stop”

–

Press key 2.

The key must snap in!

The sewing unit is in “safe stop” mode.

The lamp in the key shines.

The foot is moved to the lower position.

The area surrounding the hook cover 3 will be illuminated.

Switching off “safe stop”

–

Press key 2 again.

The key must be released.

1

1

6.1.4 Quick stop

The safety system of the sewing unit provokes the immediate stopping

of the unit in case of faulty operation, needle breakage etc. w ith the

following options:

Press the program-stop switch 4.

·

The running operations on the sewing unit will immediately be

aborted.

Turn the main switch 1 counter-clockwise.

·

The sewing unit will immediately be dead.

9

Page 14

1

3

2

10

4

Page 15

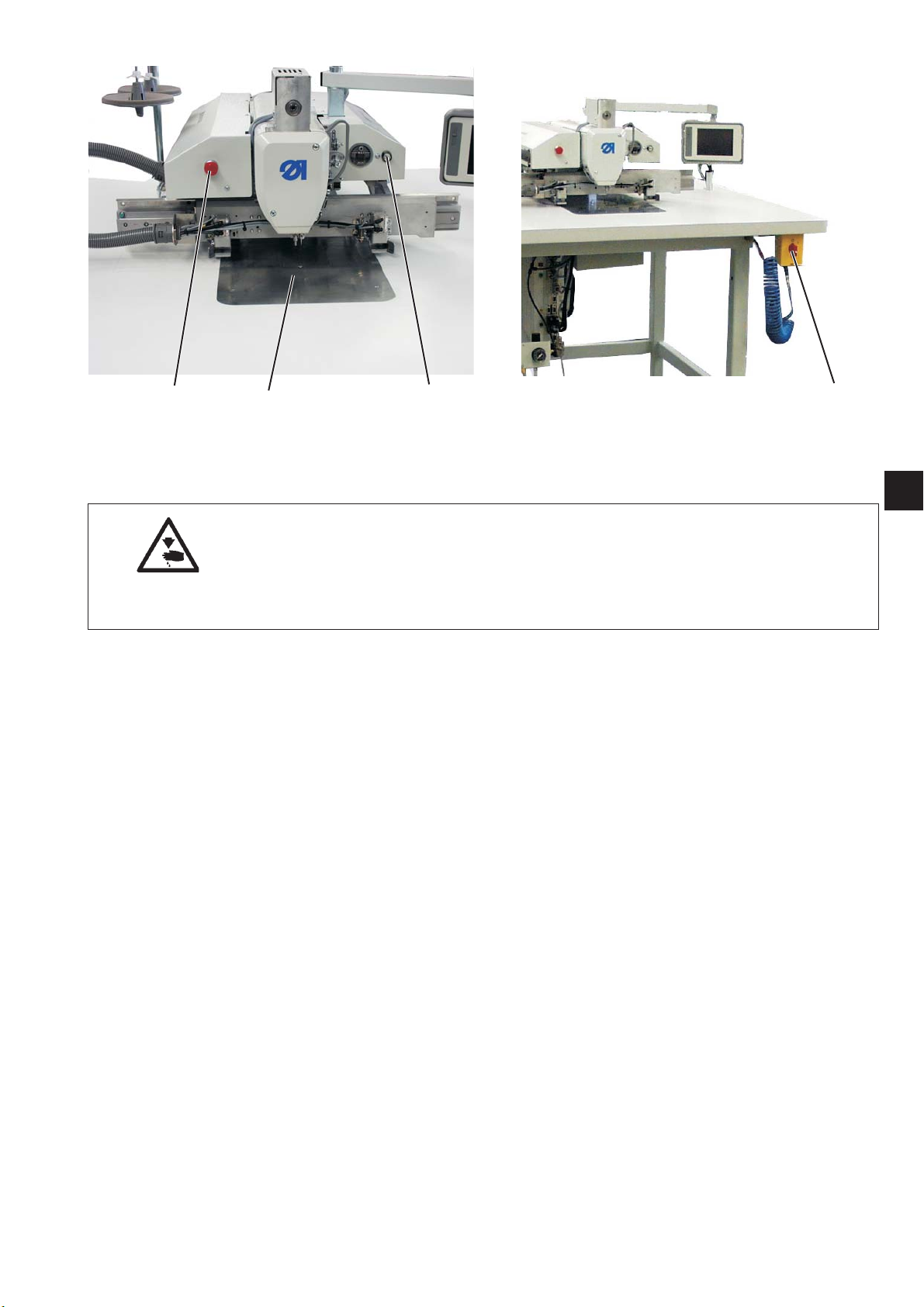

6.2 Raising the machine head

The sewing head can be raised for maintenance work.

The carriage drive 2 must stand at the rear.

Caution: Risk of injury!

Turn the main switch off!

Maintenance may only be carried out with the sewing unit switched

off!

Raising the sewing head

–

Release the locking lever 1 underneath the table top.

–

Raise the machine head in the area of the face cover 3 and swing

it up carefully.

Additionally, the latch 4 will also snap in.

The space under the machine table can be accessed for cleaning

now.

Caution: Risk of injury!

Keep clear of the area within the table top cutout when the machine

head is tilted up.

1

Swinging the machine head back

–

Keep hold of the machine head in the area of the face cover 3.

–

Release the latch 4.

–

Swing the machine head back carefully.

ATTENTION: Danger of breakage!

Keep hold of the sewing head until it has reached its final position.

–

Engage the locking lever 1 under neath the table top.

11

Page 16

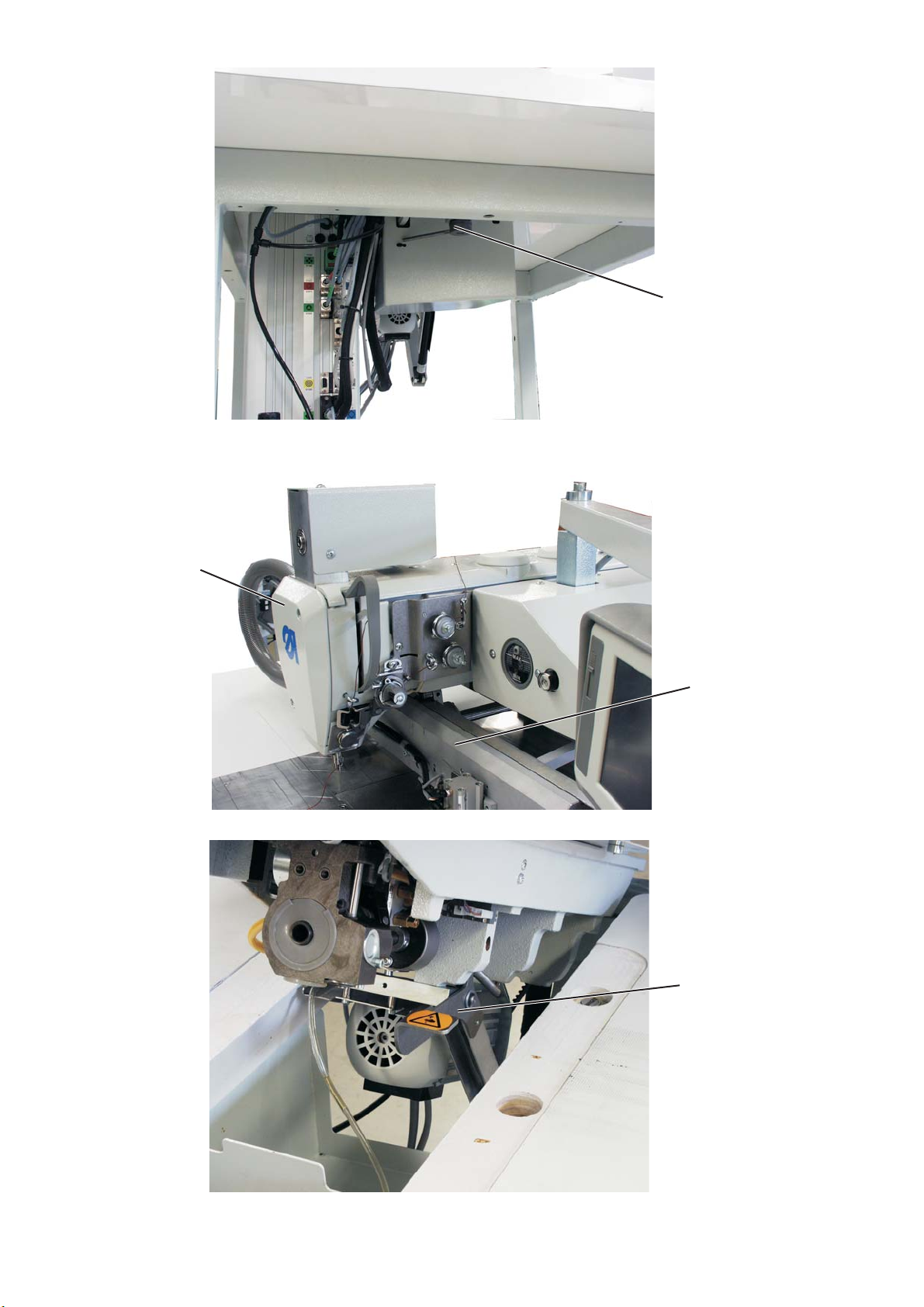

6.3 Changing the needle

1

2

3

4

Caution: Risk of injury!

Turn the main switch off!

The needle may only be changed with the sewing unit switched off.

–

Turn the machine with crank 4 until the needle bar 1 reaches its

highest position.

–

Loosen screw 2.

–

Pull the needle downwards out of the needle bar 1.

–

Insert the new needle into the hole of the needle bar 1 and push it

until it stops.

Caution!

The needle scarf 3 must point towards the hook.

–

Tighten screw 2.

ATTENTION!

When changing to another needle size, the distance between hook

and needle must be readjusted (see service instructions).

Ignoring the above mentioned hint can cause the following errors:

Use of a thinner needle:

Missed stitches

·

Thread damage

·

12

Use of a thicker needle:

Damage on the hook tip.

·

Damage of the needle

·

Page 17

6.4 Threading the needle thread

Caution: Risk of injury!

Turn off the main switch!

The needle thread may only be threaded with the sewing unit

switched off.

11

10

1

2

9

3

1

8

7654

–

Put the thread reel on the thread stand and lead the needle thread

through the unwinder arm.

The unwinder arm must be in vertical position above the thread

reels.

–

Thread in the thread through threading guide 1.

–

Conduct the thread counter-clockwise around the pre-tensioner

wheel 2.

–

Conduct the thread clockwise around the pre-tensioner wheel 3.

–

Conduct the thread through threading guides 4 and 5.

–

Conduct the thread clockwise around the deflector 6.

–

Pull the thread underneath the thread take-up spring 7 and

conduct it through the threading guide 9, the thread regulator 10

to the thread lever 11.

–

Conduct the thread through the thread lever 11 a nd the threading

guide 8.

12

13

14

15

–

Conduct the thread through the needle thread monitor 12, the

thread clamp 13 and the threading guides 14 and 15.

–

Thread the thread into the needle eye.

13

Page 18

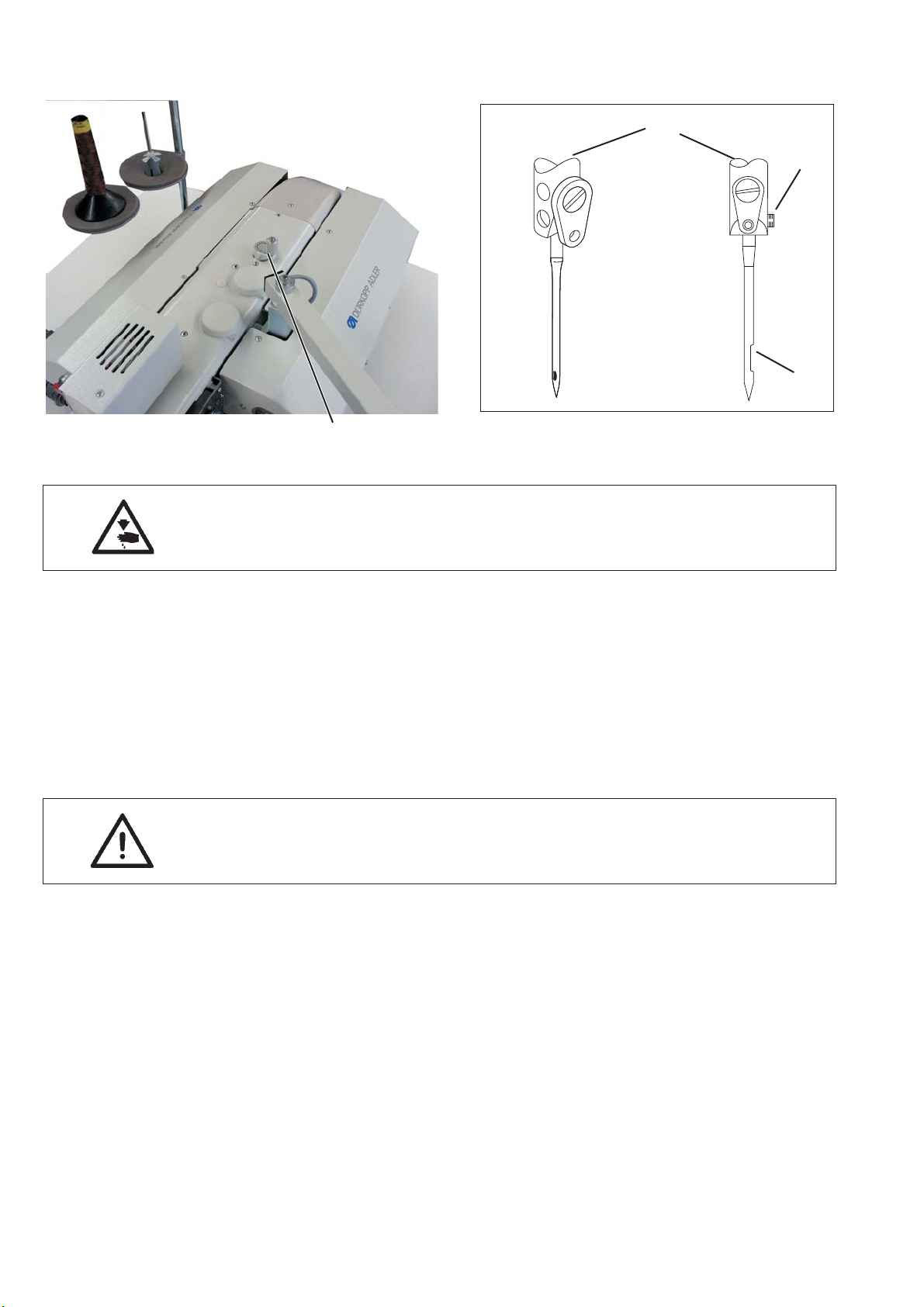

6.5 Adjusting the thread regulator

Caution: Risk of injury!

Turn off the main switch.

The thread regulator may only be adjusted with the sewing unit

switched off.

21

The thread regulator 2 controls the quantity of needle thread required

for stitch formation.

The thread regulator must be precisely adjusted for an optimum

sewing result.

With correct setting the needle-thread loop must slide with low

tension over the thickest point of the hook.

–

Loosen screw 1.

–

Adjust the position of the thread regulator 2.

Thread regulator to the left = more thread

Thread regulator to the right = less thread

–

Tighten the screw 1.

Adjustment information:

If the maximum quantity of thread is required the thread-tensioning

spring must be pulled upwards about 0.5 mm from its lower limit

position. This is the case w hen the needle-thread loop passes the

maximum hook diameter.

14

Page 19

6.6 Winding on the hook thread

1

43 2

1

The separate bobbin winder makes it possible to wind the hook thread

independently from the sewing operation.

–

Remove remaining thread from the bobbin hubs before winding.

–

Put the thread reel on the thread stand.

–

Thread the thread through the drill-hole 1 of the unwinder arm.

–

Conduct the thread through threading guide 4.

–

Conduct the thread through the bobbin thread tension 2.

–

Wind up the thread to the right.

Press the bobbin retainer 3 against the bobbin hub.

The bobbin winder starts.

After reaching the set bobbin filling level the bobbin winder stops

automatically.

See Service instructions for setting the bobbin filling level.

15

Page 20

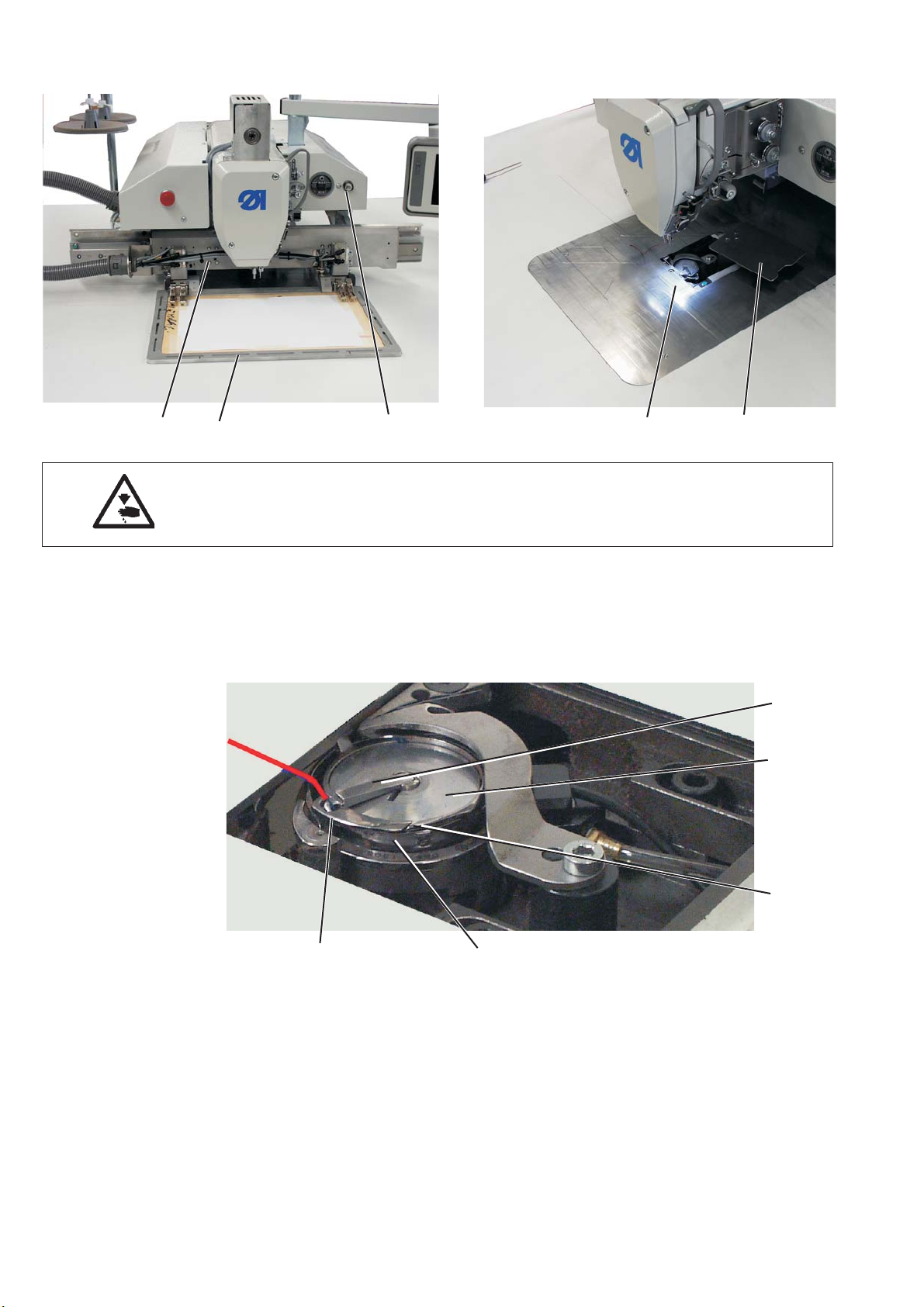

6.7 Changing the hook-thread bobbin

32 1

Caution: Risk of injury!

The hook-thread bobbin may only be changed with the sewing unit in

“safe stop” mode.

–

Remove the material holder 2 (only with change-over frame).

–

Press the key 1 “safe stop”.

The drive carriage rides to the “bobbin change position”.

The cover plate 4 will pivot to the side.

The foot is moved to the lower position.

–

The light 5 is switched on.

54

6

7

16

10 9

Remove the empty bobbin.

–

Rise up the flap 6 and remove the empty bobbin.

Insert a full bobbin.

–

Insert the bobbin 7 in a way that it moves in the opposite direction

of the hook when unwinding.

–

Close the flap 6.

–

Conduct the thread through slot 8 and under neath the spring 9.

–

Pull the hook thread through the threading guide 10 and continue

pulling until it stands out about 3 cm.

–

Release key 1 “safe stop”.

The cover plate 4 will pivot back into its original position.

8

Page 21

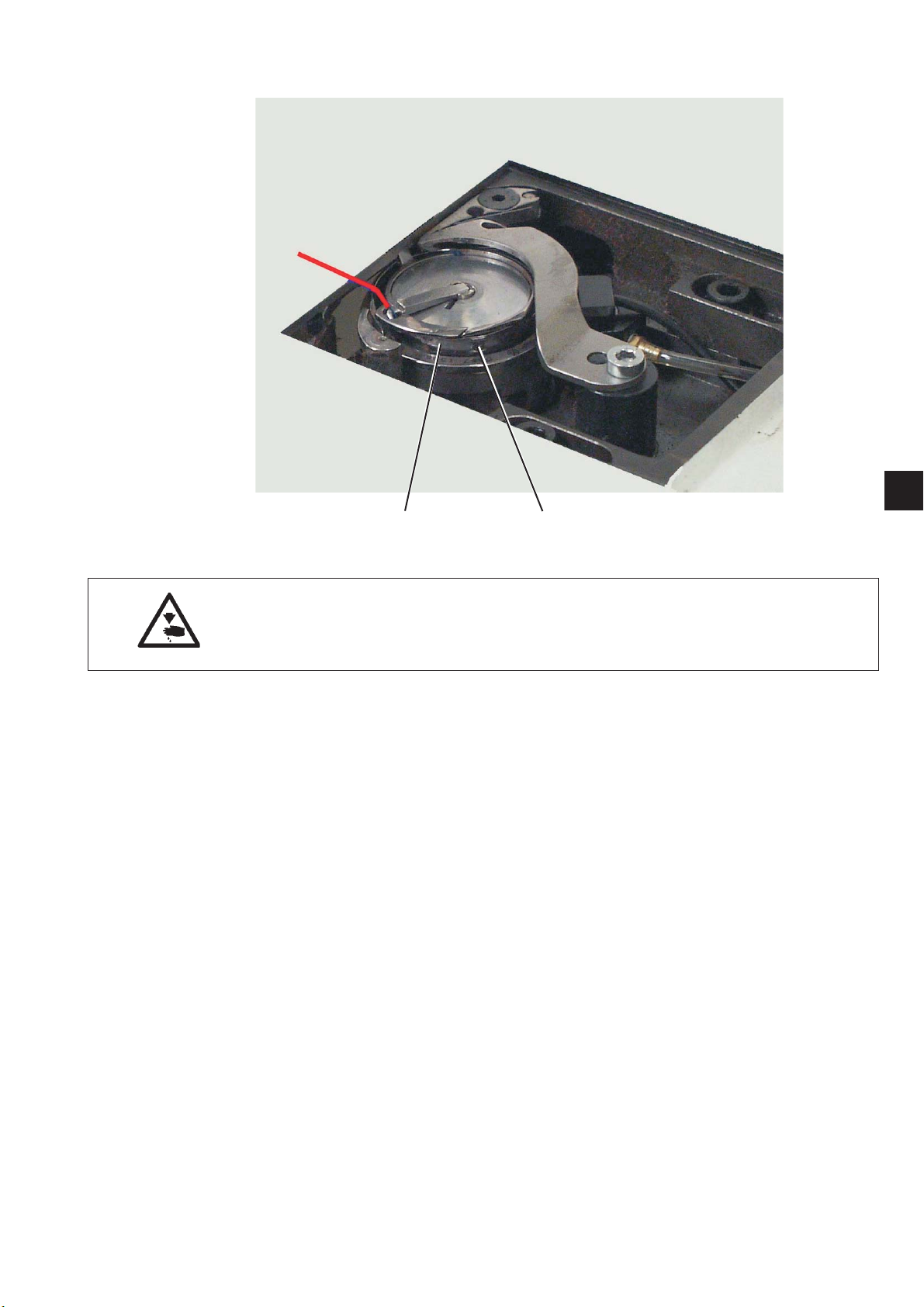

6.8 Setting the hook thread tension

1

21

Caution: Risk of injury!

Turn off the main switch.

The hook-thread tension may only be adjusted with the sewing unit

switched off.

The necessary hook thread tension should be generated from the

thread tension spring 2.

Setting the tension spring

–

Set the tension spring 2 by turning the adjustment screw 1 until

the needed tension value is reached.

17

Page 22

7. Operating the control of the 911

7.1 The control panel

The data entry is done through a touch screen monitor.

USB connection

USB-Stick order-no. 9805 791113

7.2 Operating the touch screen panel

Activate a function by touching (with a fingertip) the symbol

representing the function in question on the screen.

–

Tip with your fingertip on the requested function symbol.

7.2.1 Window “General”

7.2.2 Input window

18

–

Close the window

“Cancel” “ESC” - > the window will be closed, the value

will not be modified

“OK” “CR” -> the window will be closed and the new

value will be saved, if it is within the

specified limit values

Page 23

7.2.3 Selection window

On this screen, the following actions can be executed:

–

If the button is bright it cannot be activated.

–

A field, in this case the sewing program, has been selected and

can be edited or appended.

1

7.2.4 Numeric input for a parameter

The title bar indicates the parameter group.

The status bar indicates which parameter will be edited.

Underneath the icon, the min. and max. values are displayed. Enter

the corresponding value in the input box.

–

The “DEL” key cancels an input.

19

Page 24

7.2.5 Numeric input for a parameter

–

–

Enter the password.

25483

Touch the button “OK”.

It will be switched over to the technician level.

7.2.6 Input of a text

“ESC” Close the window

“Aa” Switching from capitals to small letters

“DEL” Deleting the last characters

“CR” Close the window, the sequence name will be adopted.

20

Page 25

7.2.7 Radio- button

With the Radio-button the selected option is marked with a black dot.

1

7.2.8 “Scroll bar”

2

Move the scroll bar 2 downwards.

The lower part of t he screen will be displayed.

21

Page 26

7.2.9 Check- button

With the Check-button the selected option is marked with a black x.

7.3 The start screen

The start screen appears after switching the sewing unit on.

–

Press the “Service” button in order to switch to the multitest

program.

–

Press the “Language” button in order to change the selected

language.

22

Page 27

7.4 The main screen

1

23

4

15

14 13 12

1Titlebar

2 Sequence name:

Number of sewing programs in t he sequence

3 Time: Hour: Minute

4 Repair mode

5 Seam patter n size

6 Max. sewing speed

7 Max. thread tension

8 Stitch length

9 Number of stitches / Bobbin thread consumption

10 Button bobbin change

11 Button counter reset

12 Slider, Tabs, Buttons for sequence c ontrol.

The name of the sewing program is in the tabs.

Presently “NP1" is active.

13 Popup-Menu

14 Active sewing program

15 Seam patter n

5

6

7

8

9

10

11

1

23

Page 28

7.5. Pop up menu structure

File

·

Delete

¡

Copy

¡

Open

¡

New

¡

·

·

Seam program

·

Sequence

·

Save as

¡

Edit

Machine parameters

¡

Sequence

¡

Seam program

¡

Parameters

·

Contour adjustment

·

Testing contour

·

Extras

Full screen on/off

¡

Zoom on/off

¡

Service

¡

Adjustments

·

System information

·

Multi-test

·

Initialization and update

·

Manufacturer

·

24

Correction

·

¡

¡

Thread tension

Sewing speed

Page 29

7.6 Menu item “File”

It is possible to sew a single sewing program several times

consequently or to sew several different sewing programs one after

the other in a sequence.

7.6.1 Create a new sewing program

See chapter Teach-in

7.6.2 Creating a new sequence

In this menu item it is possible to occupy the individual memory

locations with sewing programs.

There are a total of 20 independent memory locations available.

Each memory location can be occupied by a sequence of up to 30

sewing programs in any imaginable order.

–

Click File -> New.. -> Sequence

A new sequence will be generated.

1

–

Tip onto the desired sewing program.

In the example NP1

–

Tip onto the button “Insert”. The sewing program is adopted and

will be displayed in t he sequence field.

–

Insert additional sewing programs.

25

Page 30

–

Tip onto the button “Set name”.

–

Enter the name.

–

Press the “Enter” button.

–

Press the “OK” button.

The sequence will be memorized.

26

Page 31

7.6.3 Opening a sewing program or a sequence

Via this menu item, sewing programs or sequences can be opened

from the DAC and then be sewn.

After opening the main screen will be updated accordingly.

–

Click File -> Open

The following screen will appear:

–

Click “File filter”.

The file filter will be opened.

1

According to the selection the following will be displayed:

All files

·

Seam programs (.fnp911)

·

Sequences (.seq911)

·

27

Page 32

7.6.4 Copying a sewing program, a sequence or machine parameters

Via t his menu item it is possible to copy sewing programs, sequences

or machine parameters onto the DAC control or onto a USB-Stick.

And a file filter can also be selected here.

Click File -> Copy

The following screen will appear:

–

Select where to copy from:

- from the DAC control unit to a n USB-stick

or

- from an USB-stick to the DAC control unit

–

Tip on the sewing program or sequence to be copied.

–

Tip on the “Copy” button. The selected program will be copied.

7.6.5 Deleting a sewing program or a sequence

Via this menu item, sewing programs or sequences can be deleted

from the DAC.

And a file filter can also be selected here.

–

Click File -> Delete

The following screen will appear:

–

Tip on the sewing program or sequence to be deleted.

–

Press the “Delete” button.

The program or the sequence will be deleted.

28

Page 33

7.7 Menu item “Edit”

7.7.1 Editing a sewing program

A sewing program consists of a contour and sewing parameters.

The contour (shape of seam) is created via Teach-in or with the help of

the DA-CAD 5000.

The program parameters are divided into different groups and are

modified as follows:

–

Click Edit -> Seam program -> Parameters

The following screen will appear:

1

PP1 - Configuration

Seam name max. 20 characters

minimal foot height

(min. = 1.0 .. max. = 10.0; def. = 10.0 mm )

Limits the programmable foot height to this

value so that with thicker material only this value

has to be adjusted.

Adjust the thread tension

(min. = 10… max. = 200; def. = 100%)

The thread tension profile of the whole contour will be

adjusted according to the percentage value. With the

value 100% no adaptation takes place.

Adjustthenoloadrunspeed

(min. = 10… max. = 200; def. = 100%)

The run speeds will be adjusted accordingly.

Clamp ID-Code

Barcode (ID-Code) max. 10 characters for a security

check before the sewing start (the optional equipment

barcode reader has to be activated)

29

Page 34

Laser marking lamps

Up to four laser marking lamps can be triggered

in order to facilitate the aligning of the material

(The optional equipment has to be activated)

Needle reverse turn mode

The following modes can be set:

Not active

The needle remains in the stopping position.

After the complete contour

After the completion of all the seams of a contour

the needle is tur ned back to the set value

(MP parameter).

After each seam (def.)

After each seam the needle will be turned back.

Needle cooler

(on/off)

Activated/deactivates the needle cooler.

Adjust the sewing speed

(min. = 10… max. = 200; def. = 100%)

The sewing speed will be adjusted accordingly.

PP2 - Load mode

Feeding mode

The following modes can be set:

Mode 1 (def.)

The clamp will be opened in the feeding position.

After actuating the pedal the c lamp will be closed.

After actuating the pedal one more time the seam will

be started.

Mode 2

The clamp will be opened in the feeding position.

After actuating the pedal the left part of the

two-piece clamp for an angular feed will be closed.

After actuating the pedal one more time the right side

will be closed.

After a further actuation of the pedal

the seam will be started.

Mode 3

The clamp will be opened in the feeding position.

After actuating the pedal the right part of the

two-piece clamp for an angular feed will be closed.

After actuating the pedal one more time the left side

will be closed.

After a further actuation of the pedal

the seam will be started.

Mode 4

Quick start mode

The clamp will be opened in the feeding position.

After actuating the pedal the c lamp will be closed.

and the seam will be started. With the

change-over clamp, the seam will be started

automatically after feeding.

This mode is only active if t he quick start

has been enabled with the machine parameters.

In order to activate the quick start mode, the machine

must be switched off and on again!

30

Page 35

Mode 5

The clamp remains closed in the feeding position.

After actuating the pedal one more time

the seam will be started.

Feeding position

(on/off)

With the feeding position activated the clamp

goes to the requested position in order to facilitate

the feeding of the material.

Feeding position X

(min. = -300… max. = 300; def. = 230 mm)

Feeding position Y

(min. = -300… max. = 300; def. = -90 mm)

PP3 - Deposit mode:

Deposit mode

The following modes can be set:

Mode 1 (def.)

The clamp will be opened in the deposit position.

1

Mode 2

The clamp remains closed in the deposit position.

After actuating the pedal the clamp will be opened.

Mode 3

The clamp remains closed in the deposit position.

After actuating the pedal the left part of the

two-piece clamp for an angular feed will be opened.

After actuating the pedal one more time the right side

will be opened.

Mode 4

The clamp remains closed in the deposit position.

After actuating the pedal the right part of the

two-piece clamp for an angular feed will be opened.

After actuating the pedal one more time the left side

will be opened.

Mode 5

The clamp remains closed in the deposit position.

Deposit position

(on/off)

With the deposit position activated the clamp

goes to the requested position after sewing in order

to facilitate the deposit of t he material.

Deposit position X

(min. = -300… max. = 300; def. = 230 mm)

Deposit position Y

(min. = -300… max. = 300; def. = -90 mm)

31

Page 36

PP4 - Soft start

Number of soft start stitches

(min. = 0.. max. = 10; def. 5)

Soft start speed

(min. = 100 .. max. 2000; def. 300 U/min)

PP5 - Sensitivity of the needle thread monitor

(min.=0..max.= 99: def. 5)

Is only active when enabled with the machine parameters.

(The higher the value the less sensitive the upper thread

monitor will be.

99 = The upper thread monitor is s witched off for this

program only.)

PP6 - Thread consumption

Material thickness (min. = 0.. max. 20.0; def. 0)

Thickness of the material when pressed together.

Adjustment of the thread consumption

(min. = -10.0.. max. 10.0; def. 0)

Correction of the calculated values.

PP7 - Move

PP8 - Scale

The contour will be shifted in the requested direction

according to this value.

Move in X direction

(min. = -5.0… max. = 5.0; def. = 0.0 mm)

Move in Y direction

(min. = -5.0… max. = 5.0; def. = 0.0 mm)

The size of the contour will be changed in the direction

desired according to this value.

Scaling in X direction

(min. = 80… max. = 120; def. = 100 %)

100% correspond to the original size.

Scaling in Y direction

(min. = 80… max. = 120; def. = 100 %)

32

Page 37

Center point of scaling in X direction

(min. = -150.0… max. = 150.0; def. = 0.0 mm)

Center point of scaling in Y direction

(min. = -150.0… max. = 150.0; def. = 0.0 mm)

1

33

Page 38

7.7.2 Contour adaptation

Via t his menu item smaller changes of the contour can be adjusted

directly at the sewing unit. Individual stitches can be shifted and

technological operations can be adjusted.

Click Edit -> Seam program -> Contour adjustment

The following screen will appear:

–

Aiming roughly at the position of the contour that is to be adjusted

with the cursor keys.

–

Press the “Go To” Button and the clamp goes to the desired

position.

–

Press the “Continue” button.

34

21

–

Select the corresponding stitch 1.

–

Change the stitch position 2.

–

Press the “Continue” button.

–

Technological operations can be added or modified.

–

Press the “Continue” button.

–

The contour adaptation will be memorized upon confirming the

reque st .

Page 39

7.7.3 Contour test

Via t he menu item a contour can be checked.

Click Edit -> Seam program -> Testing contour

The following screen will appear:

–

Run along the contour with the “Reverse” (backwards) or

“Forwards” (forwards) keys and check it.

1

35

Page 40

7.7.4 Edit the machine parameters

Via t he machine parameters the basic machine settings and some of

the parameters for all programs are defined.

–

Click Edit -> Machine parameters.

MP1 - Configuration

Needle cooling

The following modes can be set:

without

The needle cooler is not activated.

Air cooling (def.)

During sewing the needle is cooled with air.

Ice cooling

Optional equipment.

Sewing foot mode

The sewing foot can be operated in the following modes:

Jumping foot

The sewing foot presses onto the material while the

needle penetrates the material.

Presser foot

The sewing foot presses continuously onto

the material.

Sewing area size

36

Sewing area normal size (def.)

A sewing field of 200*300 mm is available.

Sewing area oversize

In connection with the change-over clamp a

larger sewing field can be used.

Page 41

Optional equipment

Reduced clamp pressure

Optional equipment that facilitates the alignment

by exercising a reduced clamp pressure at the

feeding moment.

Laser marking lamp

Optional equipment that facilitates the alignment

at feeding by providing orientation lines.

Here this option is only enabled and then with

each program up to four laser marking lamps can

be activated.

Bar code reader

Optional equipment for a security check before

the sewing process. With each program a barcode

can be deposited. It will be cross-checked with

the barcode on the clamp.

Only if the codes are identical the sewing process

will be started.

Clamp type

The following kinds of clamps are available:

One-piece clamp for L-shape adaptation

Single-piece parallel clamp with angular feed

One-piece clamp for with bow (def.)

Single-piece parallel clamp with bow feed

Split clamp for L-shape adaptation

Two-piece parallel clamp with angular feed

Exchangeable clamp

Removable clamp

Special clamp

Individual clamp

1

Clamp limitation

Preset limitation (def.)

No additional structures are taken into account.

Special limitation

Individual limits are taken into account.

Set Pedal mode

The following modes are available:

Mode 1

The recent position of the pedal is evaluated.

Mode 2 (def.)

The pedal has to be pushed back into the initial

position after each actuation before a further

actuation is taken into account.

Mode 3

The recent position of the pedal is evaluated.

Additionally the quick start mode is enabled (see

the program parameter feeding mode). The recent

position of the pedal is evaluated.

Additionally the quick start mode is enabled (see

the program parameter feeding mode)

In order to activate the quick start mode, the machine

must be switched off and on again!

Hand switch

In the hand switch mode one sensor is used only for

the operation of the clamp movement (up and down).

The other sensor serves to start the sewing process.

37

Page 42

MP2 - Limit values

Set max. sewing speed

(min. = 500 .. max. 3000; def. 3000 U/min)

Limitation of all sewing programs to this speed.

Set max. run empty speed

(min. = 10 .. max. 100; def. 100%)

Limitation of all clamp movements between seam

to this value.

Set feeding start

(min. = 30 .. max. 350; def. 180 degrees)

At this angle of needle movement the clamp starts

to move during the stitch.

Set feeding phase

(min. = 30 .. max. 100; def. 80%)

This parameter determines how the clamp movement

takes place during the stitch. (At 100% the requested

clamp movement is equally divided over the

whole stitch).

Set needle reversing position

(min. = 0 .. max. 359; def. 0 degrees)

The needle will be turned back to this angle in order

to enlarge the distance to the clamp.

Editing timings distances

This function is reserved for the Dürkopp-Adler service

personnel.

MP3 - Needle thread monitor

Upper thread monitor mode

The following modes are available:

Threading position (def.)

After detecting thread breakage the thread will be

trimmed and the clamp will then go to the threading

position.

Thread cutting

After detecting thread breakage the thread will be

trimmed and the clamp moves according to the

set reverse drive to the contour position.

Pausing

After detecting thread breakage the sewing movement

will be stopped.

Not activated

The needle thread monitor is ignored.

38

Page 43

Set return path after thread breakage

(min.=0..max.20;def.5stitches)

Number of stitches of the reverse drive effectuated after

detection of thread breakage.

Position of bobbin change X

(min. = -300… max. = 300; def. = 230 mm)

Position of bobbin change Y

(min. = -300… max. = 300; def. = +90 mm)

MP4 - Thread cutting

Cutting speed

(min. = 70 .. max. 500; def. 180 U/min)

Speed of the trimming stitch.

Cutting position on

(min. = 0 .. max. 359; def. 180 degrees)

Angular position of the needle at which the thread trimming

knife is switched on.

Cutting position off

(min. = 0 .. max. 359; def. 359 degrees)

Angular position of the needle at which the thread trimming

knife is switched off.

Set thread tension during thread cutting

(min. = 00 .. max. 100; def. 10%)

Thread tension of the trimming stitch.

Position for thread tension during t hread cutting

(min. = 0 .. max. 400; def. 370 degrees)

Starting angle for the thread tension at trimming (with an angle

of more than 359 degrees the t hread tension is only activated

with the next stitch.

MP5 - Clamping thread

1

Closing the thread clamp, first stitch

(min. = 0 .. max. 250; def. 180 degrees)

Starting angle for the closing of the tread clamp during

the first stitch.

Open the thread clamp, first stitch.

(min. = 0 .. max. 359; def. 340 degrees)

Starting angle for the opening of the tread clamp during

the first stitch.

If the angles for closing and opening are identical the t hread

clamp will not be activated.

39

Page 44

MP6 - Counter

Counter type

The following possibilities available:

Increment counter (def.)

After each sewn program the counter will step up.

Decrement counter

After each sewn program the counter will step down.

Increment sequence counter

After each sewn sequence the counter will step up.

Decrement sequence counter

After each sewn sequence the counter will step down.

Reset value for the counter

(min. = 0 .. max. 9999; def. 0)

Reset value for the counter

Set seam count for bobbin reserve

(min. = 0 .. max. 100; def. 0)

After the sewing of the set seams the user will receive a message.

Not active when set to the value 0.

Set capacity for bobbin reserve

(min. = 0.0 .. max. 400.0; def. 0.0m)

After the consumption of t he capacity a message is generated

for the user.

Not active when set to the value 0.

40

Page 45

7.8 Menu item “Extras”

7.8.1 Service

–

Click Extras -> Service -> Adjustments

–

Enter the password

The following screen will appear.

Language

–

Press the requested language.

–

Press the “OK” button.

The selected language will be adopted.

Date and time

–

Enter the date and the hour.

–

Press the “OK” button.

The settings will be adopted.

1

Setting the control panel

Touch Calibration

Contrast Brightness

Touch Test

41

Page 46

Full screen on / off

Full screen off

Full screen on

7.8.3 Zoom on / off

Zoom off

Zoom on

42

Page 47

7.8.2 System information

–

Click Extras -> Service -> System information

The following screen will appear.

Control unit events

A list with the errors that occurred lately will appear.

1

Log configuration

This function is reserved for the Dürkopp-Adler service personnel.

Log visualizer

A list with the last log settings will appear.

State of the operation panel

After effectuating the button the status will appear in the log display.

43

Page 48

7.8.3 Multitest

–

Click Extras -> Service -> Multi-test .

The following screen will appear.

Switching input/output elements

Test the input elements

With this test function the functioning of the input

elements will be tested.

Caution: Risk of injury!

Do not reach into the running machine during the function test of the

input elements.

–

Press the button “Input elements”.

–

Press “selected”.

–

Enter the desired input element and select it.

Input number Signification

S1 Clamp to the right below

S2 Clamp to the left below

S9 Upper thread monitor active

S10 Bobbin cover closed

S11 Machine head lock closed

S13 Pedal forwards

S14 Pedal backwards

S16 Pre ss u re monit or

S17 Quick stop

S100 Reference sewing motor

S101 Ref. X-axis

S102 Ref. Y-axis

S103 Ref. Z-axis

44

Page 49

Test the output elements

With this test function the functioning of the output

elements will be tested.

Caution: Risk of injury!

Do not reach into the running machine during the function test

of the output elements.

–

Press the button “output elements”.

–

Press “selected”.

–

Enter the desired output element and select it.

Output number Signification

Y1 Sewing foot mode:

Y2 Open the bobbin case latch

Y3 Needle cooler on

Y4 Clamp right side

Y5 Clamp left side

1

Y9 Lamp thread in button on

Y10 Warning light oil level on

Y25 Laser marking lamp 1 (Z)

Y26 Laser marking lamp 2 (Z)

Y27 Laser marking lamp 3 (Z)

Y28 Laser marking lamp 4 (Z)

45

Page 50

Test sewing motor

With this program the sewing motor is tested.

CAUTION !

Pull out the threads from needles a nd thread lever.

–

Enter the sewing speed.

(300 … 2000 U/min)

–

Enter the trimming speed.

(70 .. 500 U/min)

–

Press “Start”.

The sewing motor runs with the set speed.

–

Press “Stop”.

The sewing motor stops.

–

Press “Stop”.

The sewing motor stops automatically and the thread

trimmer is actuated.

46

Page 51

Feed clamp

This function is reserved for the Dürkopp-Adler service personnel.

Set stroke position

Perform a reference run

Switching between jumping and presser foot

Set the drives currentless

Go to a position

1

47

Page 52

7.8.5 Initialization and Update

–

Click Extras -> Service -> Initialization and Update.

–

Enter the password

The following screen will appear.

Control unit initialization

ATTENTION!

All entries will be set back to factory setting.

7.8.6 Manufacturer

Operation panel initialization

ATTENTION!

All entries will be set back to factory setting.

Update of the control unit

This menu is only accessible for Dürkopp Adler personnel.

48

Page 53

7.9 Menu item “Correction”

7.9.1 Thread tension

Upon changing this parameter all seams that are sewn subsequently

will be adjusted. With v alues below 100% all the thread tensions and

sewing speeds will be reduced. With values above 100% all the thread

tensions and sewing speeds will be increased.

These adjustments are only scheduled for a short “trial period” and

only remain set until the machine is switched off.

–

Click Correction -> Thread tension.

The following screen will appear.

1

7.9.2 Sewing speed

–

Enter the desired thread tension value.

(10 … 200)

–

Press the “OK” button.

–

Click Correction -> Sewing speed.

The following screen will appear.

–

Enter the desired sewing speed.

(10 … 200)

–

Press the “OK” button.

ATTENTION !

The values changed here are not automatically saved.

Should the changes be saved, please enter the values in the

sewing program (see chapter 7.7.1).

49

Page 54

7.10 Menu item “?”

7.10.1 Info

This screen indicates the current software version.

–

Click ?->Info.

The following screen will appear.

50

Page 55

7.11 Teach-in

With the sewing unit 911 it is possible to create freely defined seam

contours and to memorize them in the control unit. The contour data

are entered at the control panel.

Line not sewing

Via t his menu item a line can be created that will not

be sewn.

1

Line sewing

Via t his menu item a line can be created that will be sewn.

Circular arc

Via t his menu item a circular arc can be created.

Param…

Via this menu item the parameters that correspond to

the line or the circular arc are entered.

Sewing speed (min = 500 .. max. = 3000 U/min)

Stitch length (min. = 0.1 max. = 12.7 mm)

51

Page 56

Thread tension value

Lift stroke ( min. = 1 mm, max. = 10 mm)

Thread trimming

Delete

Via this menu item the line/circular arc entered last can

be deleted.

Memo…

Via this menu item the newly created seam contour

is memorized.

ñòñò Clamp movement

By pressing on of the arrow keys a clamp movement

into the corresponding direction is effectuated.

X=0.0 Y=0.0 Position request

By pressing on the area of the current clamp position

an edit window will pop up in which the new position

can be entered. After confirming the position by

pressing “OK” the clamp will go to the requested position.

Pedal actuation

Depending on the preselected direction of the

movement the clamp goes step by step to the right/left

or downwards/upwards.

52

Page 57

7.11.1 Creating a new seam contour

Step 1

–

–

In the first step the starting point of the seam segment

is determined.

1

Go to the desired starting point by using the arrow keys “ñ ”,

“ò ”,“ñ ”or“ò ”.

Press the “ OK ” button.

The starting point will be adopted.

The starting point will be displayed in green.

ATTENTION !

Pay attention to the specific clamp limits so that the seam contour is

inside the possible sewing field and that no collision will take place!

Run a contour test in order to check the clamp motion.

The sewing can be started afer a successful run.

The input of circular arcs requires particular attention since the

intermediate points will be interpolated!

53

Page 58

Step 2

In the second step it will be determined whether:

a non sewing line

·

a line or a circular arc will be sewn.

·

–

Select the desired button for the next entry.

–

Select the “Line sewing” or “circular arc” button. The menu for the

seam parameters will pop up.

Step 3

–

Enter the seam parameters for t he new seam segment.

–

Enter the desired seam segment by using the arrow keys “ñ”,

“ò”,“ñ”or“ò”.

–

Enter all further seam segments.

–

Press the “Memorize” button.

Enter the desired name and press “ Enter ”.

54

–

Adjust the program parameters.

ATTENTION !

Run a contour test in order to check the contour movement. After

a successful test the seam can be sewn.

Page 59

7.12 Repair mode

Via this button the repair mode can be called up.

That way a faulty seam contour, for example after a thread breakage

can be resewn from a certain point.

–

Switch on the repair mode.

–

Go to the point from where the sewing shall continue with the two

buttons “Forwards” (forwards) or “Reverse" (backwards).

–

Press the “Continue sewing” button.

From this repair point the seam will be sewn to the seam end.

1

55

Page 60

7.13 Thread breakage

After a thread breakage the thread can be threaded in again and the

sewing of the seam contour can be continued from any point.

–

Press the “Bobbin change” button.

The work clamp will go t o the bobbin change position.

–

Change the bobbin

–

Go to the point from where the sewing shall continue with the two

buttons “forwards” or “backwards”.

–

Press the “Continue sewing ” button.

From this repair point the seam will be sewn to the seam end.

56

Page 61

8. DA-CAD 5000

Selecting the machine class

With the program DA-CAD 5000 that is optionally available, sewing

programs can be created with an ordinary PC.

For the exact description please read the “Instruction manual

DA-CAD 5000".

1

Creating the seam contour

In the first step the machine class is selected.

In the second step the seam contour is drawn.

57

Page 62

Memorizing the seam contour

In the last step the finished seam program is copied onto a USB-stick.

In order to do so select the following menu item:

Data transmission

-> USB-Memory stick

-> Memorize (PC->USB)"

After successful memorizing on the USB-stick the following steps

have to be effectuated on the machine:

- Plug in the USB-stick and copy the desired data file onto the DAC.

- Open the copied program.

- Adjust the program parameters (particularly the min. sewing foot

height!).

- Run a contour test in order to check the c ontour movement.

- After successful checking/adjustment the program can be sewn.

58

Page 63

9. Error messages/Information messages

9.1 Error messages

Error code Description Remedy

Sewing motor

1051 Sewing motor timeout

- Faulty cable to the sewing motor reference

switch

- Faulty reference switch

- Machine head rough-running or belt tension too

high

1052 Sewing motor excess current

- Faulty sewing motor cable

- Faulty sewing motor

- Faulty control

1053 Sewing motor mains voltage too high

1055 Sewing motor overload

- Sewing motor blocked/seized up

- Faulty sewing motor

- Control faulty

1056 Sewing motor overheat

- Sewing motor seized up

- Faulty sewing motor

- Control faulty

1058

1302

1342

1344

Stepping motors

Sewing motor speed

- Faulty sewing motor

Failure sewing motor IDMA Autoincrement

Control receives no impulse from impulse

transmitter in the motor

Faulty sewing motor

Internal error

- Replace the cable

Replace the reference switch

- Check whether machine head is

rough-running

and belt tension

- Replace the sewing motor cable

- Replace the sewing motor

- Replace the control

Check the mains voltage

- Eliminate blocking/seizing

- Check the sewing motor

- Check the control

- Eliminate seizing

- Replace sewing motor

- Replace the control

- Replace the sewing motor

- Check the cable from the impulse

transmitter in the motor to the

control

- Switch the machine off and on

again

- Software update

1

2101 Stepping motor X-axis time out referencing

- Setting reference switch faulty

- Faulty cable to the reference switch

- Faulty reference switch

2102 Stepping motor X-axis faulty current supply

- Stepping motor blocked

- Encoder cable disconnected/faulty

- Encoder faulty

2152 Stepping motor X-axis excess current

2153 Stepping motor X-axis excess voltage

- Mains voltage too high

2155 Stepping motor X-axis overload

- Feeding system rough-running

- Obstacles at feeding movements

- Ali gn the referen ce swit c h

- Replace the cable

- Check the reference switch

- Remove the blocking

- Check/replace the encoder cable

- Replace the stepping motor

- Replace the stepping motor

- Replace the control

Check the mains voltage

- Remove the blocking

- Remove the obstacles/

Adapt the movements

59

Page 64

Error code Description R emedy

2156 Stepping motor X-axis overheat

- Stepping motor seized up

- Faulty stepping motor

- Control faulty

- Eliminate seizing

- Replace stepping motor

- Replace the control

2201 Stepping motor Y-axis time out referencing

- Setting reference switch faulty

- Faulty cable to the reference switch

- Faulty reference switch

- Al ig n the referenc e switc h

- Replace the cable

- Replace the reference switch

2202 Stepping motor Y-axis faulty current supply

- Stepping motor blocked

- Encoder cable disconnected/faulty

- Encoder faulty

- Remove the blocking

- Check/replace the encoder

cable

- Replace the encoder

2252 Stepping motor Y-axis excess current

- Replace the stepping motor

- Replace the control

2253 Stepping motor Y-axis excess voltage

- Mains voltage too high

Check the mains voltage

2255 Stepping motor Y-axis overload

- Feeding system rough-running

- Obstacles at feeding movements

- Remove the blocking

- Remove the obstacles/

Adapt the movements

2256 Stepping motor Y-axis overheat

- Feeding system blocked

- Faulty stepping motor

- Control faulty

- Eliminate seizing

- Replace stepping motor

- Replace the control

2301 Stepping motor stroke position time out

referen c in g

- Setting reference switch faulty

- Faulty cable to the reference switch

- Al ig n the referenc e switc h

- Replace the cable

- Replace the reference switch

- Faulty reference switch

2302 Stepping motor stroke position faulty current

supply

- Stepping motor blocked

- Encoder cable disconnected/faulty

- Encoder faulty

2352 Stepping motor stroke position excess current

- Remove the blocking

- Check/replace the encoder

cable

- Replace the stepping motor

- Replace the control

2353 Stepping motor stroke position excess voltage

Check the mains voltage

- Mains voltage too high

2355 Stepping motor stroke position overload

- Feeding system rough-running

- Obstacles at feeding movements

- Remove the blocking

- Remove the obstacles/

Adapt the movements

2356 Stepping motor stroke position overheat

- Feeding system blocked

- Faulty stepping motor

- Control faulty

- Eliminate seizing

- Replace stepping motor

- Replace the control

Control/Machine

3100 Machine control voltage

Temporary mains voltage drop

3102 Machine voltage intermediate circuit sewing motor

Temporary mains voltage drop

3103 Machine voltage intermediate circuit stepping

motors

Temporary mains voltage drop

60

Check the mains voltage

Check the mains voltage

Check the mains voltage

Page 65

Error code Description R emedy

3107 Machine temperature

- Vent holes closed

- Ventilation grid soiled

3109 Safe stop is switched on

3121 Insufficient or missing compressed air

3123 Oil sensor active

3210 Thread breakage

3215 Empty bobbin (Residual thread monitoring)

3220 Empty bobbin (Residual thread monitoring)

3500 Error calculation of the contour data

3501 Aim position of XY-clamp outside the movement

limits

3502 Aim position of XY-clamp within “defended areas”

- Check the vent holes

- Clean the ventilation grid

Switch off the safe stop

Increase the flow or stabilize the

compressed air

Topupoil

Re-thread the thread again

Insert a full bobbin.

Insert a full bobbin.

- Reload contour data

- Check contour data

Adjust the contour data

Adjust the contour data

3721

3722

Control/Machine

4201 Inter nal CF-card faulty

5301 Program not sewable

6551

6554

6651

6653

6751

6761

6952 Error stepping motor drive

Communication

Internal error

Error machine head position/ AD-Converter/

Processor error

Internal error

Internal error

- Switch the machine off and on

again

- Software update

- Inform the DA-Service

- Switch the machine off and on

again

- Ret ro fi t/ re pl a ce the contro l

- Copy the program to the DAC

- Switch the machine off and on

again

- Software update

- Inform the DA-Service

- Switch the machine off and on

again

- Software update

- Inform the DA-Service

1

7801 Communication control panel interface

- Line interruption

-Cable

8151

8156

8159

8152

8154

IDMA error

-Failure

- Faulty control

IDMA error

- Inter nal error

- Switch the machine off and on

again

- Software update

- Inform the DA-Service

- Switch the machine off and on

again

- Replace the control

- Switch the machine off and on

again

- Software update

- Inform the DA-Service

61

Page 66

Error code Description Remedy

8252

8257

Error booting ADSP/ Booting Xilinx/ Booting

Fault

- Switch the machine off and on

again

8258

8256

8254

8351 Error t estpins

- Switch the machine off and on

again

- Software update

- Inform the DA-Service

9601 Stop during sewing on the contour

Continue sewing process?

9700 The latch for the bobbin change is not closed

OK-key = Continue sewing

ESC-key = Abort sewing process

Close the latch for the bobbin

change

9701 Parallel clamp not down

- Remove obstacles

- Align the sensors

9900 Machine parameters faulty

9901 Faulty sequences

9902 Faulty program parameters

Initialize data

Initialize data

Initialize data

62

Page 67

9.2 Information messages

Info Description Remedy

8400 The control panel has no valid program for the DAC

8401

8402

8403 The program in the DAC is no more up-to-date

8404

8407

8408 Waiting for the reset by the DAC

8411 Checking of the DAC program active

8414 Successful update of the DAC

8801

8805

8806

8890

8891

System

9000 Reference run active

9002 Machine head not locked Lock the machine head

9006 Quick stop switch is actuated

9016 Wrong barcode-ID

9100 The counter has not reached the preset value

The control panel has no valid program for the DAC

Faulty update of the DAC

Error testpins/ Signal- / Event processing/ Memory

wrapper /List of functions

Internal error

Load the current program onto the

control panel with a USB-stick

Load the current program onto the

control panel with a USB-stick

Load the current program onto the

DAC

- Re-try update

- Check the cable connection

- Replace the DAC

Wait until restart is finished (takes a

few seconds)

Wait until checking is finished (takes

a few seconds)

- Switch the machine off and on

again

- Software update

- Inform the DA-Service

Releasethequickstopswitch

Change the program

Actuate the OK-key. The counter

will then be reset

1

63

Page 68

10. Maintenance

10.1 Cleaning and Checking

Caution: Risk of injury!

Turn the main switch off!

The maintenance may only be carried out with the sewing unit

switched off!

Maintenance work must be carried out no less frequently than at the

intervals given in the tables (see “operating hours” column).

Maintenance intervals may need to be shorter when processing

heavy-shedding materials.

A clean sewing unit is a trouble-free sewing unit.

1

Maintenance work Explanation Operating

to be carried out hours

Machine head

8

- Remove sewing dust,

lint and thread waste

(e.g. with an air blow gun)

Control box

Places in special need of cleaning:

- - Area around the needle 1

- Area around the hook 2

- Keep the ventilation grid free

8

2

64

Page 69

10.2.Oil lubrication

1

1

Caution: Risk of injury!

Oil can cause skin rashes.

Avoid longer skin contact.

After contact wash yourself thoroughly.

ATTENTION!

The handling and disposal of mineral oils is subject to legal

regulations.

Deliver used oil to an authorized collecting station.

Protect your environment.

Be careful not to spill any oil.

To lubricate the sewing unit use only DA 10 lubricating oil or an

equivalent oil with the following specifications:

–

Viscosity at 40° C: 10 mm²/s

–

Ignition point : 150° C

DA 10 is available from DÜRKOPP ADLER AG retail outlets under the

following parts number:

250 ml container: 9047 000011

1-litre container: 9047 000012

2-litre container: 9047 000013

5-litre container: 9047 000014

Maintenance work Explanation Operating

to be carried out hours

Lubrication of

the sewing unit

The sewing unit is equipped with a central oil

wick lubrication. The bearings are supplied out

of oil reservoir 1.

8

- The oil level must not fall below the marking

line 3 (MIN) of the oil reservoir.

- Fill in oil through the bore hole 2 up to the

marking line “Max”.

65

Page 70

Notes:

66

Loading...

Loading...