able of Contents

T

1 Introduction

2 General Characteristics

3 Composition and Chemistry

3.1 Active Components: Positive and Negative Electrodes

3.2 Electrolyte

3.3 Cell Reactions

4 Battery Construction

4

.1 Basic Cell Construction

4.2 Cylindrical Cell Construction

4.3 Prismatic Cell Construction

5 Performance Characteristics

5.1 General Characteristics

5.2 Discharge Characteristics: Effect of Discharge Rate

and Temperature

5.3 Capacity: Effect of Discharge Rate

and Temperature

5.4 Energy Density

Ni-MH Rechargeable Batteries

5.5 Constant Power Discharge Characteristics

5.6 Polarity Reversal During Overdischarge

5.7 Internal Impedance

5.8 Self-Discharge and Charge Retention

5.9 Voltage Depression (“Memory Effect”)

6 Charging Sealed Nickel-Metal Hydride Batteries

6.1 General Principles

6.2 Techniques for Charge Control

6.2.1 Timed Charge

6.2.2 Voltage Drop (-∆V)

6.2.3 Voltage Plateau (zero ∆V)

6.2.4 Temperature Cutoff

6.2.5 Delta Temperature Cutoff (∆TCO)

6.2.6 Rate of Temperature Increase (dT/dt)

7 Cycle and Battery Life

7.1 Cycle Life

7.2 Battery Life

8 Safety Considerations

9 Proper Use and Handling

9.1

Care and Handling

9.2 Transportation

9.3 Waste Management: Recycling and Disposal

6.3 Charging Methods

6.3.1 Duracell’s Recommendation:

Three-Step Charge Procedure

6.3.2 Low-Rate Charge

6.3.3 Quick Charge

6.3.4 Fast Charge

6.3.5 Trickle Charge

6.4 Thermal Devices

Ni-MH Rechargeable Batteries

Introduction

1

Rapid advancements in electronic technology have expanded the number of battery-powered portable

devices in recent years, stimulating consumer demand for higher-energy rechargeable batteries capable of

delivering longer service between recharges or battery replacement.

The trend towards smaller, lighter more portable battery-powered devices is expected to continue well

into the future, with the so-called “3C” applications — cellular phones, portable computers and consumer

electronics — expanding rapidly beyond the traditional business user and into the consumer marketplace.

As with other battery-powered consumer devices, battery performance and convenience will influence

the rate of consumer acceptance for 3C devices. Yet conventional rechargeable batteries often fail to meet the

needs of consumers, as well as equipment designers, in terms of their size and weight, operating time, easeof-use, availability and environmental acceptability. New battery systems are needed to meet their growing list

of demands.

The sealed nickel-metal hydride (Ni-MH) battery is one rechargeable battery system that is responding

to these demands by offering significant improvements over conventional rechargeable batteries in terms of

performance and environmental friendliness. First introduced to the commercial market in 1988, nickel-metal

hydride battery technology is at a very early stage of maturity and manufacturers such as Duracell have

identified many opportunities to improve battery performance. These improvements will make DURACELL

nickel-metal hydride batteries an attractive power source for 3C devices for many years to come.

General Characteristics

2

Many of the operating characteristics of the sealed nickel-metal hydride rechargeable battery are similar to those of the sealed nickel-cadmium rechargeable battery. The nickel-metal hydride battery, however, has

the advantage of higher energy density (or capacity) which translates into longer service life. In addition, the

nickel-metal hydride battery is environmentally friendlier than nickel-cadmium and other battery systems

because it contains no added cadmium, mercury or lead.

Features of the sealed nickel-metal hydride battery include:

Higher capacity — Up to 40 percent longer service

•

life than ordinary nickel-cadmium batteries of

equivalent size.

High rate discharge — Efficient discharge at rates

•

as high as 2C.

Fast charge — Can be charged in approximately

•

one hour.

Safe — Designed to safely withstand abusive

•

conditions in consumer devices.

Long cycle life — Up to 500 charge/discharge cycles.

•

Performs at extreme temperatures — Capable of

•

operation on discharge from -20°C to 50°C (-4°Fto

122°F) and charge from 0°C to 45°C (32°F to

113°F).

Environmentally friendlier than nickel-cadmium

•

batteries — Zero percent cadmium.

Similar operating voltage to nickel-cadmium

•

batteries — Allows user to upgrade easily to longer

lasting nickel-metal hydride batteries.

1

Ni-MH Rechargeable Batteries

Composition and Chemistry

3

A rechargeable battery is based on the principle that the charge/discharge process is reversible, that is, the

energy delivered by the battery during discharge can be replaced or restored by recharging.

3.1 Active Components: Positive and Negative Electrodes

Nickel oxyhydroxide (NiOOH) is the active material in the positive electrode of the nickel-metal hydride

battery in the charged state, the same as in the nickelcadmium battery.

The negative active material, in the charged state,

is hydrogen in the form of a metal hydride. This metal

alloy is capable of undergoing a reversible hydrogen

absorbing/desorbing reaction as the battery is charged

and discharged, respectively.

The unique attribute of the hydrogen storage

alloy is its ability to store hundreds of times its own

volume of hydrogen gas at a pressure less than atmospheric pressure. Many different intermetallic compounds have been evaluated as electrode materials for

nickel-metal hydride batteries. Typically, these fall into

two classes: AB

alloys, of which LaNi5is an example,

5

3.2 Electrolyte

An aqueous solution of potassium hydroxide is

the major component of the electrolyte of a nickelmetal hydride battery. A minimum amount of electrolyte is used in this sealed cell design, with most of

and AB

ogy is based on the use of AB

AB

tics, resulting in longer cycle life and better rechargeability following storage. The composition of the metal

alloy is formulated for optimal stability over a large

number of charge/discharge cycles. Other important

properties of the alloy include:

this liquid being absorbed by the separator and the

electrodes. This “starved electrolyte” design facilitates

the diffusion of oxygen to the negative electrode at the

end-of-charge for the “oxygen recombination” reaction.

alloys, of which TiMn2or ZrMn2are examples.

2

DURACELL nickel-metal hydride battery technol-

instead of AB2alloys.

5

alloys offer better corrosion resistance characteris-

5

Large hydrogen storage capability for high energy

•

density and battery capacity.

Favorable kinetic properties for high rate capability

•

during charge and discharge.

Low hydrogen pressure alloy and high purity mate-

•

rials to minimize self-discharge.

3.3 Cell Reactions

During discharge, the nickel oxyhydroxide is

reduced to nickel hydroxide

NiOOH + H

and the metal hydride (MH) is oxidized to the metal

alloy (M).

MH + OH-——> M + H

O + e-——> Ni(OH)2+ OH

2

O + e

2

-

-

The overall reaction on discharge is:

MH + NiOOH ——> M + Ni(OH)

The process is reversed during charge.

2

2

Composition and Chemistry (cont.)

Ni-MH Rechargeable Batteries

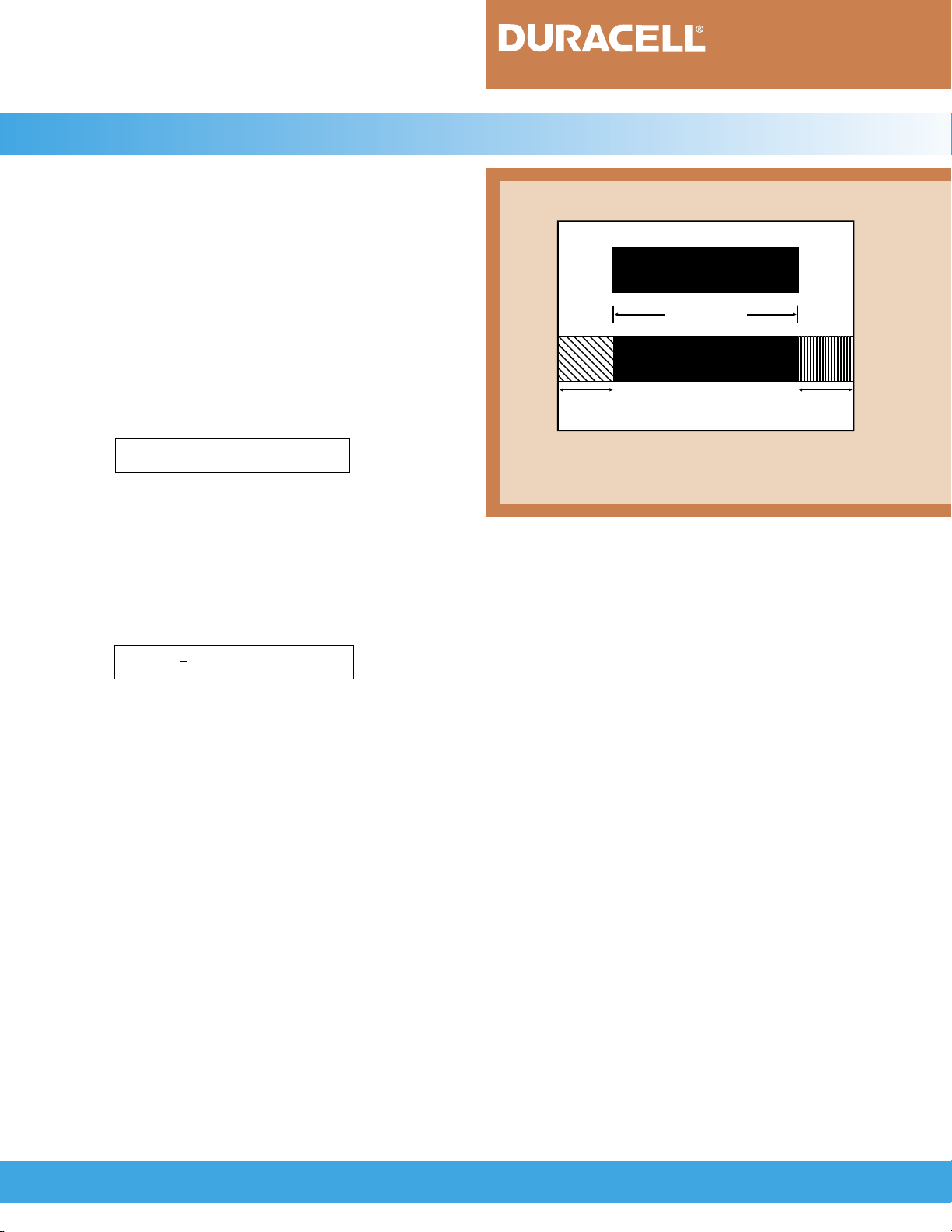

The sealed nickel-metal hydride cell uses the

“oxygen-recombination” mechanism to prevent a buildup of pressure that may result from the generation of

oxygen towards the end of charge and overcharge.

This mechanism requires the use of a negative electrode

(the metal hydride/metal electrode) which has a higher

effective capacity than the positive (nickel oxyhydroxide/nickel hydroxide electrode) electrode. A schematic

drawing of the electrodes is shown in Figure 3.3.1.

During charge, the positive electrode reaches

full charge before the negative electrode which causes

the evolution of oxygen to begin:

2OH

- _____

> H

O +

2

1

O2+ 2e

2

-

The oxygen gas diffuses through the separator

to the negative electrode, a process which is facilitated

by the “starved-electrolyte” design and the selection of

an appropriate separator system.

At the negative electrode, the oxygen reacts

with the metal hydride and oxidizes or discharges the

metal hydride to produce water:

FIGURE 3.3.1

Positive Electrode

NiOOH/Ni(OH)

Useful Capacity

MH/Alloy

Charge

Reserve

Schematic representation of the electrodes, divided

into useful capacity, charge reserve and discharge

reserve.

Negative Electrode

2

Discharge

Reserve

2MH +

O

2

2

> 2M + H

O

2

1

_____

Thus, the negative electrode does not become fully

charged and pressure does not build up.

The charge current, however, must be controlled at the end of charge and during overcharge to

limit the generation of oxygen to below the rate of

recombination. Thus, charge control is required to prevent the build-up of gases and pressure. Duracell recommends that continuous overcharge not exceed C/300

for optimal performance.

As shown in Figure 3.3.1, the nickel-metal

hydride cell is designed with a discharge and charge

reserve in the negative electrode. The discharge

reserve minimizes gassing and degradation of the cell in

the event of overdischarge. The charge reserve ensures

that the cell maintains low internal pressure on overcharge.

The negative electrode has excess capacity

compared to the positive electrode and is used to

handle both overcharge and overdischarge. Thus,

the useful capacity of the battery is determined by

the positive electrode.

3

Ni-MH Rechargeable Batteries

Battery Construction

4

DURACELL standard-sized nickel-metal hydride batteries are constructed with cylindrical and prismatic nickelmetal hydride cells. DURACELL nickel-metal hydride batteries are a sealed construction designed for optimal performance and maximum safety. The batteries are manufactured to strict quality control standards to ensure reliability

and consumer satisfaction and offer such features as:

High energy density — Minimizes battery volume

•

and weight

Wide voltage range — Meets operating voltage

•

requirements of 3C devices

Thin profiles — Innovative wall-less design

•

Advanced interconnect — Self securing, voltage-

•

keyed interconnect provides a highly reliable batteryto-device contact

4.1 Basic Cell Construction

The electrodes in both cylindrical and prismatic

cell configurations are designed with highly porous

structures which have large surface areas to provide low

internal resistance which results in superior high rate

performance. The positive electrode in the cylindrical

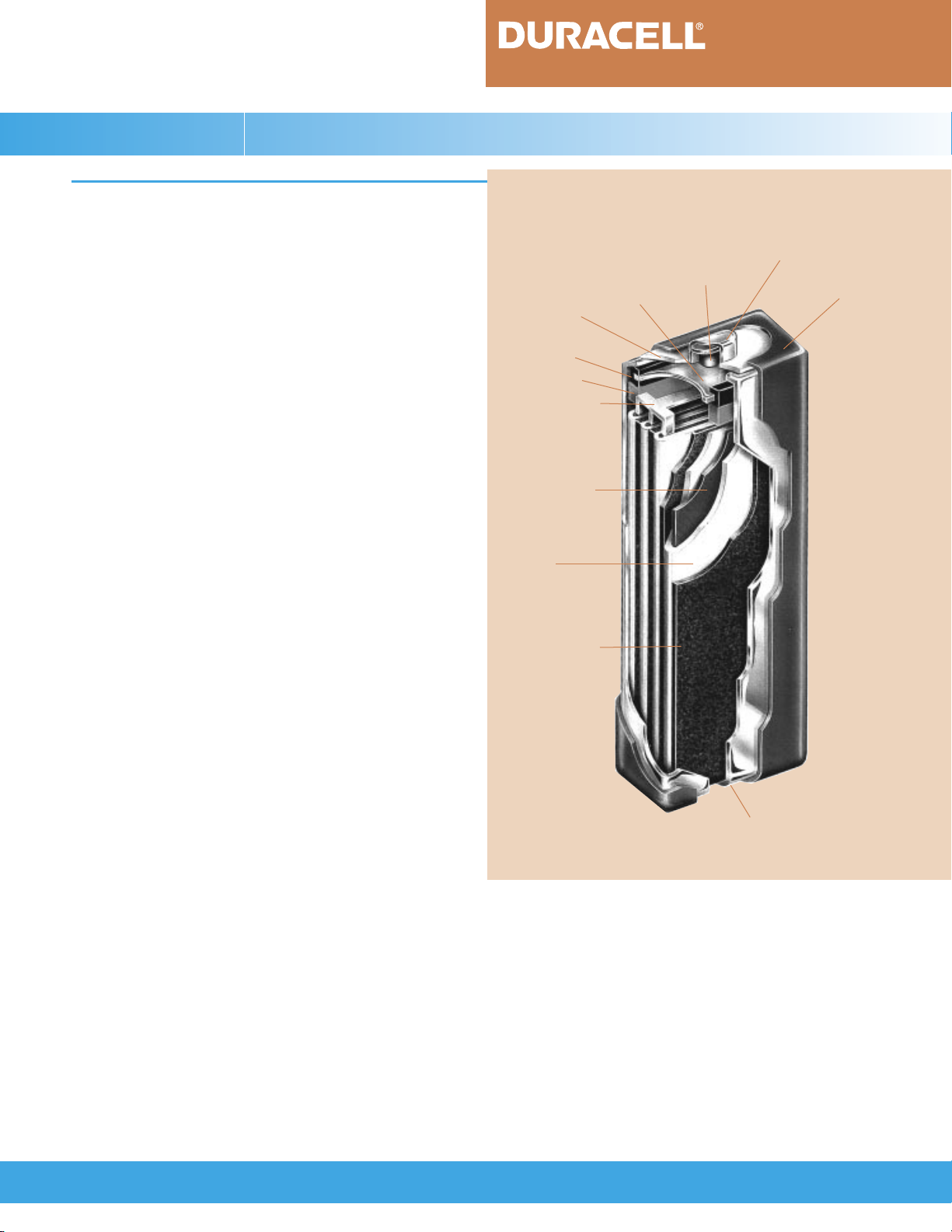

4.2 Cylindrical Cell Construction

The assembly of a cylindrical cell is shown in

Figure 4.2.1. The electrodes are separated by the separator which is a synthetic, non-woven material that

serves as an insulator between the two electrodes and as

a medium for absorbing the electrolyte. The electrodes

are spirally-wound and inserted into a cylindrical nickelplated steel can. The electrolyte is added and contained

within the pores of the electrodes and separator.

The positive electrode is connected to the metal

lid with a tab. The cell is then sealed by crimping the

Durability — Manufactured with LEXAN®and

•

LUSTRAN

retardant polymers

UL listing — Independent approval of battery use

•

in devices

nickel-metal hydride cell is a highly porous nickel-felt

substrate into whichthe nickel compounds are pasted.

Similarly, the negative electrode is a perforated nickelplated steel foil onto which the plastic-bonded, active

hydrogen storage alloy is coated.

top assembly to the can. The top assembly incorporates

a resealable safety vent, a metal lid and a plastic gasket.

A heat-shrink tube is placed over the metal can. The

bottom of the metal can serves as the negative terminal

and the metal lid as the positive terminal. The insulator

and gasket insulate the terminals from each other. The

vent provides additional safety by releasing any excess

pressure that may build up if the battery is subjected to

abusive conditions.

®

polycarbonate high impact and flame

LEXAN®is a registered trademark of the General Electric Company.

LUSTRAN®is a registered trademark of the Monsanto Company.

FIGURE 4.2.1

Safety Vent

(+) Positive Terminal

Metal Can

Separator

Negative Electrode

Heat Shrink Tube

Positive Electrode

(-) Negative Terminal

Insulator

Positive Tab

Metal Lid

Cosmetic Disk

Gasket

4

Battery Construction (cont.)

Ni-MH Rechargeable Batteries

4.3 Prismatic Cell Construction

The basic differences between the prismatic

c

ell and the cylindrical cell are the

the electrodes and the shape of the

cells are designed to meet the needs

equipment where space for the battery is

The rectangular shape of the prismatic cell

more efficient battery assembly by eliminating

voids that occur in a battery constructed with

cylindrical cells. Thus, the volumetric energy density

of a battery can be increased by constructing it with

prismatic instead of cylindrical cells.

Figure 4.3.1 shows the structure of the pris-

matic nickel-metal hydride cell. The electrodes are

manufactured in a manner similar to those of the

cylindrical cell, except that the finished electrodes are

flat and rectangular in shape. The positive and

negative electrodes are interspaced by separator

sheets. The assembly is then placed in a nickel-plated

steel can and the electrolyte is added. The positive

electrodes are connected to the metal lid with a tab.

The cell is then sealed by crimping the top assembly to

the can. The top assembly incorporates a resealable

safety vent, a metal lid and a plastic gasket that is

similar to the one used in the cylindrical cell. A heatshrink tube is placed over the metal can. The bottom

of the metal can serves as the negative terminal and

the top metal lid as the positive terminal. The insulator and gasket insulate the terminals from each

other. The vent provides additional safety by releasing any excess pressure that may build up if the

battery is subjected to abusive conditions.

construction of

can. Prismatic

of compact

limited.

permits

the

FIGURE 4.3.1

Cosmetic

Disk

Gasket

Insulator

Positive Tab

Positive Electrode

Separator

Negative Electrode

Metal Lid

(+) Positive Terminal

Safety Vent

Heat Shrink Tube

(-) Negative Terminal

5

5

Ni-MH Rechargeable Batteries

Performance Characteristics

5.1 General Characteristics

The discharge characteristics of the nickel-metal

hydride cell are very similar to those of the nickelcadmium cell. The charged open circuit voltage of both

systems ranges from 1.25 to 1.35 volts per cell. On

discharge, the nominal voltage is 1.2 volts per cell and

the typical end voltage is 1.0 volt per cell.

Figure 5.1.1 illustrates the discharge characteristics of nickel-metal hydride and nickel-cadmium

rechargeable cells of the same size. As shown, the voltage profile of both types of cells is flat throughout most

of the discharge. The midpoint voltage can range from

1.25 to 1.1 volts per cell, depending on the discharge

load. Figure 5.1.1 can also be used to compare the

capacity of the two rechargeable types. Note that the

capacity of the nickel-metal hydride cell is typically up to

40 percent higher than that of a nickel-cadmium cell of

equivalent size.

FIGURE 5.1.1

1.5

1.4

1.3

1.2

1.1

Voltage (V)

1.0

.9

0 20 40 60 80 100 120 140 160

Ampere-Hour Capacity (%)

Comparison of discharge voltage and capacity of

same-size Ni-MH and Ni-Cd cells.

[Conditions: Charge: C/3 for 5 hours, Temperature: 21°C (70°F)]

C/5

Ni-Cd

C/5

Ni-MH

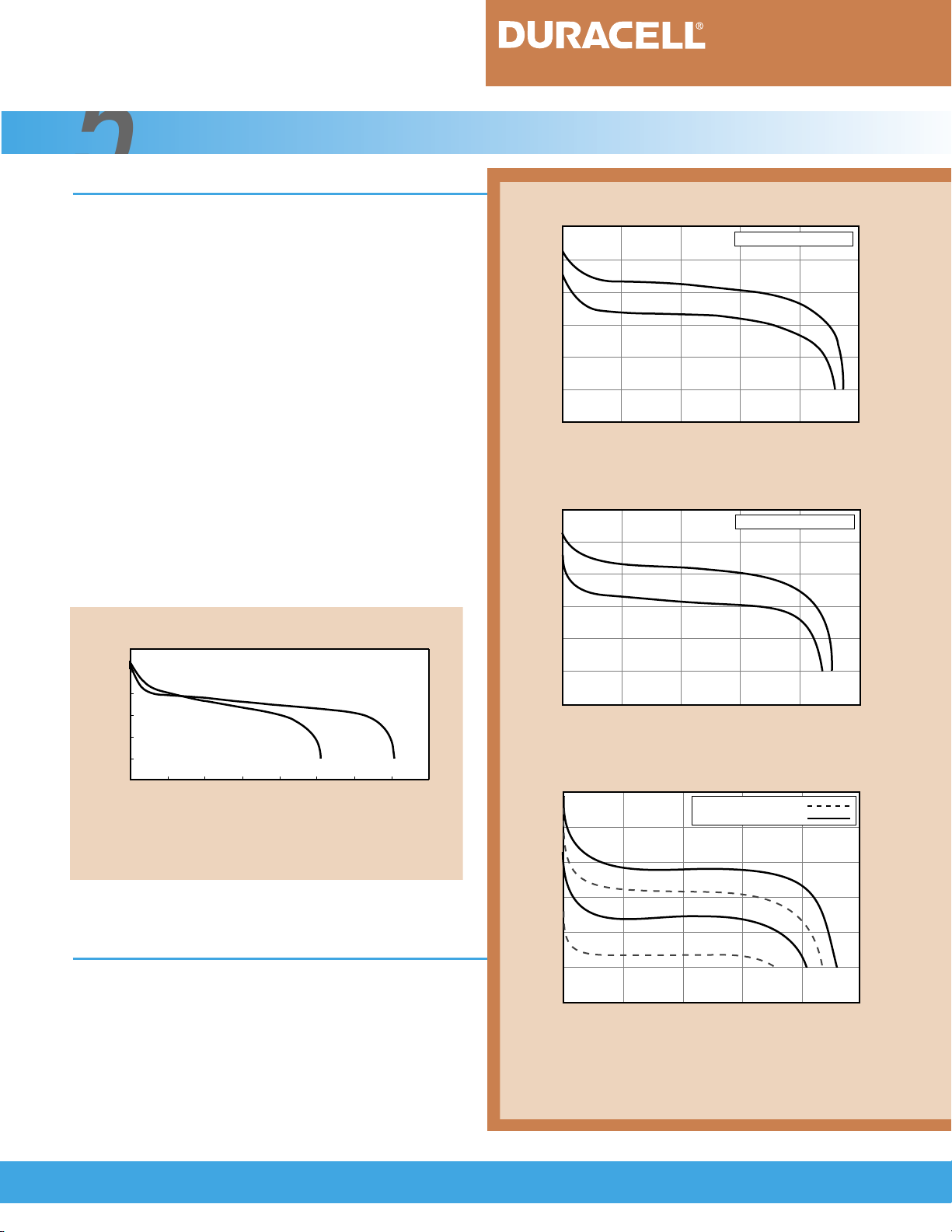

5.2 Discharge Characteristics: Effect of

Discharge Rate and Temperature

Typical discharge curves for DURACELL nickel-

metal hydride batteries under constant current loads at

various temperatures are shown in Figures 5.2.1 to

5.2.3. Discharge voltage is dependent on discharge

current and discharge temperature.

FIGURE 5.2.1

8.5

8.0

7.5

7.0

Voltage (V)

6.5

6.0

5.5

0 0.5 1.0 1.5 2.0 2.5

FIGURE 5.2.2

8.5

8.0

7.5

7.0

Voltage (V)

6.5

6.0

5.5

0 0.5 1.0 1.5 2.0 2.5

Discharge Capacity (Ah)

Discharge Capacity (Ah)

Temperature: 45°C (113°F)

C (2.4A)

Temperature: 21°C (70°F)

C (2.4A)

FIGURE 5.2.3

8.5

8.0

7.5

7.0

Voltage (V)

6.5

6.0

5.5

0 0.5 1.0 1.5 2.0 2.5

Voltage and capacity of DURACELL DR30 Ni-MH

batteries at various discharge temperatures

and rates.

[Conditions: Charge: 1C to -∆V = 60mV @ 21°C (70°F)]

C/5 (0.48A)

C (2.4A)

C (2.4A)

Temperature: -20°C (-4°F)

Temperature: 0°C (32°F)

C/5 (0.48A)

C (2.4A)

Discharge Capacity (Ah)

C/5 (0.48A)

C/5 (0.48A)

6

Performance Characteristics (cont.)

Ni-MH Rechargeable Batteries

Typically, when the current is higher and the

temperature is lower, the operating voltage will be

lower. This is due to the higher “IR” drop that

occurs with increasing current and the cell’s increasing resistance at the lower temperatures. However,

at moderate discharge rates (≈C/5), the effect of

low temperature on the capacity of the nickel-metal

hydride battery is minimal.

5.3 Capacity: Effect of Discharge Rate

and Temperature

The ampere-hour capacity of the battery is

dependent on the discharge current and temperature,

as can be observed in Figure 5.3.1. It should be noted

that the delivered capacity is dependent on the cutoff

or end voltage. The delivered capacity can be increased

by continuing the discharge to lower end voltages.

However, the battery should not be discharged to too

low a cut-off voltage (less than 0.9 volts per cell) as

the cells may be damaged (see Section 5.6). The

recommended cutoff voltage for nickel-metal hydride

batteries is 1.0 volt per cell.

Typically, optimum performance of the nickelmetal hydride battery is obtained between 0°C and 45°C

(32°F and 113°F). The performance characteristics of

the battery are affected moderately at higher temperatures. At lower discharge temperatures, performance

decreases more significantly, caused primarily by the

increase in internal resistance. Similarly, the effects of

temperature on performance are more pronounced at

higher discharge rates. The capacity of the battery

decreases more noticeably as the current increases,

particularly at lower temperatures.

FIGURE 5.3.1

2.5

2.0

1.5

1.0

Capacity (Ah)

0.5

0

C/5 (0.48)

Discharge Rate (A)

Typical capacity of DURACELL DR30 batteries under

constant current discharges at various temperatures.

[Conditions: Charge: 1C to -∆V = 60mV @ 21°C (70°F); Discharge

to 6.0V]

C (2.4)

°C (70°F)

21

45°C (113°F)

0°C (32°F)

-20°C (-4°F)

2C (4.8)

5.4 Energy Density

Energy density is the ratio of the energy available

from a battery to its volume or weight. A comparison of

the performance of various battery systems is normally

made on practical, delivered energy density per-unitweight or volume using production-based batteries and

performance as opposed to theoretical energy density.

Comparing energy densities, one must consider the

influence of cell size, internal design, discharge rate and

temperature conditions, as these parameters strongly

impact performance characteristics.

7

Performance Characteristics (cont.)

Ni-MH Rechargeable Batteries

Figure 5.4.1 compares the gravimetric and

volumetric energy density of nickel-metal hydride

and nickel-cadmium cells. As indicated, nickel-metal

hydride cells deliver more energy per weight or

volume than nickel-cadmium cells.

5.5 Constant Power Discharge Characteristics

The output energy characteristic of nickel-metal

hydride batteries under the constant power mode at

different power levels is shown in Figure 5.5.1.

As illustrated, the energy delivered does not vary

significantly with increasing power. The power levels

are shown on the basis of E-Rate. The E-Rate is

calculated in a manner similar to calculating the C-Rate.

For example, at the E/10 power level, the power

for a battery rated at 17.3 watt-hours is 1.73 watts.

5.6 Polarity Reversal During Overdischarge

When cells are connected in series, the cell

with the lowest capacity will reach a lower point of

discharge than the others. The more cells that are

connected in series, the greater the possibility of a cell

being fully discharged and driven into overdischarge

and polarity reversal. During reversal, hydrogen gas

evolves from the positive electrode. Hydrogen gas

will be reabsorbed by the negative electrode and

eventually oxygen gas will evolve from the negative

electrode. Extended overdischarge will lead to elevated

cell pressure and opening of the safety vent within

the nickel-metal hydride cells.

To minimize the occurrence of polarity reversal,

the cells in DURACELL rechargeable batteries have

capacities that are “matched” to each other. Device

designers can help prevent overdischarge by designing a

cutoff voltage for device operation of 1.0 volt per cell.

FIGURE 5.4.1

200

150

100

50

Wh/kg

0

Gravimetric and volumetric energy density of Ni-Cd

and Ni-MH cells.

Wh/L

Wh/kg

Ni-Cd Ni-MH

FIGURE 5.5.1

20

15

10

Energy (Wh)

5

0

E/10 (1.7)

Typical energy of DURACELL DR30 batteries under

constant power discharges.

[Conditions: Charge: 1C to -∆V = 60mV; Discharge to 6.0V;

Temperature: 21°C (70°F)]

Power (W)

Wh/L

E (17.3)E/3 (5.8)

8

Performance Characteristics (cont.)

Ni-MH Rechargeable Batteries

5.7 Internal Impedance

DURACELL nickel-metal hydride batteries have low

internal impedance because they are manufactured using

cells designed with thin plate electrodes which offer large

surface areas and good conductivity. Figure 5.7.1 shows

the change in internal impedance with depth of discharge.

As demonstrated, the impedance remains relatively constant

during most of the discharge. Towards the end of the discharge, the impedance increases due to the conversion of

the active materials to a non-conductive form.

5.8 Self-Discharge and Charge Retention

The state-of-charge and capacity of the nickelmetal hydride battery decrease during storage due to

self-discharge of the cells. Self-discharge results from

the reaction of residual hydrogen in the battery with the

positive electrode, as well as the slow and reversible

decomposition of the positive electrode. The rate of

self-discharge is dependent upon the length of time and

temperature at which the battery is stored — the higher the temperature, the greater the rate of self-discharge. As illustrated in Figure 5.8.1, cells stored at

0°C (32°F) retain more of their capacity than those

stored at 20°C and 45°C (68°F and 113°F), particularly

after 30 days.

Generally, long term storage of a nickel-metal

hydride battery in either a charged or discharged condition has no permanent effect on capacity. Capacity loss

due to self-discharge is reversible and nickel-metal

hydride batteries can recover to full capacity by proper

recharging. For example, full capacity of a nickel-metal

hydride battery that was stored at room temperature

for up to one year can be restored by cycling through

repeated charge/discharge cycles.

As with operation at elevated temperatures,

however, long term storage at high temperatures can

lead to deterioration of seals and separators and should

be avoided. The recommended temperature range for

long term storage of nickel-metal hydride batteries is

10°C to 30°C (50°F to 86°F).

FIGURE 5.7.1

180

)

Ω

175

DR30

170

Internal Impedance (m

165

0 20 40 60 80 100

Discharge Capacity (%)

Internal impedance of DURACELL DR30 Ni-MH

batteries at various discharge capacities.

[Conditions: Charge: C/5 for 7.5 hours; Discharge: C/5;

Temperature: 21°C (70°F); Measurements at 1000 Hz]

FIGURE 5.8.1

10 0

80

60

40

Residual Capacity (%)

20

0

0 5 10 15 20 25 30

Self-discharge characteristic of Ni-MH cells at

various temperatures.

[Conditions: Charge: C/3 for 5 hours; Discharge: C/5 to 1.0V;

Temperature: 21°C (70°F)]

Storage Time (Days)

0°C (32°F)

20°C (68°F)

45°C (113°F)

9

Performance Characteristics (cont.)

Ni-MH Rechargeable Batteries

5.9 Voltage Depression (“Memory Effect”)

Although many years of premium performance

can be enjoyed from a nickel-metal hydride battery that

is properly handled, the capacity delivered in each

charge/discharge cycle will eventually begin to decrease.

This inevitable decrease in capacity can be accelerated by

overcharging, storage or usage at high temperatures, or

through poor matching of cells within a pack. Often,

battery users who experience short service life have

incorrectly attributed capacity loss to a phenomenon

called “memory effect.”

The term memory effect is used synonymously with the term “voltage depression.” Voltage

depression is a scientifically measurable characteristic of

all batteries, however, nickel-cadmium batteries demonstrate particularly acute sensitivity. A properly designed

application with nickel-metal hydride batteries will result

in neither permanent performance loss nor perceivable

temporary capacity decreases from this characteristic.

A reversible drop in voltage and loss of capacity

may occur when a nickel-metal hydride battery is partially discharged and recharged repetitively without the

benefit of a full discharge, as illustrated in Figure 5.9.1.

After an initial full discharge (Cycle #1) and charge, the

cell is partially discharged to 1.15 volts and recharged

for a number of cycles. During this cycling, the discharge voltage and capacity drop gradually in very small

increments (Cycles #2 to #18). On a subsequent full

discharge (Cycle #19), the discharge voltage is

depressed compared to the original full discharge

(Cycle #1).

Because the cell appears to “remember” the

lower capacity, this voltage depression phenomenon is

often referred to as memory effect. However, the cell

can be quickly restored to full capacity with a few full

discharge/charge cycles, as indicated in Cycles #20

and #21.

The voltage drop occurs because only a portion

of the active materials in the cell is discharged and

recharged during shallow or partial discharging. The

active materials that have not been cycled change in

FIGURE 5.9.1

1.35

1.25

1.15

1.05

Voltage (V)

0.95

0.85

0 0.2 5 0.5 0.75 1.0

Time (Hours)

Effects on Ni-MH cell capacity due to repetitive partial

discharges.

[Conditions: Charge: (Cycle #1– #21) = 1C to -∆V = 12mV. Discharge: Cycle #1 = 1C

to 1.0 V, (Cycle #2– #18) = 1C to 1.15V, (Cycle #19 – #21) = 1C to 1.0V; Temperature:

21°C (70°F)]

Cycle #2

Cycle #18

Cycle #20

Cycle #19

physical characteristics and increase in resistance.

Subsequent full discharge/charge cycling will restore the

active materials to their original state.

The extent of voltage depression and capacity

loss depends on depth of discharge and can be avoided by

discharging the battery to an appropriate cutoff

voltage. Voltage depression is most apparent when the

discharge is terminated at higher cutoff voltages, such as

1.2 volts per cell. A smaller voltage depression and

capacity loss occurs if the discharge is cut off between

1.15 volts to 1.10 volts per cell. Discharging to 1.0

volts per cell should not result in significant voltage

depression or capacity loss during subsequent discharges.

A device properly designed with nickel-metal

hydride batteries will minimize the effects of voltage

depression and capacity loss. The voltage depression

and capacity loss in DURACELL nickel-metal hydride

batteries is only a small fraction (less than 5 percent

in worst cases) of the battery’s capacity and most users

will never experience a perceptible performance loss.

Cycle #1

Cycle #21

10

6

Ni-MH Rechargeable Batteries

Charging Sealed Nickel-Metal Hydride Batteries

6.1 General Principles

Recharging is the process of replacing energy

that has been discharged from the battery. The subsequent performance of the battery, as well as its overall

life, is dependent on effective charging. The main criteria for effective charging are:

Choosing the appropriate rate

•

Limiting the temperature

•

Selecting the appropriate termination technique

•

The recharging characteristics of nickel-metal

hydride batteries are generally similar to those of

nickel-cadmium batteries. There are some distinct

differences, however, particularly on the requirements

for charge control because the nickel-metal hydride

battery is more sensitive to overcharging. Caution

should be exercised before using a nickel-cadmium

battery charger interchangeably for both battery types

because it may not optimally charge a nickel-metal

hydride battery, particularly on high rate chargers.

The most common charging method for the

nickel-metal hydride battery is a constant current

charge with the current limited in order to avoid an

excessive rise in temperature. Limiting the charge

current also reduces the risk of exceeding the rate of

the oxygen recombination reaction to prevent cell

venting.

Figure 6.1.1 compares the voltage profiles of

nickel-metal hydride and nickel-cadmium batteries during charge at a constant current rate. The voltages of

both systems rise as the batteries accept the charge. As

the batteries approach 75 to 80 percent charge, the

voltages of both battery types rise more sharply due to

the generation of oxygen at the positive electrode.

However, as the batteries go into overcharge, the voltage profile of the nickel-metal hydride battery does not

exhibit as prominent a voltage drop as the nickelcadmium battery.

In Figure 6.1.2, the temperature profiles of the

nickel-metal hydride and nickel-cadmium batteries are

compared during charge at a constant current charge

rate. Throughout the first 80 percent of charge, the

temperature of the nickel-cadmium battery rises gradually because its charge reaction is endothermic (absorbs

heat). The temperature of the nickel-metal hydride

FIGURE 6.1.1

2.0

1.8

1.6

1.4

Voltage /Cell (V)

1.2

1.0

0 20 40 60 80 100 120

Charge Input (% of Typical Capacity)

Typical charge voltage characteristics of Ni-MH and

Ni-Cd batteries.

[Conditions: Charge: 1C @ 21°C (70°F) to -∆V = 10mV/cell]

FIGURE 6.1.2

55

50

45

C)

°

40

35

30

25

Temperature (

20

15

0 20 40 60 80 100 120

Charge Input (% of Typical Capacity)

Typical charge temperature characteristics of Ni-MH

and Ni-Cd batteries.

[Conditions: Charge: 1C @ 21°C (70°F) to -∆V = 10mV/cell]

Ni-Cd

Ni-MH

Ni-MH

Ni-MH

Temperature (°F)

131

122

113

104

Ni-Cd

battery, on the other hand, rises quickly because its

charge reaction is exothermic (releases heat). After

80 to 85 percent of charge, the temperature of both

battery types also rises due to the exothermic oxygen

recombination reaction, causing the voltage to drop as

the batteries reach full charge and go into overcharge.

Both the voltage drop after peaking (-∆V) and

the temperature rise are used as methods to terminate

the charge. Thus, while similar charge techniques can

be used for nickel-metal hydride and nickel-cadmium

batteries, the conditions to terminate the charge may

differ because of the varying behavior of the two battery systems during charge. To properly terminate

charging of DURACELL nickel-metal hydride batteries,

95

86

77

68

59

11

Ni-MH Rechargeable Batteries

Charging Sealed Nickel-Metal Hydride Batteries (cont.)

Duracell recommends the charge termination method

described in Section 6.3.1.

The voltage of the nickel-metal hydride battery

during charge depends on a number of conditions,

including charge current and temperature. Figures

6.1.3 and 6.1.4 show the voltage profile of the nickelmetal hydride battery at different ambient temperatures

and charge rates, respectively. The battery voltage rises

with an increase in charge current due to an increase in

the “IR” drop and overpotential during the electrode

reaction. The battery voltage decreases with increasing

temperature as the internal resistance and overpotential

during the electrode reaction decrease.

A rise in temperature and pressure at high

charge rates occurs and underscores the need for proper charge control and effective charge termination

when “fast charging.” Excessive pressure and temperature increases can result in activation of cell vents or

battery safety electronics, as described in Section 6.4.

Temperature also affects charge efficiency.

Charge efficiency decreases at higher temperatures due

to the increasing evolution of oxygen at the positive

electrode. Thus, charging at high temperatures results

in lower capacity. At lower temperatures, charge efficiency is high due to decreasing oxygen evolution.

However, oxygen recombination is slower at lower temperatures and a rise in internal cell pressure may occur

depending on the charge rate.

Proper charging is critical not only to obtain

maximum capacity on subsequent discharges but also

to avoid high internal temperatures, excessive overcharge and other conditions which could adversely

affect battery life.

6.2 Techniques for Charge Control

FIGURE 6.1.3

10.0

9.5

9.0

8.5

Voltage (V)

8.0

7.5

0 0.2 0.4 0.6 0.8 1.0 1.2

Charge voltage of DURACELL DR30 Ni-MH batteries

at various temperatures.

[Conditions: Discharge: C/5 to 6.0V @ 21°C (70°F); Charge: 1C to -∆V =

60mV]

FIGURE 6.1.4

10.0

9.5

9.0

8.5

8.0

Voltage (V)

7.5

7.0

0 1.0 2.0 3.0 4.0

Charge voltage of DURACELL DR30 Ni-MH batteries

at various rates.

[Conditions: Discharge: C/5 to 6.0V; Charge: 1C to -∆V = 60mV, C/5 to

7.5 hrs.; Temperature: 21°C (70°F)]

0°C (32° F)

21

°C (70° F)

Charge Time (Hours)

Charge Capacity (Ah)

C (2.4A)

C/5 (0.48A)

The characteristics of the nickel-metal hydride

battery define the need for proper charge control in

order to terminate the charge and prevent overcharging

or exposure to high temperatures. Each charge control

technique has its advantages and disadvantages. For

example, higher capacity levels are achieved with a 150

percent charge input, but at the expense of cycle life;

long cycle life is attained with a 105 to 110 percent

charge input, albeit with slightly lower capacity due to

less charge input. Thermal cutoff charge control may

reduce cycle life because higher temperatures are

reached during the charge; however, it is useful as a

backup control in the event that the primary termination method is not effective during charge.

12

Ni-MH Rechargeable Batteries

Charging Sealed Nickel-Metal Hydride Batteries (cont.)

The following summary explains some of the

recommended methods for charge control. The characteristics of each of these methods are illustrated in

Figure 6.2.1. In many cases, several methods are

employed, particularly for high rate charging.

FIGURE 6.2.1

Voltage (V)

-∆V

6.2.1 Timed Charge

Under the timed charge control method, the

charge is terminated after the battery is charged for a

predetermined length of time. This method should be

used only for charging at low rates (less than C/3) to

avoid excessive overcharge because the state-of-charge

of the battery, prior to charging, cannot always be

determined. If a timed charge termination is used, a

time of 120 percent charge input is recommended with

a backup temperature cutoff of 60°C (140°F).

Voltage drop is widely used with nickel-cadmi-

batteries. With this technique, the voltage during

um

charge is monitored and the charge is terminated

when the voltage begins to decrease. This approach

can be used with nickel-metal hydride batteries, but

as noted in Section 6.1, the voltage drop of the nickelmetal hydride battery is not as prominent as that of

the nickel-cadmium battery and may be absent in

charge currents below the C/3 rate, particularly at

elevated temperatures. The voltage sensing circuitry

TCO

Voltage (V)

Temperature (T)

dT/dt

Temperature Differential Output (

Charge Time (t)

Charge characteristics of Ni-MH batteries using

various charge termination methods.

dT/dt)

must be sensitive enough to terminate the charge

when the voltage drops, but not so sensitive that it

will terminate prematurely due to noise or other

normal voltage fluctuations. A charge rate of 1C and

a 5 to 10 millivolt per cell drop is recommended for

the nickel-metal hydride battery with a backup temperature cutoff of 60°C (140°F). A top-up charge is

not necessary with this charge termination method.

)

dT/dt

(

Temperature (T)

Temperature Differential

13

6.2. 3 Voltage Plateau (Zero ∆V)

Since the nickel-metal hydride battery does

not always show an adequate voltage drop, an alternate method used is to terminate the charge when

the voltage peaks and the slope is zero, rather than

waiting for the voltage to drop. The risk of over-

6.2. 4 Temperature Cutoff

Another technique for charge control is to

monitor the temperature rise of the battery and terminate the charge when the battery has reached a

temperature which indicates the beginning of overcharge. It is difficult, however, to precisely determine

charge is reduced as compared to the -∆V method.

If this method is employed, a charge rate of 1C and a

backup temperature cutoff of 60°C (140°F) is recommended. A top-up charge can follow to ensure a full

charge.

Duracell does not recommend this termina-

tion method because of the risk of premature cutoff.

this point because it is influenced by ambient temperature, cell and battery design,

factors. A cold battery, for

charge rate, and other

instance, may be overcharged before reaching the cutoff temperature, while

a warm battery may be undercharged.

Ni-MH Rechargeable Batteries

Charging Sealed Nickel-Metal Hydride Batteries (cont.)

6.2.4 Temperature Cutoff (cont.)

Usually this method is used in conjunction with

other charge control techniques primarily to terminate

the charge in the event that the battery reaches excessive temperatures before the other charge controls

6.2. 5 Delta Temperature Cutoff (∆TCO)

This technique measures the battery temperature rise above the starting temperature during charging

and terminates the charge when this rise exceeds a predetermined value. In this way, the influence of ambient

temperature is minimized. The cutoff value is dependent on several factors, including cell size, configuration

and number of cells in the battery, and the heat capacity

of the battery. Therefore, the cutoff value should be

6.2. 6 Rate of Temperature Increase (dT/dt)

In this method, the change in temperature with

time is monitored and the charge is terminated when a

predetermined rate of temperature rise is reached. The

influence of ambient temperature is reduced. A dT/dt cutoff is a preferred charge control method for nickel-metal

hydride batteries because it provides long cycle life.

Figure 6.2.2 shows the advantage of using a dT/dt

method compared to -∆V in terminating a fast charge.

The dT/dt method senses the start of the overcharge

earlier than the -∆V method. The battery is exposed to

less overcharge and overheating, resulting in less loss of

cycle life. A charge rate of 1C and a temperature increase

of 1°C (1.8°F) per minute with a back-up temperature cut-

off of 60°C (140°F) is recommended for dT/dt. A top-up

charge of C/10 for 1/2 hour is also recommended.

activate. A charge rate of 1C and a temperature cutoff

at 60°C (140°F) is recommended. A top-up charge is

not recommended if this termination method is used.

determined for each type of battery. This value will

be greater for nickel-metal hydride batteries than for

nickel-cadmium batteries. A charge rate of 1C and a

temperature change of 15°C (27°F) with a backup

temperature cutoff of 60°C (140°F) is recommended

for ∆TCO charge termination. A top-up charge is not

necessary with this termination method.

FIGURE 6.2.2

3.0

2.5

dT/dt = 1°C(1.8°F)/min

2.0

1.5

Discharge Capacity (Ah)

1.0

0 100 200 300 400 500

Cycle life and capacity of DURACELL DR30 Ni-MH

batteries as a function of charge termination.

[Conditions: Charge: 1C; Discharge: C/5 to 6.0V; Cycled to 70% of

initial capacity; Temperature: 21°C (70°F)]

- ∆V= 60 mV

Cycle Number

6.3 Charging Methods

Nickel-metal hydride batteries can be charged

employing the same methods used for charging nickel-cadmium batteries. However, the charge termination technique may differ because of the varying behavior of the

two battery systems. For proper charging of nickel-metal

hydride batteries, the charge termination technique used

should be appropriate for the particular charge rate. The

charge rate and appropriate termination technique is summarized in Table 6.3.1.

Some of the various methods used to properly

charge nickel-metal hydride batteries are explained in

Sections 6.3.1 to 6.3.5. In order to optimize performance,

Duracell recommends a three-step charge procedure.

Charge Rate Termination Technique

1C to C/2 Voltage or temperature based

C/2 to C/3 Voltage based

C/3 to C/10 Not recommended

C/10 and below Time limited

Table 6.3.1 Recommended charge termination techniques

for particular charge rates.

14

Ni-MH Rechargeable Batteries

Charging Sealed Nickel-Metal Hydride Batteries (cont.)

6.3.1 Duracell’s Recommendation: Three-Step Charge Procedure

For fast charging and optimum performance,

Duracell recommends a three-step procedure that provides a means of rapidly charging a nickel-metal hydride

battery to full charge without excessive overcharging or

exposure to high temperatures. The steps in sequential

order are:

6.3. 2 Low-Rate Charge (≈12 hours)

Charging at a constant current at the C/10 rate

with time-limited charge termination is a convenient

method to fully charge nickel-metal hydride batteries.

At this current level, the generation of gas will not

exceed the oxygen recombination rate. The charge

should be terminated after 120 percent charge input,

or approximately 12 hours for a fully discharged bat-

6.3. 3 Quick Charge (≈4 hours)

Nickel-metal hydride batteries can be efficiently

and safely charged at higher rates than described in

Section 6.3.2. Charge control is required in order to

terminate the charge when the rate of oxygen recombination is exceeded or the battery temperature rises

excessively. A fully discharged battery can be charged

at the C/3 rate terminated with a -∆V = 10 mV/cell. In

addition, a timer control set to a 120 percent charge

input (3.6 hours) and a temperature cutoff of 60°C

(140°F) should be used as a backup termination to

1) Charge at the 1C rate, terminated by using

dT/dt = 1°C(1.8°F) /minute.

2) Apply a C/10 top-up charge, terminated by

a timer after 1/2 hour of charge.

3) Apply a maintenance charge of indefinite

duration at C/300 rate.

The three-step charging method should be used

with a backup temperature cutoff of 60°C (140°F).

tery. Excessive overcharging should be avoided, as it

can damage the battery.

The temperature range for this charge method

is 0°C to 45°C (32°F to 113°F), with optimum

performance being obtained between 15°C to 30°C

(59°F to 86°F).

avoid exposing the battery to excessively high temperatures. This charging method may be used in an ambient

temperature range of 10°C to 45°C (50°F to 113°F). A

top-up charge is not necessary if this termination method

is used.

At the C/3 rate, a dT/dt termination method

should not be used because the rate of temperature

increase may not be sufficient to terminate the charge.

6.3. 4 Fast Charge (≈1 hour)

Another method of charging nickel-metal

hydride batteries in even less time is to charge at the

C/2 to 1C constant current rates. At these high charge

rates, it is essential that the charge be terminated early

during overcharge. However, timer control is inadequate, as the time needed for charge can not be predicted — a partially charged battery could easily be

overcharged while a fully discharged one could be

undercharged, depending on how the timer control

is set.

15

With fast charging, the decrease in voltage

(-∆V) and the increase in temperature (∆T) can be used

to terminate the charge. For better results, termination

of fast charge can be controlled by sensing the rate of

temperature increase (dT/dt). A temperature increase

of 1°C (1.8°F) per minute with a backup temperature

cutoff of 60°C (140°F) is recommended. A top-up

charge of C/10 for 30 minutes should follow to ensure

a full charge.

Ni-MH Rechargeable Batteries

Charging Sealed Nickel-Metal Hydride Batteries (cont.)

6.3. 5 Trickle Charge

A number of applications require the use of

batteries which are maintained in a fully-charged state.

This is accomplished by trickle charging at a rate that

will replace the loss in capacity due to self-discharge.

In these applications, a trickle charge at a C/300 rate is

6.4 Thermal Devices

DURACELL nickel-metal hydride batteries contain a temperature sensing device and thermal protective devices. Thermal protective devices terminate

charge/discharge in the event high temperatures are

reached. This protection is particularly important when

fast charging methods are used. The types of devices

used are:

1) Negative Temperature Coefficient (NTC)

Thermistor: This device senses internal battery temperature and provides this information by means of a calibrated resistance

value to an external control circuit. The

thermistor is attractive because the control

can be set, external to the battery, to meet

the particular conditions of the charge. This

device is used in dT/dt charge control.

2) Thermostat: This bimetal thermal protective device operates at a fixed temperature

and is used to cut off the charge (or discharge) when a pre-established internal battery temperature or current is reached.

These temperature cutoff (TCO) devices

reset automatically after the overtemperature or overcurrent condition has decreased

below a reset threshold.

3) Thermal Fuse: This device is wired in series

with the cell stack and will open the circuit

when a predetermined temperature is

reached. Thermal fuses are included as a

protection against thermal runaway and are

normally set to open at approximately 91°C

(196°F). This device cannot be reset once

opened.

recommended. The preferred temperature range for

trickle charging is between 10°C to 35°C (50°F to

95°F). Trickle charge may be used following any of the

previously discussed charging methods.

4) Positive Temperature Coefficient (PTC)

Device: This is a resettable device whose

resistance rapidly increases at a predetermined current, thereby reducing the current

in the battery to a low and acceptable level.

The PTC device will respond to high current

beyond design limits (e.g. a short circuit) and

acts like a fuse. Unlike a one-time fuse, the

PTC device will reset to its low resistance

state when the latching current is removed.

It will also respond to high temperatures

around the PTC device, in which case it

operates like a temperature cut-off (TCO)

device.

The location of thermal devices in the battery

assembly is critical to ensure that they will respond properly as the temperature may not be uniform throughout

the battery. Thermal devices in DURACELL nickel-metal

hydride batteries are set so the cells are not exposed to

temperatures above 91°C (196°F). The inclusion of

thermal protective devices in DURACELL nickel-metal

hydride batteries helps ensure safe battery operation.

16

7

Ni-MH Rechargeable Batteries

Cycle and Battery Life

7.1 Cycle Life

The cycle life of nickel-metal hydride batteries

depends on the many conditions to which the battery

has been exposed, as is true for all types of rechargeable batteries. These include such variables as:

Temperature during charge and discharge

•

Charge and discharge current

•

Depth of discharge

•

Method of charge control

•

Exposure to overcharging and overdischarging

•

Storage conditions

•

Typically, under a C/5 charge/discharge at

normal ambient temperatures (20°C or 68°F), up to

500 cycles can be achieved with the battery delivering

at least 80 percent of its rated capacity. The gradual

decrease in capacity results from an increase in the battery’s internal resistance, caused by minor irreversible

changes in the structure of the electrodes, electrolyte

distribution and separator dry-out.

For optimum battery life and maximum cycle

life, nickel-metal hydride batteries should be operated at

or near room temperature (20°C or 68°F). Repeated

operation at extreme temperatures during charge and

discharge will adversely affect the performance of the

cells (and thus the battery), as shown graphically in

Figure 7.1.1. Operation at high temperatures, particularly in the overcharged condition, can cause the cell to

vent, releasing gas and possibly electrolyte through the

safety vent. High temperatures will also hasten the

deterioration of the separator and other materials in the

cell. At temperatures below 0°C (32°F), the oxygen

recombination reaction slows down and the cell is more

sensitive to overcharging, thus gas pressure will build up

more rapidly.

FIGURE 7.1.1

32 50 68 86 104 122

100

90

80

70

60

Cycle Life (%)

50

40

30

20

10

0 10 20 30 40 50

Impact on cycle life from repeated charging and

discharging at various ambient temperatures.

[Conditions: Charge: C/4 for 3.2 hours; Discharge: C/4 for 2.4 hours;

Capacity measured every 50 cycles @ 21°C (70°F): Charge: C/3 for

5 hours; Discharge: 1C to 1.0V]

Temperature (°F)

Temperature (°C)

17

Cycle and Battery Life (cont.)

Ni-MH Rechargeable Batteries

Charge rate and amount of charge input during

overcharging are also important factors affecting cycle

life. If the battery is charged at a rate that exceeds the

oxygen recombination rate, oxygen that is generated

during overcharge will not react, causing a build up in

gas pressure and a rise in temperature which will have

damaging effects on battery and cycle life. Prompt use

of an effective charge termination method when

deleterious overcharge begins will lessen the effect

on cycle life.

7.2 Battery Life

The same factors that affect cycle life affect

overall battery life. Operation or storage at extreme

temperatures, overcharging, cell venting and abusive

use will reduce battery life. Operation and storage of

Table 7.2.1

Recommended Permissible

Cycle life is also affected by the depth of discharge. Depending upon the charge termination method,

up to 500 cycles can be obtained with the battery being

fully discharged on each cycle (100 percent depth of discharge, or “DOD”). Considerably higher cycle life can be

obtained if the battery is cycled at shallower charge/

discharges.

batteries at or about room temperature (20°C or 68°F)

will maximize battery life. Recommended and permissible temperature limits are shown in Table 7.2.1.

Low Rate Charge 15°C to 30°C (59°F to 86°F) 0°C to 45°C (32°F to 113°F)

Quick Charge 10°C to 30°C (50°F to 86°F) 10°C to 45°C (50°F to 113°F)

Fast Charge 10°C to 30°C (50°F to 86°F) 10°C to 45°C (50°F to 113°F)

Trickle Charge 10°C to 30°C (50°F to 86°F) 10°C to 35°C (50°F to 95°F)

Discharge 0°C to 40°C (32°F to 104°F) - 20°C to 50°C (-4°F to 122°F)

Storage, Short Term 10°C to 30°C (50°F to 86°F) - 20°C to 50°C (-4°F to 122°F)

Storage, Long Term 10°C to 30°C (50°F to 86°F) - 20°C to 35°C (-4°F to 95°F)

Table 7.2.1 Recommended and permissible temperature limits for operation and storage of DURACELL

nickel-metal hydride rechargeable batteries

.

18

Ni-MH Rechargeable Batteries

Safety Considerations

8

Duracell’s nickel-metal hydride batteries are designed to ensure maximum safety. Each cell includes a

resealable pressure relief mechanism (safety vent) to prevent excessive build-up of pressure in the cell in the event

it is overcharged excessively, exposed to extreme high temperatures, or otherwise abused. Duracell’s nickel-metal

hydride batteries contain protective devices, as discussed in Section 6.4, to prevent excessive heating during fast

charging, high rate discharging beyond design limits, or abusive use.

DURACELL nickel-metal hydride batteries have been tested by the Underwriters Laboratories in accordance

with UL Standard 2054 “Outline of Investigation for Household and Commercial Batteries.” Duracell successfully

met all of the test criteria. The tests required under this Standard and the results of the tests on DURACELL cells

and batteries are summarized in Table 8.0.1. These tests cover operational and abusive conditions to which

batteries may be exposed during their use.

DURACELL nickel-metal hydride cells and batteries that are listed by Underwriters Laboratories under

UL Standard 2054 are identified in File No. MH17905. Some DURACELL nickel-metal hydride batteries used in

computers are listed under UL Standard 1950 “Safety of Information Technology Equipment, including Electrical

Business Equipment,” and are identified in File No. E158164.

19

Ni-MH Rechargeable Batteries

Safety Considerations (cont.)

Table 8.0.1

Test Test Conditions Test Results

Flat Plate Crush Test Cell is crushed between No explosion, sparks, or flames.

two flat surfaces.

Impact Test A 20 lb. weight is dropped from No explosion, sparks, or flames.

height of 2 feet on cell.

Short Circuit Test* Sample is shorted until discharged. No evidence of venting, leakage, bulging or

Test conducted at 20°C and other visible changes on individual cells.

60°C (68°F and 140°F). Maximum case temperature was

129°C (264°F). In batteries, safety devices

operated, protecting battery from external

short. Maximum battery case temperature

was within 5°C (41°F) of ambient.

Forced-Discharge Test The cell, after discharge, No venting, leakage, fire or explosion on test

(Voltage Reversal) is over-discharged for 1.5 conducted at C/3 discharge rate.

times rated capacity.

Abnormal Charge Cell is charged for 2.5 No venting, leakage, fire or explosion on

Test times rated capacity. test conducted at C/3 charge rate.

Abusive Overcharge Sample is charged by Individual cells vented. No explosion or fire.

Test* power supply up to Maximum temperature on cell case was

200 watts until sample 200°C (392°F). In batteries, safety devices caused

vents or explodes. charging circuit to open periodically, protecting

battery as designed. Maximum battery case

temperature was within 25°C (77°F) of ambient.

Heat Test The cell is heated in an oven to No damage to cells; no bulging, venting,

150°C (302°F). fire or explosion.

Fire Exposure Test* Sample is heated by a burner Cells and batteries vented without

fueled with methane. exploding. No significant flaming or spark.

No projectiles.

Table 8.0.1 Results of DURACELL nickel-metal hydride cells and/or batteries tested under UL Standard 2054

test regimes.

*Note: These tests were conducted on both individual cells and batteries. Tests

as deemed adequate by UL to demonstrate safety of both cells and batteries.

not

marked with an asterisk were conducted on individual cells only,

20

Ni-MH Rechargeable Batteries

Proper Use and Handling

9

Nickel-metal hydride batteries can give years of safe and reliable service if they are used in accordance with

recommended procedures and are not abused. The batteries can be used in any operating position. Other than

charging, the only maintenance that should be required is to keep them clean and dry both during use and storage.

As previously discussed, nickel-metal hydride batteries, as with all battery systems, should not be exposed to

extreme temperatures for any long period of time. They can be stored for many months in a charged or discharged

state without any detrimental effects. Storage and operation at normal room temperatures is preferred, but wider

temperatures can be safely tolerated as discussed in detail in this bulletin.

DURACELL nickel-metal hydride batteries are shipped in a partially charged state. Therefore, caution should

be exercised to avoid short-circuiting the battery during handling.

After storage or periods during which the battery has not been used, the battery should be charged, using

any of the methods discussed in this bulletin, before being placed in service. Extended overcharging or overheating

of the battery should always be avoided.

The care and handling procedures outlined in the following section should be carefully followed.

9.1 Care and Handling

Disassembly

The battery should not be disassembled, opened

or shredded under any conditions — high short

circuit currents and fire could result. Nickelmetal hydride cells contain an alkaline electrolyte which can cause injury. In the event that

the electrolyte comes into contact with skin or

eyes, immediately flush with fresh water and

seek medical advice.

Handling

DURACELL nickel-metal hydride batteries are

designed to withstand normal handling. They

should not be dropped or subjected to strong

mechanical shock.

High Temperatures/Fire

Never subject the battery to heat or dispose of it

in a fire — the battery can explode, leak or burn

if exposed to fire or very high temperatures. For

optimum life, batteries should be shielded from

or placed away from heat sources. See Section

7.2 which describes recommended temperatures

for use, operation and storage of nickel-metal

hydride batteries.

Vented Battery Compartments

It is possible that cells may vent if the battery is

overcharged or otherwise abused. Nickel-metal

hydride cells release hydrogen gas during venting

which could form potentially explosive mixtures

with air. Caution should be exercised to prevent

the gas from collecting in the battery or equipment. Exposure to a source of ignition and airtight device compartments should be avoided.

Severe Use Applications

Short-term use of nickel-metal hydride

batteries outside of specified ranges may be

possible. Please consult Duracell if such a

requirement exists.

21

Proper Use and Handling (cont.)

9.2 Transportation

Ni-MH Rechargeable Batteries

Procedures for the transportation of batteries

are specified by the United States Department of

Transportation in the “Code of Federal Regulations,”

CFR49, entitled “Transportation.” Internationally, air

transportation is specified by the International Civil

Aviation Organization (ICAO) in their publication

“Technical Instructions for the Safe Transport of

9.3 Waste Management: Recycling and Disposal

The management of waste products in the

United States is regulated by the U.S. Environmental

Protection Agency (EPA). The EPA Regulations are

listed in the “Code of Federal Regulations”, CFR40,

entitled “Protection of Environment.” Individual states

and local communities also may establish regulations

covering the disposal of waste products. These may be

more stringent than the federal regulations and cover

the management of household waste, which is not

included in the federal regulations.

The U.S. EPA has not provided any specific

regulations or guidelines for the waste management of

sealed nickel-metal hydride cells or batteries. As a

result, a number of states and local governments have

passed or are considering legislation which may require

special procedures for the disposal of these batteries.

Thus, state and local agencies should be contacted for

their waste management guidelines. Internationally,

procedures for waste management may vary from

country to country.

In the absence of regulations or guidelines, the

following is recommended for recycling and disposing

of used nickel-metal hydride batteries:

Dangerous Goods By Air.”

The nickel-metal hydride battery supplied by

Duracell is recognized by the regulatory agencies as a

“dry battery.” As such, it is not subject to regulation

and can be shipped in normal packaging and transported

on any mode of transportation without special

handling.

B) Disposal:

Household Use

posed of with other household wastes.

Commercial Use

accumulated, the commercial user may want to consider disposing the batteries in a secure waste land-

fill. Since these batteries are not classified as a

“hazardous waste,” they can be shipped to the

secure waste facility as “non-hazardous waste.”

Local regulations, which specify other methods

for the disposal of nickel-metal hydride batteries,

supersede these recommendations. Waste management companies can provide assistance for the disposal

of these batteries. As previously stated, nickel-metal

hydride batteries should not be disassembled, opened

or shredded.

– Individual batteries can be dis-

– When ten or more batteries are

A) Recycling;

Duracell encourages the recycling of DURACELL

nickel-metal hydride batteries and offers a special

worldwide recycling program. For information on

recycling DURACELL nickel-metal hydride rechargeable

batteries, please contact your nearest Duracell office.

In North America, call toll-free 1-800-551-2355

(9:00 a.m. to 5:00 p.m. E.S.T.).

22

Loading...

Loading...