Duke XGRR User Manual

Speci cations

F.O.B. Sedalia, Missouri 65301

Approval Stamp(s):

X-GREEN

™

F.O.B. Sedalia, Missouri 65301

OPTIONS:

RJ-45 communications connection

Wireless communications connection

Clip on drainboards

Cart mounted salad spinner

Drop in manual salad spinner

Drop in electric salad spinner

Poly cutting board

Scrap block

Stainless steel undershelving

Table mounted overshelf

®

Fruit and Vegetable Wash Program

Fit

DIRECTIONAL FLOW:

Left to Right

Right to Left

PRODUCT INFORMATION:

PROJECT: ____________________________

ITEM: ____________________________

QUANTITY: ____________________________

MODEL:

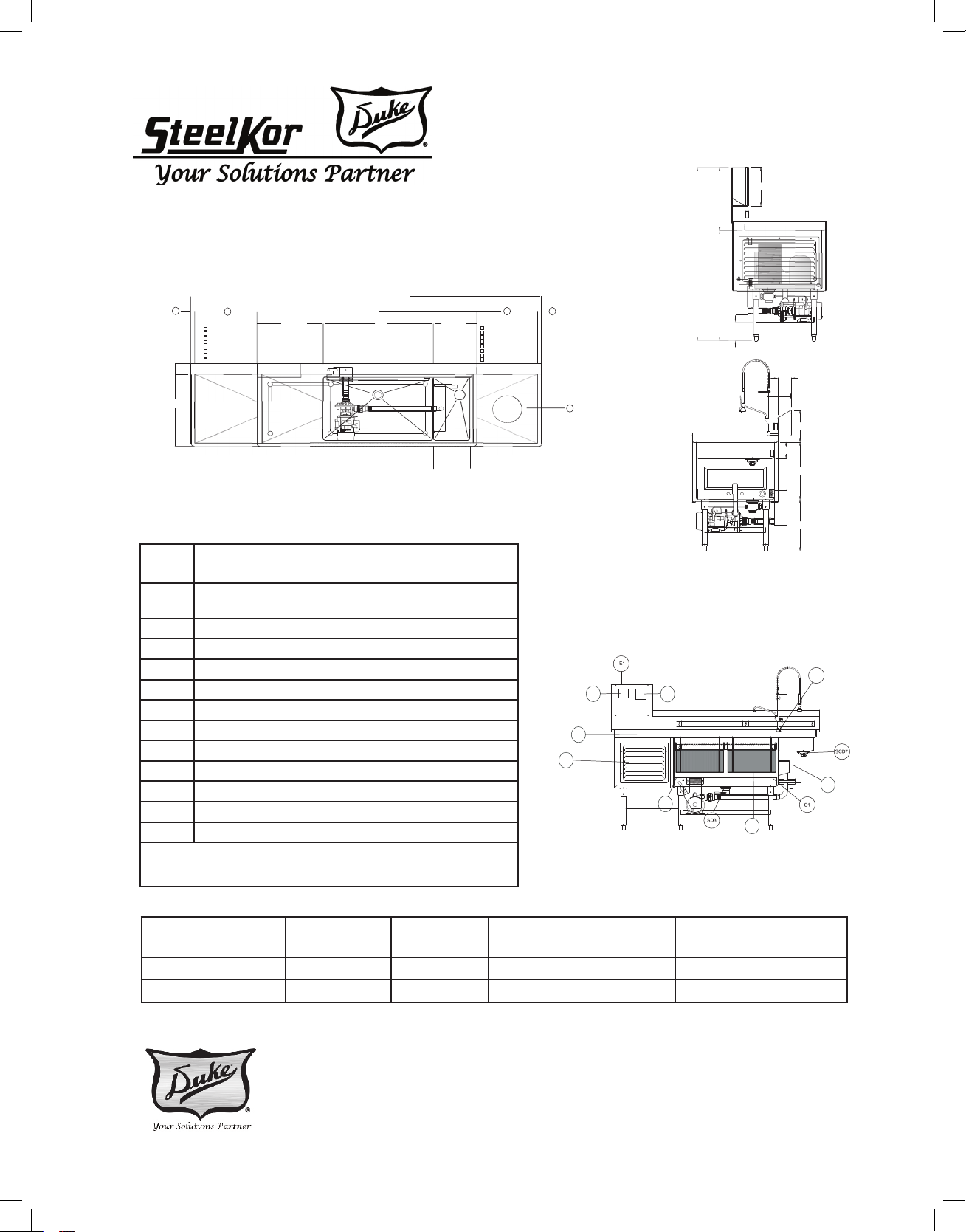

X-Green™ Produce Safety System

XGRR

BODY:

300 series stainless steel

16-gauge stainless tanks and drainboards

10” high x 4” deep backsplash

1/2” pre-rinse with a 1/2” add at faucet

Twist handle drain

Self contained refrigeration (134A) with a stainless steel coil

1-5/8” stainless steel cross rails

Adjustable stainless steel bullet feet

Fully insulated wash tank and pump

2 standard produce baskets

Produce wash cart

Fully skirted stainless steel front

Two piece false bottom

CONTROLS:

Single point connection with touch screen display

4 programmable wash cycles

Monitor pH levels and automatically injects produce wash solution

Monitors and adjusts temperature

Statistical reporting package for traceability

Plug n’ Play components

Integrated printer for labeling

Integrated low water detection

PUMPS:

1-1/2 H.P. fully enclosed (TEFC) pump

Inherent motor overload protection with manual reset

Catalog No. XGREEN

AGENCY LISTINGS:

DUKE MANUFACTURING CO.

2305 N. Broadway

St. Louis, MO 63102

800.735.3853 Toll Free

314.231-1130 In Missouri

314.231.5074 Fax

www.dukemfg.com

SHORT FORM SPECIFICATIONS:

A.I.A. File No. 35-C-13

X-Green™ Produce Safety System - Shall be constructed of 300 series

stainless steel. The top will consist of 16 gauge with a 10” high x 4” deep

backsplash. Wash tank to be 36-1/8”x 22-13/16” x 18” and will be fully

insulated and fully skirted. Legs to be constructed of 1-5/8” (.065 wall) stainless

steel with fully adjustable feet. Unit to also have self-contained refrigeration

(134A) with stainless steel coil. Controls to have touch screen display with pH

monitoring, temperature monitoring, integrated label printer and communications

reporting package. System to have integrated produce wash injection. Wash

pump shall be a 1-1/2 H.P. TEFC motor. The pumps and controller will incorporate

Plug n’ Play serviceability. System to have a single cold water pre-rinse sprayer

head with a 10” add a faucet. Wash tank to have a 2” NPS stainless steel twist

handle drain. Each system will included 2 standard produce baskets and produce

wash cart.

XS-03

A.I.A. File No. 35-C-13

X-Green Produce Safety System

36"

72"

Optional salad

spinner

A

B

C

D

E

Produce sanitize tank

O/A

Rinse tank

O/A

Drainboard with

cutting board

O/A

Clip On Drainboard

Clip On Drainboard

12"

18"

20"

24"

36"

42"

54"

60"

12"

18"

20"

24"

36"

42"

54"

60"

1 1/4"

Square channel

1 1/4"

Square channel

O/A Length = A + B + 72" + C + D

14 5/8 "

21 3/8 "

4"

30"

Model XGRR

Rinse tank

dimension

12 1/8"

X-Green Produce Safety System

36"

72"

Optional salad

spinner

A

B

C

D

E

Produce sanitize tank

O/A

Rinse tank

O/A

Drainboard with

cutting board

O/A

Clip On Drainboard

Clip On Drainboard

12"

18"

20"

24"

36"

42"

54"

60"

12"

18"

20"

24"

36"

42"

54"

60"

1 1/4"

Square channel

O/A Length = A + B + 72" + C + D

14 5/8 "

21 3/8 "

4"

30"

Model XGRR

6"

34"

12"

53 7/16"

19 7/16"

4"

10"

5"

18"

16"

Rinse tank

dimension

12 1/8"

Optional salad

spinner

C

D

E

Rinse tank

O/A

Clip On Drainboard

12"

18"

20"

24"

36"

42"

54"

60"

1 1/4"

Square channel

14 5/8 "

4"

10"

5"

18"

16"

Rinse tank

dimension

12 1/8"

X-Green Produce Safety System

ELECTRICAL SPECS. WITH REFRIGERATION

ELECTRICAL SPECS. WITHOUT REFRIGERATION

220/240/1

20

20

30

Model XGRR

Catalog No. XGREEN

MODEL:

X-Green™ Produce Safety System

XGRR

X-GREEN

LEGEND

C1 Chemical Feed Connection: (over primary faucet). 1” Dia. hole for hose

grommet, 43-7/8” AFF.

E1 Electrical Connection: motors & controls

CW1 Cold Water Connection: Pre-rinse sprayer 1/2” FPT. 36-15/16” AFF

SD3 Sink Drains: 2” NPS

SCD7 Scrapper Drain: 1-1/2” MPT, 25-5/8” AFF

F1 1” Foam Insulation

R1 Self Contained Refrigeration

C2 Removable Cutting Board

L1 Label Printer

T1 Touch Screen Controls

FB1 False Bottom

PB1 Produce Baskets and Lids

All dimensions taken from nished oor line. May increase 3/4” or decrease 1/2”

depending on leg adjustment. Recommend 7-3/4” AFF wall drain location.

X-Green™ System Elec. Specs Rated Amps

w/ Refrigeration 220/240/1 20 25 30

w/o Refrigeration 115/120/1 10 15 20

CONNECTION INFORMATION

(AFF - ABOVE FINISHED FLOOR)

DUKE MANUFACTURING CO.

2305 N. Broadway

St. Louis, MO 63102

800.735.3853 Toll Free

800.231.1130 In Missouri

314.231.5074 Fax

www.dukemfg.com

L1

C2

R1

Minimum supply circuit

conductor ampacity

Specication subject to change

10

115/120/1

T1

FB1

PB1

Maximum overcurrent

protective device

© 2011, Duke Manufacturing Co.

20

CW1

F1

01/11

Printed in U.S.A

Loading...

Loading...