Duke X-GREEN User Manual

Your Solutions Partner

™

X-GREEN

PRODUCE

SAFETY SYSTEM

The X-Green™ System automatically injects a wash

solution into a cold, agitated bath and removes pesticides,

wax, soil, and bacteria from produce. The X-Green™ System

is an entire food safety program, complete with reporting

and traceability features to protect the health and safety

of your customers.

Your Solutions Partner

™

FILL LINE

X-GREEN

SYSTEM

SOLUTIONS FOR FOOD SAFETY

The Centers for Disease Control and Prevention (CDC) estimates that each year roughly 1 out of 6

Americans (or 48 million people) get sick, 128,000 are hospitalized, and 3,000 die from foodborne

diseases. A recent report by The Produce Safety Project at Georgetown University estimates

acute foodborne illnesses cost the United States an estimated $152 billion per year in healthcare,

workplace and other economic losses, a quarter of which are produce related.

The X-Green

foodborne illnesses. The unique features of the X-Green™ System make it an integral part of your food

safety program.

®

Fit

We recommend using Fit® Antibacterial Fruit and Vegetable Wash for best results with the X-Green™

System. When used in the X-Green™ System, Fit® removes pesticides, wax, soil, and bacteria from

the surface of fruits and vegetables. In fact, Fit® kills 99.9% of dangerous bacteria, such as E. Coli,

Campylobacter, Salmonella, Botulism, and Listeria. Fit® is made of 100% natural food ingredients,

including citric acid and grapefruit oil. It is completely safe with no aftertaste or smell.

™

System, when combined with Fit® produce wash, destroys 99.9% of the harmful bacteria that cause

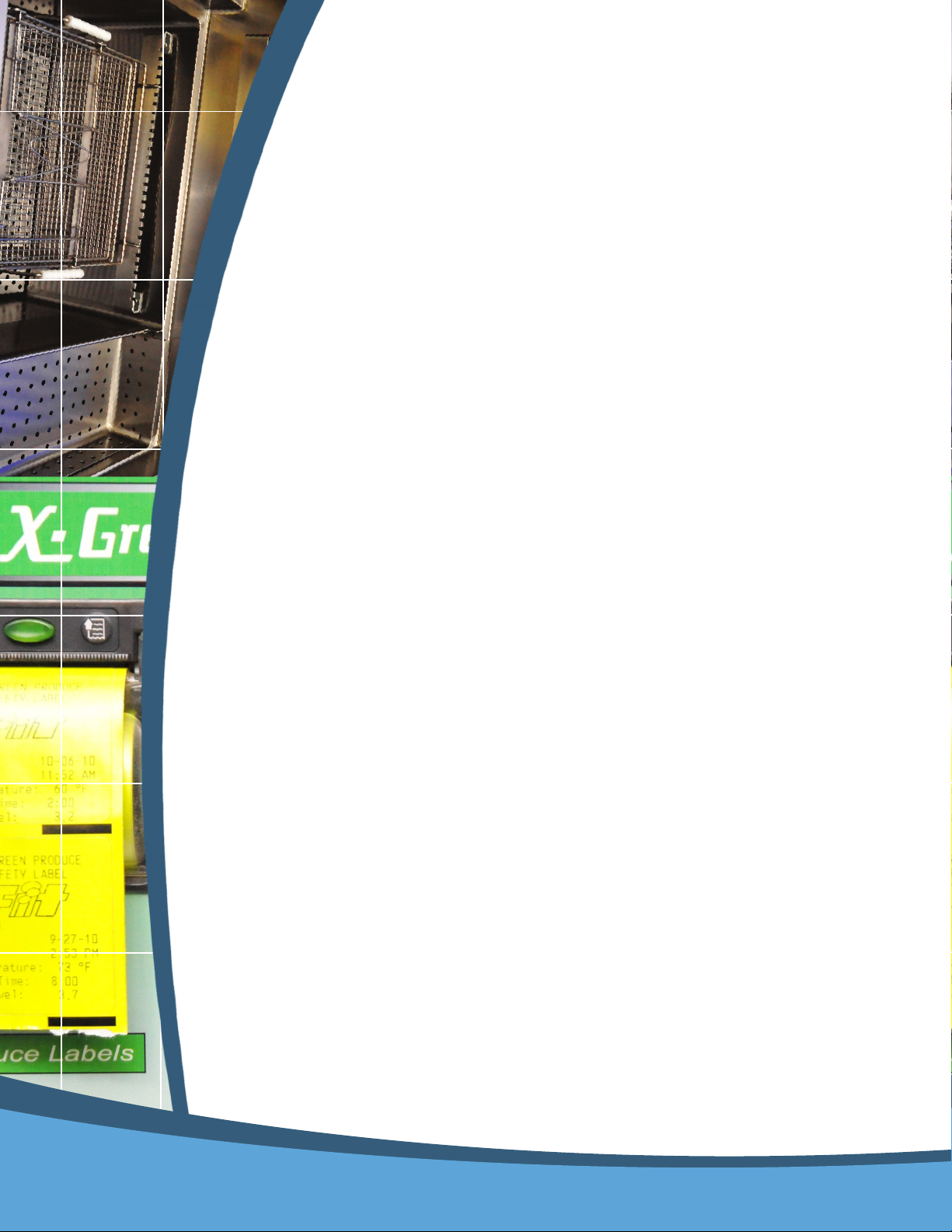

X-GREEN™ SYSTEM INTELLIGENT CONTROL CENTER

The X-Green™ System ensures compliance with and the efcacy of your food safety program.

• Programmable wash cycles tailored to your operation

• Monitors and corrects temperature and pH to destroy bacteria

• Eliminates human error caused by manual pH or chemical correction

• Timer alerts users when the produce is clean and label is ready to print

• Records data, which can be exported, used for reports, or printed for packaging labels

• Allows traceability of the sanitation process of every batch of fruits or vegetables

KEY FEATURES

• Automatically injects wash agent (Fit®) to assure proper concentration of pH levels

• Agitation increases cleaning and sanitation effectiveness by creating surface friction

• Monitors and chills temperature (45F) to aid the crisping and hydration process

• Statistical reporting provides key data to monitor compliance with food safety programs

• Labeling allows you to track key sanitation data directly on storage or display containers

• Basketing allows produce of different types to be washed simultaneously, allows for

smaller batches and provides ergonomic transfer

• Timer alarms allow you to multi-task and notify you when a cycle is completed

• Water ltration reduces the amount of food particles and soils in the wash tank

RETURN ON INVESTMENT

In addition to the condence and pride that you are taking an extra step to protect the health and

safety of your patrons, the following benets are attributable to the X-Green™ System:

• Labor savings through automation, multi-tasking and elimination of redundant processes

• Cost reduction through reduced shrink and extended shelf life of produce

• Increased revenue through your differentiated produce and safety awareness campaign

» Safer, heavier, better looking, better tasting, longer lasting produce

• Lower risk to your operations due to automation, monitoring and reporting capabilities

Loading...

Loading...