Duke TM-SP User Manual

SUGGESTED SPECIFICATIONS FOR CONVEYOR

MODEL TM-SP

Tray Make-up Conveyor to be

model TMSP, UL and ETL Listed, and NSF approved commercial kitchen conveyor.

Conveyor Belt to be low friction, acetal slats, 10” wide. Slats joined with stainless steel removable pin

connectors.

Conveyor Bed to be constructed on #14-gauge, 300 series stainless steel with 1-1/2” high x 2” wide

channel edge on both sides and ends turned down square. Sides formed integral to top. Polish stainless

steel to a #3 finish.

Drive Housing to be a welded stainless steel frame with removable 16-gauge stainless steel access

door. Stainless steel scrap pan located beneath drive housing for easy removal. Drive housing to be

supported by four 1-5/8" O.D., 16-gauge stainless steel legs and stainless steel adjustable bullet feet.

Drive Type to be variable speed, DC motor, 120 volts, 60-cycle, 1-phase, ½ H.P. controlled by on/off

switch and variable speed controller.

Drive end of conveyor furnished with one bed mounted Limit Switch to control the flow of trays.

Anti-jam silver saver plate provided to prevent foreign material form jamming drive system.

Conveyor supported by 1-5/8” 16-gauge stainless steel tubing Legs with welded stainless steel cross

rails. Leg frames fitted into enclosed, round stainless steel gussets welded to stainless steel channel

braces and fitted with stainless steel adjustable bullet feet.

SOUTHERN ENGINEERING SYSTEMS by Duke Mfg Co.,

Optional UL Listed Electrical Raceway constructed of 16-gauge, 300 series stainless steel with #3

finish. Raceway furnished with removable top cover and fitted with properly sized receptacles and

stainless steel face plates, pre-wired to a panel box at the end of the conveyor. Panel box to be housed

in stainless steel enclosure fitted with hinged, locking, 18-gauge stainless steel door.

Conveyor to be pre-wired and factory tested.

Conveyor to carry UL and ETL listing and shall be NSF approved. E

quipment built in an ISO

9001:2000 approved manufacturing facility.

2305 N. Broadway

St. Louis, MO 63012

Ph 314-231-1130

Fax 314-231-5074

www.dukemfg.com

5/07

BY

"Your Solutions Partner"

Optional Accessories

12” Wide Slat-Pin Belt S/S Belt Cover W/Hanger Brackets

Stainless Raceway & Panel Box Movable Over Shelf _____Dbl.

Mobile Package (Note: Max 100Amp Main Stationary Over Shelf _____Dbl

Cord & Plug with Optional Raceway) Stationary Under Shelf

Flanged Feet Removable Under Shelf

Additional Start-Stop Station 3” High x 1-1/4” Rolled Rim Sides

Foot Switch (Momentary Stop) 7/8” High x 1-1/4” Marine Edge Sides

Cord & Plug (Without Raceway) Other _____________________________

Auto-wash System _____________________________

Flush-Wash (Drip pan and Drains only.)

Prison Security Package

COMMENTS/NOTES ____________________________________________________________

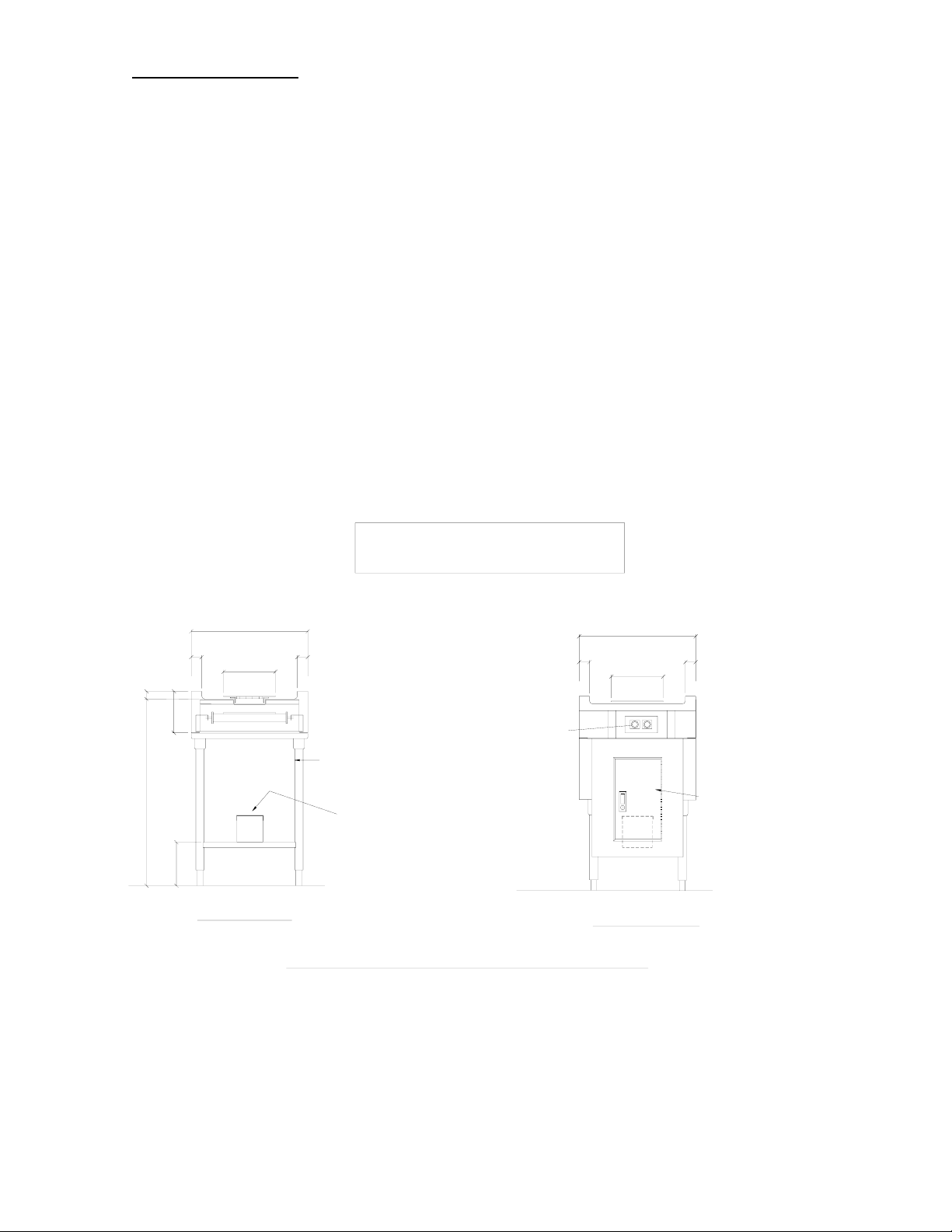

SHOWN WITH OPTIONAL S.S. RACEWAY & S.S.

PANELBOX. RACEWAY FITTED WITH OPTIONAL

22 1/2"

2" 2"

10"

BELT

1 1/2"

8"

1 5/8" O.D. 16 GA. S.S. TUBING LEGS

WITH 1 1/4" O.D. 16 GA. S.S. TUBING

CROSSRAILS.

3'-0"

ACCESS COVER TO

ELECTRIC WIRING

8 3/8"

SECTION VIEW

NOTE: CASTERS NOT AVAILABLE WHEN PANEL BOX INCOMING

SERVICE EXCEEDS 100AMPS.

RECEPTACLES

START STOP STATION

RECESSED INTO END

PANEL.

22 1/2"

2"

10"

BELT

END ELEVATION

2"

18 GA. S.S. ACCESS DOOR TO ENCLOSE

ELECTRIC PANEL BOX. DOOR MOUNTED

ON FULL HEIGHT PIANO HINGE AND

FITTED WITH RECESSED HANDLE,

KEY LOCK

Loading...

Loading...