Duke NC74C7 Service Manual

MECHANICALLY

COOLED

BUFFETS AND

Service Manual

SALAD BARS

Please read this manual completely before attempting

to install, operate or service this equipment

This document is prepared for trained Duke service technicians. It is not to be used by anyone not

properly qualied to perform these procedures.

This Service Manual is not all encompassing. If you have not been trained on servicing this product,

be sure to read the manual completely before attempting servicing. Be sure all necessary tools, test

equipment, and skills are available. Those procedures for which you do not have the proper skills

and test equipment must be performed only by a qualied Duke trained service technician.

This manual is copyright ©2011 Duke Manufacturing Company. All rights reserved. Reproduction without

written permission is prohibited. Duke is a registered trademark of the Duke Manufacturing Company.

Duke Manufacturing Company

2305 N. Broadway • St. Louis, MO 63102

800.735.3853 • 314.231.1130

Fax: 314-231-5074

www.dukemfg.com

P/N 219231B

Mechanically Cooled Buffets and Salad Bars

IMPORTANT WARNING AND SAFETY INFORMATION

WARNING

READ THIS MANUAL THOROUGHLY BEFORE OPERATING, INSTALLING, OR

PERFORMING MAINTENANCE ON THE EQUIPMENT.

WARNING

FAILURE TO FOLLOW INSTRUCTIONS IN THIS MANUAL CAN CAUSE PROPERTY

DAMAGE, INJURY OR DEATH.

WARNING

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

DO NOT OPERATE THIS EQUIPMENT WITHOUT PROPERLY PLACING AND

SECURING ALL COVER AND ACCESS PANELS.

CAUTION

Observe the following:

• Provide and maintain adequate minimum clearances from all walls and combustible materials.

• Provide and maintain adequate clearance for air openings.

• Keep the equipment area free and clear of combustible material.

• Operate equipment only on the type of electricity indicated on the specication plate.

• Retain this manual for future reference.

2

Mechanically Cooled Buffets and Salad Bars

TABLE OF CONTENTS

MECHANICALLY ASSISTED COLD PAN SPECIFICATIONS .......................................... 4

INSTALLATION .................................................................................................................4

LOCATION................................................................................................................... 4

LEVELING ...................................................................................................................4

STABILIZING ...............................................................................................................4

ELECTRICAL CONNECTION ..................................................................................... 4

PARTS REMOVAL AND REPLACEMENT PROCEDURES ..............................................5

THERMOSTAT REPLACEMENT.................................................................................5

POWER ON/OFF SWITCH ......................................................................................... 5

EVAPORATOR ............................................................................................................6

REFRIGERATION SYSTEM REPLACEMENT ............................................................6

DRAIN REPLACEMENT..............................................................................................6

PLEXIGLAS CANOPY REPLACEMENT .....................................................................7

ECONOMATE AND AEROHOT SALAD BARS ...........................................................7

CASTER REPLACEMENT .........................................................................................8

Economate .............................................................................................................8

Heritage, Thurmaduke & AHC Duke Salad Bar Models ........................................8

RECHARGING REFRIGERATION SYSTEM .................................................................... 9

TOOLS.........................................................................................................................9

CHARGING PROCEDURE ......................................................................................... 9

TROUBLESHOOTING PROCEDURE ............................................................................10

MAINTENANCE ..............................................................................................................10

STAINLESS STEEL CARE AND CLEANING ............................................................10

CARE AND CLEANING: PAINTED OR POWDER COATED UNITS ........................ 11

CLEANING THE CONDENSER COIL ....................................................................... 11

3

Mechanically Cooled Buffets and Salad Bars

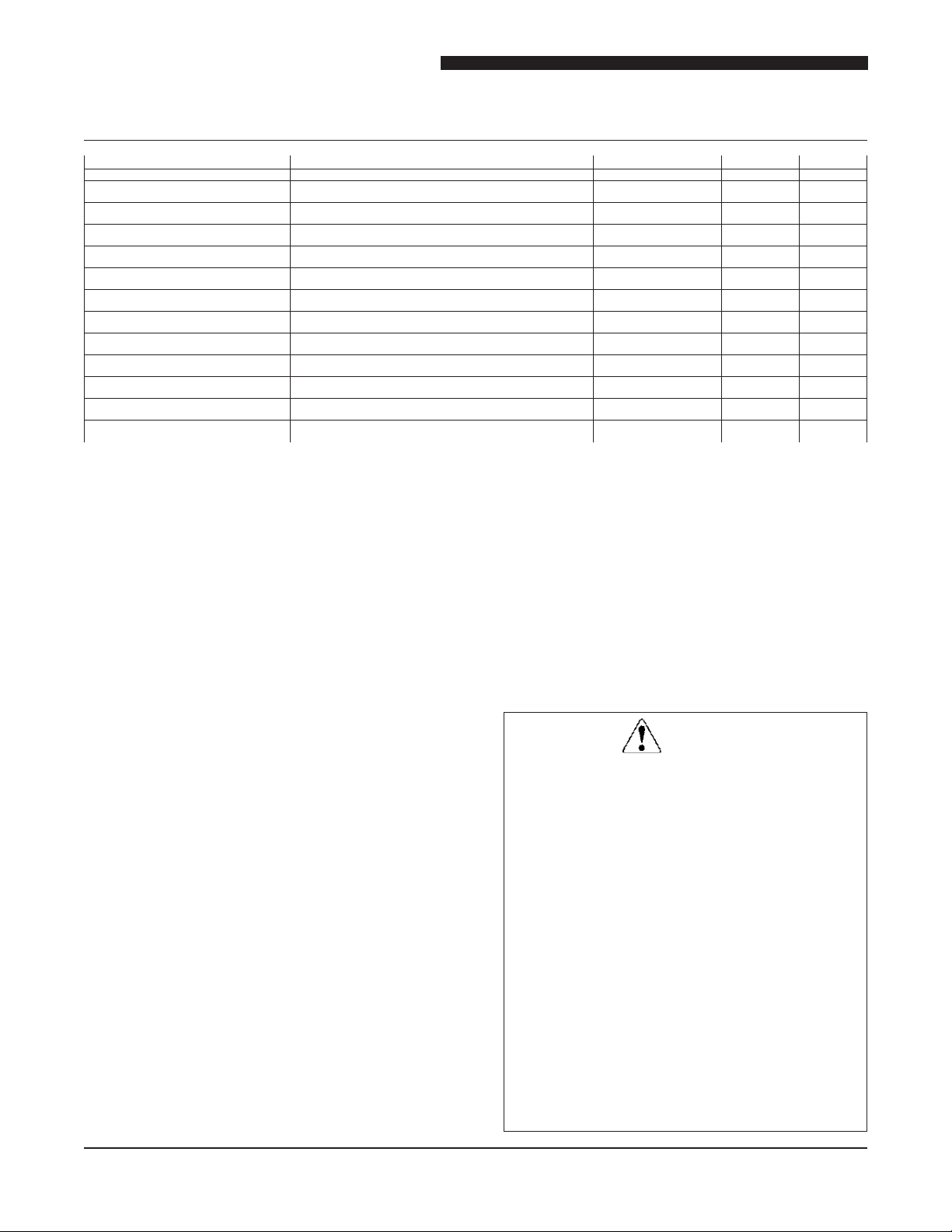

MECHANICALLY ASSISTED COLD PAN SPECIFICATIONS

MODEL DESCRIPTION VOLTAGE HEIGHT WIDTH

HB3CM – HB5CM Heritage 120VAC & 220VAC 36" 24 ½"

HB3CM-N7 – HB5CM-N7 Heritage – NSF Standard 7 120VAC & 220VAC 36" 24 ½"

315-25 – 316-25 & 327-25 AeroServ 120VAC & 220VAC 36" 24 ½"

31525N7 – 31625N7 & 32725N7 AeroServ – NSF Standard 7 120VAC & 220VAC 36" 24 ½"

TCM-32, 46, 60, 74 & 88 Thurmaduke Serving System 120VAC & 220VAC 36" 32"

TCM -32, 46, 60, 74 & 88-N7 Thurmaduke Serving System – NSF Standard 7 120VAC & 220VAC 36" 32"

NG32, 46, 60, 74C Next Generation 5" Deep 120VAC 36" 32 ¾"

NG32, 46, 60, 74CP Next Generation 8" Deep 120VAC 36" 32 ¾"

NG32, 46, 60 , 74C7 Next Generation 8"Deep – NSF Standard 7 120VAC 36" 32 ¾"

NG32, 46, 60, 74CP7 Next Generation 10" Deep – NSF Standard 7 120VAC 36" 32 ¾"

AHC-5M – 7M Duke Salad Bar 120VAC & 220VAC 36" 24 ½"

AHC-5M – 7M-N7 Duke Salad Bar – NSF Standard 7 Cold Pan 120VAC & 220VAC 36" 24 ½"

Note: Table does not include canopy dimensions.

INSTALLATION

LOCATION

The unit represented in this manual is intended

for indoor use only. Be sure the chosen location

has a oor strong enough to support the total

weight of the unit. Reinforce the oor if necessary

to provide for maximum loading. For the most

efcient operation, be sure to provide good air

circulation inside and out.

LEVELING

Be sure that the units are placed on a rm, at

surface/oor. Check for cracks in ooring or tile

and avoid these areas if possible. If necessary

place support pads, properly rated for the weight

of the unit, to “bridge” uneven or cracked ooring.

Use the adjustable legs to level unit properly.

STABILIZING

Use the leg adjustments to insure that the unit is

solid to the oor surface at all four contact points.

Insure that the unit does not “rock” when pressure

is applied to the top corners.

Locking casters are provided on portable models.

Stabilize the unit by placing spacers between one

of the locking casters and the oor until the unit

is rm at all four corners. Make sure the casters

are locked whenever the unit is in service.

ELECTRICAL CONNECTION

Most cold pan models are available as a 120VAC,

60 Hz or as a 220VAC, 50 Hz. Check the model

specications for the correct power source. All

electrical connections must be performed by a

certied electrician and must comply with local

electrical codes for the municipality.

WARNING

REFER TO THE AMPERAGE DATA

LIST IN THE SPECIFICATIONS OR

THE SERIAL TAG DATA AND YOUR

LOCAL CODE OR THE NATIONAL

ELECTRICAL CODE TO BE SURE

UNIT IS CONNECTED TO THE

PROPER POWER SOURCE. A

PROTECTED CIRCUIT OF THE

CORRECT VOLTAGE AND AMPERAGE

MUST BE RUN FOR CONNECTION

OF THE SUPPLY CORD OR

PERMANENT CONNECTION TO

THE UNIT. THE POWER MUST BE

TURNED OFF AND DISCONNECTED

WHENEVER PERFORMING

MAINTENANCE OR REPAIR

FUNCTIONS.

4

Loading...

Loading...