Duke MUHC-51 Installation Manual

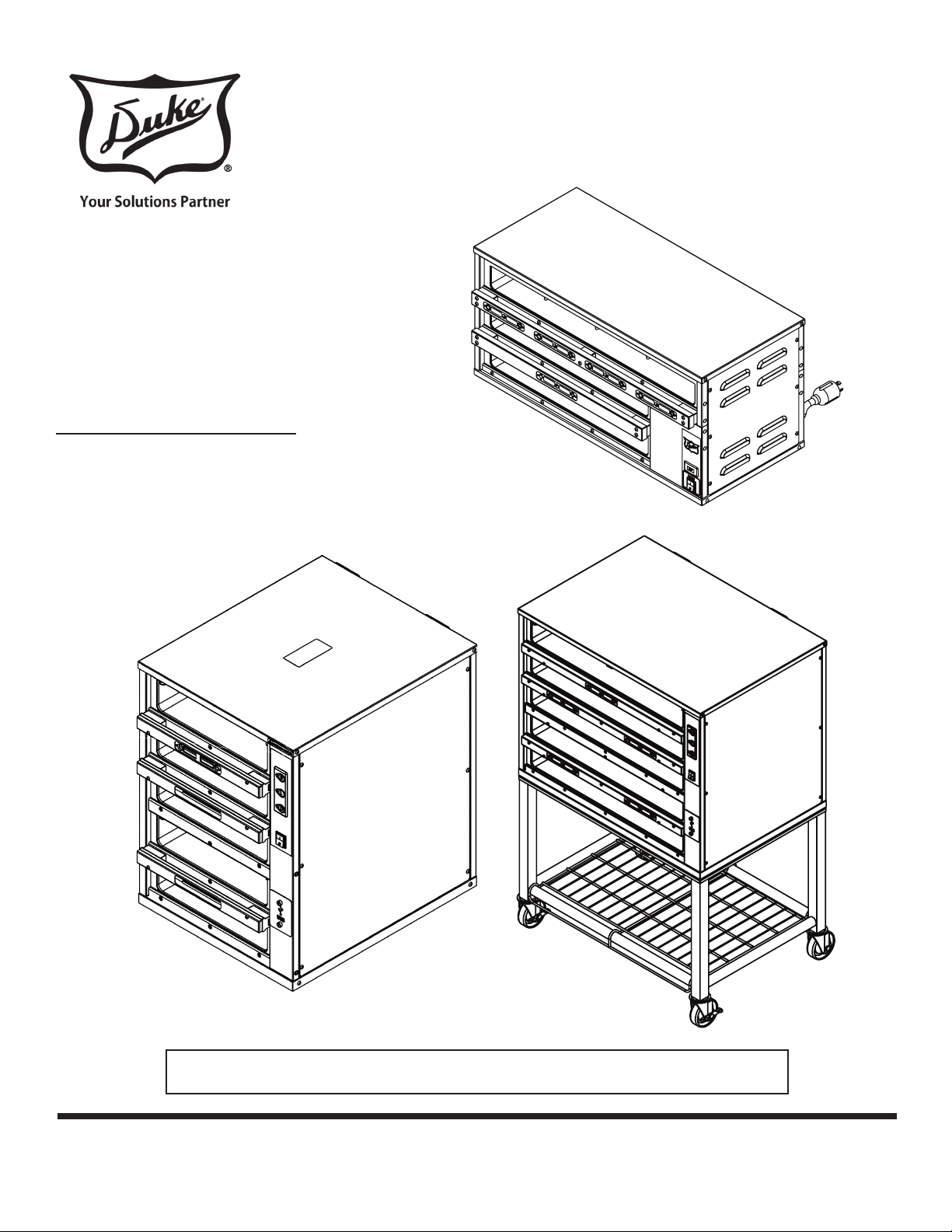

MUHC

(MULTI-USE HOLDING CABINET)

U.S. and Foreign Patents Pending

MODEL

MUHC 51 SERIES

MUHC 52 SERIES

MUHC 34 SERIES

Installation and

Operation Manual

CAUTION:

This manual is Copyright © 2018 Duke Manufacturing Co. All rights reserved.

Reproduction without written permission is prohibited. Duke is a registered

Please read this manual completely before attempting

to install, operate or service this equipment

trademark of the Duke Manufacturing Co.

P/N 165008

REV L 10/05/2018

Installation and Operation of MUHC

TABLE OF CONTENTS

SAFETY INFORMATION .......................................................................................................................3

INTRODUCTION .....................................................................................................................................5

INSTALLATION ........................................................................................................................................6

OPERATION ..............................................................................................................................................8

WEB PROGRAMMING ........................................................................................................................ 13

CLEANING INSTRUCTIONS .............................................................................................................. 16

TROUBLESHOOTING .......................................................................................................................... 17

PARTS LISTS AND ILLUSTRATIONS ...........................................................................................18-21

SPEC SHEETS AND WIRING SCHEMATICS ............................................................................22-30

MUHC-51 Spec Sheet ...................................................................................................................... 22

MUHC-51 Wire Diagram ............................................................................................................... 23

MUHC-52 Spec Sheet ...................................................................................................................... 24

MUHC-52 Wire Diagram ............................................................................................................... 25

MUHC-34SM/CH Spec Sheet ........................................................................................................ 26

MUHC-34SM/CH Wire Diagram .................................................................................................. 27

MUHC-34 Spec Sheet ...................................................................................................................... 28

MUHC-34 Wire Diagram ............................................................................................................... 29

MUHC-34SM Wire Diagram.......................................................................................................... 30

2

Installation and Operation of MUHC

SAFETY INFORMATION

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL

ELECTRICAL EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD STARTUP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

READ THIS MANUAL THOROUGHLY BEFORE OPERATING, INSTALLING OR PERFORMING

MAINTENANCE ON THE EQUIPMENT.

: Failure to follow all the instructions in this manual can cause property

damage, injury or death.

: Improper installation, adjustment, alteration, service or maintenance

can cause property damage, injury or death.

: (US/CAN ONLY) Electrical connections should be performed only by

a certied professional.

: Electrical and grounding connections must comply with the applicable

portions of the National Electric Code and/or all local electric codes. Failure to

comply with this procedure can cause property damage, injury or death.

: Before connecting the unit to the electrical supply, verify that the

electrical and grounding connections comply with the applicable portions of the

National Electric Code and/or other local electrical codes. Failure to comply with

this procedure can cause property damage, injury or death.

: Before connecting the unit to the electrical supply, verify that the

electrical connection agrees with the specications on the data plate. Failure to

comply with this procedure can cause property damage, injury or death.

: UL73 grounding instructions: This appliance must be connected to a

grounded, metal, permanent wiring system. Or an equipment-grounding conductor

must be run with the circuit conductors and connected to the equipment-grounding

terminal or lead on the appliance. Failure to comply with this procedure can cause

property damage, injury or death.

: Appliances equipped with a exible electric supply cord, are provided

with a three-prong grounding plug (or a CEE7 Plug for International CE Units).

It is imperative that this plug be connected into a properly grounded receptacle.

Failure to comply with this procedure can cause property damage, injury or death.

: If the receptacle is not the proper grounding type, contact an electrician.

Do not remove the grounding prong from the plug. Failure to comply with this

procedure can cause property damage, injury or death.

3

Installation and Operation of MUHC

SAFETY INFORMATION continued

: Before performing any service that involves electrical connection

or disconnection and/or exposure to electrical components, always perform the

Electrical LOCKOUT/TAGOUT Procedure. Disconnect all circuits. Failure to comply

with this procedure can cause property damage, injury or death.

: Before removing any access panels or servicing this equipment,

always perform the Electrical LOCKOUT/TAGOUT Procedure. Be sure all circuits are

disconnected. Failure to comply with this procedure can cause property damage,

injury or death.

: Do not operate this equipment without properly placing and securing

all covers and access panels. Failure to comply with this procedure can cause

property damage, injury or death.

: For your safety, do not use or store gasoline or other ammable

vapors or liquids in the vicinity of this or any other appliance. Failure to comply

can cause property damage, injury or death.

: In the event of a power failure, do not attempt to operate this

appliance. Failure to comply can cause property damage, injury or death.

: This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning use

of the appliance by a person responsible for their safety.

: Never use a high-pressure water wash for this cleaning procedure as

water can damage electrical components

Observe the following:

• Minimum clearances must be maintained from all walls and combustible materials.

• Keep the equipment area free and clear of combustible material.

• Maintain adequate clearance for air openings.

• Operate equipment only on the type of electricity indicated on the data sticker.

• Retain this manual for future reference.

4

Installation and Operation of MUHC

INTRODUCTION

e Duke MUHC was developed for extended food-holding capabilities to provide consistently high, “just cooked”

food quality.

e MUHC utilizes Duke’s patented “heat sink” holding technology that provides even heat distribution to food

pans through the bottom and sides. is allows pre-cooked foods to be held for extended periods without noticeable

degradation of quality, reducing food scrap/waste.

e self contained, individually formed, sealed compartments of the MUHC eliminates food odor and taste transfer.

Because the compartments are sealed and feature fully radiused corners, no disassembly is required for cleaning

or product changes.

e unique design of the MUHC allows multiple temperature operation for all existing product groups.

SERIAL NUMBER LOCATION

e Serial Number Data Label is located on the rear of the unit, above the power cord connection. Refer to the

Serial Number Data Label for proper electrical requirements. e serial number and model number are required

when communicating with the Duke Service Dept.

5

Installation and Operation of MUHC

INSTALLATION

Before installing, verify that the electrical service agrees

with the specications on the data label located on the

rear of the unit, above the power cord connection. If the

electrical service does not agree with the data label, do

not proceed with installation. Contact your dealer or

local Authorized Duke Servicer immediately.

UNPACKING

1. Inspect the shipping carton and/or container, carefully

noting any exterior damage on the delivery receipt.

2. Contact the carrier immediately and le a damage

claim with them. Save all packing materials when ling

a claim. Freight damage claims are the responsibility

of the purchaser and are not covered by the warranty.

3. Unpack and Inspect the unit for damage.

4. Report any dents or breakage to the source of purchase

immediately.

: Do not attempt to use the unit if damaged.

1. Local codes.

2. Canadian Electrical Code (CSA C22.2 No. 3, latest

edition) available from the Canadian Standards

Association, 5060 Spectrum Way, Mississauga,

Ontario, Canada L4W 5N6.

LOCATION

: To avoid risk of electrical shock

or death, this unit must be grounded and plug

must not be altered.

• e MUHC is designed for access from either side.

• e power outlet should be located so that plug is

accessible when the unit is in place.

• Proper airow around the unit cools its electrical

components. With restricted airow, the unit may

not operate properly and life of the electrical parts

is reduced.

5. Remove all materials from the unit interior.

6. If the unit has been stored in extremely cold area,

wait a few hours before connecting the power.

INSTALLATION CODES AND STANDARDS

In the United States, the MUHC must be installed in

accordance with the following:

1. State and local codes.

2. National Electrical Code (ANSI/NFPA No. 70, latest

edition) available from the National Fire Protection

Association, Batterymarch Park, Quincy, MA 02269.

3. Vapor Removal from Cooking Equipment, (NFPA-96,

latest edition) available from NFPA.

In Canada, the MUHC must be installed in accordance

with the following:

• Install unit on level counter or oor.

• Outlet should be located so that the plug is accessible

when the unit is in place.

: Do not install the unit next to or above heat

sources, such as oven or deep fat fryer.

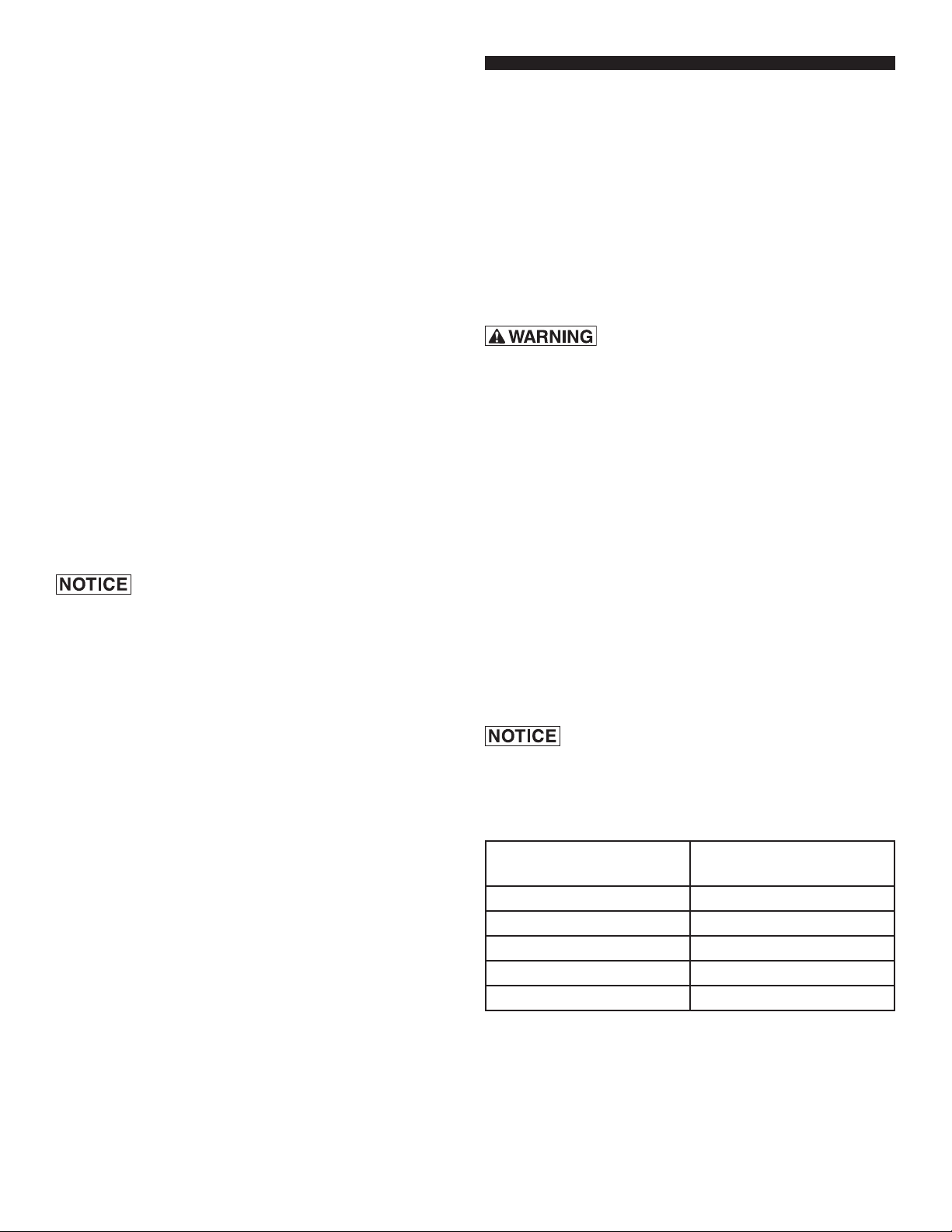

Clearance Requirements

CLEARANCE

REQUIREMENT

Top 0/0

Right Side 1.00"/25.4 mm

Left Side 1.00"/25.4 mm

Bottom 0/0

Rear OPEN

CLEARANCE

IN/mm

ELECTRICAL CONNECTION

e US MUHC models are factory wired for 120 Volts

6

INSTALLATION

Installation and Operation of MUHC

AC, single phase, 60 Hz.

: BEFORE CONNECTING THE UNIT

TO THE POWER SOURCE, VERIFY THAT THE

VOLTAGE AND PHASE OF THE POWER SOURCE

ARE IDENTICAL TO THE VOLTAGE AND PHASE

INFORMATION ON THE DATA LABEL.

: ELECTRICAL AND GROUNDING

CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL

ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

For international units, the MUHC must be

installed in accordance with the following:

1. Local codes

2. European (IEC/CENELEC) Electrical Code.

: DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR LIQUIDS IN

THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

Refer to wiring diagram in this manual for proper

connection. Do not store ammables near unit.

1. At the circuit breaker, turn o power to the circuit to

which the unit is to be connected.

THE UNIT MUST BE GROUNDED. Grounding reduces

risk of electric shock by providing an escape wire for the

electric current if an electrical short occurs. is unit is

equipped with a cord having a grounding wire with a

grounding plug. e plug must be plugged into a receptacle

that is properly installed and grounded.

Consult a qualied electrician or service agent if grounding

instructions are not completely understood, or if doubt exists

as to whether the oven is properly grounded.

DO NOT USE AN EXTENSION CORD. If the product

power cord is too short, have a qualied electrician install

a three-slot receptacle (or the country specic receptacle

for International Units). is unit should be plugged into

a separate circuit with the electrical rating as provided

on the product data plate.

EXTERNAL EQUIPOTENTIAL BONDING

TERMINAL EXPORT ONLY

is equipment has supplemental bonding terminal. e

terminal provides an external bonding connection used in

addition to the earthing prong on the plug. e terminal

provides a connection for bonding to the equipment

enclosure. e external equipotential bonding terminal

is located on the rear outside surface of the oven, the

terminal is marked with this symbol.

2. Check that the unit Power ON/OFF Switch is in the

OFF position.

3. Connect the power cord on the back of the unit to

the electrical power source.

4. At the circuit breaker, turn on power to the circuit.

: If the supply cord is damaged, it must be

replaced by a special cord or a special cord assembly

available from Duke Manufacturing Co. or its service

agent.

Earthing Instructions

7

Installation and Operation of MUHC

OPERATION

e following procedures must be performed on a daily basis.

OPENING CHECKLIST

1. Ensure proper Pan Covers are inserted into the correct

locations for fried and broiled products.

2. Place empty pans in all locations.

3. Place the Power Switch, located on the front of the MUHC,

in the ON position.

CLEANING INSTRUCTIONS

1. Wipe down the interior and exterior of the Product Holding

Cabinet with warm water and mild detergent using a so

cloth. Do not use excessive amounts of water.

2. Clean pans and pan covers using mild detergent and warm

water.

3. Ensure all soap is rinsed from plastic pans and pan covers.

4. Allow the MUHC to heat for at least 20 min. or until the

temperature disappears and the menu bars display the

pre-programmed product names: “EGGS”, “FISH”, “----“

or “EMTY” (no product).

OPERATION INSTRUCTIONS AND

ADJUSTMENTS

1. If the menu bars display temperature at any time during

operation of the Product Holding Cabinet, discontinue

use of the aected shelf until the cabinet is serviced.

2. Refer to the Keypad Programming section of the manual

for instructions on using and programming the keypad.

CLOSING CHECKLIST

1. Place the Power Switch in its OFF position.

2. Remove all pans and pan covers.

3. Allow the cabinet to cool for approximately 30

minutes.

4. Refer to the Cleaning Instructions section of the manual

for proper care and cleaning of the cabinet.

: Electrical Shock Hazard, unplug the

cabinet before cleaning it.

: Do not wash with water jet or hose.

: Bottom and sides of warmer wells

are very hot and cool slowly.

CAUTION: Do not use caustic cleaners, acids, ammonia

products or abrasive cleaners or abrasive cloths. ese

can damage the stainless steel and plastic surfaces.

STAINLESS STEEL CARE

Cleaning

Stainless steel contains 70-80% iron, which will rust if not

properly maintained. It also contains 12-30% chromium,

which forms an invisible passive, protective lm that shields

against corrosion. If the lm remains intact, the stainless

steel will remain intact. However, if the lm is damaged, the

stainless steel can break down and rust. To prevent stainless

steel breakdown, follow these steps:

CAUTION: Never use any metal tools. Scrapers, les,

wire brushes or scouring pads (except for stainless steel

scouring pads) will mar the surface.

CAUTION: Never use steel wool, which will leave behind

particles that rust.

CAUTION: Never use acid-based or chloride-containing

cleaning solutions, which will break down the protective

lm.

CAUTION: Never rub in a circular motion.

CAUTION: Never leave any food products or salt on the

surface. Many foods are acidic. Salt contains chloride.

For routine cleaning, use warm water, mild soap or detergent

and a sponge or so cloth.

For heavy-duty cleaning, use warm water, a degreaser and a

plastic, stainless steel or Scotch-Brite pad.

Always rinse thoroughly. Always rub gently in the direction

of the steel grain.

8

Preserving & Restoring

Installation and Operation of MUHC

OPERATION continued

2. Arrow Buttons

Special stainless steel polishing cleaners can preserve and

restore the protective lm.

Preserve the life of stainless steel with a regular application of

a high quality stainless steel polishing cleaner as a nal step

to daily cleaning.

If signs of breakdown appear, restore the stainless steel surface.

First, thoroughly clean, rinse and dry the surface. en, on a

daily basis, apply a high-quality stainless steel polish according

to manufacturer’s instructions.

Heat Tint

Darkened areas, called heat tint, may appear on stainless steel

exposed to excessive heat, which causes the protective lm to

thicken. It is unsightly but is not a sign of permanent damage.

To remove heat tint, follow the routine cleaning procedure.

Stubborn heat tint will require heavy-duty cleaning.

To reduce heat tint, limit the exposure of equipment to

excessive heat.

KEYPAD PROGRAMMING

a. Used for Starting/Stopping/Resetting Timer.

b. Used for Programming.

c. Indicate which pan the adjacent Status LED and

Pan Display are linked to (i.e. Status LED and Pan

Display on le side of keyboard are linked to the

pan above the keyboard and the Status LED and

Pan Display on right side of keyboard are linked

to the pan below).

3. Pan Display

a. When timer is inactive: Displays product name

and lid type.

b. When timer is active: Displays product name and

time remaining.

4. Enter Button

a. Used to enter Menu Mode.

Power Up

1. Place the Power Switch in the ON position. Soware

initializes at startup.

1. Status LEDs: Used for indicating status of pan.

a. Non-Illuminated

I. Timer is Inactive - no product in pan,

OR

II. Timer is Active - product in pan – use pan

with GREEN STATUS LED rst.

b. Green = Timer is Active - product in pan (use

rst)

c. Flashing Green = Cook Warning Time reached

(cook more product) or keyboard in EDIT MODE

(programming).

2. Until warmer reaches preprogrammed operating

temperature, all displays will show actual temperature.

3. When the set point is reached, Product Name appears on

all Pan Displays.

Note: For these instructions only the pertinent keypads will be

shown, for simplicity, and not the warmer or pans. It is implied

that a product pan is located above and below each keypad.

9

Loading...

Loading...