Duke K-5000 Parts Diagram

K5000 Control Retro-Fit

Kits

116924

Installation Instructions

116925

116926

116927

Please read this manual completely before attempting

CAUTION:

This manual is Copyright © 2018 Duke Manufacturing Co. All rights reserved.

Reproduction without written permission is prohibited. Duke is a registered

to install, operate or service this equipment

trademark of the Duke Manufacturing Co.

Duke Manufacturing Co.

2305 N. Broadway

St. Louis, MO 63102

Phone: 314-231-1130

Toll Free: 1-800-735-3853

Fax: 314-231-5074

www.dukemfg.com

P/N 116948

REV A 1/30/2018

Retrot Instructions for K5000

WARNING

CAUTION

CAUTION

TABLE OF CONTENTS

Important Safety Instructions .......................................................................................... 2

Tools Required................................................................................................................ 4

Parts Included In Kit ....................................................................................................... 4

Removal of Old Control .................................................................................................. 6

Installation of New Control.............................................................................................. 7

Wiring Control ................................................................................................................. 9

Wire Diagrams .............................................................................................................. 13

IMPORTANT SAFETY INSTRUCTIONS

Throughout this manual, you will nd the following safety words and symbols that signify

important safety issues with regards to operating or maintaining the equipment.

Indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Indicates electrical shock hazard which, if not avoided, could

Indicates hot surface which, if not avoided, could result in

Indicates Important Information

result in death or serious injury and/or equipment damage.

minor or moderate injury.

2

Retrot Instructions for K5000

In addition to the warnings and cautions in this manual, use the following guidelines

for safe operation of the unit.

• Read all instructions before using equipment.

• For your safety, the equipment is furnished with a properly grounded cord connector. Do

not attempt to remove or disconnect the grounded connector.

• Install or locate the equipment only for its intended use as described in this manual.

• Do not use corrosive chemicals in this equipment.

• Do not operate this equipment if it has a damaged cord or plug, if it is not working

properly, or if it has been damaged or dropped.

• This equipment should be serviced by qualied personnel only. Contact the nearest Duke

authorized service facility for adjustment or repair.

• Do not block or cover any openings on the unit.

• Do not immerse cord or plug in water.

• Keep cord away from heated surfaces.

• Do not allow cord to hang over edge of table or counter.

The following warnings and cautions appear throughout this manual and should be

carefully observed.

• Turn the unit off, disconnect the power source and allow unit to cool down before

performing any service or maintenance on the unit.

• The procedures in this manual may include the use of chemical products. You must read

the Material Safety Data Sheets before using any of these products.

• The unit should be grounded according to local electrical codes to prevent the possibility

of electrical shock. It requires a grounded receptacle with dedicated electrical lines,

protected by fuses or circuit breaker of the proper rating, in accordance with all applicable

regulations.

• Disposal of the unit must be in accordance with local environmental codes and/or any

other applicable codes.

• This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning use of the appliance

by a person responsible for their safety.

3

Retrot Instructions for K5000

BLU

From Heater

BLU

Small Straight Blade Screw Driver

Tools Required

3/16” Straight Blade Screw Driver

Phillips Screw Driver

Wire Strippers

Enclosed In Kit

*155811 Wago-2

Connector

*Quantity

based on kit

Masking Tape

Channel Locks

514803 Wago-3

Connector 3ea.

212106 Wago-5

Connector 1ea.

BRN

DMC K5000

208/240V Retrofit WD

Duke Mfg NPD-StL 11/29/17

ELC0245 Rev A

Front Cover

External

USB

RED

BLU

BRN

BRN

Control Panel

Power Switch

BLU

RED

Cooling

BLU

Fan

BRN

BLK

BLK

RED

RED

BLK

RED

BRN

L2

L3

L1

TERMINAL BLOCK

BRN

RED

BLK

Contactor

RED

RED

ELC0245 Electrical

Diagram for Kits

Part Number based on unit.

116924 and 116925

Also on Page 13

RED

RED

12Vur

-

BLK

P16

GND

P14

+

Beeper

VFD Enable

T-cpl 4

12V

P13

BLU

RX

GRN

-

TX

Beeper

+

T-cpl 3

P1

P2

P12

IO4

-

P15

pcb

+

T-cpl 2

P11

VFD_ft2

VFD_ft3

VFD_ft1

Hi Limit 1

Chem P2

Hi Limit 2

Chem P1

USB

BRN

BRN

BLK

RED

BRN

15A

GND

Stud

ORN

COIL

-

GND

+

0-10V

P17

T-cpl 1

12V

GND

P3

P5

San

Float

GRN

ORN

BLK

YEL

WHT

RED

YEL

BLU

GRN

BRN

PWR PCB

120011

12V

HL 1

HL 2

Chem P2

Chem P1

208 / 230V

BLU

BRN

YEL

BLU

BLU

ORN

GRY

- T4

Connections used for

sanitizer connections

- T3

RED

RED

BLK

BRN

ORN

BRN

COIL

WASH

H1

CONTACTOR

15A

15A

CONTACTOR

CHEM.

PUMP 1

(Optional)

High

Limit

Wash Element:

(2.5K, 5K, 7.5KW)

Sanitizer Connections

P10

SW1 SW2

P4

Chemical Pump Sanitizer

Option

A1

T3

Sw 2

Sw 1

1 2 3 4

1 2 3 4

GRY

BRN

GRY

P1P2

PC

A1 AC

MA MC

S1 SC

H1

HC

Fq. Drive

Variable

S/L2

T/L3

R/L1

U/T1

V/T2

W/T3

Wash T-couple Water

Wash T-couple – Dry Fire

SANITIZER

CHEMICAL

PUMP

BLK

BLK

RED

WHT

RED

BRN

(Optional)

Heated Sanitizer Option

BLK

RED

L1-TB

RED

BRN

L3-TB

BLU

COIL

T4

SANITIZER CONTACTOR

BRN

YEL

GRN

WASH

PUMP 1

WASH

PUMP 2

A1

A1

BLK

H1

T-couples

T-couples

Dry Fire

SANITIZER

Wash Water Temp

FLOAT

SWITCH

High

Limit

Sanitizer Water Temp

*Remove Sheath Strap

Sanitizer Element:

& Bend Sensor Away

2.5kW

DMC K5000

480V Retrofit WD

Duke Mfg NPD-StL 11/29/17 TS

ELC0246 Rev A

BLU

RED

Cooling

Fan

BLK

BLK

RED

BRN

RED

RED

BRN

L2

L3

L1

TERMINAL BLOCK

Transformer

H4

H1

X1 X4

ELC0246 Electrical

Diagram for Kits

116926 and 116927

Also on Page 14

BRN

RED

RED

12Vur

BLK

P16

+

GND

P14

T-cpl 4

Beeper

VFD Enable

12V

P13

BLU

RX

GRN

+

TX

Beeper

T-cpl 3

P1

P2

P12

IO4

Front Cover

USB

External

USB

RED

BLU

BRN

BRN

Control Panel

Power Switch

BRN

BRN

BLU

BRN

GND

Stud

RED

RED

RED

+

P15

pcb

T-cpl 2

P11

VFD_ft2

VFD_ft3

----

VFD_ft1

Hi Limit 1

Chem P2

Hi Limit 2

Chem P1

+

GND

0-10V

P17

T-cpl 1

12V

GND

P3

P5

San

Float

GRN

ORN

BLK

YEL

WHT

RED

YEL

BLU

GRN

PWR PCB

120011

12V

HL 2

HL 1

Chem P2

Chem P1

208 / 230V

BLU

BRN

YEL

BLU

BLU

ORN

GRY

- T4

Connections used for

sanitizer connections

- T3

BLK

RED

RED

RED

BRN

ORN

COIL

CONTACTOR

BLK

BRN

BLU

H1

Contactor

ORN

BRN

COIL

BLK

CHEM.

PUMP 1

(Optional)

High

Limit

Wash Element:

(2.5K, 5K, 7.5KW)

Sanitizer Connections

P10

SW1 SW2

P4

Chemical Pump Sanitizer

Option

T3

A1

Sw 2

Sw 1

1 2 3 4

1 2 3 4

GRY

BRN

GRY

P1P2

PC

A1 AC

MA MC

S1 SC

H1

HC

BRN

Fq. Drive

Variable

S/L2

T/L3

R/L1

U/T1

V/T2

W/T3

SANITIZER

CHEMICAL

PUMP

BLK

BLK

RED

WHT

RED

BRN

(Optional)

Heated Sanitizer Option

BLK

RED

L1-TB

RED

BRN

L3-TB

BLU

Wash T-couple Water

Wash T-couple – Dry Fire

COIL

T4

SANITIZER CONTACTOR

BRN

YEL

WASH

PUMP 1

PUMP 2

A1

A1

GRN

WASH

BLU

BLK

H1

T-couples

T-couples

SANITIZER

FLOAT

Wash Water Temp

SWITCH

High

Limit

Dry Fire

Sanitizer Water Temp

*Remove Sheath Strap

Sanitizer Element:

& Bend Sensor Away

2.5kW

From Heater

4

Retrot Instructions for K5000

CAUTION

K5000 RETROFIT INSTALLATION INSTRUCTIONS

Removal Of Old Control Box

Step 1

Turn O or disconnect power supply.

Before performing any service perform the

Electrical LOCKOUT/TAG OUT Procedure.

Disconnect all circuits. Failure to comply with this procedure can cause property

damage, injury or death.

Reference: LOCKOUT / TAG OUT PROCEDURE

The worker shall check to be sure that no one is operating the machinery BEFORE turning -o

the power. The machine operator shall be informed before the power is turned o. Sudden loss

of power could cause an accident.

All energy sources that could activate the machine shall be locked out (blocked/tagged).

The main valve or main electrical disconnect shall be tested to be sure that the power to the

machine is o.

Electrical circuits shall be checked with proper and calibrated electrical testing equipment. An

electrical failure could energize the equipment even if the switch is in the o position.

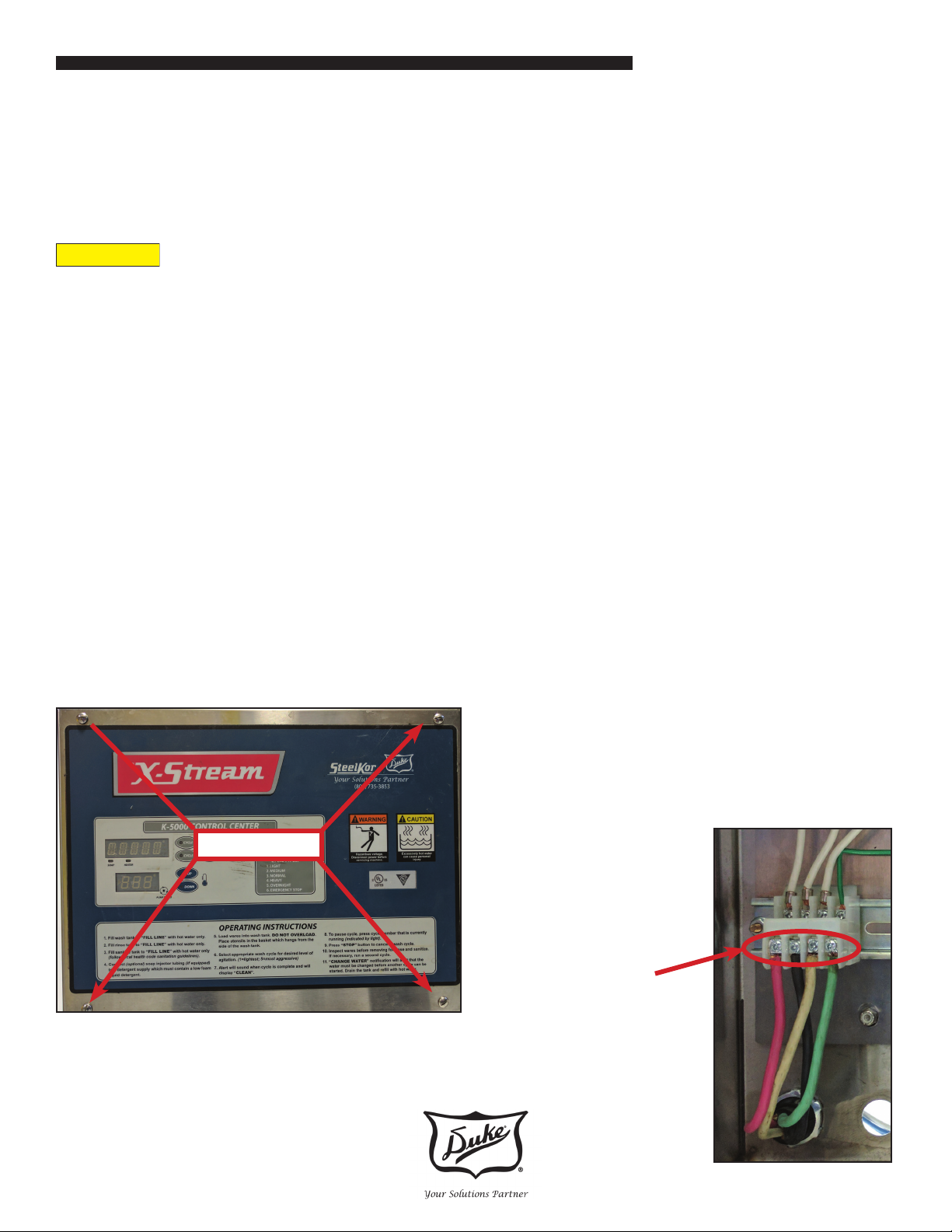

Step 2

Open the control box by removing the four

screws on the front of the control box cover.

REMOVE

Step 3

Using masking tape label all conduits on the

back and all connecting wires.

• Pump 1

• Pump 2

• Chemical Pump

• Element Wash Sink

• Element Sanitizer - If Installed

• Main Power

Step 4

Disconnect the main

power line from the

terminal block.

5

Loading...

Loading...