Duke HVXST User Manual

SUGGESTED SPECIFICATIONS FOR VENTILATOR MODEL

HVXST

Exhaust Ventilator to be SOUTHERN ENGINEERING SYSTEMS by Duke Mfg Co., model

HVXST, Type I, UL Listed, hood assembly for commercial cooking appliances and be in compliance

with NFPA Bulletin No. 96 Ventilator shall be high velocity, low volume, cartridge type and have a

nominal 95% grease extraction efficiency certified by an independent testing laboratory.

Canopy, constructed of 18-gauge stainless steel (where exposed) with bottom perimeter edges

gutterless. Weld extraction chamber, plenum, and external seams and joints to form a liquid tight

construction. Polish stainless steel to a #3 finish.

Exhaust plenum Extraction Chamber to be same material as canopy, full length of section at the

back. Furnish welded stainless steel self-draining cartridge inserts, installed horizontally. Cartridge

housing to form a high velocity slot. Inserts to lift out using tool provided exposing access to plenum

chamber for easy cleaning. Bottom of exhaust plenum to be formed into a pitched gutter to accept

gravity flow residue and drain to a covered stainless steel container.

Grease Container constructed of 18-gauge stainless steel having a maximum capacity of one gallon.

Fabricate container so as to be easily removable for daily cleaning. Removal of container exposes 11/2” ID stainless steel tube to allow capture of cleaning solution when hood and duct system are

cleaned.

Furnish Duct Collar, fully welded, complete with fire detection thermostat, in top of canopy within

exhaust plenum area. Duct collar size based on an average 1800 F.P.M. air velocity.

Option with automatic Fire Damper constructed of 12-gauge steel within exhaust duct collar. Damper

operated by an externally mounted spring-loaded mechanism and controlled by a fusible link.

Canopy shall be UL Listed and NSF approved. All equipment built in an ISO 9001:2000

approved manufacturing facility

2305 N. Broadway

St. Louis, MO 63012

BY

"Your Solut ions Par tner"

Ph 314-231-1130

Fax 314-231-5074

www.dukemfg.com

6/07

Exhaust Requirements

CFM ________________ SP (“w.g.) _____________

Duct Collar ________ “x ______________”

Fire Protection Lighting Fixtures

(Submit cooking equipment plan showing make (Not Available)

and model on equipment.)

Ansul Wet #R-102

Other ___________________________________ Enclosure paneling

Internal Piping Only (Finished ceiling higher than 9’0”)

Complete System Fan switch

By Others Loose duct collars

NOTE: Fuel shut-off devices by others (unless specified UL Exhaust Fire Damper

otherwise).

Optional Accessories

Shipping Wt. 80 lbs./Linear Ft.

COMMENTS/NOTES __________________________________________________________________

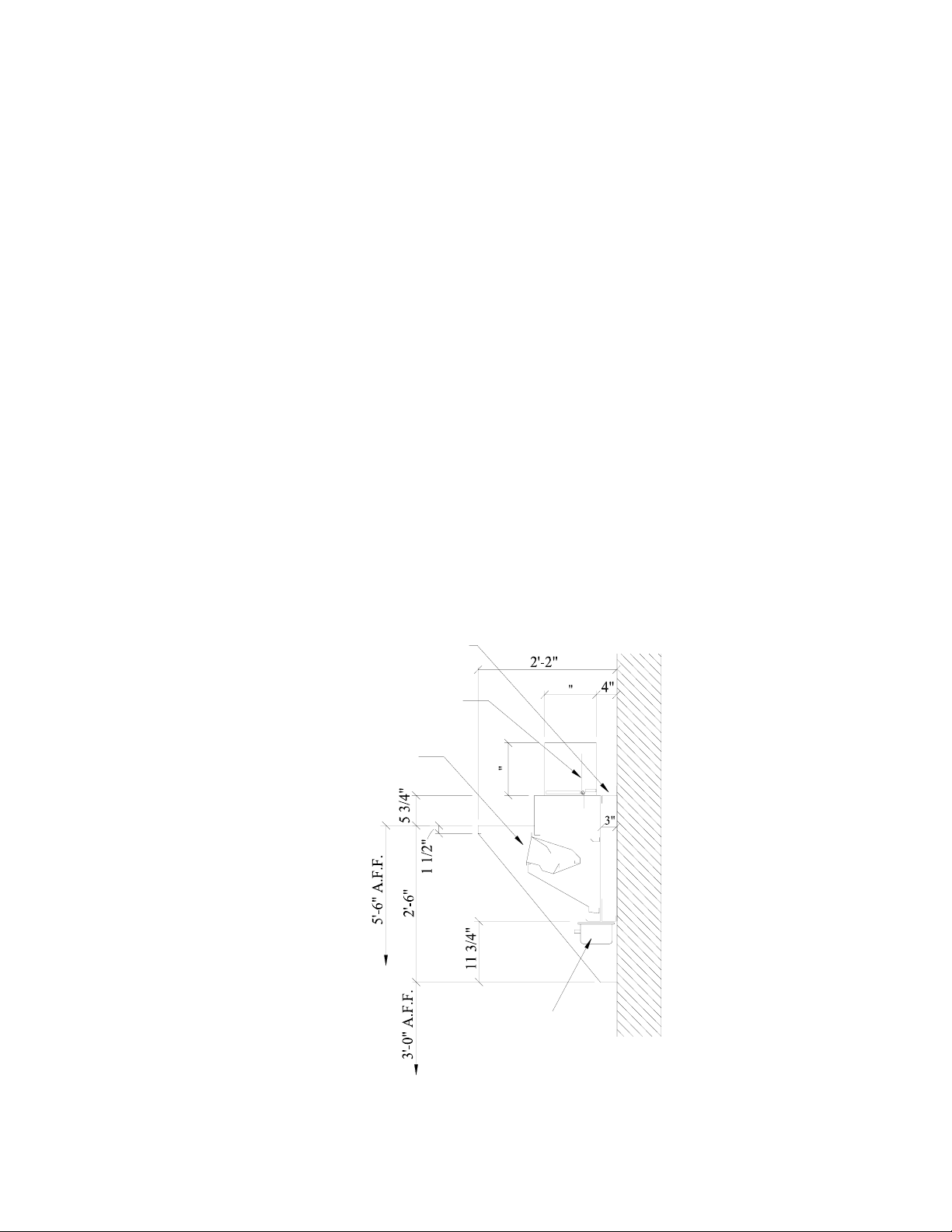

G.I. ANGLE AT REAR

FOR WALL MOUNTING

(OPTIONAL) UL LISTED FIRE DAMPER

REMOVABLE S.S.

GREASE CARTRIDGES

GREASE CONTAINER

REMOVABLE S.S.

Loading...

Loading...