Page 1

WARNING

This manual contains information on limitations regarding product use and function and information on the

limitations as to liability of the manufacturer. The entire manual should be carefully read.

Installation

Manual

Software Version 2.3 / DLS-1 v6.7 and up

See Back Cover for New Features in Version 2.3

Page 2

WARNING Please Read Carefully

Note to Installers

This warning contains vi tal infor mation. As the only individual in contact with system users, it is your

responsibility to bring each item in this warning to the attention of the users of this system.

System Failures

This system has been carefully designed to be as e ffective as possible. There are circu mstances, however,

involving fire , burglary, or other types of emergencies where it may not provide prote ction. Any alar m system of any type may be compromised deliberately or may fail to opera te as expected for a variety of reasons.

Some but not all of thes e reasons may be:

■ Inadequate Installation

A security system must be installed properly in order to provide adequate protection. Every i nstallation

should be evaluat ed by a secu rity profes sional to ensure that all access points an d areas are covered. Locks

and latches on windows and doors m ust be sec ure and op erate as i ntended. Windows, doors, walls, ceilings

and other building materials must be of sufficient strength and construction to provide the level of protection

expected. A reevaluation must be done during and after any construction activity. An evaluation by the fire

and/or police department is highly recommended if this ser vice is available.

■ Criminal Knowledge

This system co ntains security features which were known to be effective at the time of manufactu re. It is possible for persons with criminal intent to develop techniques which reduce the effectiveness of these features.

It is important that a security system be reviewed periodically to ensure that its features remain effective and

that it be updated or replaced if it is found that it does not provide the protection expected.

■ Access by Intruders

Intruders may enter through an unprotected acces s point, c ircumvent a sensing device , evade detection by

moving through an area of insufficient coverage, disconnect a warning device, or interfere with or prevent

the proper op eration of the system.

■ Power Failure

Control units, intrusion detectors, smoke detectors and many other security devices require an adequate

power supply for proper operation . If a device operates from batteries , it is pos sible for the batteries t o fail.

Even if the batt eries have not failed, they must be charged, in good condition and installed correctly. If a

device operates only by AC power, any inter ruption , however brief, will render that device inoperative while

it does not have power. Power inter ruptions of any length are often accompanied by voltage fluctuatio ns

which may damage electronic equipment such as a security system. After a power interruption has occurred,

immediately conduct a compl ete system test to ensure that the system oper ates as intended.

■ Failure of Replaceable Batteries

This system’s wireless transmitters have been designed to provide several years of battery life under normal

conditions. The expected battery life i s a function o f the device environment, usage a nd type. Ambient conditions such a s high humidity, high or low temperatures, or large temperature fluctuations may red uce the

expected battery life. While each tr ansmitting device has a low battery monitor which iden tifies when the

batteries nee d to be replaced, this monito r may fail to operate as expected. Regu lar testing and mainte nance

will keep the system in good operating condition.

■ Compromise of Radio Frequency (Wireless) Devices

Signals may not reach the receiver und er all circumstances which could include metal objects placed on or

near the radi o path or d eliberate ja mming or other inadvertent radio s ignal interference.

■ System Users

A user may not be able to operate a panic or emergency switch possibly due to permanent or temporary

physical disabili ty, inability to reach the d evice in time, or unfamiliari ty with the cor rect operat ion. It is

important that all system users be trained in the correct operation of the alarm system and that they know

how to respond when the system indicates an alarm.

■ Smoke Detectors

Smoke detectors that are a part of this system may not properly alert occupants of a fire for a number of reasons, some of which follow. The smoke detec tors may have been improperly installed or positioned. Smoke

may not be able t o reach the smoke dete ctors, such as when the fire is in a chimney, walls or roofs , or on the

other side of c losed doors. Smoke detectors may not detect smoke from f ires on ano ther level of the residence or building.

Every fire is different in the amount of smoke produced and the rate of burning. Smoke detectors cannot

sense all types of f ires eq ually well. Smoke detectors may not provide timely warning of fires caused by

carelessness or safety hazards suc h as smoking in bed, violen t explosions, escaping gas, improper storage of

flammable materials, overloaded electrical circuits, chil dren playing with matches or arson.

Even if the smoke detector operates as intended, there may be circumstances when there is insuff icient warning to allow all occupants to escape in time to avoid injury or death.

■ Motion Detectors

Motion detectors can only detect motion within t he designate d areas as shown in their respective insta llation

instructions. They cannot discriminate between intruders and intended occupants. Motion detectors do not

provide volumetric area pr otection. They have multip le beams of detection and motion can only be detected

in unobstructed areas covered by these beams. They cannot detect motion which occurs behind walls, ceilings, floor, closed doors, glass partitions, glass doors o r windows. Any type of t ampering whether intentional

or unintentional such as masking, painting, or spraying o f any material on the lenses, mir rors, windows or

any other part of the detection system will impair its proper operation.

Passive infr ared moti on de tect ors opera te by se nsin g changes in tempera ture . However their effectiven ess

can be reduced when the ambient t emperature rises near or a bove body temperature or if there are intention al

or unintentional sources of heat in or near the det ection area. Some of these heat sourc es could be heaters,

radiators, st oves, barbeques, firepl aces, sunlight, steam vents, lighting and so on.

■ Warning Devices

Warning devices such as sirens , bells, h orns, or strobes may not warn people or waken someone sl eeping if

there is an intervening wall or door. If warning devices are located on a different level of the residence or

premise, then it is less likely that the occupants w ill be alerted or awakened. Audible warning devices may be

interfered wit h by other noise sources such as ste reos, radios, televisions, air conditioners or other appliances, or passi ng tr aff ic. Audible war ning devices, however lo ud, may not be heard by a hearing-im pair ed

person.

■ Telephone Lines

If telephone lines are used to transmit alarms, they may be out of service or busy for certain periods of time.

Also an intruder may cut the te lephone line or defe at its op eration by mo re sophist icated mea ns which may

be difficult to dete ct.

■ Insufficient Time

There may be circumstances when the sy stem will operate as intended, yet the occupants will not be protected from the emergency due to their inability to respond to the warnings in a timely manner. If the system

is monitored, the response may not occur in time to protec t the occupants or their belongings.

■ Component Failure

Although every effort has been made to make this system as reliable as possible, the system may fail to function as intended due to the failure of a compo nent.

■ Inadequate Testing

Most problems that would prevent an alar m system from operating as inte nded can be found by regular testing and maintenance. The complete system shou ld be tested weekly and immediately after a break-in, an

attempted break-in, a fire, a storm, an earthquake, an accident, or any kind of construction activity insid e or

outside the premises. The testing should include all sensing devices, keypads, consoles, alarm indicating

devices and any other operational devices that are part of the system.

■ Security and Insurance

Regardless of its capabilities, an alarm system is not a substitute for property or life insurance. An alarm system also is not a substitute for property owners, renters, or other occupants to act prudently to prevent or

minimize the harmful effects of an emergency situation.

Limited Warranty

Digital Security Controls Ltd. warrants the original purchaser that for a period of twelve months from the

date of purchase, the product shall be free of defects in materials and workmanship under normal use. During the war ranty perio d, Digital Securi ty Control s Ltd. shal l, at its option, re pair or replace any defe ctive

product upon return of the product to its factory, at no charge for labour and materials. Any replacement and/

or repaired parts ar e warrante d for the remainder o f the original warranty or nine ty (90) days, whichever is

longer. The original owner must promptly notify Dig ital Securi ty Controls Ltd. in wri ting that there is defect

in material or workmanship , such wri tten notice to be re ceived in all events prior to expiration of the warranty period.

International Warranty

The warranty for international customers is the same as for any customer within Canada and the United

States, with the exception that Digital Security Controls Ltd. shall not be responsible for any custo ms fees,

taxes, or VAT that may be due.

Warranty Procedure

To obtain service under this warranty, please return the item(s) in question to the point of purchase. All

authorized distributors and dealers have a warranty program. Anyone returning goods to Digital Security

Controls Ltd. must first obtain an authorization number. Digital Security Controls Ltd. will not accept any

shipment whatsoever for which prior authorization has no t been obtained.

Conditions to Void Warranty

This warranty applies only to defects in parts and workmanship relating to normal use. It does not cover:

• damage incurred in sh ipping or handling;

• damage caused by disaster such as f ire, flood, wind, earthquake or lig htning;

• damage due to causes beyond the control of Digital Security Controls Ltd. such as excessive voltage,

mechanical shock or water damage;

• damage caused by unauthoriz ed attachmen t, alterations, modif ications or foreign objects;

• damage caused by peripheral s (unless such peripherals were supplied by Digital Security Controls Ltd.);

• defects caused by failure to provide a suitable installation environment for the products;

• damage caused by use of the products for purposes other than those for which it was designed;

• damage from improper maintenance;

• damage arising out of any other abuse, mishandling or improper application of the products.

Digital Securi ty Controls Ltd.’s liability for failure to repair the product under this warranty aft er a reasonable number of attempts will be limited to a replacement of the product , as the exclus ive remedy for breach

of warranty. Under no circumsta nces shall Digital Security Controls Ltd. be liable for any special, incidental,

or consequential damages based upon breach of warranty, breach of contract, negl igence, strict liability, or

any other legal theor y. Such damages includ e, but are not limited to, loss of prof its, loss of the product or any

associated equipment, cost of capital, cost of substitute or replacement equipm ent, facilit ies or services,

down time, purchaser’s time, the claims of third parties, including customers, and injury to property.

Disclaimer of Warranties

This warranty contains the entire warranty and shall be in lieu of any and all other warranties,

whether expressed or implie d (including all implied warranties of merchantability or f itness for a particular purpose) And of all oth er obligations or liabi lities on the part of Digital Security Controls Ltd.

Digital Securi ty Controls Ltd. neit her assumes nor authorizes any other person purporting to act on

its behalf to modify or to change this warranty, nor to assume for it any other warranty or l iability

concerning this product.

This disclaim er of warranties and limited warranty a re governed by the laws of the province of

Ontario, Canada.

WARNING: Digital Securi ty Controls Ltd. recommends that the entire system be complet ely tested on a

regular basis . However, despite frequent te sting, and due to, but not limited to, crimi nal tamperin g or electrical disruption, it is possible for this product to fail t o perform as expected.

Installer’s Lockout

Any products returned to DSC which have t he Install er’s Lockout option enabled and exhibit no other problems will be subject to a service charge.

Out of Warranty Repairs

Digital Security Controls Ltd. will at its opti on repair or replace o ut-of-warranty products which are returned

to its factory according to the following conditions. Anyone returning goods to Digital Security Controls

Ltd. must first obtain an authorization number. Digital Security Controls Ltd. will not accept any shipment

whatsoever for which prior authorization has not been obtained.

Products which Digital Security Controls Ltd. determines to be repairable will be repaired and returned. A

set fee which Digital Security Controls Ltd. has predetermined and which may be revised from time to time,

will be charged for each u nit repaired .

Products which Digital Security Controls Ltd . determines not to be repairable will be replaced by the near est

equivalent product available at that time. The current market price of the replacement pro duct will be

charged for each replacement unit.

Page 3

Table of Contents

Section 1: System Introduction 1

1.1 Specifications ........................................................................1

1.2 Additional Devices ..............................................................2

1.3 Out of the Box .......................................................................2

Section 2: Getting Started 3

2.1 Installation Steps ..................................................................3

2.2 Terminal Descriptions .........................................................3

2.3 Keybus Operation and Wiring ...........................................4

2.4 Current Ratings – Modules and Accessories ...................4

2.5 Keypad Assignment ............................................................4

2.6 Supervision ...........................................................................5

2.7 Removing Modules ..............................................................5

2.8 Zone Wiring ..........................................................................5

2.9 Fire Zone Wiring ..................................................................6

2.10 LINKS Zone Wiring .............................................................6

2.11 Keypad Zones .......................................................................6

Section 3: Keypad Commands 8

3.1 Arming and Disarming .......................................................8

3.2 Auto Bypass – Stay Arming ...............................................8

3.3 Automatic Arming ...............................................................8

3.4 [*] Commands .......................................................................8

3.5 Function Keys .....................................................................11

3.6 Features Available for the LCD5500Z .............................12

Section 4: How to Program 13

4.1 Installer’s Programming ...................................................13

4.2 Programming Decimal Data .............................................13

4.3 Programming HEX Data ...................................................13

4.4 Programming Toggle Option Sections ............................14

4.5 Viewing Programming ......................................................14

Section 5: Program Descriptions 15

5.1 Programming Security Codes ..........................................15

5.2 Zone Programming ............................................................15

5.3 Zone Attributes ..................................................................16

5.4 Assigning Keypad Zones ................................................. 17

5.5 Communicator – Dialing .................................................. 17

5.6 Communicator – Account Numbers .............................. 17

5.7 Communicator – Telephone Numbers ........................... 17

5.8 Communicator – Reporting Codes ................................. 18

5.9 Communicator – Reporting Formats .............................. 19

5.10 Downloading ..................................................................... 20

5.11 PGM Output Options ....................................................... 21

5.12 Telephone Line Monitor (TLM) ...................................... 23

5.13 Bell ....................................................................................... 23

5.14 Test Transmission .............................................................. 23

5.15 Transmission Delay .......................................................... 23

5.16 Fire, Auxiliary and Panic Keys ........................................ 23

5.17 Arming/Disarming Options ........................................... 24

5.18 Entry/Exit Delay Options ................................................ 24

5.19 Swinger Shutdown ............................................................ 25

5.20 Event Buffer ....................................................................... 25

5.21 Keypad Lockout Options ................................................. 25

5.22 Keypad Blanking ............................................................... 25

5.23 Keypad Backlighting ........................................................ 25

5.24 Loop Response ................................................................... 25

5.25 Keypad Tampers ............................................................... 26

5.26 LINKS1000 Cellular Communicator ............................... 26

5.27 Additional System Modules ............................................ 26

5.28 Clock Adjust ....................................................................... 26

5.29 Timebase ............................................................................ 27

5.30 Resetting Factory Defaults ............................................... 27

5.31 Installer’s Lockout ............................................................. 27

5.32 Walk Test (Installer) .......................................................... 27

Section 6: Programming Worksheets 28

Appendix A: Reporting Codes 43

Appendix B: Programming LCD Keypads 45

i

Page 4

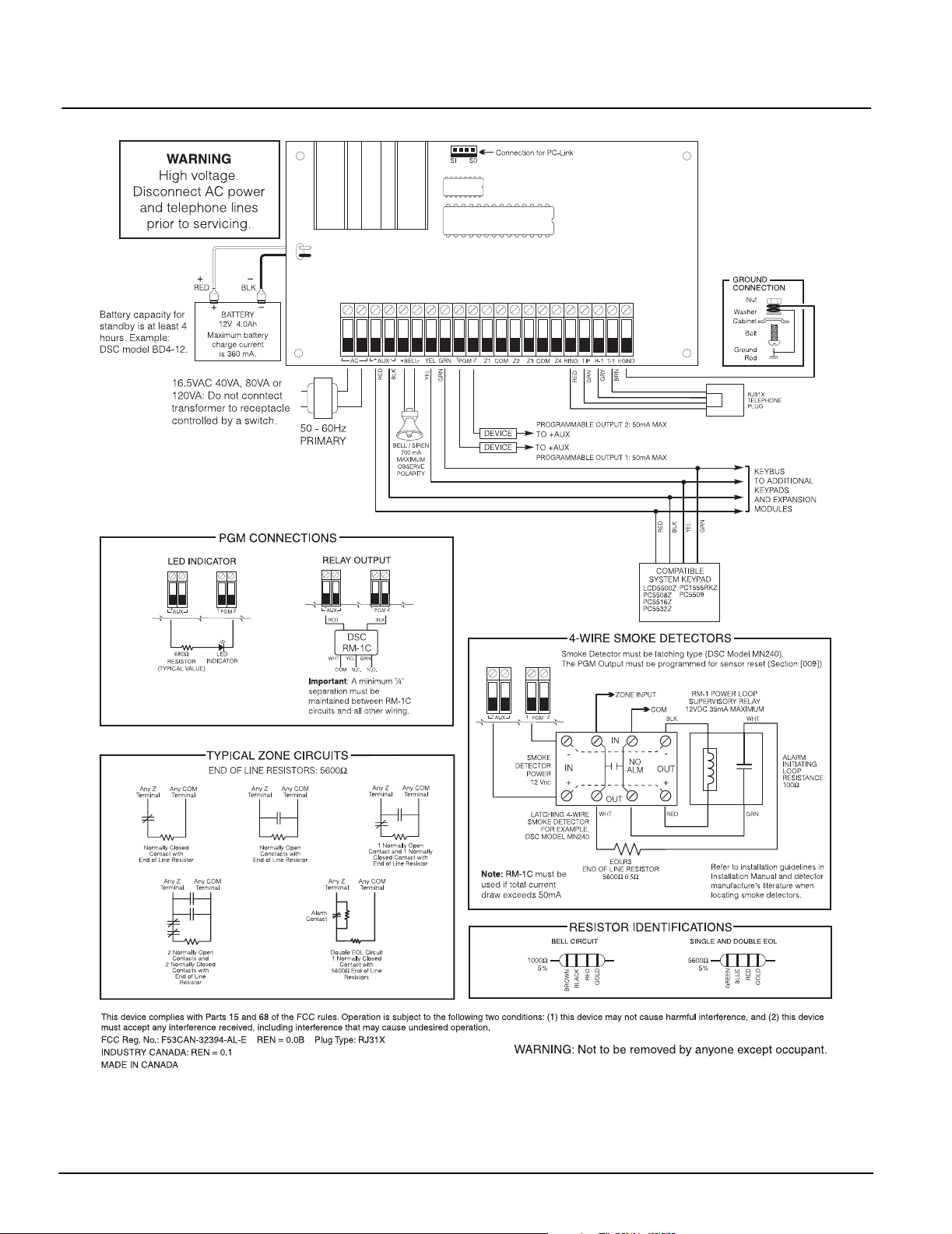

PC585 Wiring Diagram

ii

Page 5

Section 1: System Introduction

1.1 Specifications

Downloading Software Support

• PC585 v2.3 uses DLS-1 v6.7 and up.

Flexible Zone Configuration

• Four fully programmable zones

• System expandable to 32 zones using:

• up to 8 keypad zone inputs and/or

• up to 32 wireless zones with the PC5132 wireless

expansion module

• 38 access codes: one master code, one maintenance

code, two duress codes, two supervision codes and 32

general access codes

• 27 zone types; 8 programmable zone attributes

• Normally closed, single EOL and double EOL zone wiring

• 32 wireless zones with the PC5132 Wireless Receiver

Audible Alarm Output

• 700mA Supervised Bell Output (current limited at 3 amps),

DC

12V

• Steady or Pulsed Output

EEPROM Memory

• Does not lose programming or system status on complete

AC and Battery failure

Programmable Outputs

• Two programmable outputs; 18 programmable options

• PGM1 = 50mA; PGM2 = 50mA

Powerful 1.5 Amp Regulated Power Supply

• 550 mA Auxiliary Supply, 12 V

• Positive Temperature Coefficient (PTC) components

replace fuses

• Supervision for loss of AC power, low battery

• Internal clock locked to AC power frequency

Power Requirements

• Transformer = 16.5 V

• Battery = 12 volt 4 Ah minimum rechargeable sealed lead

acid battery

Remote Keypad Specifications

• Keypads available:

- PC5509 eight zone LED keypad

- PC1555RKZ eight zone LED keypad with zone input

- PC5508Z eight zone LED keypad with zone input

- PC5516Z sixteen zone LED keypad with zone input

- PC5532Z thirty-two zone LED keypad with zone input

- LCD5500Z Alphanumeric keypad with zone input

• All keypads (except PC5509) have five programmable

function keys

• Connect up to eight keypads

• 4-wire (Quad) connection to Keybus

• Built in piezoelectric buzzer

AC, 40VA

DC

Digital Communicator Specifications

• Supports major communication formats including SIA and

Contact ID

• Event-initiated personal paging

• Three programmable telephone numbers

• Two account numbers

• Supports LINKS1000 cellular communication

• Supports LINKS2X50 long range radio transmitter

• DTMF and pulse dialing

• DPDT line seizure

• Anti-jam feature

• Split reporting of selected transmissions to each telephone

number

System Supervision Features

The PC585 continuously monitors a number of possible trouble conditions including:

• AC power failure • AUX Power Supply Trouble

• Fault by zone • Loss of internal clock

• Tamper by zone • Bell output trouble

• Fire trouble • Telephone line trouble

• Failure to communicate • Low battery condition (panel)

• Low battery by zone (wireless)

• Module fault (supervisory or tamper)

False Alarm Prevention Features

• Audible Exit Delay • Quick Exit

• Audible Exit Fault • Cross Zone Burglary Alarm

• Communication Delay • Rotating Keypress Buffer

• Urgency on Entry Delay • One Restart of Exit Delay

Additional Features

• Auto Arm at specified time

• Keypad-activated alarm output and communicator test

• All modules connect to the system via a four wire Keybus

up to 1000’/305m from main panel

• An event buffer which records the past 128 events with

both the time and date at which they occurred; buffer can

be printed using PC5400 serial interface module, or

viewed with the LCD5500Z keypad and DLS-1 software

• Supports the addition of the PC5132 wireless receiver for

integration of wireless devices

• Uploading and downloading capability

• Local downloading capability through the use of the

PC-LINK adaptor

• Added Keybus fault protection: clock and data outputs

have been programmed to withstand shorts to +12v to prevent control panel damage

1

Page 6

1.2 Additional Devices

In addition to the information below, see the back cover for a

DSC module compatibility table.

PC5132 Wireless Receiver

The PC5132 Wireless Receiver can be used to connect up to

32 wireless devices to the system. All devices are spread

spectrum, 900 MHz, fully supervised devices which use standard ‘AAA’ or ‘AA’ alkaline batteries.

Seven devices are available. They are as follows:

WLS904 Wireless Motion Detector:

tection to your system

WLS905 Wireless Universal Transmitter:

or window contacts to your system.

WLS906 Wireless Smoke Detector:

your system.

WLS907 Wireless Slimline Universal Transmitter:

wireless door or window contact.

WLS908 Wireless Panic Pendant:

the system. When used, the unit will indicate a non-medical emergency to the central station.

WLS909 Wireless Key :

arming and disarming to the system, as well as one-button access to

several programmable functions.

Adds a simple and mobile method of

WLS910 Wireless Hand held Keypad:

allows arming and disarming from anywhere on the premises.

PC5400 Printer Module

The PC5400 Printer Module allows the panel to print out all

events that occur on the system to any serial printer. The printout will contain the time, date and the event that occurred.

LINKS1000 Cellular Communicator

The LINKS1000 Cellular Communicator can be used three different ways: as the sole communicator for the panel, as a

backup for either or both telephone numbers or as a redundant backup to the land line communicator where the panel

will call both the land line and via the LINKS.

LINKS2X50

Either the LINKS2150 or LINKS2450 may be used to transmit

alarm information over a long range radio network.

Adds wireless space pro-

Adds wireless door

Adds smoke detection to

A smaller

Adds personal protection to

A portable keypad which

Cabinets

Several different cabinets are available for the PC585 modules. They are as follows:

PC5003C Cabinet

Main control cabinet for the PC585 main panel. Dimensions

288mm x 298mm x 78mm / 11.3” x 11.7” x 3” approximately.

PC500 Cabinet with Removable Door

Main control cabinet for the PC585 main panel. Dimensions

213mm x 235mm x 78mm / 8.4” x 9.25” x 3” approximately.

PC5004C Cabinet

Cabinet to house the PC5400 Printer Module. Dimensions

229mm x 178mm x 65mm / 9” x 7” x 2.6” approximately.

1.3 Out of the Box

Please verify that the following components are included in

your system:

• one PC5003C main control cabinet

• one PC585 main control circuit board

• one PC1555RKZ keypad with zone input

• one Installation Manual with programming worksheets

• one Instruction Manual for the end user

• one hardware pack consisting of:

- one mylar cabinet label

- four plastic circuit board standoffs

- ten 5600Ω (5.6K) resistors

- one 2200Ω (2.2K) resistor

- one 1000Ω (1K) resistor

- ground connection assembly

- one cabinet door plug

2

Page 7

Section 2: Getting Started

The following sections provide a thorough description of how

to wire and configure devices and zones.

2.1 Installation Steps

Read this section completely before you begin. Once you

have an overall understanding of the installation process,

carefully work through each step.

Step 1: Create a Layout

Draw a rough sketch of the building to get an idea of where all

alarm detection devices, keypads and other modules are to

be located.

Step 2: Mounting the Panel

Mount the panel in a dry area close to an unswitched AC

power source and the incoming telephone line. Before attaching the cabinet to the wall, be sure to press the four circuit

board mounting studs into the cabinet from the back. After

you have attached the cabinet to the wall, stick the provided

DSC logo sticker on the front of the cabinet.

NOTE:You must complete all wiring before connecting the battery, or applying AC to the panel.

Step 3: Wiring the Keybus (Section 2.3)

Wire the Keybus to each of the modules following the guidelines provided in Section 2.3 of this manual.

Step 4: Zone Wiring (Section 2.8)

You must power down the control panel to complete all zone

wiring. Please refer to 2.8

necting zones using normally closed loops, single EOL resistors, double EOL resistors, Fire zones and Keyswitch Arming

zones.

Step 5: Complete Wiring (Section 2.2)

Complete all other wiring including bells or sirens, telephone

line connections, and ground connections following the guidelines provided in Section 2.2 (“Terminal Descriptions”).

Step 6: Power up the Control

Once all zone and Keybus wiring is complete, power up the

control panel. First, connect the red battery lead to the positive terminal and the black lead to negative. Then, connect the

AC.

NOTE: Connect the battery bef ore con nectin g the A C . You

must apply AC power to the panel for at least 10 seconds, or

the panel will not function. The panel will not power up on the

battery connection alone.

Step 7: Keypad Assignment (Section 2.5)

In order for keypads to be properly supervised, each must be

assigned to a different slot. Please follow the guidelines provided in Section 2.5 when assigning keypads.

Step 8: Supervision (Section 2.6)

The supervision of each module by the panel is automatically

enabled upon power up. Please verify that all modules appear

on the system according to the instructions in Section 2.6.

Step 9: Programming the System (Sections 4 & 5)

Section 4 explains how to program the panel. Section 5 contains a complete description of the various programmable features, which options are available and how they function. Fill

out the Programming Worksheets completely before attempting to program the system.

“Zone Wiring”

on page 5 when con-

Step 10: Testing the System

Test the panel thoroughly to ensure that all features and functions are operating as programmed.

2.2 Terminal Descriptions

Battery Connection

A 12V 4Ah rechargeable battery is used as a backup source

of power in the event of an AC power failure. The battery also

provides additional current when the panel’s demands exceed

the power output of the transformer, such as when the panel is

in alarm.

The High Current Charge/Standard Battery Charge option

(section [701], option [7]) allows you to choose between a high

current battery charge and the standard battery charge rate.

High Current/Standard Battery Charge. . . .Section [701]: [7]

NOTE:Do not connect the battery until all other wiring is complete. Connect the battery before connecting the AC.

Connect the RED battery lead to the positive battery terminal;

connect the BLACK lead to negative.

AC Terminals – AC

The panel requires a 16.5VAC, 40VA transformer. Connect the

transformer to an unswitched AC source and connect the

transformer to these terminals.

The panel can be programmed to accept a power line frequency of either 50Hz AC or 60Hz AC in programming section

[701], option [1].

NOTE:Do no t conn ec t the tr a nsf ormer until all ot her wiring is

complete.

Auxiliary Power Terminals – AUX+ and AUX-

These terminals provide up to 550 mA of additional current at

12 VDC for devices requiring power. Connect the positive side

of any device requiring power to the AUX+ terminal, the negative side to AUX- (ground). The AUX output is protected. This

means that if too much current is drawn from these terminals

(such as a wiring short), the panel will temporarily shut off the

output until the problem is corrected.

Bell Output Terminals – BELL+ and BELL-

These terminals provide up to 700 mA of continuous current at

12 V

DC for powering bells, sirens, strobes or other warning-

type equipment. Connect the positive side of any alarm warning device to BELL+, the negative side to BELL–. Please note

that the Bell output is protected: if too much current is drawn

from these terminals (such as a wiring short), the Bell PTC will

open. Three amps can be drawn for short periods only.

The Bell output is supervised. If no alarm warning devices are

in use, connect a 1000Ω resistor across BELL+ and BELL– to

prevent the panel from displaying a trouble condition. For

more information, please refer to

page 9).

Keybus Terminals – AUX+, AUX-, YEL, GRN

The Keybus is used by the panel to communicate with modules and vice versa. Each module has four Keybus terminals

that must be connected to the four Keybus terminals on the

panel. For more information, see section 2.3

tion and Wiring”

on page 4.

“[*][2] Trouble Display”

“Keybus Opera-

on

3

Page 8

Programmable Output Terminals – PGM1 and PGM2

Each PGM output is designed so that when activated by the

panel, the terminal will switch to ground

PGM1 can sink up to 50mA of

current. Connect the positive

side of the LED or buzzer to

AUX+, the negative side to

PGM1. PGM2 operates similarly to PGM1. If more than 50

mA of current are required, a

relay must be used.

Please study PGM wiring in

the accompanying diagram.

For a list of the programmable

output options, please see

section 5.11

Options”

Zone Input Terminals –

Z1 to Z4

Each detection device must be connected to a zone on the

control panel. We suggest that one detection device be connected to each zone; wiring multiple detection devices to a

single zone, however, is possible. For zone wiring specifics,

please see section 2.8

Telephone Connection Terminals – TIP, RING, T-1, R-1

If a telephone line is required for central station communication or downloading, connect an RJ-31X telephone jack in the

following manner:

“Zone Wiring”

on page 5.

“PGM Output

on page 21.

NOTE:Please ensure that all pl ugs and jacks meet the dimension, tolerance and metallic plating requirements of 47 C.F.R.

Part 68, SubPar t F. For proper operation, no other telephone

equipment should be connec te d betwe en th e contro l pa nel and

the telephone company facilities. Do not connect the alarm

panel communicator to telephone lines intended for use with a

fax machine. These lines may incorporate a voice filter which

disconnects the line if anything other than fax signals are

detected, resulting in incomplete transmiss io ns.

2.3 Keybus Operation and Wiring

The Keybus is used by the panel to communicate with all connected modules and vice versa. The red (AUX+) and black

(AUX-) terminals are used to provide power, while the yellow

(YEL) and green (GRN) terminals are clock and data respectively.

NOTE: The four Keybus terminals of the panel must be connected to the four Keybus terminals or wires of all modules.

The following restrictions apply to Keybus wiring:

• Keybus should be run in minimum 22 gauge quad

(0.5mm); two pair twist is preferred.

• The modules should be home-run to the panel but can be

connected in series or T-tapped.

• Any module can be connected anywhere along the Keybus. You do not need to run a separate Keybus wire for

keypads, etc.

• No module can be more than 1,000'/305m (in wire length)

from the panel.

• Shielded wire should not be used.

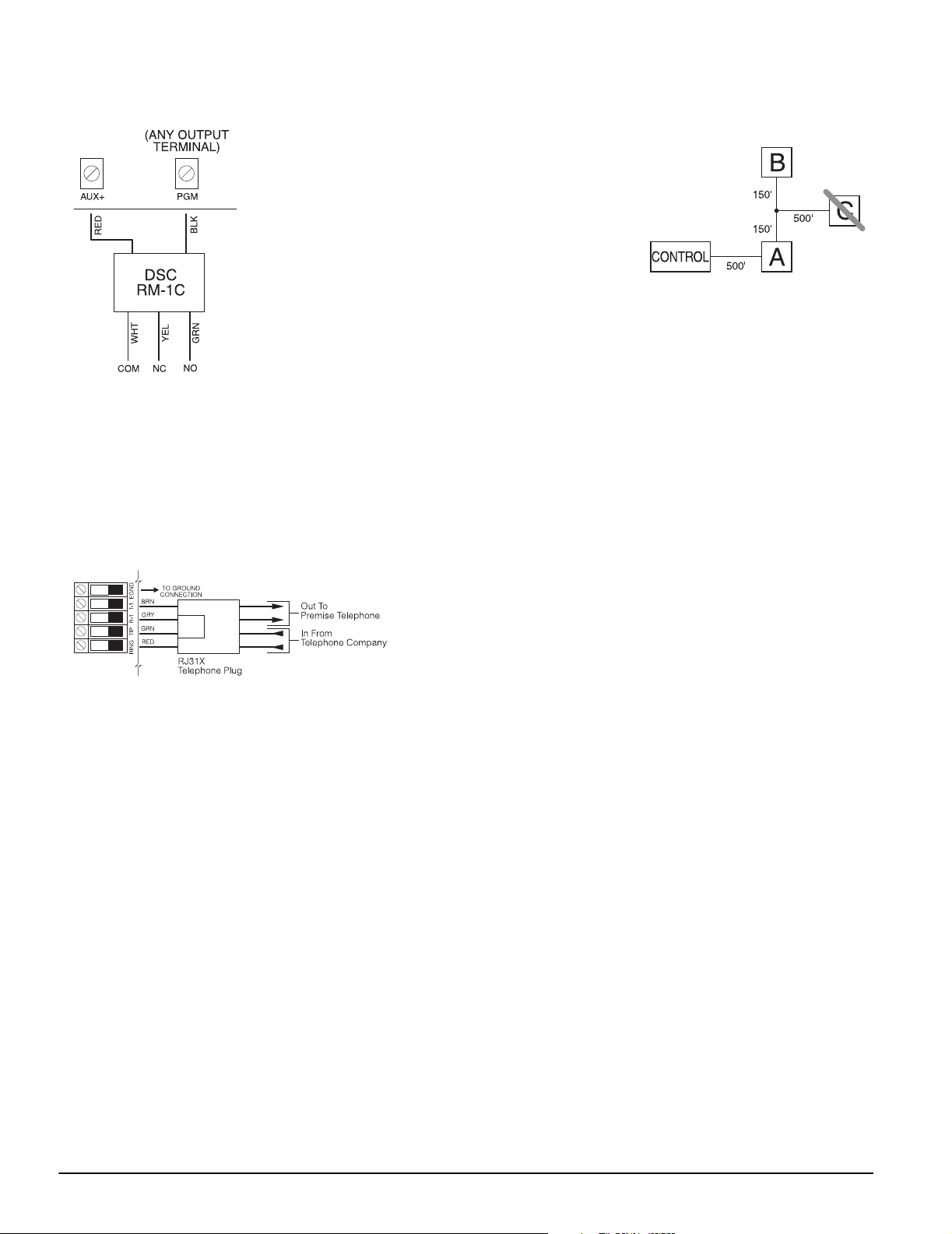

Example of Keybus Wiring

NOTE:

Module (A) is correctly

wired within 1,000'/

305m of wire from the

panel.

Module (B) is correctly

wired within 1,000'/

305m of wire from the

panel.

Module (C) is NOT wired correctly as it is further than 1,000'/

305m from the panel, in wire distance.

2.4 Current Ratings – Modules and Acces-

sories

In order for the PC585 system to operate properly, the power

output capabilities of the main control and the expansion

devices must not be exceeded. Use the data presented below

to ensure that no part of the system is overloaded and cannot

function properly.

PC585 (12 V

AUX+: ........550mA: Subtract the listed rating for each key-

BELL: .........700mA continuous rating; 3.0A short term. Avail-

PC585 Device Ratings (at 12 V

• LCD5500Z Keypad: 85mA max.

• PC1555RKZ Keypad: 85mA max.

• PC5508Z, PC5516Z, PC5532Z Keypads: 85mA max.

• PC5509 Keypad: 85mA max.

• PC5400 Serial Module: 65mA

• PC5132 Wireless Receiver: 125mA

Other Devices

Please read the manufacturer’s literature carefully to determine the maximum current requirements for each device—

during activation or alarm—and include the proper values for

loading calculations. Connected devices must not exceed

system capabilities during any possible operational mode.

DC)

pad, expansion module and accessory connected to AUX+ or Keybus.

able only with standby battery connected.

DC)

2.5 Keypad Assignment

There are eight available slots for keypads. LED keypads by

default are always assigned to slot 1. LCD5500Z keypads are

always assigned to slot 8. You will need to assign each keypad to its own slot (1 to 8). Keypad assignment is required, as

it tells the panel which slots are occupied. The panel can then

generate a fault when a keypad supervisory is not present.

NOTE: One LCD keypad must be assigned to slot 8 in order to

upload keypad programming using DLS-1 so ftware.

NOTE: PC5509 keypads are always assigned to slot 1. They

cannot be reprogrammed.

How to Assign Keypads

Do the following at each keypad installed on the system:

1. Enter [*][8][installer’s code] to go to installer programming

2. Enter [000] for Keypad Programming

3. Enter [0] for Slot Assignment

4. Enter a two digit number (11-18) to specify which supervisory slot the keypad will occupy.

4

Page 9

Getting Started: 2.6 Supervision

5. Press [#] twice to exit installer programming.

After assigning all keypads, perform a supervisory reset by

entering section [902] in installer’s programming. The panel

will now supervise all assigned keypads and enrolled modules

on the system.

How to Program Function Keys

By default, the 5 function keys on each keypad are programmed as Stay Arm (03), Away Arm (04), Chime (06), Sensor Reset (14) and Quick Exit (16). You can change the

function of each key on every keypad:

1. Go to the keypad where you want to change the function

key programming and enter Installer Programming.

2. Press [000] for Keypad Programming.

3. Enter [1] to [5] to select a function key to program.

4. Enter the 2 digit number, [00] to [17] to select the feature

you want the function key to have. For a complete list of

Function Key options see section 3.5

page 11.

5. Continue from step 3 until all function keys are programmed.

6. To exit Installer Programming, press [#] twice.

“Function Keys”

on

2.6 Supervision

By default, all modules are supervised upon installation.

Supervision is enabled at all times so that the panel can indicate a trouble if a module is removed from the system.

To check which modules are currently connected and supervised, enter programming section [903] from installer’s programming. The LCD keypad will allow you to scroll through the

display of connected modules. A connected module which

does not show as being present will appear as a trouble condition and the Trouble light on the keypad will turn ON. This

condition may be due to one or more of the following reasons:

• the module is not connected to the Keybus

• there is a Keybus wiring problem

• the module is more than 1,000'/305m from the panel

• the module does not have enough power

For more information regarding module supervision troubles,

please refer to

“[*][2] Trouble Display”

on page 9.

2.7 Removing Modules

The panel must be instructed to no longer supervise a module

being removed from the system. To remove the module, disconnect it from the Keybus and reset the supervision field by

entering [902] in the installer’s programming. The panel will be

reset to recognize and supervise all existing modules on the

system.

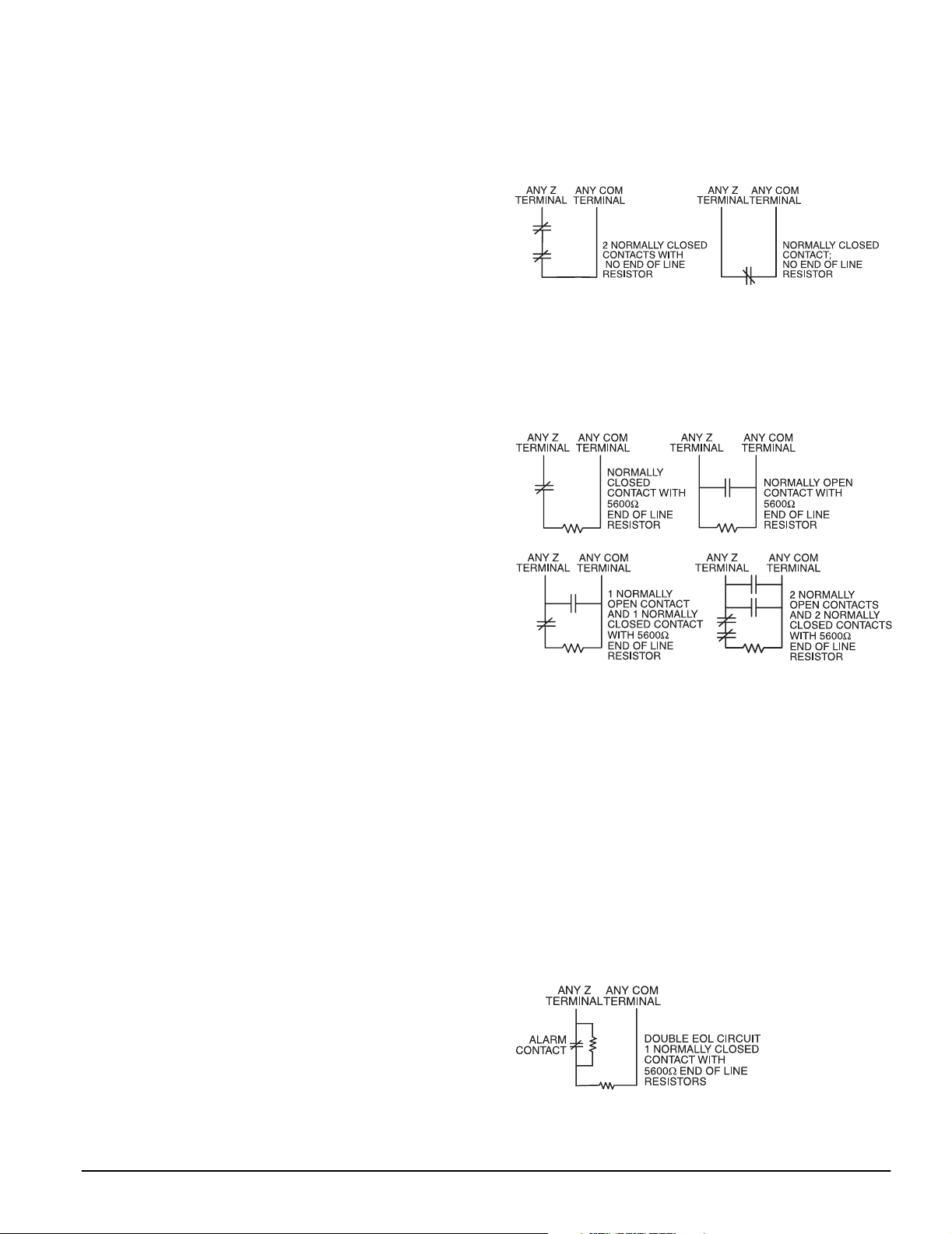

2.8 Zone Wiring

For a complete description of the operation of all zone types,

please refer to 5.2

There are several different ways in which zones may be wired,

depending on which programming options have been

selected. The panel can be programmed to supervise normally closed, End of Line, or Double End of Line loops. Please

refer to the following diagrams to study each type of individually supervised zone wiring.

NOTE:An y z one pro gr am med for Fire or 24 Hour Supervisory

must be wired with a single End of Line (EOL) resistor regardless of the type of zone wiring supervision selected for the

panel (section [013]: [1] -[2]). See 5.2 “Zone Programming” on

page 15.

“Zone Programming”

on page 15.

NOTE:If y ou chang e the zone supervision options from DEOL

to EOL or from NC to DEOL (section [013], options [1] or [2]),

you should power down the system completely, and then

power it back up. If you do not, the zones may not work correctly.

Normally Closed (NC) Loops

To enable normally closed loops, programming section [013],

option [1] must be ON.

NOTE:This option shou ld only be select ed if Normally Closed

(NC) detection devices or contacts are being used.

Single End Of Line (EOL) Resistors (5600Ω)

To enable panel detection of single end of line resistors, programming section [013], options [1] and [2] must be OFF.

NOTE:This option shoul d be selected if e ither Normally Closed

(NC) or Normally Open (NO) detection devices or contacts are

being used.

Double End of Line (DEOL) Resistors

Double End of Line resistors allow the panel to determine if the

zone is in alarm, tampered or faulted.

To enable panel detection of double end of line resistors, programming section [013], option [1] must be OFF and option

[2] must be ON.

NOTE: If the Do ub le EOL su pervision o ption is en ab led, all

hardwire zones on the main panel must be wired for Double

EOL resistors, except for Fire and 24 Hour Supervisory zones.

NOTE:Do not wire DEOL resistors on keypad zones.

NOTE: Do not use DEOL resistors f o r Fir e z ones o r 24 Hour

Supervisory zones. Do not wire Fire zones to keypad zone terminals if the DEOL supervision option is sel e cted.

NOTE: Thi s option can only be sele cted if Normally Clo sed

(NC) detection devices or contacts are being used.

5

Page 10

NOTE:Only one NC contact can be connected to each zone.

Wiring multiple detection devices or contacts on a single loop

is not allowed.

The following chart shows zone status under certain conditions:

Loop Resistance Loop Status

0Ω (shorted wire, loop shorted) Fault

5600Ω (contact closed) Secure

Infinite (broken wire, loop open) Tamper

11200Ω (contact open) Violated

End of Line Resistors. . . . . . . . . . . . . . . . . .Section [013]: [1]

Double End of Line Resistors . . . . . . . . . . .Section [013]: [2]

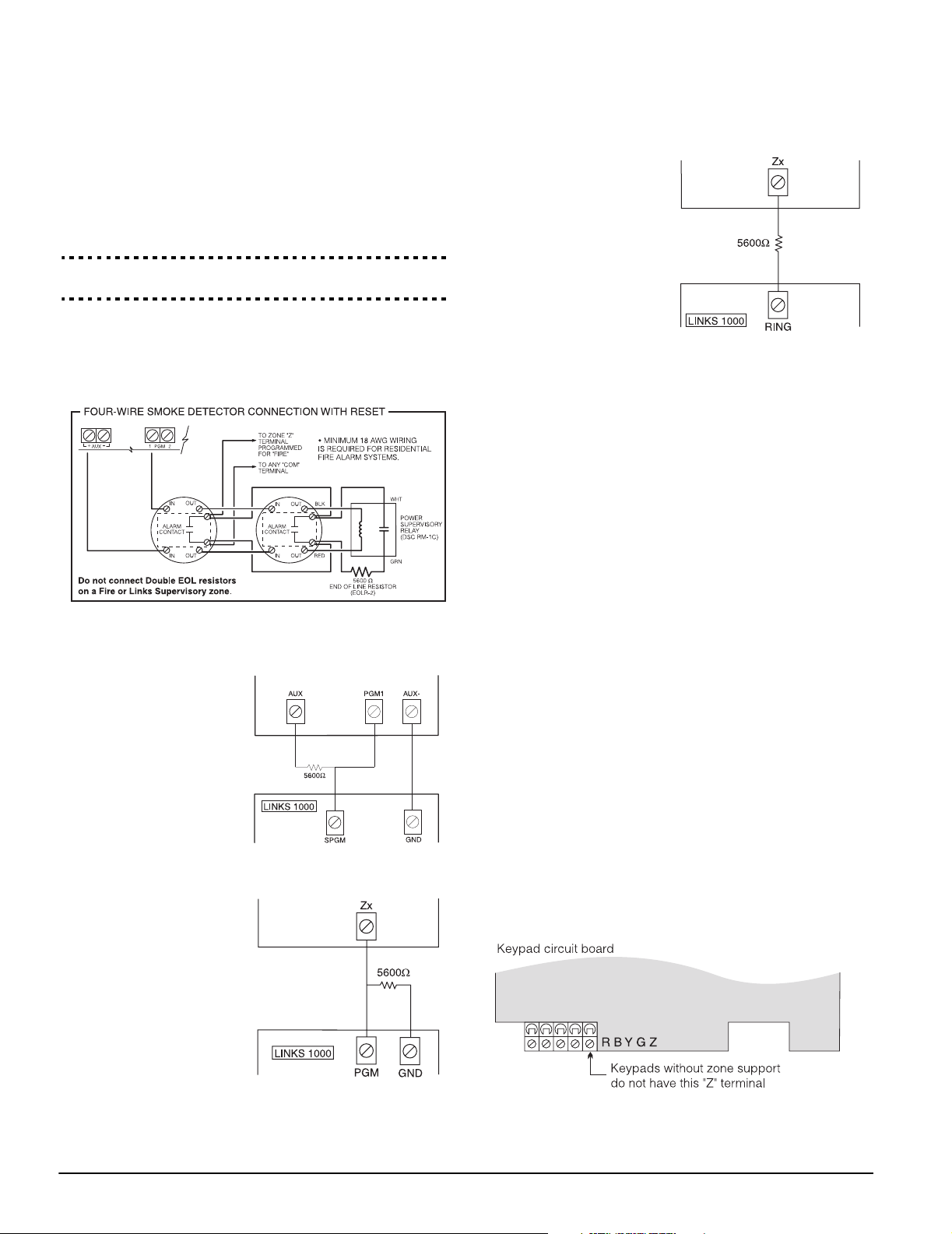

2.9 Fire Zone Wiring

NOTE:4-Wire Smoke Detectors

All fire zones must be wired according to the following diagram:

This type of zone always requires a single EOL resistor

(5600Ω).

Wire this zone according to the above diagram.

LINKS Answer

When using the LINKS1000

cellular communicator, any

main board zone may be

configured for LINKS

Answer.

A zone configured for

LINKS Answer allows

downloading to be performed in the event of telephone line failure. When

the LINKS receives a telephone call, it will activate

the RING terminal on the

LINKS circuit board. The

zone programmed as

LINKS Answer always

requires a single EOL resistor (5600Ω).

Wire the LINKS Answer zone according to the above diagram.

NOTE: The LINKS Answer zone is only required for downloading to the panel via the LINKS.

NOTE: When using the LINKS, Busy Tone Detection must not

be used.

NOTE: Keypad zones cannot be used for 24 Hour Supervisory

or LINKS Answer.

2.10 LINKS Zone Wiring

LINKS Support

When using the LINKS1000

cellular communicator, connect the LINKS to the main

panel according to the following diagram:

LINKS Supervision (24 Hour Supervisory)

When using the

LINKS1000 cellular communicator, any main board

zone may be configured

for LINKS Supervision. Program this zone as zone

type [09], 24 Hour Supervisory in section [001].

With a LINKS Supervisory

zone, if the LINKS1000

experiences a trouble, the

zone will be violated, causing the panel to report the

event to the central station.

2.11 Keypad Zones

Each “z” keypad on the system has a zone input to which a

device - such as a door contact - can be connected. This

eliminates the need to run wires back to the control panel for

every device.

To install the keypad, open the keypad plastic by removing the

screw at the bottom of the unit. Locate the five terminals on

the keypad circuit board. Connect the four Keybus wires from

the control panel: the red wire to R, the black to B, the yellow

to Y and the green to G.

To connect the zone, run one wire to the Z terminal and the

other to B. For powered devices, use red and black to supply

power to the device. Run the red wire to the R (positive) terminal and the black wire to the B (negative) terminal.

When using end of line supervision, connect the zone according to one of the configurations outlined in section

Wiring”

. End of line resistors must be placed on the device

end of the loop, not at the keypad.

NOTE: Keypad zones do not support DEOL resistors.

2.8 “Zone

6

Page 11

Assigning Keypad Zones

When using keypad zone inputs, each input used must be

assigned a zone number in Installer’s Programming.

First, ensure that you have enrolled all installed keypads into

the desired slots. (See 2.5

Next, enter programming section [020] to assign the zones.

There are eight programming locations in this section, one for

each keypad slot. Enter a 2-digit zone number for each of the

keypad zones. This number must be entered in the location

corresponding to the keypad to which each zone is connected.

Example: The zone on an LCD5500Z keypad in slot 8 is to be

assigned zone 3. In section [020], scroll to option [8] and

enter (03).

“Keypad Assignment”

on page 4.)

NOTE:K e ypad zones 1-4 will replac e zone terminal s Z1-Z4 on

the control panel.

NOTE: Once the keypad zones are assigned, you must also

program zone definitions and zone attributes. (See also 5.4

“Assigning Keypad Zones” on page 17).

Getting Started: 2.11 Keypad Zones

7

Page 12

Section 3: Keypad Commands

Use any system keypad to enter commands and/or program

the PC585 security system. The LED keypad uses function

and zone indicator lights to represent alarm functions and status. If you have a PC1555RKZ keypad, the System light acts

as a Trouble, Memory, Program and Bypass indicator. Unlike

other LED keypads, these conditions will only be represented

by the System light.

The LCD keypad provides a written description on the liquid

crystal display and uses function indicator lights to communicate alarm status to the user.

The PC585 Instruction Manual provides basic directions for

arming and disarming the system, bypassing zones and performing user functions from the keypads. The following sections provide additional details on these functions.

3.1 Arming and Disarming

For a description of basic arming and disarming, please see

the PC585 Instruction Manual. For other methods of arming,

please refer to

Delay”

and 3.5

“[*][0] Quick Arm”, “[*][9] Arming Without Entry

“Function Keys”

on page 11.

NOTE: The event buffer will log “Armed in Stay Mode” or

“Armed in Awa y Mode” wh en ever the system is armed.

In an attempt to prevent false alarms, the Audible Exit Fault

will notify the user of an improper exit when they arm their system. If a non force-arming Delay 1 or Delay 2 type zone is left

open at the end of the exit delay, the entry delay will begin

immediately and the bell or siren will sound a steady alarm for

the entry delay period. At the end of the entry delay period, if

the system has not been disarmed it will go into alarm. This

feature can be turned OFF in programming section [013],

option [6]. (See 5.17

24.)

“Arming/Disarming Options”

on page

3.2 Auto Bypass – Stay Arming

Stay arming allows the user to arm the system without leaving

the premises. All zones programmed as stay/away will be

bypassed when the user stay arms the system, so that the

user does not have to bypass interior zones manually. (See

5.2

“Zone Programming”

When the system is armed using a valid access code, if any

zones on the system have been programmed as stay/away

zones, the Bypass light will turn ON. The panel will then monitor all zones programmed as Delay 1 and Delay 2 zones, such

as designated entry/exit doors. If a delay zone is not violated

by the end of the exit delay, the panel will bypass all stay/away

zones. The Bypass light will remain on to inform the user that

the interior zones have been automatically bypassed by the

panel. If a delay zone is violated during the exit delay, the system will arm in Away mode and all stay/away zones will be

active after the exit delay expires.

The user can arm the stay/away zones at any time by entering

the [*][1] keypad command. (See

vating Stay/Away Zones”

Stay arming can also be initiated by pressing and holding the

Stay function key for two seconds on the PC5508Z and

LCD5500Z keypads, if programmed by the installer. For more

information regarding Stay arming, please see 3.5

Keys”

on page 11.

on page 15.)

“[*][1] Bypassing and Acti-

on page 8.)

“Function

3.3 Automatic Arming

The system can be programmed to Auto-Arm at a specific

time every day if it is in the disarmed condition. In order for the

Auto-Arm function to work properly, you must program the correct Time of Day. For programming the clock and auto-arm

times, see

When the system’s internal clock matches the Auto-Arm Time,

the panel will check the system status. If the system is armed,

the panel will do nothing until the next day at the auto-arm

time, when it will check the system again. If the system is disarmed at the auto-arm time, the panel will sound the buzzer of

all keypads for one minute. If the Bell Squawk During Auto

Arm option is enabled (section [014], option [2]), the bell will

squawk once every 10 seconds while the system is auto-arming. If a valid access code is entered, auto-arming will be

aborted.

“[*][6] User Functions”

on page 10.

NOTE: If auto-arm is canc elled , th e nu mber o f th e user who

cancelled the auto-arm will be logged in the event b uffer.

If no code is entered, the panel will auto-arm. If a zone is violated, the panel will transmit a Partial Closing Reporting Code

– if programmed – to indicate to the central station that the

system is not secure. If the zone is restored, the panel will add

the zone back into the system.

NOTE: Auto arming can only be cancelled by entering a valid

access code at any keypad.

3.4 [*] Commands

The [*] key commands provide an easy way for the user to

access basic system programming – such as programming

access codes or bypassing zones. The user can also use the

[*] key commands to check on the system’s status, including

viewing trouble conditions and displaying the event buffer on

the LCD keypad.

The [*] key commands can be performed from both LCD and

LED keypads. The LED keypad uses the zone indicator lights

to display command information. The LCD display provides

written information, guiding the user through each command.

The commands in this section are explained as viewed from

an LED keypad. When using an LCD keypad, use the arrow

keys (< >) to scroll through information provided. Otherwise,

the functions remain the same for both keypad types.

[*][1] Bypassing and Activating Stay/Away Zones

Use the [*][1] keypad command to bypass individual zones. A

bypassed zone will not cause an alarm.

NOTE: Zones can only be b ypass ed whe n th e sys tem is not

armed.

If the Code Required for Bypass option is enabled (section

[015], option [5]), only access codes with the bypass attribute

enabled will be able to bypass zones. (See 5.1

Security Codes”

If the Bypass Status Displayed While Armed option is cho-

sen, the Bypass (or System) light will be ON while the system

is armed to indicate any bypassed zones. (See 5.17

Disarming Options”

on page 15.)

on page 24.)

NOTE: When you disarm the s ystem, all man ually -bypa ssed

zones will be unbypassed.

“Programming

“Arming/

8

Page 13

Keypad Commands: 3.4 [*] Commands

Activate Stay/Away Zones

If the system is armed in stay mode, the [*][1] command can

be used to activate the stay/away zones.

[*][2] Trouble Display

The panel constantly monitors itself for several different trouble conditions. If a trouble condition is present, the Trouble (or

System) light will be on and the keypad will beep twice every

10 seconds. The trouble beep can be silenced by pressing

any key on any keypad. If Bell Squa wk on Trouble is enabled

(section [014], option [5]), the bell will squawk every 10 seconds when a trouble condition is present.

Light Trouble

1

Service Required: Press [1] to determine the specific trouble. Lights 1 - 5 will light up to indicate the trouble:

• Light [1] Low Battery: Main panel backup battery charge is low (below 11.5 volts under load).Trouble is restored

• Light [2] Bell Circuit Trouble: The bell circuit is open (see section 5.13

• Light [3] General System Trouble: The printer connected to the PC5400 Printer module has a fault and is off-line.

• Light [4] General System Tamper: Tamper has been detected in a module.

• Light [5] General System Supervisory: The panel has lost communication with a module connected to the Keybus

NOTE:

NOTE:

2

AC Failure: AC power is no longer being supplied to the control panel. The Trouble (or System) light will flash if an AC

Failure is present, if the Trouble Light Flashes if AC Fails option is programmed (section [016], option [2]). This trouble

will not be displayed if the AC Trouble Displayed option is disabled (section [016], option [1]). See section 5.8

municator – Reporting Codes”

3

Telephone Line Monitoring Trouble (TLM): There is a problem with the telephone line (See section 5.12

phone Line Monitor (TLM)”

4

Failure to Communicate (FTC): The communicator failed to communicate with any of the programmed telephone

numbers (see section 5.5

5

Zone Fault (including Fire Zone): A zone on the system is experiencing trouble, meaning that a zone could not

provide an alarm to the panel if required to do so (e.g. a fire zone is open, or there is a short on a DEOL zone, or a supervisory fault on a wireless zone). When a zone fault trouble condition occurs, the keypad(s) on the system will start to

beep. Press [5] while in Trouble mode to view the affected zones.

NOTE:

6

Zone Tamper: A zone configured for Double End Of Line resistor supervision has a tamper condition, or the tamper

switch is open on a wireless device. When a tamper condition occurs, the keypad(s) will start to beep. Press [6] while in the

Trouble mode to view the affected zones. If a zone is tampered or faulted, it must be fully restored to clear the trouble.

NOTE:

as open on the keypad, and will be hidden from the end user. If the option is disabled, Faults and Tampers will be displayed on the keypad

NOTE:

7

Device Low Battery: A wireless device has a low battery condition. Press [7] one, two, or three times to view which

devices are experiencing battery failure. An LED keypad will indicate battery failure using zone lights 1 to 8. The following will occur:

Press [7] 1 Zones with low batteries (LED keypad - zone lights 1 to 32)

Press [7] again 2 Handheld keypads with low batteries (LED keypad - zone lights 1 to 4)

Press [7] again 3 Wireless keys with low batteries (LED keypad - zone lights 1 to 8)

8

Loss of System Time: When the panel is powered up, the internal clock needs to be set to the correct time. This

trouble is cleared when an attempt is made to reset the clock.

when the battery charges over 12.5 volts.

(see section 2.6

All tamper conditions must be physically restored before the trouble condition will clear.

Lights [6-8] – Not used

“Supervision”

on page 18 for information on AC trouble reporting.

on page 23.)

on page 5). The event buffer will log the event.

“Communicator – Dialing”

A Fire zone trouble will be generated and displayed in the armed state.

By enabling

Once a zone is tampered or faulted, it must be completely restored before the trouble condition will clear.

Tampers/Faults Do Not Show as Open

Keypad beeps: Keypad displays:

To view the battery conditions of wireless keys 9 through 16, you must use an LCD keypad.

To view trouble conditions from an LED keypad:

1. Press [*][2].

2. The keypad will flash the Trouble (or System) light. The

zone indicator lights corresponding to the present trouble

conditions will be ON.

When using an LCD keypad, the trouble conditions will be

listed on the display. Use the arrow (< >) keys to scroll through

the list of present trouble conditions.

NOTE:Troubles can be viewe d while armed using the LCD k e y pad, provided the keypad is version 2.0 or later. Older keypads

will incorrectly display “Fire Trouble”. If using older LCD keypads, progr amming se ction [01 3], opt ion [3] as OF F will ensure

troubles are displayed correctly.

The various troubles are described below:

“Bell”

on page 23).

“Com-

“Tele-

on page 17).

in section [013], option [4], Faults and Tampers will not show

[*][3] Alarm Memory

The Memory (or System) light will be on if any alarm occurred

during the last armed period or – in the case of 24 hour zones

– if an alarm occurred while the panel was disarmed.

To view alarm memory, press [*][3]. The keypad will flash the

Memory (or System) light and the zone indicator lights corresponding to the alarm or tamper conditions which occurred

during or since the last armed period. To clear the Memory (or

System) light, arm and disarm the system.

[*][4] Door Chime On/Off

The door chime feature is used to sound a tone from the keypad whenever a zone programmed as a chime zone is activated. (See 5.3

“Zone Attributes”

on page 16.) If the door

chime feature is enabled, the keypad will emit five short beeps

whenever a chime zone is activated. Designated entry/exit

doors are often defined as chime zones. The feature can be

turned on or off while the system is armed or disarmed.

9

Page 14

[*][5] Programming Access Codes

There are 37 access codes available to the user. They are:

Access code (40)..................... One master code

Access codes (01)-(32)............ 32 general access codes

Access codes (33)-(34)............ Two duress codes

Access codes (41)-(42)............ Two supervisor codes

All access codes have the ability to arm or disarm the system

and can activate the PGM Outputs using the [*][7] commands. Access codes can be either four or six digits (See 5.1

“Programming Security Codes”

For a description of how to program access codes from LCD

or LED keypads, see the PC585 Instruction Manual.

on page 15.)

Master Code – Access Code (40)

This code can be used to program all access codes. The

Master code has all Access Code Attributes enabled by

default, so that the Master code can be used to perform any

keypad function. Master code attributes cannot be changed.

If the Master Code N ot Changeable option is enabled, (sec-

tion [015], option [6]) the Master Code can only be changed

by the Installer.

General Access Codes – Access Codes (01) to (32)

General access codes can arm and disarm the system. When

the Code Required for Bypassing option is enabled, users

will need to enter a valid access code when bypassing zones.

Individual access codes can have the Zone Bypassing

attribute disabled under Access Code Attribute programming.

For more information regarding access code options, please

see 5.1

“Programming Security Codes”

on page 15.

Duress Code – Access Code (33) and (34)

Duress codes will send a duress reporting code to the central

station when entered.

NOTE: If a duress c ode is prog ra mmed, whe n it is use d, the

panel will always send a reporting code to the central station,

even if the attributes of the duress code are turned off.

Supervisor Codes – Access Code (41) and (42)

These codes can be used to program general access and

duress codes. The two supervisor codes have all attributes on

by default. These settings can be changed.

Access Code Attributes

There are three access code attributes which can be programmed for each code.

To program each attribute, enter [*][5][Master Code][9] to

enter the attribute programming mode. Then enter the code

number [01-32,33,34,41,42]. Enter the attribute number:

Attribute [1].......... User enabled for arming, disarming, alarm

reset, [*][7][1-2] options, auto arm cancel-

lation

Attribute [2]..........Not used

Attribute [3]..........Zone bypassing enabled

Attribute [4]-[6].... Not used

Attribute [7]..........Bell squawk on access code entry

Example

have wireless key access codes squawk the bell, while other

codes are silent. To do this, enable attribute [7] on all access

codes associated with wireless keys.

: You can use the arm/disarm bell squawk attribute to

NOTE: If you enable the Bell Squawk on Arming/Disarming

(section [014], option [1]), the bell will sound arm/disarm bell

squawks for all access codes, regardless of the programming

for attribute [7]. See 5.17 “Arming/Disarming Options” on

page 24.

NOTE: Master code attributes cannot be changed.

[*][6] User Functions

This command can be used to program several different functions:

To program User Functions:

1. Press [*][6][Master Code]. The Program (or System) light

will flash.

2. Press the number [1] to [6] for the item to be programmed.

• [1] – Time and Date

The time and date must be accurate for the auto-arm or

test transmission functions to work properly and for the

event buffer to time and date stamp all events.

- Enter the time (hour and minute) using 24hr format [HH

MM] from 00:00 to 23:59.

- Enter the date by month, day and year [MM DD YY].

• [2] – Auto-Arm Enable/Disable

To enable or disable auto-arming, press [2]. The keypad

will sound three short beeps when auto-arm is enabled

and one long beep when disabled. For more information,

see 3.3

• [3] – Auto-Arm Time

The system can be programmed to arm automatically at a

pre-set time. When programming the auto-arm time, enter

the time (hour and minute) using 24hr format [HH MM]. For

more information, see 3.3

• [4] – System Test

When [4] is pressed the panel will test the bell output, keypad lights and the communicator for two seconds. The

panel will also send a System Test Reporting code, if programmed. (See 5.8

page 18.)

• [5] – Enable DLS (Downloading)

When [5] is pressed, the panel will enable the downloading

option for one hour or six hours depending on the option

selected in programming section [702]: [7]. During this

time, the panel will answer incoming downloading calls.

(See 5.10

• [6] – User Initiated Call-Up

When [6] is pressed, the panel will initiate a call to the

downloading computer.

Additional Features Available from the LCD Keypad

Additional features, including access to the event buffer, are

available using the LCD keypad. Use the arrow keys (< >) to

scroll through the [*][6] menu and press the [*] key to select

the following commands:

“Automatic Arming”

“Automatic Arming”

“Communicator – Reporting Codes”

“Downloading”

on page 20.)

on page 8.

on page 8.

on

Viewing the Event Buffer from an LCD Keypad

Select “View Event Buffer” from the [*][6] menu. The keypad

will display the event, event number, time and date along with

the zone number and access code, if applicable. Press [*] to

toggle between this information and the event itself. Use the

arrow keys (<>) to scroll through the events in the buffer.

When you have finished viewing the event buffer, press [#] to

exit.

Brightness Control

You can select from 10 different backlighting levels. Use the

arrow keys (< >) to scroll to the desired backlighting level.

Press [#] to exit.

Contrast Control

You can select from 10 different display contrast levels. Use

the arrow keys (< >) to scroll to the desired contrast level.

Press [#] to exit.

10

Page 15

Keypad Commands: 3.5 Function Keys

Keypad Sounder Control

You can select from 21 different keypad tones. Use the arrow

keys (< >) to scroll to the desired keypad sound level and

press [#] to exit. This feature can be accessed on LED keypads by pressing and holding the [*] key.

[*][7] Command Output Functions

The user can activate programmable output functions using

the [*][7][1-2] commands. The outputs may be activated when

the system is either armed or disarmed.

[*] [7] [1] – Command Output Option #1:

Press [*] [7] [1] [Access Code, if required] to activate outputs

programmed as PGM output option [19]. This output can be

used for operating devices such a garage door opener, lighting or door strikes.

[*][7][2] – Command Output Option #2:

Press [*][7][2][Access Code, if required] to activate all outputs

programmed as one of PGM output options [03] or [20].

Special Note:

resetting smoke detectors. Smoke detectors should now be

programmed as output [03] “Sensor Reset” . If using output

option [03], do not program [20] Command Output Option #2.

Please see 5.11

information.

[*][8] Installer’s Programming

Enter [*][8] followed by the Installer’s Code to access

Installer’s Programming. See sections 4 and 5 for more information.

[*][9] Arming Without Entry Delay

When the system is armed with the [*][9] command, the panel

will cancel the entry delay. Delay 1 and Delay 2 type zones will

be instant and Stay/Away zones will be bypassed as soon as

the exit delay has ended (see section 5.2

ming”

on page 15). The user must enter a valid access code

after pressing [*][9].

[*][0] Quick Arm

If the Quick Arm option is enabled (section [015], option [4]),

enter [*][0] to arm the panel without an access code. (See

5.17

“Arming/Disarming Options”

Arm option is disabled, users will need to enter an access

code after pressing a function key.

Traditionally, [*][7][2] has been reserved for

“PGM Output Options”

on page 21 for more

“Zone Program-

on page 24.) If the Quick

NOTE: Quick Arm cannot be used to cancel auto arm.

[*][0] Quick Exit

The Quick Exit function, if enabled, will allow someone to

leave an armed premises through a Delay type zone without

having to disarm and re-arm the system. (See 5.17

Disarming Options”

When [*][0] is entered, the panel will provide a two minute window for the user to exit the premises. During this time, the

panel will ignore only one activation of a Delay zone. When the

Delay zone is secured, the panel will end the two minute quick

exit delay.

If a second Delay zone is tripped, or if the zone is not restored

after two minutes, the panel will begin entry delay 1.

on page 24.)

“Arming/

NOTE: If the Exit Delay is in progress, performing a Quick Exit

will not extend the Exit Delay.

3.5 Function Keys

There are five function keys on each keypad labelled Stay,

Away, Chime, Reset and Exit. Each of these keys is programmed by default to perform one of the functions described

below. Press and hold the appropriate key for two seconds to

activate a function.

If the Quick Arm option is disabled (section [015], option [4]),

users will need to enter an access code after pressing a function key.

NOTE:On the PC1555RKZ k e y pad, us e nu mber k e ys 1 - 5 for

the function ke y s.

“Stay” – (03) Stay Arm

The system will arm in the Stay mode (see 3.2

Stay Arming”

gramming section [015], option [4]) to have this key function

without the need to enter an access code. If Quick Arm is not

enabled, the user will have to enter an access code before the

system will stay arm.

“Away” – (04) Away Arm

The system will arm in the Away mode (see 3.2

– Stay Arming”

gramming section [015], option [4]) to have this key function

without the need to enter an access code. If Quick Arm is not

enabled, the user will have to enter an access code before the

system will away arm.

When the panel is being Away armed, users can restart the

exit delay once, by pressing the Away button before the exit

delay expires. This will not work if the panel is being Stay

armed.

“Chime” – (06) Door Chime On / Off

The Door Chime feature will turn ON or OFF. (See

Chime On/Off”

“Reset” – (14) Sensor Reset or [*][7][2]

The panel will activate all PGM outputs programmed as option

[03] Sensor Reset or [20] Command Output Option #2. (See

“[*][7] Command Output Functions” .)

“Exit” – (16) Activate Quick Exit

The panel will activate the Quick Exit feature (See

Quick Exit”

Additional Function Key Options

The programming of any function key on any keypad may be

changed to one of the options listed below. (See 2.5

Assignment”

key programming.) Each option is listed according to the programming code, followed by the corresponding [*] key command. For more information regarding each function, please

refer to the appropriate part of Section 3.4, “[*] Commands”.

on page 8). Enable the Quick Arm feature (pro-

on page 8). Enable the Quick Arm feature (pro-

on page 9.)

on page 11.)

on page 4 for instructions on changing function

“Auto Bypass –

“Auto Bypass

“[*][4] Door

“[*][0]

“Keypad

NOTE: The PC5509 function keys cannot be ch anged from the

defaults listed above.

[00] Null Key: The key is not used and will perform no

function when pressed.

[01]-[02] For future use

[03] Stay Arm: As described above.

[04] Away Arm: As described above.

[05] [*][9] No-Entry Delay Arm: A valid access code

must also be entered.

[06] [*][4] Door Chime On / Off: As described above.

[07] [*][6][----][4] System Test: A valid master code must

also be entered.

[08] [*][1] Bypass Mode: A valid access code may need

to be entered.

[09] [*][2] Trouble Display

[10] [*][3] Alarm Memory

11

Page 16

[11] [*][5] Programming Access Codes: A valid master

code must also be entered.

[12] [*][6] User Functions: A valid master code must also

be entered.

[13] [*][7][1] Command Output Option #1: A valid

access code may need to be entered.

[14] [*][7][2] Reset (Command Output Option #2): As

described above.

[15] For future use

[16] [*][0] Quick Exit: As described above.

[17] [*][1] Reactivate Stay/Away Zones

[18] - [20] For future use

3.6 Features Available for the LCD5500Z

These features are only available for LCD5500Z keypads with

zone inputs:

Automatic Scrolling of Alarms in Memory

The LCD5500Z keypad allows automatic scrolling through

alarms in memory while the keypad is idle. This feature, if

enabled, will override the clock display. This option can be

programmed in LCD programming section [66], option [4].

24 Hour Time Display Option

The LCD5500Z can be programmed to display time using a

24- hour clock, instead of a 12-hour, am/pm clock. This option

can be programmed in LCD programming section [66], option

[3].

Keypad Zones

See 2.11

Viewing Troubles While Armed

See

to view troubles.

Backlighting Boost

The LCD5500Z, PC55XXZ and PC1555RKZ zone input keypads will provide extra number pad lighting when any key is

pressed. The backlighting boost will last for an additional 30

seconds after the last keypress.

“Keypad Zones”

“[*][2] Trouble Display”

on page 6.

on page 9 for information on how

12

Page 17

Section 4: How to Program

The following section of the manual describes the Installer’s

Programming function and how to program the various sections.

NOTE: Read the following section of the manual very carefully

before you begin programming. We also recommend filling out

the Programming Worksheets section before you program the

panel.

For your reference, the corresponding programming sections

for the functions listed are highlighted in text boxes such as

this one.

4.1 Installer’s Programming

Installer’s Programming is used to program all communicator

and panel options. The Installer’s Code is [5555] by default

but should be changed to prevent unauthorized access to

programming.

Installer’s Code. . . . . . . . . . . . . . . . . . . . . . . . . Section [006]

From an LED Keypad:

1. Enter [*][8][Installer’s Code].

The Program light (or System light on the PC1555RKZ) will

flash to indicate that you are in programming mode.

The Armed light will turn on to indicate that the panel is

waiting for the three-digit programming section number.

2. Enter the three-digit section number corresponding to the

section you wish to program.

The Armed light will turn off.

The Ready light will turn on to indicate that the panel is

waiting for the information required to complete programming the selected section.

3. Enter the information required to complete section programming (i.e.: numbers, HEX data, or ON/OFF options).

NOTE: If the three-digit section number entered is invalid, or if

the module which pertains to the section is not present, the

keypad will sound a two second error tone.

From an LCD Keypad:

1. From any keypad, enter [*][8][Installer’s Code]. The Keypad will display ‘Enter Section’ followed by three dashes.

2. Enter the three-digit number corresponding to the programming section number you wish to program. The keypad will now display the information required to complete

programming the selected section.

3. Enter the information required to complete section programming (i.e.: numbers, HEX data, or ON/OFF options).

If you enter information into a section and make a mistake,

press the [#] key to exit the section. Select that section again

and re-enter the information correctly.

NOTE: There must be one digit in each box in the programming section in order for the change to be valid.

4.2 Programming Decimal Data

A set number of programming boxes are allotted for each section requiring decimal data (e.g.: codes, telephone numbers).

If a digit is entered for each program box, the panel will automatically exit from the selected programming section. The

Ready light will turn OFF and the Armed light will turn ON.

On the PC1555RKZ and PC5508Z keypads, you can also