Dry-Lam Office Laminators Instruction Manual

DryLam 27" Professional

Series Roll Laminator

Instruction Manual

Dry-Lam School & Office Laminators

27"(120V)

Dry-Lam 652755 - Rev. 3b

11/20/08

Instruction Manual

• Read all the safety and operating instructions before connecting or using this unit.

• Retain this notice and the owner’s manual for future reference.

• Adhere to all warnings and operating instructions.

• Do not use this unit near water (e.g. near a bathtub, etc.)

• The wearing of ties or jewelry while operating a laminator may be hazardous to the operator.

• Warning do not touch Hot Surfaces such as heat shoes and heat rollers.

• Do not install optional slitter kit if Heatshoe is hot.

• This unit should be installed so that its location or position does not interfere with its proper

ventilation. For example, it should not be situated on a bed, sofa, rug or similar surface that may

block the ventilation openings; or placed in a built-in installation, such as bookcase or cabinet or

against the wall, that may impede the flow of air through its ventilation openings.

• This unit should be situated away from heat sources such as radiators, heat registers, stoves, etc.

• This unit should only be connected to a power supply outlet of the voltage, amperage and

Frequency marked on its serial tag.

• For 120 volt machines the socket outlet shall be installed near the equipment and be easily

accessible.

•For 240 volt machines a readily accessible disconnect device shall be incorporated in the building

installation wiring.

• The power supply cord should be routed so that it is not likely to be walked upon or pinched,

especially near the plug, convenience receptacles, or where the cord exits from the unit.

EQUIPMENT W ARRANTY

We warrant to the original purchaser the equipment manufactured by us to be free from defects in material and

workmanship under normal use and service. Our obligation under this warranty shall be limited to the repair or exchange

of any part or parts which may thus prove defective under normal use and service within one year from the date of shipment

and which our examination shall disclose to our satisfaction to be thus defective. When necessary, purchaser shall properly

pack and return the unit to the nearest Dry-Lam Service Center, freight and insurance prepaid. THIS WARRANTY IS

EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED INCLUDING THE WARRANTIES OF THE MERCHANTABILITY AND FITNESS FOR USE AND OF ALL OTHER OBLIGATIONS OR

LIABILITIES ON OUR PART, AND WE NEITHER ASSUME NOR AUTHORIZE ANY OTHER PERSON TO

ASSUME FOR US, ANY OTHER LIABILITY IN CONNECTION WITH THE SALE OF THIS MACHINE OR ANY

PART THEREOF WHICH HAS BEEN SUBJECT TO ACCIDENT, NEGLIGENCE, ALTERATION, ABUSE OR

MISUSE. WE MAKE NO WARRANTY WHATSOEVER IN RESPECT TO ACCESSORIES OR PARTS NOT

SUPPLIED BY US. THE TERM "ORIGINAL PURCHASER" AS USED IN THIS WARRANTY, SHALL BE DEEMED

TO MEAN THE PERSON OR COMPANY WHO FIRST PUTS THE DRY-LAM EQUIPMENT INTO SERVICE. THIS

WARRANTY SHALL APPLY ONLY WITHIN THE BOUNDARIES OF THE CONTINENTAL UNITED STATES.

SERVICE CENTER

• Unplug the machine during any machine repairs.

• Clean unit only as recommended in this instruction manual.

• Make sure to remove the Feed Table before reversing the machine!

• Care should be taken so that objects do not fall, and liquids are not spilled, into the enclosure

through any openings.

• Caution: The Cutter blade is extremely sharp. Please handle carefully and dispose of properly.

NOTE: When pressing the slitters through

the laminating film, try cutting a slot in the

film with a utility knife first.

5) Install feedtable on machine. On the same

side of the feedtable, press both wedges in

between the sidepanel and the feedtable. The

wedges will keep the tray from moving and

keep the alignment of the feed guide and

slitters true. (See Figure 3)

General Specifications:

25" 27"

Height "51"51

Width "43"23

Depth (with feed tray) "02"02

Net weight 120V/240V . 65 lbs./68 lbs. 66 lbs.

Shipping weight .sbl 27.sbl 27

Width of Lamination "72"52

Electrical: (120V) 120V AC, 60 Hz, 120V AC, 60 Hz,1400w

Electrical: (240V)

SaveYour Carton! Dry-Lam ships laminators in special cartons which protect them

from damage. Please store your cartons in case your laminator should ever require

servicing.

Remove the laminator from its box by grasping the housings and pulling up.

Do not use rollers or shafts as handles- this could cause damage.

The power supply cord should be unplugged from the wall outlet when it is

to be unused for a long period of time.

This manual is provided as an Operator’s Manual and covers most situations you

will encounter while using your laminator. It is not a Technical Service manual. For

technical assistance beyond what this manual provides, contact Dry-Lam, at the

Service Center below.

Dry-Lam is a product line of

Dry-Lam

7650 W. 185th. St.

Tinley Park, IL 60477

Phone (708) 614-0211, Fax (708) 614-1266

Important Information

i

21

FIGURE 3

SIDEPANEL

FEEDTABLE WEDGES

FEEDTABLE

Item 25STA(120V) Item 27STA(120V)

10908 Strang Line Road

Lenexa, KS 66215

Phone (888) 633-1973

Notes

Appendix C

Installing the Slitter Kit

A slitter kit ,(item #202005 25" kit),(item # 202000 27" kit) may be obtained from an Authorized Dry-Lam Reseller.

Before installation, please check contents of your kit.

Unplug the laminator prior to installation.

Caution: Do not install kit if Heatshoe is hot!

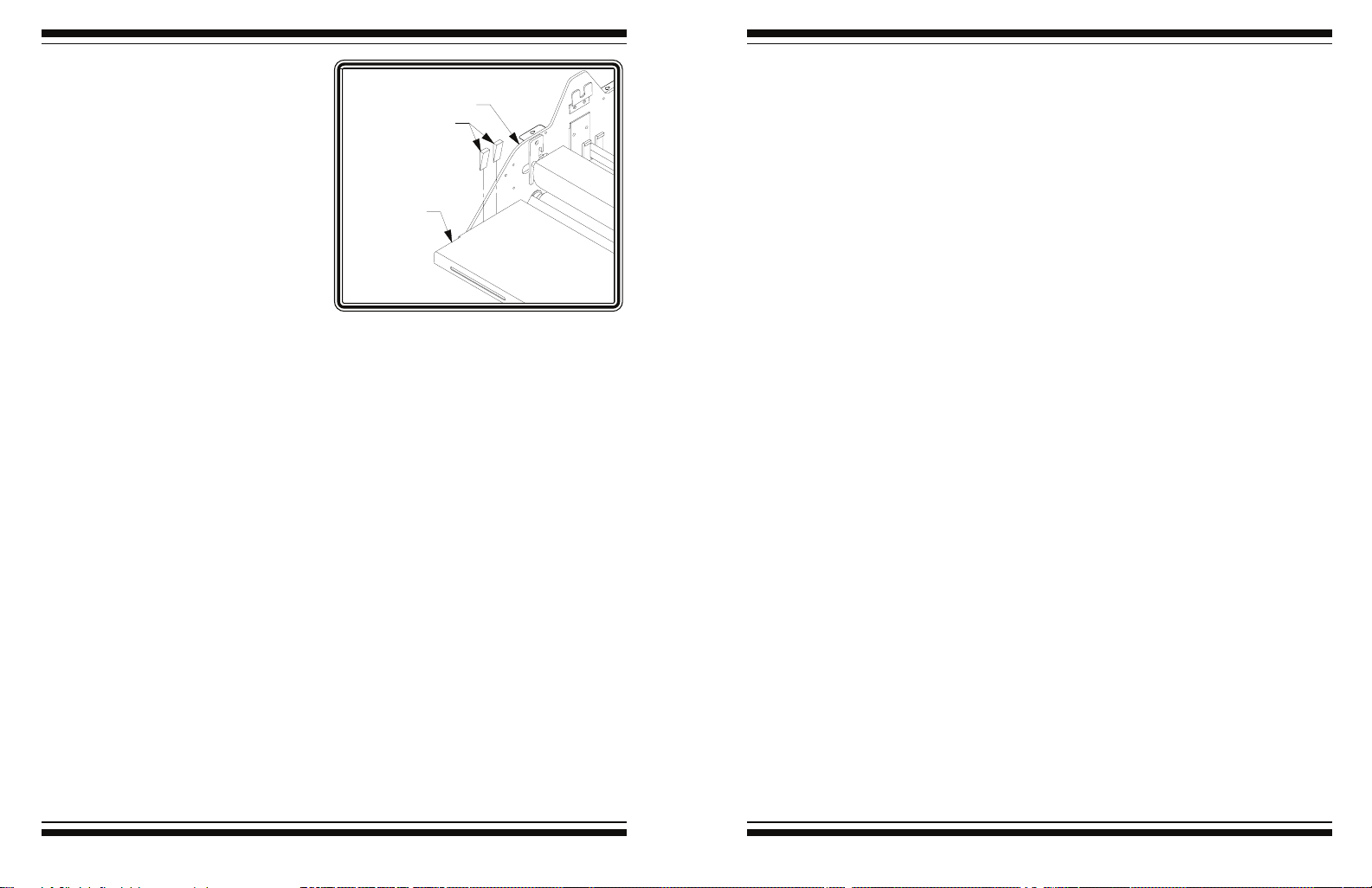

1) Molded on the back of the Mounting

Bracket are two pins. These pins fit into the

rivet heads. (See Figure 1) Hold the Mounting Bracket in place with the pins in the rivet

heads. Mounting bracket holes will be lined

up with the sidepanel holes. Secure with

screws provided. Repeat on other side.

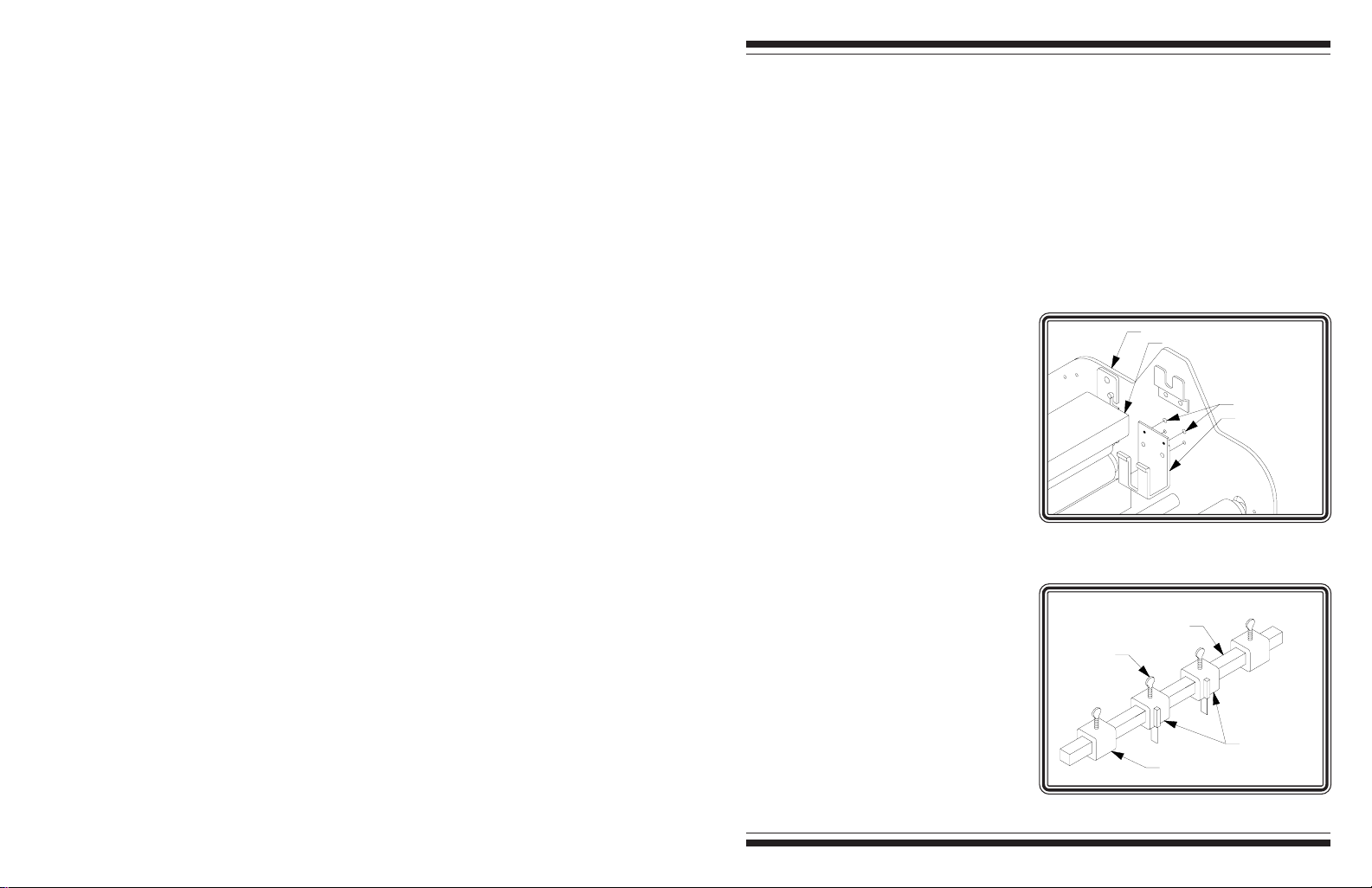

2) Take the thumb screws and screw one

into each of the slitter bar locking blocks and

slitter assemblies. Do not tighten the thumb

screws - only start them at this point.

3) T ake the slitter bar and slide on one locking block, both slitters, and then the other

locking block. Be sure the thumb screws

are all on top, and both slitter edges are facing the front of the laminator. (See Figure

2) Adjust slitters to cut where you wish and

tighten the thumb screws. Remove protective coating from slitter blades.

FIGURE 2

THUMB

SCREW

SIDEPANEL

HEATSHOE

SLITTER BAR

FIGURE 1

RIVET HEADS

MOUNTING

BRACKET

4) Drop slitter into the mounting brackets

and press slitters through laminating film.

Once slitter bar is in place, slide each locking block out until it contacts the mounting

brackets, tighten the thumb screws.

ii 20

LOCKING BLOCK

SLITTERS

Loading...

Loading...