Drylam LPV1200 User Manual

LPV1200/1600 DUO SYSTEM

LPV1200/1600 DUO SYSTEM

Instruction Manual

Ver. 1 1/28/14, 2/28/14, 8/13/14, 11/5/14, 12/4/14, 5/14/15 to add LPV1600, 7/29/15 Brian Jennett

Page 1 of 42

LPV1200/1600 DUO SYSTEM

Contents

1. Specifications ............................................................................................................. 3

2. Applications & Characteristics of the LPV1200/1600 DUO SYSTEM.................... 5

3. Requirements for Use ................................................................................................ 6

4. Safety Requirements .................................................................................................. 7

5. Sketches of the machine ............................................................................................ 9

6. Control Panel ........................................................................................................... 12

7. Removal & Installation of Laminator ...................................................................... 14

8. Preparations Before Starting Up .............................................................................. 23

9. Adjustment of Roller Pressure ................................................................................. 26

10. Film Tension Adjustment ....................................................................................... 27

11. Operation Instructions ............................................................................................ 28

12. Common Solutions To Quality Issues ................................................................... 37

14. Maintenance & Repairs ......................................................................................... 41

15. Service.................................................................................................................... 42

Page 2 of 42

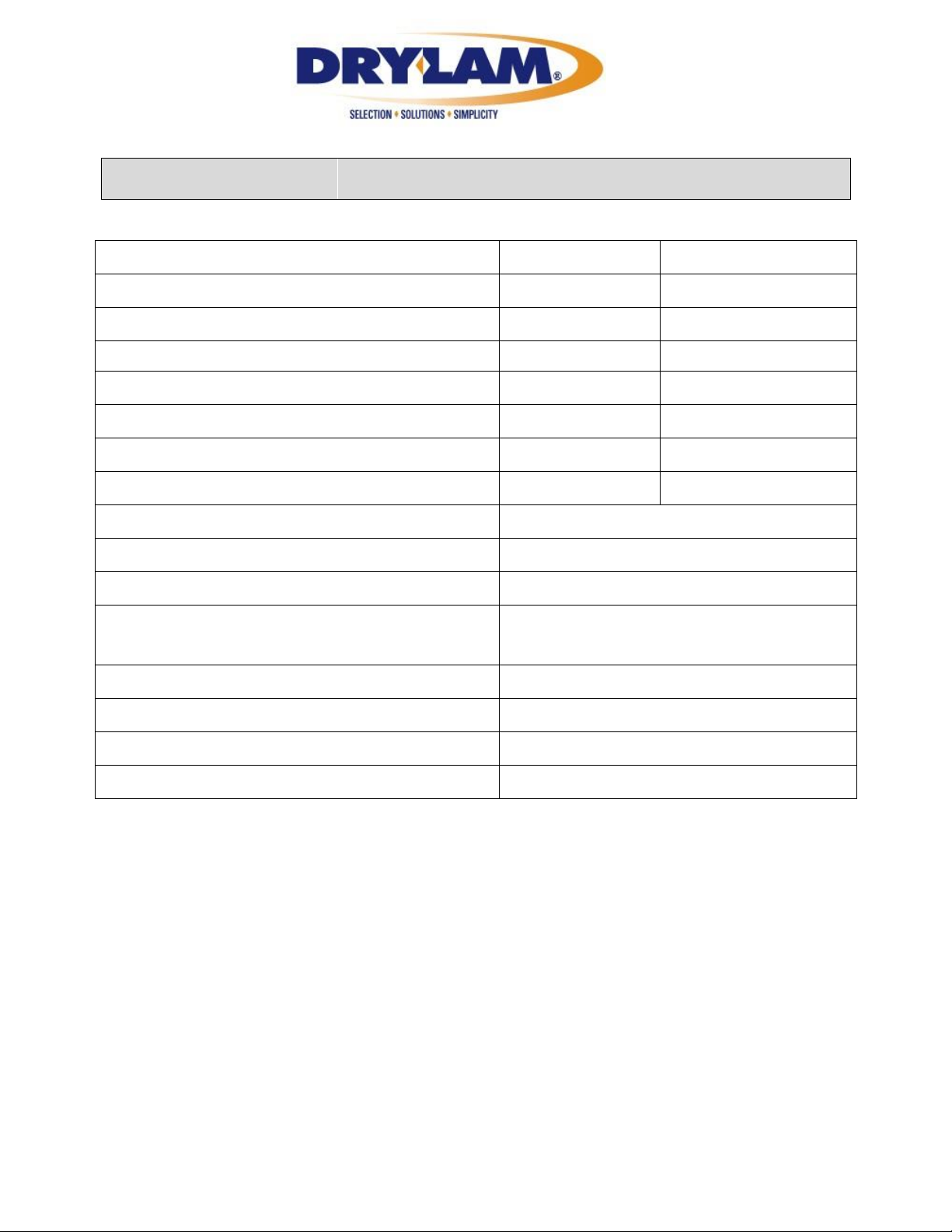

LPV1200/1600 DUO SYSTEM

Type

LPV1200 DUO

LPV1600 DUO

Maximum Laminating Width

47.2”

65”

Maximum Lift of the rollers

1.2”

1”

Maximum rated input power

4250W

6000W

Amperage

17.7A

25A

Carton Dimensions (WxLxH)

75” x 39” x 35”

94” x 39” x 35”

Assembled Laminator Dimensions (WxLxH)

67” x 34” x 50”

85” x 34” x 50”

Net Weight

529 lbs.

704 lbs.

Speed Adjustment Range

0.3 ~ 12.5 ft/min

Temperature Adjustment Range

86°F ~ 266°F

Rated operating voltage and frequency

AC240V 60Hz

Plug

NEMA #6-30 (requires 6-30R

receptacle)

Ambient operating temperature range

50°F to 105°F

Storage and Transportation Temperature

-68°F - 140°F

Ambient operating humidity

40%—70% Perfect humidity: 55%.

Minimum operating space

10’ x 10’

1. Specifications

Warning: Please pay attention to the rated voltages of this machine. Do not

misuse the source voltages.

Please read and understand this manual and the machine’s limitations before

operating!

NOTES:

Record serial number here:

Page 3 of 42

LPV1200/1600 DUO SYSTEM

Dear User,

Thank you for choosing the LPV1200/1600 DUO SYSTEM. This

laminator can give you great performance and long lasting reliability. It

can help you enjoy its various perfect laminating features and achieve

good-quality re-making texts and drawings with simple operations. It can

also bring you a comfortable and high-quality new laminating standard

with satisfying results.

Attention:

To ensure safety to the operator and avoid damage to electric

equipment, be sure to check the reliability of the earth protective

conductor of the power receptacle before operating the machine.

Please retain this operation manual for future reference.

Please pay special attention to paragraphs with warning symbols, which are vital to

the proper use and maintenance of the machine and to the safety of users.

Please comply with the operational warnings in this manual.

Page 4 of 42

LPV1200/1600 DUO SYSTEM

2. Applications & Characteristics of the

LPV1200/1600 DUO SYSTEM

The LPV1200/1600 DUO SYSTEM laminator was designed for lamination of large

scale computer text, drawings and prints. The DUO will perform cold and/or hot

laminating and plastic packaging. “1200” or “1600” refers to the maximum width (in

mm) that this machine is capable of laminating.

This laminator is more applicable for materials of adhesive films and application

requirements during the laminating operation, so that cold and hot adhesive films

could be used for the cold laminating and plastic packaging of large pictures, winding

films for continual mounting of text and drawings while used for continual single and

double surface laminating for text and drawings under high-temperature during the

laminating operations.

This laminator is suited to various industries, particularly printing, color sprayed

drawings, advertisement, manufacturing, etc.

Proper design, simple solid structure, adjustable temperature/speed and nimble

maneuverability make the LPV1200/1600 DUO SYSTEM the perfect machine for

quick and effective mounting, laminating and plastic packaging.

Page 5 of 42

LPV1200/1600 DUO SYSTEM

3. Requirements for Use

This machine should be used in ambient temperatures of 50°F to 105°F. Avoid higher

temperatures and high humidity levels (see specifications, page 3).

Due to static adherence of adhesive films, the production environment should be kept

as clean as possible.

This machine should only be operated on its own stand.

Operating space: enough space should be kept so as to ensure safe and effective

application. The recommended minimum operating space for the machine is 10’ x

10’.

Do not place this machine in direct sunlight.

Do not leave pictures and articles on, or between the rubber-covered rollers for long

periods of time after laminating.

If the machine is to be unused for a long period of time it is recommended to remove

the adhesive film, pictures and articles. Avoid long-term adherence of the adhesive

film to the surface of the rubber-covered roller.

To prevent color change of cold mounting film it is recommended that laminated

prints not be affixed to rubber materials.

It can laminate continuously an object less than 0.47” thick. And for an object over

1/2” but below 1”, the work can be done by using the pedal switch.

Page 6 of 42

LPV1200/1600 DUO SYSTEM

4. Safety Requirements

The power supply wires should be connected with air switches with leakage

protection and the rated current should be 20A or more.

The outlet should be near the machine for convenient use. Do not use extension

cords.

All building wiring and other electrical components should comply with the power

requirements of this machine.

This machine must be grounded to ensure safe use during operation.

No one, except the trained operator of this machine, is allowed to touch any

components or control buttons.

Don’t use damaged wiring and outlets with electric leakage. Wires and cords should

not be squeezed or crushed by any hard objects.

If abnormal circumstances occur, shut off the power supply.

This machine is equipped with a heating system. Do not touch the surface of

rollers during operations so as to avoid burns.

When laminating, start by operating at low speed and by using the pedal switch.

Keep rigid materials away from the surfaces of the rollers during operations,

otherwise the rollers could be damaged which will adversely affect lamination

quality.

During operation, ensure that clothing and hair do not come in contact with

the machine.

During laminating operation don’t place anything except materials to be laminated on

Page 7 of 42

LPV1200/1600 DUO SYSTEM

the machine. Any accidental entanglements will cause damage to rollers or other parts

the machine or the operator.

Do not attempt to laminate metal materials or other hard objects. Do not put

sharp objects into the machine (for example, tools, rulers and knives, etc.).

To avoid damage to rollers do not cut adhesive films directly on the surfaces of the

rollers.

To avoid foot injuries be cautious of the casters.

When service is required no one except professionals shall open the machine for

repairs.

Before repairing any mechanical or electrical problems, first shut off the

power supply. Never adjust or service the machine with the power on. Shut off this

machine after laminating is finished.

Unplug the machine if it is not being used for long periods of time and lift the

upper roller to avoid any distortion of roller’s surface.

Do not use corrosive liquids to clean this machine, otherwise the machine or rollers

could be damaged. Use only alcohol and a soft dry cloth to wipe the surfaces of the

rollers.

Page 8 of 42

LPV1200/1600 DUO SYSTEM

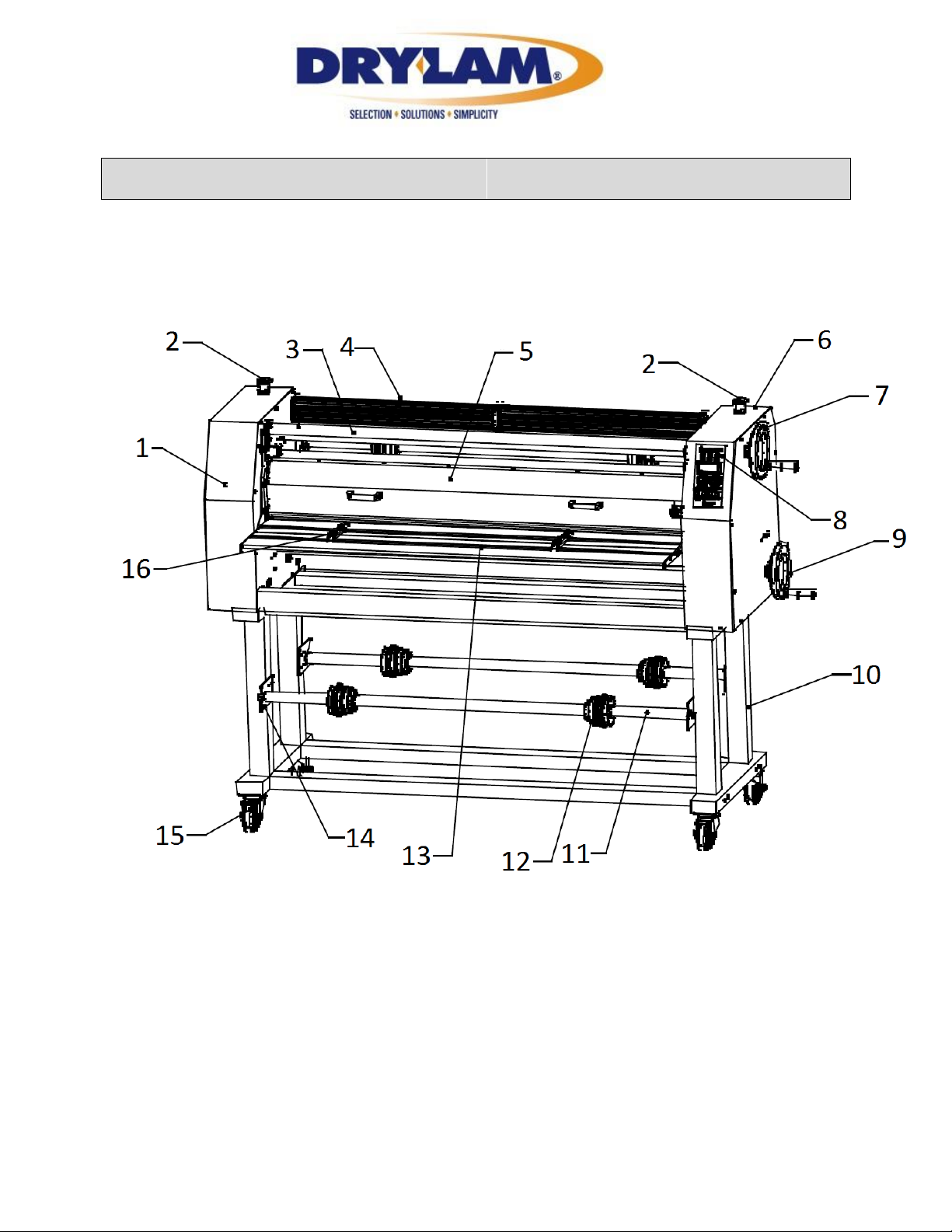

5. Sketches of the machine

Fig 1a FRONT

Page 9 of 42

LPV1200/1600 DUO SYSTEM

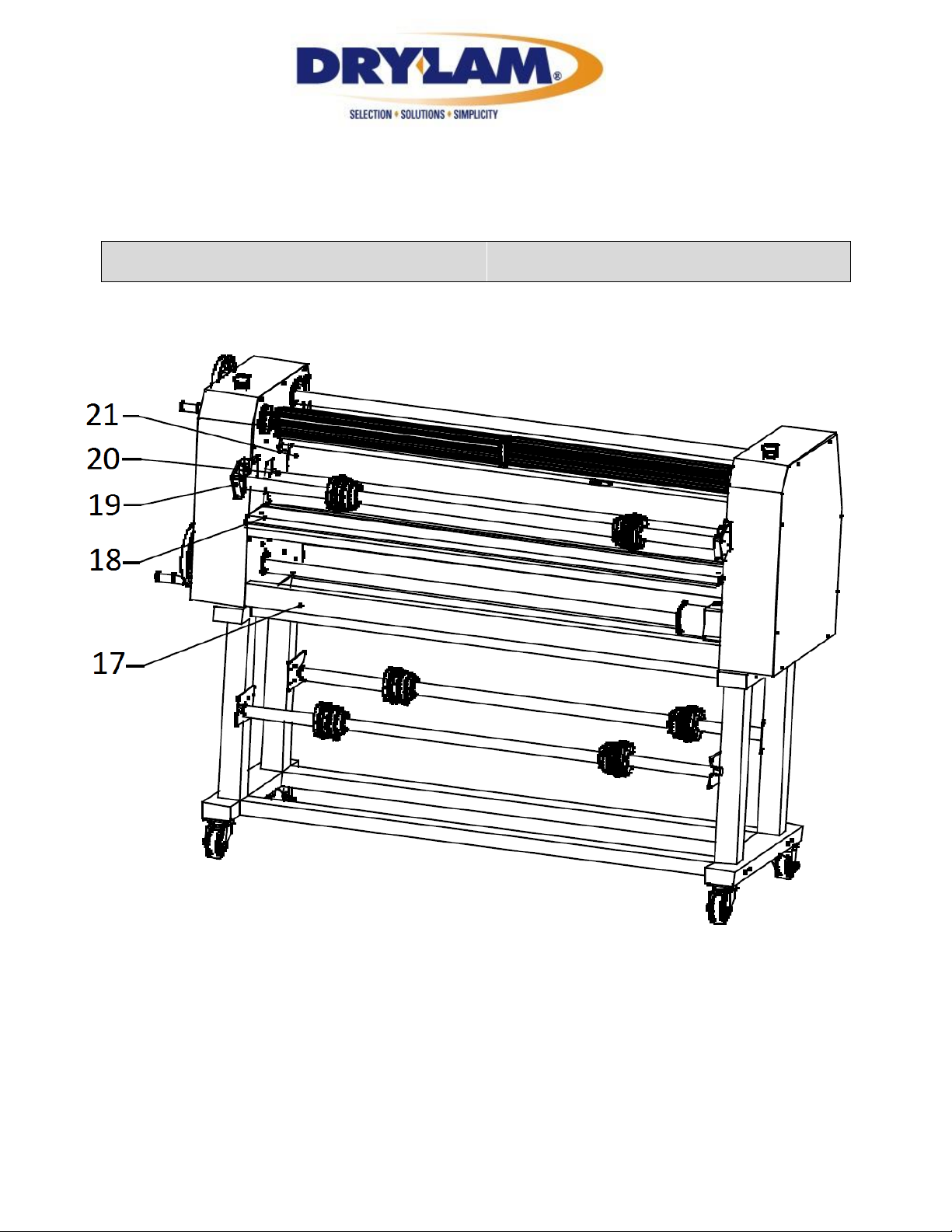

5. Sketches of the machine

Fig 1b REAR

Page 10 of 42

LPV1200/1600 DUO SYSTEM

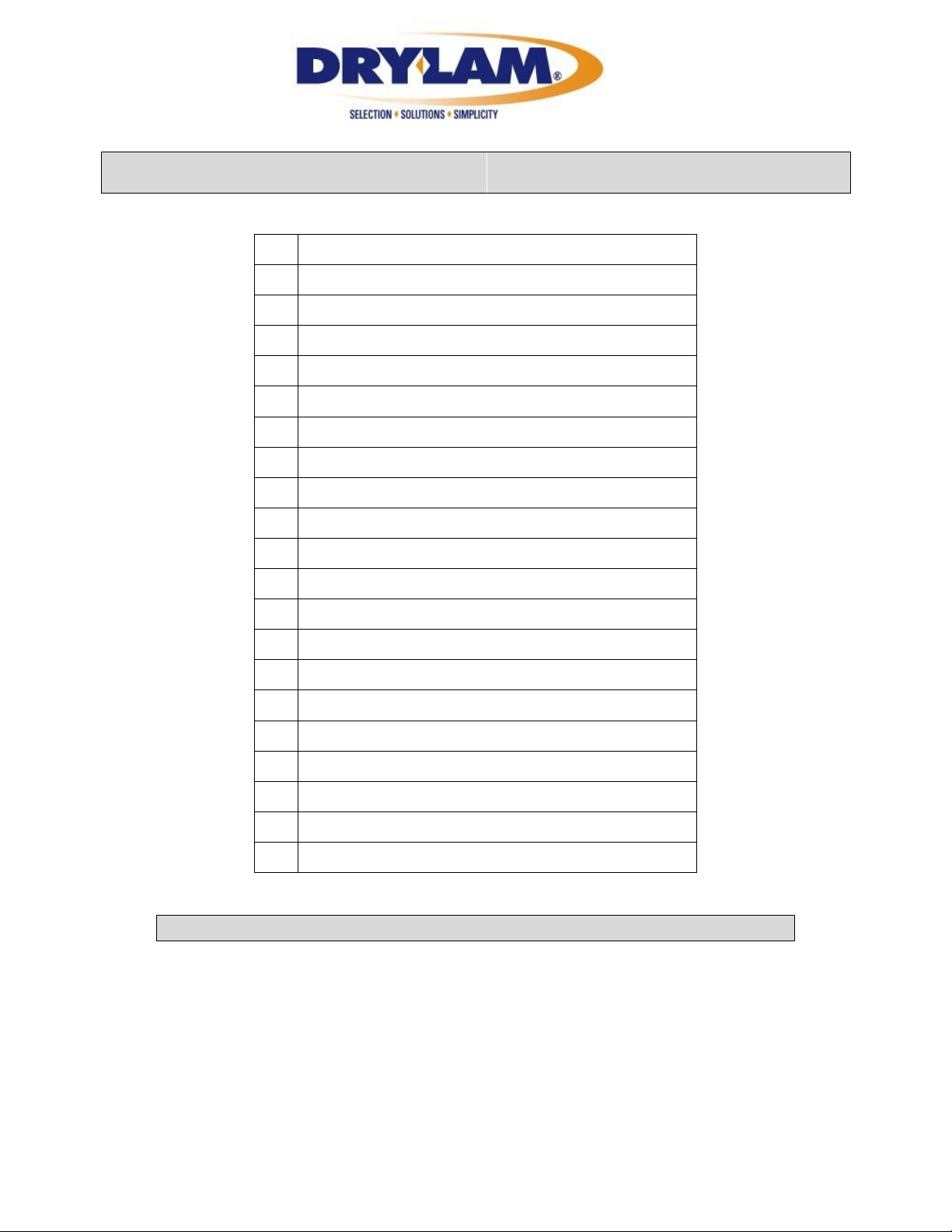

1

Left cabinet

2

Emergency stop switch

3

Linkage shaft for pressure adjustment

4

Backing paper mandrel

5

Front guard shield

6

Right cabinet

7

Pressure adjust hand wheel of front roller

8

Control panel

9

Pressure adjust hand wheel of rear roller

10

Stand

11

Mandrel shaft

12

Sleeve of mandrel

13

Front working panel

14

The lower support plate of feeding roller

15

Castor

16

Positioning plate of front working panel

17

Support beam

18

Rear working panel

19

Brackets of upper mandrel

20

Rear upper roller

21

Front upper roller

5. Sketches of the machine

See the Exploded Views/Parts List for more detail and replacement parts.

Page 11 of 42

LPV1200/1600 DUO SYSTEM

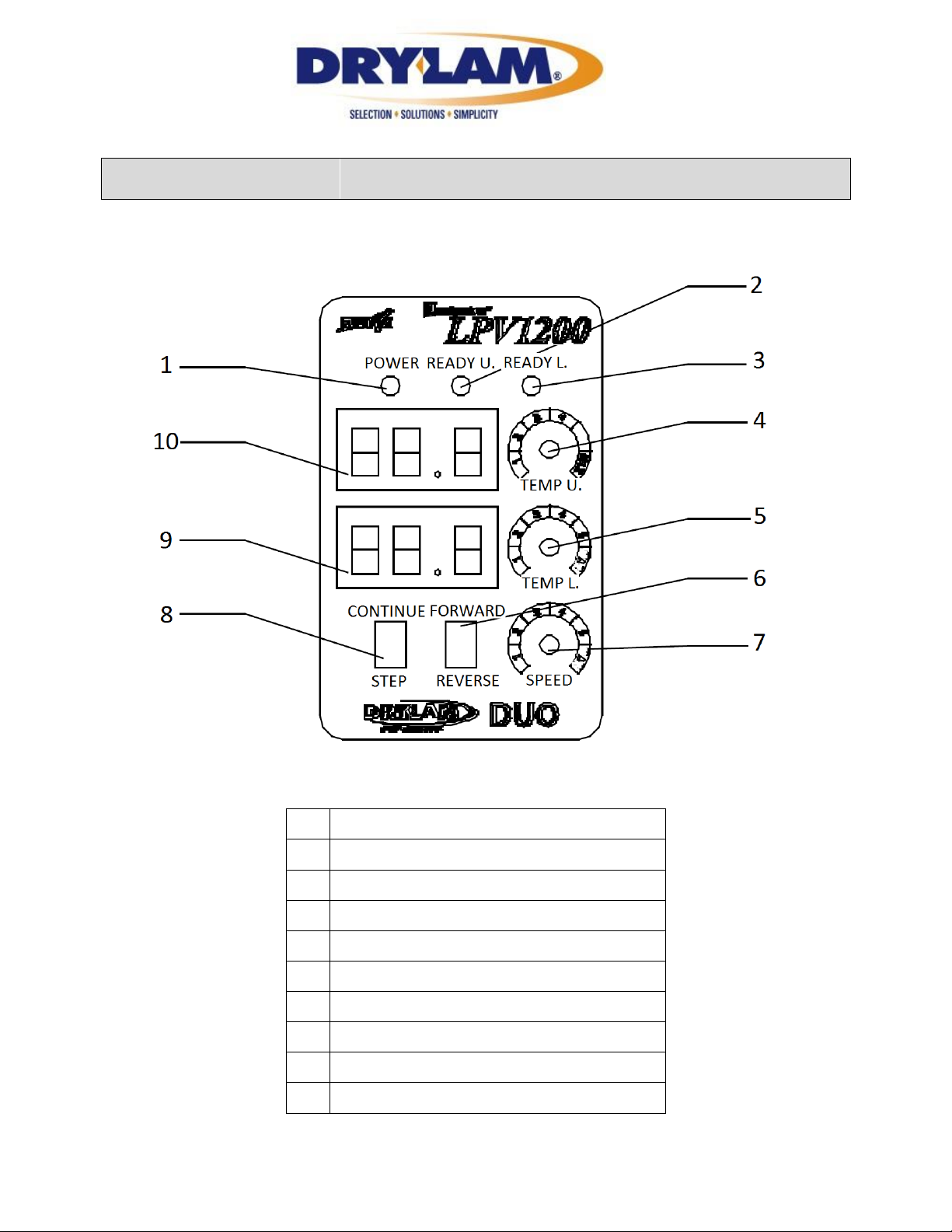

1

Power Indicator

2

Upper Roller Heat Indicator

3

Lower Roller Heat Indicator

4

Temperature adjustment for Upper Roller

5

Temperature adjustment for Lower Roller

6

Motor Direction Switch

7

Speed Control Adjustment

8

Continue/Step Switch

9

Temperature Display For Lower Roller

10

Temperature Display for Upper Roller

6. Control Panel

Fig.2

Page 12 of 42

LPV1200/1600 DUO SYSTEM

6. Control Panel (cont’d)

● The control board and display are located on the right side of the machine. These

functions include motor speed regulating, forward/reverse rotation, upper roller

heating, lower roller heating and continue/step conversion setting.

● The roller temperature controls have switches. When turned counterclockwise

the roller stops heating; when turned clockwise the rollers will heat.

● The two digital display screens show the temperature of the rollers.

● When the machine is connected to power and switched on the power indicator

lights up.

● Upper roller heating indicator and lower roller heating indicator are “Red” during

heating and “Green” when fully heated.

● The speeds of roller rotation can be adjusted with the speed control.

● Roller direction can be exchanged by pressing the Forward / Reverse button.

● The pedal switch can be used with the switch in “STEP” mode.

● Precautions during operations:

EARLY MODELS (S/N beginning with 1308, and lower): When the machine is

stopped by an optical sensor there is a 5 second waiting period for the motor to start

again. Please turn to “STEP” first after 5 seconds and then turn to “Continuous” again

to restore motor operation.

LATER MODELS (S/N beginning with 1408, and higher): These models are not

equipped with an optical sensor. Raising the heat guard stops the motor and shuts off

all power to the laminator.

Page 13 of 42

Loading...

Loading...