Drive.web DW11 User Manual

Operation Manual

drive.web

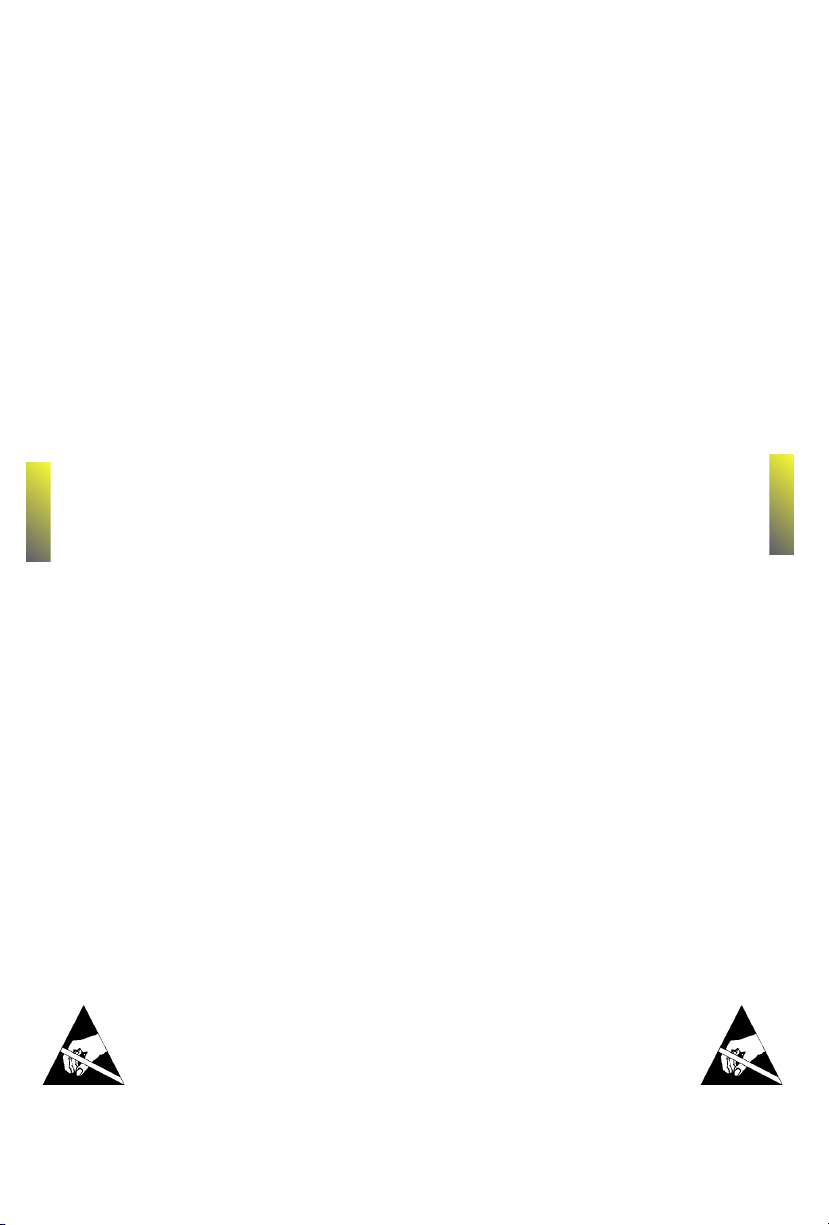

Your speedy sp

Run Mode Ramp

0%

Stopped

41)Crawl Speed

10.00 %

27)Forward Minimum Speed

0.83 %

26)Ramp Input

0.00 %

28)Reverse Minimum Speed

0.00 %

37)Jog Speed 1

5.00 %

38)Jog Speed 2

-5.00 %

39)Slack Speed 1

5.00 %

40)Slack Speed 2

-5.00 %

42)Jog Mode Select

Disabled

C17d)RMR System Reset Pulse Input 29)Ramp Auto Preset

Enabled

30)Ramp External Preset

Disabled

31)Ramp Preset Value

0.00 %

C11s)Run Mode Ramp Demand Output

996)Run Mode Ramps GOTO

65)Ramped Speed Reference 4

21)Ramp Output Monitor

0.83 %

35)Ramping Flag

Low

34)Ramping Threshold

0.50 %

33)Ramp Hold

Disabled

22)Forward Up Time

3.0 secs

23)Forward Down Time

3.0 secs

24)Reverse Up Time

3.0 secs

25)Reverse Down Time

3.0 secs

32)Ramp S-Profile %

2.50 %

43)Jog/Slack Ramp

1.0 secs

56)Stop Ramp Time

6.0 secs

168)Internal Running Mode Monitor

STOP

689)At Jog Flag

Low

714)In Slack Flag

Low

166)Drive Start Flag

Low

dw111 - Installation &

drive.web automation

speedy sp

Contents!! ! ! ! Page

Warnings, speedy sp Features ! ! 1

Options, Winder specials! ! ! 2

speedy sp Installation! ! ! 2-3

Ethernet networking, Get savvy!! 3

Get started with savvy, savvy-SFD 3-6

savvyPanel Operator Touch Station App! 7,8

ModbusTCP, drive.web highlights, training!8

Warning! ! It is essential that you read and understand this entire

manual, the PL Series Product Manual, HG501441, and the entire

contents of the savvy software “Help” menu before proceeding with

your installation and product configuration. For more information and

copies of product manuals and software, go to www.driveweb.com.

Warning!! Your use of savvy software, drive.web devices and PL

Series drives may cause motors and machinery to power up with high

voltages or start or operate in an unexpected, dangerous or lethal way. It

is essential that you are completely familiar with savvy and all of the

equipment and the system design you are working with before attempting

to program or edit a program or connect to any live device.

Warning!! You are entirely responsible for the configuration or use of

any drive.web product. By configuring or using these products you

agree to indemnify and hold harmless Bardac Corporation, its’

employees, directors, officers, distributors and resellers against the

consequences of your configuration or use of the products.

Product Identification speedy sp Model dw111

Intelligence, system connectivity for PL-Series Digital DC drives:

Bardac Corporation, PL series DC drives

Eurotherm, ERCPL series DC drives

Sprint Electric Ltd., PL series DC drives.

drive.web Distributed Process Control over Ethernet

savvyPanel Operator Touch Station, option 26. See page 7.

ModbusTCP/IP over Ethernet with option 04. See page 8.

ModbusRTU for Serial Networks. Option 02, 12 Server, Client. Pg.2.

Easy upgrades with savvy software. See page 6.

System libraries; Basic and Optional; Process, Winder and Math.

and monitoring, Math, logic, PID, comparator, filter, latch, timer, counter,

ramps, winder diameter, taper tension, torque compensator, more.

speedy sp HG502277Iss4.0! www.driveweb.com ! Page 1/8

Function Blocks; Extensive PL-Series DC Drive parameter control

drive.web automation

!

!

speedy-sp Options

Add software Options 04, 05, 06, 10 and 26 with savvy. See Upgrading, page 6.

See savvy User Manual, Appendix A for current list of available function blocks.

02* ModbusRTU slave. 250V isolated EIA485(RS485), up to 19.2 kbps

04 ModbusTCP/IP. Ethernet, 10baseT enabled Modbus slave/server. See page 6.

05 Process Control. Function Block Library 1 - arithmetic, logic, PID, switches,

comparators, user log, profiler, latches, filters, counters, timers, more.

06 Winder Control Function Block Library 2 - Diameter Calculator, Taper

Tension, Torque Compensator.

10 Math Function Block Library 3 - trig, polynomials, log, exponent, more.

12* ModbusRTU Master. 250V isolated EIA485/RS485 serial, up to 115kbps

26 savvyPanel Operator Touch Station. See page x

*

ModbusRTU Options 02 and 12 are mutually exclusive. It is essential that you

read and understand the entire drive.web Modbus Installation and Operation

Manual, HG502421, included with these options before installing them.

speedy sp Winder Specials

Include options 05 and 06, generic engineered solution and a wiring diagram.

dw111-1101 speedy sp winder 1 Open Loop Constant Tension Center Winder.

dw111-1102 speedy sp winder 2 Closed Loop Dancer Control Center Winder.

dw111-1103 speedy sp winder 3 Closed Loop Loadcell Control Center Winder.

speedy sp Installation

Dimensions and Weight: 7.8”w, 4.0”h, 1.5”d (198, 101, 38mm) 0.5 lb (0.2 Kg)

Power Requirements: 5VDC, 50mA supplied from the PL-series drive.

Storage and Operation Environment: Temperature range; 0 to 50˚C.

Humidity less than 95% non-condensing.

Ethernet Port “RJ45” 8P8C, 10BaseT. LEDs; green, link and yellow, activity.

Warning!

Components on your speedy sp and PL-series printed

circuit boards are ESD Static Sensitive!

Do NOT proceed with installation, nor remove your

speedy sp from its ESD-safe packaging without

grounding yourself and your work area with static

control equipment.

speedy sp HG502277Iss4.0! www.driveweb.com ! Page 2/8

drive.web automation

speedy sp Installation continued...

Warning!

Risk of electric shock resulting in injury or death!

Your PL-series drive is powered from more than one

source of high voltage electricity. Remove and isolate all

sources of electric power before proceeding.

Only qualified personnel should proceed with installation!

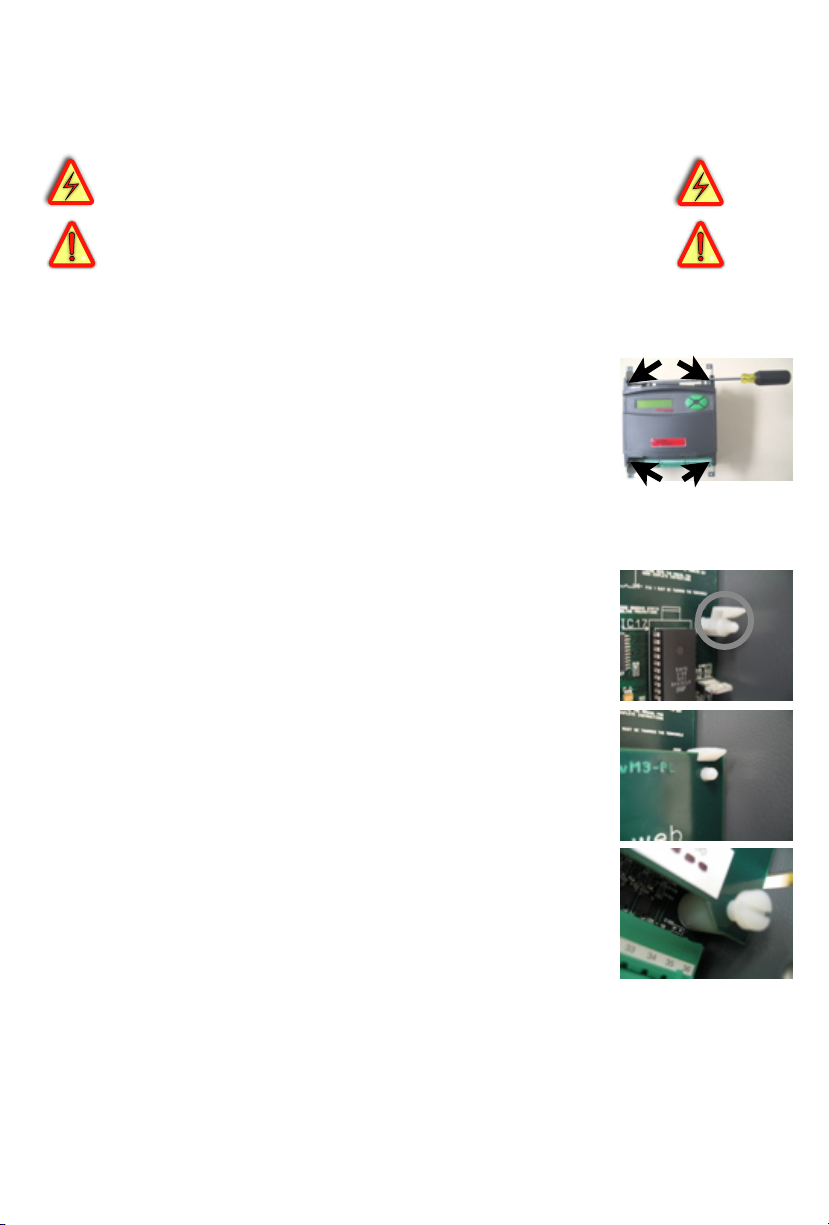

1.Ensure all sources of electricity are removed and safely isolated.

2.Loosen the thumb screws and remove the upper and lower

terminal covers.

3.Locate and remove the four Philips head screws that hold the

drive cover and display assembly in place. You will need a long #2

Philips head screwdriver to remove these.

4.Gently lift the cover and display assembly and rotate it upwards

and away from the drive. Support the assembly above the drive

so that you do not strain the two ribbon cables.

5.Remove the two nylon screws that hold the PL-series control

circuit board in place at its’ bottom corners. You will be replacing

these two nylon screws with the longer nylon screws and spacers

provided with your speedy sp.

6.Ensure that you are grounded with ESD control equipment.

Remove your speedy sp from its’ static-safe bag and carefully

locate it’s parallel interface plug over the corresponding socket on

the PL-series control board. Snap-clips should align with the holes

in the top corners of your speedy sp.

7.Gently push down, inserting the plug into the socket and allowing

the clips to engage the top edge of the speedy sp circuit board.

Use two hands and apply pressure above the socket and at the snap

clips to avoid flexing the circuit board.

8.Now locate the provided nylon spacers between the PL-series

control board and the speedy sp board at the bottom corners.

Insert and tighten the two provided longer nylon screws.

9.Replace the PL series cover and display assembly and reinstall

the four mounting screws.

10.Reconnect the power sources to your PL-series drive.

11.Replace the PL terminal covers and tighten the thumb screws.

12.The speedy sp installation procedure is complete.

speedy sp HG502277Iss4.0! www.driveweb.com ! Page 3/8

Loading...

Loading...