Drill Doctor 400 User Manual

2. SHARPEN BITS

1. ALIGN BITS

JOURNEYMAN 400

User’s Guide

Guía del usuario

Mode d’emploi

3. SPLIT POINTS

Thank you...

for buying your Drill Doctor® 400. It will become a valuable tool

because you will now have sharp drill bits before a project,

during a project, and after a project.

I am very proud of the quality of our products and I am equally

proud of the great people at Drill Doctor who design and produce

them. If you have questions or need help with your Drill Doctor,

please call 1-800-597-6170 and one of our customer

representatives will be there to help. We support what we build!

Use this User’s Guide to learn to operate your Drill Doctor. I also

want to invite you to visit our website at www.DrillDoctor.com.

There you will find:

• Demonstrations of all operations with the sights and sounds

leading to successful drill bit sharpening

• Downloadable copies of the User’s Guide

• Warranty registration

• Service and contact numbers

Again, thank you for buying a Drill Doctor. Now enjoy its

convenience and quality.

Hank O’Dougherty, President, Drill Doctor

®

Contents

English

Safety .......................................................................... 2

Getting to Know Your Drill Doctor®............................ 3

Identifying Basic Drill Bits ........................................... 4

Anatomy of a Drill Bit ................................................. 4

The Drill Doctor® Sharpening Process ......................... 5

Aligning the Drill Bit ................................................... 5

Grit Tube Attachment .................................................. 7

Sharpening the Drill Bit .............................................. 8

Identifying Correctly Sharpened Drill Bits ...................9

Split Points ............................................................... 10

Creating or Replacing a Split Point .......................... 10

Identifying Correctly Split Bits ................................. 11

Sharpening Bits of Different Lengths

and Diameters ....................................................... 12

Aligning and Sharpening Masonry Drill Bits ............ 13

Questions and Answers ........................................... 14

English

Drill Doctor® Maintenance ....................................... 18

Accessories and User-Replaceable Parts .................. 20

Warranty .................................................................. 21

Español ........................................................... 22

Français .......................................................... 45

www.DrillDoctor.com

1

Safety

• Carefully read this User’s Guide before operating the Drill

Doctor.

• When using electric tools, basic safety precautions should

always be followed to prevent the risk of fire, electric shock

and personal injury.

• Always disconnect the Drill Doctor when cleaning or

inspecting. Make sure the switch is in the OFF position before

plugging in the power cord.

• Do not use in wet or damp locations.

• Do not abuse the cord.

• Wear eye protection when using or cleaning the Drill Doctor.

• Never touch internal parts of the sharpener when it is turned

on or plugged in. The rotating diamond wheel can cause injury.

• As with any power tool, the Drill Doctor should be kept out

of the reach of children.

WARNING: Some dust created by power sanding,

grinding, miscellaneous construction activities, as well

as contents from the machine including the molding,

wiring, grinding wheel, or any other parts may contain

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm and can

be hazardous to your health.

2

www.DrillDoctor.com

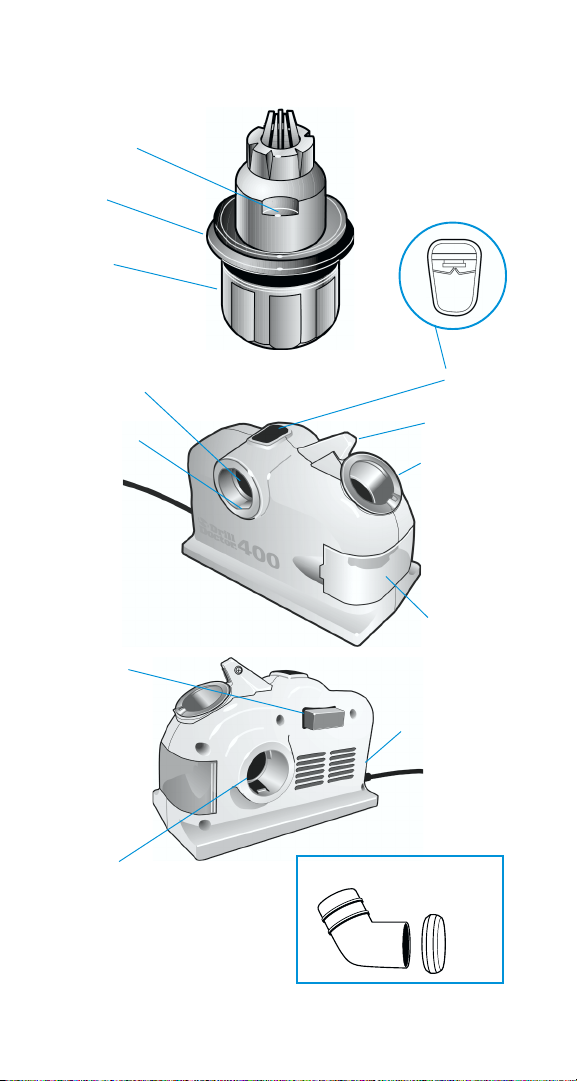

Getting to Know Your Drill Doctor

®

Flat Spot

Cam

Chuck

Knob

Alignment

Hole

Flat Spot

Alignment

Button

Chuck

Window

Cam Guide

Sharpening

Hole

Wheel Access

Cover

Power Switch

(at cord end)

Split

Point

Hole

www.DrillDoctor.com

Grit Tube and Cap

3

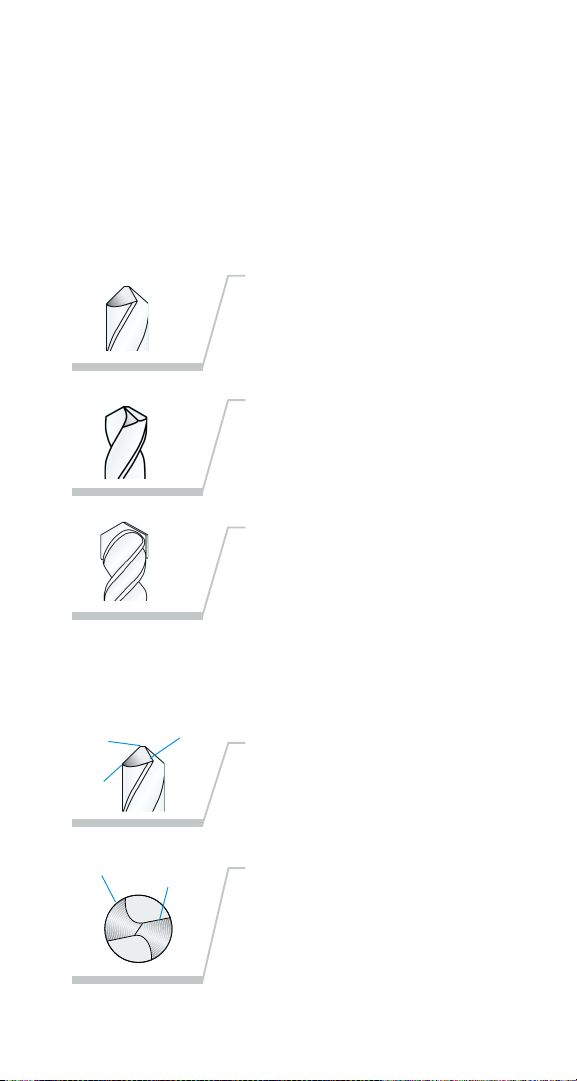

Identifying Basic Drill Bits

The Drill Doctor® is most efficient when used to resharpen a

drill bit’s original point angle. With its standard diamond grinding wheel it will sharpen high-speed steel, cobalt, TiN-coated,

carbide and masonry drill bits.

It has been designed and engineered to sharpen three of the

most common drill bit types:

Standard Point

This general purpose point is used for

drilling softer materials like cold

rolled steel, aluminum, and wood.

Split point bits are self-centering

and are generally used for tempered

steels, hard alloys or hard cast

materials.

Masonry bits have a carbide insert

at the point and are used for drilling

materials like cement, brick, and

ceramic.

Anatomy of a Drill Bit

Chisel

Edge

Heel

Heel

Cutting

Edge

Cutting

Edge

It is important to understand that

each bit has a Chisel Edge, a Cutting

Edge, and a Heel.

When viewing a well sharpened bit

from the end, the entire surface from

the Cutting Edge to the Heel will have

a finely ground surface without ridges

or indentations. And, the Heel will

always be lower than the Cutting Edge.

4

www.DrillDoctor.com

The Drill Doctor® Sharpening Process

The sharpening process includes 3 easy procedures:

1. Align the bit in the Chuck.

2. Sharpen the bit.

3. Split the point (if you choose).

Be sure to complete all three of the procedures to sharpen

and split a bit and always sharpen the bit prior to splitting it.

Aligning the Drill Bit

(See page 13 to align and sharpen a Masonry drill bit.)

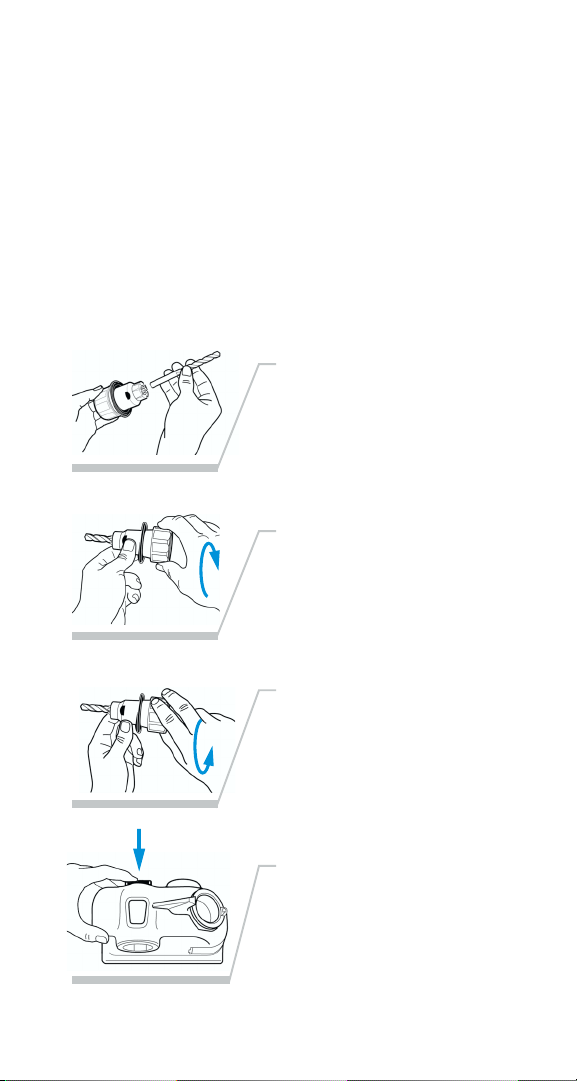

1.

2.

3.

4.

Turn the Chuck Knob to the left

to open the Chuck and Insert

your drill bit into the Chuck

(about halfway in is fine for

now).

Turn the Chuck Knob to the right

to tighten.

Turn the Chuck Knob to the left

just until the bit will slide and

rotate in the Chuck.

With one hand, press in and

hold the Alignment Button on

the Drill Doctor (do not release

until Step 7).

www.DrillDoctor.com

5

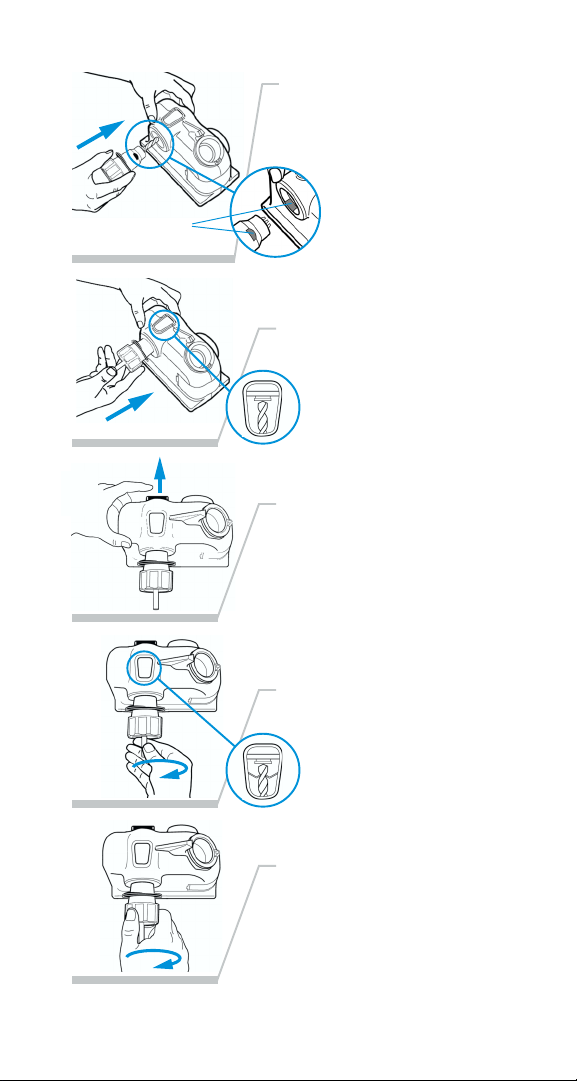

5.

6.

7.

8.

Flat Spots

With your free hand, insert the

Chuck into the Alignment Hole—

make sure the flat spots on the

Chuck match the flat spots in

the hole.

At this point, the Chuck

should be inserted into the

Alignment Hole with the

flat spots hidden, and the

Chuck should be locked in the hole.

With the Alignment Button held

in, push the drill bit forward until

it is against the Drill Stop.

Look at the drill bit through

the Window over the

Alignment Hole—it should be

against the Drill Stop.

Release the Alignment Button.

While looking in the Window,

turn the drill bit to the right until

you feel the Bit Clamps grip

the bit at its narrowest

point (the bit is now difficult

to turn either way).

9.

6

Turn the Chuck Knob to the right

until it is tight but make sure that

the bit did not turn or the Chuck

did not back out of the Hole.

www.DrillDoctor.com

Loading...

Loading...