DRESSTA 515C, 520C Operator's Manual

OM515C520C99/1E

OPERATOR`S MANUAL

515C - 520C

SERIAL NUMBER 7001

AND UP

9001 AND UP FOR 515CH

SERIAL NUMBER 11001

AND UP

13001 AND UP FOR 520CH

DRESSTA Co. Ltd.

A JOINT VENTURE OF KOMATSU AMERICA INTERNATIONAL CO. AND HUTA STALOWA WOLA S.A.

FOREWORD

Welcome to the growing group of value-conscious people who operate DRESSTA machines

This manual covers the instructions for safe operation, lubrications, adjustments and maintenance

for normal daily care. These instructions are divided into six sections to simplify your reference to

the information most important to you. Refer to the contents page at the beginning of the section for

a complete list of the subjects covered except for Section 2, which should be read entirely.

This manual has been prepared to help you operate and maintain your machine with utmost

efficiency and safety. Read this manual thoroughly and learn your machine before you attempt to

operate it.

It is our policy to improve our products whenever it is possible and practical to do so. We reserve

the right to make changes or add improvements at any time without incurring any obligation to

install such changes on products sold previously.

Due to this continuous program of research and development, periodic revisions may be made to

this publication. It is recommended that customers contact their distributor for information on the

latest revision.

We hope you will be able to use our machines safety and to the best advantage.

DRESSTA Co. Ltd.

This material is proprietary to DRESSTA Co. Ltd. and is not to be reproduced, used or disclosed

except in accordance with written authorization from DRESSTA Co. Ltd.

DRESSTA OM515C520C99/1E

OM515C520C99/1E DRESSTA

SECTION INDEX

Section 1 Introduction.......................................................................................................................1.1

Section 2 Safety Precautions...........................................................................................................2.1

Section 3 Storage and Shipping.......................................................................................................3.1

Section 4 Operating..........................................................................................................................4.1

Section 5 Maintenance.....................................................................................................................5.1

Section 6 Specifications...................................................................................................................6.1

DRESSTA OM515C520C99/1E

SECTION CONTENTS

SECTION 1 - INTRODUCTION

This section discusses the use of this manual and serial number locations.

SECTION 2 - SAFETY PRECAUTIONS

This section lists safety rules concerning personal safety. Read this section carefully and observe

safety precautions specified herein.

SECTION 3 - STORAGE AND SHIPPING

This section discusses how to ship or store this machine.

SECTION 4 - OPERATING

The front portion of this section provides you with instructions for trouble free operation of the

machine. A universal symbol chart for instruments and controls designation is provided. The

instruments and controls area is designed to tell you "where it is, what it does and how to use it".

Read this area carefully. The remaining portion of this section outlines and illustrates the step-bystep procedures for starting, operating and stopping the machine and discusses a few operating

suggestions and techniques and simple ideas to help ease the work and lengthen the useful life of

your machine.

SECTION 5 - MAINTENANCE

The beginning of this section outlines a complete scheduled maintenance program, which helps to

reduce down-time and expense, and increase the profit and work from your machine. Read and

use this area. Following the maintenance program are the lubrication recommendations and

requirements for the machine. The remainder of the section is devoted to clearly explaining the

"how to" of the many maintenance and adjustment procedures listed in the maintenance program.

SECTION 6 - SPECIFICATIONS

This section covers the general dimensions schematics, forces and weights, refill capacities,

ground speeds and the standard and special torque values.

DRESSTA OM515C520C99/1E

SECTION CONTENTS

1. INTRODUCTION

1.1. Introduction ............................................................................................................................. 3

1.2. Serial Numbers ....................................................................................................................... 5

2. SAFETY PRECAUTIONS

2.1. General ................................................................................................................................... 3

2.2. Before Starting the Engine ...................................................................................................... 4

2.3. Operating the Machine ............................................................................................................ 4

2.4. General Maintenance Precautions ......................................................................................... 6

2.5. When Parking ....................................................................................................................... 10

2.6. Safety Graphics Location ..................................................................................................... 11

3. MACHINE TRANSPORT AND STORAGE

3.1. Machine Transport ...................................................................................................................3

3.2. Lifting on Slings ........................................................................................................................5

3.3. Moving a Disabled Machine .....................................................................................................6

3.4. Machine Storage ......................................................................................................................7

4. OPERATING

4.1. General ................................................................................................................................... 3

4.2. Universal Symbols for Instruments and Controls ................................................................... 4

4.3. Instruments and Controls ....................................................................................................... 8

4.4. Cab Door and Windows ....................................................................................................... 20

4.5. Operator’s Seat .................................................................................................................... 21

4.6. Seat Belt ............................................................................................................................... 24

4.7. Cab Heating and Ventilation .................................................................................................. 25

4.8. Air Cleaner Service Indicator .................................................................................................27

4.9. Electrical Master Switch ....................................................................................................... 27

4.10. Dome Lights with Switches .................................................................................................. 28

4.11. Starting and Stopping the Engine ......................................................................................... 28

4.12. Driving the Machine .............................................................................................................. 30

4.13. Shifting Gears ....................................................................................................................... 32

4.14. Steering ................................................................................................................................. 32

4.15. Stopping the Machine ........................................................................................................... 33

4.16. Parking the Machine ............................................................................................................. 34

4.17. Loader Operations ................................................................................................................ 34

4.18. Loader Techniques ............................................................................................................... 41

4.19. Economical Operation of the Machine ................................................................................. 54

4.20. Quickcoupling ........................................................................................................................54

4.21. Ride Stabilizing Mechanism ..................................................................................................56

4.22. High-Dump Bucket ............................................................................................................... 57

DRESSTA OM515C520C99/1E

5. MAINTENANCE

5.1. General Precautions ............................................................................................................... 3

5.2. Scheduled Maintenance Guide ............................................................................................... 4

5.3. Maintenance and Service Chart .............................................................................................. 6

5.4. Lubrication ............................................................................................................................... 9

5.5. Seasonal Preparations .......................................................................................................... 14

5.6. Air Cleaning System .............................................................................................................. 15

5.7. Brakes ................................................................................................................................... 19

5.8. Cooling System ..................................................................................................................... 22

5.9. Drive Axles ............................................................................................................................ 27

5.10. Electrical System .................................................................................................................. 29

5.11. Engine ................................................................................................................................... 31

5.12. Ether Injector ......................................................................................................................... 37

5.13. Fuel System .......................................................................................................................... 38

5.14. Hydraulic System .................................................................................................................. 42

5.15. Seat Belt ................................................................................................................................ 47

5.16. Steering Gear ........................................................................................................................ 47

5.17. Tires and Rims ...................................................................................................................... 47

5.18. Transmission System ........................................................................................................... 48

5.19. ROPS Cab and ROPS Canopy .............................................................................................53

5.20. Hood Assembly and Radiator Grill ........................................................................................ 54

5.21. Loader Equipment ................................................................................................................. 55

5.22. Air Conditioner or Heater ....................................................................................................... 56

6. SPECIFICATIONS

6.1. Application ............................................................................................................................... 3

6.2. Technical Description ............................................................................................................. 3

6.3. Schematic of 515C and 520C Wheel Loader Drive Train ...................................................... 4

6.4. Schematic of Transmission Hydraulic System ...................................................................... 5

6.5. Loader Equipment and Steering Hydraulic System Schematic ............................................. 6

6.6. Wiring Diagram...................................................................................................................... 14

6.7. Brake Hydraulic System Schematic...................................................................................... 25

6.8. Specifications ........................................................................................................................ 26

6.9. 515C and 520C Loader Equipment ...................................................................................... 32

6.10. Torque Values for Standard Metric Fasteners ...................................................................... 35

6.11. Torque Values for Standard English Fasteners .................................................................... 35

6.12. Torque Values for Split Flange Connections ........................................................................ 36

6.13. Torque Values for Hydraulic Tubes and Fittings ................................................................... 37

6.14. Torque Values for Hose Clamps ........................................................................................... 37

6.15. Torque Values for Air Conditioning Tubes and Fittings ......................................................... 38

6.16. Torque Values for Air Conditioning O-Ring Connections ..................................................... 38

6.17. Special Torques .................................................................................................................... 39

6.18. Service Tools ........................................................................................................................ 40

OM515C520C99/1E DRESSTA

SECTION 1

INTRODUCTION

INTRODUCTION SECTION 1

SECTION CONTENTS

1.1. Introduction ............................................................................................................................. 3

1.2. Serial Numbers ....................................................................................................................... 5

DRESSTA OM515C520C99/1E

INTRODUCTION SECTION 1

Page 3

1.1. INTRODUCTION

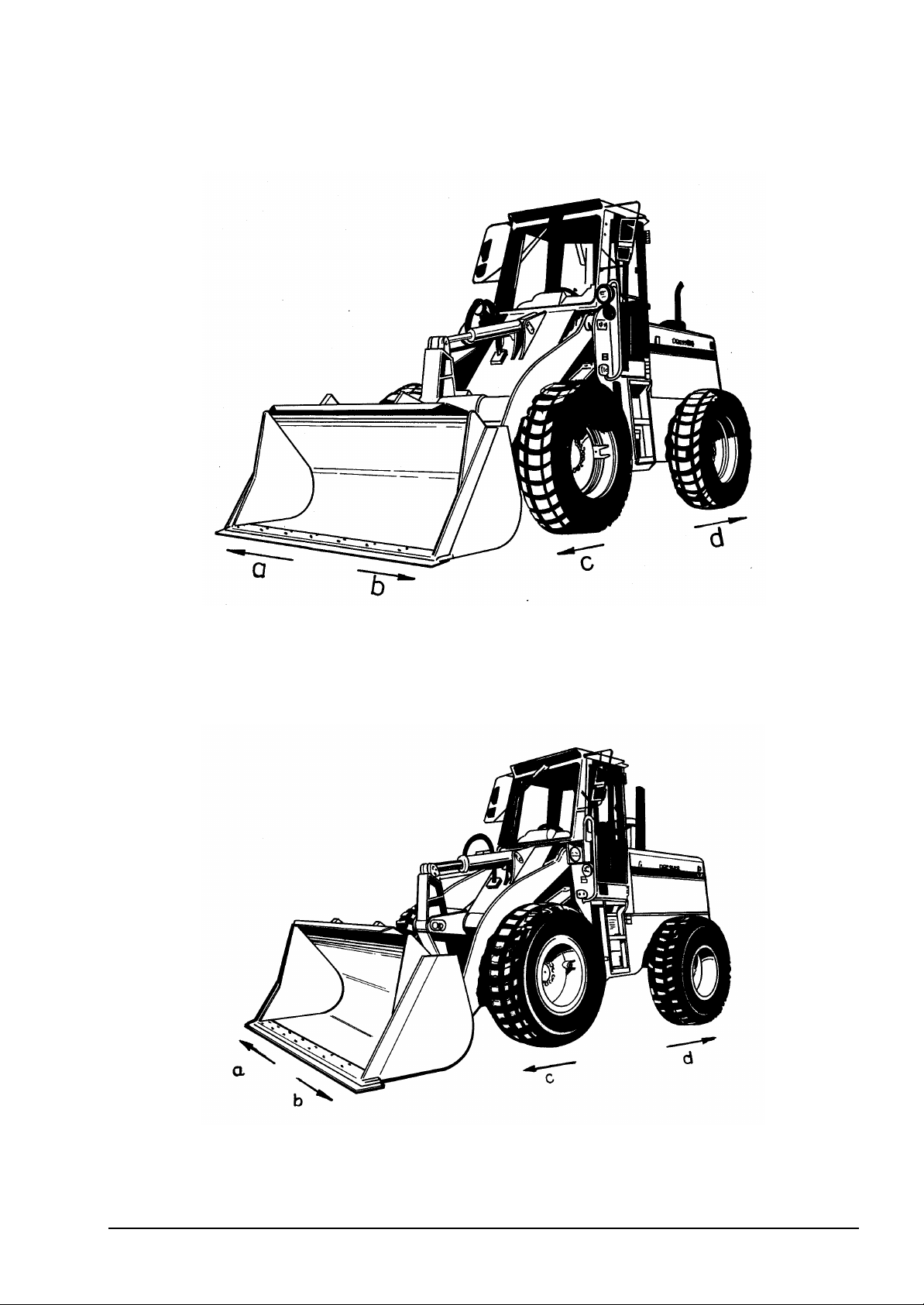

Fig. 1.1. 515 Series C Wheel Loader

a - Right Hand Side of the Machine

b - Left Hand Side of the Machine

c - Front of the Machine

d - Rear of the Machine

Fig. 1.2. 520 Series C Wheel Loader

a - Right Hand Side of the Machine

b - Left Hand Side of the Machine

DRESSTA OM515C520C99/1E

c - Front of the Machine

d - Rear of the Machine

SECTION 1 INTRODUCTION

Page 4

INTRODUCTION

GENERAL

Throughout this manual there will be two types of cross references. One type - numerical - refers to

a heading within the same section. The other type - numerical followed by the section

title - refers to a heading in another section. Refer to the section contents page at the beginning of

the individual sections for specific page numbers.

Throughout this manual the use of the terms "left", "right", "front", and "rear" must be understood to

avoid confusion when following the instructions. "Left" and "right" indicate the left and right sides of

the machine when facing forward in the operator's seat. The „front” is in front of the operator, the

„rear” - behind his back. See Fig. 1.1, 1.2.

Some illustrations are of general application of this model and may not show your machine

accurately in all details.

The loaders are available in 2 different versions:

1. standard version equipped with a mechanical feedback steering and a hydraulic system

controlled with either 2 or 3 levers mechanically connected with a 2 or 3-spool control valve

respectively.

2. upgraded version: equipped with a hydraulic feedback steering and a hydraulic system controlled

with 1 or 2 levers hydraulically connected with a 2 or 3-spool control valve respectively. In this

version it can be configured as CE version according to EC directives.

WARNING!: This symbol and text in bold letters is used throughout this manual

to call your attention to instructions concerning personal safety. Observe and

follow these instructions. Be certain anyone operating and servicing this

machine is aware of these rules. Failure to follow these rules may result in injury

or death.

IMPORTANT: This sign and text in italics is used throughout this manual to call your attention to

key problems for machine operation. Failure to follow such instructions may result in damage of the

machine and heavy material losses.

NOTE: This sign and text in italics is used throughout this manual to call your attention to important

function having influence on the right functioning of the machine or for informational purposes.

OM515C520C99/1E DRESSTA

INTRODUCTION SECTION 1

Page 5

1.2. SERIAL NUMBERS

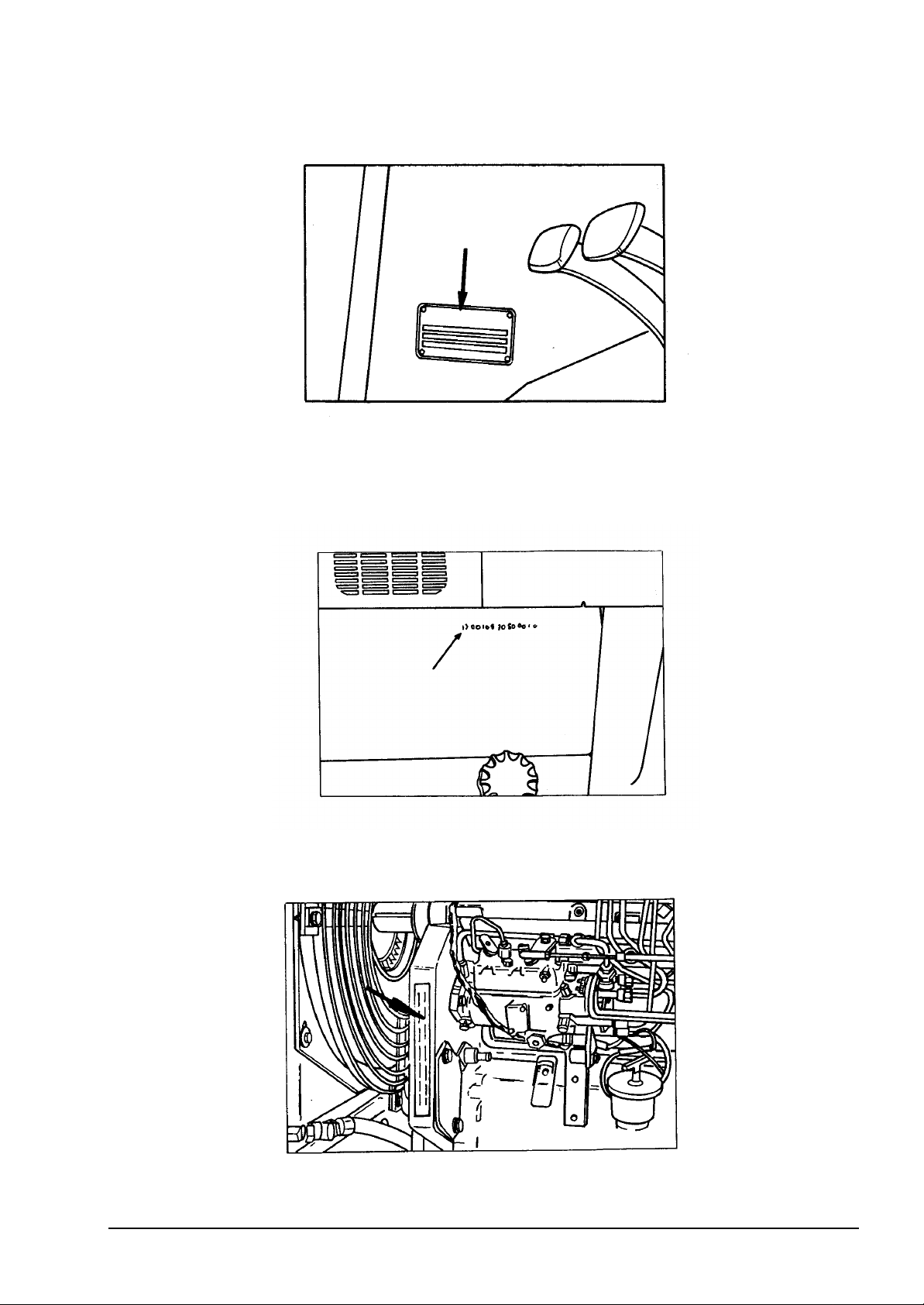

Fig.1.3. Location of Machine Serial Number plates

1. The machine serial number plate is located at the bottom of the left hand side of the cab. It is

also stamped on the left rear corner of the rear frame.

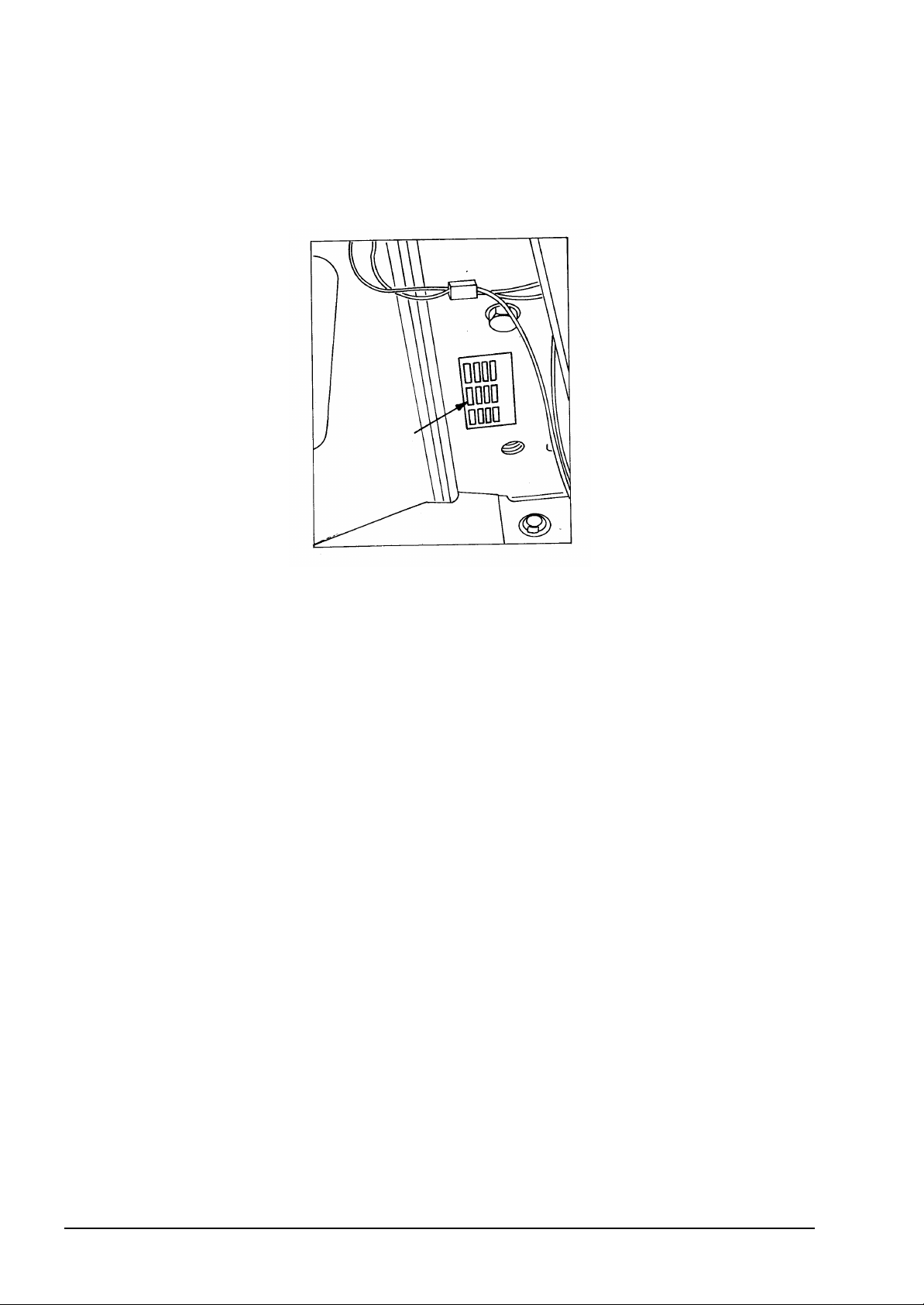

Fig.1.4. Location of stamped machine serial number

Fig.1.5. Engine Serial Number Plate

DRESSTA OM515C520C99/1E

SECTION 1 INTRODUCTION

Page 6

SERIAL NUMBERS

2. The engine serial number plate is located on the left hand side of the engine in the space

designated “Engine serial number” (Fig. 1.5).

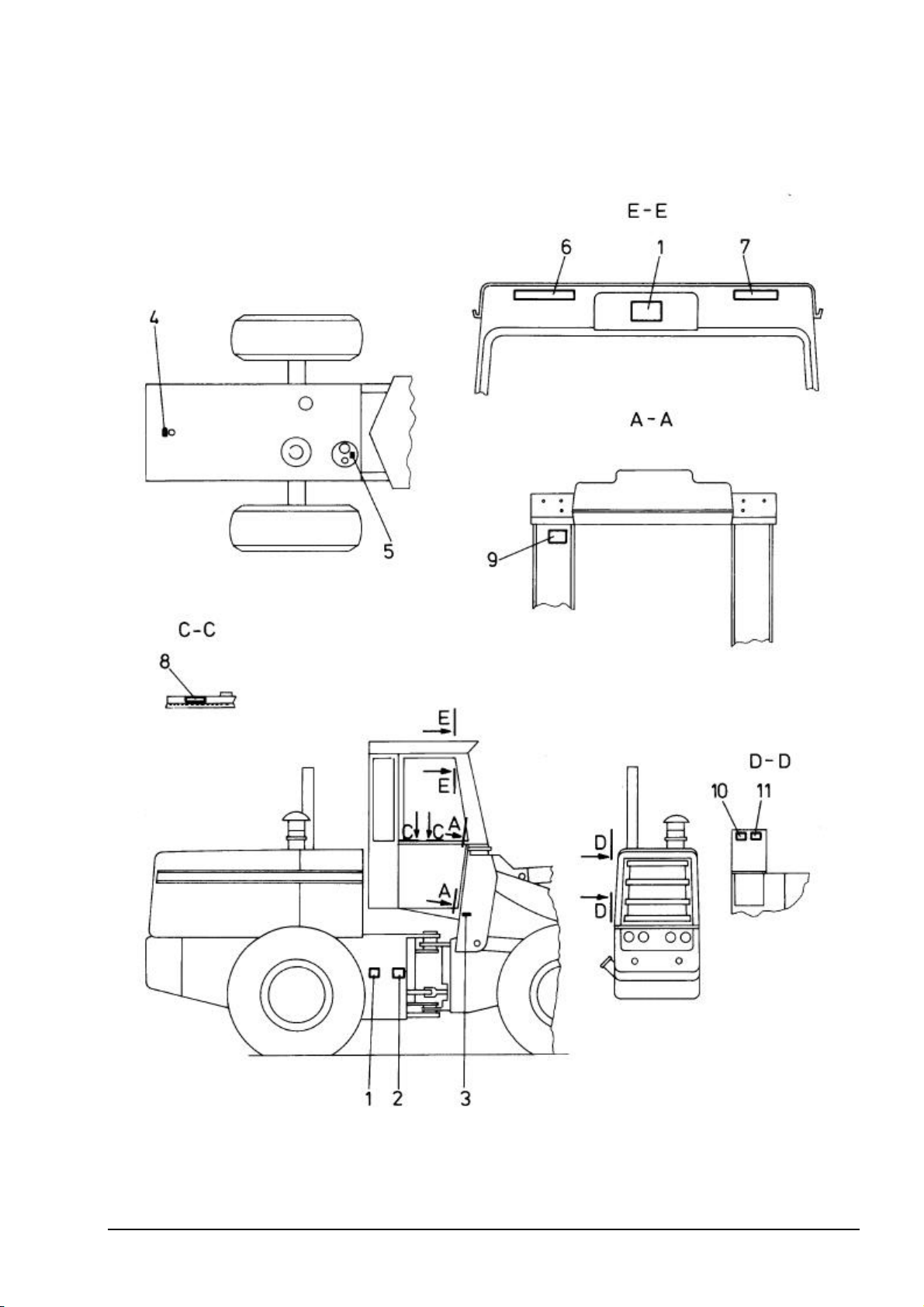

Fig.1.6. Cab Serial Number Plate

3. The cab serial number plate is located inside the cab in the right front corner near the floor board

(Fig. 1.6).

All other main components having serial numbers are each equipped with a separate serial number

plate or the number is stamped on the component body.

Use respective serial numbers when requesting information or ordering parts and proper numbers

from Parts Catalogue.

OM515C520C99/1E DRESSTA

SECTION 2

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS SECTION 2

SECTION CONTENTS

2.1. General .............................................................................................................................. 3

2.2. Before Starting the Engine ................................................................................................ 4

2.3. Operating the Machine ...................................................................................................... 4

2.4. General Maintenance Precautions .................................................................................... 6

2.5. When Parking .................................................................................................................. 10

2.6. Safety Graphics Location ................................................................................................ 11

2.6.1. Safety Graphics ..................................................................................................... 12

2.6.2. Safety Graphics (Version CE) ................................................................................ 16

DRESSTA OM515C520C99/1E

SAFETY PRECAUTIONS SECTION 2

Page 3

2.1. GENERAL

WORK SAFELY - FOLLOW THESE RULES

WARNING!: This symbol and text with bold letters is used throughout this manual

to call your attention to instructions concerning personal safety. Observe and

follow these instructions. Be certain anyone operating and servicing this

machine is aware of these rules. Failure to follow these rules may result in injury

or death.

Recommendations and information given in this Section do not cover all subjects to be acquired for

safe operating of the machine. Detailed information respecting safe operating of the machine are

specified in the following Sections. Observe and follow these rules.

Operating and servicing this machine can be hazardous if performed improperly. Personnel must have

necessary skill information and use proper procedures and recommendations included in this manual.

Only trained and authorized personnel should be allowed to operate and service this machine.

Do not rush. Hurrying can lead to accidents. Haste, carelessness and lack of training are the primary

causes of equipment-related injuries.

The machine must be equipped with a fully charged fire extinguisher recharged immediately after use

and first-aid kit. The fire extinguisher is fixed on the floor at the left band side of the operator’s seat.

Operator’s seat must be equipped with safety belt. Also, the machine must be equipped with

a safety triangle.

If the machine is equipped with outside ventilation check the engine exhaust system periodically for

leaks. Exhaust gases are dangerous to the operator. On machines equipped with a cab without

outside ventilation, keep sliding windows open to outside air.

The operator must not wear loose fitting or hanging clothing, belts or jewelry and must wear shoes with

non-slipping soles as well as a hard hat insulated during cold weather.

Do not jump on or off the machine. Keep two hands and one foot, or two feet and one hand in contact

with the steps and handholds at all times. Always face the machine when climbing on or off to reduce

the chances of slipping and injury.

Follow all machine-mounted safety signs before starting, operating, maintaining or servicing the

machine.

The operator must be alert, physically fit and free from the influences of alcohol, drugs or

medications that might affect his eyesight, hearing, reactions or judgment.

Do not use controls or hoses as hand holds when climbing on or off the machine. The hoses and

controls can move and do not provide solid support. Movement of the controls may cause

inadvertent and unexpected movement of the machine or its equipment.

Be sure the area of the operator's compartment, all mounting steps and grab handles are free of

oil, grease, loose objects, ice and mud to lessen the possibility of slipping. All damaged steps or

grab handles should be repaired immediately. Remove or secure all maintenance and personal

items so they will not interfere with the operator or jam the controls.

DRESSTA OM515C520C99/1E

SECTION 2 SAFETY PRECAUTIONS

Page 4

2.2. BEFORE STARTING THE ENGINE

Never start the engine indoors unless proper exhaust ventilation is provided to remove deadly

exhaust gases. Once the engine is operating, move the machine outdoors as soon as possible.

Perform a visual check of the machine before starting the engine. Look for such things as

improper fluid levels, oil leaks, lack of safety equipment, concentration of dirt and loose, damaged

or missing parts. Do not start the engine until any unsafe conditions are corrected.

Be sure all filler caps, dipsticks, plugs, latches, service doors, etc. are secure before starting.

Walk completely around the machine before entering the operator's compartment, clear the

immediate area surrounding the machine of personnel and obstructions.

Know the alternative exit route from the operator's compartment for use in an emergency.

Sit in the operator's seat before starting the engine. Keep hands and footwear free of grease, water

and mud to insure positive control movement.

Before starting the engine or when the machine is standing with the engine running idle; lock the

transmission shift lever in neutral (N), apply the parking brake, and lower the bucket if raised.

Before operating the machine, check that the frame locking bar and pin are stowed on the rear frame.

Broken or lost frame locking bar and pin should be repaired or replaced immediately so that this device

is always available for use.

When using a booster battery and jumper cables, switch off the master switch, then connect the

positive terminal on the booster battery to the positive terminal of the battery on the machine. Connect

the negative terminal on the booster battery to the negative terminal of the battery on the machine.

2.3. OPERATING THE MACHINE

Release the parking brake before moving the machine. The brake could burn or be damaged if the

machine is driven with the brake applied.

Before driving the machine, adjust the seat and fasten the seat belt. Never wear the seat belt across

the abdomen.

Always carefully check overhead clearance before operating in areas with overhead obstructions such

as guy wires, power lines, bridges, tree branches and building doors).

Do not smoke when using the ether injector. Do not use the ether injector when the air temperature is

above freezing. Follow the correct method for starting the engine.

Before moving the machine, sound the horn to warn the nearby personnel.

Check the brakes, steering and attachment controls. All systems must be fully operative.

After starting and while operating, observe instruments and warning lights frequently. Investigate any

unusual indications or noises in the machine.

OM515C520C99/1E DRESSTA

SAFETY PRECAUTIONS SECTION 2

Page 5

OPERATING THE MACHINE

Before work know the locations of underground cables, water mains, gas lines, etc. A broken gas line

or electrical cable could cause personal injury or death.

Avoid undercutting high banks because the bank may cave in. Ramp up and remove the top layers

first.

Avoid operating too close to an overhang, deep ditch, or excavation because the machine's weight

may cause the edge to collapse and result in personal injury.

If the ground driven steering light comes on, immediately stop the machine in a safe place. Shut off the

engine and apply the parking brake. Correct the cause before operating again.

Keep the work area free from obstructions and as smooth as possible.

Turn on the machine's lights at night and times of poor visibility to see and be seen.

When loading trucks, be careful not to hit the truck with the loader or its bucket.

If engine has a tendency to stall for any reason under load or at idle, stop the machine immediately

and correct the malfunction.

Trucks should be loaded from the driver's side whenever possible. When the truck is being loaded, be

sure the driver either stays in the cab (on cab-protected trucks) or away from the truck and loader.

If the machine begins to tip over because of an overload, immediately lower the bucket to regain

stability.

Do not swing a load over the heads of other workers or a truck cab.

A machine's weight and the vibration it creates can cause the edge of a high wall to collapse. Keep

your machine back from the edges of banks and excavations. If this cannot be avoided, face the

machine towards the bank's edge while operating.

Operating in rough virgin terrain with such hazards as trees, logs, large rocks and brush calls for

special attention. Avoid falling branches and upturning roots.

When pushing over trees never allow the machine to climb up the root structure, especially when the

tree is being felled. Use extreme care when pushing over any tree with dead branches.

Operate at speeds low enough to ensure complete control of the machine. Travel slowly in congested

areas or on rough ground, slopes or near drop-offs or on snow, ice or slippery surfaces.

Maintain a safe distance between your machine and other vehicles according to the condition of the

road and load.

Keep the machine as close to the side of the road as is possible to provide for oncoming or passing

vehicles. Pass other vehicles only when the road is clear and there is enough room and reserve power

to pass.

Never try to get on or off the machine while it is moving. A serious injury or death could result.

DRESSTA OM515C520C99/1E

SECTION 2 SAFETY PRECAUTIONS

Page 6

OPERATING THE MACHINE

Never shift the transmission direction lever into neutral when travelling downhill. The machine may go

out of control and a rollover could result or the transmission, torque converter or engine could be

damaged when the transmission is again placed in gear. Always put the transmission in the low range

position before starting downhill. Use the accelerator pedal and brake pedal to slow the machine.

Never haul passengers. Only the operator should be on the machine when it is moving.

If the brake system warning light and buzzer come on during operation, immediately stop the machine

in a safe place. Apply the parking brake. Correct the cause before operating again.

Lock the levers when roading the machine so as not to actuate the levers accidentally.

Maintain clear vision of all work and travel areas. Keep the windows and mirrors clean and repaired.

Look in the mounted equipment control intended travel direction to be sure the personnel and allied

equipment do not interfere with the machine's work pattern. Do not operate if exposed personnel enter

the immediate work area.

When traveling fast or downhill never apply the brake and transmission disconnect pedal as this shifts

the transmission into neutral (N). The machine could go out of control or the power train could be

damaged when the pedal is released and the transmission is shifted into gear again.

Do not drive the machine without checking the brakes for correct operation.

Avoid sidehill travel whenever possible. Drive straight up and down the hill. If the machine starts

slipping sideways, turn downhill immediately, and lower the bucket.

Do not overspeed the engine. Excessive speeds can be hazardous and harmful to the power train.

Select the proper gear before starting downhill. Control the speed with the brakes.

Avoid crossing obstacles such as ditches, ridges, curbs, logs, rocks, and railroad tracks. If you cannot

avoid them, reduce speed and cross at an angle.

Never use the bucket as a brake except in an emergency.

Do not adjust the seat while the machine is moving because a loss of control may result. Stop the

machine, apply the parking brake and then adjust the seat.

Never allow anyone to stand on the ladder when the bucket is raised or the machine is moving.

Carry the bucket low for maximum visibility and stability when traveling.

Use extra caution when moving with the bucket raised. The stability is reduced as the bucket is raised.

Know the traffic flow patterns of the job site. Obey flagmen, signs and signals.

There is no substitute for good judgment when working on a slope. Slope operation should be limited

according to the ground and traction conditions, the load being carried, and the speed of the machine.

OM515C520C99/1E DRESSTA

SAFETY PRECAUTIONS SECTION 2

Page 7

2.4. GENERAL MAINTENANCE PRECAUTIONS

Replace any missing or defaced product graphics. When parts which have product graphics on them

are replaced, be sure to install new product graphics. New product graphics are available from the

Authorized Distributor of Construction Equipment.

Never let anyone near the machine's articulation pivot. If the machine is turned, they could be crushed.

Before servicing the machine use the frame safety bar to prevent accidental articulation.

Before servicing the machine, be sure the engine is off, the bucket is lowered, the transmission shift

lever is locked in neutral (N), the electrical system master switch is off and the key is removed. Tag the

machine.

Use only approved parts for repairs and maintenance. Failure to do so could compromise personal

safety, machine performance, and reliability.

Before working under the machine, block the tires to prevent machine movement.

It is not possible to anticipate all conceivable ways or conditions under which this machine may be

serviced or to provide precautions for all the possible hazards that may result. Safety is always the

most important rule. Constantly be aware of dangers involved in working on the machine and take

proper precautions. Standard and accepted safety precautions and equipment should be used.

Never attempt to start servicing close to the operating fan as it may result in serious injury.

When changing cutting edges, securely support the bucket for your protection.

If the bucket is provided with teeth, use special hammer for installation to prevent teeth breakage.

Wear safety goggles.

Lift and handle all heavy parts with lifting devices of adequate capacity. Secure the parts with proper

slings and hooks. Use lifting eyes provided. Warn the nearby personnel to stand clear.

Keep work area clean and dry. Remove water and oil spills immediately to reduce the chance

of slipping and injury.

Do not pile up oily or greasy rags; they are a fire hazard. Store them in an approved, closed metal

container.

Do not carry loose objects in your pockets because they might catch on the machine and result in

a fall or injury.

Use the proper tool for the job. Be sure all tools are in good condition. Do not use tools which are

worn, bent or have mushroomed heads because they can lead to injury.

Do not use the loader bucket or forks to lift personnel or as a work platform.

When service requires access to areas that cannot be reached from the ground or service platform on

the machine, use a ladder or platform of adequate size and capacity.

Never adjust relief valves higher than the specified pressure because this may damage the machine

and lead to injury. When checking pressures, use the correct gauge for the expected pressure.

Consult the Authorized Distributor of Construction Equipment

DRESSTA OM515C520C99/1E

SECTION 2 SAFETY PRECAUTIONS

Page 8

GENERAL MAINTENANCE PRECAUTIONS

Jacking up the machine can be hazardous if performed improperly. Use jacking equipment with

sufficient capacity. Be sure the jacking points are strong enough for the expected load. Be sure the

supports for the jacks are stable. Before jacking up the machine, block the tires on the opposite side of

the machine. Because the rear axle pivots, securely block it in position. Do not run the engine with the

machine on jacks. For your safety, support the machine before servicing if.

This machine is assembled using high strength fasteners. Replacement fasteners must be of the

same size and strength as the originals.

Refer to the parts catalog for this machine. Tighten fasteners to the proper torque.

When cutting, grinding, pounding, prying, or whenever material could fly or fall, wear proper protective

equipment (such as goggles, hard hat, safety shoes, and heavy gloves).

During servicing do not allow anyone in the operator's compartment who is not trained and assisting in

the servicing.

When it is necessary to make any checks or adjustments with the engine running, use two people.

A trained operator must be at the controls to safeguard the mechanic making the checks

or adjustments. Be sure the transmission shift lever is locked in neutral (N), the parking brake is

applied and the frame halves are locked together.

Never stand near the bucket or tires while the engine is running.

If compressed air or water under pressure is used for cleaning parts, wear safety goggles. Limit air

pressure to 200 [kPa] and water pressure to 270 [kPa].

Never run the engine when cleaning or lubricating the machine because serious injury could result

from contacting moving parts. Use a nontoxic, nonflammable commercial solvent for cleaning parts

unless otherwise specified.

Avoid use of gasoline, diesel fuel, kerosene or other flammable solvents for cleaning parts.

Never place these solvents in an open pan.

Use gloves and safety goggles when draining hot fluids.

For your safety lower the bucket before servicing the machine. Be sure no one is standing near the

bucket when it is being lowered.

Do not service the air conditioning system (if equipped) unless you are completely familiar with air

conditioning and the safety precautions for handling liquid refrigerant which can cause severe frostbite.

Contact the Authorized Distributor of Construction Equipment

Before working on the engine or electrical system turn off the starting switch and the master switch

and take the keys out. Tag the cables and controls to warn against starting.

Keep the engine exhaust manifold(s) and exhaust system clear of combustible material to reduce the

chance of fire.

Never remove any guards or shields with the engine running because of the danger of contacting

rotating parts.

OM515C520C99/1E DRESSTA

SAFETY PRECAUTIONS SECTION 2

Page 9

GENERAL MAINTENANCE PRECAUTIONS

Before working on the hydraulic system, be sure the system pressure is relieved. To do so lower the

bucket on the ground, move boom control lever in float position and switch off the engine.

Do not use hands to search for hydraulic leaks. Hydraulic oil escaping under pressure from a very

small hole can be almost invisible yet have sufficient force to penetrate the skin. Use a piece of

cardboard or wood to search for suspected leaks. If injured by escaping oil, see a doctor immediately

because of the possibility of infection or reaction to the oil.

Never work or walk under a raised bucket without proper blocking.

Use extra caution when adjusting the loader's bucket leveler or boom kick-out. Use two trained people

and guard against accidental movement of the machine or loader linkage.

The roll-over protective structure ROPS provides operator protection in the event of machine rollover

or upset. It is designed to bend during a rollover to protect the operator from sudden impact loads. Do

not attempt to repair a ROPS after an accident. Repaired structures do not provide the original

strength and protection. Contact the Authorized Distributor of Construction Equipment for information

on ROPS (or cab) replacement. Do not operate the machine again until the ROPS has been replaced.

Periodically inspect the ROPS for fatigue cracks. Cracks indicate a weakened structure which should

be replaced for your protection. Bolts fastening cab or ROPS must be torqued to

a specific value. Do not cut, grind, weld, drill or tap holes in the ROPS This could weaken the structure

or affect the overall energy absorption capability. Always wear the seat belt during all operation in

order to realize protection of the ROPS (or cab).

When transporting the machine, lock the frame halves together with the frame locking bar and pins.

Corrosion inhibitors are volatile and flammable. Use them only in a well ventilated area. Keep flames

and sparks away. Do not smoke. Store container in a cool, well ventilated place.

For your safety never push or tow a disabled machine farther than absolutely necessary. When using

a chain or cable, be sure it is strong enough for the expected load and properly secured to the drawbar

pin or towhook. Avoid kinking. Do not pull with a kinked chain or cable because the high stresses could

cause failure in a kinked area. Wear heavy gloves when handling chain or cable. When pulling with a

chain or cable, take up the slack slowly to avoid jerking. A chain or cable which fails under load can

whip and cause serious injury. Do not pull or tow unless the operator's compartment is guarded

against or out of reach of a whipping chain or cable. Hitch only to the drawbar pin or towhook. Prior to

towing release the parking brake.

Rims and tires must be repaired in specialized shops featuring proper technology. Improper repairs

may result in malfunctions and accidents.

Never inflate a flat tire without inspecting the tire and rim for damage. Be sure the components are

properly assembled. Unmounted tires being inflated or deflated should be placed in a tire safety cage.

Inflate a tire to 100 – 140 [kPa] and check that all components are properly seated. Never stand

directly in front of a tire and rim assembly while inflating. Use a clip-on chuck with a hose long enough

to allow person inflating the tire to stand to the side. Serious injure could result if the tire and rim were

to separate.

DRESSTA OM515C520C99/1E

SECTION 2 SAFETY PRECAUTIONS

Page 10

2.5. WHEN PARKING

Avoid parking on a slope. If necessary to park on a slope, park at a right angle to the slope and block

the tires.

Park the machine in place free from grease and fuel to prevent tire damage.

Never leave the machine with the engine running or the bucket raised. When parking a machine, shut

off the engine, lower the bucket to the ground, lock the transmission shift lever in neutral (N), apply the

parking brake, turn off the starting switch and the electric system master switch, and remove the keys.

Park the machine in a nontraffic area. If parking near or in traffic lanes cannot be avoided, identify the

machine in accordance with traffic rules.

Always lock the machine, including any anti-vandalism attachments when leaving it unattended.

If the loader is equipped with a multi-purpose bucket, close the clam before dismounting.

When operating in bad weather and storm lightning is nearby, dismount and seek shelter away from

the machine. Lightning will be attracted to the machine and cause serious injury or death.

ADDITIONAL INFORMATION

1. The vibration level measured at the operator’s seat does not exceed the admissible value

of 1.25 [m/s2] according to PN-91/N-01352 standard.

2. The noise level measured at the operator’s seat during intensive operation does not exceed the

admissible value of 85 [dB] (A) according to PN-86/M-47015.

3. Sound level LA produced by a machine does not exceed a value of 85 [dB] (A) according

to PN-86/M-47016.

4. A loader can be operated in temperature ranging from -34 [oC] to +49 [oC].

A wheel loader in standard configuration is not adapted to operation in terrain where a mixture of

gasses, vapors, aerosols or dust with air creates explosion hazard zones.

5. A wheel loader in CE configuration was given TÜV Hannover Laboratory DE 10-893 641 16 Noise

Level Certificate on 17 May 1999. The level of noise produced by a brand new machine reached

104 [dB] (A) when measured according to ISO-6395 standard (admissible value according to

EEC/662/86 directive is 107 [dB] (A)).

OM515C520C99/1E DRESSTA

SAFETY PRECAUTIONS SECTION 2

2.6.SAFETY GRAPHICS LOCATION

Page 11

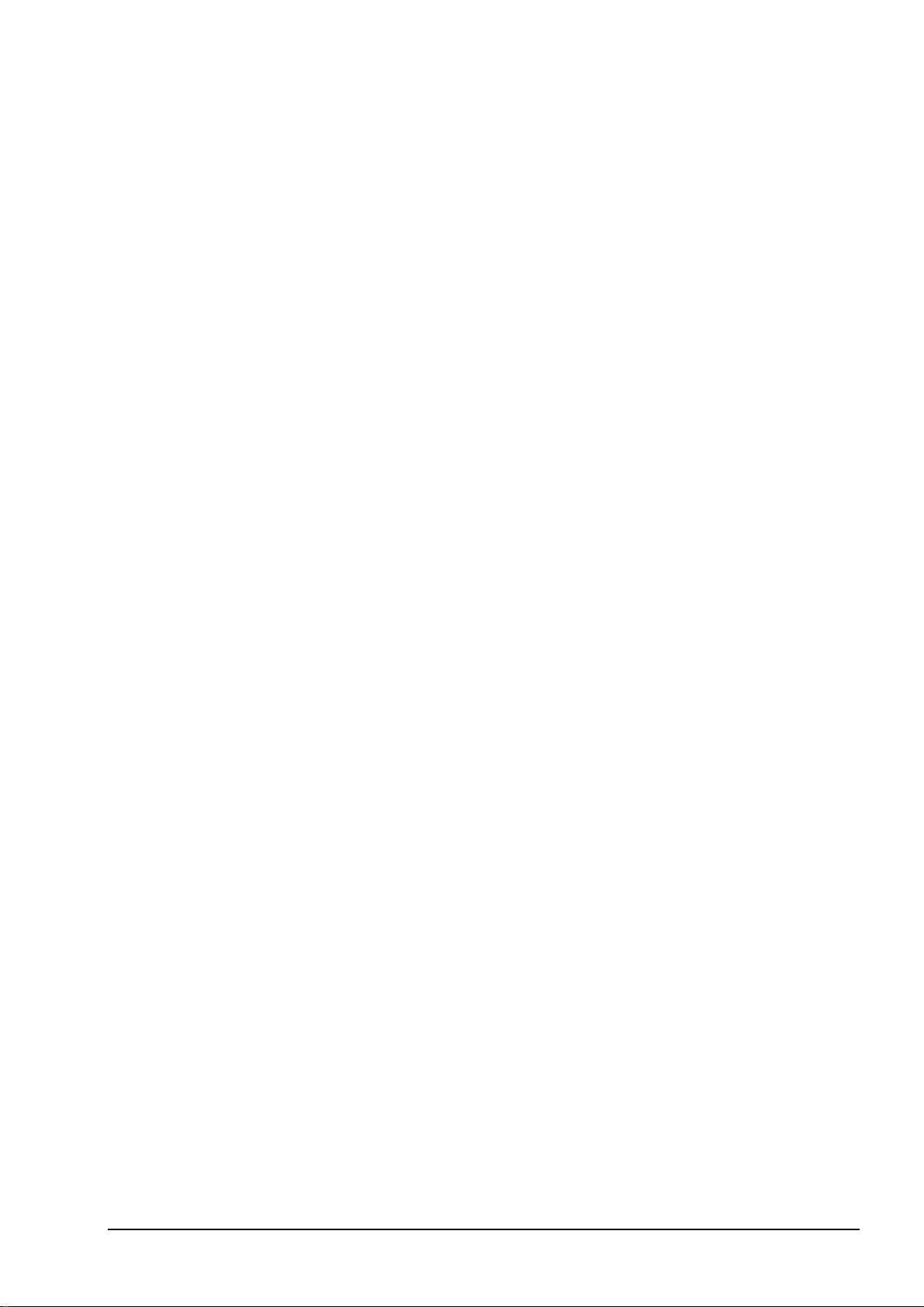

Fig. 2.1. Safety Graphics Location

DRESSTA OM515C520C99/1E

SECTION 2 SAFETY PRECAUTIONS

Page 12

SAFETY GRAPHICS LOCATION

2.6.1. SAFETY GRAPHICS

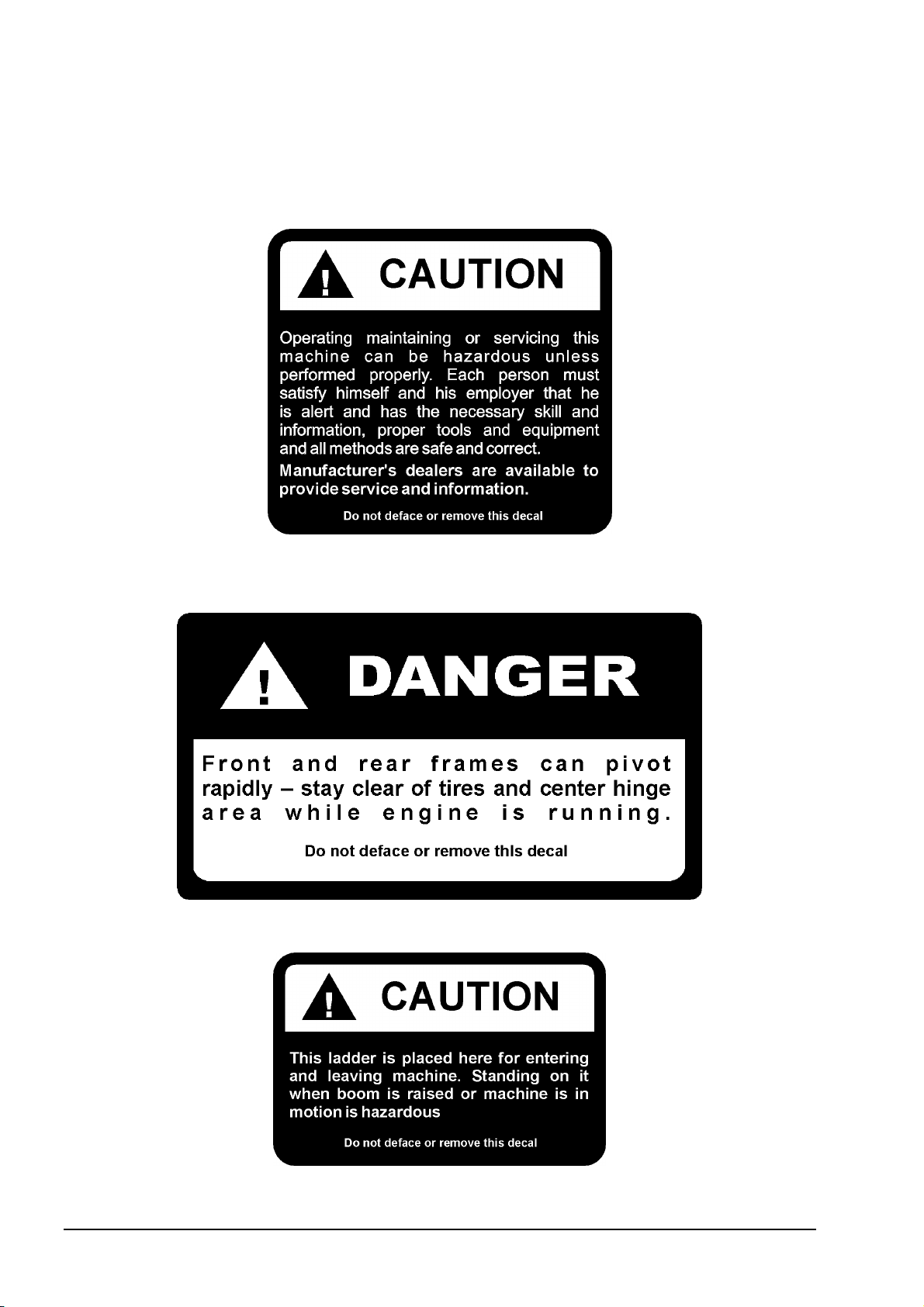

Decal 1 - On the rear frame near the center articulation pivot and on the instrument panel in

the operator’s cab

Decal 2 - On the rear frame near the center articulation pivot

Decal 3 - Near the ladders and steps

OM515C520C99/1E DRESSTA

SAFETY PRECAUTIONS SECTION 2

Page 13

SAFETY GRAPHICS LOCATION

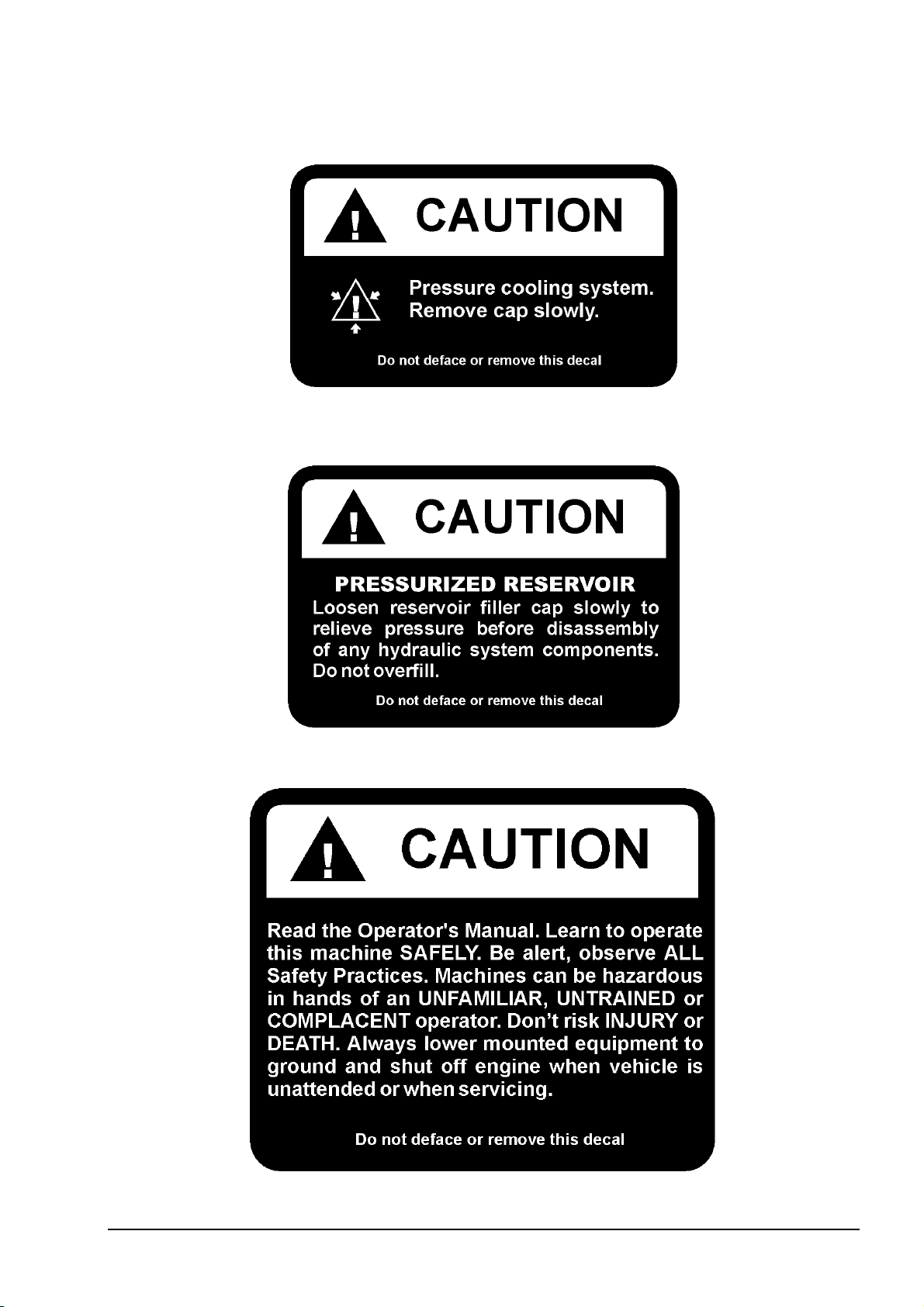

Decal 4 - Near the radiator filler cap

Decal 5 - On the hydraulic reservoir

Decal 6 - In the operator’s cab

DRESSTA OM515C520C99/1E

Loading...

Loading...