Draw-Tite STRAIGHT COUPLERS User Manual [en, es, fr]

Stamped Coupler

Read, Understand, Follow and Save These Instructions

• Read, understand and follow all instructions before installing and using this product. Never allow anyone unfamiliar with these instructions to use this

product.

• Read, understand and follow all instructions provided by the manufacturer of the product(s) on which this product will be installed.

• Installation of this product must conform to the following mounting instructions.

• Save these instructions for use as a reference in the future.

Failure to follow these warnings and instructions may result

WARNING

• Purchaser/owner must ensure that product is installed according to these

instructions. Purchaser/owner must not alter or modify the product.

• Operator and bystanders should never position any part of body under any

portion of this product or the load being supported.

• Do not allow children to play on or around this product or the load being

supported.

• Weigh your trailer plus added load. Do not exceed lesser of mounting

bracket, coupler, hitch, vehicle, ball, or trailer weight ratings (including

load).

• Use only the proper ball for this coupler as indicated on the coupler body.

If uncertain, contact Cequent Performance Products at 1-800-632-3290 or

www.cequentgroup.com.

• Always secure load, vehicle and trailer (by blocking wheels) before

latching/unlatching coupler.

• Use caution when uncoupling as tongue may rise suddenly due to negative

tongue load.

• After installing mounting bracket and/or coupler, if coupler operation has

been impared in any way, do not use it.

• Keep the ball pocket and mechanism clean. When parking or storing your

in property damage, serious bodily injury, and/or death.

trailer, keep the coupler off the ground so dirt and/or other foreign material

will not build up in the coupler ball pocket.

• Do not tow if ball is not fully seated and/or coupler is not closed.

• All welding must be performed by a certified AWS welder.

Before Towing:

• Check vehicle, mounting bracket, hitch, hitch ball and coupler for signs of

wear or damage and that the coupler handle opens and closes freely. If

coupler and/or mounting bracket is deformed or damaged, replace

complete coupler and mounting bracket.

• Replace bent, broken, or worn parts before using this product.

• Close coupler securely by ensuring that the hitch ball is fully seated in the

coupler ball pocket and the handle or latch is in the closed position.

• Check mounting bracket hardware for wear and proper tightness. Replace

bent, broken, or worn hardware.

• Make sure that the trailer safety chains are properly connected to the

towing vehicle and trailer according to SAE J684.

• Make sure that all trailer lighting is hooked up and working properly.

Coupler Installation

Before mounting the coupler confirm that there will be no interference from the tow vehicle, tongue, ground, and any other mounted accessories while

stationary or in motion. Before installing, check for interference in open and closed positions. Check for interference again after installation is

complete. All welding must be performed by an AWS certified welder. The coupler must be rigidly attached to the trailer in order for the coupler to

support its maximum rated load according to SAE J684. After installation, check to make sure that coupler operation has not been impaired in any way.

Do not use coupler if its operation has been impaired.

Warning: Failure to follow all installation instructions could

result in coupler failure.

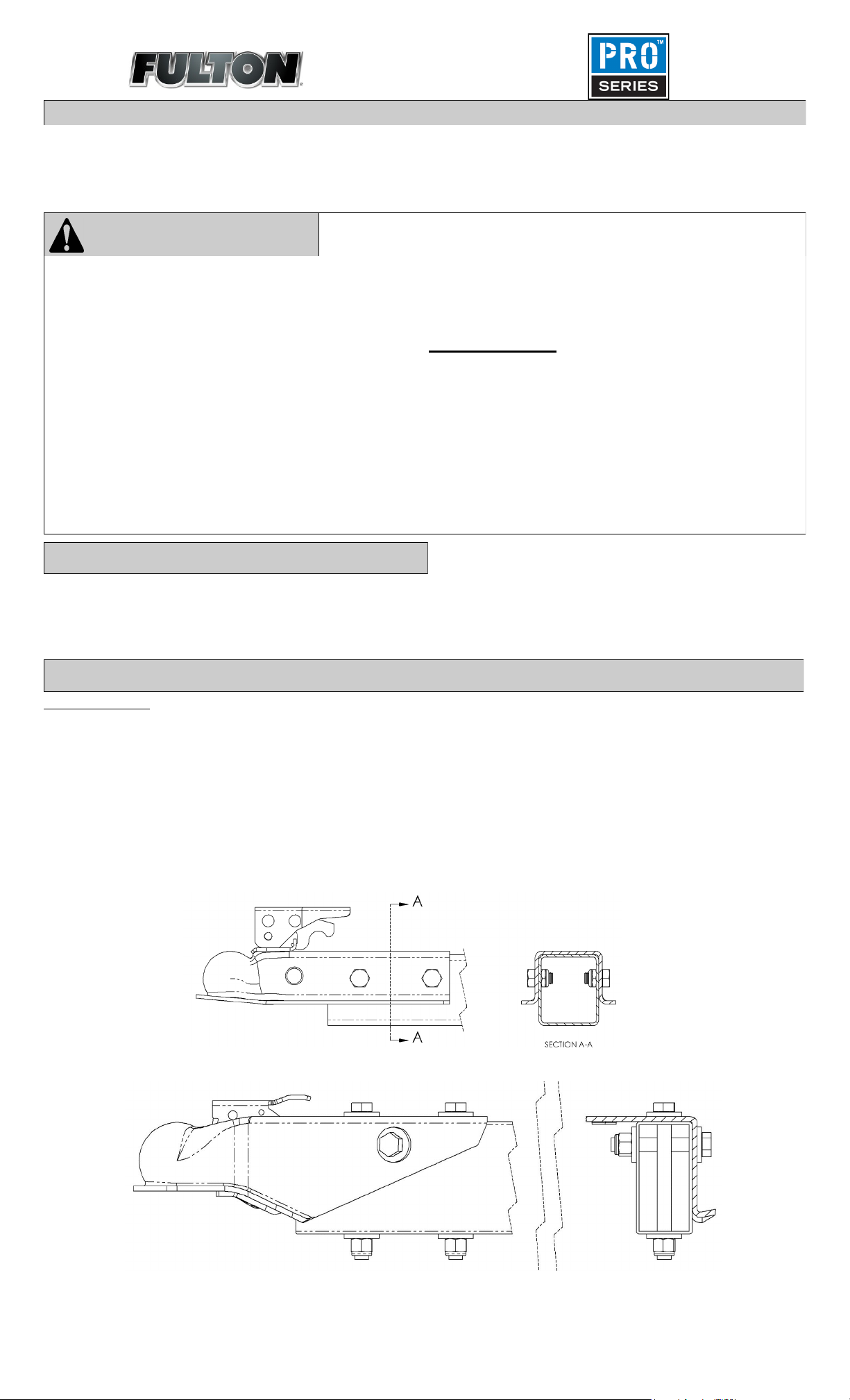

Bolt-on Couplers:

Bolting Instructions:

Assure coupler’s internal stop is butted against end of trailer tongue for maximum overlap.

Straight Tongue Couplers: For Class 1 couplers, the preferred method is to use (4) 3/8” bolts through side holes and torque to 15-20 ft-lbs. (See

Bolt-on detail) An alternate method is to use (2) 3/8” grade 5 through bolts and locknuts providing they can be torqued to at least 20 ft-lbs. without

excessive deformation of coupler or trailer tongue. For Class 2, 3 & 4 couplers, the preferred method is to use (4) 1/2” bolts through side holes

and torque to 30-35 ft-lbs. (See Bolt-on detail) An alternate method is to use (2) 1/2” grade 5 through bolts and locknuts providing they can be

torqued to at least 35 ft-lbs. without excessive deformation of coupler or trailer tongue.

A-Frame Couplers: This coupler can only be used with 50 degree trailer tongues. Using all available mounting holes in coupler housing, bolt

coupler to tongue members using 1/2” grade 5 hardware with locknuts. Use washers beneath all bolt heads and locknuts. (See Bolt-on detail).

Torque to at least 35 ft-lbs. without excessive deformation of coupler or trailer tongue.

After installation is complete, check that the coupler operation has not been impaired in any way. Do not use coupler if its operation has been impaired.

Bolt-on detail

A-Frame

Printed in China

Straight Tongue

F3484 (C-3267) 3/14

Weld-on Couplers:

Welding instructions:

All welding must be performed by an AWS certified welder.

Assure coupler’s internal stop is butted against end of trailer tongue for maximum overlap. A minimum coupler/tongue overlap of 6.5” is required.

Straight Tongue Couplers: Place the coupler on trailer tongue members. Weld on both sides and the top using a 1/8" minimum fillet weld as

shown.

A-Frame Couplers: This coupler can only be used with 50 degree trailer tongues. Place the coupler on trailer tongue members. Weld on both sides

and the top using a 3/16" minimum fillet weld as shown.

If coupler is to be primed/painted after installation, make sure excess paint/primer buildup is removed from ball pocket and latching mechanism.

After installation is complete, check that the coupler operation has not been impaired in any way. Do not use coupler if its operation has been impaired.

Weld-on detail

6.5” min. overlap

Weld on top side

(see weld instructions)

Weld sides along coupler

(see weld instructions)

6.5” min.

overlap

Operation

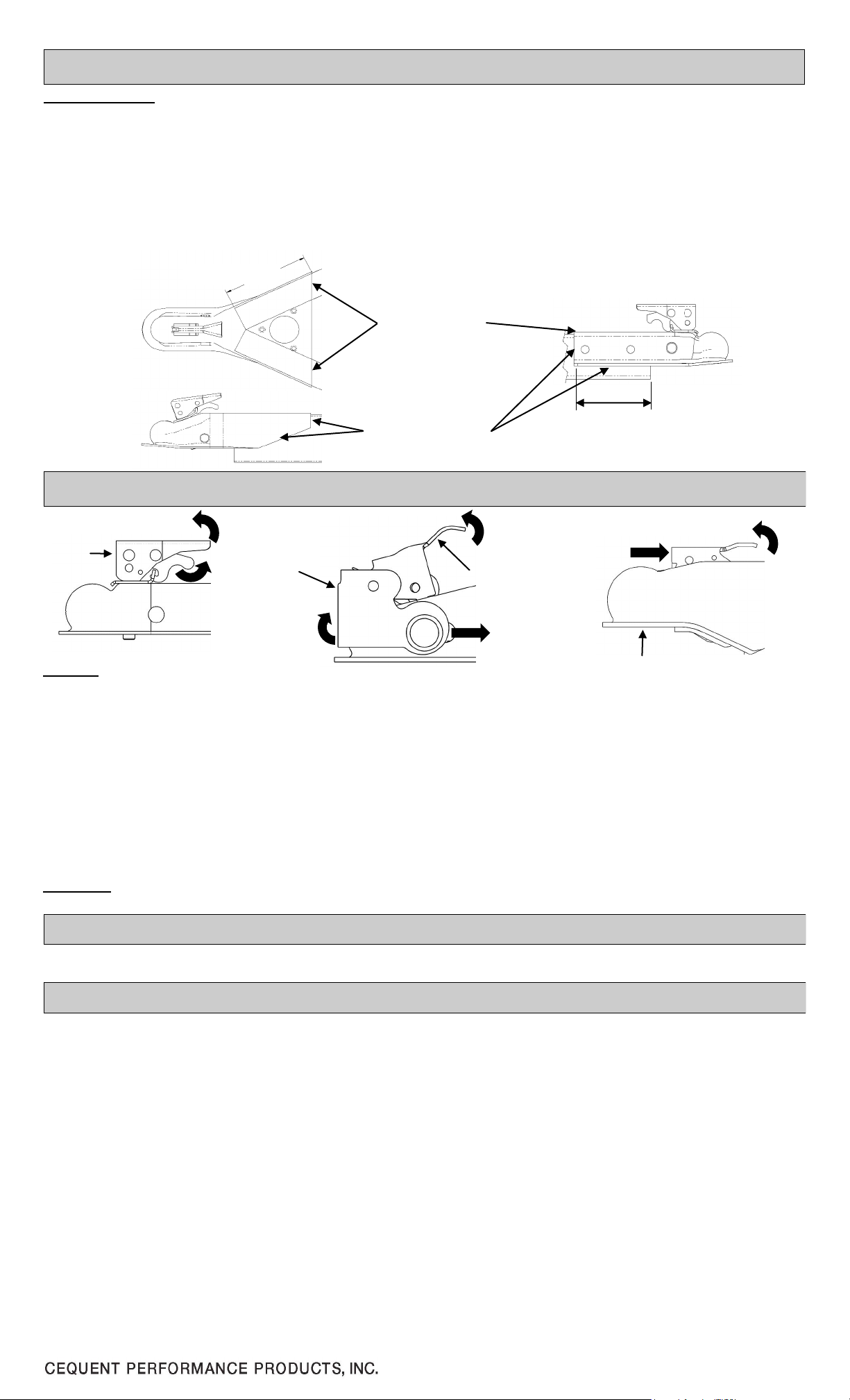

Fas-Lok®

Locking

Lever

To Couple: (The above coupler images are shown in closed position)

Block trailer wheels. Align hitch ball beneath coupler ball pocket.

Fas-Lok® style Coupler: Open coupler by pulling latch trigger and lifting the locking lever. Lower the coupler over the hitch ball until ball is fully

seated into the ball pocket. Move locking lever to the closed position. Check that the latch is engaged by lifting up on back of locking lever. Also,

check that the hitch ball is fully seated and ball clamp is below the ball. If the ball is not seated with lever in the closed position and latch engaged,

DO NOT TOW. Repeat the above steps.

Yoke-style Coupler: Open coupler by (1) lifting latch, (2) raising yoke and (3) pulling back, resting it on top of coupler nose. Lower the coupler over

the hitch ball until ball is fully seated into ball pocket. Push latch handle forward until yoke drops over coupler nose and latch handle tips enter slots

on top of coupler. Check that the hitch ball is fully seated and ball clamp is below the ball. If the ball is not seated with yoke in closed position and

latch handle engaged, DO NOT TOW. Repeat the above steps.

Low-Latch Coupler: Open coupler locking lever by (1) lifting latch upward and (2) pulling back. Lower the coupler over the hitch ball until ball is

fully seated into ball pocket. Move locking lever forward until latch handle tips enter slots on top of coupler. Check that the hitch ball is fully seated and ball clamp is below the ball. If the ball is not seated with lever in the closed position, DO NOT TOW. Repeat the above steps.

To Uncouple:

Block trailer wheels. Open locking lever and raise trailer off of hitch ball. Return handle to closed position.

2

Yoke-Style

Low-Latch

1

1

2

1

Yoke

Latch

2

3

Ball Pocket

Maintenance

Keep ball pocket and mechanism clean. The following procedures should be performed at least annually:

•Check welds and mounting bolt torque •Grease ball pocket •Oil pivot points with SAE 30 wt. motor oil

Limited Warranty

Limited Warranty. Cequent Performance Products, Inc. (“We” or “Us”) warrants to the original consumer purchaser only (“You”) that the product

will be free from material defects in both material and workmanship for a period of five years for Bulldog® and Fulton® products and one year

for the Pro-Series® products, ordinary wear and tear excepted; provided that installation and use of the product is in accordance with product instructions. There are no other warranties, express or implied, including the warranty of merchantability or fitness for a particular purpose. If the

product does not comply with the applicable limited year warranty, Your sole and exclusive remedy is that We will replace the product without

charge to You and within a reasonable time or, at our option, refund the purchase price. This warranty is not transferable.

Limitations on the Warranty. This limited warranty does not cover: (a) normal wear and tear; (b) damage through abuse, neglect, misuse, or as a

result of any accident or in any other manner; (c) damage from misapplication, overloading, or improper installation, including welds; (d) improper

maintenance and repair; and (e) product alteration in any manner by anyone other than Us, with the sole exception of alterations made pursuant to

product instructions and in a workmanlike manner.

Obligations of Purchaser. To make a warranty claim, contact Us at 47912 Halyard Dr. Suite 100, Plymouth, MI 48170, 1-800-632-3290, identify the

product by model number, and follow the claim instructions that will be provided. Any returned product that is replaced or refunded by Us becomes

our property. You will be responsible for return shipping costs. Please retain your purchase receipt to verify date of purchase and that You are the

original consumer purchaser. The product and the purchase receipt must be provided to Us in order to process Your warranty claim.

Remedy Limits. Repair or replacement is Your sole remedy under this limited warranty or any other warranty related to the product. We shall not be

liable for service or labor charges incurred in removing or replacing a product or any incidental or consequential damages of any kind.

Assumption of Risk. You acknowledge and agree that any use of the product for any purpose other than the specified use(s) stated in the product in-

structions is at Your own risk.

Governing Law. This limited warranty gives You specific legal rights, and You also may have other rights which vary from state to state. This lim-

ited warranty is governed by the laws of the State of Michigan, without regard to rules pertaining to conflicts of law. The state courts located in Oakland County, Michigan shall have exclusive jurisdiction for any disputes relating to this warranty.

47912 Halyard Dr. Suite 100

Plymouth, MI 48170 USA

www.cequentgroup.com

800/632-3290

Loading...

Loading...